A kind of SICN ceramic airgel and its preparation method and application

A technology of airgel and ceramics, which is applied in the field of SiCN ceramic airgel and its preparation, can solve the problems of affecting high-temperature oxidation resistance and mechanical properties, unfavorable airgel microstructure control, and increased free carbon content, so as to benefit Effect of strengthening, low free carbon content and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] As mentioned above, the present invention provides a kind of preparation method of SiCN ceramic airgel in the first aspect, described preparation method comprises the following steps:

[0021] (1) Preparation of precursor solution: polysilazane containing Si-H bond in molecular structure and -CH=CH 2 The silazane oligomer is used as a precursor, and is prepared into a precursor solution under an inert protective atmosphere;

[0022] (2) Preparation of precursor wet sol: adding a curing agent to the precursor solution for curing reaction to obtain a precursor wet gel;

[0023] (3) Preparation of precursor airgel: drying the precursor wet gel to obtain precursor airgel;

[0024] (4) Preparation of ceramic airgel: in an inert protective atmosphere, the precursor airgel is pyrolyzed to obtain SiCN ceramic airgel.

[0025] In some preferred embodiments, the molecular structure of the polysilazane is shown in the following formula (I):

[0026]

[0027] The molecular st...

Embodiment 1

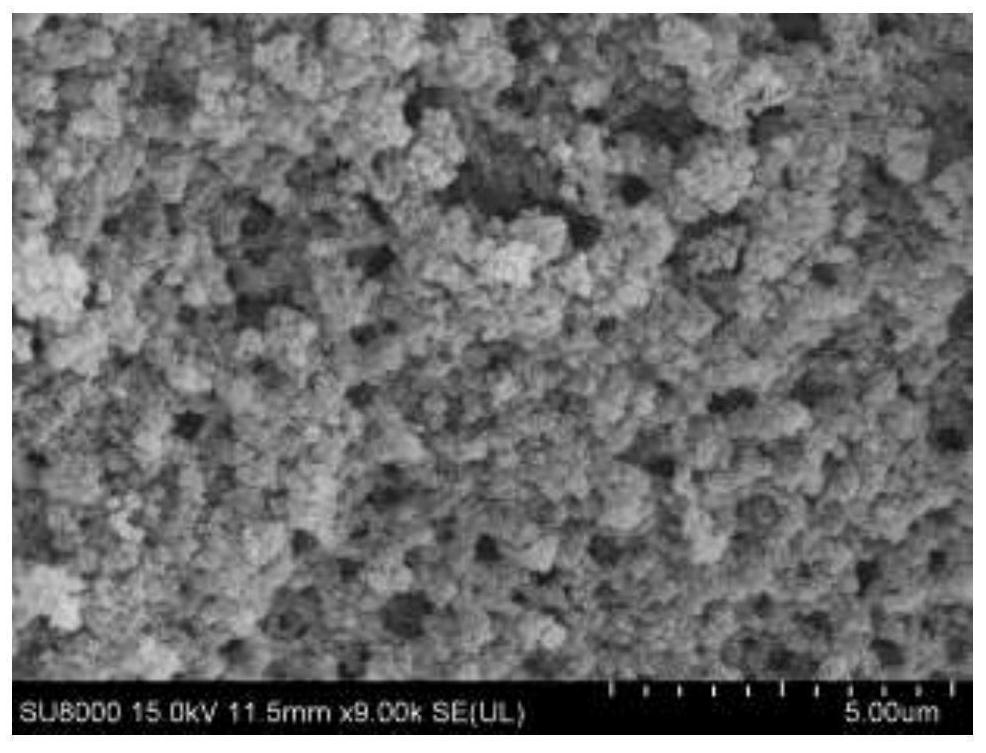

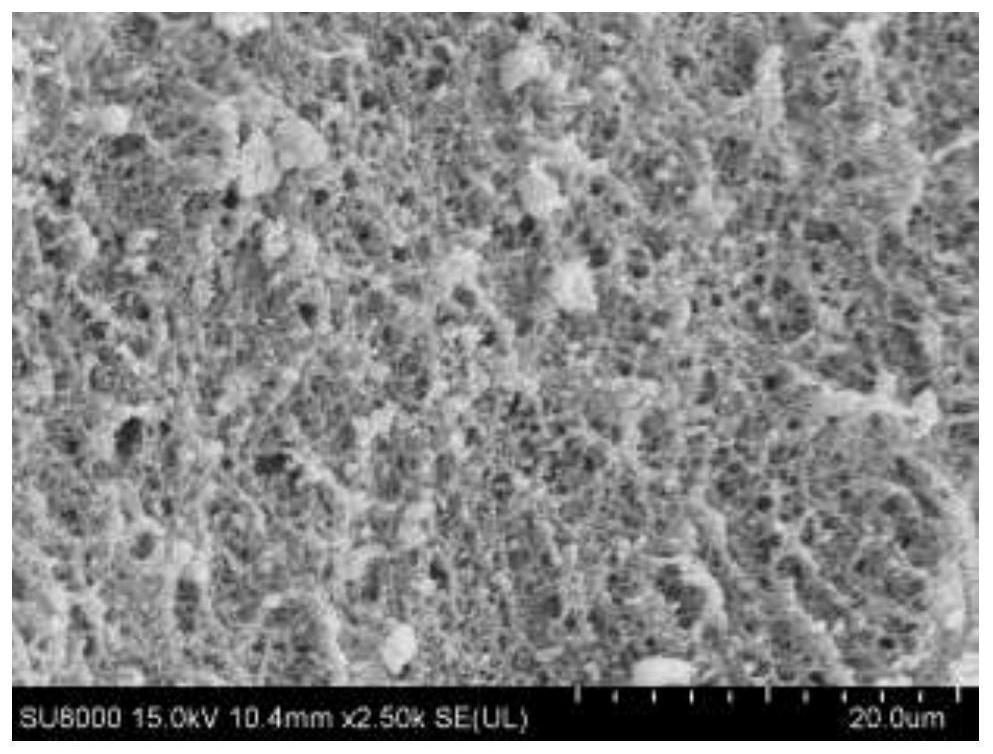

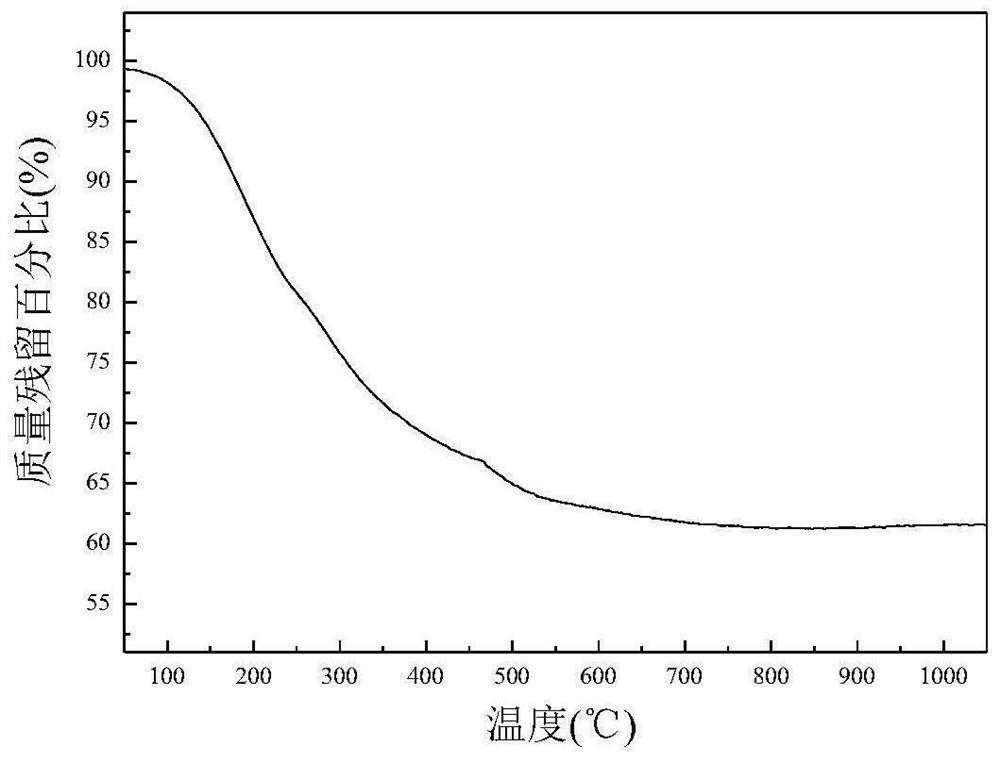

