Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1560 results about "Ethylene acrylic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene/acrylic acid copolymer - Green circle - The chemical has been verified to be of low concern based on experimental and modeled data. from EPA Safer Choice Literature

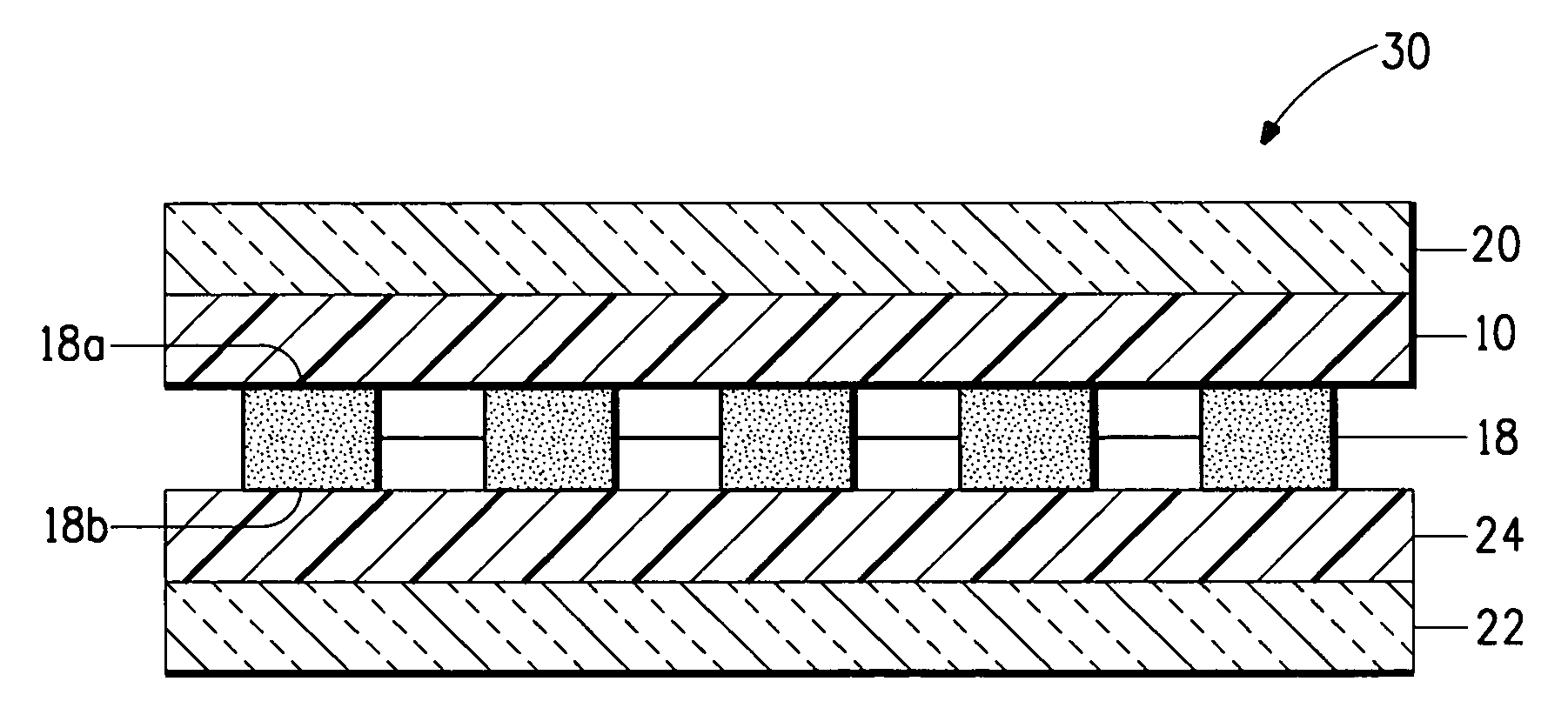

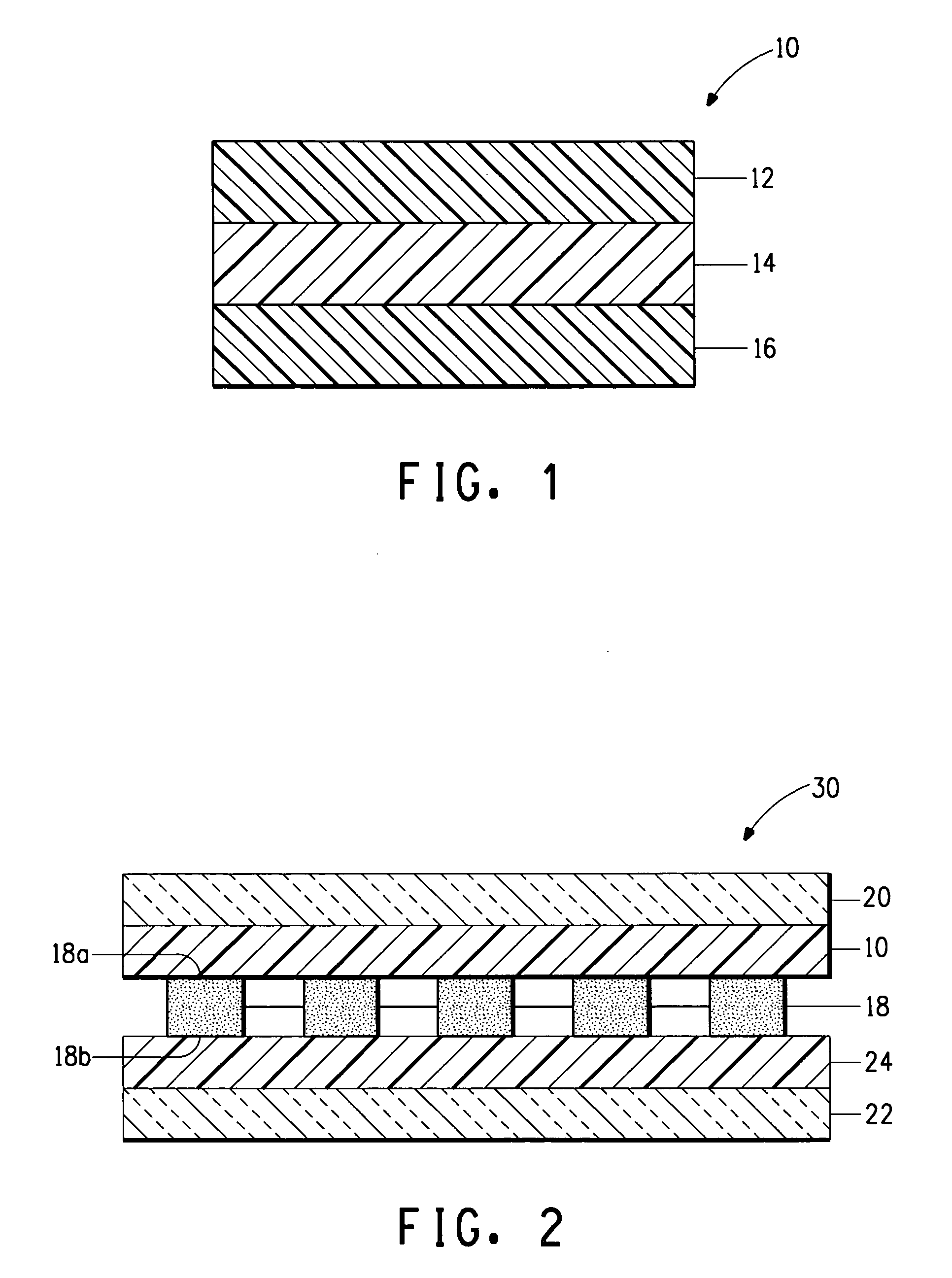

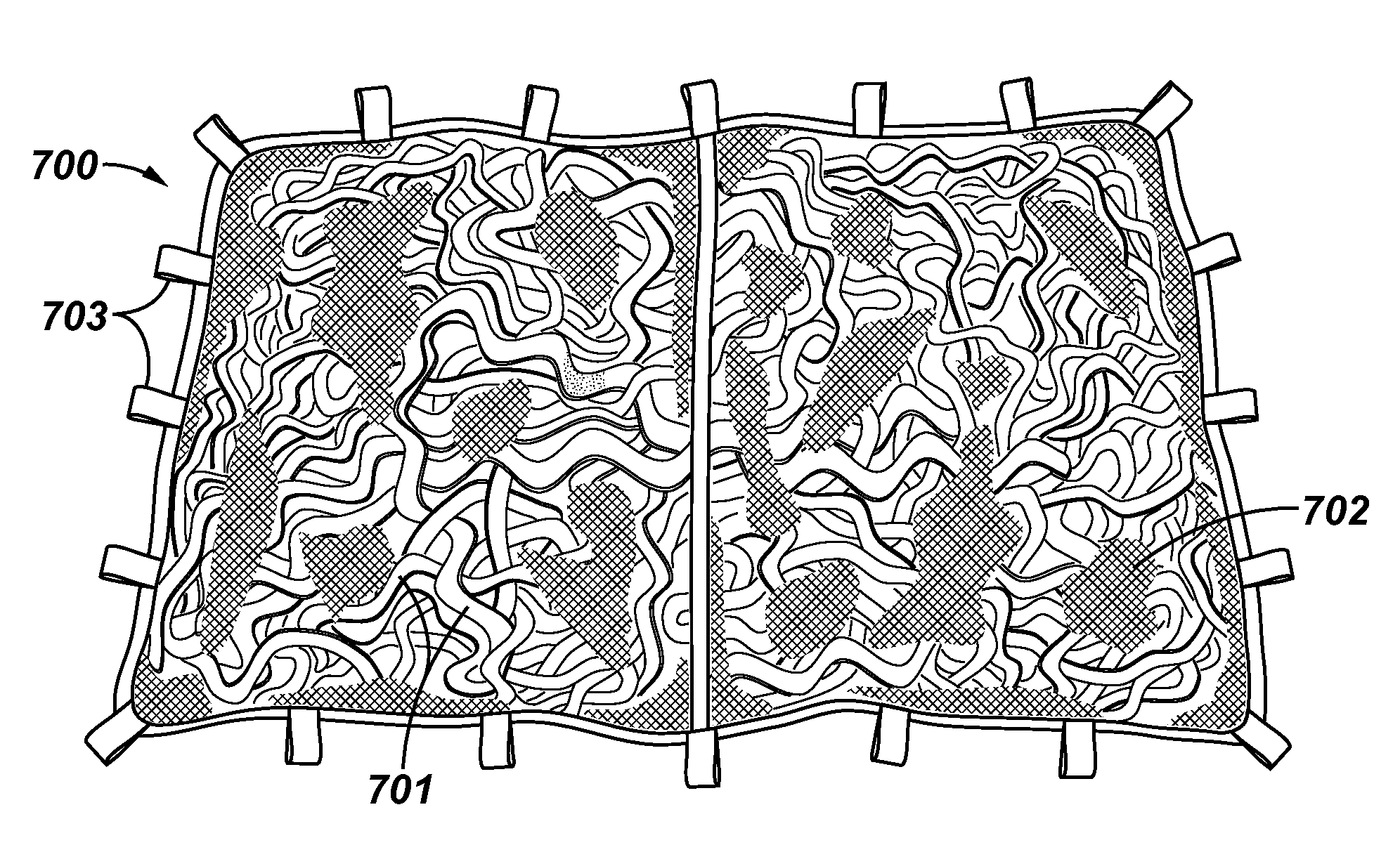

Embossed tissue products

InactiveUS20070137813A1Preserve strengthHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

