Production method of spherical basic cobalt carbonate with controllable particle size

A production method and technology of cobalt carbonate, applied in the direction of cobalt carbonate, etc., can solve the problems of unfavorable fine production, uneven product particles, unstable product performance, etc., and achieve shortened nucleation induction period, good fluidity, and shortened induction shape. nuclear phase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

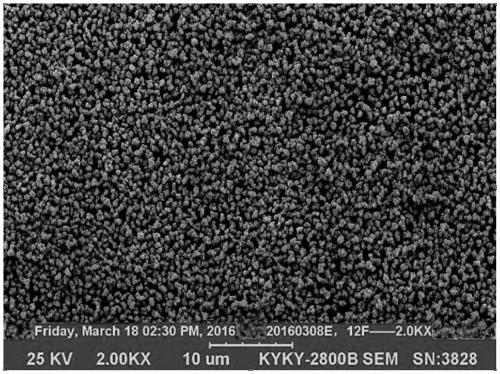

[0029] This embodiment is a production method of spherical cobalt basic carbonate with controllable particle size, comprising the following steps:

[0030]a. Preparation of solution; ①The preparation of cobalt solution, select CoCl 2 solution as a cobalt source, formulated as Co 2+ Soluble cobalt salt solution with a concentration of 0.5mol / L. ② Preparation of precipitant solution, prepare Na with soda ash 2 CO 3 solution, and Na 2 CO 3 The solution removes calcium and magnesium ions by ion exchange, and Na after removing calcium and magnesium ions 2 CO 3 Solution concentration is controlled at 80g / L, among them, Ca2 CO 3 The solution and deionized water are added into the reactor at a volume ratio of 1:1 as bottom water, heated up and stirred, wherein the stirring speed is controlled at 300rpm, and the reaction temperature is 45°C;

[0031] b. magnetically induced nucleation; open the magnetic field generating device, adjust the current size of the magnetic field gene...

Embodiment 2

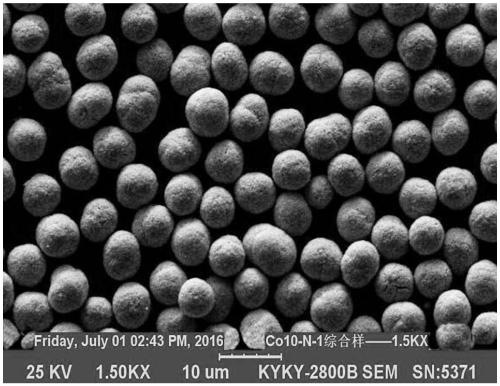

[0036] This embodiment is a production method of spherical cobalt basic carbonate with controllable particle size, comprising the following steps:

[0037] a. Preparation solution; ①The preparation of cobalt solution, choose CoSO 4 solution as a cobalt source, formulated as Co 2+ Soluble cobalt salt solution with a concentration of 2mol / L. ② Preparation of precipitant solution, prepare Na with soda ash 2 CO 3 solution, and Na 2 CO 3 The solution removes calcium and magnesium ions by ion exchange, and Na after removing calcium and magnesium ions 2 CO 3 Solution concentration is controlled at 150g / L, among them, Ca2 CO 3 The solution and deionized water are added into the reactor at a volume ratio of 1:1 as bottom water, heated up and stirred, wherein the stirring speed is controlled at 500rpm, and the reaction temperature is 60°C;

[0038] b. magnetic induction nucleation; open the magnetic field generating device, adjust the current size of the magnetic field generator...

Embodiment 3

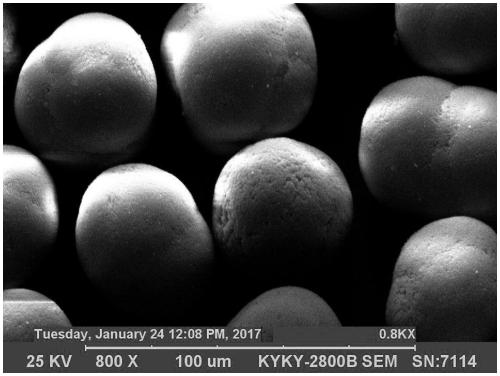

[0043] This embodiment is a production method of spherical cobalt basic carbonate with controllable particle size, comprising the following steps:

[0044] a. preparation solution; ① the preparation of cobalt solution, select Co(NO 3 ) 3 solution as a cobalt source, formulated as Co 2+ Soluble cobalt salt solution with a concentration of 2.5mol / L. ② Preparation of precipitant solution, prepare Na with soda ash 2 CO 3 solution, and Na 2 CO 3 The solution removes calcium and magnesium ions by ion exchange, and Na after removing calcium and magnesium ions 2 CO 3 Solution concentration is controlled at 200g / L, among them, Ca2 CO 3 The solution and deionized water are added into the reactor at a volume ratio of 1:1 as bottom water, heated up and stirred, wherein the stirring speed is controlled at 1000rpm, and the reaction temperature is 85°C;

[0045] b. magnetically induced nucleation; open the magnetic field generating device, adjust the current size of the magnetic fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com