[0043] Under the protection of flowing nitrogen, the polysilazane (n is 5, m is 12.5) with formula (I) and the silazane oligomer (x is 9) with formula (II) are in a molar ratio of 1.2:1 , dissolved in cyclohexane, and stirred evenly to obtain a precursor solution containing 60% solvent, then add 0.01wt% platinum catalyst to it, continue to stir until uniform, transfer to a pressure reactor filled with nitrogen, at 180 ℃ reaction for 20h to obtain a light yellow silicon nitride precursor wet gel; after taking it out, soak it in cyclohexane for 6 days, during which the cyclohexane was replaced 3 times (replaced at 24h, 60h and 90h after soaking); The wet gel was passed through supercritical CO 2 Dry to obtain the precursor airgel; place the airgel in a high-temperature tube furnace, raise the temperature to 800°C at a rate of 2°C / min under high-purity argon, and keep it for 3 hours to obtain SiCN ceramic airgel glue. The obtained SiCN ceramic airgel has a density of 0.114g / cm ...

Embodiment 2

[0045] Under the protection of flowing argon, the polysilazane (n is 10, m is 25) with formula (I) and the silazane oligomer (x is 10) with formula (II) are 1.5 according to molar ratio: 1. Dissolve in n-hexane and stir evenly to obtain a precursor solution containing 65% solvent, then add 0.35wt% dicumyl peroxide to it, continue stirring until uniform, and transfer to a pressure reactor filled with nitrogen in 160°C for 10 hours to obtain a light yellow silicon nitride precursor wet gel; after taking it out, soak it in n-hexane for 6 days, during which n-hexane was replaced 3 times (replaced at 24h, 60h and 90h after soaking) ; The wet gel was freeze-dried to obtain a precursor airgel; the airgel was placed in a high-temperature tube furnace, and under high-purity argon, the temperature was raised to 1400 °C at a rate of 10 °C / min, and Keep it warm for 1 hour to get SiCN ceramic airgel. The obtained SiCN ceramic airgel has a density of 0.116g / cm 3 , the specific surface are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com