VOCs high-efficiency processing method

A catalytic oxidation and petrochemical technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of large area occupied by biological methods, inappropriate treatment of organic waste gas, high operating costs, etc., and achieve low engineering cost, Significant economic and social benefits, the effect of less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

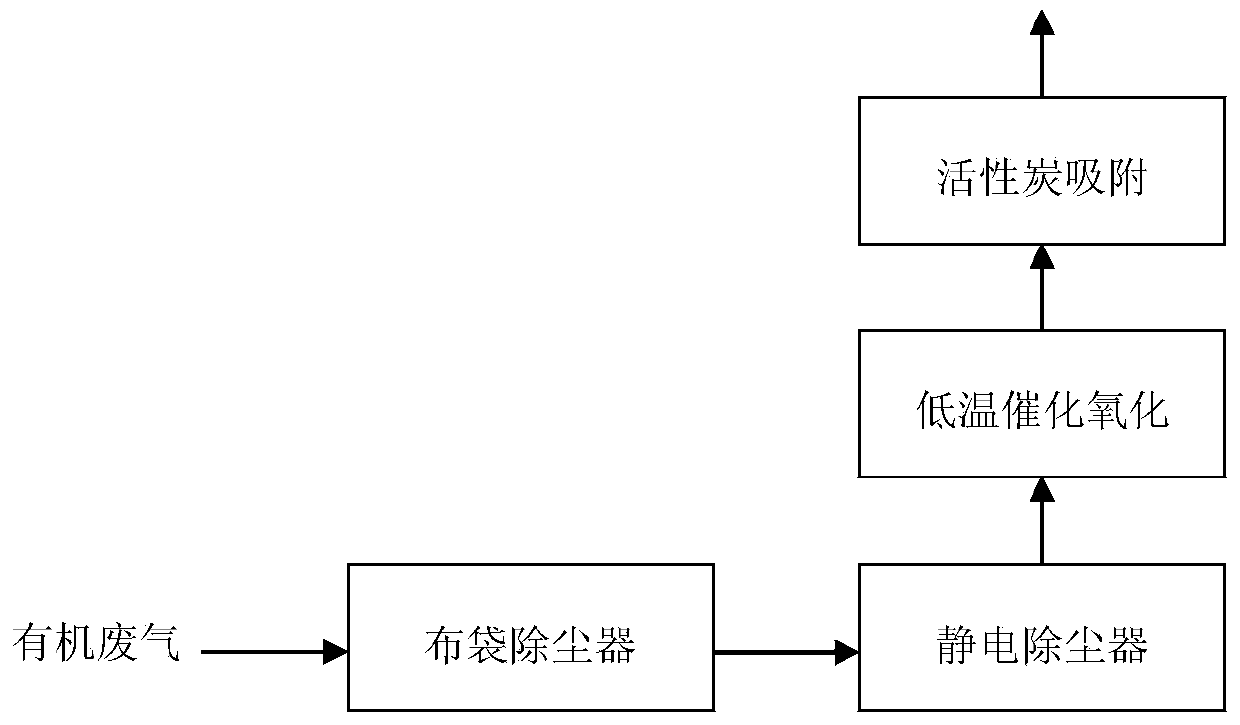

[0048] An efficient treatment method for VOCs, the method uses catalytic oxidation and adsorption processes to treat petrochemical industry organic waste gas, and the method includes the following steps:

