Bogie of narrow gauge railway vehicle

A technology for railway vehicles and bogies, which is applied in the directions of bogies, railway car body parts, devices for lateral relative movement between the underframe and the bogies, etc., which can solve the problem that the steering bearing structure and the vibration reduction design cannot be applied to the narrow gauge requirements. , wide track gauge, large carrying capacity of railway vehicles, etc., to achieve the effect of stabilizing the turning resistance torque, improving the anti-diamond stiffness, and increasing the running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in combination with specific embodiments. The specific embodiments are further explanations of the principles of the present invention and do not limit the present invention in any way. The same or similar technologies as the present invention do not exceed the protection scope of the present invention.

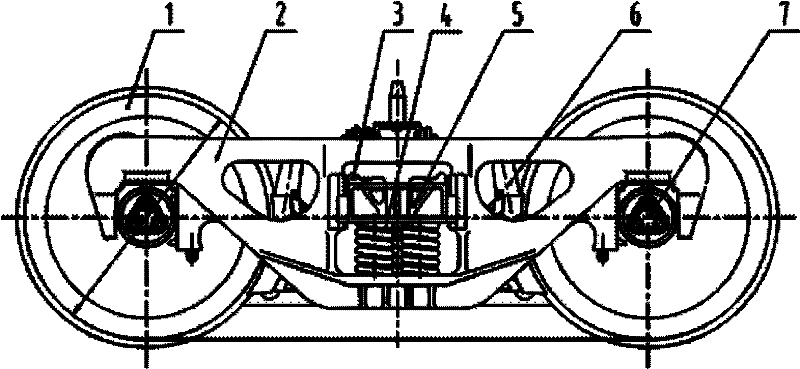

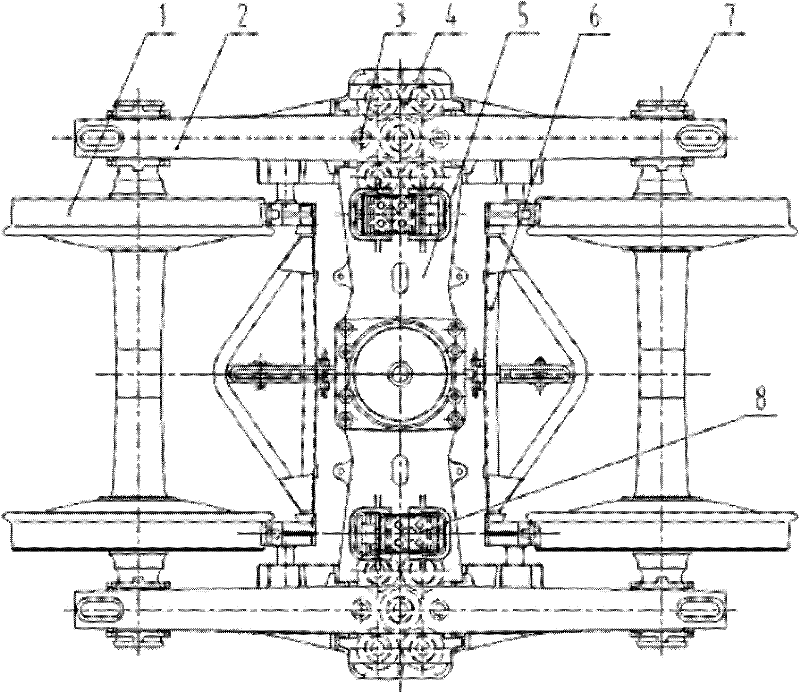

[0026] Combine Figure 1 to Figure 7 .

[0027] Narrow gauge railway vehicle bogie, including wheel set 1, side frame 2, damping device 3, bolster 5 and braking device 6. Wheel set 1 is connected to side frame 2 through rolling bearing device 7 and side frame 2 passes through the center The suspension 4 and the bolster 5 constitute the main structure of the bogie; the double-acting elastic side bearing 8 is placed in the bolster side bearing box, and the bolster side bearing box and the bolster 5 are cast as a whole.

[0028] The double-acting elastic side bearing 8 includes a side bearing device and a roller device; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com