Electroplastic incremental forming device for plate and working method thereof

An incremental forming and electroplastic technology, applied in the field of metal processing, can solve the problems of large lateral processing resistance of the upper forming indenter, can not be always facing, and high processing cost, and can improve the forming limit and forming quality of sheet metal, pulse current The effect of consistent direction and high precision of sheet metal forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, the following will be described in detail with reference to the accompanying drawings and specific embodiments.

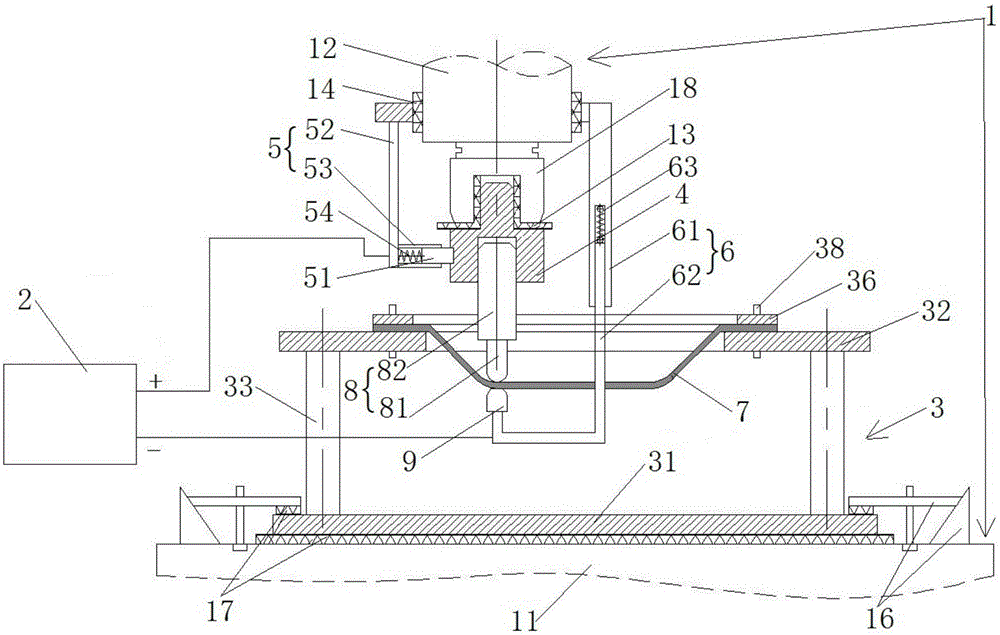

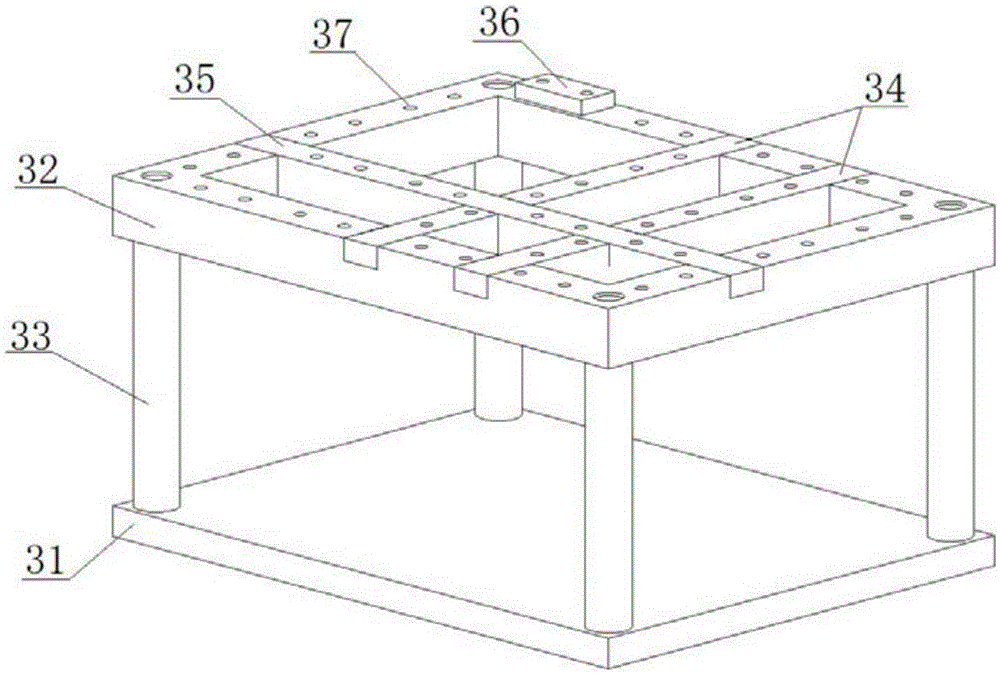

[0039] On the one hand, the present invention provides a progressive electroplastic forming device for sheet metal, such as figure 1 As shown, including a machine tool 1 and a pulse power supply 2, a sheet clamping device 3 is fixed on the workbench 11 of the machine tool 1, and a clamping block 4, a brush holder 5 and a holder 6 are arranged on the main shaft 12 of the machine tool 1, wherein :

[0040] The clamping block 4 is connected with a tool head 8 ( figure 1 Among them, 18 is the handle of a knife, and the clamping block 4 is fixed on the handle of a knife 18);

[0041]The brush holder 5 is L-shaped, the upper end is fixed on the main shaft 12, and the lower end is connected with a brush 51 for abutting against the clamping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com