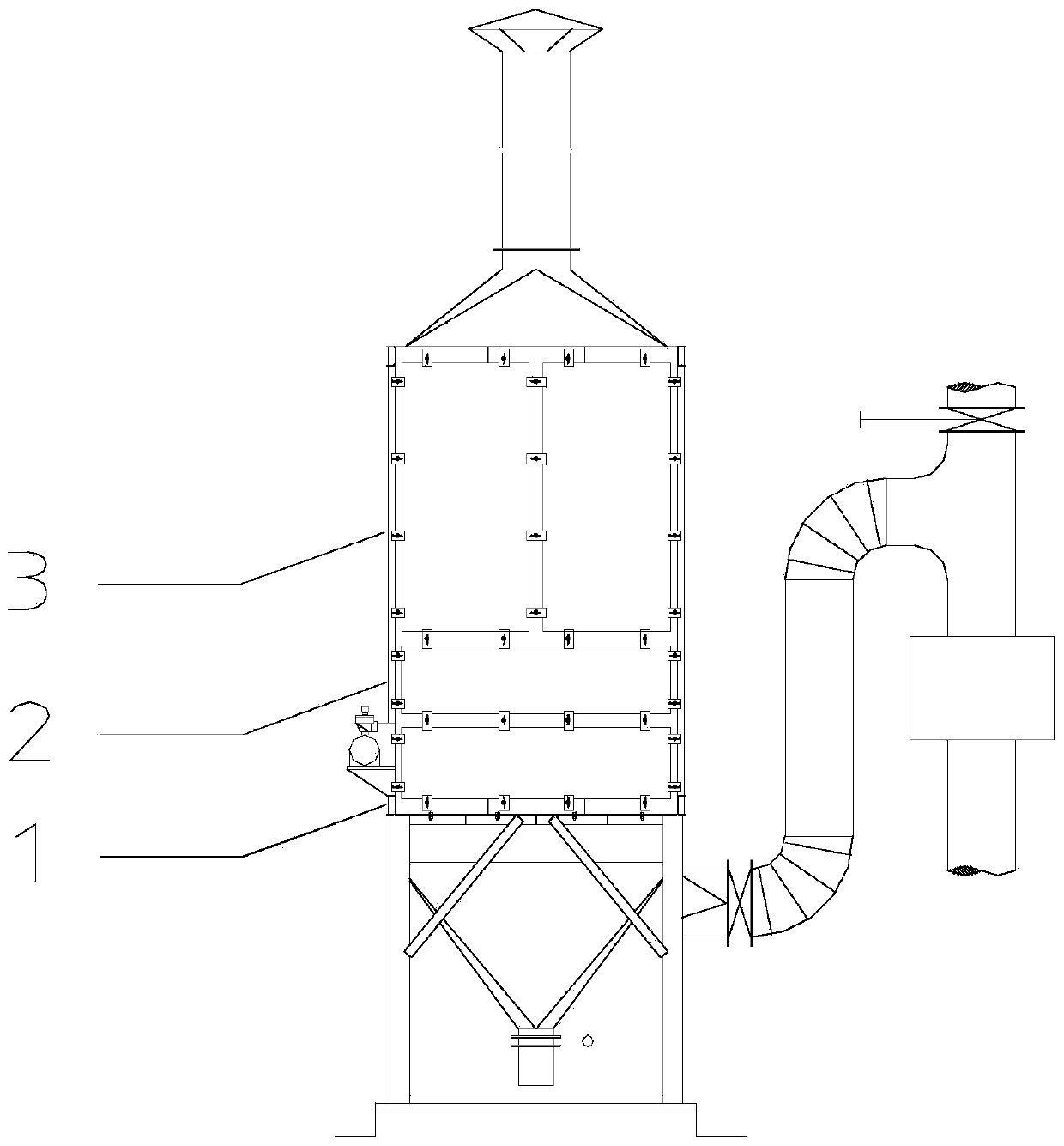

[0049] (1) Use a bag filter to pretreat the petrochemical industrial organic waste gas, recover some materials, and then introduce an electrostatic precipitator for electrostatic dust removal to further recover materials; the bag filter is installed at the drying tail gas of petrochemical products;

[0050] (2) Catalytic oxidation treatment is performed on the exhaust gas treated in step (1); the catalyst used in the catalytic oxidation treatment is a Pt catalyst; a temperature control system is set near the surface of the Pt catalyst, and an ozone generator is set above;

[0051] (3) The waste gas treated in step (2) is subjected to activated carbon adsorption treatment and then discharged.

Embodiment 2

[0053] An efficient treatment method for VOCs, the method uses catalytic oxidation and adsorption processes to treat petrochemical industry organic waste gas, and the method includes the following steps:

[0054] (1) Use a bag filter to pretreat the petrochemical industrial organic waste gas, recover some materials, and then introduce an electrostatic precipitator for electrostatic dust removal to further recover materials; the bag filter is installed at the drying tail gas of petrochemical products;

[0055] (2) Perform catalytic oxidation treatment on the waste gas treated in step (1); the catalyst used in the catalytic oxidation treatment is a manganese oxide catalyst; a temperature control system is installed near the surface of the manganese oxide catalyst, and an ultraviolet ozone generator is arranged above;

[0056] (3) The exhaust gas treated in step (2) is subjected to activated carbon adsorption treatment and then discharged. The activated carbon is in the form of fi...

Embodiment 3

[0058] An efficient treatment method for VOCs, the method uses catalytic oxidation and adsorption processes to treat petrochemical industry organic waste gas, and the method includes the following steps:

[0059] (1) Use a bag filter to pretreat the petrochemical industrial organic waste gas, recover some materials, and then introduce an electrostatic precipitator for electrostatic dust removal to further recover materials; the bag filter is installed at the drying tail gas of petrochemical products;

[0060] (2) Perform catalytic oxidation treatment on the waste gas treated in step (1); the catalyst used in the catalytic oxidation treatment is a manganese oxide catalyst; a temperature control system is installed near the surface of the manganese oxide catalyst, and an ultraviolet ozone generator is arranged above;

[0061] (3) The exhaust gas treated in step (2) is subjected to activated carbon adsorption treatment and then discharged. The activated carbon is in granular form,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com