Preparation method of nano-ZSM-5 molecular sieve

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of inability to prepare high crystallinity, nano-molecular sieve grain growth, and high cost problem, achieve the effects of shortening crystallization time, reducing production cost, and simplifying the aging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

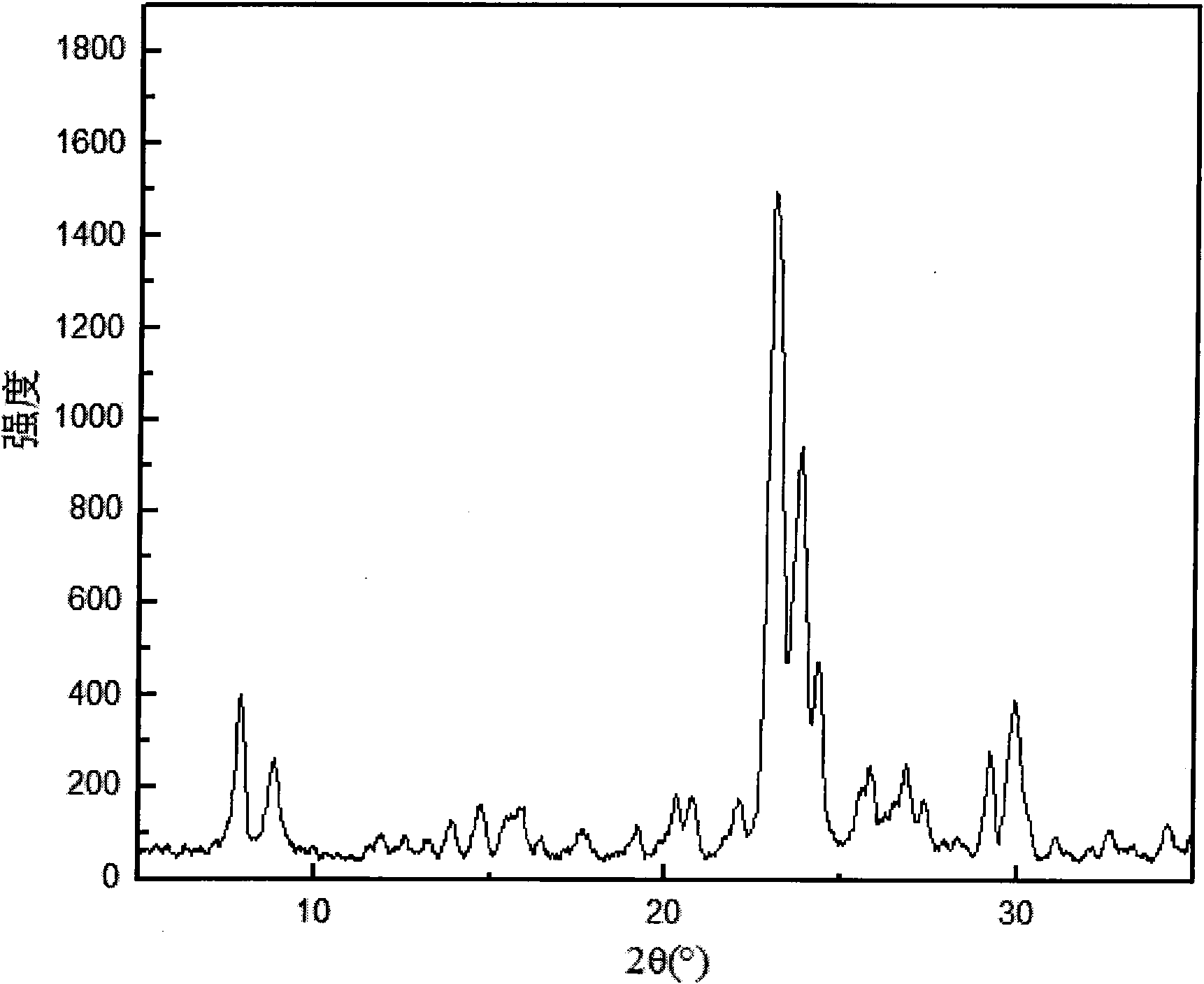

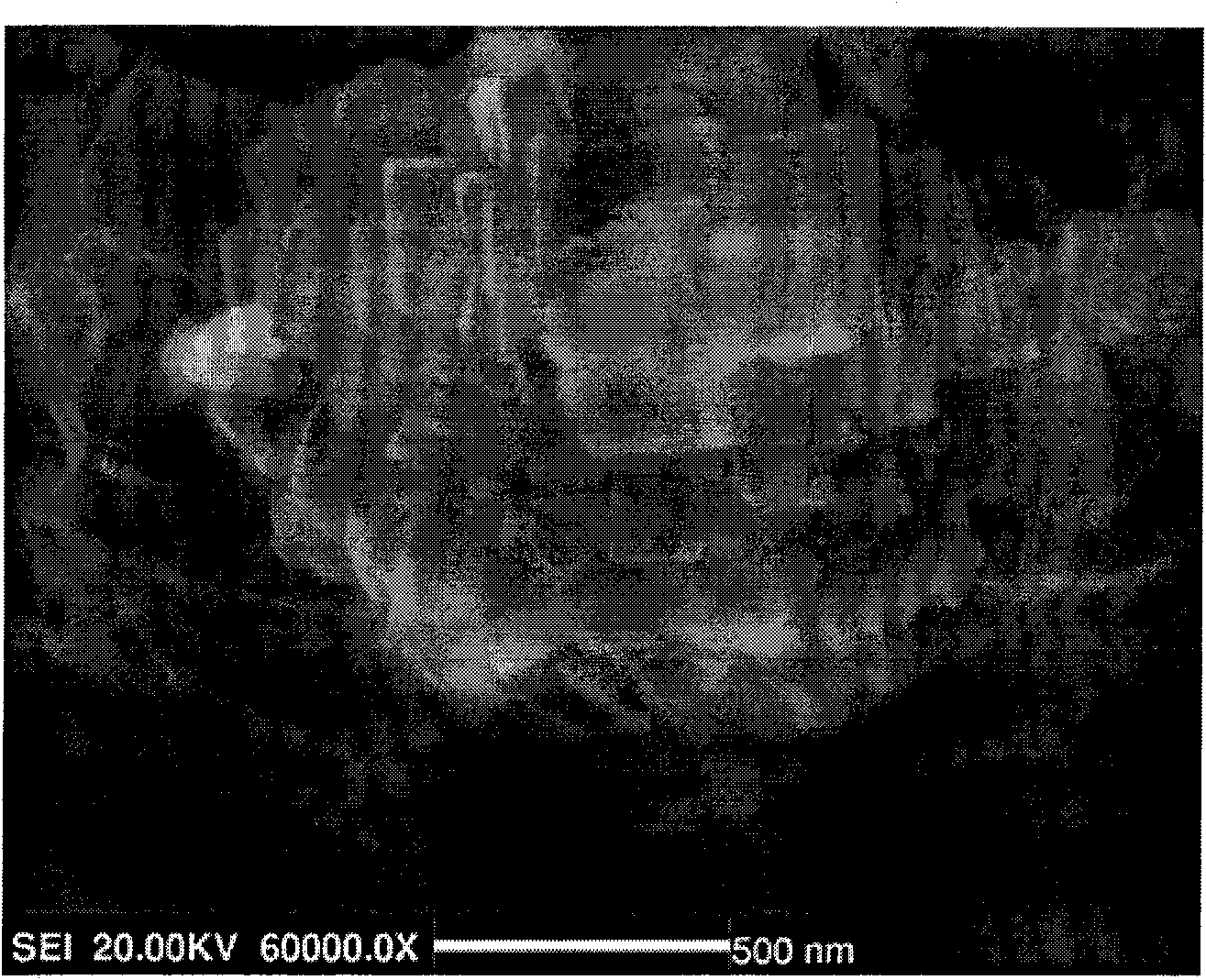

[0010] Specific embodiment one: the preparation method of nanometer ZSM-5 molecular sieve is realized by the following steps in the present embodiment: one, the preparation of precrystallization seed crystal: a, the aluminum isopropoxide of 1 part by weight ratio Add 42-113 parts of tetrapropylammonium hydroxide and 28-77 parts of deionized water, stir evenly, and prepare A solution; b. Stir 31-83 parts by weight of ethyl orthosilicate and deionized water Evenly, prepare solution B; c. Stir solution A at a speed of 300-700r / min, slowly add solution B, finish adding within 20 minutes, and then stir at a speed of 100-300r / min for 3 hours to make a mixed gel C, the mixed gel C is composed of 1 mole of Al in molar ratio 2 o 3 , 60-160 moles of SiO 2 , 21.4 to 57.1 moles of tetrapropylammonium hydroxide and 650 to 1760 moles of H 2 O composition; d, the mixed gel C is placed in a closed stainless steel reaction kettle with a polytetrafluoroethylene liner, crystallized at a tempe...