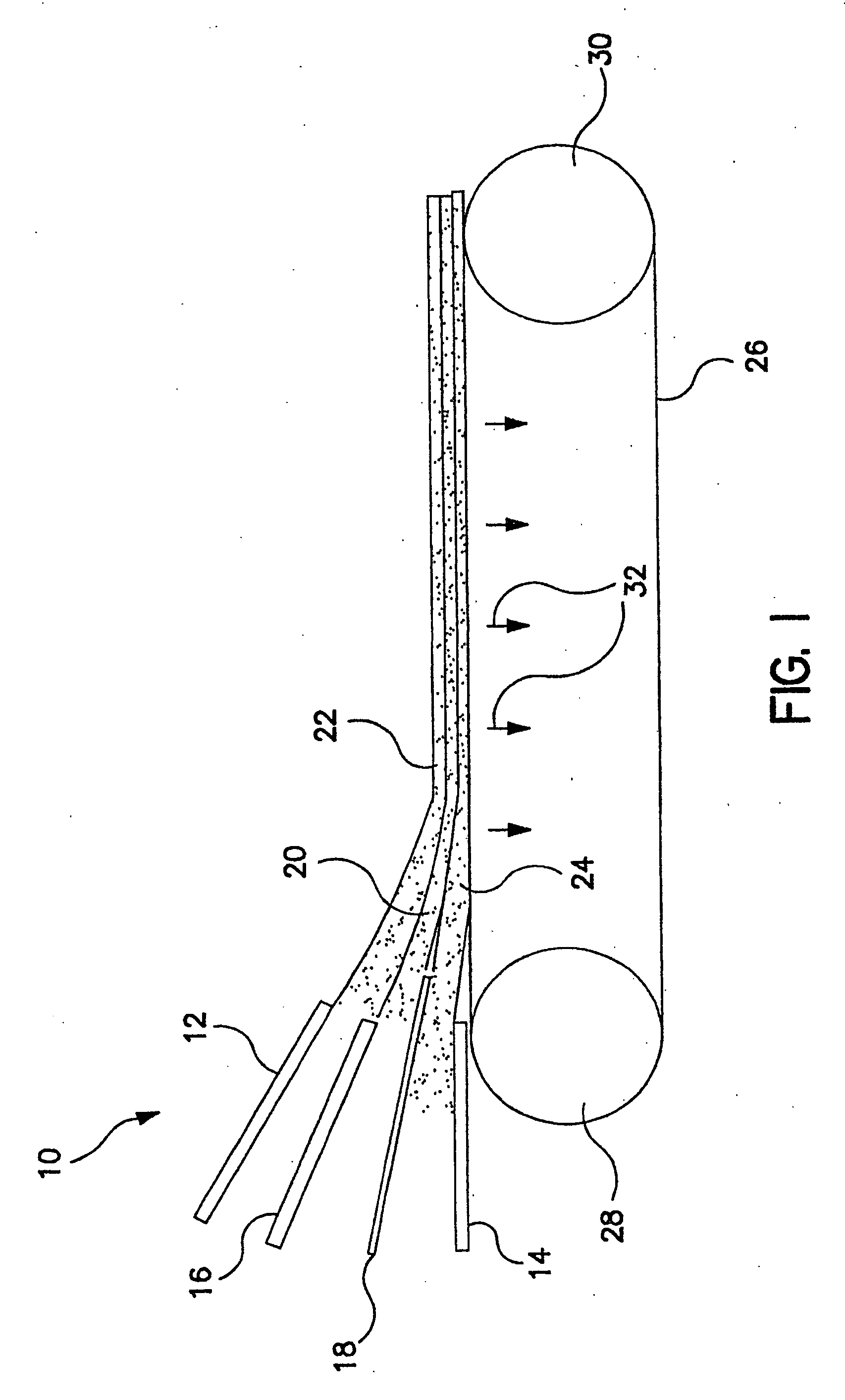

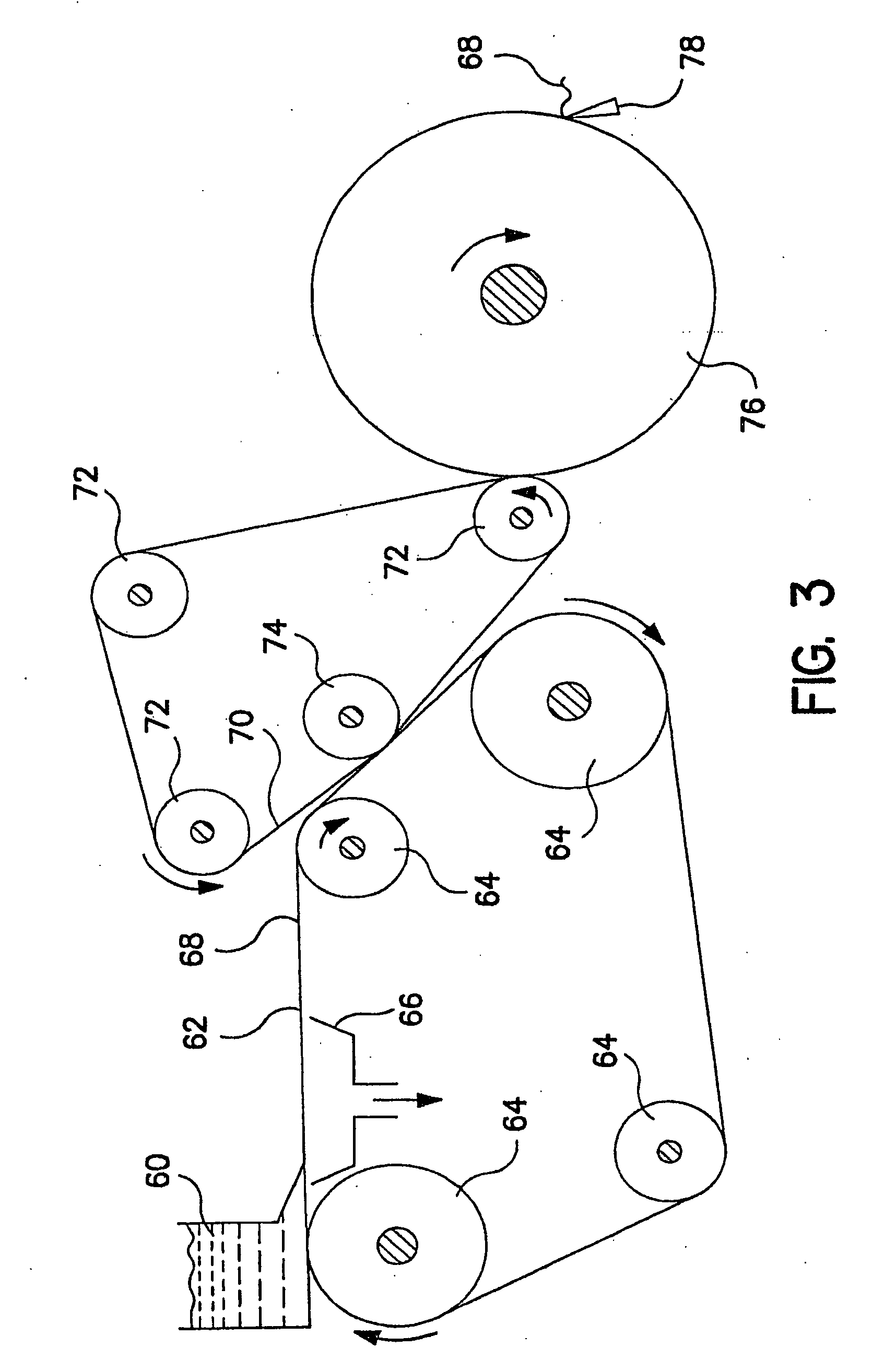

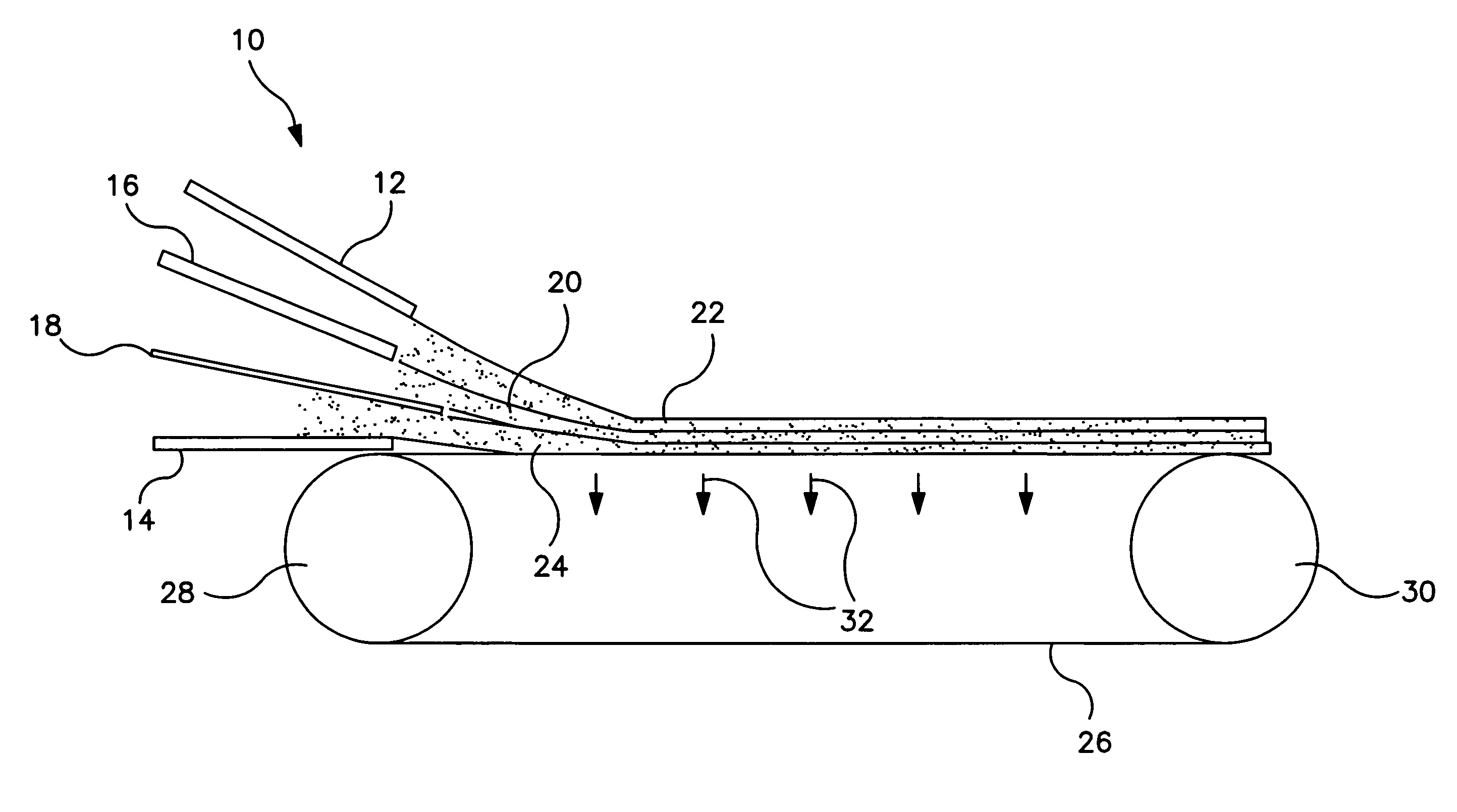

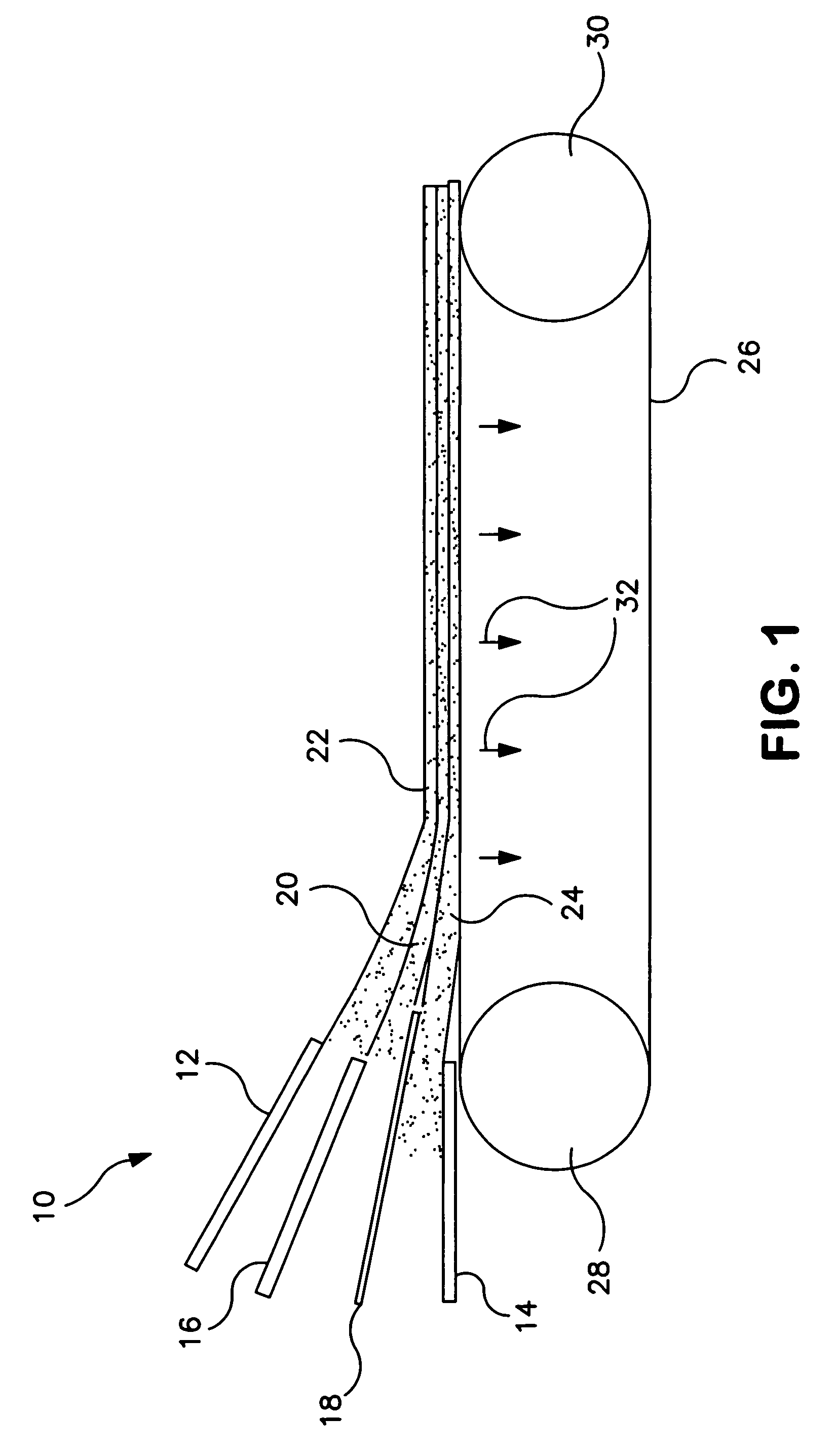

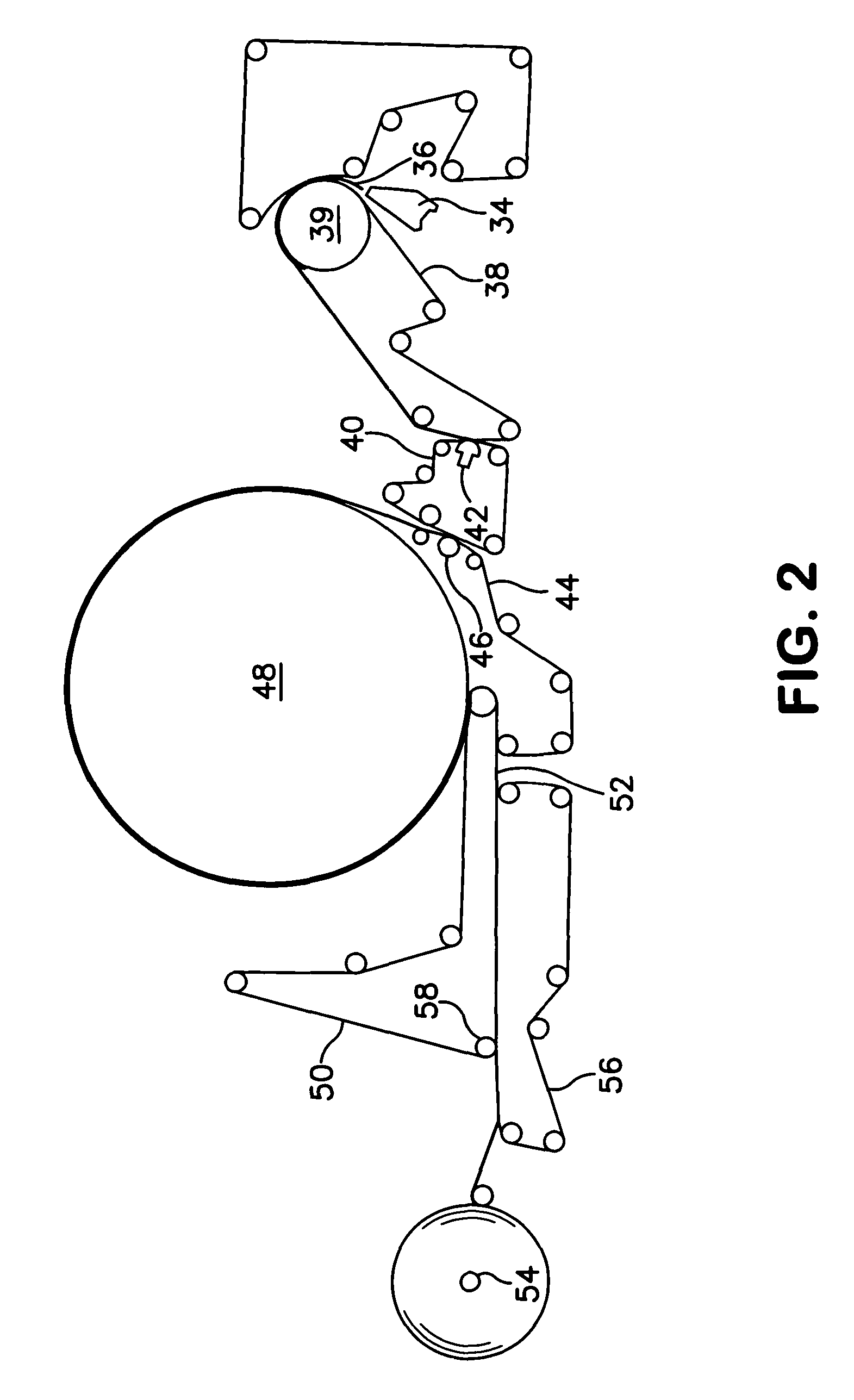

