Connecting rod horizontal type corrective pinch device

A horizontal, connecting rod technology, applied in the field of metallurgical steel rolling machinery, can solve the problems of difficult automatic belt threading, high manufacturing cost, large floor space, etc., and achieve the effect of good effect, simple installation and strong deviation correction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment, the present invention is further described:

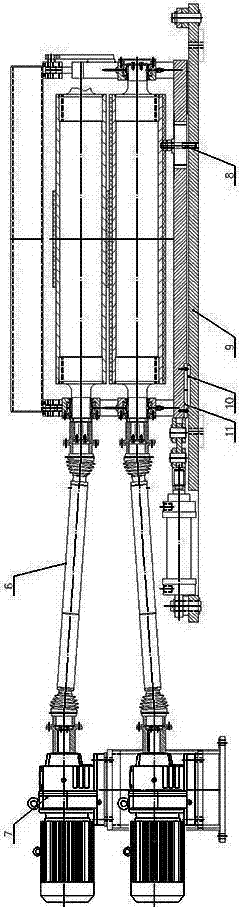

[0025] Such as figure 1 figure 2 image 3 The connecting rod horizontal correction and pinching device shown includes a fixed frame 9, a motor, a pressure roller swing frame 4, a pressure roller 3 and a pinch roller 2, and a movable moving frame 1 is installed on the fixed frame 9, The mobile frame 1 is in surface contact with the fixed frame 9, and an upper wear plate 11 and a lower wear plate 10 are installed on the contact surface of the two, and connecting rods 12 are installed on both sides of the fixed frame, and the connecting rod 12 Connect the fixed frame 9 and the mobile frame 1 respectively, and connect with the deviation correction hydraulic cylinder 13. The deviation correction hydraulic cylinder 13 can push the connecting rod 12 to drive the mobile frame 1 to move. The lead screw 8.

[0026] In this embodiment, the upper wear-resistant plate 11 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com