Preparation method of whisker and pacticle toughening ceramic base composite

A technology for composite materials and toughened ceramics, which is applied in the field of preparation of whiskers and granular ceramic matrix composite materials, can solve the problems of low performance, limited application range of hot pressing sintering, low performance of composite materials, etc., and achieve good performance and designability Strong, toughness-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

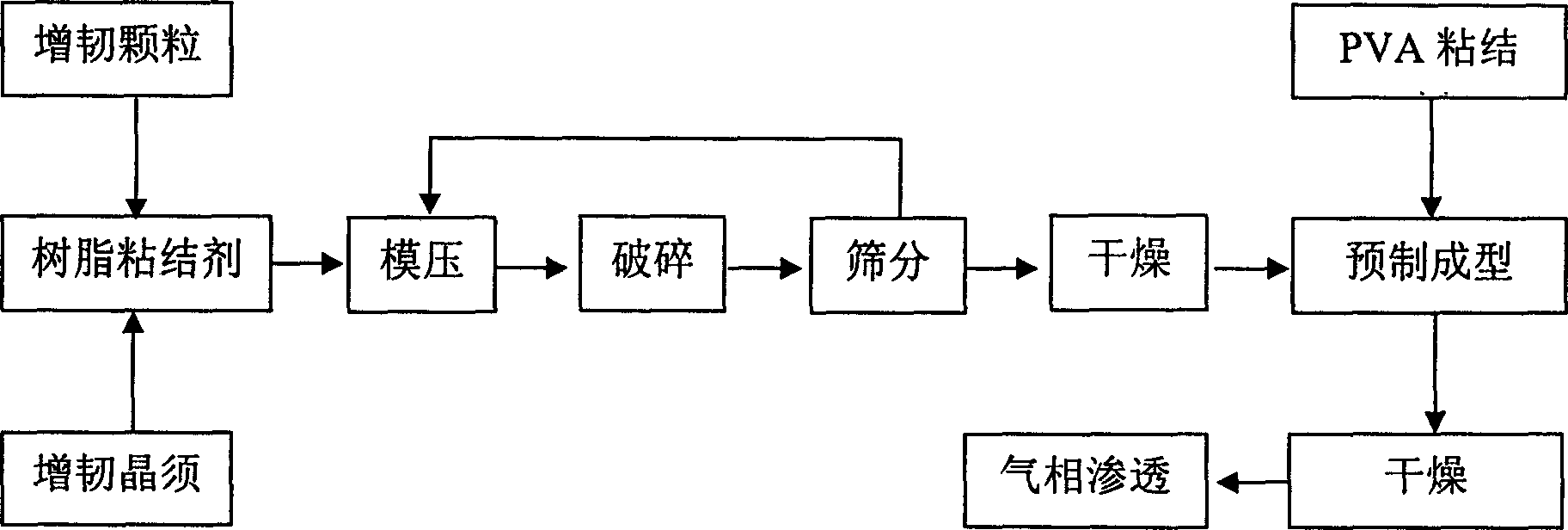

Method used

Image

Examples

Embodiment 1

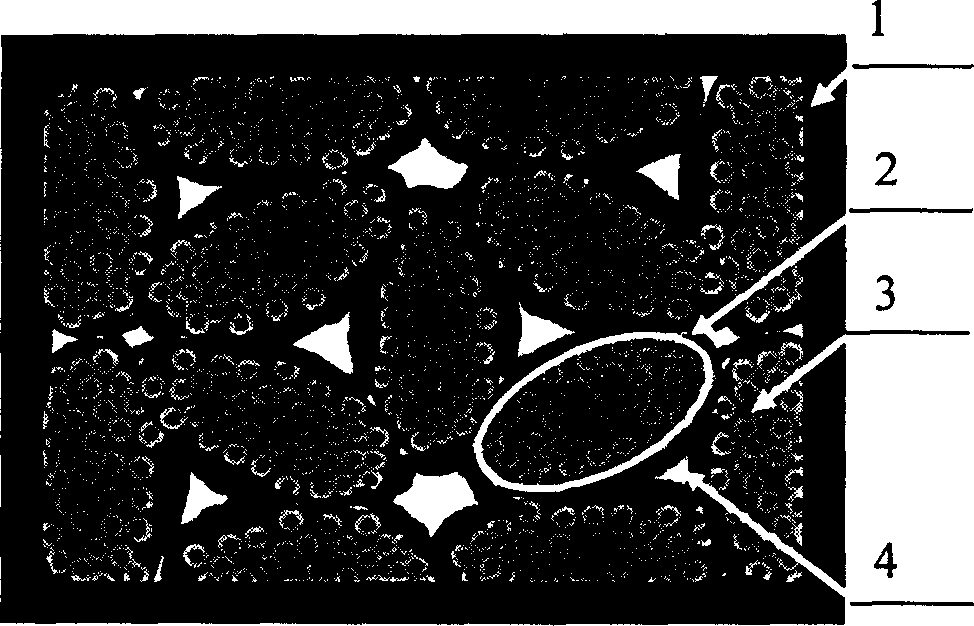

[0030] This example is the preparation of silicon carbide whisker toughened silicon carbide ceramic matrix composite material.

