Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

129 results about "Sliding wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

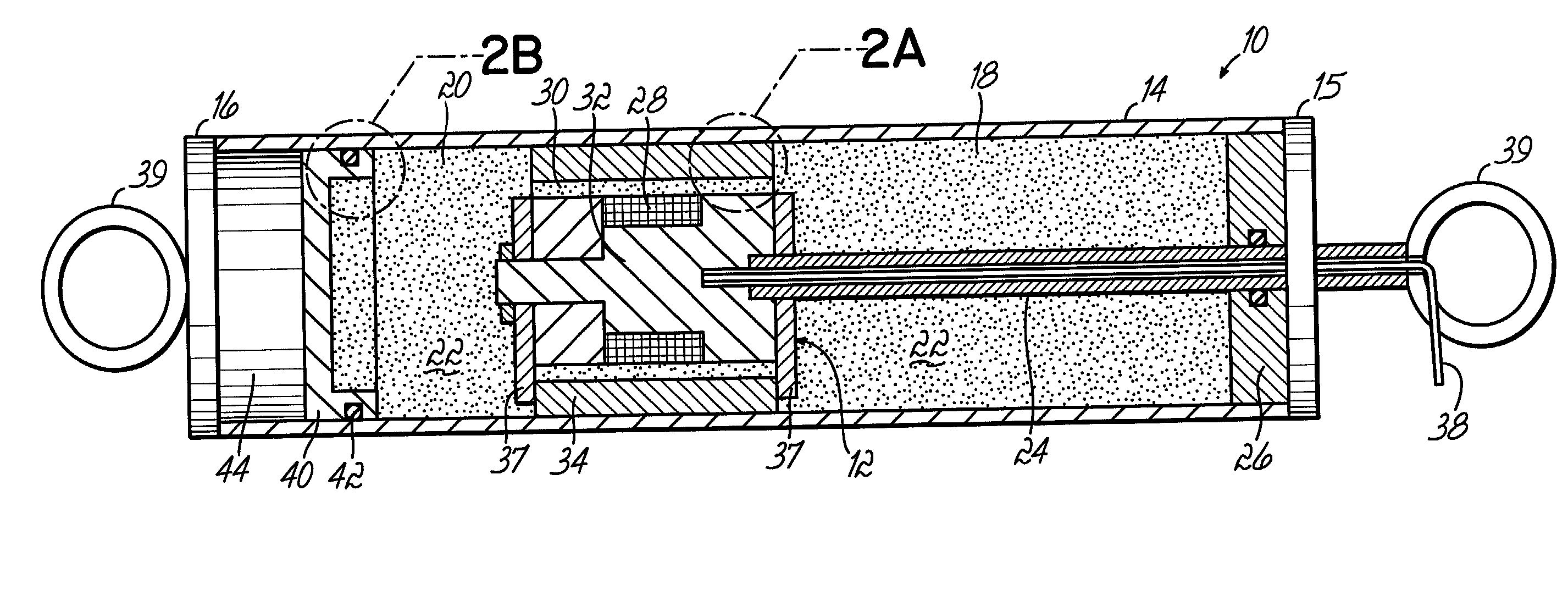

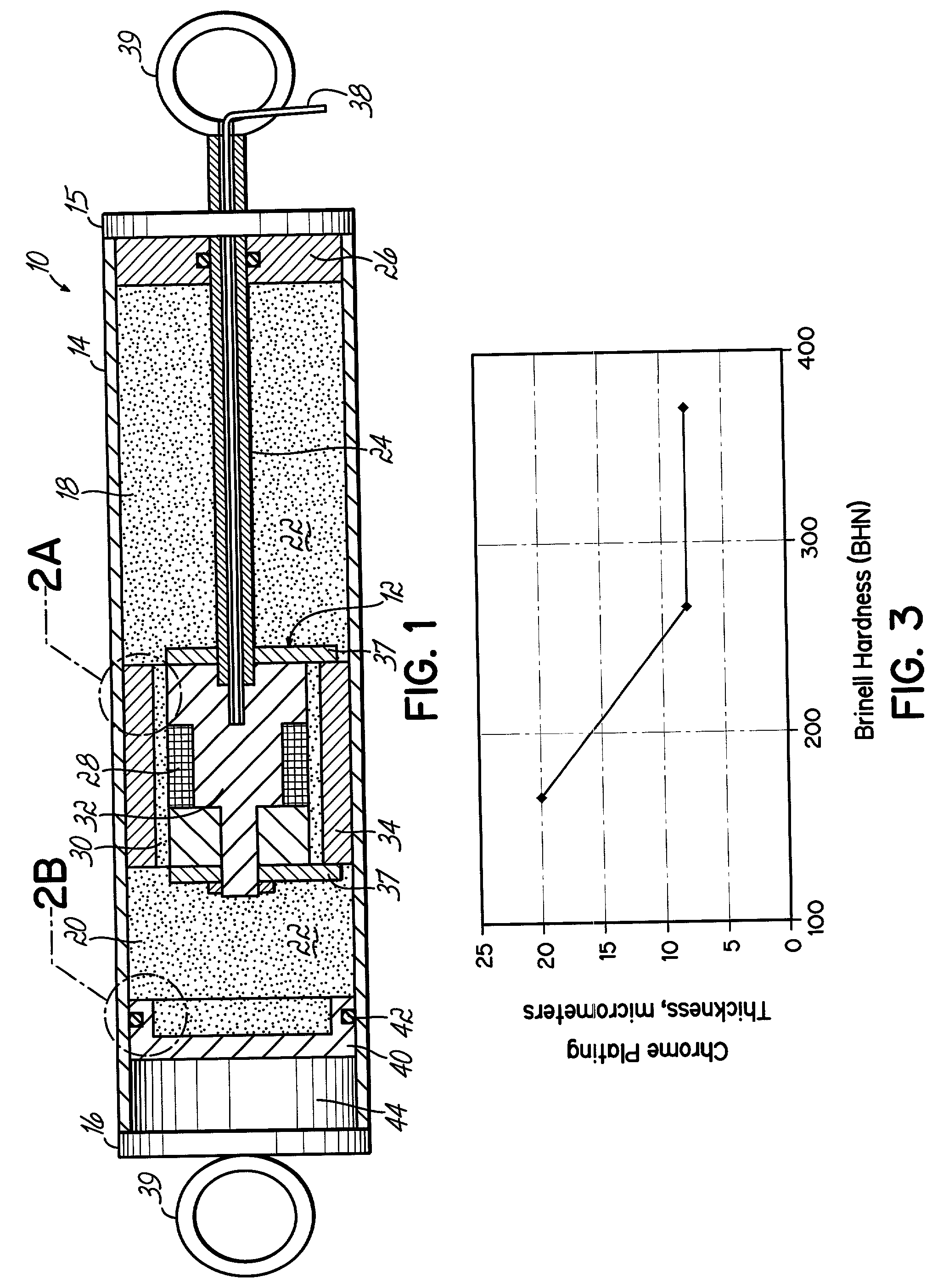

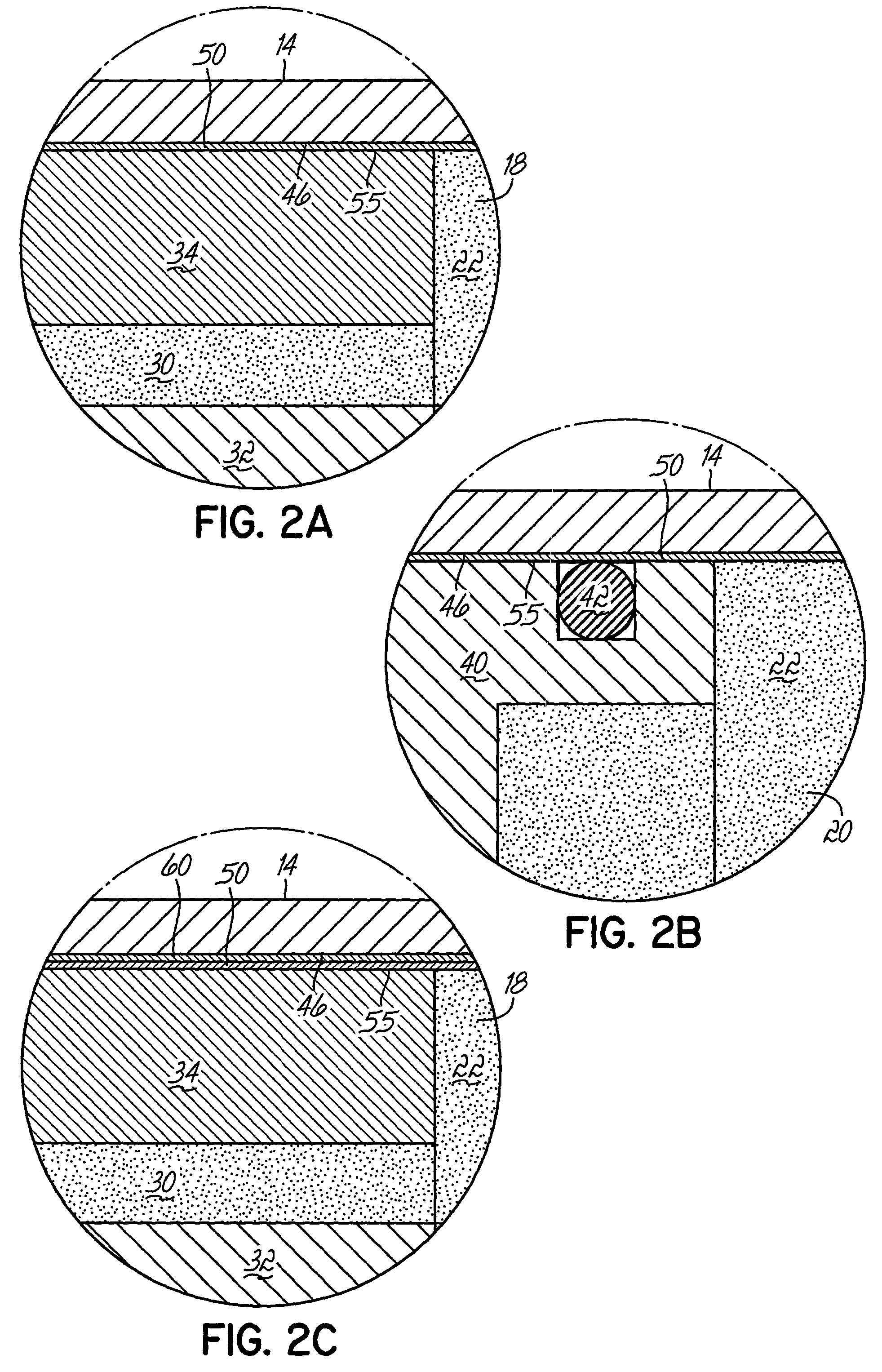

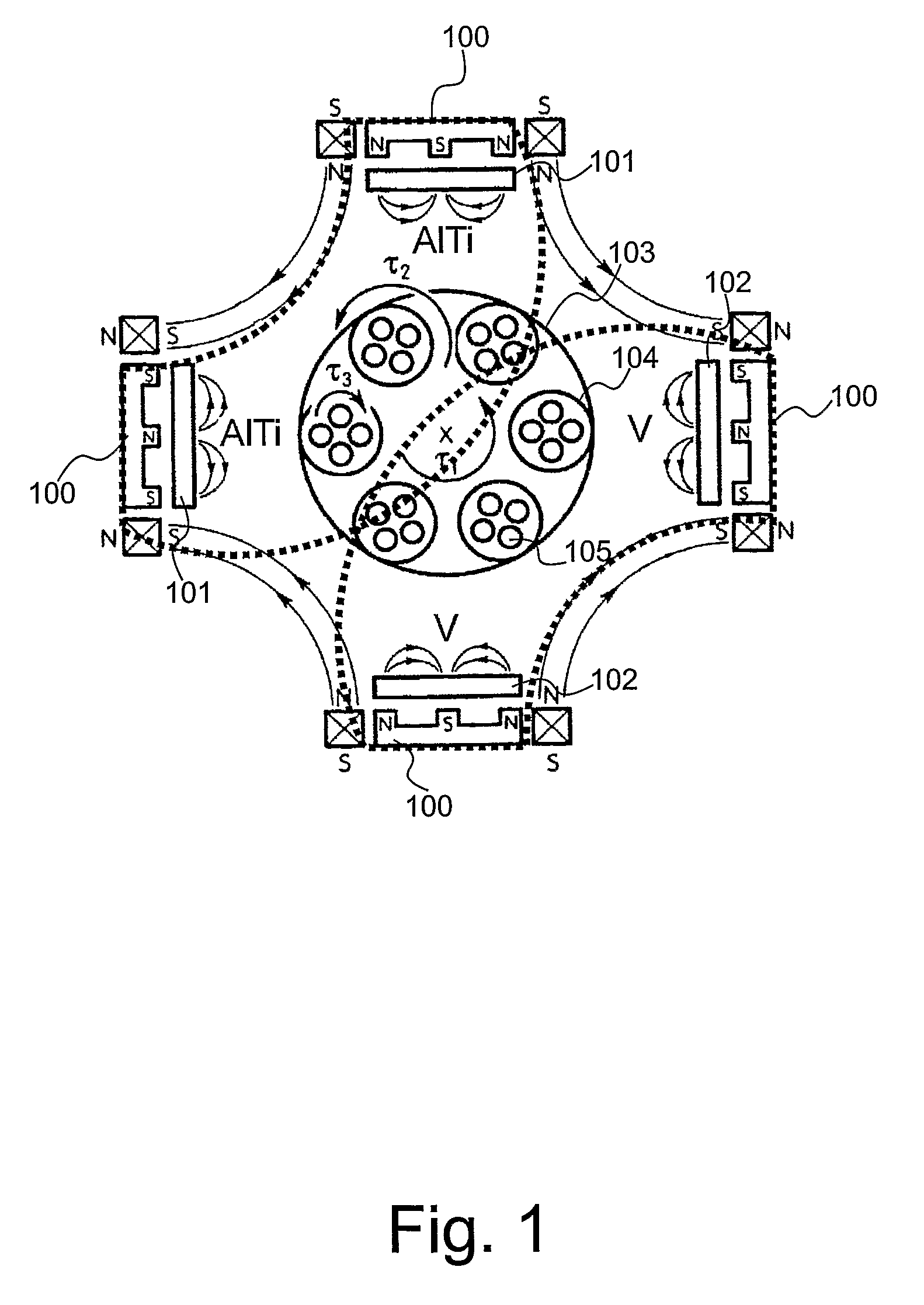

Magnetorheological dampers with improved wear resistance

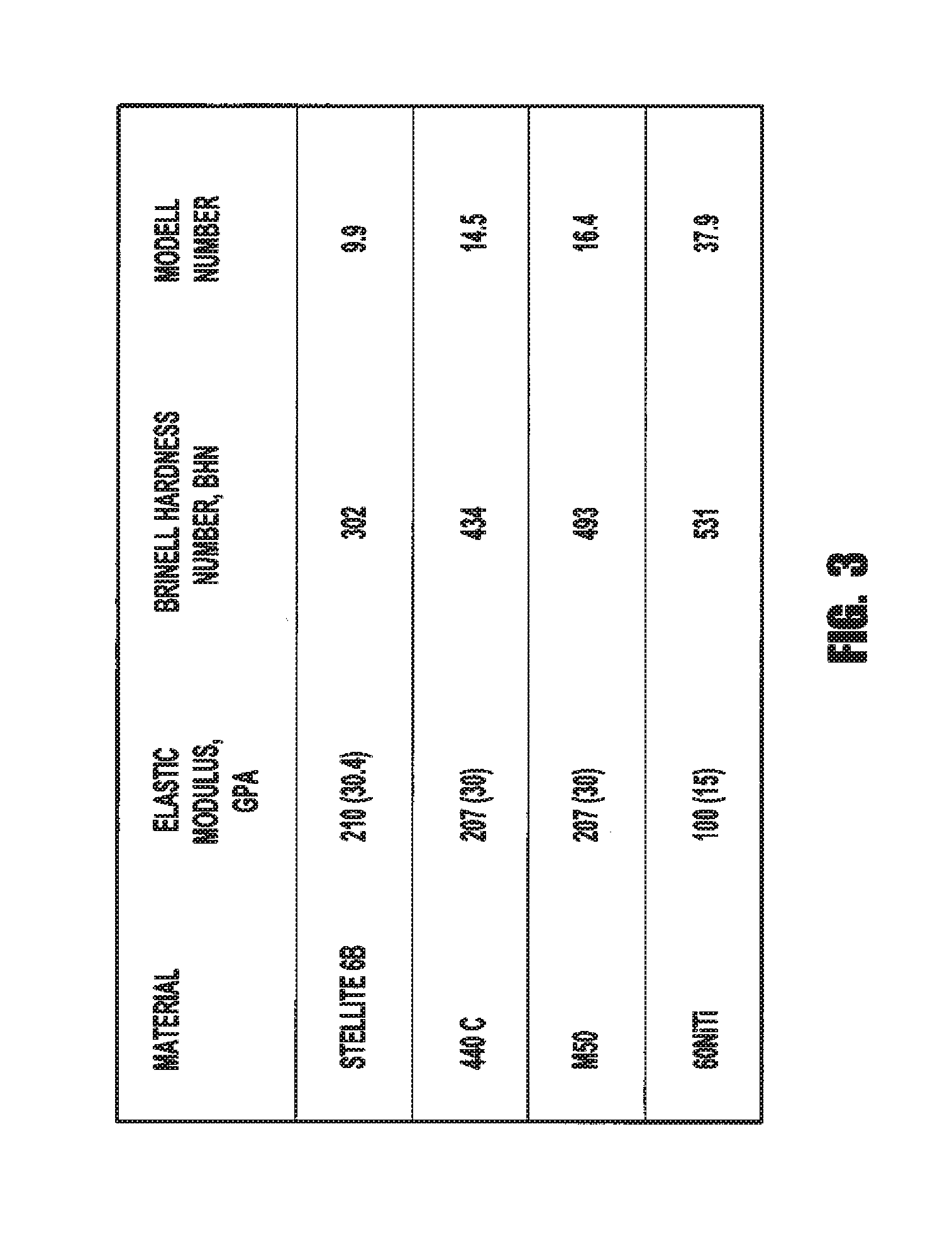

InactiveUS20020130003A1Improve wear resistanceIncrease effective viscositySpringsNon-rotating vibration suppressionEngineeringHardness