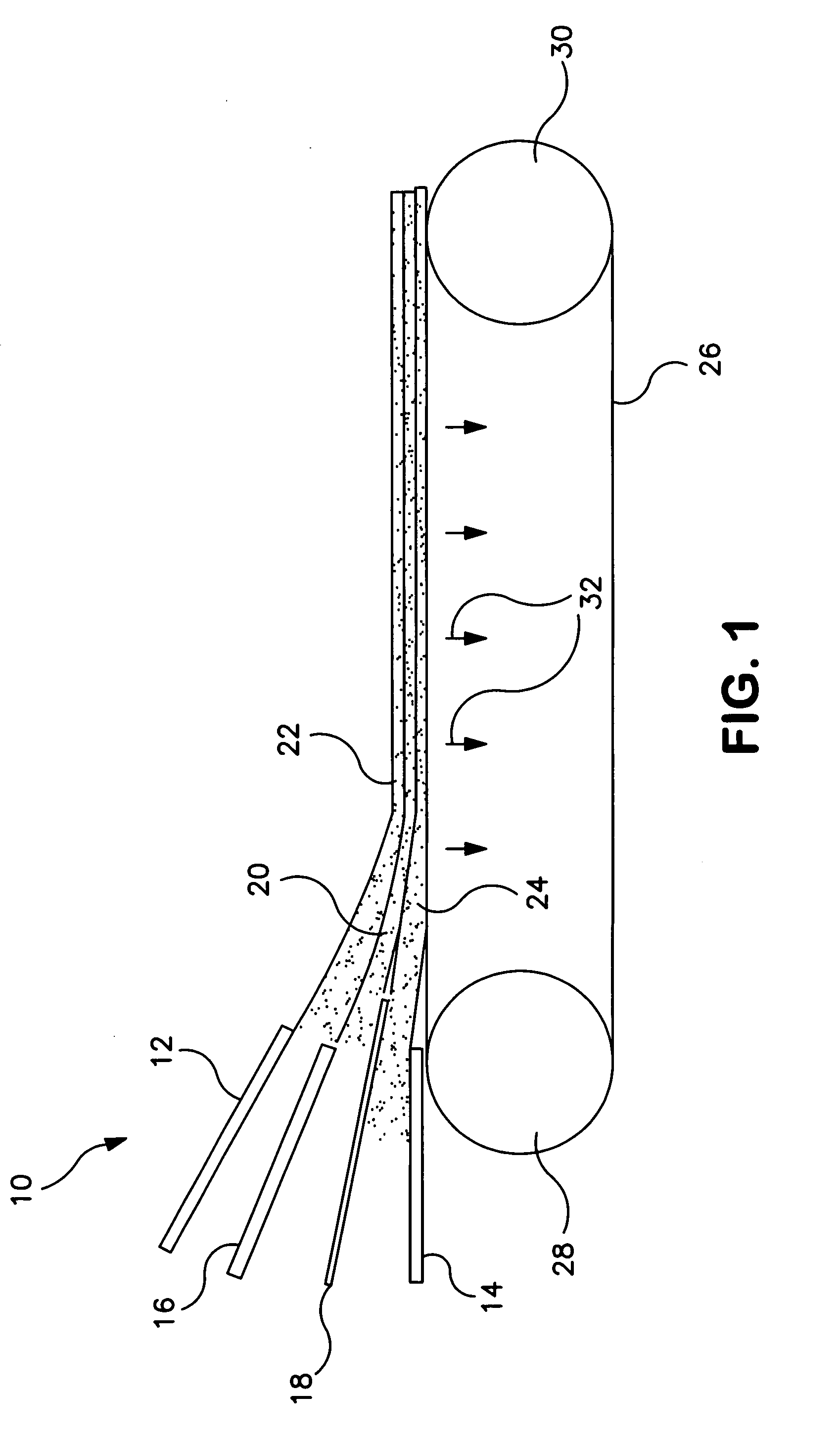

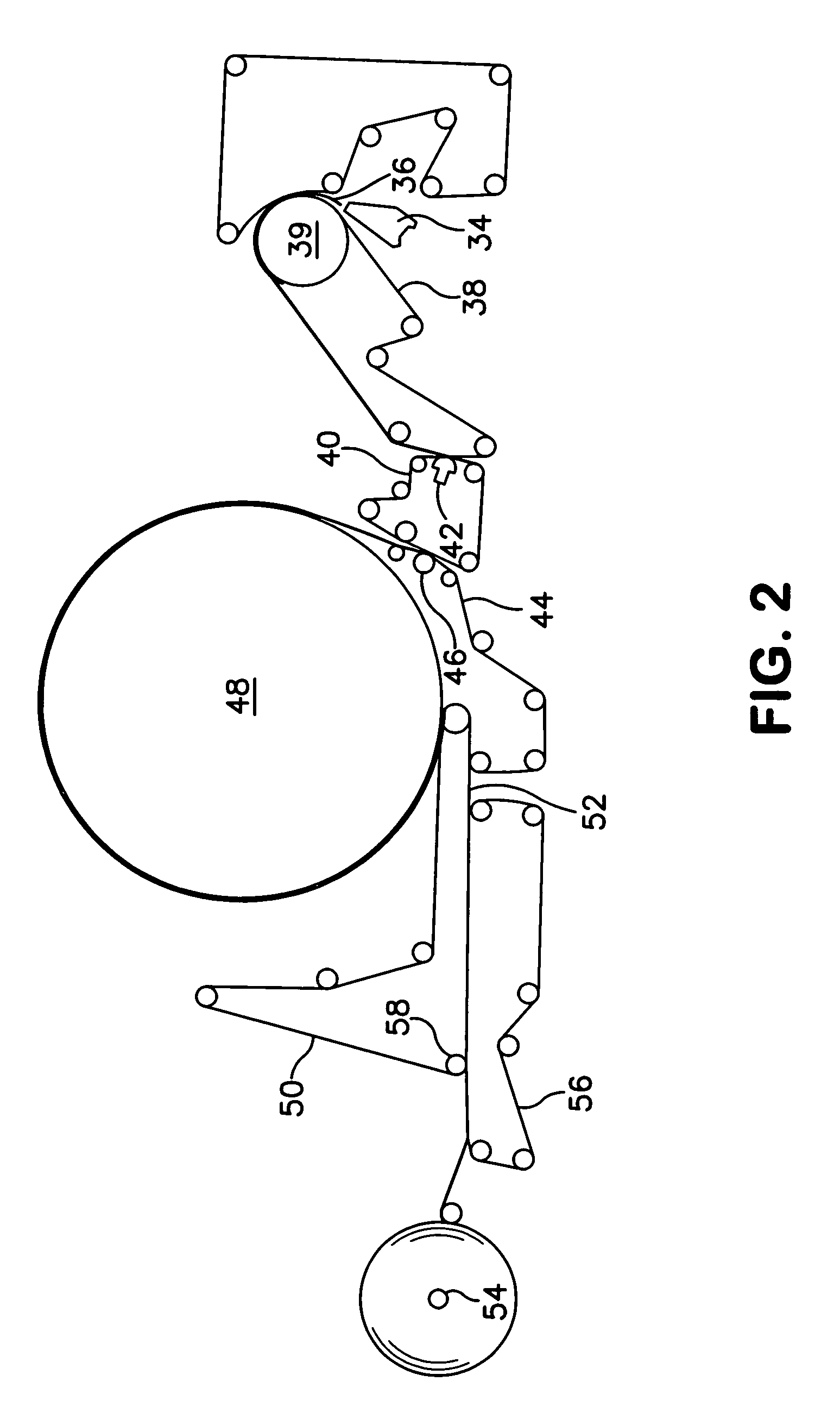

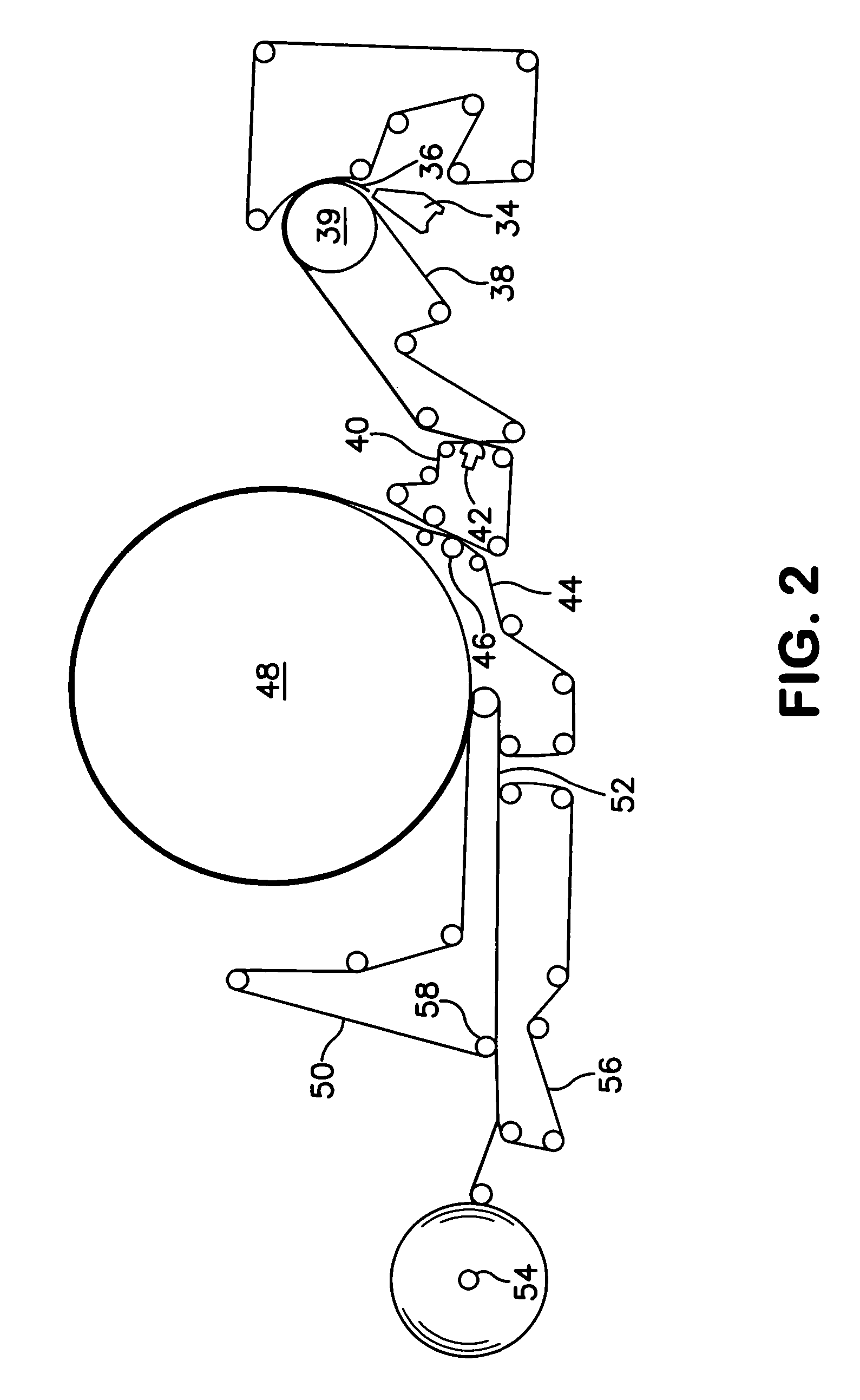

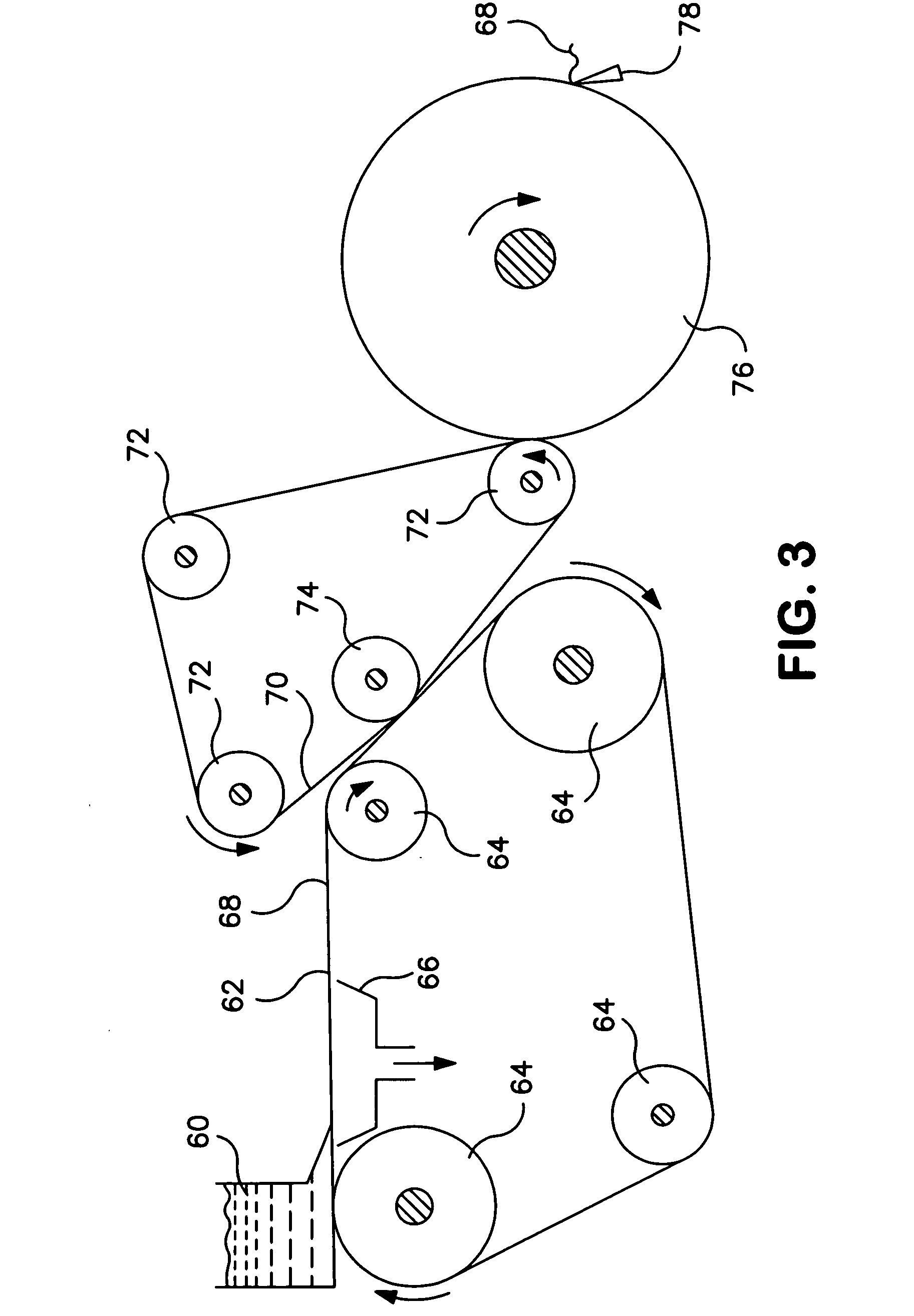

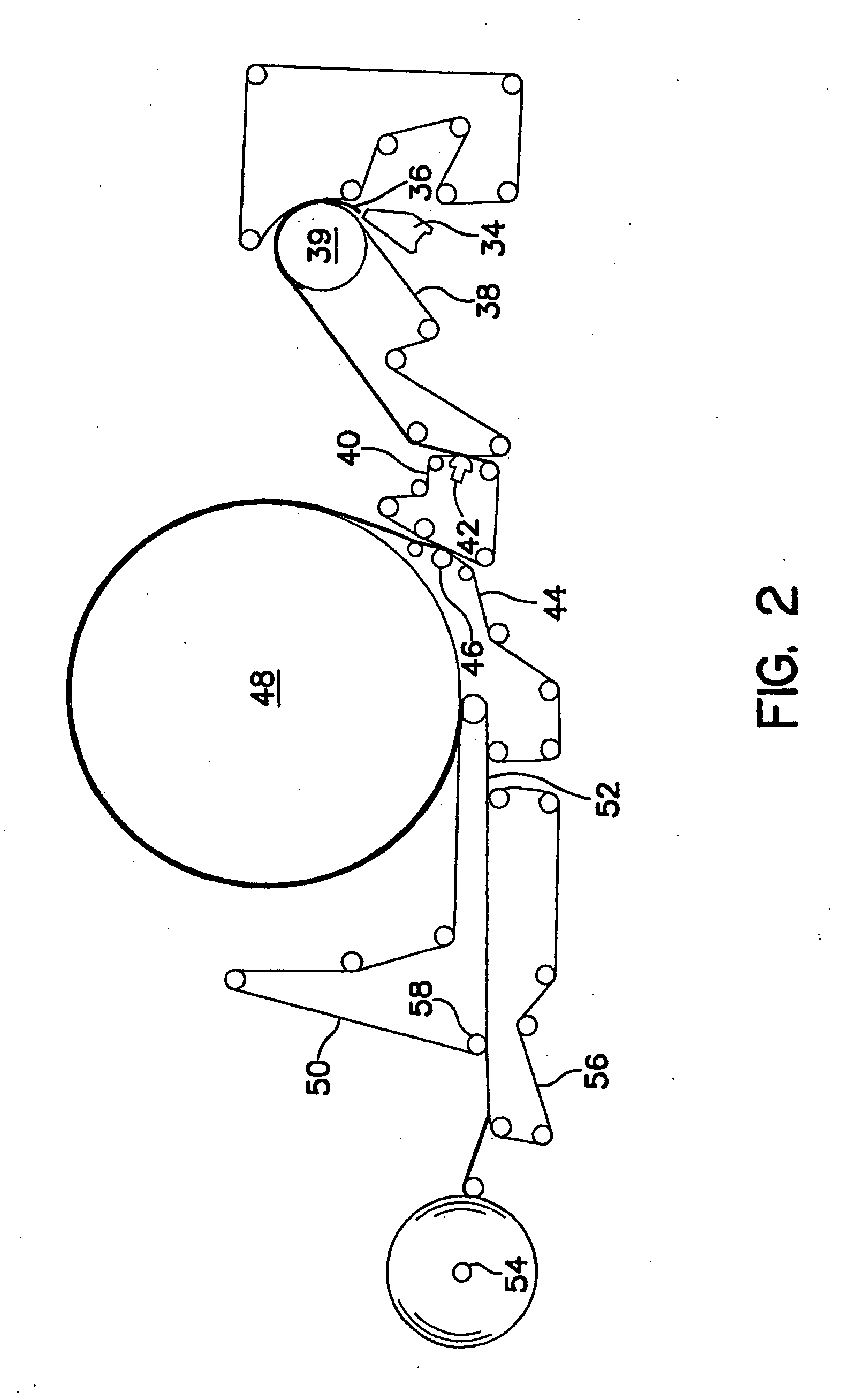

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. After the additive composition is applied to the web or otherwise incorporated into the tissue web, the tissue web is embossed. During embossing, the additive composition forms well defined embossments in the web that are water resistant. In one embodiment, the additive composition may also be used to bond multiple tissue webs together to form a multiple ply product during the embossing operation.

