Carbonaceous double-layer paper-based friction material and preparation method thereof

A technology of paper-based friction material and carbonaceous material, applied in the preparation of carbonaceous double-layer paper-based friction material, in the field of carbonaceous double-layer paper-based friction material, can solve the problem of low friction coefficient, achieve simple molding process, friction The effect of increasing the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

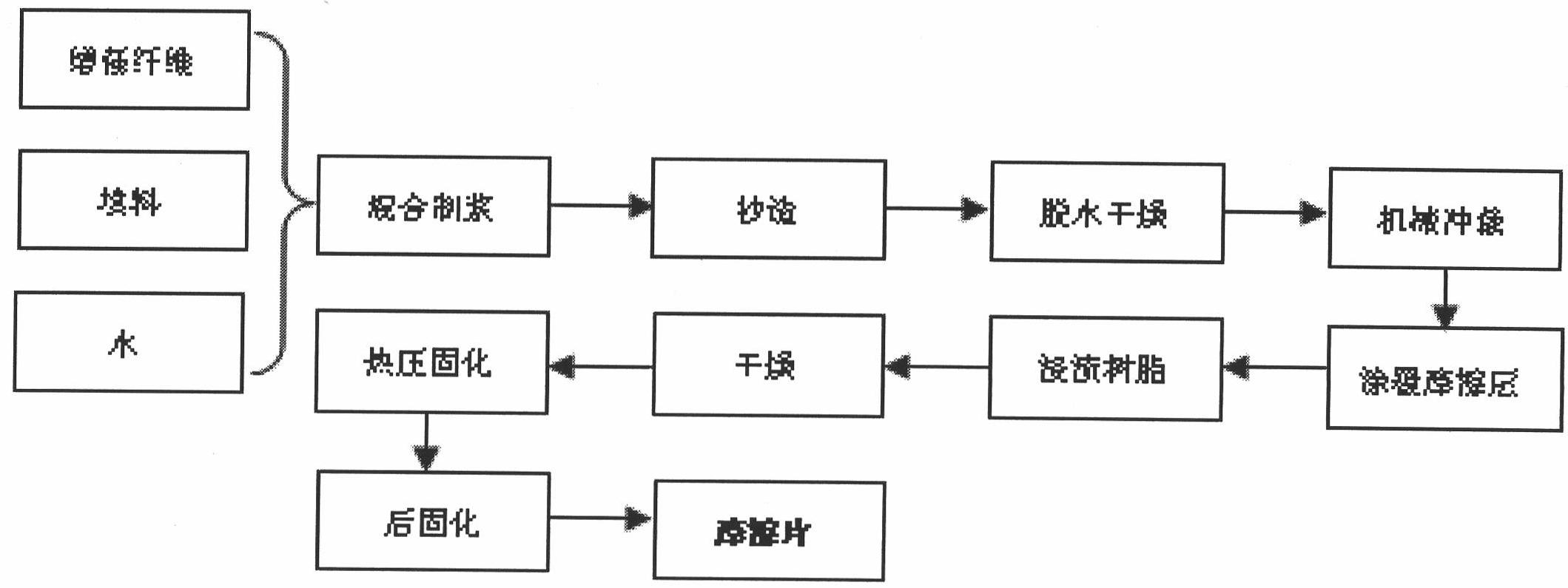

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Preparation of paper-based friction material support layer preform: take 7g of paper fiber, 5g of aluminum silicate ceramic fiber, and 3g of mineral wool fiber; take 12g of kaolin, 9g of mineral powder, and 10g of calcium carbonate, and mix paper fiber, aluminum silicate Ceramic fiber, mineral wool fiber, kaolin, mineral powder and calcium carbonate are mixed and beaten to prepare a uniform slurry, and a paper-based friction material support layer prefabricated body is formed by a wet process.

[0022] Take 10g of carbon nanotubes, 4g of alumina and 1g of graphite, and mix them into a friction layer mixture. Among them, aluminum oxide and graphite are friction performance modifiers.

[0023] After drying the prefabricated body of the support layer, it is mechanically punched and uniformly coated with a layer of friction layer mixture on its surface; the impregnation concentration is 10wt% cashew nut shell oil modified phenolic resin solution, the content of c...

Embodiment 2

[0026] Embodiment 2: Preparation of paper-based friction material support layer prefabricated body: get hemp fiber 8g, polycrystalline mullite ceramic fiber 5g, glass fiber 7g; get kaolin 10g, barite 17g, calcium carbonate 8g, hemp fiber, polycrystalline The crystal mullite ceramic fiber, glass fiber, kaolin, barite and calcium carbonate are mixed and beaten to prepare a uniform slurry, and the paper-based friction material support layer prefabricated body is formed by a wet process.

[0027] Take 5g of pyrolytic carbon, 4g of alumina and 4g of graphite, and mix them into a friction layer mixture. Among them, aluminum oxide and graphite are friction performance modifiers.

[0028] Dry the prefabricated body of the support layer and punch it out mechanically, and evenly coat the surface with a layer of friction layer mixture; impregnate the cashew nut shell oil modified phenolic resin solution with a concentration of 5 wt%, and the content of the cashew nut shell oil modified p...

Embodiment 3

[0030] Example 3: Preparation of a paper-based friction material support layer preform: Take 11.5g of bamboo fiber and 10g of silicon carbide ceramic fiber; take 10g of the leftover material of the support layer in Example 1; take 6g of barite, 3.5g of mineral powder, and oxidize Zinc 9g, bamboo fiber, silicon carbide ceramic fiber, the leftover material of the support layer in Example 1, barite, mineral powder and zinc oxide are mixed and beaten to prepare a uniform slurry, and the paper-based friction material support is formed by a wet process layer prefab.

[0031] Take 15g of carbon nanotubes, 6g of aluminum oxide and 4g of graphite, and mix them into a friction layer mixture. Among them, aluminum oxide and graphite are friction performance modifiers.

[0032] Dry the prefabricated body of the support layer and punch it mechanically, and evenly coat the surface with a layer of friction layer mixture; impregnate the cashew nut shell oil modified phenolic resin solution wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com