[0031] Silicon carbide whiskers with a diameter of 1.5 μm and an aspect ratio of 8 to 10 are selected as the reinforcement, 5% PVA aqueous solution is used as the prefabricated binder, and the phenolic resin ethanol solution is used as the granulation binder, and the concentration of the solution is 0.5 g / ml.

[0032] During preparation, mix 150g of silicon carbide whiskers with 100ml of phenolic resin solution, press and crush it four times with a pressure of 10-20MPa, dry in the shade at room temperature for 24 hours, and dry at 120°C for 2 hours. After crushing, sieving and granulation, the granule group with a diameter of 0.6-1.0mm is selected to be mixed with 15-30%wt PVA aqueous solution, and prefabricated under a pressure of 3-8MPa. The molded preform was dried in the shade at room temperature for 24 hours, dried at 120°C for 2 hours, and the...

Embodiment 2

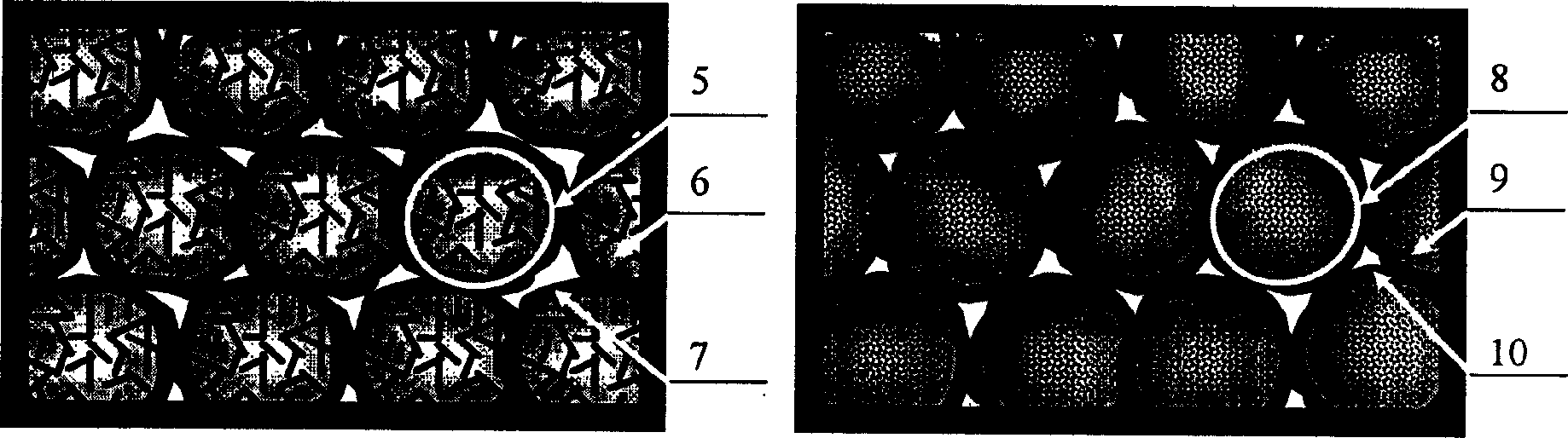

[0035] This example is the preparation of silicon nitride particle toughened silicon nitride ceramic matrix composite material

[0036] Silicon nitride powder with a diameter of 6 μm is selected as the particle reinforcement, 5% PVA aqueous solution is used as the prefabricated binder, and phenolic resin ethanol solution is used as the granulation binder, and the concentration of the solution is 0.5g / ml.

[0037] During preparation, mix 150g of silicon nitride powder with 50ml of phenolic resin solution, press and crush it four times with a pressure of 10-20MPa, dry in the shade at room temperature for 24 hours, and dry at 120°C for 2 hours. After crushing, sieving and granulation, the granule group with a diameter of 0.6-1.0mm is selected to be mixed with 10-25%wt PVA aqueous solution, and prefabricated under a pressure of 3-8MPa. The molded preform was dried in the shade at room temperature for 24 hours, dried at 120°C for 2 hours, and then placed in a deposition furnace to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com