Hydraulic driving underwater drilling machine drill bit structure

A technology for driving water and drill bits, which is applied to drill bits, drilling equipment, earthwork drilling and production, etc. It can solve problems such as low degree of automation, easy wear and failure of circlips, and complicated coring process, achieving ingenious structural design and prolonging service life. , the effect of slowing down wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

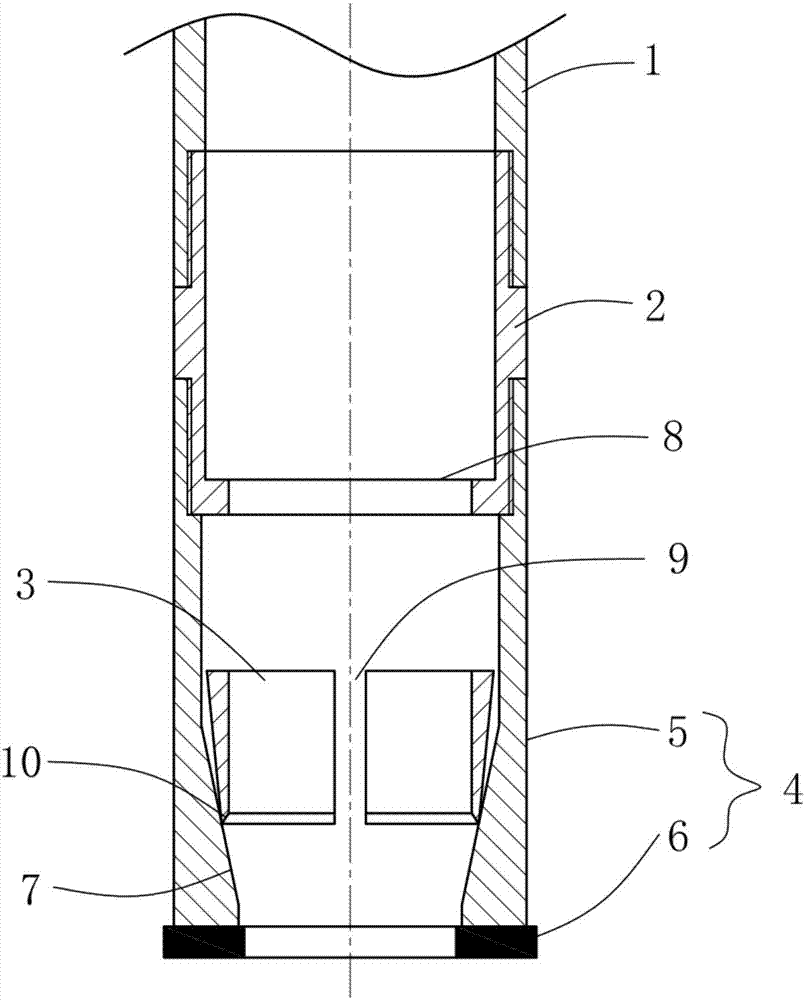

[0014] like figure 1 As shown, a drill bit structure of a hydraulically driven underwater drilling rig includes a core pipe 1 , a straight-through joint 2 , a retaining spring 3 and a drill bit 4 arranged coaxially. With the drilling direction of the drill bit 4 as the front, the front end of the core pipe 1 is threadedly connected to the rear end of the through joint 2. The drill bit 4 is an integrated structure formed by hot pressing of the drill steel body 5 at the rear end and the diamond matrix 6 at the front end. The inner wall of the rear end of the body 5 is threadedly connected with the front end of the through joint 2, and the inner wall of the front end is provided with an inverted conical surface 7. The minimum inner diameter of the inverted conical surface 7 is greater than the inner diameter of the diamond matrix 6, and the largest inner diameter is the inner wall aperture of the drill steel body 5. Circlip 3 is an inverted conical elastic tubular structure consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com