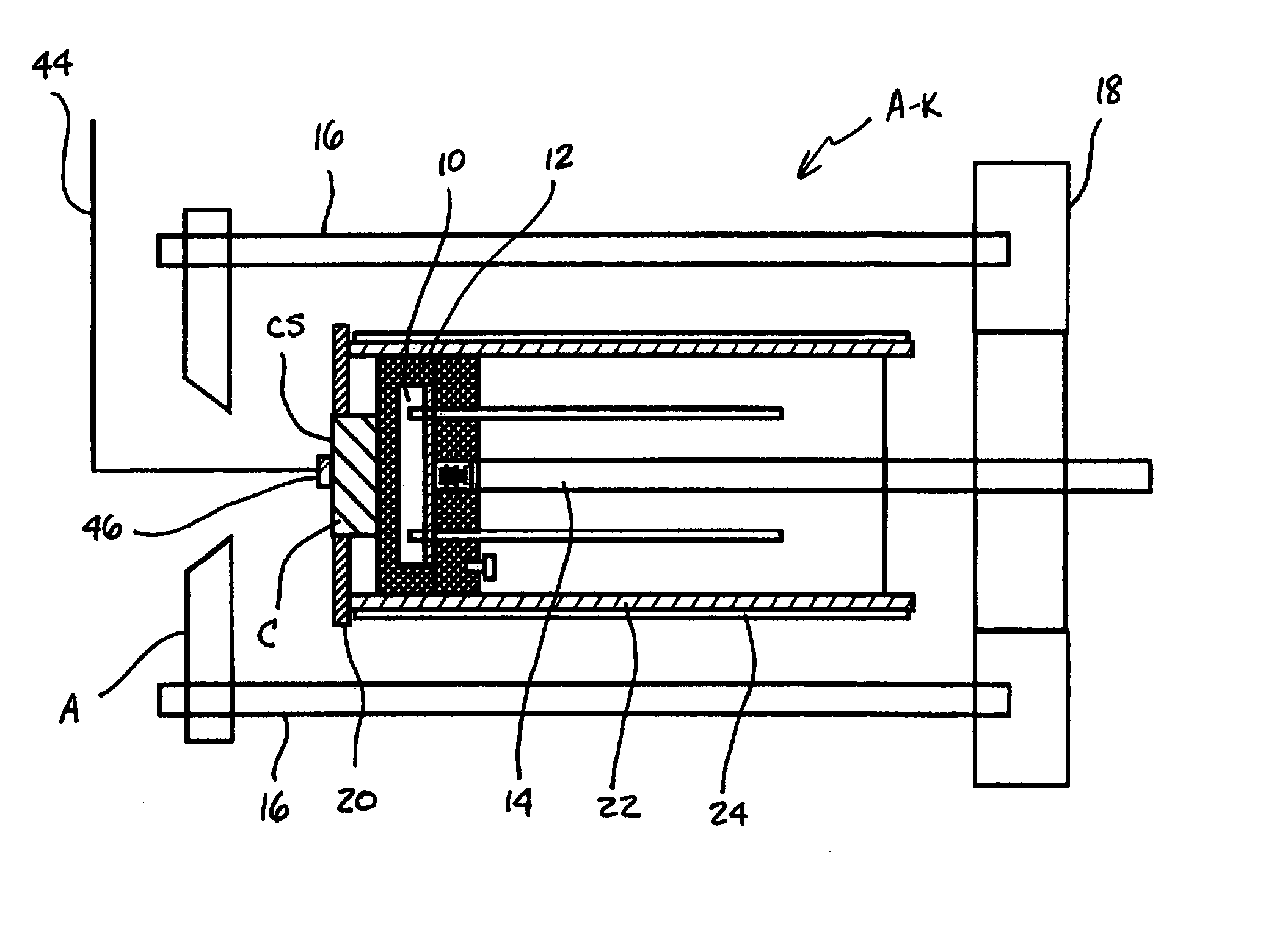

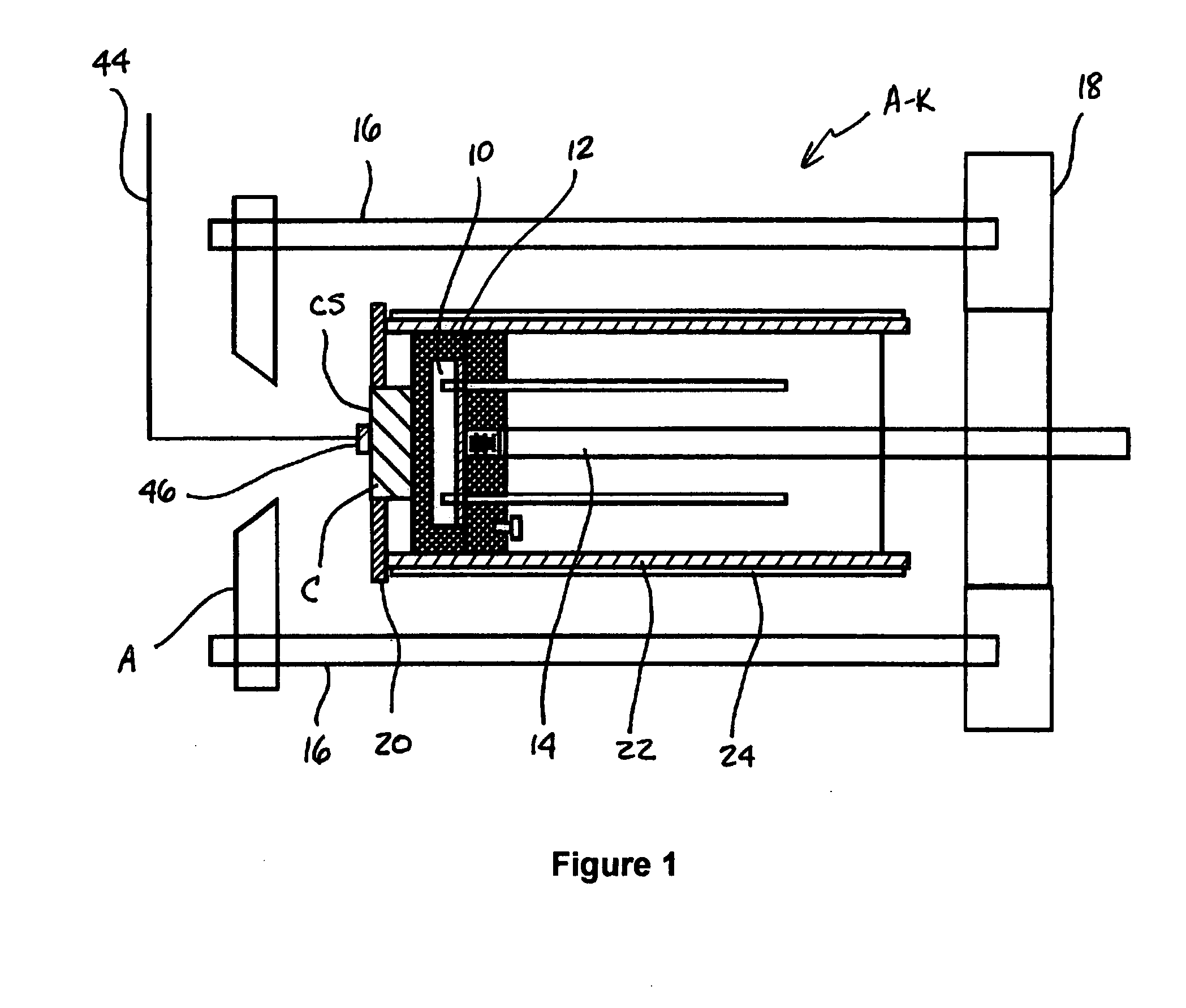

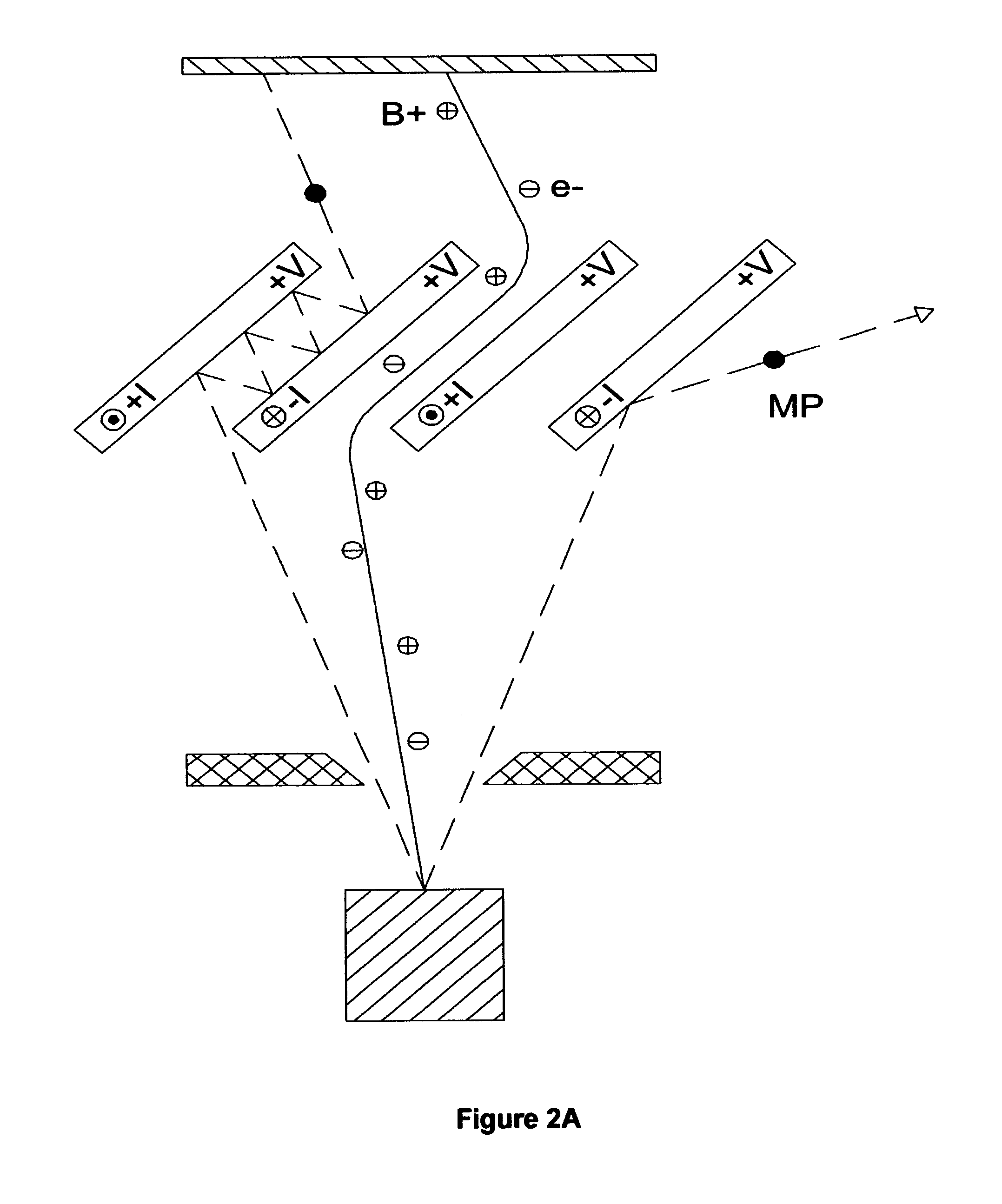

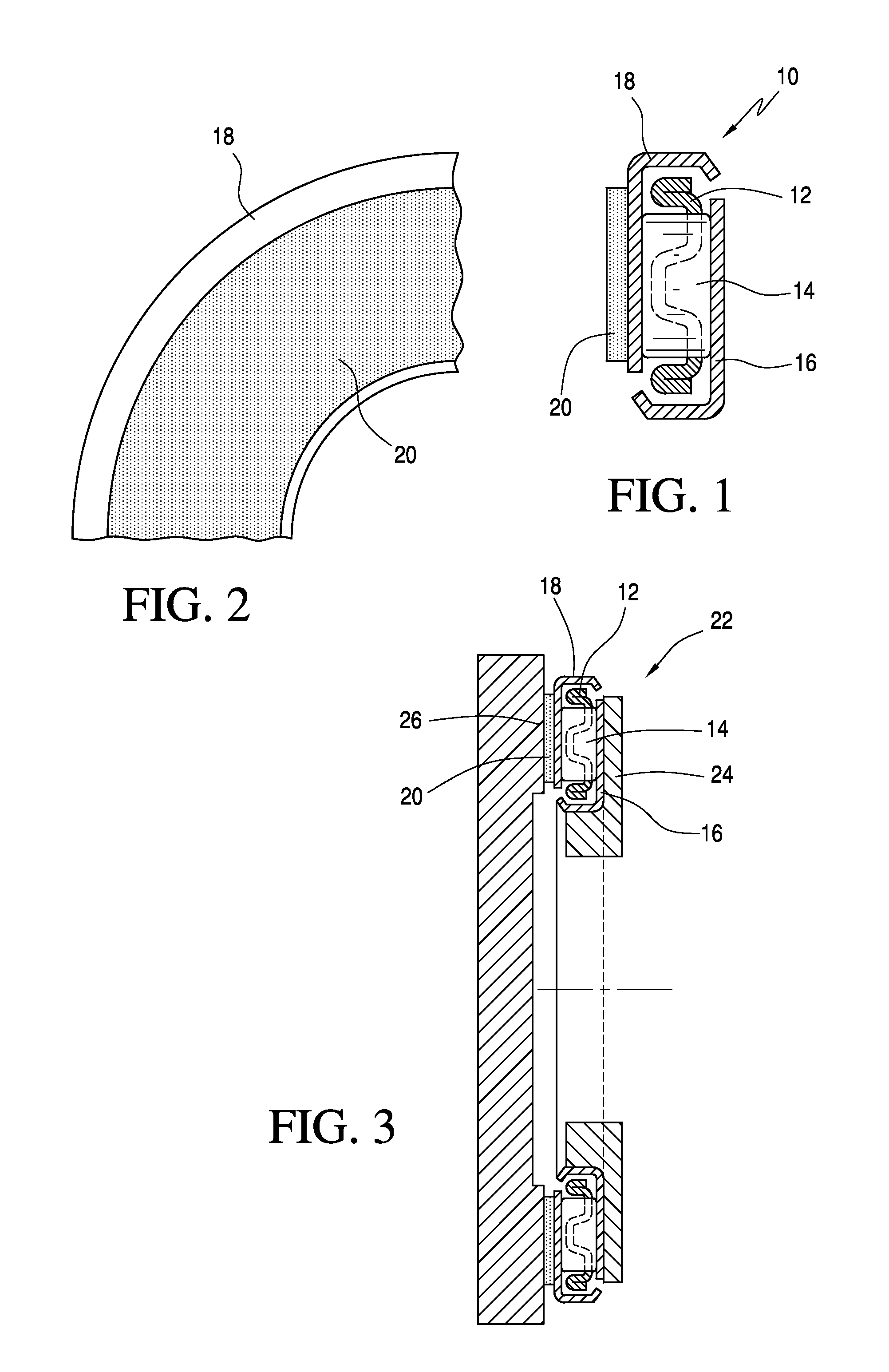

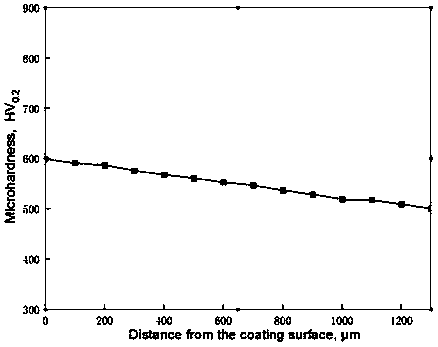

A damper body for a magnetorheological (MR) damper and associated methods of forming the damper body. The damper body is formed of a base material, such as a steel, and is coated with an abrasion-resistant layer comprising chromium. The layer of chromium provides a sliding wear surface for sliding contact with a reciprocating piston. To avoid high-stress abrasive wear over the expected service life of the magnetorheological damper, the layer of chromium has a minimum thickness greater than or equal to a minimum thickness of about 8 .mu.m. In other embodiments, be fore applying the abrasion-resistant layer of chromium, the damper body is coated with a layer of a hard coating material having a hardness greater than the hardness of the base material. The effective hardness of the damper body is a composite of the respective hardnesses of the base material comprising the damper body and the layer of hard coating material. The thickness of abrasion-resistant layer of chromium is chosen in direct relation to the effective hardness.

