Ferrographic image multi-information fusing method based on D-S evidence theory

A technology of multi-information fusion and evidence theory, applied in the field of mechanical equipment fault diagnosis, can solve problems such as mixing, multi-impurity information, lack of filtering process, etc., and achieve the effect of improved recognition accuracy and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with drawings and embodiments.

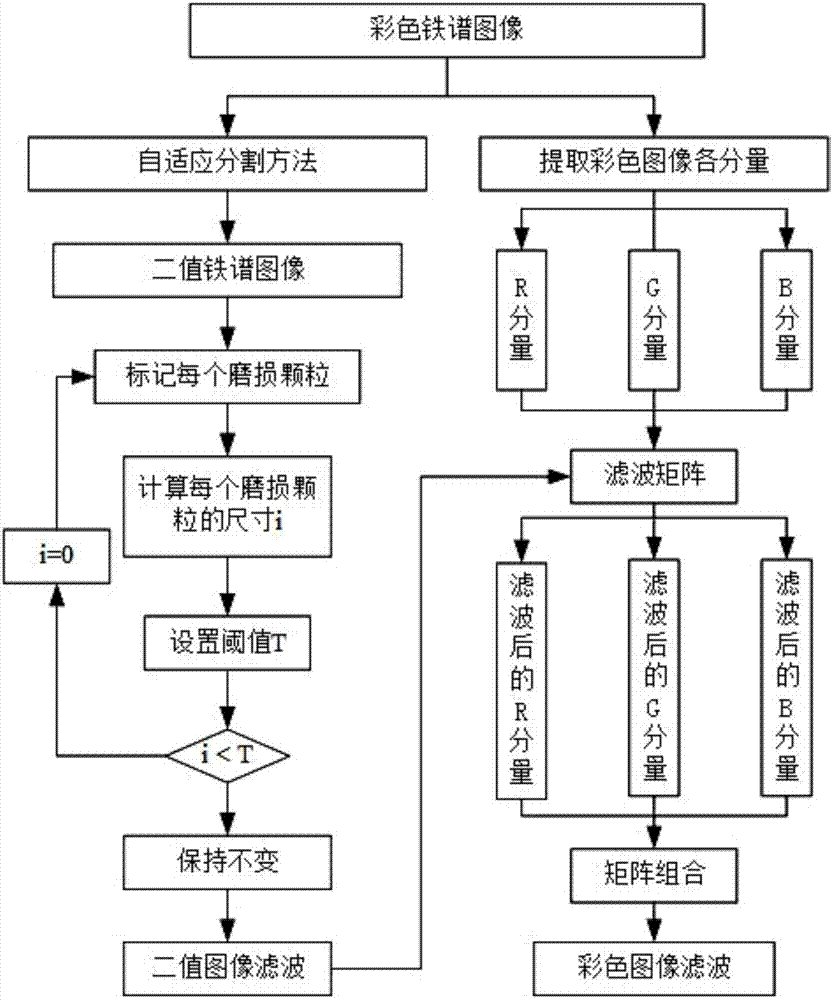

[0043] The present invention first performs relatively fine filtering on the basis of binary filtering to obtain a binary filtered image. At the same time, combined with the R, G, and B three components of the color ferrographic image, a color image that filters out uninteresting abrasive particles and impurities is obtained. Then, feature extraction is performed on the filtered binary image and color image respectively to obtain the morphological feature information and color feature information of the ferrographic image. By adjusting the parameter settings of the support vector machine (SVM), the probability output of the wear particle sample identification result is realized, and the probability assignment function (BPA) required by the D-S evidence theory for fusion of heterogeneous information is formed. Using the D-S evidence theory, the wear particle shape infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com