specific Embodiment approach 2

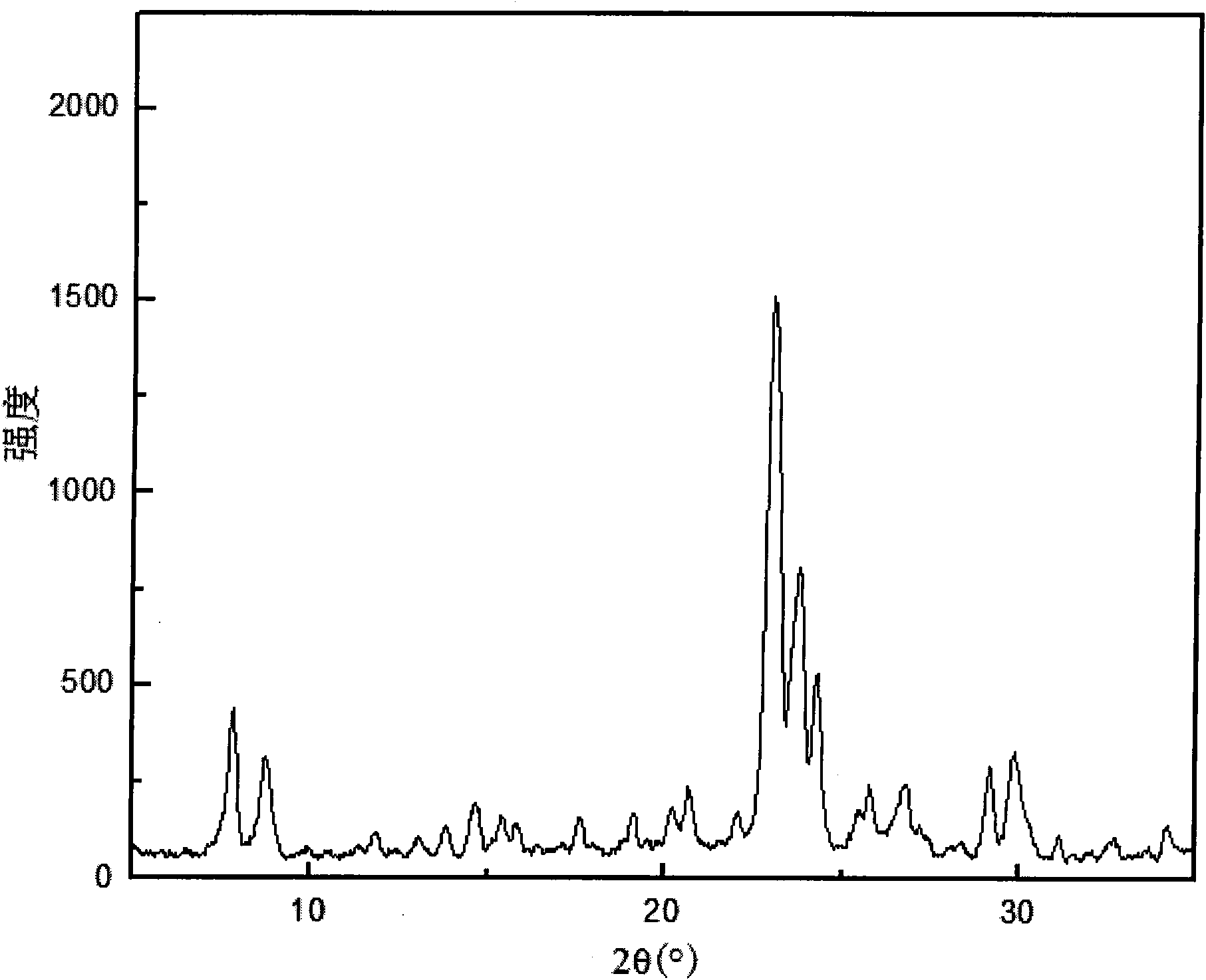

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that: the crystallization temperature in step d of step 1 is 130-150°C. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment is different from Embodiment 1 in that: the crystallization temperature in step d of step 1 is 140°C. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com