Owner:BWI CO LTD SA +1

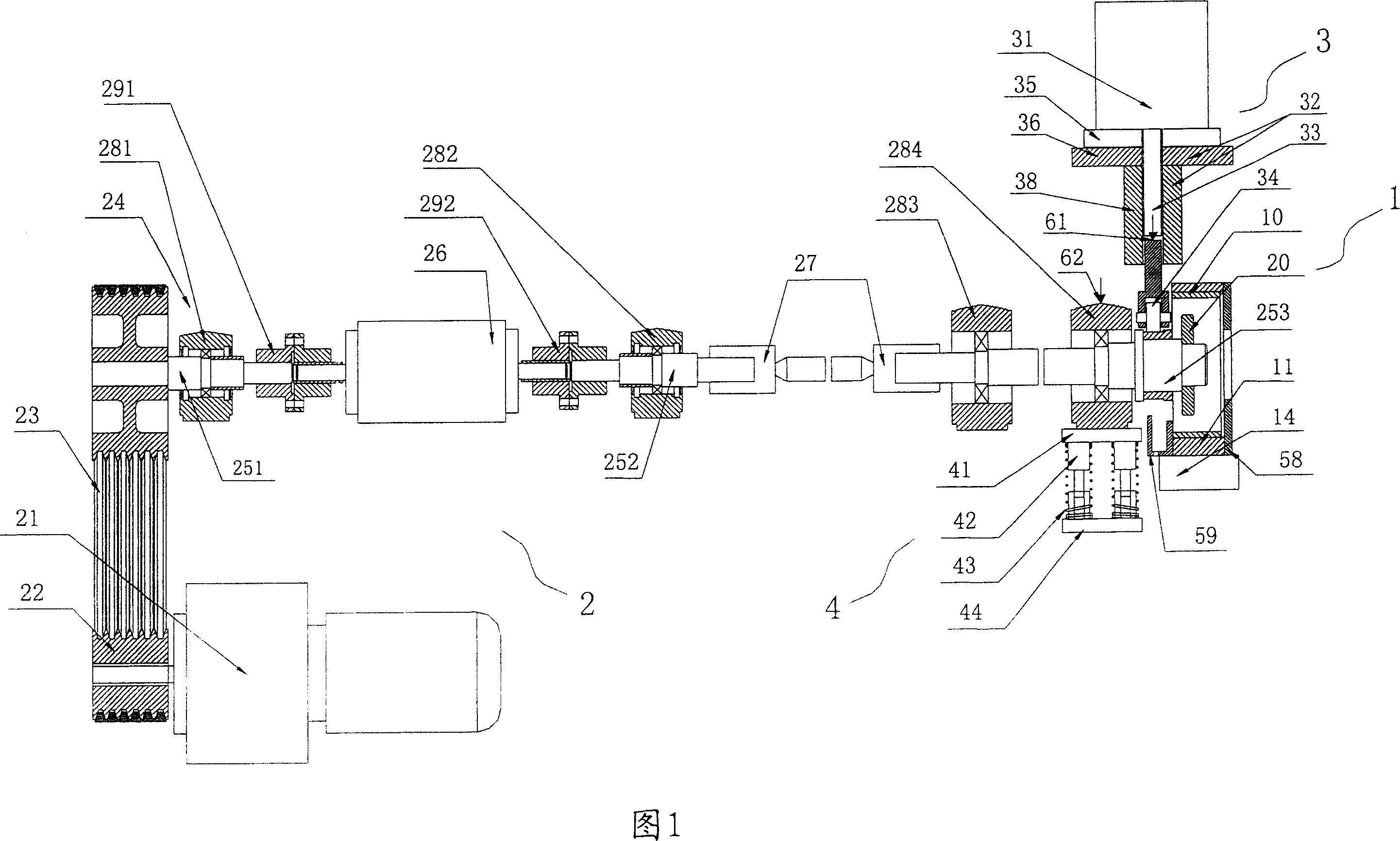

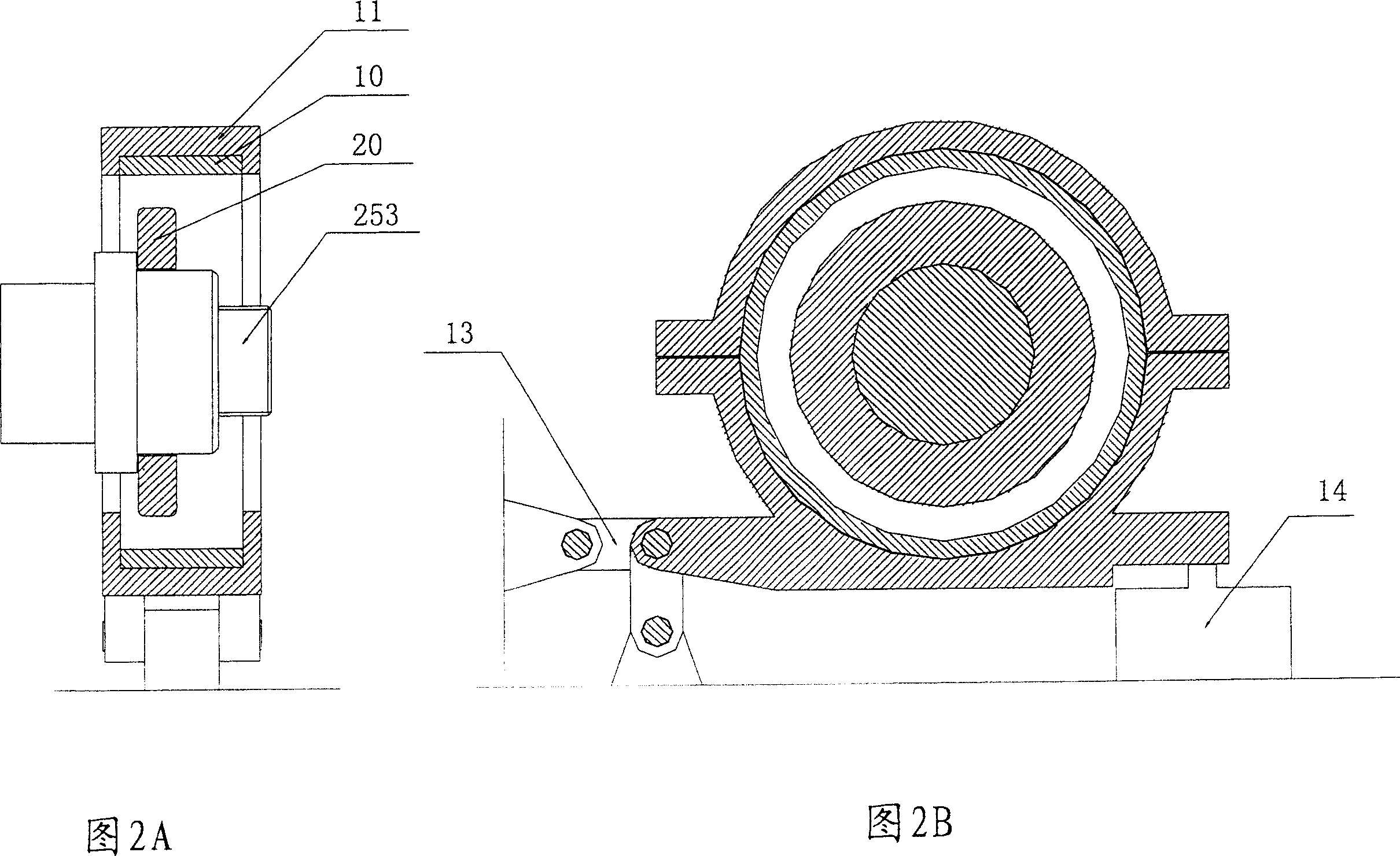

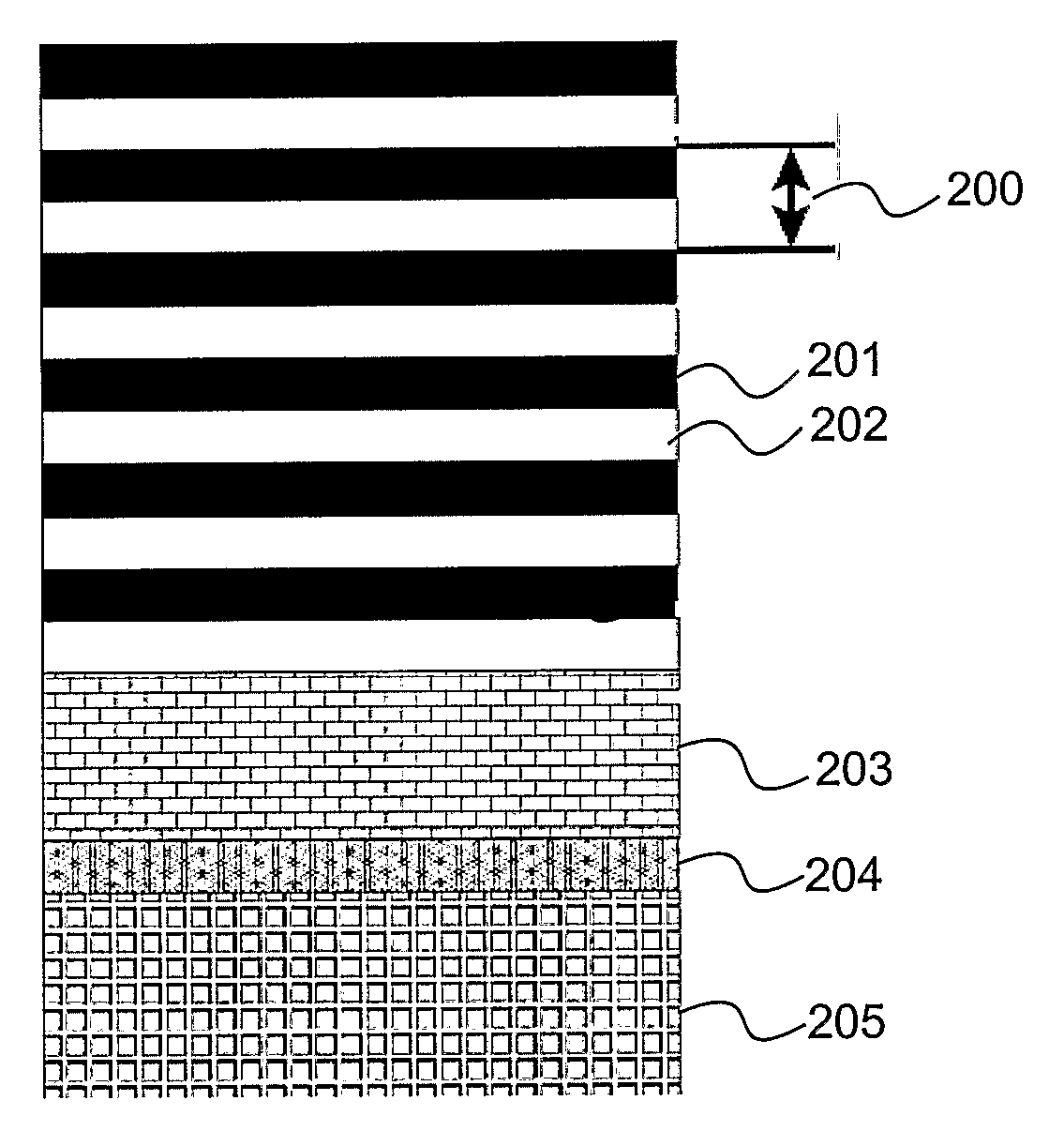

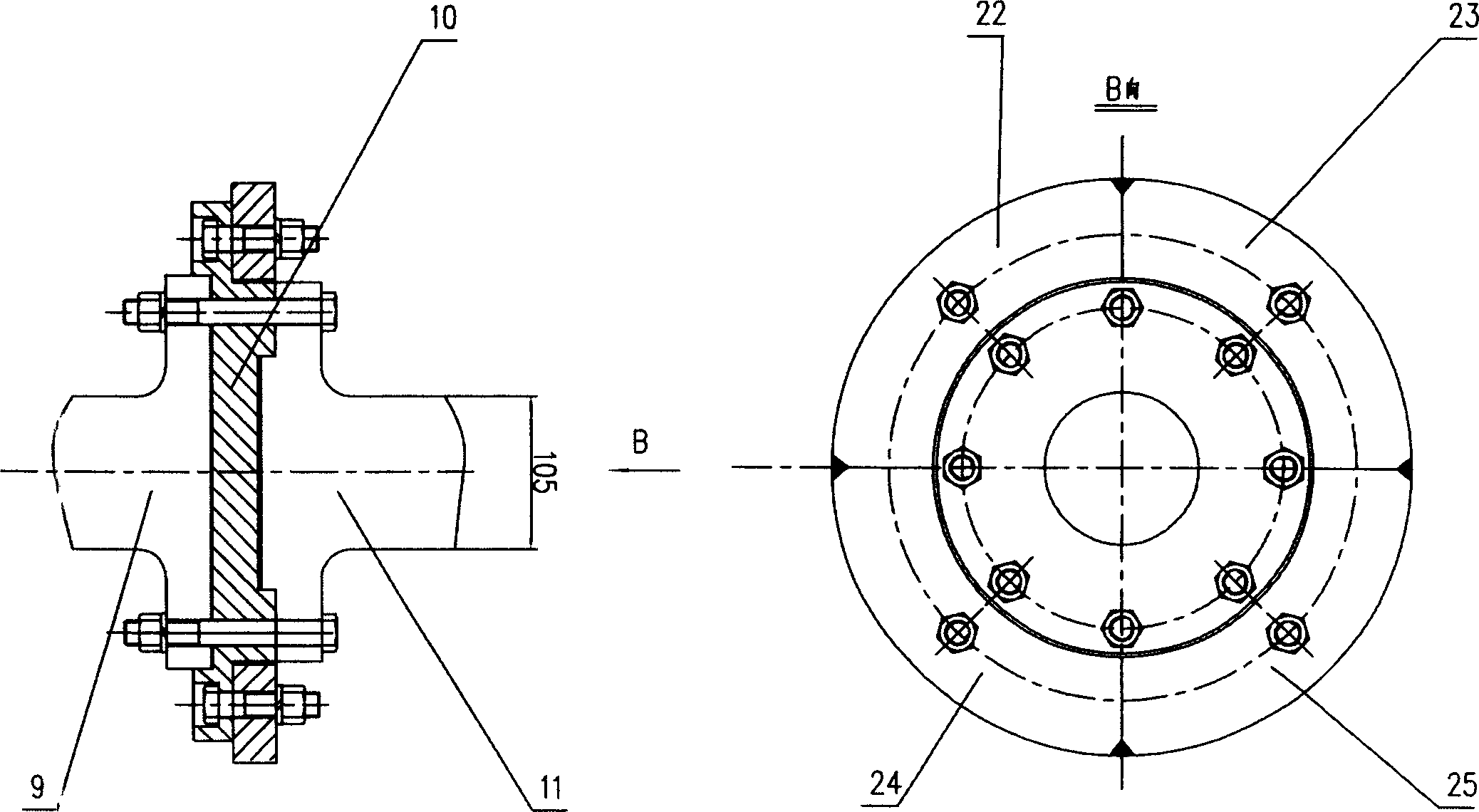

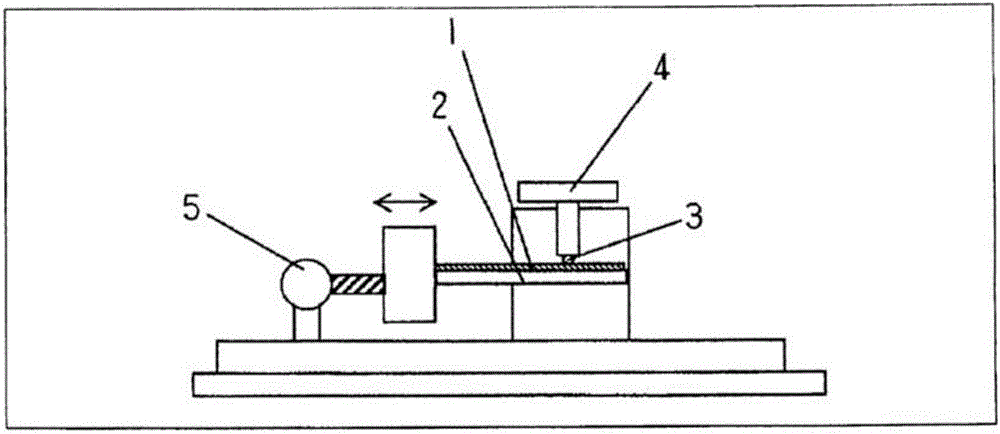

Petroleum drilling pipe shocking and sliding wear tester

InactiveCN1967202ARealize multi-phase circulationFlow adjustableStructural/machines measurementUsing mechanical meansOil drillingPetroleum

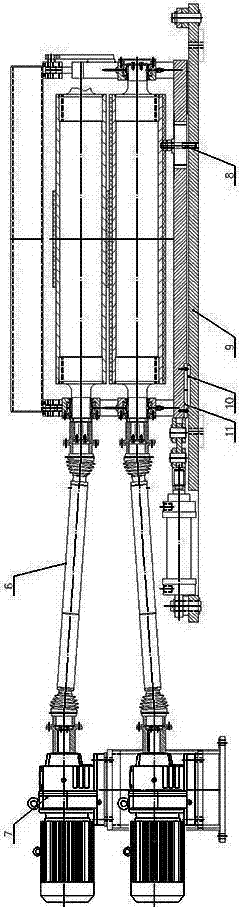

The invention discloses an oil drilling rod shock slide abrasion tester, including the fixture system, the transmission system and the excitation system, in which the said fixture system clamping fixes the tubular specimen, and the one end of the said transmission system equips the rod specimen corresponding to the tubular specimen, and the said transmission system drives the rod specimen rotating with the axis, and the said excitation system provides radial shock to the said rod specimen, to drive the rod specimen shocks the tubular specimen fixed in the fixture system at the same time of rotating, to realize the composite shock slide friction, and through the friction, transmit the torque to the rod specimen. The invention overcomes the limitation of the existing abrasion testers, and it can realize rod friction and abrasion study of shock slide composite working conditions of controlled shock load type under the condition of multiphase cycle lubricating medium, and it can not only realize multiphase media cycle of adjustable flow and variable components, but also realize the complex impact of adjustable shock size, controllable wave-type.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

