Method for ultrasonic-assisted extraction of olive pomace oil

A technology of olive pomace oil and olive pomace, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve the problems of olive pomace oil quality that is easily damaged, unfriendly environment, and long extraction time, etc. To achieve the effect of improving the utilization rate of clay, good decolorization effect and short decolorization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

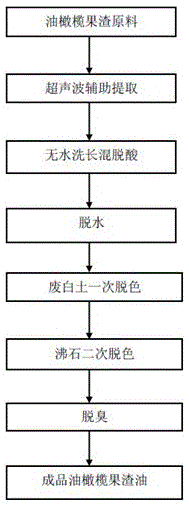

Image

Examples

preparation example Construction

[0022] Step 1. Preparation of olive pomace raw material: select olive fruit and carry out cold pressing treatment, the pressing pressure is 55-60Mpa, the pressing temperature is 45-55°C, and the pressing time is 2-8 hours, until the oil content is 15-20%. Obtaining the olive pomace; drying the olive pomace at a temperature of 45-55° C. in the dark for 1-2 hours, crushing through a 30-50 mesh sieve, and continuing to dry until the moisture content is 4-6%, so as to obtain the raw material of the olive pomace;

[0023] Step 2: Add n-hexane to the raw material of olive pomace, and conduct ultrasonic-assisted extraction under the conditions of solid-liquid ratio (g / ml) 1:4-10, temperature 40-60°C, ultrasonic frequency 2KHz, ultrasonic power 400-800W 30 to 60 minutes, and separated by a rotary evaporator to obtain crude olive pomace oil and solvent, and recover the solvent at the same time, then vacuum dry the crude olive pomace oil. The vacuum drying conditions are: vacuum degree i...

Embodiment 1

[0029] Select the olive fruit for cold pressing, the pressing pressure is 55MPa, the pressing temperature is 50°C, and the pressing time is 4 hours until the oil content is 15%, and the olive pomace is obtained; the olive pomace is dried at a temperature of 45°C in the dark After 2 hours, crush through a 40-mesh sieve, and continue to dry until the moisture content is 5%, to obtain the olive pomace raw material; 1. Under the condition of ultrasonic power 400W, the ultrasonic-assisted extraction was carried out for 60 minutes, and the virgin olive pomace crude oil and solvent were separated by a rotary evaporator, and the solvent was recovered at the same time, and then the virgin olive pomace crude oil was vacuum-dried. The vacuum drying conditions were: The vacuum degree is 0.08MPa, the temperature is 50°C, and the drying time is 90 minutes to obtain olive pomace crude oil; the olive pomace crude oil is subjected to anhydrous washing long-mixing deacidification treatment, and ...

Embodiment 2

[0031] Select the olive fruit for cold pressing, the pressing pressure is 60Mpa, the pressing temperature is 45°C, and the pressing time is 6 hours, until the oil content is 20%, and the olive pomace is obtained; the olive pomace is dried at a temperature of 55°C in the dark 1 hour, crushed through a 30-mesh sieve, continued to dry until the moisture content was 4%, and obtained the raw material of olive pomace; 1. Under the condition of ultrasonic power 800W, ultrasonic-assisted extraction was performed for 30 minutes, and the virgin olive pomace crude oil and solvent were separated by a rotary evaporator, and the solvent was recovered at the same time, and then the virgin olive pomace crude oil was vacuum-dried. The vacuum drying conditions were: The vacuum degree is 0.09MPa, the temperature is 55°C, and the drying time is 60 minutes to obtain olive pomace crude oil; the olive pomace crude oil is subjected to anhydrous washing and long-mixing deacidification treatment, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com