TiBw-NiTi composite coating and preparation method thereof

A technology of composite coating and cladding layer, applied in the direction of coating, metal material coating process, improvement of process efficiency, etc., can solve the problems of poor plastic deformation resistance and toughness, poor fatigue resistance, etc. The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

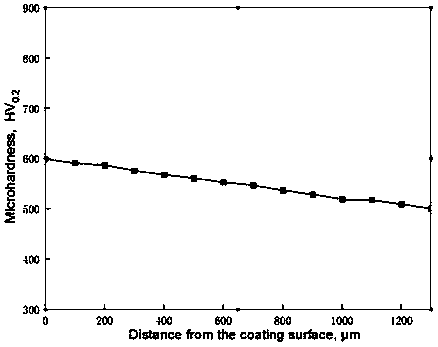

Image

Examples

Embodiment 1

[0033] This embodiment provides a TiB w -The preparation method of NiTi composite coating, comprises the steps:

[0034] (1) Preliminary preparation: Ti-6Al-4V alloy is selected as the substrate, and its composition is calculated by weight percentage: aluminum 6.01%, vanadium 3.84%, iron 0.3%, sulfur 0.15%, carbon 0.1%, oxygen 0.1%, nickel 0.15% % and the balance of titanium; put the Ti-6Al-4V alloy substrate into a closed atmosphere controllable processing protection room, and place the induction heater on the lower part of the substrate and fasten it; put the TiB with a purity of 99.9% 2 Powder and Ti powder with a purity of 99% are compounded at a weight ratio of 1:3 to obtain a mixed powder, TiB 2The particle size of the powder is 0.5-10 μm, and the particle size of the Ti powder is 1-10 μm; the mixed powder is mixed in a vertical high-energy ball mill for 120 minutes, then dried at 120 ° C for 60 minutes, and then put into a coaxial powder feeder; Argon gas with an atom...

Embodiment 2

[0038] This embodiment provides a TiB w -The preparation method of NiTi composite coating, comprises the steps:

[0039] (1) Preliminary preparation: select TA2 alloy as the substrate, and its composition is calculated by weight percentage: nitrogen 0.03%, hydrogen 0.015%, iron 0.3%, oxygen 0.25%, carbon 0.1% and the rest of the titanium; the purity is 99.9% TiB 2 Powder and Ti powder with a purity of 99.1% are compounded at a weight ratio of 1:2 to obtain a mixed powder, TiB 2 The powder particle size is 130-150 μm, and the Ti powder particle size is 180-200 μm; mix the mixed powder in a vertical high-energy ball mill for 150 minutes, then dry it at 120 ° C for 90 minutes, and then put it into a coaxial powder feeder; Argon gas with an atomization size of 50-70 μm and a purity of 99.99% is used as a shielding gas and a mixed powder delivery gas, and the amount of mixed powder delivered is 30g / min;

[0040] (2) Prepare the cladding layer: turn on the laser beam heat source ...

Embodiment 3

[0043] This embodiment provides a TiB w -The preparation method of NiTi composite coating, comprises the steps:

[0044] (1) Preliminary preparation: Ti-6Al-4V alloy is selected as the substrate, and its composition is calculated by weight percentage: aluminum 6.01%, vanadium 3.84%, iron 0.3%, sulfur 0.15%, carbon 0.1%, oxygen 0.1%, nickel 0.15% % and the balance of titanium; put the Ti-6Al-4V alloy substrate into a closed atmosphere controllable processing protection room, and place the induction heater on the lower part of the substrate and fasten it; put the TiB with a purity of 99.9% 2 Powder and Ti powder with a purity of 99.1% are compounded at a weight ratio of 1:2.5 to obtain a mixed powder, TiB 2 The particle size of the powder is 90-100 μm, and the particle size of the Ti powder is 80-90 μm; the mixed powder is mixed in a vertical high-energy ball mill for 120 minutes, and then an appropriate amount of 2123 phenolic resin is used as a binder, and the TiB 2 The powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com