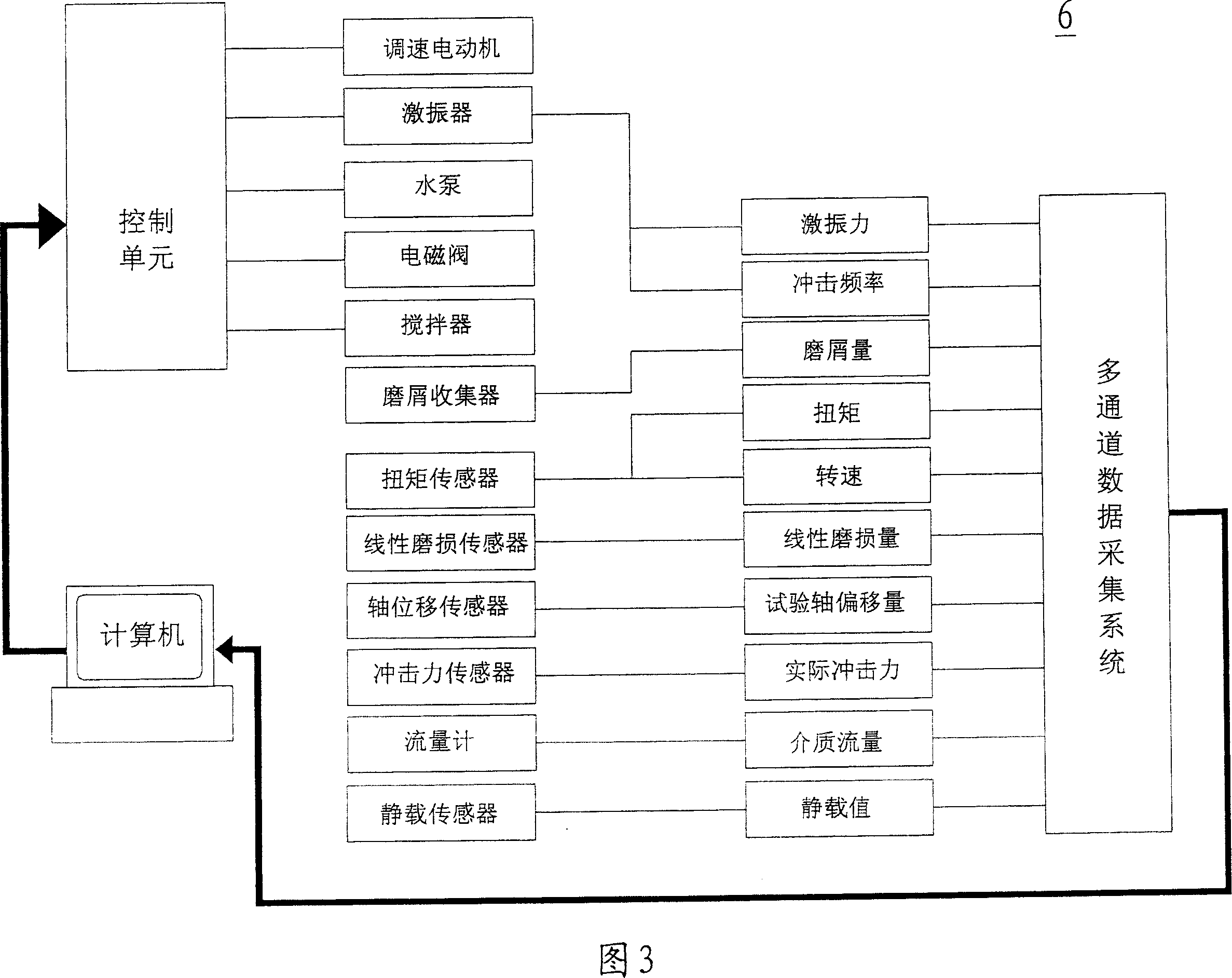

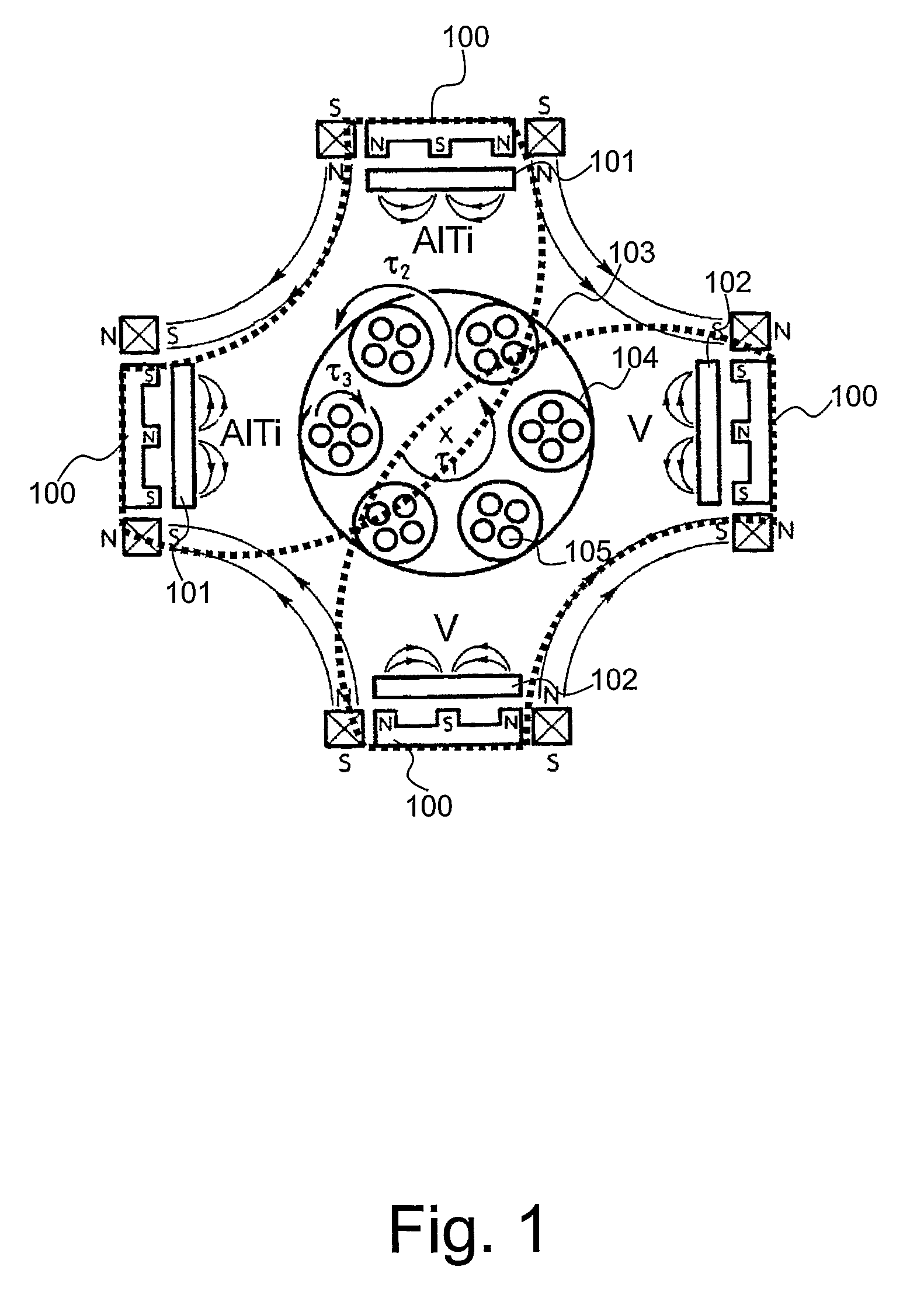

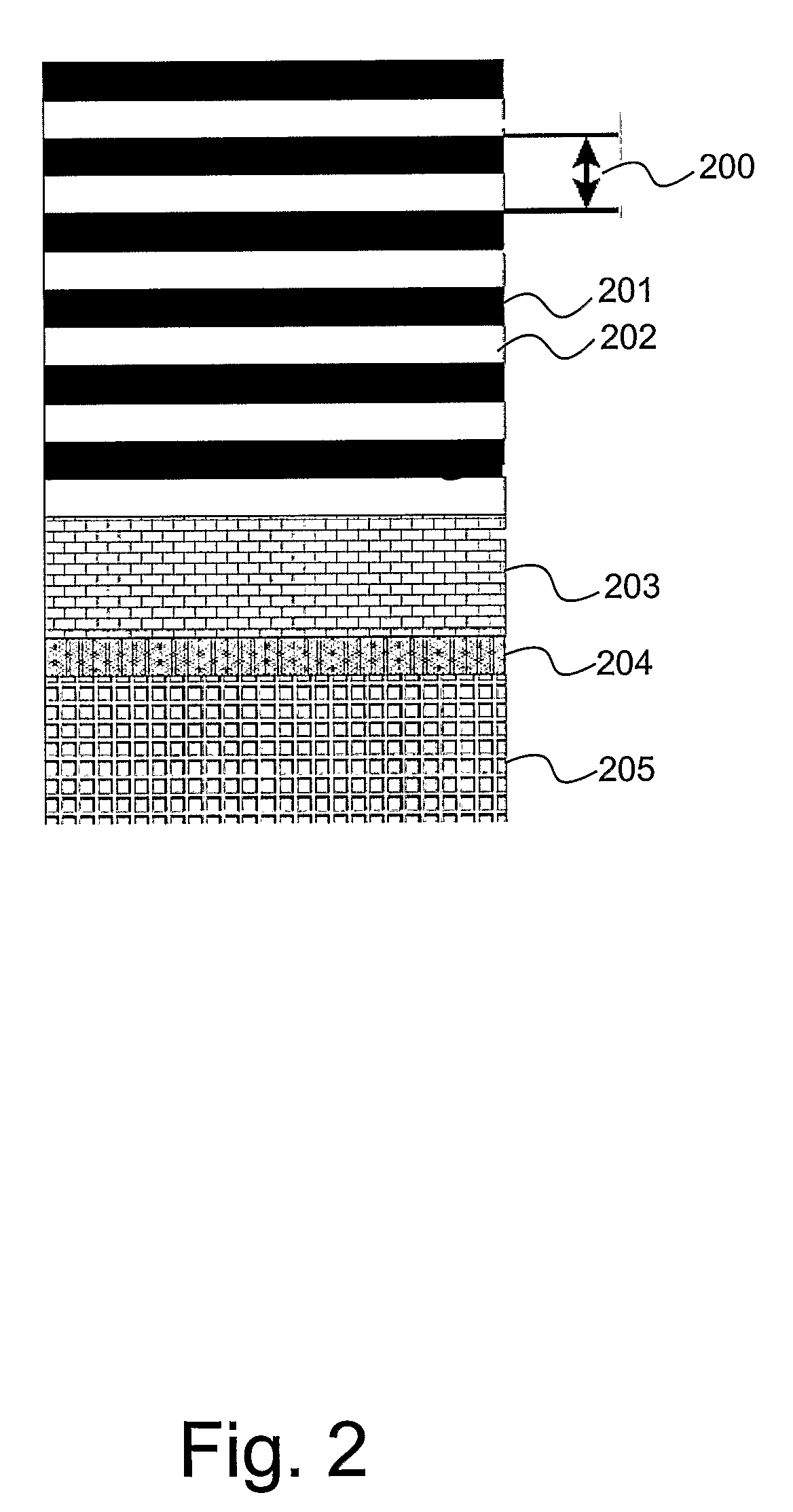

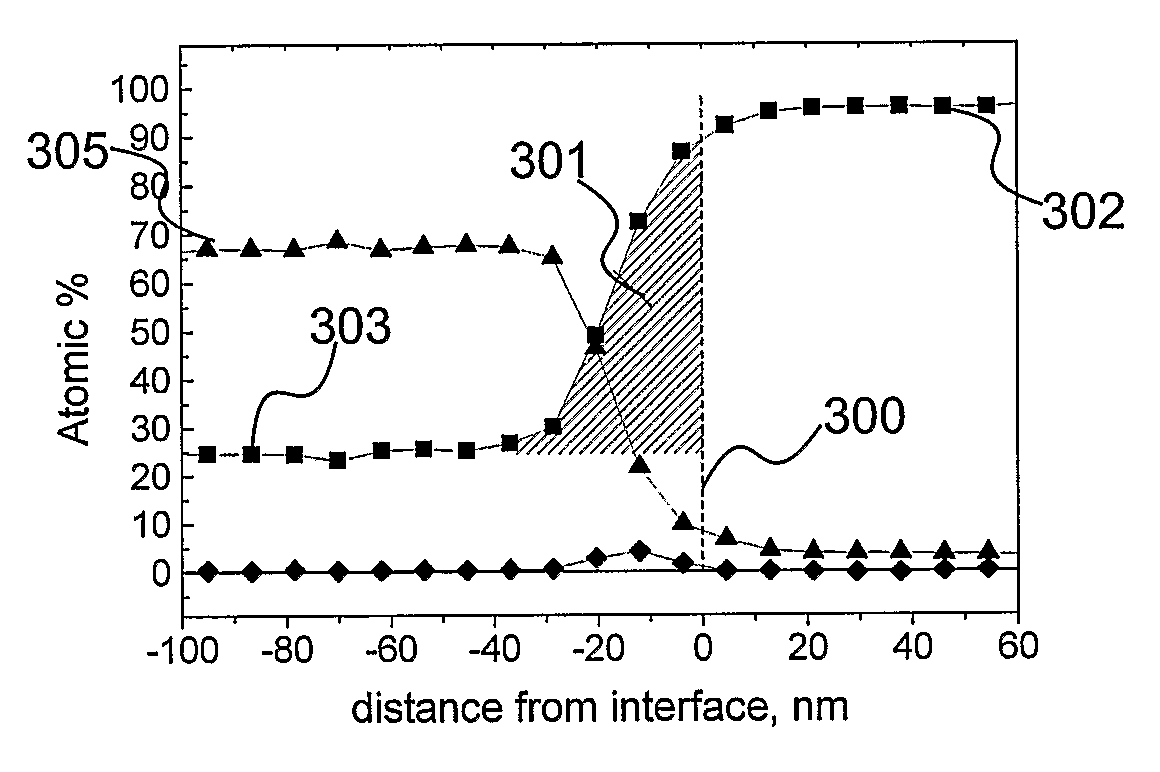

Pvd Coated Substrate

InactiveUS20080260478A1High hardnessReduce coefficient of frictionPigmenting treatmentVacuum evaporation coatingMetal alloyHardness

A PVD coating is disclosed, and in particular a nanoscale multilayer superlattice PVD coating comprising high hardness, a low friction coefficient and increased chemical inertness. The multilayer coating comprises a repeating bilayer represented by (VxMe(i-x))CyN(i-y) / (MezV(1-z))CyN(i-y) where 0.1≦x≦0.9; 0.01<y<0.99 and 0.1≦z≦0.9 and Me is a substantially pure metal or a metal alloy. The composition of the coating through the layers alternates from layer to layer according to a V-rich layer and a Me-rich layer modulated sequence. Vanadium is incorporated within the layer composition and has been found to act as a lubricating agent during sliding wear. Carbon, also incorporated within the coating, serves to further stabilise the friction coefficient thereby increasing the chemical inertness between cutting tool and workpiece material.

Owner:SHEFFIELD HALLAM UNIVERSITY

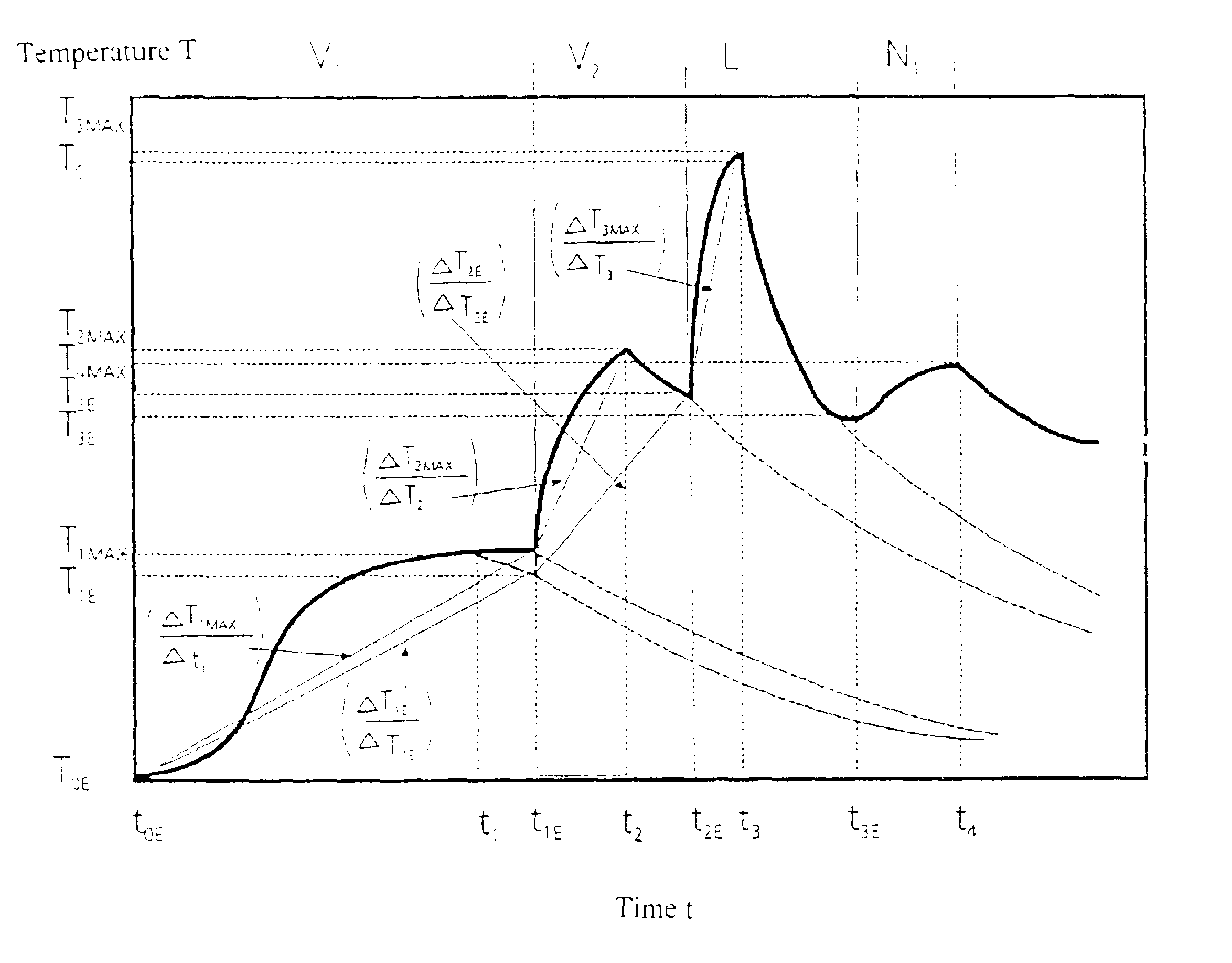

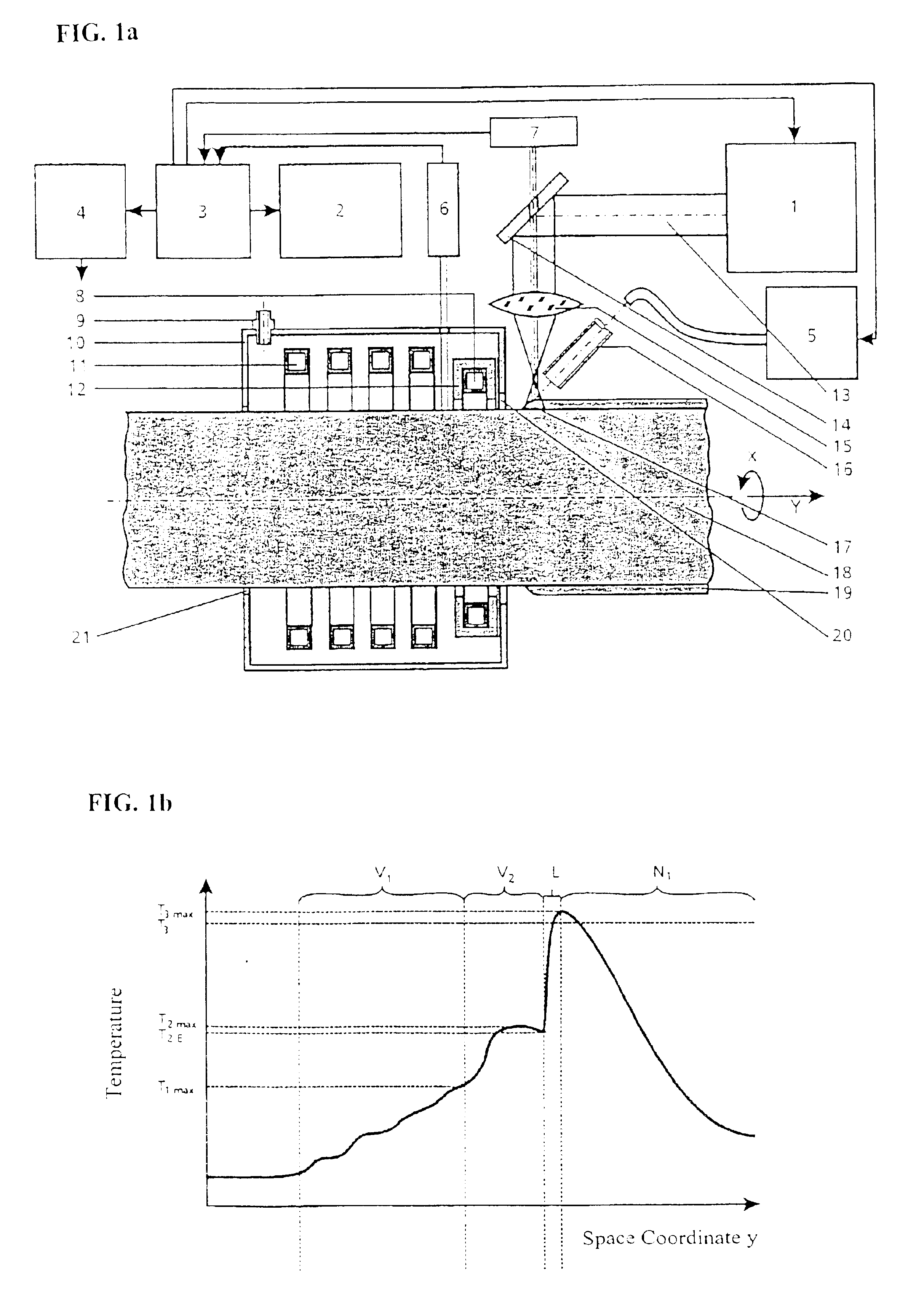

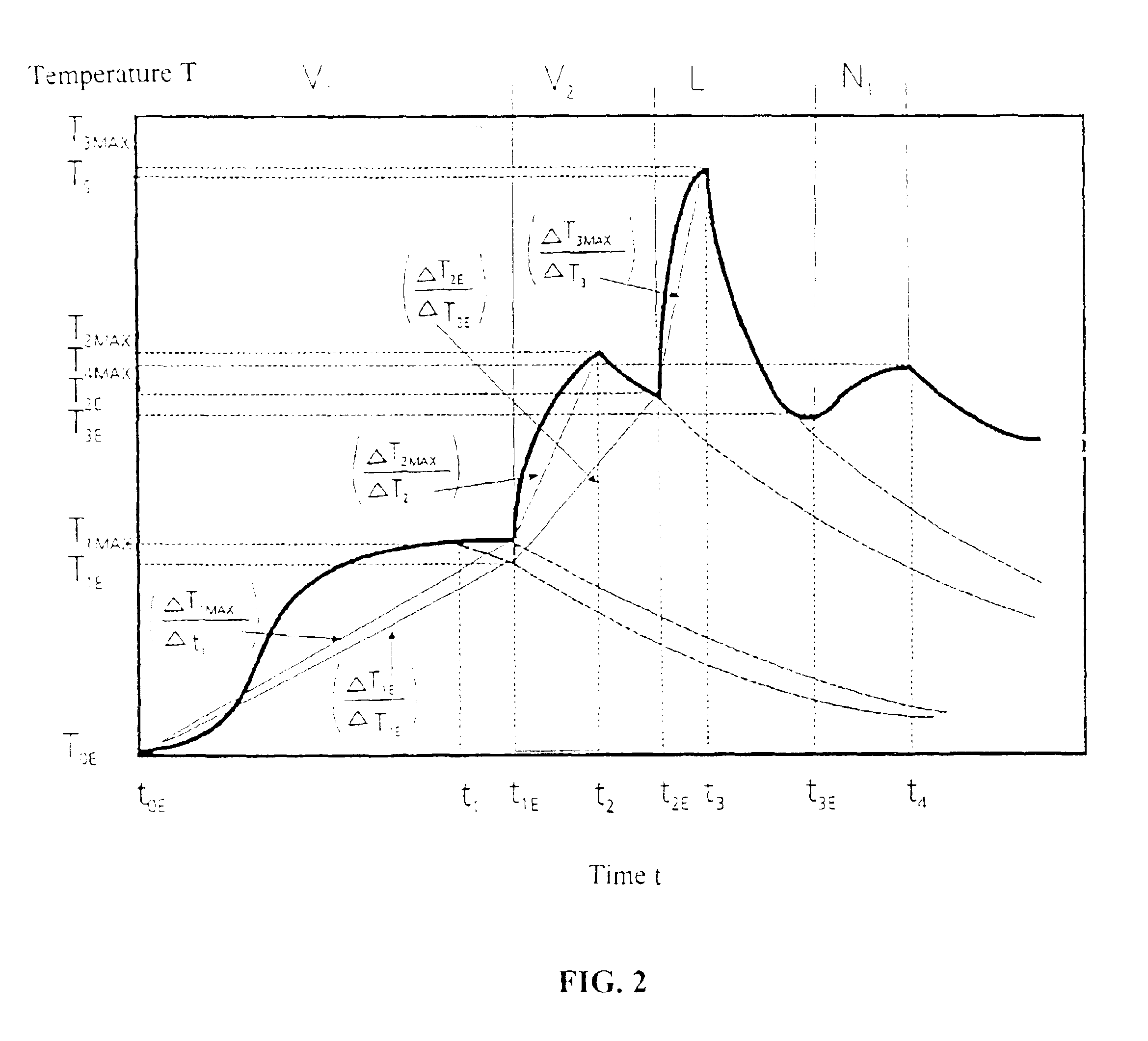

Process for producing wear-resistant surface layers

InactiveUS6843866B2Increase feed rateReduce power densityFurnace typesPlasma welding apparatusSurface layerWear resistant

Process for the effective production of very wear-resistant layers in the thickness range of 0.2 to approx. 3 mm by way of inductively supported surface layer modification. It can be used particularly advantageously for the protection of components of hardenable steels and cast iron with abrasive, corrosive, high-temperature corrosive or mineral sliding wear loading. With the process according to the invention a local two-stage inductive short-time preheating takes place directly before the surface layer coating. Due to the invention it is possible to coat even hardenable steels or other materials difficult to coat without cracking. Furthermore, even harder coating materials susceptible to cracking which provide better wear-resistances can be used. In addition, process speeds and surface coating performances can be achieved that are higher by a factor of 10 compared with conventional laser build-up welding. This abstract is neither intended to define the invention disclosed in this specification nor intended to limit, in any manner, the scope of the invention.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Assembly type solar photovoltaic power generation road surface module and application thereof

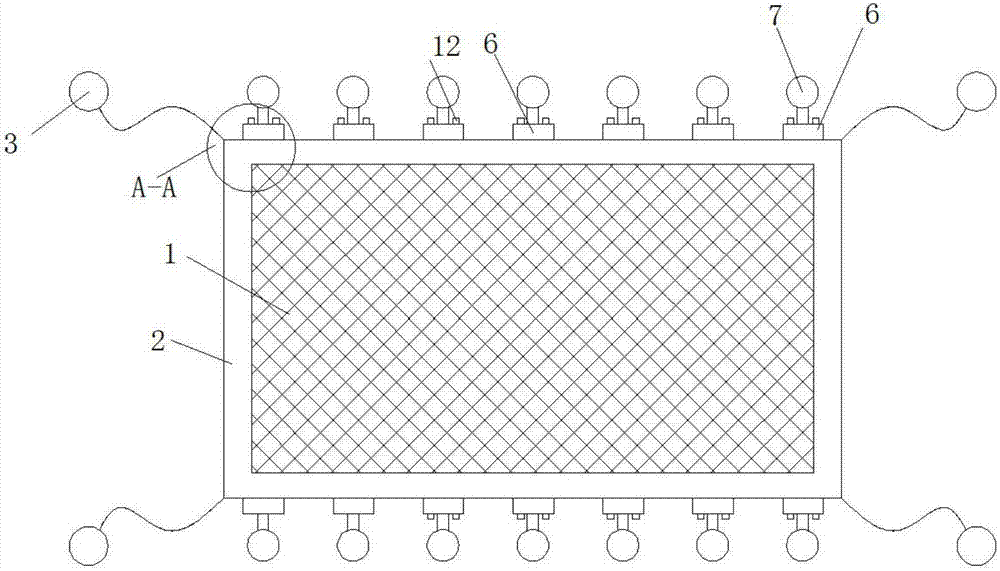

InactiveCN106549629AIncrease profitCapable of bearing pressurePhotovoltaic supportsPhotovoltaic energy generationComputer moduleRoad surface

The present invention provides an assembly type solar photovoltaic power generation road surface module and application thereof. The module comprises at least the following structures from bottom to top: an insulated sealing layer, a solar photovoltaic panel layer, and a transparent anti-slide wearing layer. The module is mainly used for solar photovoltaic power generation. The assembly type solar photovoltaic power generation road surface module can meet both the road bearing demand and the solar photovoltaic power generation demand, and has a broad market prospect.

