Nano bean pulp processing method

A processing method and soybean meal technology, applied in the field of soybean meal grinding and processing, can solve the problems of immature separation and purification technology, poor product flavor, limited enzyme source, etc., and achieve the goal of reducing allergies, pollution-free production, and easy process control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Commercially available soybean meal 2000g, the recorded protein content is 46%, and the oil content is 1.02%. It is directly sterilized by high-pressure steam at 120° C. in an autoclave for 10 minutes, and then cooled rapidly after sterilization. When the water content is 7%, take it out, cool it in a dry environment, slowly add the impeller type ultra-fine impact mill to pulverize, and pass through a 200-mesh sieve (more than 95% of the particle size is 300-500 mesh) , to obtain the secondary grinding product, which can then be directly added to the ball mill in batches for grinding, the ball mill speed is controlled at 800 rpm, the grinding medium is agate balls, the diameter is 1cm, the filling rate of the grinding medium is 30%, and the grinding is performed for 20 hours.

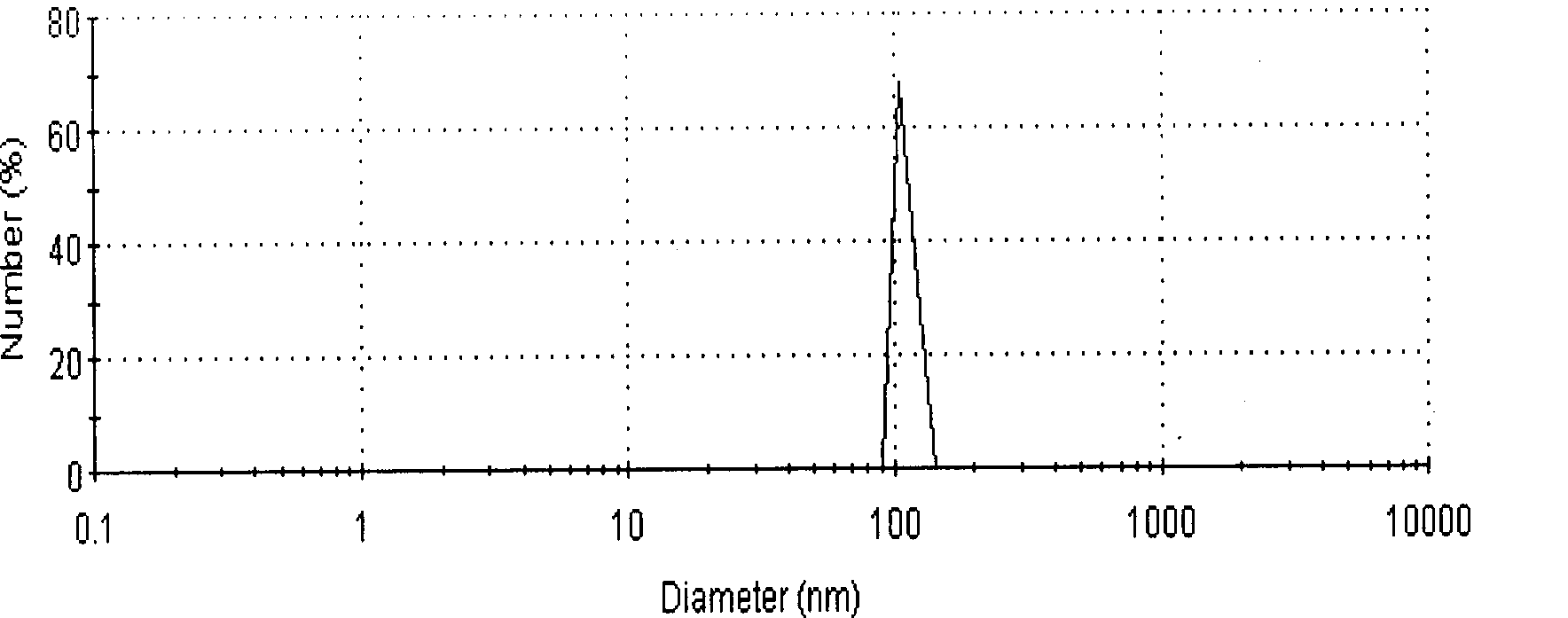

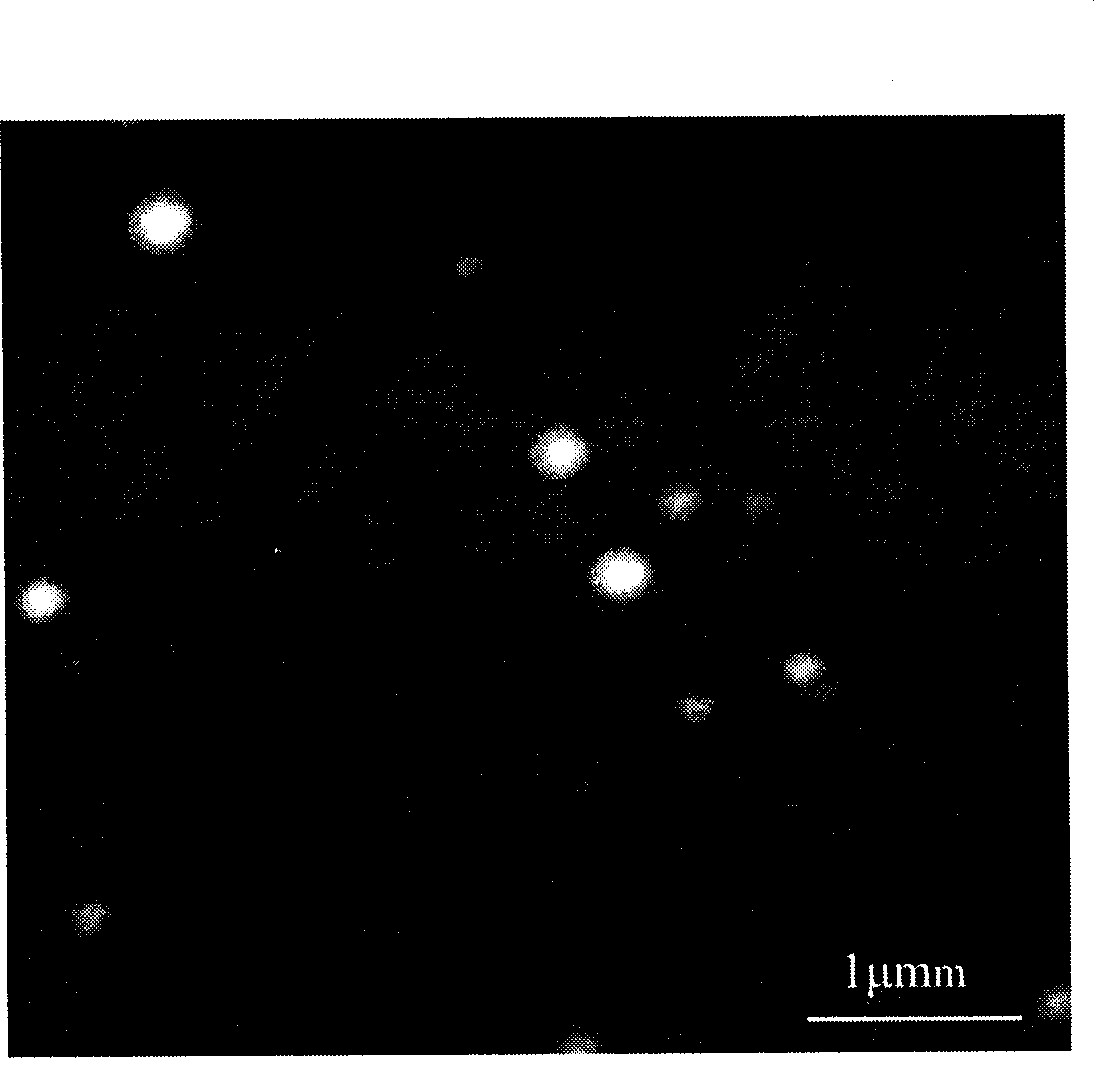

[0029] The nano-soybean meal was characterized by laser particle size analyzer and atomic force microscope, and the results were as follows: figure 1 , figure 2 shown. After grinding, the part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com