Owner:KIMBERLY-CLARK WORLDWIDE INC

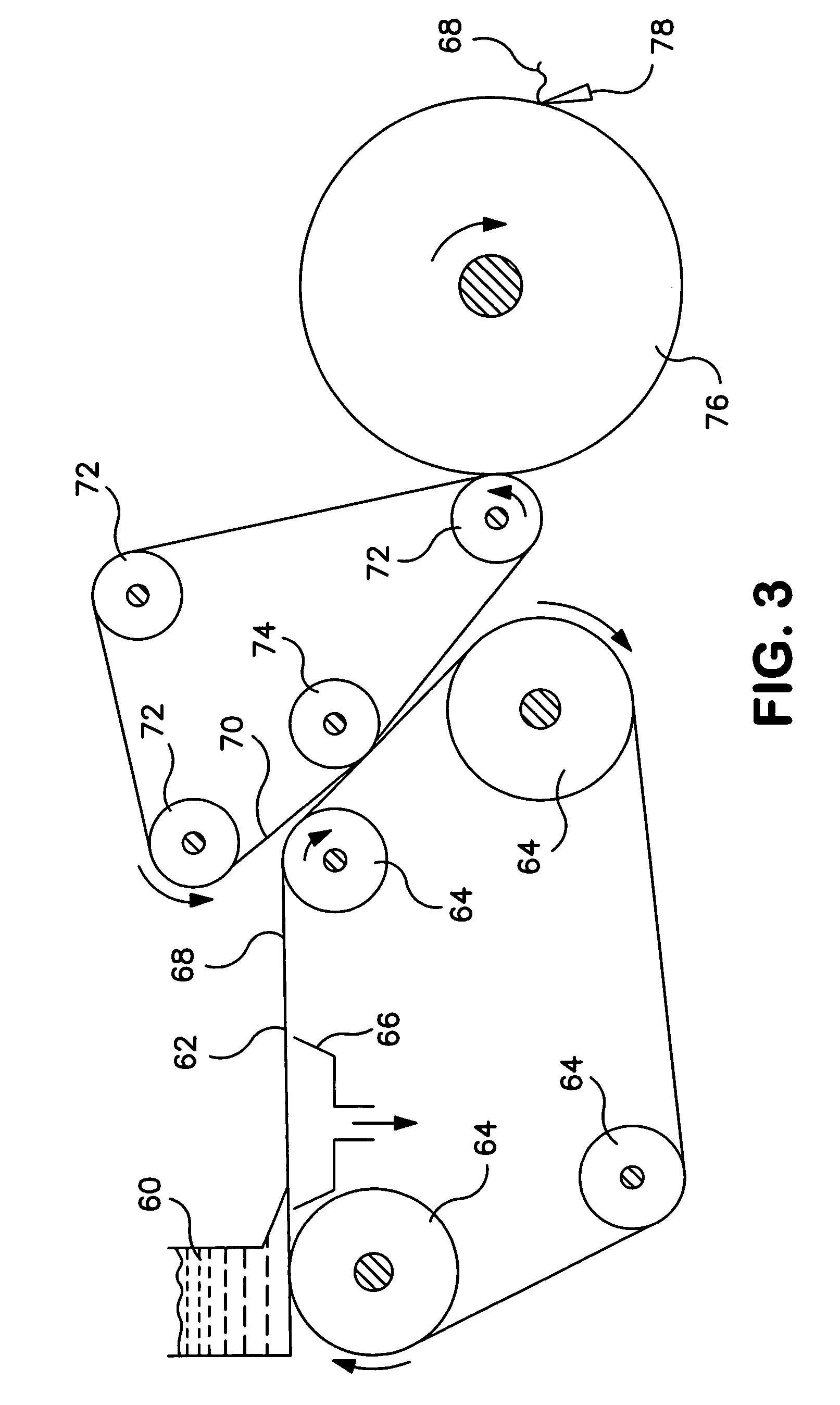

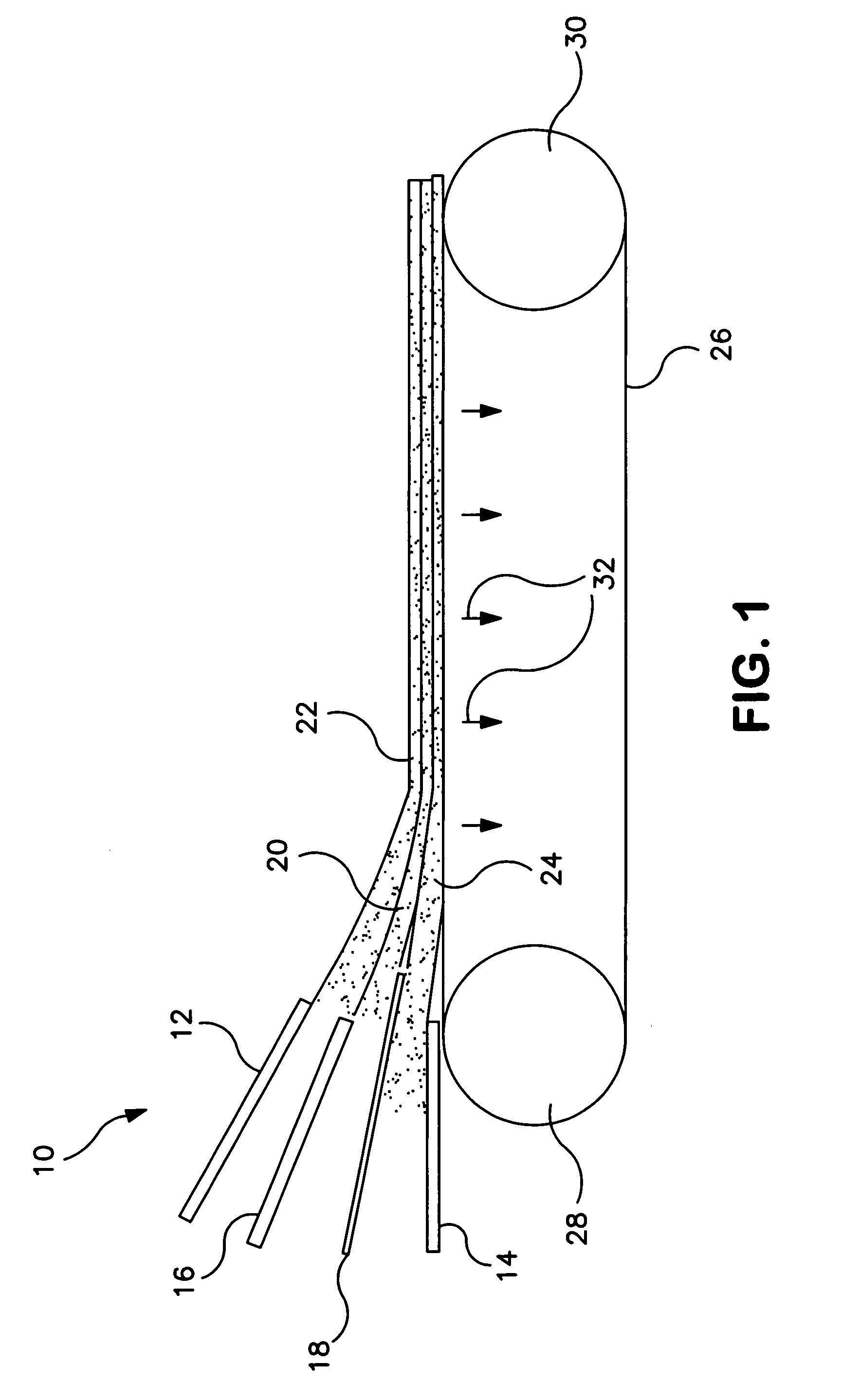

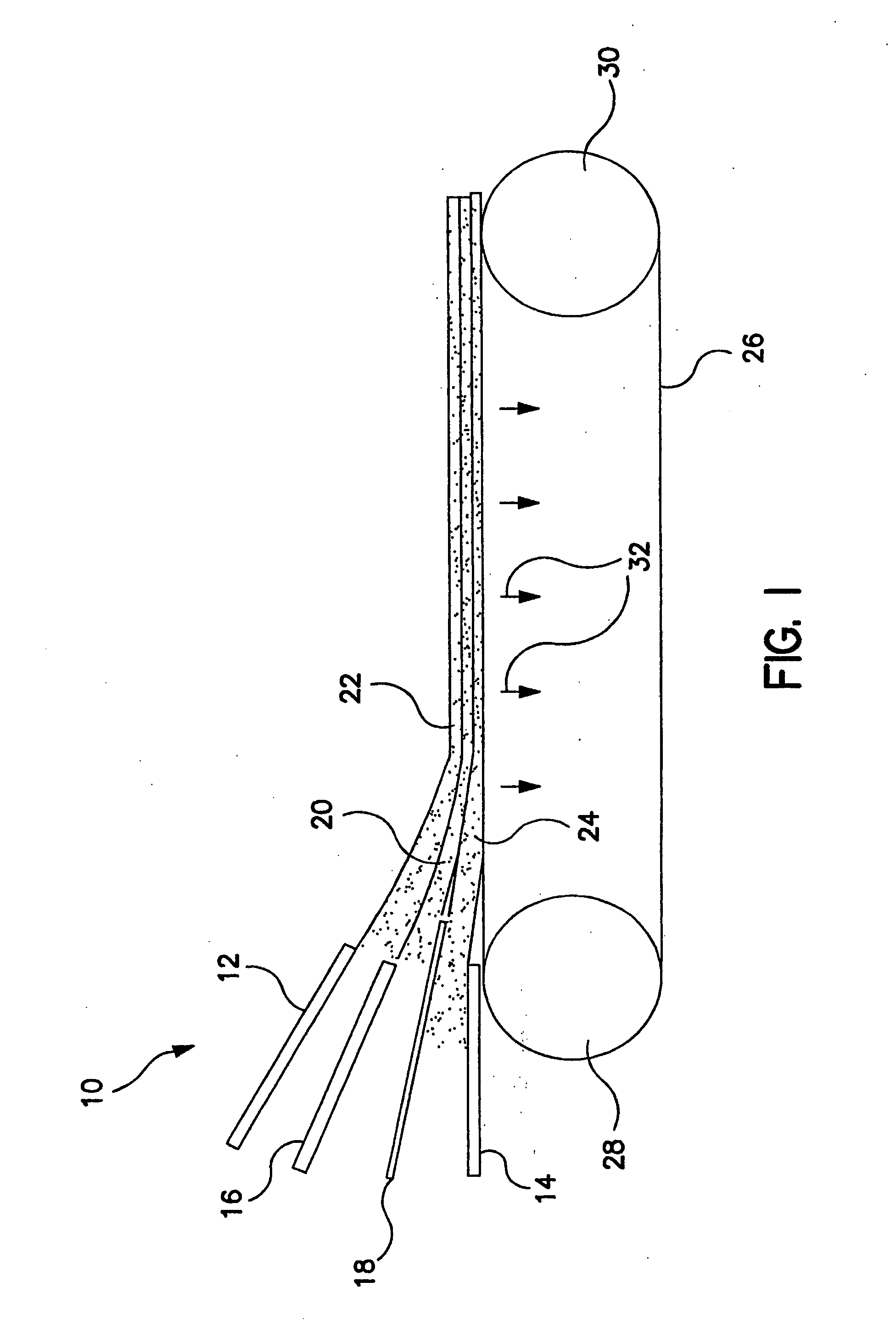

Creping process and products made therefrom

ActiveUS7883604B2Reduced strengthHigh strengthNatural cellulose pulp/paperMechanical working/deformationFiberPolymer science