Owner:张宏超 +1

Device for measuring high-speed electrical sliding wear

InactiveCN101008596AEffective electrical wear test resultsUsing mechanical meansInvestigating abrasion/wear resistanceMeasurement deviceDevice form

This invention discloses one high speed slide electrical friction loss measurement device, which comprises electrical loss mechanic device, power control part, resistance box and test meter, wherein, the mechanic device forms loop circuit between copper disc and test materials through high speed rotation copper disc and slide electrical contact materials to make the test materials generate electrical arc erosion by relative motion to test for one load charge, one line or weight friction loss and rotation ring number; the power control part is to provide direct power to the mechanic device and the resistance box is to adjust interface friction mechanic device current size.

Owner:XIAN UNIV OF TECH

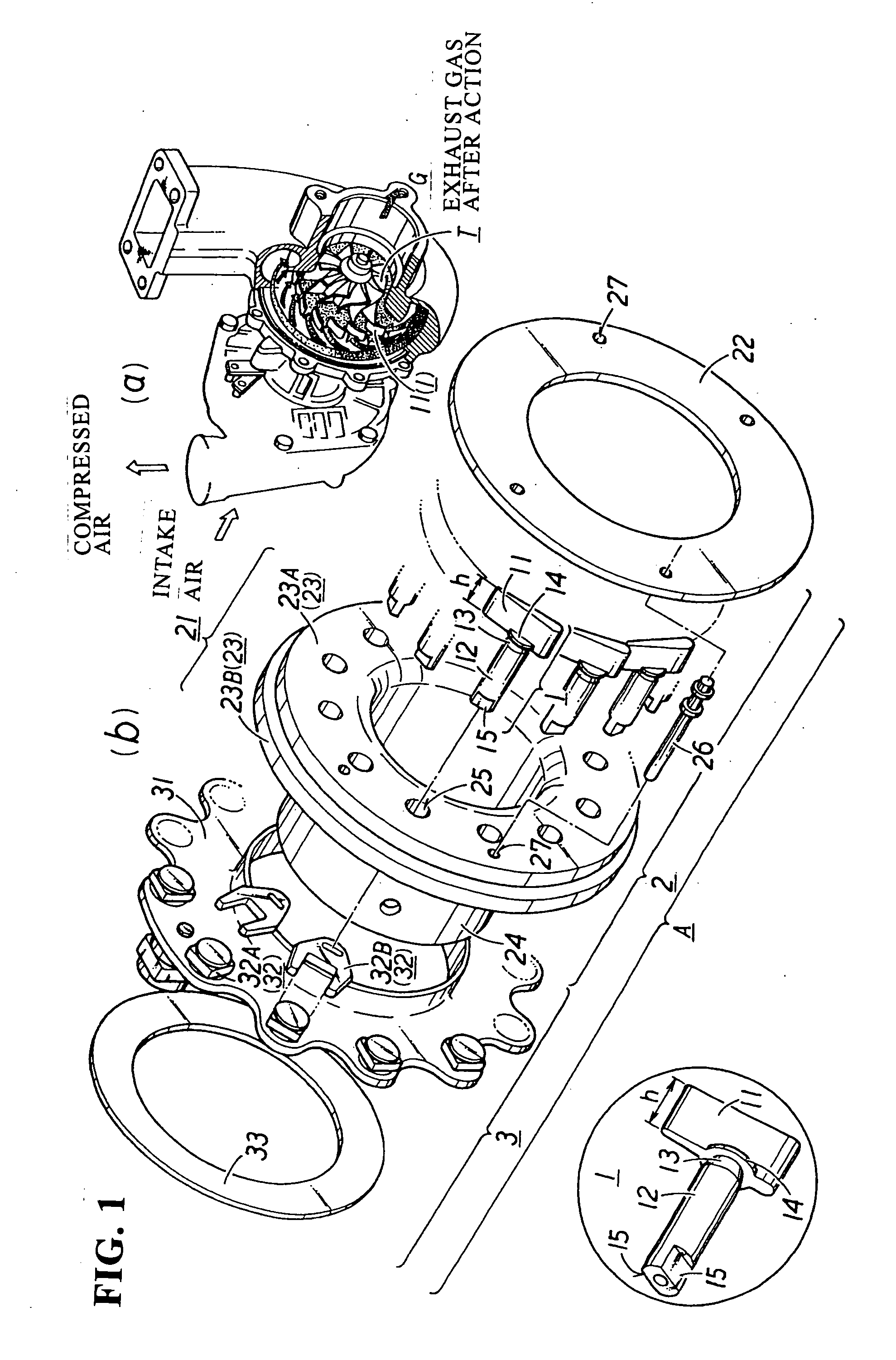

Surface-reformed exhaust gas guide assembly of vgs type turbo charger, and method surface-reforming component member thereof

InactiveUS20050011192A1Increased durabilityExcellent high temperature durabilityHot-dipping/immersion processesInternal combustion piston enginesTurbochargerEngineering

A novel exhaust gas guide assembly with an improved high-temperature sliding wear resistance, oxidation resistance, high-temperature strength or the like for a VGS turbocharger is provided. The invention is characterized in that a surface modification is applied to a component member of the exhaust gas guide assembly (A), such as adjustable blades (1), a turbine frame (2), a blade adjusting mechanism (3), or the like.

Owner:AKITA FINE BLANKING +1

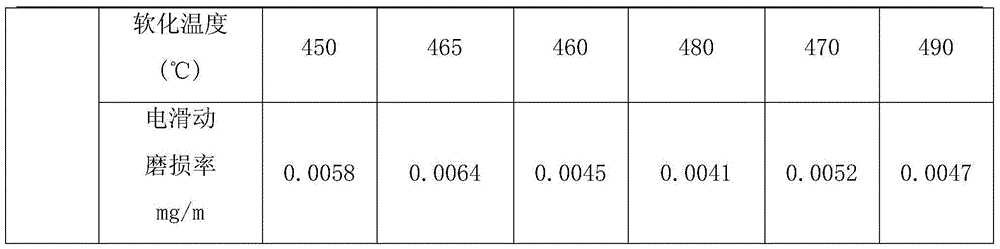

Copper-chromium-titanium alloy contact wire and preparation method thereof

The invention discloses a copper-chromium-titanium alloy contact wire and a preparation method thereof. The copper-chromium-titanium alloy contact wire is prepared from a copper alloy through the processes of atmospheric smelting, upward continuous casting, continuous extrusion, heat treatment, rolling and drawing and the like, wherein the copper alloy contains Cu, 0.15-0.35% of Cr, 0.10-0.23% of Ti, 0-0.05% of Mg and 0-0.02% of Si, and the total amount of impurities of the copper alloy is not more than 0.1%. Under the conditions that the process is simplified and equipment and alloy components are relatively simple, large-scale industrialized production can be realized, and the contact wire has relatively high tensile strength, excellent electric conductivity and softening resistance and good electrical sliding wear performance.

Owner:JIANGXI UNIV OF SCI & TECH +1

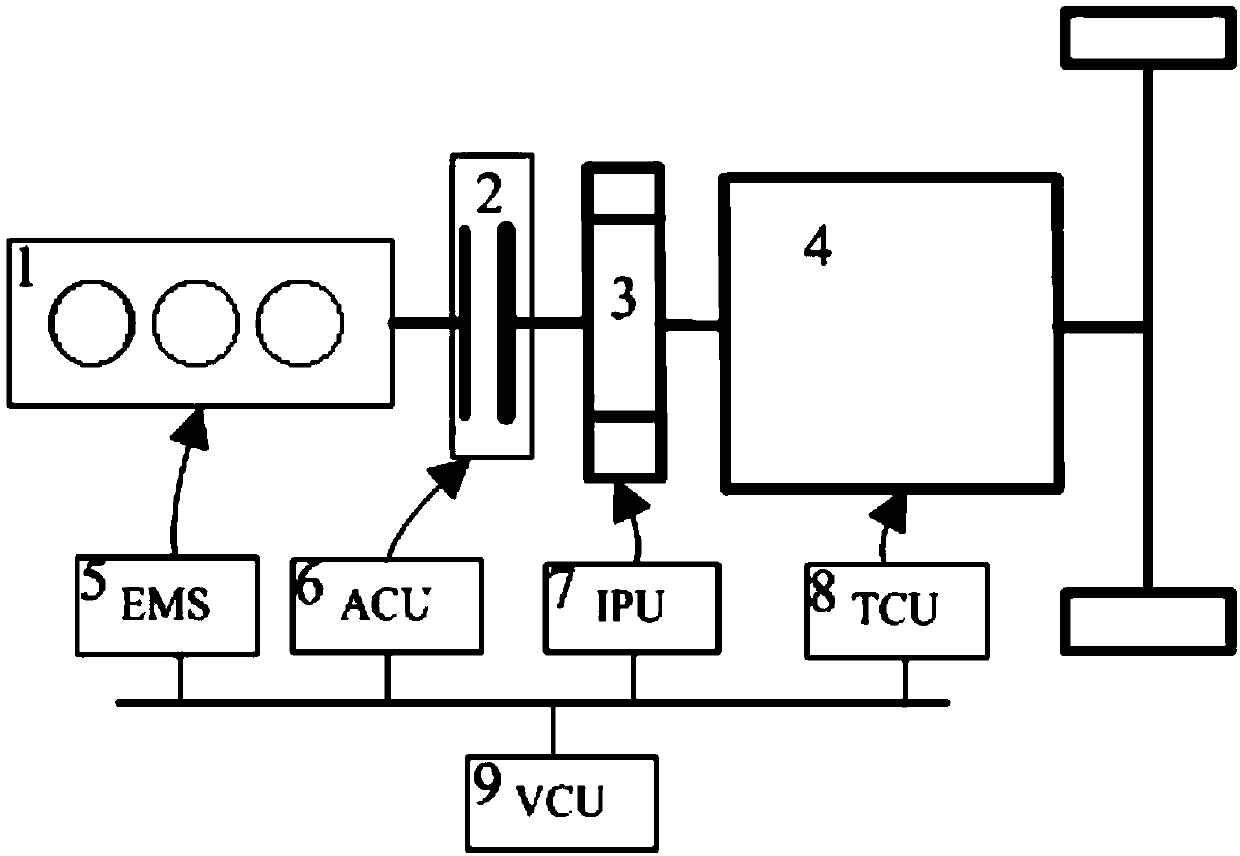

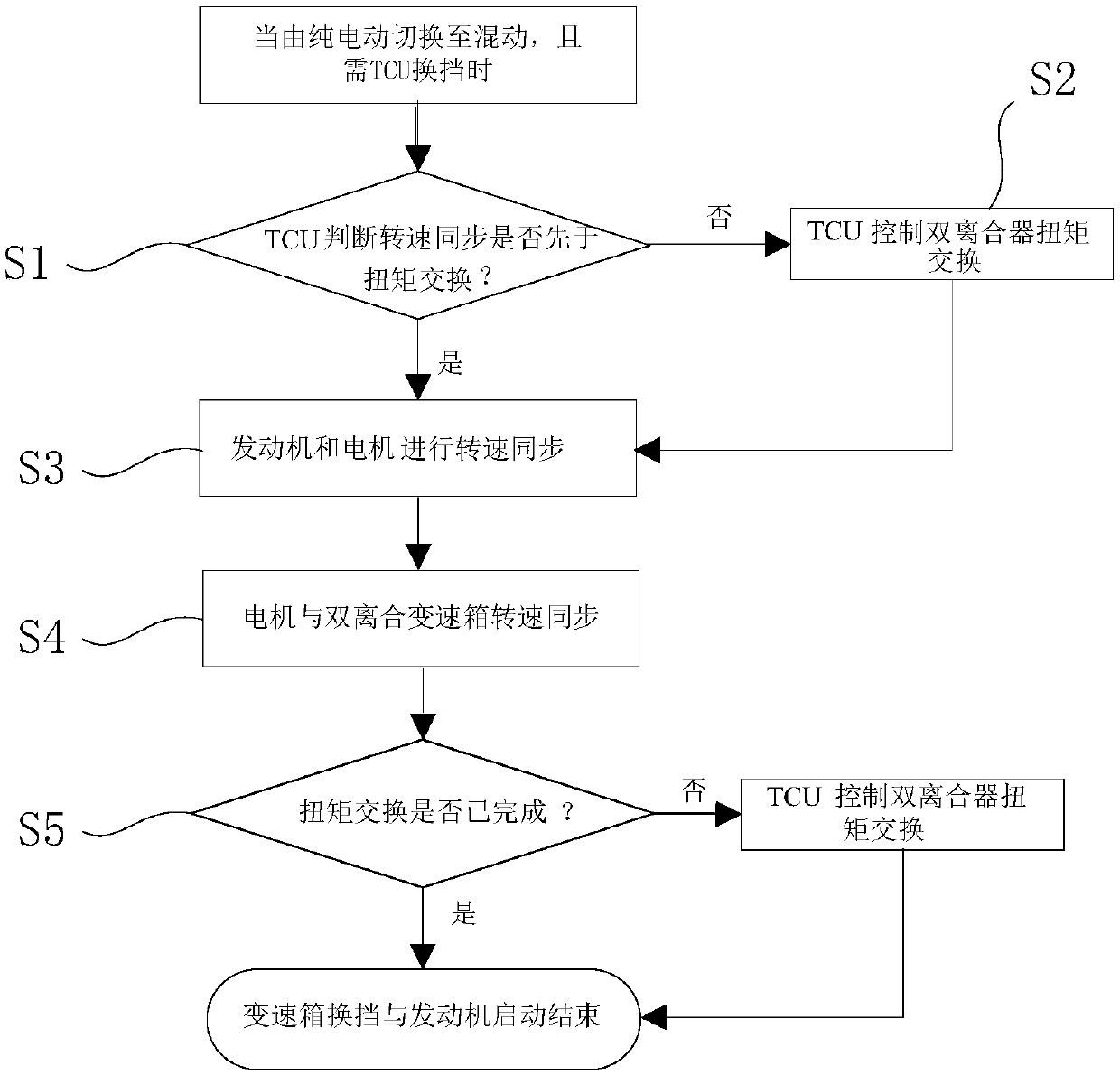

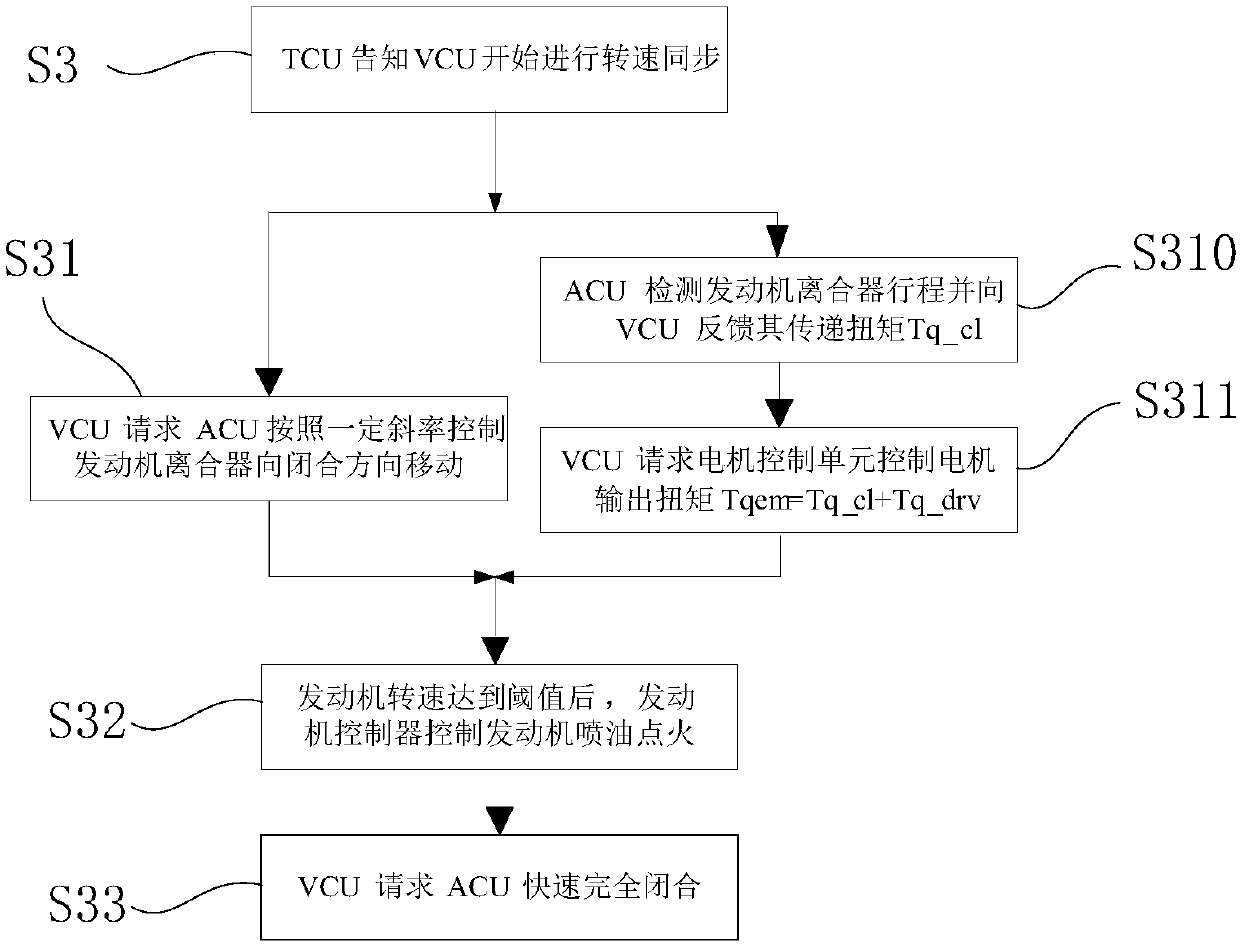

Hybrid electric vehicle and engine start control method thereof

The invention provides an engine starting control method of a hybrid electric vehicle, Hybrid electric vehicles operate in pure electric mode, when power is required to start that engine due to an external environment or lack of power, and when it is necessary to shift the double-clutch gearbox, In order to avoid the impact of engine startup and gear shifting, at the same time, As that electric motor is close to a predetermined position in a sliding state by an engine clutch, and the first clutch and the second clutch in the double clutch gearbox are in a sliding wear state when the gear position of the double clutch gearbox is switched, and the engine clutch and the double clutch gearbox are simultaneously sliding worn to absorb the impact, thereby solving the impact problem in the powerswitching process of the hybrid electric vehicle. The invention also provides a hybrid electric vehicle.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

