Automatic edible fungi bag filler

A fully automatic bagging machine technology, applied in applications, packaging, gardening, etc., can solve problems such as easy fatigue, low bagging efficiency, and difficult output, and achieve strong operability, easy control, and improved labor efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

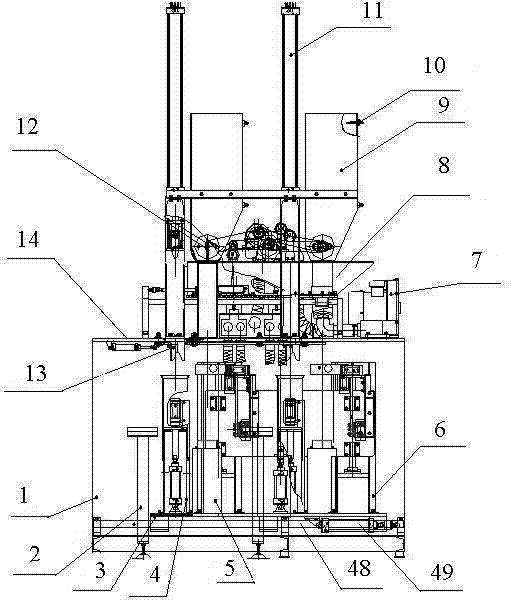

[0036] Embodiment 1, with reference to Figure 1-9 , a fully automatic bagging machine for edible fungi,

[0037] It includes a frame 1, the top of the frame 1 is provided with an upper top plate 14 with a blanking opening 22, the bottom of the frame 1 is provided with a base 3, and the bottom of the base 3 is provided with a base guide rod 48 connected to the frame 1, The base 3 is also connected with a base cylinder 49, and the base 3 is connected with the base guide rod 48 by a slide block;

[0038] Above the upper top plate 14, be provided with a pounding device 11 and a storage hopper 9 fixed on the frame 1, and the inner bottom of the storage hopper 9 is provided with an agitator 12; Connected tamper bar 16;

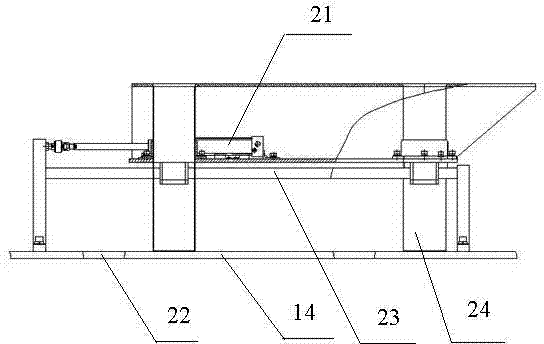

[0039] Below the storage hopper 9, there is a mobile barrel device 8, which includes a quantitative barrel 24, which is connected with a barrel cylinder 21, and the quantitative barrel 24 is guided by a slide block and a barrel connected to the frame 1. Rod 23 c...

Embodiment 2

[0070] Embodiment 2, in the edible mushroom automatic bagging machine described in Embodiment 1: the pressure bearing plate 38 is directly fixed on the base 3 or the support cylinder 39, or connected to the solid cylinder 40 fixed on the base 3 superior.

Embodiment 3

[0071] Embodiment 3, in the edible mushroom automatic bagging machine described in embodiment 1 or 2: a compacting device is provided on the bottom of the stamping rod 16; the compacting device includes an upper connecting plate 17 and a compacting plate 20 , Between the upper connecting plate 17 and the compacting plate 20, a compaction guide rod 19 is connected, and a spring 18 is arranged on the stamping rod 16 between the upper connecting plate 17 and the compacting plate 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com