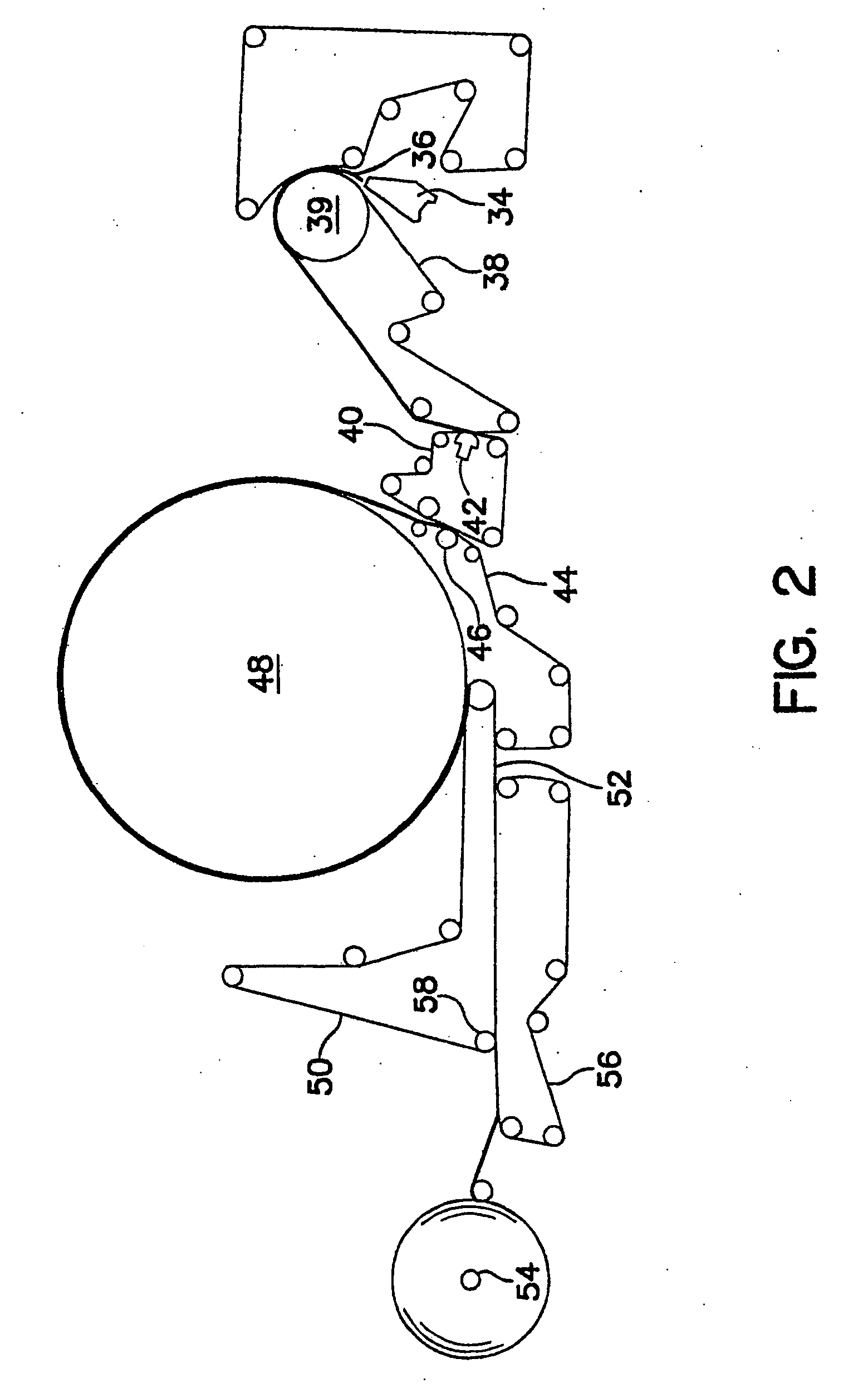

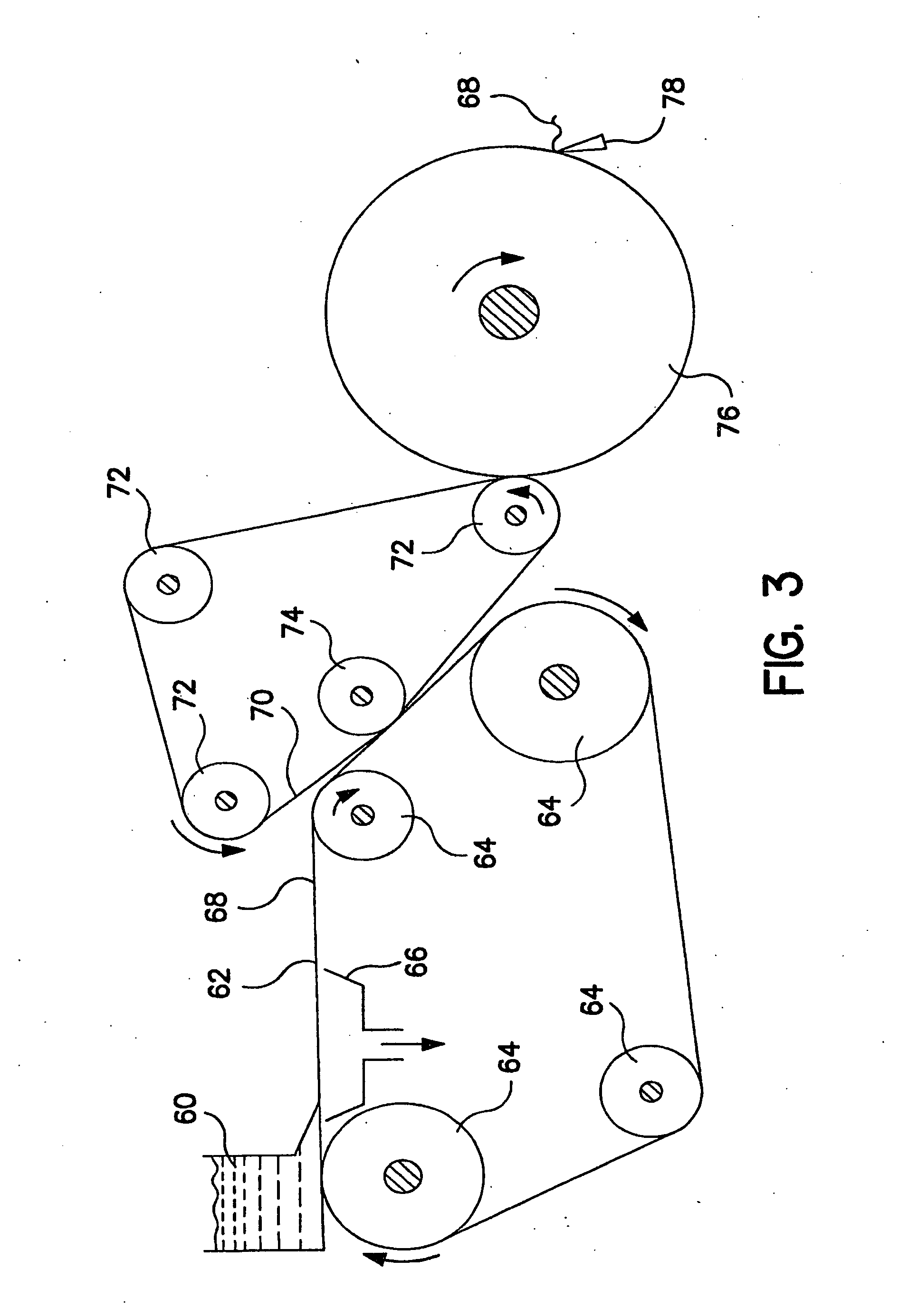

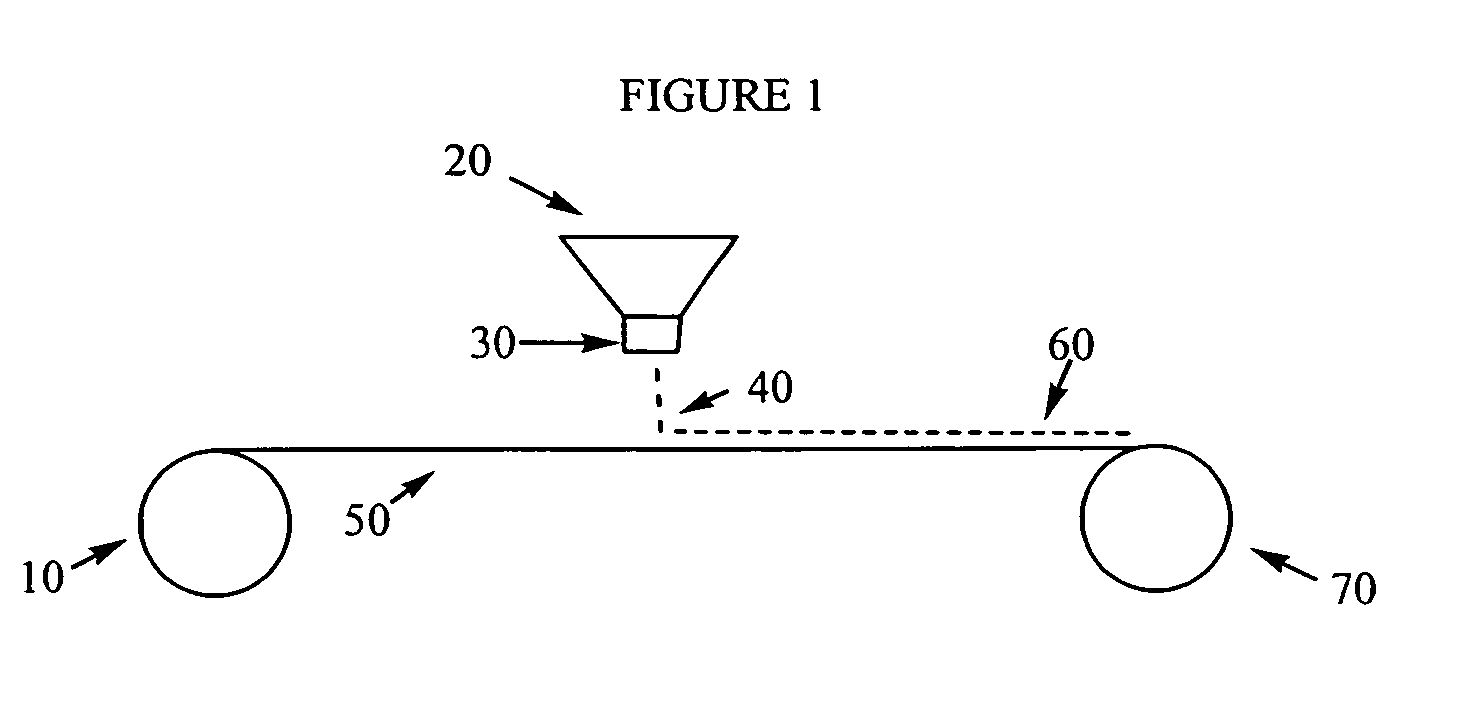

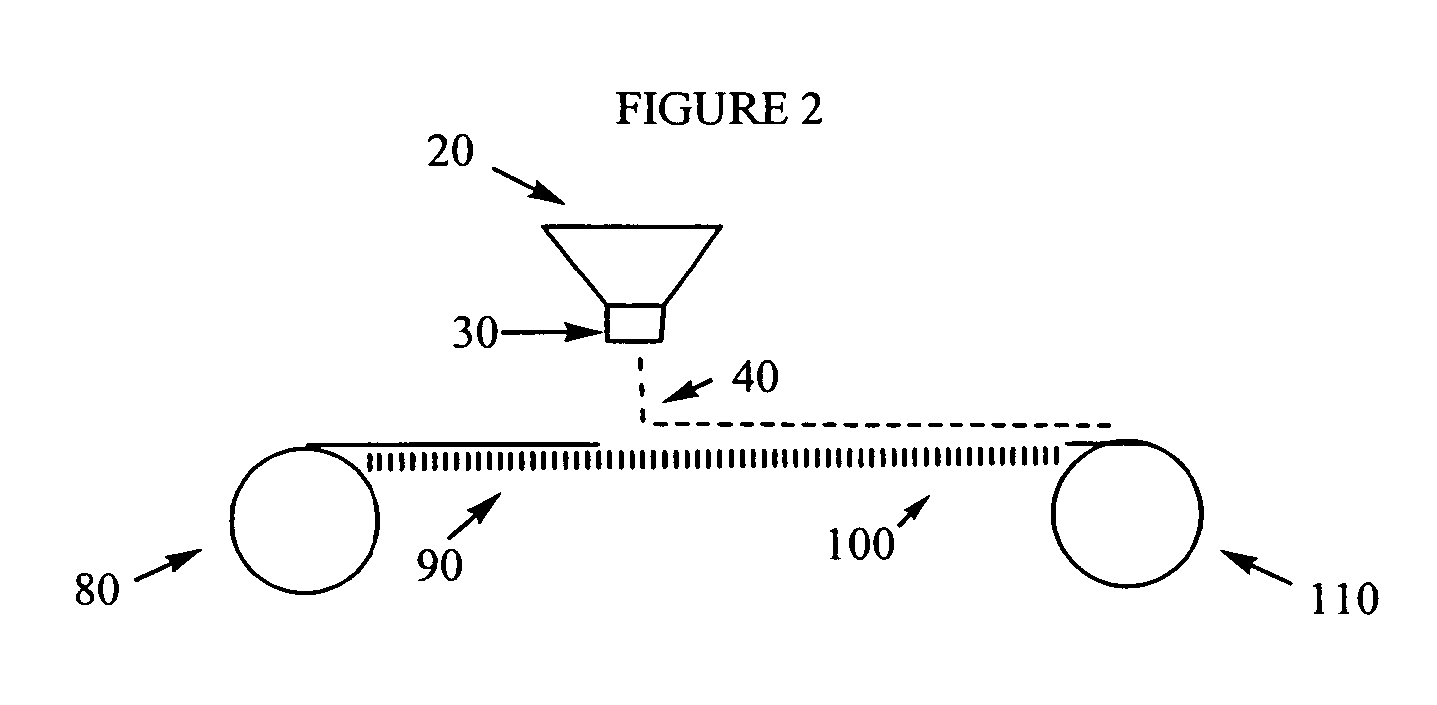

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an alpha-olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The alpha-olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Treated tissue products having increased strength

InactiveUS20070137808A1Reduced strengthHigh strengthBiocideNatural cellulose pulp/paperFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Low modulus solar cell encapsulant sheets with enhanced stability and adhesion

The present invention provides a thermoplastic film or sheet comprising two surface layers made of acid copolymers, or ionomers, or combinations thereof and at least one inner layer made of ethylene acrylate ester copolymers, a solar cell module comprising at least one encapsulant layer derived therefrom, and a process of manufacturing the solar cell module.