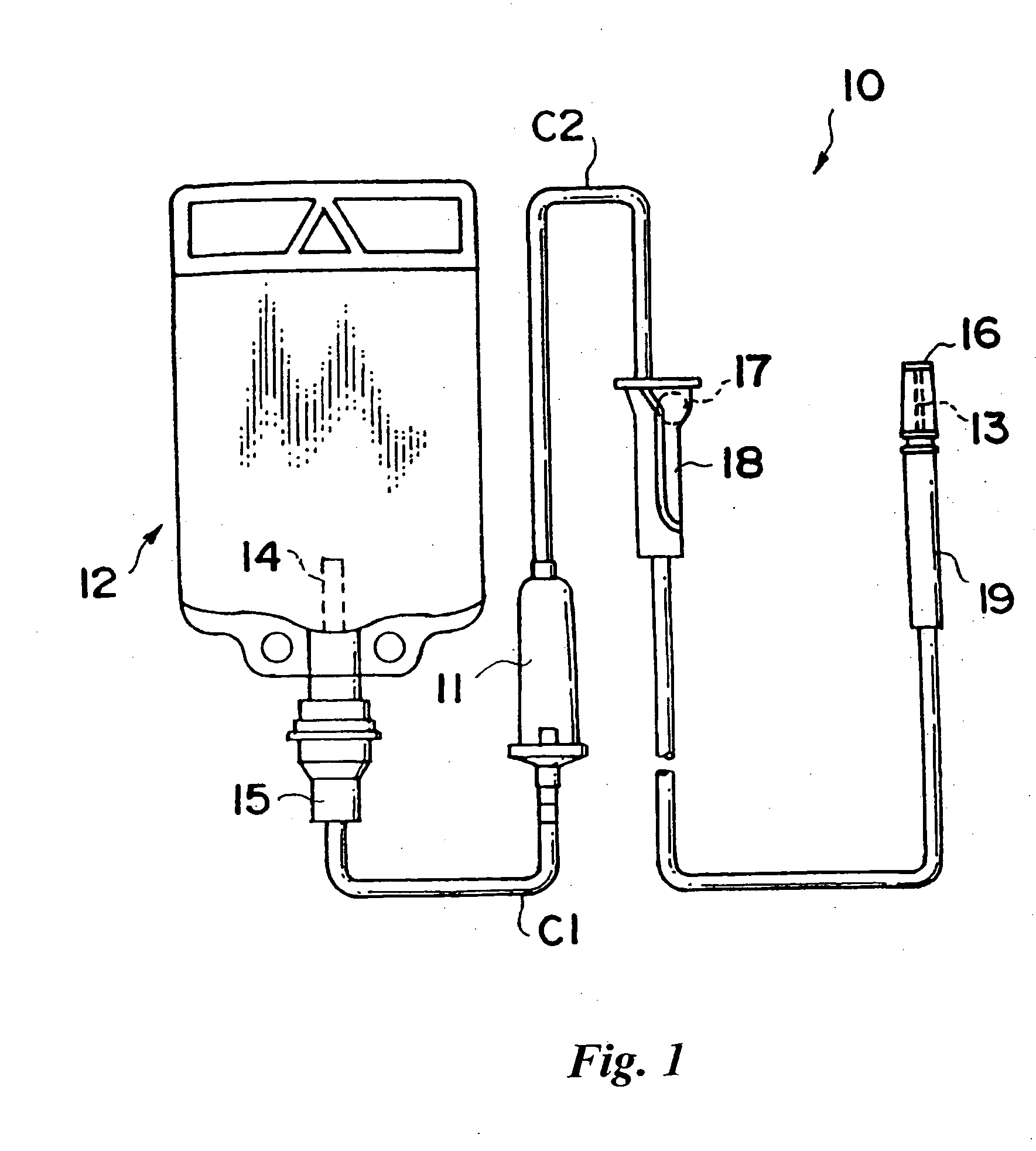

Coated medical device and method of making

InactiveUS20080027431A1Improve wear resistanceSmoother wear surfaceInternal osteosythesisJoint implantsBiocompatibility TestingReactive bonding

A boron coating is applied to selected surfaces of surgical devices, including orthopedic prosthetic alloys and surgical tools to improve sliding wear and provide other benefits. The coating may be applied to CoCrMo, stainless steel, or titanium alloy components of artificial hips, knees, shoulders, and other articulating joints, which bear on wear partners and which experience rubbing wear during use of the joint. In such cases, the coating is preferably applied in particular to the rubbing wear surface of the CoCrMo alloy component to reduce wear of either the alloy component or the mating polymer component, for corrosion improvement, for biocompatibility, or for improvement in infection performance of the device. The boron coating may show evidence for reactive bonding to the substrate, which may include evidence of in-diffusion or of interdiffusion between the boron and the substrate material. The inventive boron or boron-based coating may also be applied to non-wear surfaces of the alloy to improve performance in terms of biocompatibility or infection resistance, as for hip joint stems or other fixation parts of devices. The inventive coating may also be applied to medical devices such as surgical tools to provide a hard, sharp cutting surface. A method of making boron-coated medical devices is also disclosed.

Owner:WILLIAMS JAMES M +1

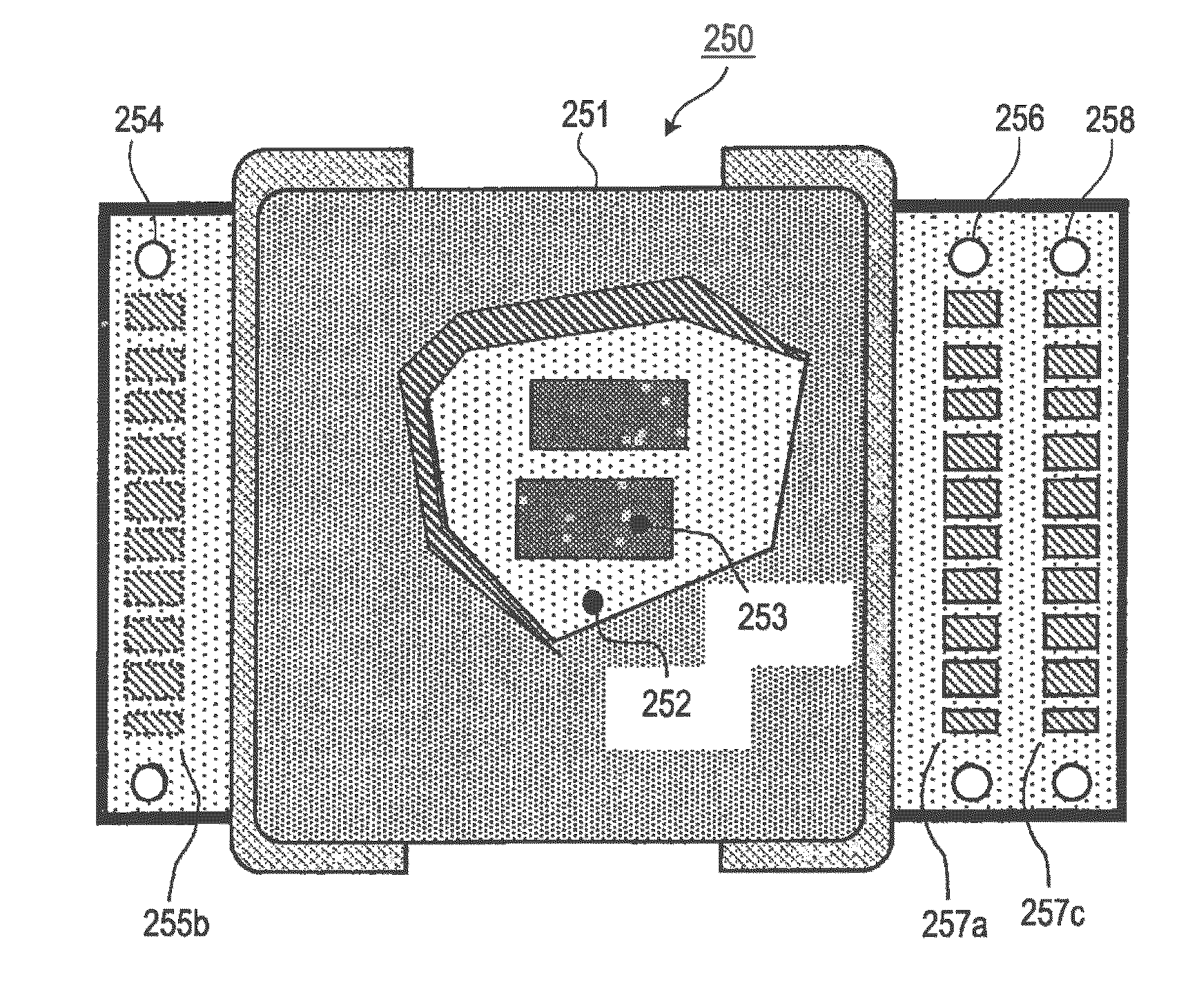

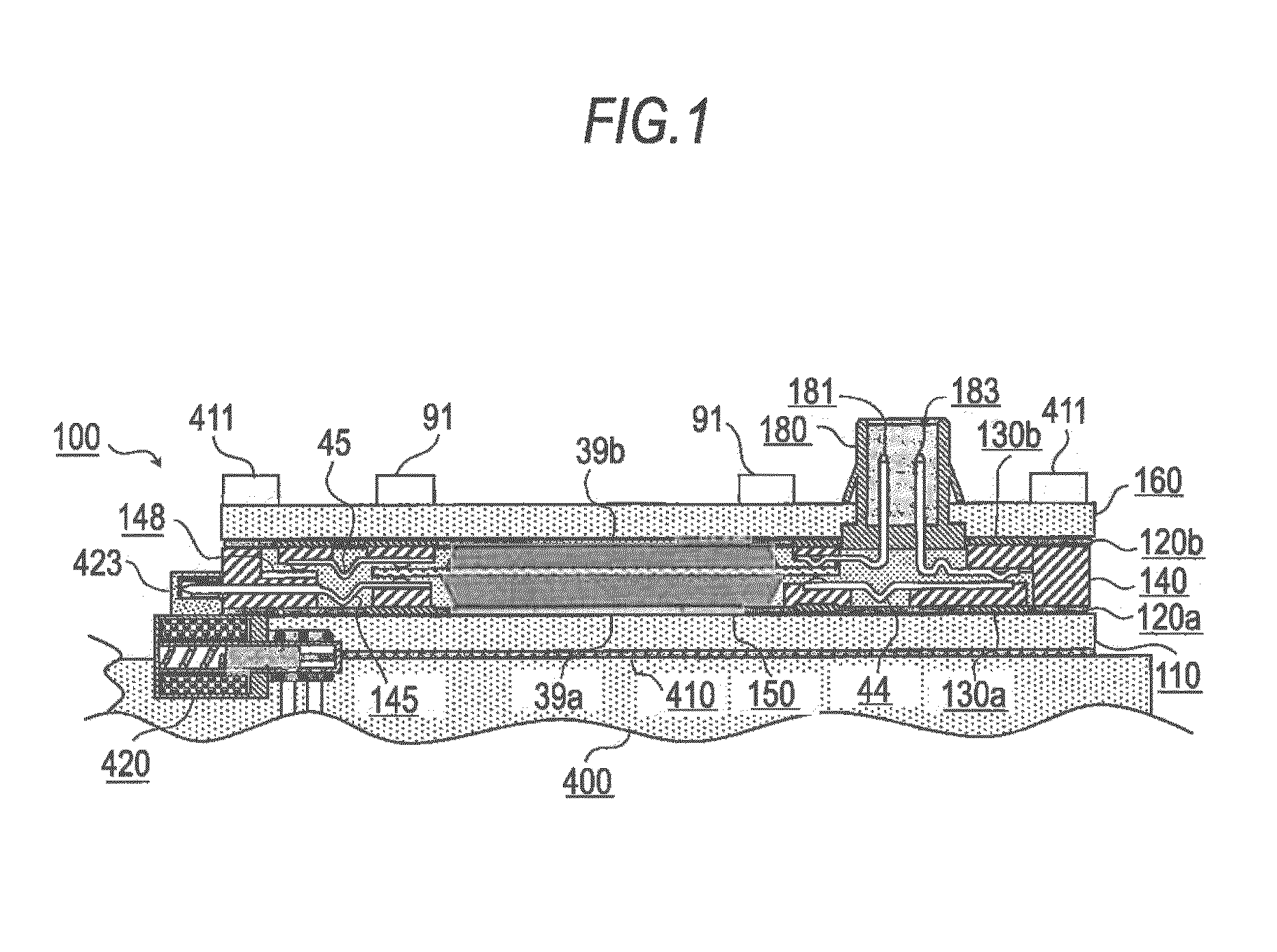

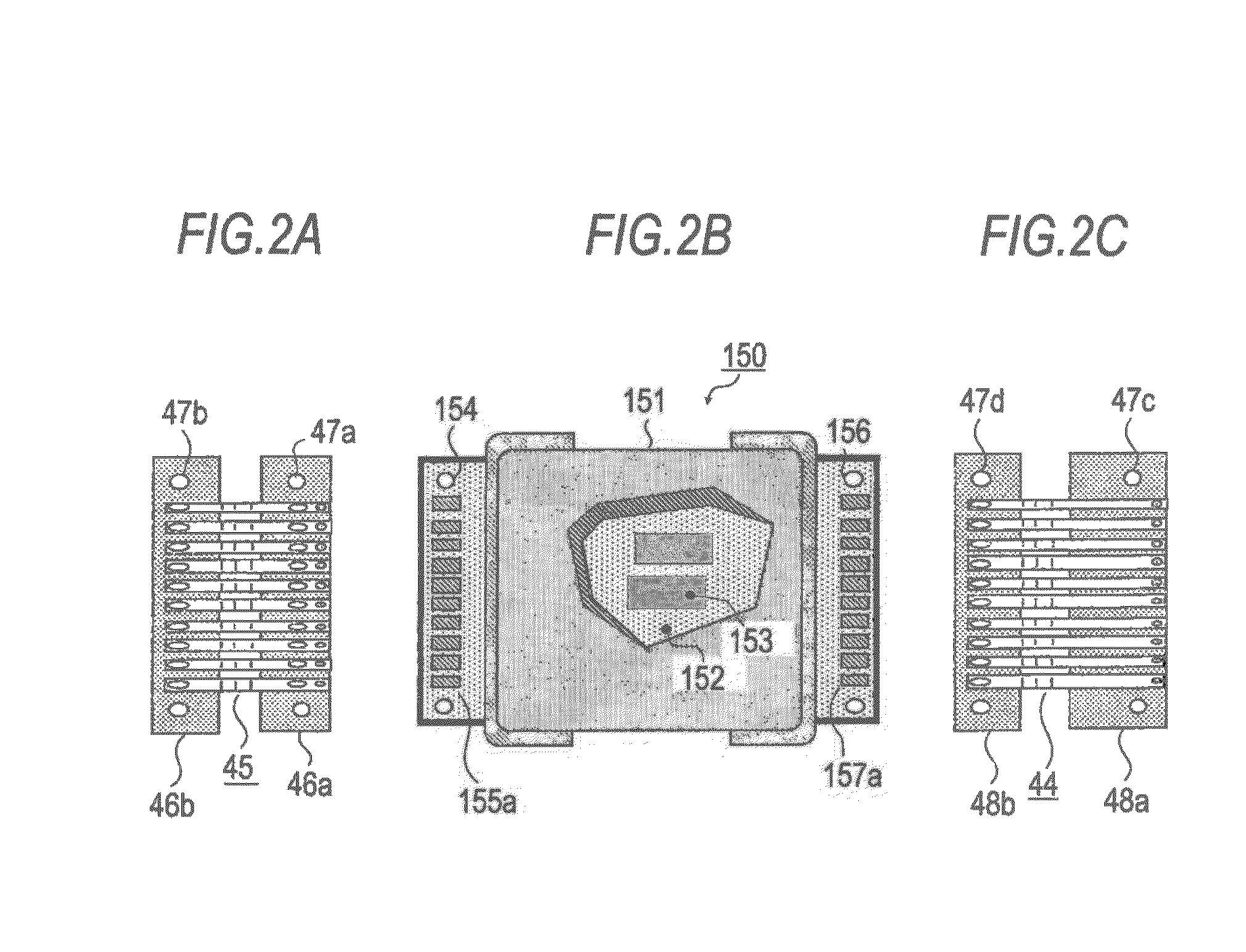

Electronic control device

ActiveUS20160128215A1Easy to implementSimple assembly lineCasings with connectors and PCBCircuit arrangements on support structuresElectrical conductorControl signal

A control unit is stored in an airtight housing constituted by a base, an annular peripheral wall member, a cover, and first and second interior packings, second wiring conductors connected to input / output equipment and first wiring conductors connected to a host controller through a control signal connector are brought into press-contact with input / output control terminals of the control unit by first and second pressing elastic mats, the relative positions of associated components are regulated by positioning pins passing through from the cover to the base, and the cover is opened by loosening blockade screws without causing an assembly dimension error or sliding wear of conductive contact portions due to thermal deformation, whereby the control unit is detached.

Owner:MITSUBISHI ELECTRIC CORP

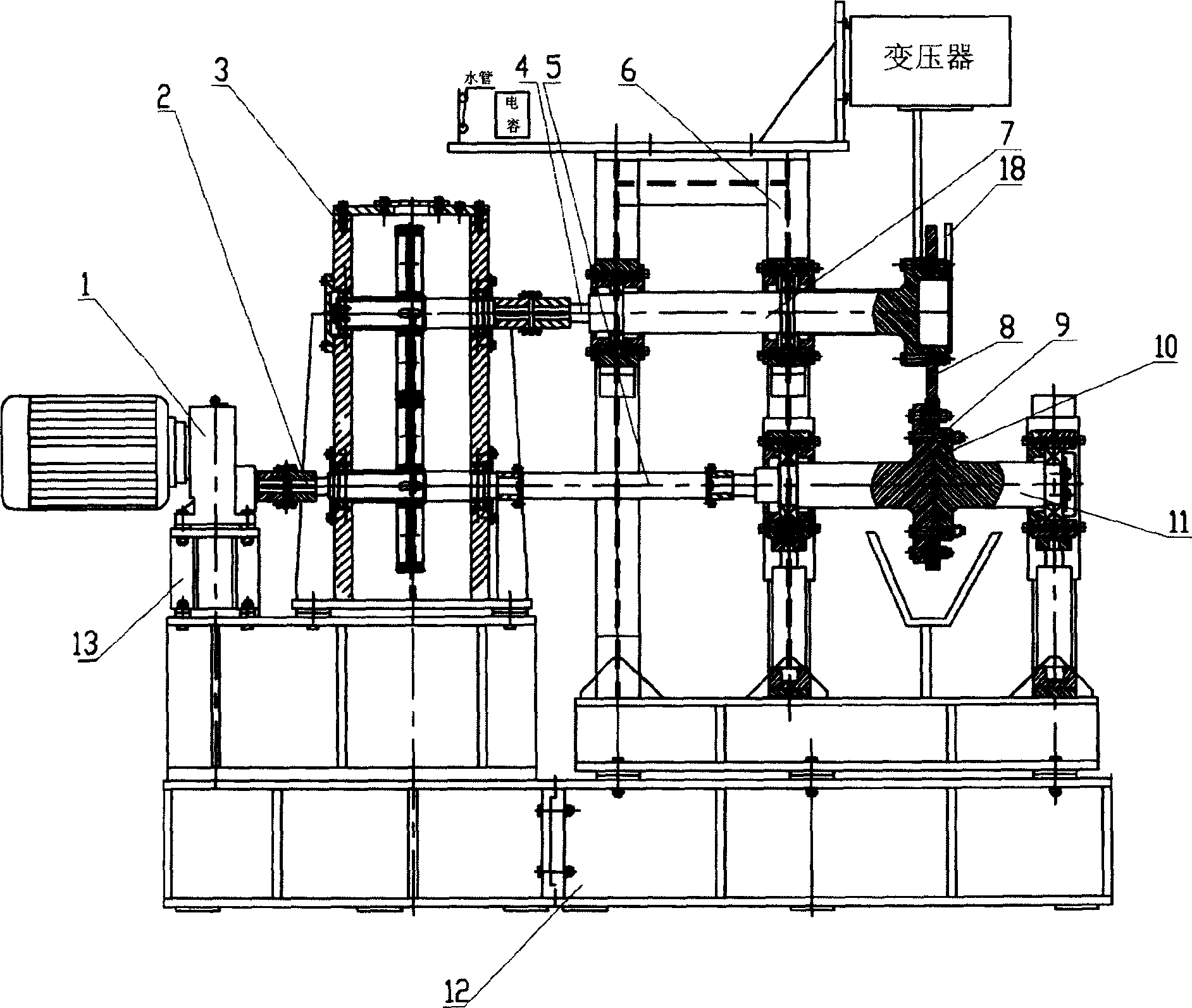

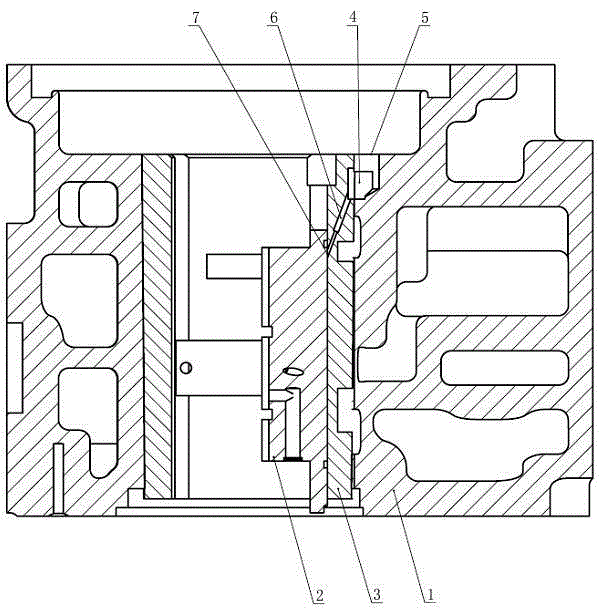

High temperature sliding wear and thermal contact fatigue testing machine for material

InactiveCN1724994AImprove efficiencyLow costUsing mechanical meansInvestigating abrasion/wear resistanceHydraulic pumpPressure sense

The invention is a tester for high temperature sliding abrasion and thermal contact fatigue material, belonging to the technical field of material processing and friction and abrasion testing, comprising friction auxiliary, pressure regulator, heater, and lubricating device, where the friction auxiliary comprises speed reducing motor, variable frequency speed regulating motor, supporting seat, shaft coupler, distribution gear box, universal connection shaft, machine frame, top friction auxiliary system, bottom friction auxiliary system, and friction piece, where the top friction auxiliary system comprises rotating shaft, bearing base, pressure plate, and top friction piece, the bottom friction auxiliary system comprises right and left rotating shafts, clamping chuck, bottom friction piece and bearing base, the pressure regulator comprises two groups of lift hydraulic cylinders, hydraulic pump, pressure sensing instrument and displaying instrument, the heater comprises induction heating coil, and water cooled system, the lubricating device comprises nozzle, and oil feeding system, the hydraulic system comprises electromagnetic switched electromagnet, and electric contact relay. The advantages of the invention lie in that: the equipment is simple in structure, the number of parts is small, the efficiency is high and the cost is low and it is applied to scientific research and production field simulation.

