Method for assembling and device for assembling roller bearing

A technology of roller bearing and assembling device, applied in the field of roller bearing, can solve the problems of rolling surface damage of rollers and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] [First example of embodiment]

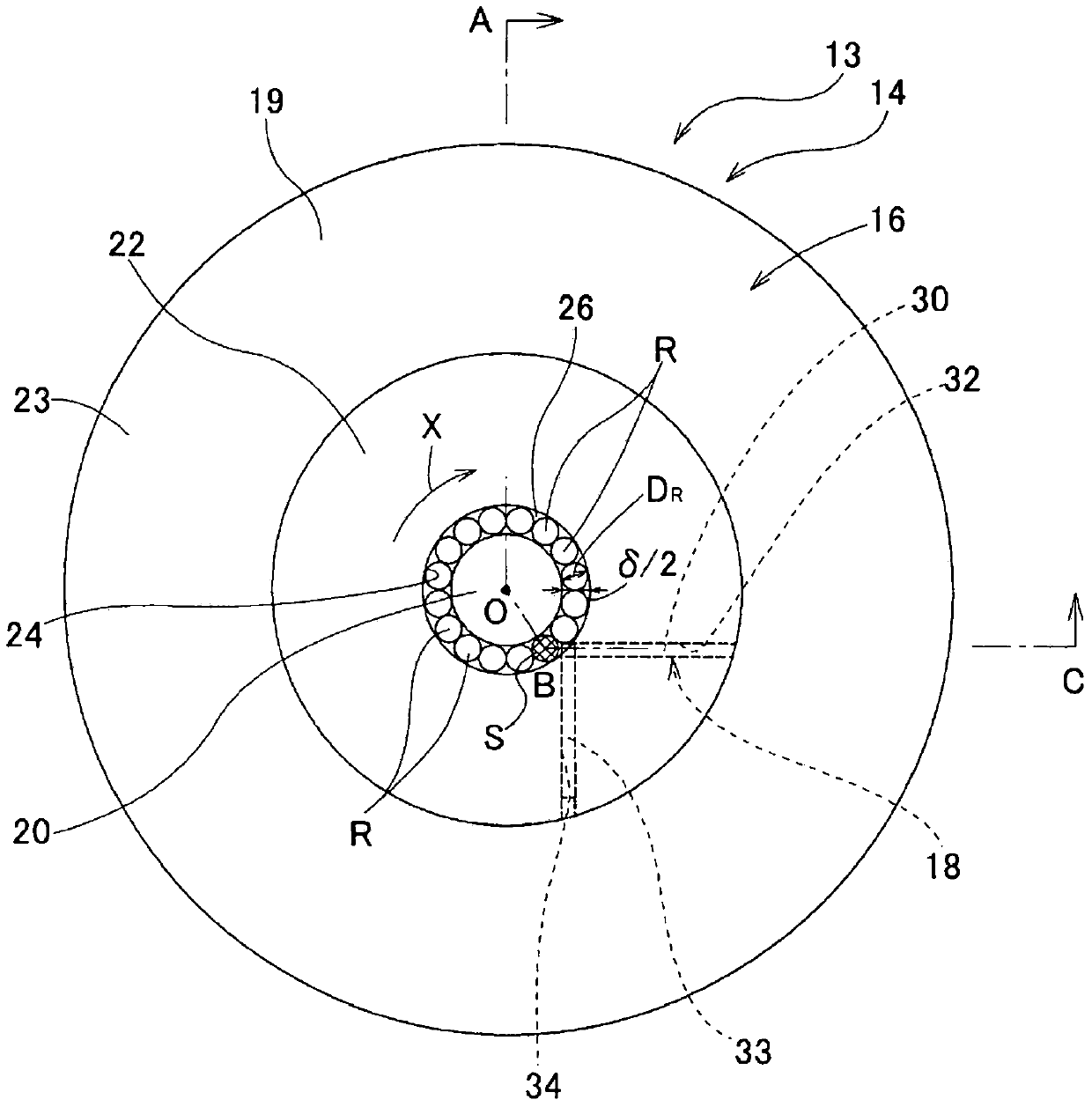

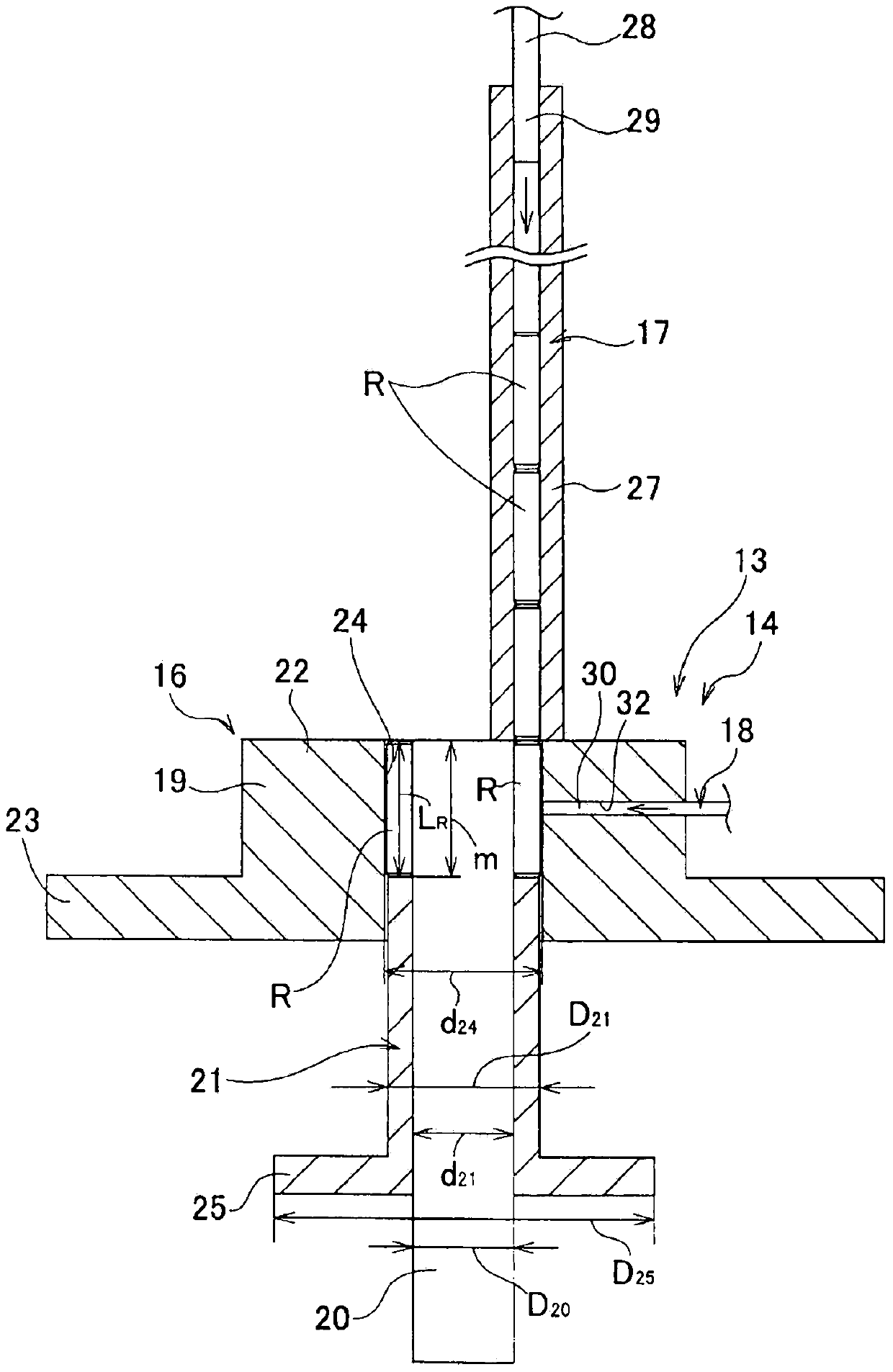

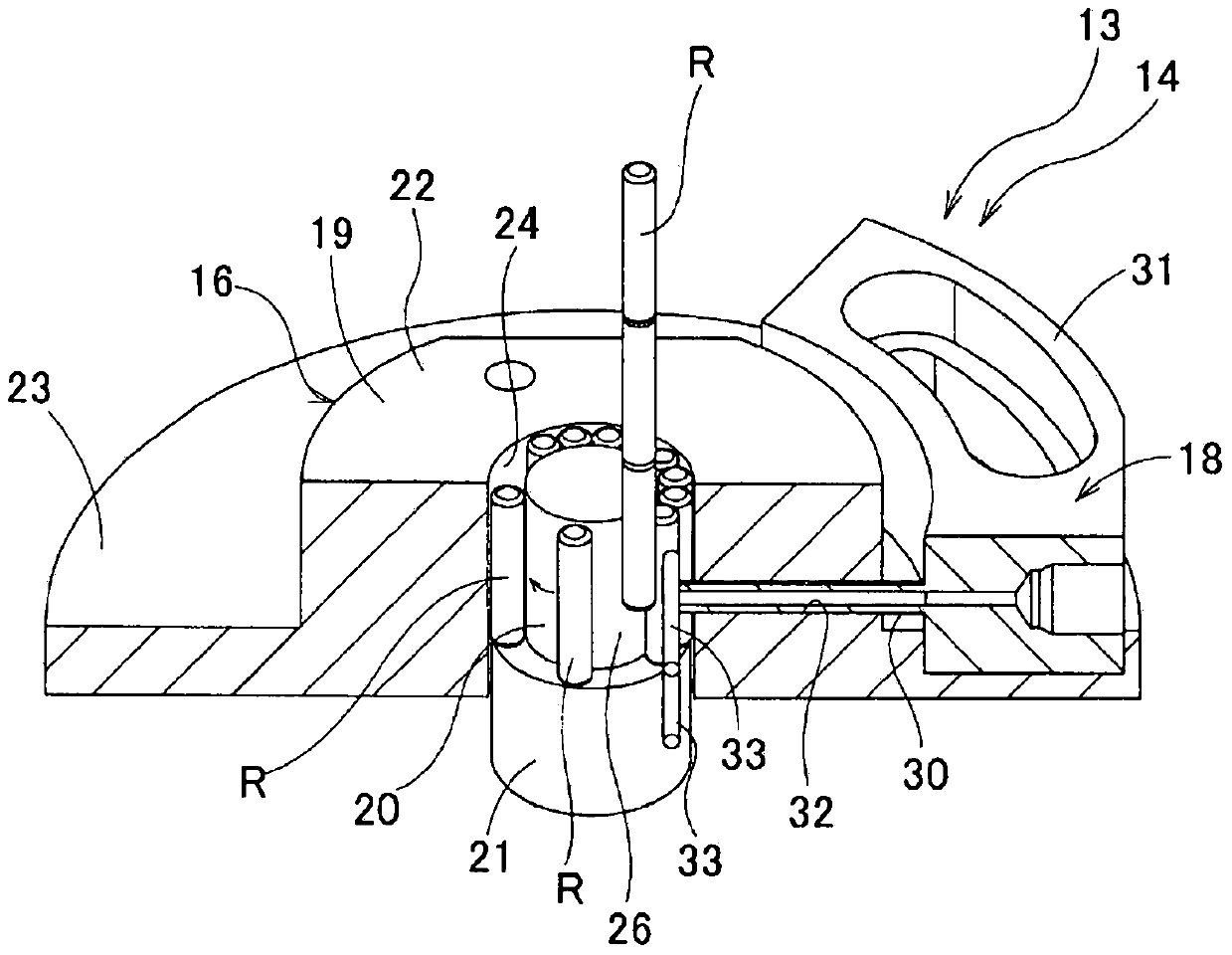

[0039] Figure 1 to Figure 8 The first example of the embodiment of the present invention is shown. The assembly device 13 is constituted by an alignment jig 14 and an insertion jig 15 for incorporating a plurality of rollers R inside an outer ring W constituting a full-roller type radial roller bearing.

[0040] The alignment jig 14 of the present invention includes a jig body 16 , a roller supply member 17 , and an alignment fluid supply member 18 . The jig main body 16 is composed of a guide cylinder 19, a guide shaft 20, an ejection jig 21, and a cover (not shown), and a predetermined spatial shape is formed in a part surrounded by these components so that a plurality of rollers can be arranged in parallel with each other. The permutation space of 26.

[0041] The guide cylinder 19 has a stepped cylindrical shape and is composed of a thick portion 22 at the inner diameter side half and a thinner portion 23 at the outer diameter sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com