Owner:UNIV OF SCI & TECH BEIJING

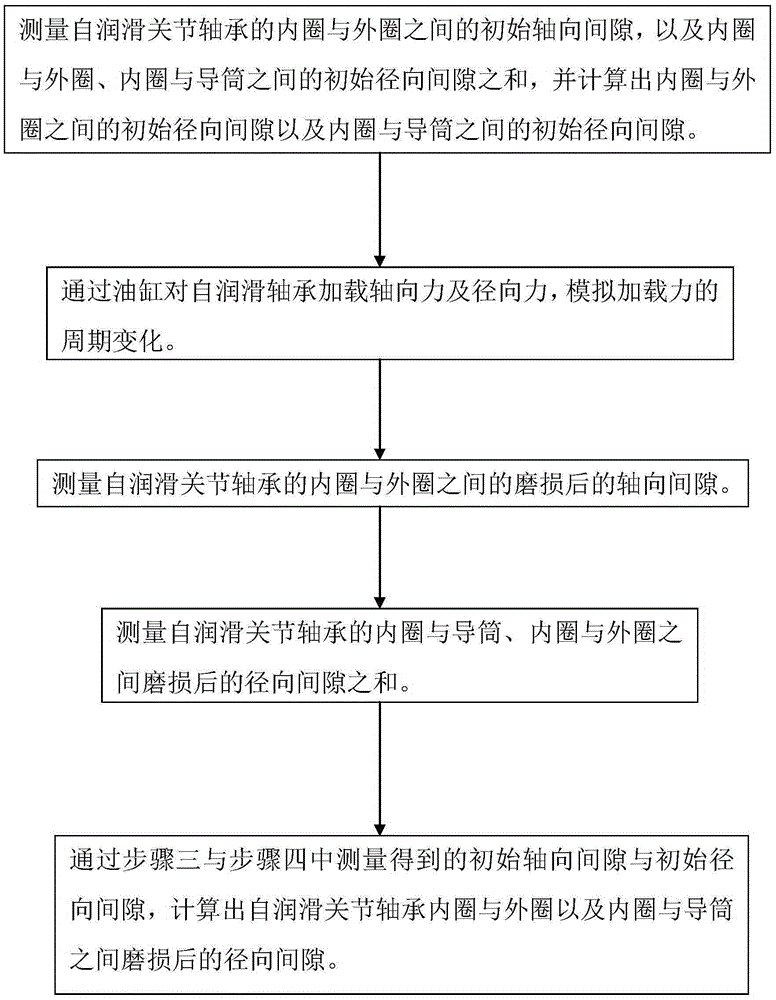

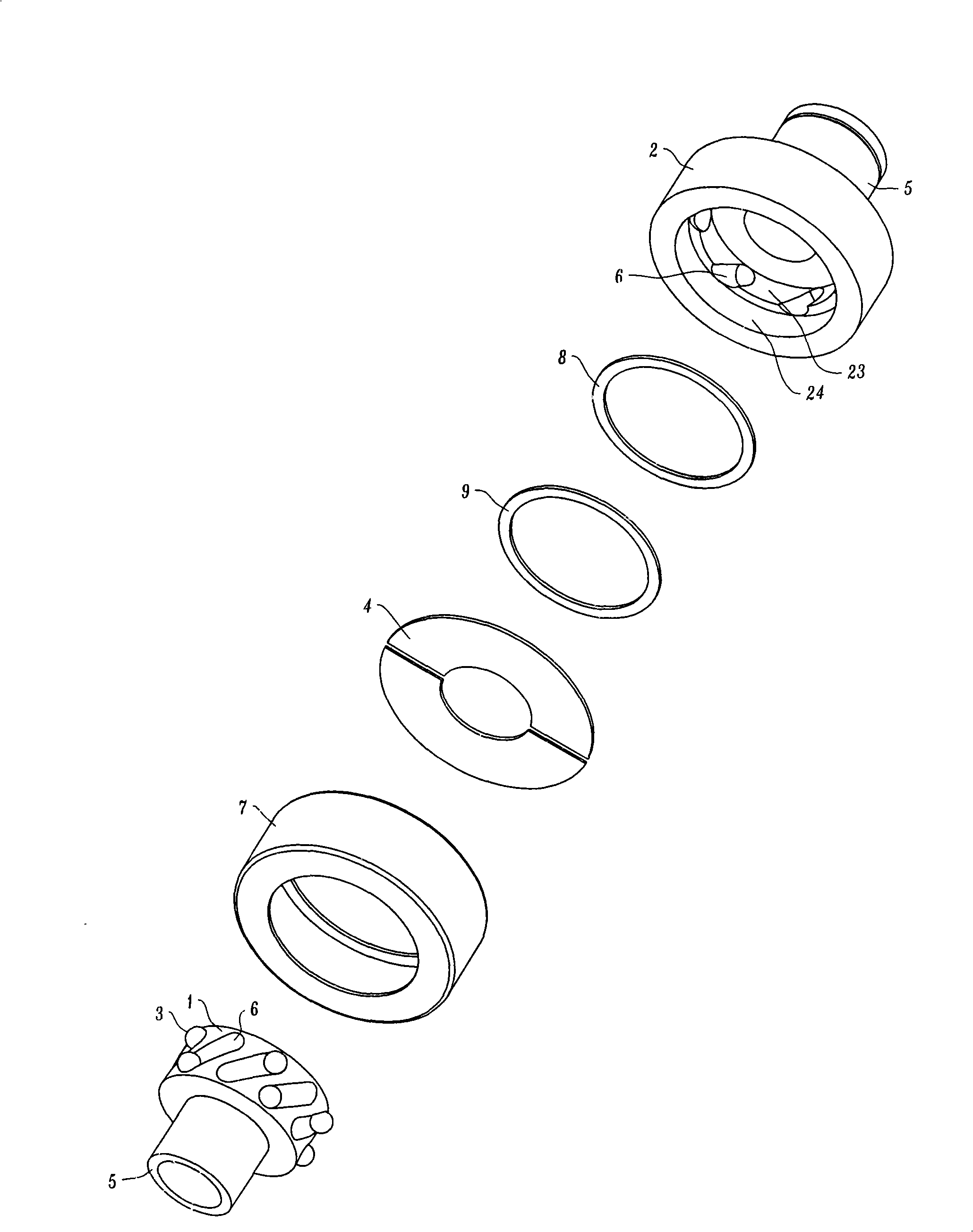

Self-lubricating joint bearing durability test method and test bench

ActiveCN105277366AAbility to realize circumferential loading in any directionGood simulation of actual working conditionsMachine bearings testingEngineeringTest equipment

The invention discloses a self-lubricating joint bearing durability test method and a test bench, and relates to the technical field of helicopters. The test method comprises the steps as follows: first, the initial radial clearance between an inner ring and an outer ring and the initial radial clearance between the inner ring and a guide cylinder are measured; then, the periodic change of loading force is simulated; and finally, the radial clearance between the inner ring and the outer ring and the radial clearance between the inner ring and the guide cylinder of a self-lubricating joint bearing after wear are measured. Support frames of the test bench are fixed to a working platform and used for supporting ropes. Three lugs are uniformly arranged on the circumference of an installation fixture. One end of each rope is connected with the corresponding lug of the installation fixture, and the other end is connected with the piston rod of one loading oil cylinder. The installation fixture sleeves a guide cylinder. A measured self-lubricating joint bearing is arranged between the installation fixture and the radial direction of the guide cylinder. Three booster cylinders are arranged in the axial direction of the installation fixture. The beneficial effect is that sliding wear test and rotating wear test of the bearing can be completed simultaneously through one piece of test equipment.

Owner:CHINA HELICOPTER RES & DEV INST

Development method for mechanical wear system on the basis of abrasive particle wear mechanism

PendingCN110208124ARealize monitoringAchieve discriminationCharacter and pattern recognitionInvestigating abrasion/wear resistanceMathematical modelSupport vector machine classifier

The invention discloses a development method for a mechanical wear system on the basis of an abrasive particle wear mechanism. The development method comprises an abrasive particle image preprocessingmodule, a characteristic extraction module and an abrasive particle identification module, wherein the image processing module is mainly used for processing an abrasive particle image; the abrasive particle characteristic extraction module is mainly used for extracting the geometric and textural characteristics of the abrasive particle; an image identification module is used for distinguishing atype to which the abrasive particle belongs; and a mathematic model for monitoring a mechanical wear state on the basis of abrasive particle characteristic identification is put forward on the basis of a situation that the abrasive particle has different shapes and textural characteristics under different wear mechanisms by aiming at the problem the monitoring accuracy of a mechanical equipment wear state is low. Through shape characteristics, spherical abrasive particles and cutting abrasive particles are identified, fatigue abrasive particles and severe sliding wear particles are identifiedby the combination of shape and textural characteristics, a characteristic vector for mechanical wear state monitoring is established on the basis of the extracted characteristic parameter, and through a support vector machine classifier model, a mechanical wear state is monitored and distinguished.

Owner:XINJIANG UNIVERSITY

Thrust needle roller bearing with isolating layer

InactiveUS20110182542A1Prevent creepAvoid sliding wearBearing componentsNeedle bearingsNeedle roller bearingAdhesive

A thrust needle bearing with an isolating layer has a cage with rollers, washers on which the rollers run, at least one of the washers is attached to the cage, backup surfaces fixed external to each of the washers and an isolating layer attached to at least one of the washers, which is interposed between the at least one of the washers and at least one of the backup surfaces of the bearing. The isolating layer is a layer of vibration-attenuating material. Alternatively, the isolating layer is a layer of material which has properties that prevent creep or sliding wear for at least one of the backup surfaces. The isolating layer is attached to the washers by bonding, use of adhesives or mechanical means.

Owner:SCHAEFFLER TECH AG & CO KG

PVD coated substrate

InactiveUS8173248B2High hardnessReduce coefficient of frictionPigmenting treatmentVacuum evaporation coatingMetal alloyHardness

A PVD coating is disclosed, and in particular a nanoscale multilayer superlattice PVD coating comprising high hardness, a low friction coefficient and increased chemical inertness. The multilayer coating comprises a repeating bilayer represented by (VxMe(i-x))CyN(i-y) / (MezV(1-z))CyN(i-y) where 0.1≦x≦0.9; 0.01<y<0.99 and 0.1≦z≦0.9 and Me is a substantially pure metal or a metal alloy. The composition of the coating through the layers alternates from layer to layer according to a V-rich layer and a Me-rich layer modulated sequence. Vanadium is incorporated within the layer composition and has been found to act as a lubricating agent during sliding wear. Carbon, also incorporated within the coating, serves to further stabilize the friction coefficient thereby increasing the chemical inertness between cutting tool and workpiece material.

Owner:SHEFFIELD HALLAM UNIVERSITY

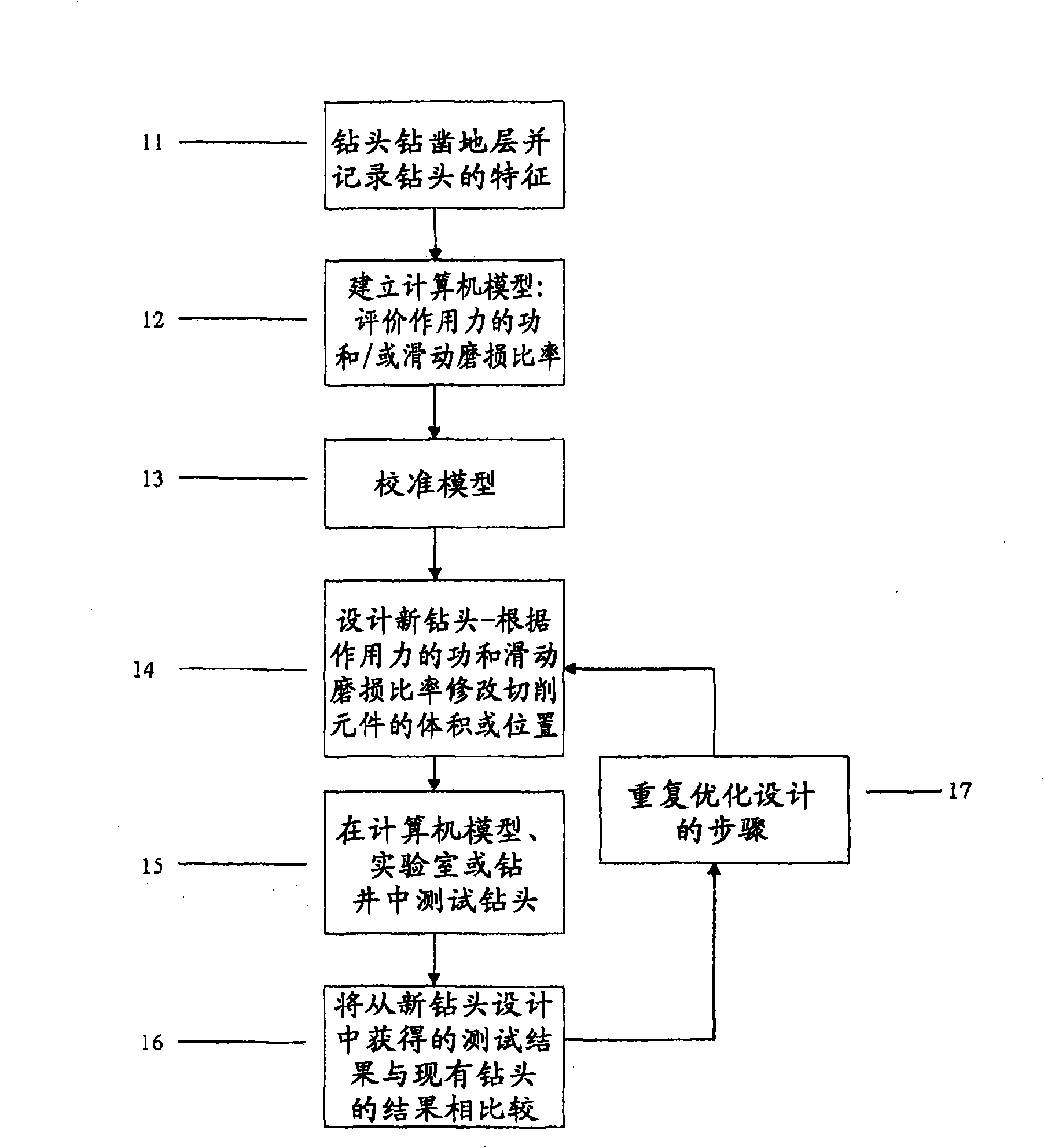

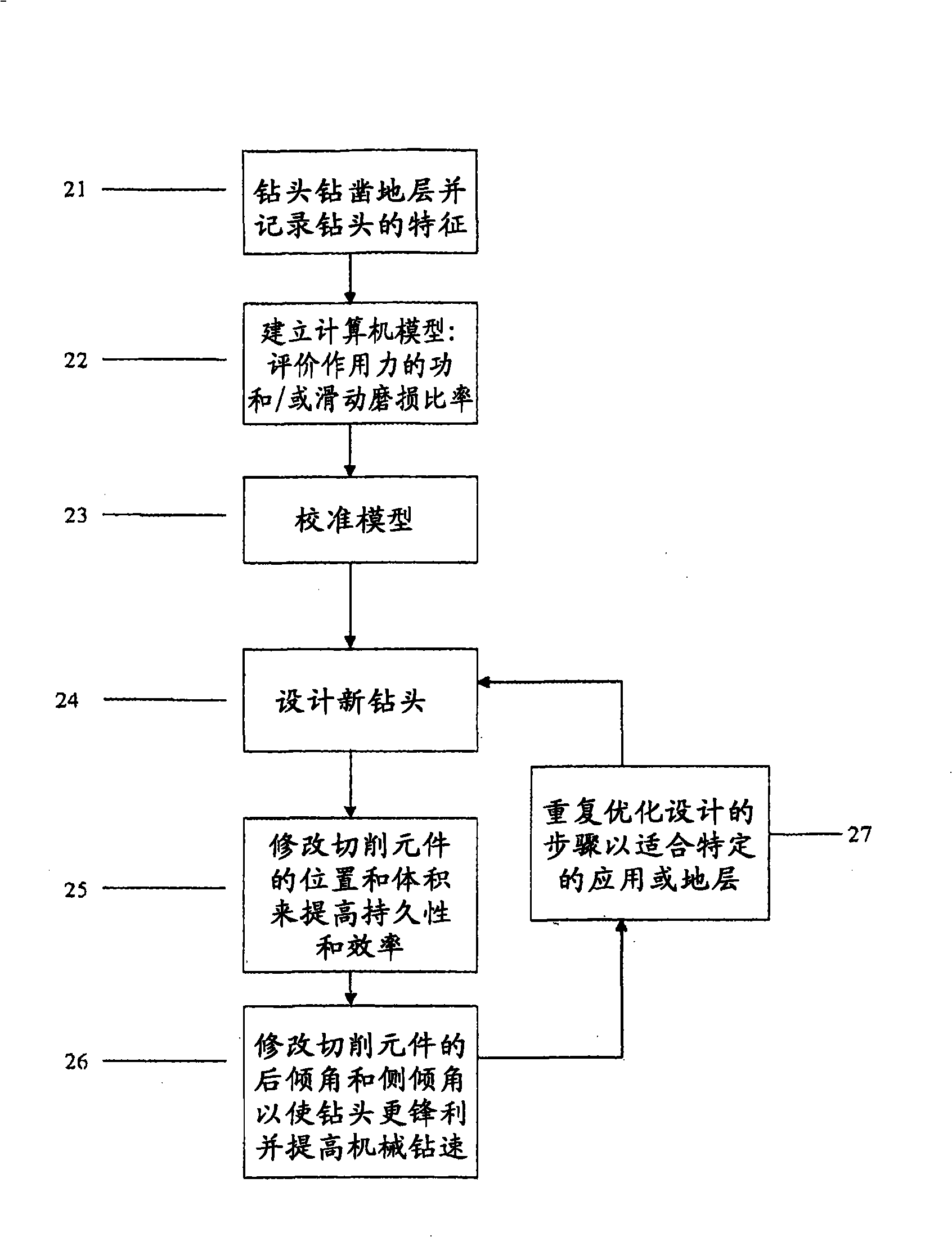

Methods for optimizing efficiency and durability of rotary drag bits and rotary drag bits designed for optimal efficiency and durability

InactiveCN101351615AModify or improve sharpnessModify or improve durability/redundancyDrill bitsBorehole/well accessoriesRate of penetrationEngineering

A method for evaluating existing drill bits and drill bit designs includes measuring several desired characteristics of a bit, including the wear experienced in drilling a formation, such as an actual formation or a simulated formation or a laboratory test fixture. A computer model may be used to evaluate the work-force and / or the sliding-wear rates that cutting elements of the bit experience as compared with the rate-of-penetration and / or durability of the bit. This information may be used to design a new drill bit, which may involve modification of the cutting elements {e.g., moving the location, volume (size and shape) or number of cutting elements from areas of the bit that receive lower work-force and sliding-wear rates to those areas that experience relatively greater work-force and sliding wear-rates.; This may permit the cutting elements to be oriented more aggressively relative to a formation to be drilled. Other parameters that may be optimized include the bit profile, blade count, hydraulics, or the like.

Owner:BAKER HUGHES INC

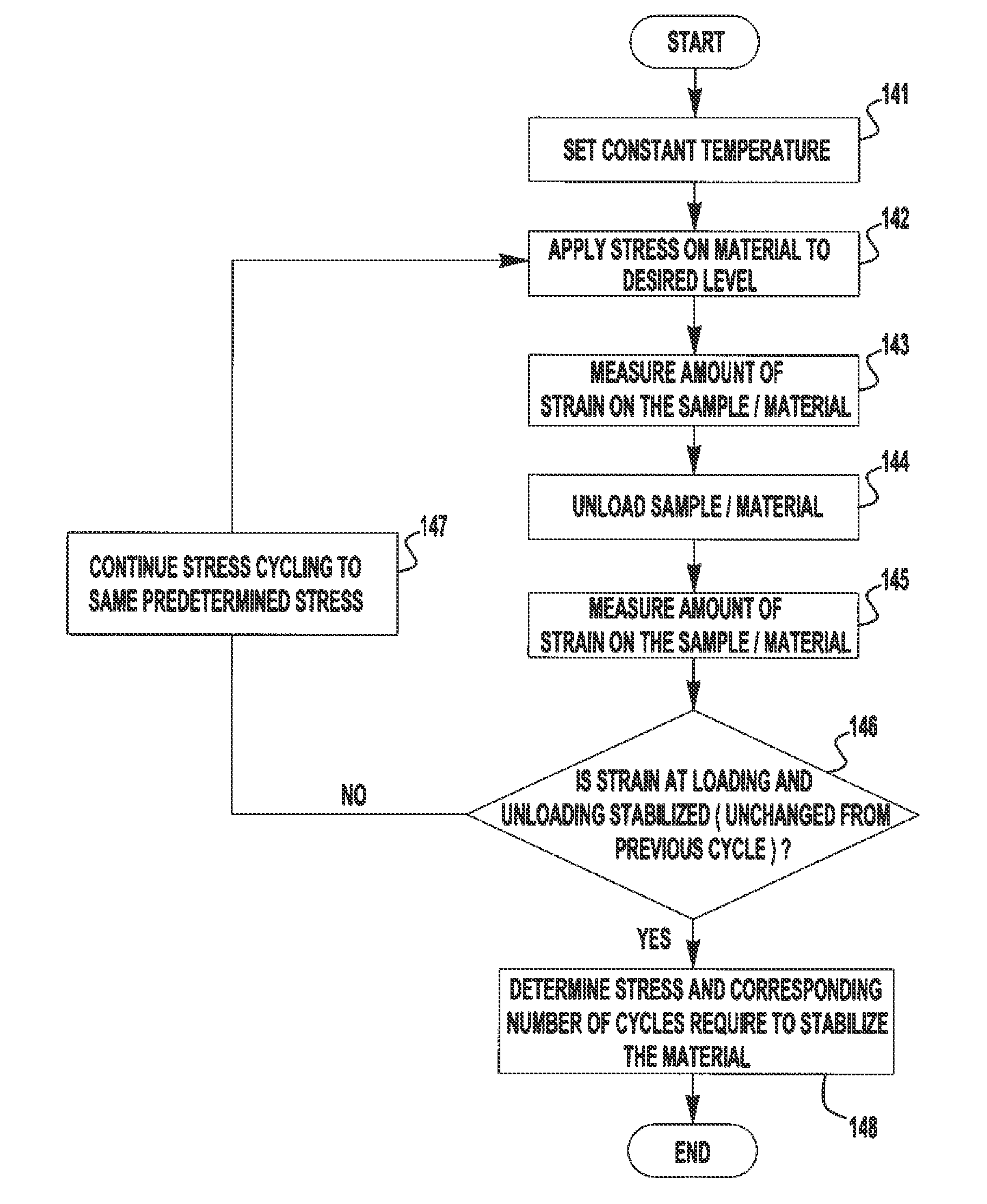

Mechanical Components From Highly Recoverable, Low Apparent Modulus Materials

ActiveUS20120080123A1Eliminate irrecoverable deformationHeat treatment process controlMechanical componentsShape-memory alloy

A shape memory alloy for use as a mechanical component is formed of an intermetallic material having a low apparent modulus and a high hardness. The intermetallic material is conditioned to have a stable, superelastic response without irrecoverable deformation while exhibiting strains of at least 3%. The method of conditioning the intermetallic material is described. Another embodiment relates to lightweight materials known as ordered intermetallics that perform well in sliding wear applications using conventional liquid lubricants and are therefore suitable for high performance mechanical components such as gears and bearings.

Owner:NASA

Coating method of anti-slide wear-proof coating layer of concrete PC beam and concrete PC beam

The invention relates to a coating method of an anti-slide wear-proof coating layer of a concrete PC beam and the concrete PC beam. The coating method comprises the following steps: (S1) preprocessing the concrete PC beam until a to-be-coated surface of the concrete PC beam is dry and neat and has no dirt and oil dirt and the surface roughness meets the preset requirements; (S2) coating the to-be-coated surface of the concrete PC beam with a primer; and (S3) after the primer is dried and solidified, coating the primer with an anti-slide wear-proof paint film, and standing until the anti-slide wear-proof paint film is dried and solidified. According to the preparation method, the to-be-coated surface of the concrete PC beam is preprocessed, so that the adhesive force of the coating to the PC beam is enhanced, and the construction quality is guaranteed; by coating the PC beam with the primer, the anti-slide wear-proof paint film is prevented from losing effect, a good bonding force is created for the surface of the PC beam and the subsequent coating layer, and a firm foundation of the coating layer is formed, so that the protection performance of the whole coating layer is improved; and by coating the primer with the anti-slide wear-proof paint film, the sliding caused due to the permeation of grease or impurities is prevented, and the service life of the coating layer is long.

Owner:重庆百信实业有限公司

Surface treated tube for medical use

InactiveUS20070009696A1Improved sliding property and sliding wear resistanceAdvantageously producedPharmaceutical delivery mechanismCatheterElastomerCrystallinity

A thermoplastic elastomer molded article having a surface treated with a silicone emulsion and / or aqueous solution of silicone containing water-soluble silicone with a silicone content of 1 to 30 wt % is provided. As the thermoplastic elastomer, a composition comprising 20 to 100 wt % of 1,2-polybutadiene having a 1,2-bond content of 70% or more and a degree of crystallinity of 5 to 50% and 0 to 80 wt % of other thermoplastic elastomers, provided that the total amount of the 1,2-polybutadiene and the other thermoplactic elastomers is 100 wt %, can be given. The molded article of the present invention can be applied to various types of tubes, sheets, and hoses as well as a tube for medical use since the surface of the article has improved sliding properties and sliding wear resistance, without impairing transparency, flexibility, lightweightness, and mechanical strength.

Owner:JSR CORPORATIOON

Conductive material for connection parts which has excellent minute slide wear resistance

ActiveCN106795643AAbutment pressure reductionThe abutment pressure is also reducedSingle bars/rods/wires/strips conductorsCoupling contact membersConductive materialsAlloy coating

A conductive material for connection parts according to the present invention is configured in such a manner that a Cu-Sn alloy coating layer having a Cu content of 20 to 70 at% and an average thickness of 0.2 to 3.0 [mu]m and an Sn coating layer having an average thickness of 0.05 to 5.0 [mu]m are formed on the surface of a base material made from a copper alloy containing specified amounts of Cr and Zr, or specified amounts of Fe and P or a specified amount of Zn.

Owner:KOBE STEEL LTD

Railway brake valve with self-lubricating function

ActiveCN102878313AExtension of timeGuaranteed lubrication effectSlide valveWorking environmentProduct processing

The invention discloses a railway brake valve with a self-lubricating function. The railway brake valve comprises a main valve body, a slide valve and a slide valve sleeve which is arranged between the main valve body and the slide valve, wherein an oil storage chamber and an oil filling port which is communicated with the oil storage chamber are arranged on the main valve body, the oil storage chamber is communicated with an oil line which is arranged on the slide valve sleeve, and an oil outlet of the oil line is formed in a non-working area of the working area of the slide valve sleeve. The oil storage chamber is arranged on the main valve body, lubricating oil in the oil storage chamber passes through the oil path in the slide valve sleeve and the oil outlet to reach the working surface for generating an oil film, the slide valve moves up and down at the oil outlet during the operation, so that automatic lubricating is formed on a slide valve surface, a slide valve pair can be enabled to be effectively lubricated, accordingly, the existence time of the oil film is prolonged, the sliding wear is reduced, the working environment of the slide valve pair is improved, and the service live of the slide valve pair is prolonged. The railway brake valve is ingenious in structure, has an obvious effect, and is easy for new product processing and old product reproduction, and the existing railway brake valve is slightly changed.

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

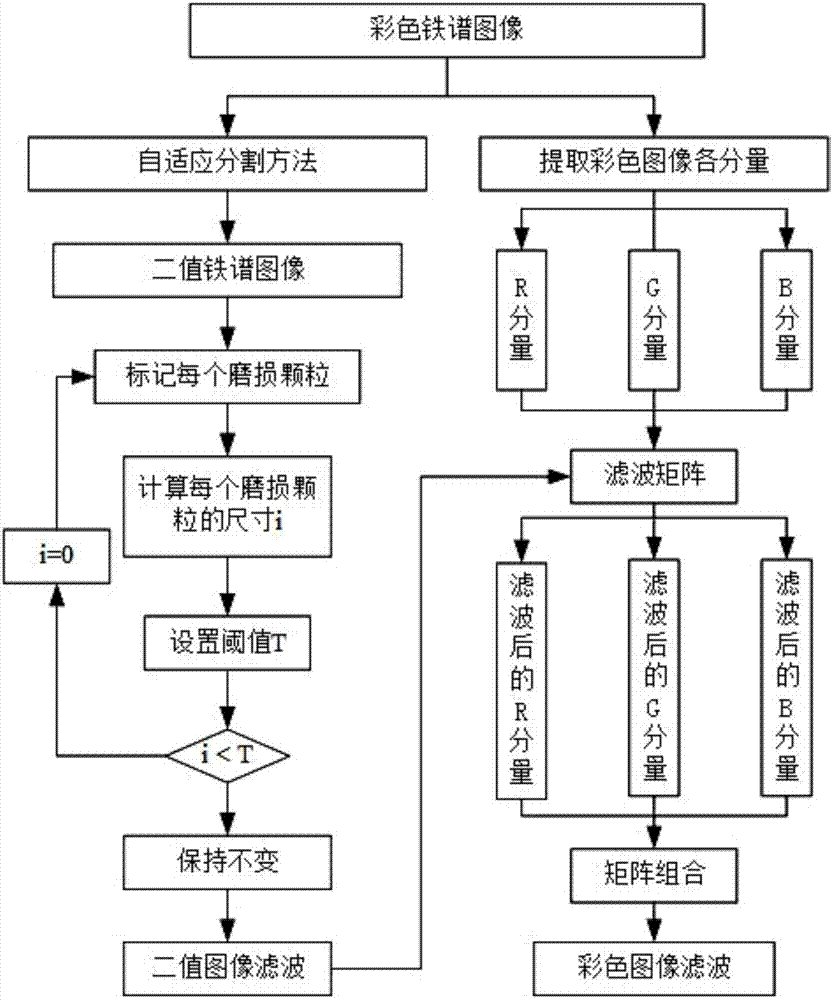

Ferrographic image multi-information fusing method based on D-S evidence theory

InactiveCN107992889ALow utilization rate of informationImprove recognition accuracyCharacter and pattern recognitionSupport vector machineWear particle

The invention discloses a ferrographic image multi-information fusing method based on a D-S evidence theory. In order to solve the technical problem that heterogeneous information in ferrographic image wear particle recognizing is low in comprehensive utilization rate, binary image filtering and colored image filtering are achieved after wear particle image binaryzation treatment; the form features and color features of a wear particle image are synchronously extracted, hard output of a support vector machine is converted into probability output through a sigmoid function, and a probability distribution function is constructed for the fusing of the heterogeneous information of the form features and the color features of a ferrographic image. Multi-information fusing is achieved through theD-S evidence theory, the advantages of the form features sensitive to cutting and oxide wear particles and the color features sensitive to slide wear particles are combined, and the effective distinguishing of three types of failure wear particles is achieved. Compared with independently used color features and form features, the recognizing accuracy of the method is improved by 16.6% or above, the comprehensive utilization rate of wear particle information is effectively improved, and a new concept is provided for device wear monitoring.

Owner:XI AN JIAOTONG UNIV

Copper-chromium-titanium alloy contact wire and preparation method thereof

The invention discloses a copper-chromium-titanium alloy contact wire and a preparation method thereof. The copper-chromium-titanium alloy contact wire is prepared from a copper alloy through the processes of atmospheric smelting, upward continuous casting, continuous extrusion, heat treatment, rolling and drawing and the like, wherein the copper alloy contains Cu, 0.15-0.35% of Cr, 0.10-0.23% of Ti, 0-0.05% of Mg and 0-0.02% of Si, and the total amount of impurities of the copper alloy is not more than 0.1%. Under the conditions that the process is simplified and equipment and alloy components are relatively simple, large-scale industrialized production can be realized, and the contact wire has relatively high tensile strength, excellent electric conductivity and softening resistance and good electrical sliding wear performance.

Owner:JIANGXI UNIV OF SCI & TECH +1

Unidirectional clutch

InactiveCN101303053AAchieve separationOvercome slipping defectsFreewheel clutchesEngineeringSliding wear

The invention relates to a one-way clutch which comprises a first rotating body and a second rotating body which are dynamically matched with a circle surface. The matching surfaces of the rotating bodies are respectively provided with semicircular guide grooves which are mutually intersected. A roll ball flexibly rotates in an intersected cavity of the two guide grooves and a cavity is formed by an outer clutch cavity of the second rotating body, in which the roll ball can freely move. The one-way clutch of the invention is characterized in that at least one end of the semicircular guide groove on the surface of the first rotating body, which faces the outer clutch cavity of the second rotating body, is a closed structure, and the semicircular guide groove of the first rotating body enters the outer clutch cavity of the second rotating body by the size where one roll ball can be contained. By the action of the two intersected guide grooves, the roll ball slides to the intersected clearance of the two guide grooves according to the changes of relative rotational speed of the two rotating bodies, thus realizing the meshing of the two rotating bodies. After the roll ball slides away from the guide groove into the cavity of the rotating body, the separation between the two rotating bodies is realized. The roll ball can roll and slide in the guide groove and the cavity so as to overcome the defect of skid caused by sliding wear of the one-way clutch due to the extrusion of a roller and the deformation of a flat spring, etc., thereby prolonging the service life.

Owner:叶常青 +2

TiBw-NiTi composite coating and preparation method thereof

ActiveCN111304648AEliminate the problemImprove toughnessIncreasing energy efficiencyMetallic material coating processesPhysical chemistrySliding wear

The invention relates to a TiBw-NiTi composite coating and a preparation method thereof. The TiBw-NiTi composite coating contains TiBw crystals and NiTi crystals, the area percentage of the TiBw crystals is 30-50%, and the area percentage of the NiTi crystals is 40-60%, and the total area percentage of Ti crystals and TiB2 crystals does not exceed 10%. The preparation method comprises the steps that (1) the TiB2 powder and Ti powder are evenly mixed, so that mixed powder is obtained; (2) in an inert atmosphere, the mixed powder obtained in the step (1) is conveyed to the surface of a base plate to be prepared into a cladding layer; and (3) the Ni powder is pre-placed on the surface of the cladding layer obtained in the step (2), and after completion, the TiBw-NiTi composite coating is obtained. The obtained TiBw-NiTi composite coating greatly eliminates existence of a Ti matrix and TiB2 in the composite coating, and the tenacity, dry sliding wear resistance and anti-fatigue performanceof the TiBw-NiTi composite coating can be significantly improved.

Owner:NANHUA UNIV

Electrical contact pair and connector terminal pair

ActiveUS20180026385A1Reduced sliding wearSmall coefficient of frictionCoupling contact membersSliding wearElectrical contacts

An electrical contact pair and a connector terminal pair that can reduce the amount of sliding wear in a contact portion. The electrical contact pair includes a first electrical contact, a second electrical contact, and a contact portion. The first electrical contact includes, above a first conductive base material, an Ag—Sn alloy layer, and a first AG layer that is laminated on a surface of the Ag—Sn alloy layer, and the first AG layer is exposed as the outermost surface. The second electrical contact includes a second AG layer above a second conductive base material, and the second AG layer is exposed as the outermost surface. The contact portion is obtained as a result of a surface of the first AG layer of the first electrical contact and a surface of the second AG layer of the second electrical contact being in contact with each other.

Owner:AUTONETWORKS TECH LTD +2

Electronic control device

ActiveUS9545020B2Easy to implementConvenient inspectionCasings with connectors and PCBElectrical apparatus contructional detailsElectrical conductorControl signal

A control unit is stored in an airtight housing constituted by a base, an annular peripheral wall member, a cover, and first and second interior packings, second wiring conductors connected to input / output equipment and first wiring conductors connected to a host controller through a control signal connector are brought into press-contact with input / output control terminals of the control unit by first and second pressing elastic mats, the relative positions of associated components are regulated by positioning pins passing through from the cover to the base, and the cover is opened by loosening blockade screws without causing an assembly dimension error or sliding wear of conductive contact portions due to thermal deformation, whereby the control unit is detached.

Owner:MITSUBISHI ELECTRIC CORP

Construction safety protective net for high buildings

The invention discloses a high-rise building construction safety protection net, which comprises a protective net body and a frame installed around the protective net body, the top and bottom of the frame are provided with a plurality of first rectangular grooves, and the first rectangular The first slide rails are welded on the inner walls of both sides of the groove, and a sliding seat that is slidingly connected with the first slide rail is placed inside the first rectangular groove, and the side of the sliding seat away from the protective net body is screwed with a A rope-threading ring on the outside of a rectangular groove, both sides of the sliding seat are provided with a first friction pad bonded to the side wall of the first rectangular groove, and two oppositely arranged rectangular pads are provided on the sliding seat. In the chamber, a second slide rail is welded on the inner wall of the two rectangular chambers close to each other. The invention is economical and practical, and the position of the rope-threading ring on the sliding seat can be adjusted inside the first rectangular groove according to actual needs, which is more convenient for the fixed installation of the protective net body.

Owner:黎庆有

Connecting rod horizontal type corrective pinch device

InactiveCN103084417AQuick correctionImprove deviationGuiding/positioning/aligning arrangementsHydraulic cylinderFixed frame

The invention provides a connecting rod horizontal type corrective pinch device which is used for processing lines of strip steels. The connecting rod horizontal type corrective pinch device comprises a fixing frame, a motor, a compression roller swing frame, a compression roller and a pinch roll. The connecting rod horizontal type corrective pinch device is characterized in that a flexible moving frame is installed on the fixing frame, the moving frame is in surface contact with the fixing frame, a slide wear-resistant plate is installed on the contact surface between the moving frame and the fixing frame, connecting rods are installed at two sides of the fixing frame and respectively connected with the fixing frame and the moving frame, the connecting rods are connected with a corrective hydraulic cylinder, the connecting rods can be pushed by the corrective hydraulic cylinder to drive the moving frame to move, and an oriented screw which is used for guiding the moving frame is further arranged on the fixing frame. The connecting rod horizontal type corrective pinch device can effectively overcome the defect of deviation in the operation of strip steels, ensure the safety of rolling equipment of the strip steels and meet the quality requirement of products.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com