Owner:DOW GLOBAL TECH LLC

Creping process and products made therefrom

ActiveUS20070137810A1High strengthImprove propertiesNatural cellulose pulp/paperMechanical working/deformationFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an alpha-olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The alpha-olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

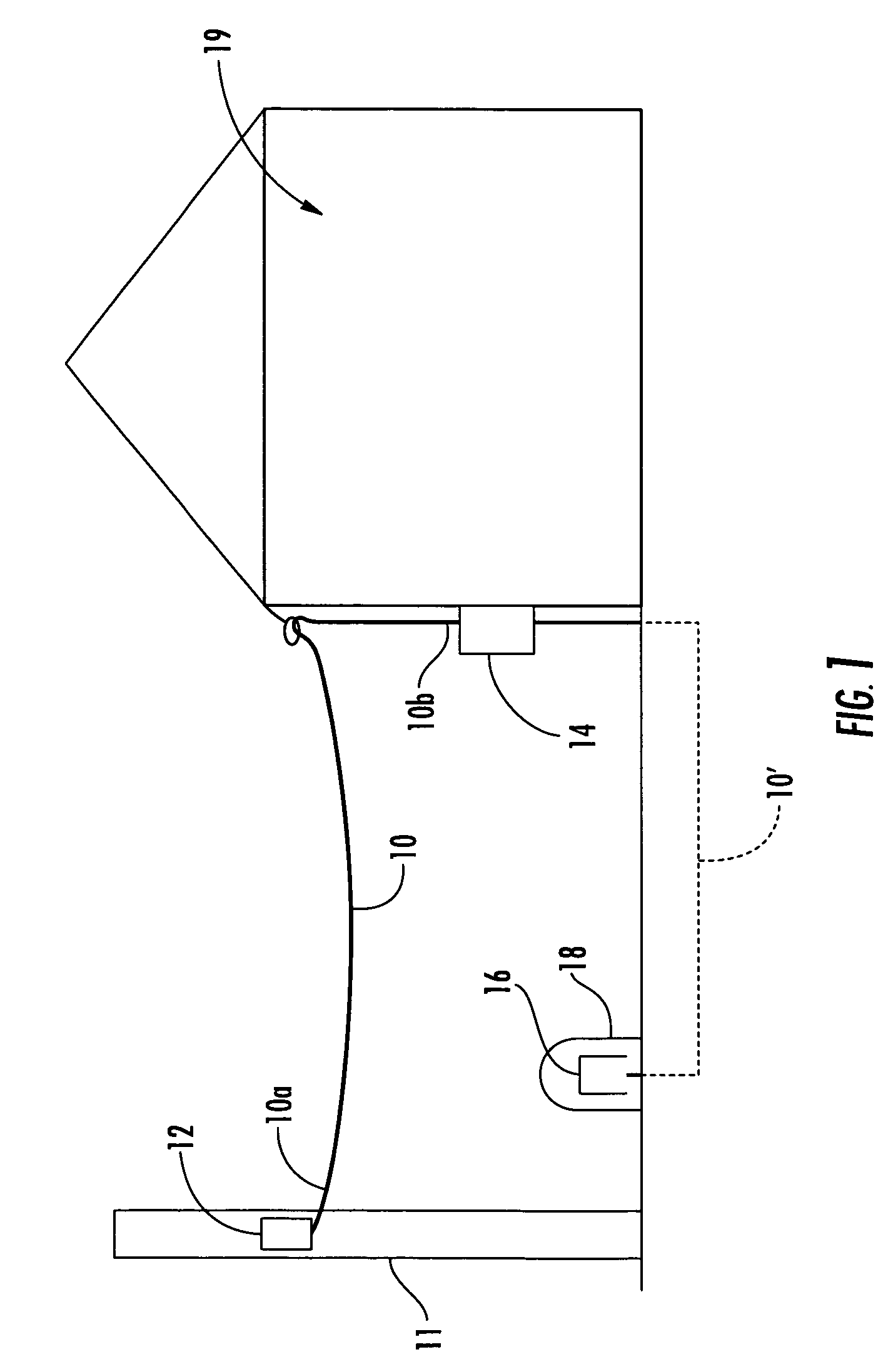

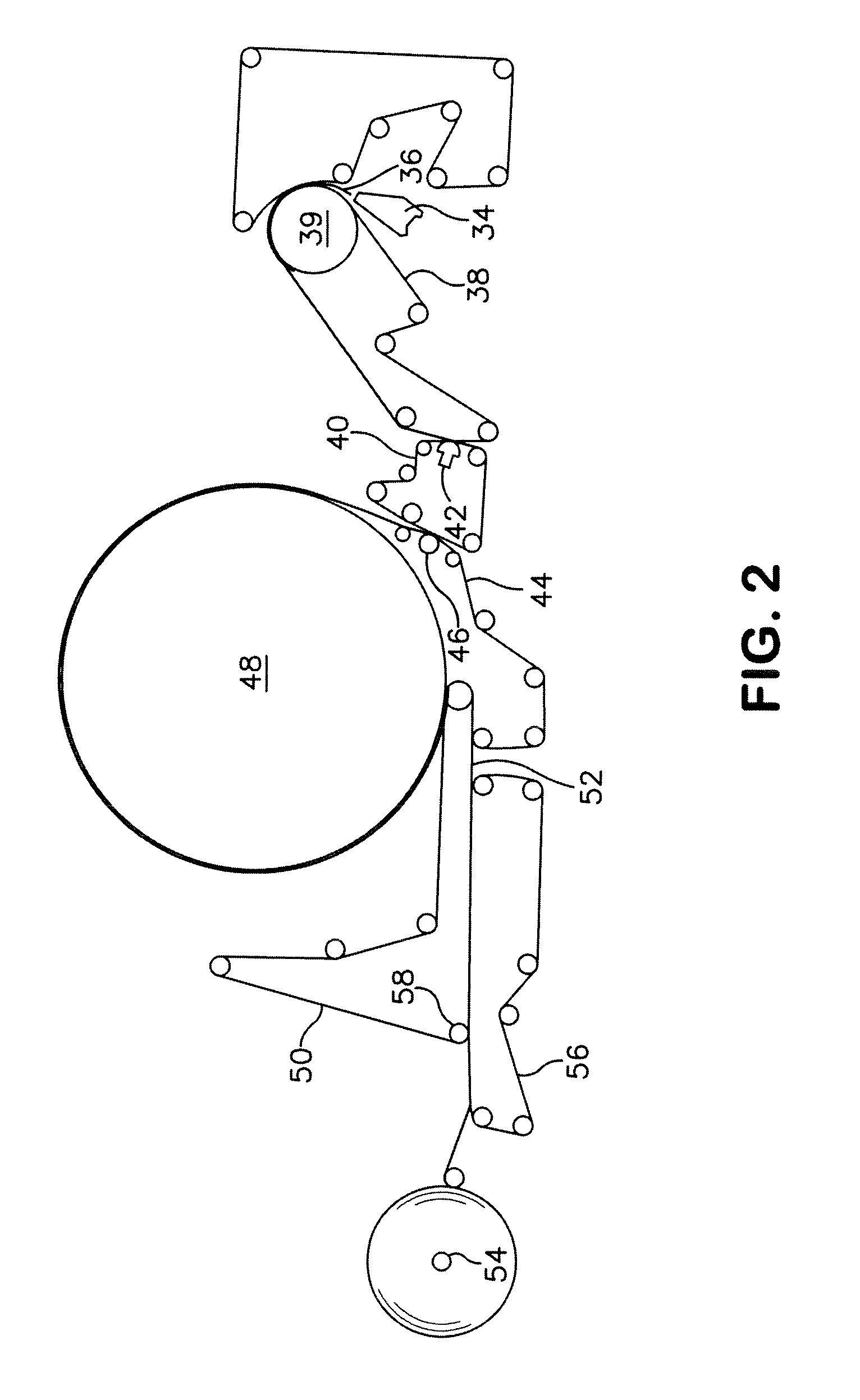

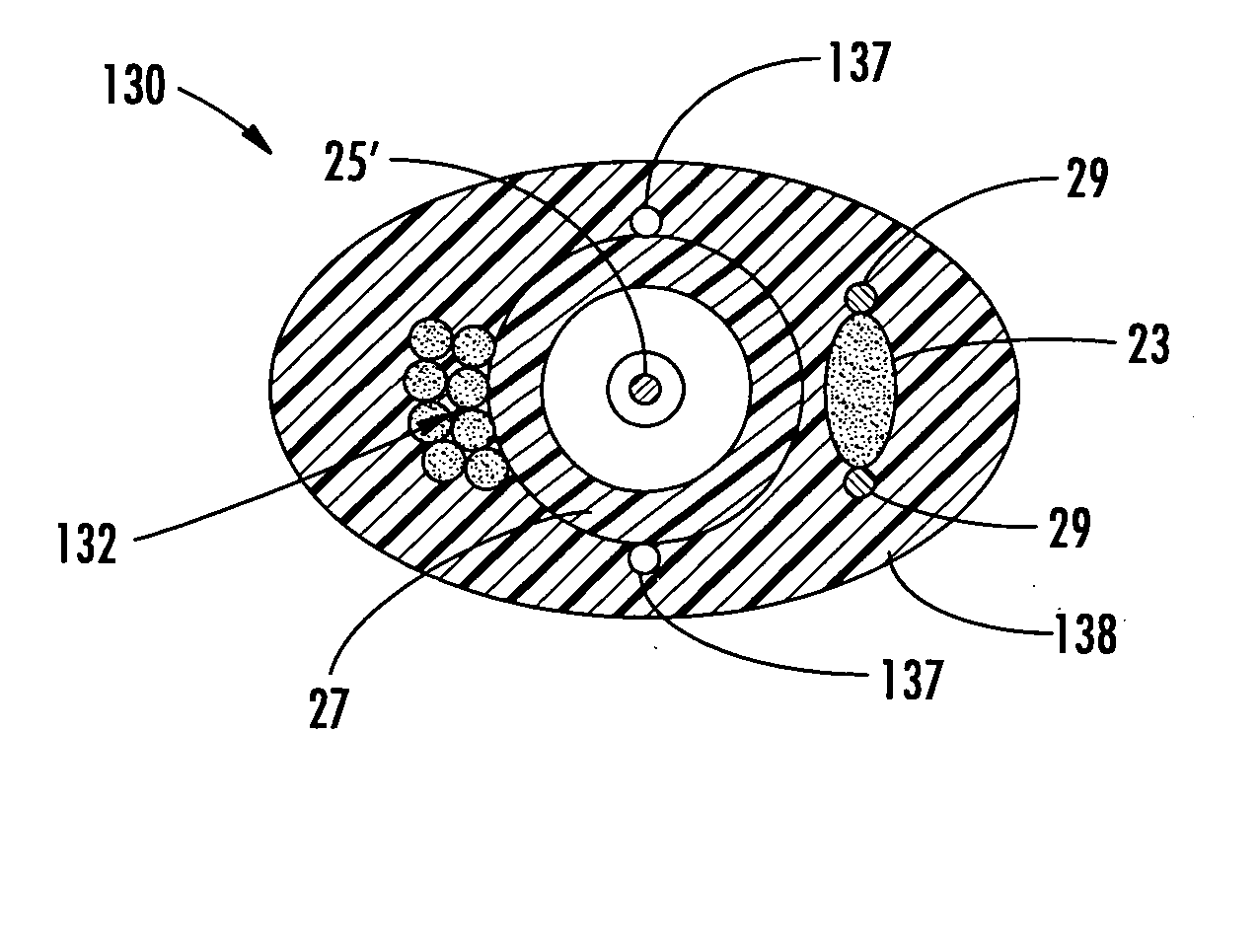

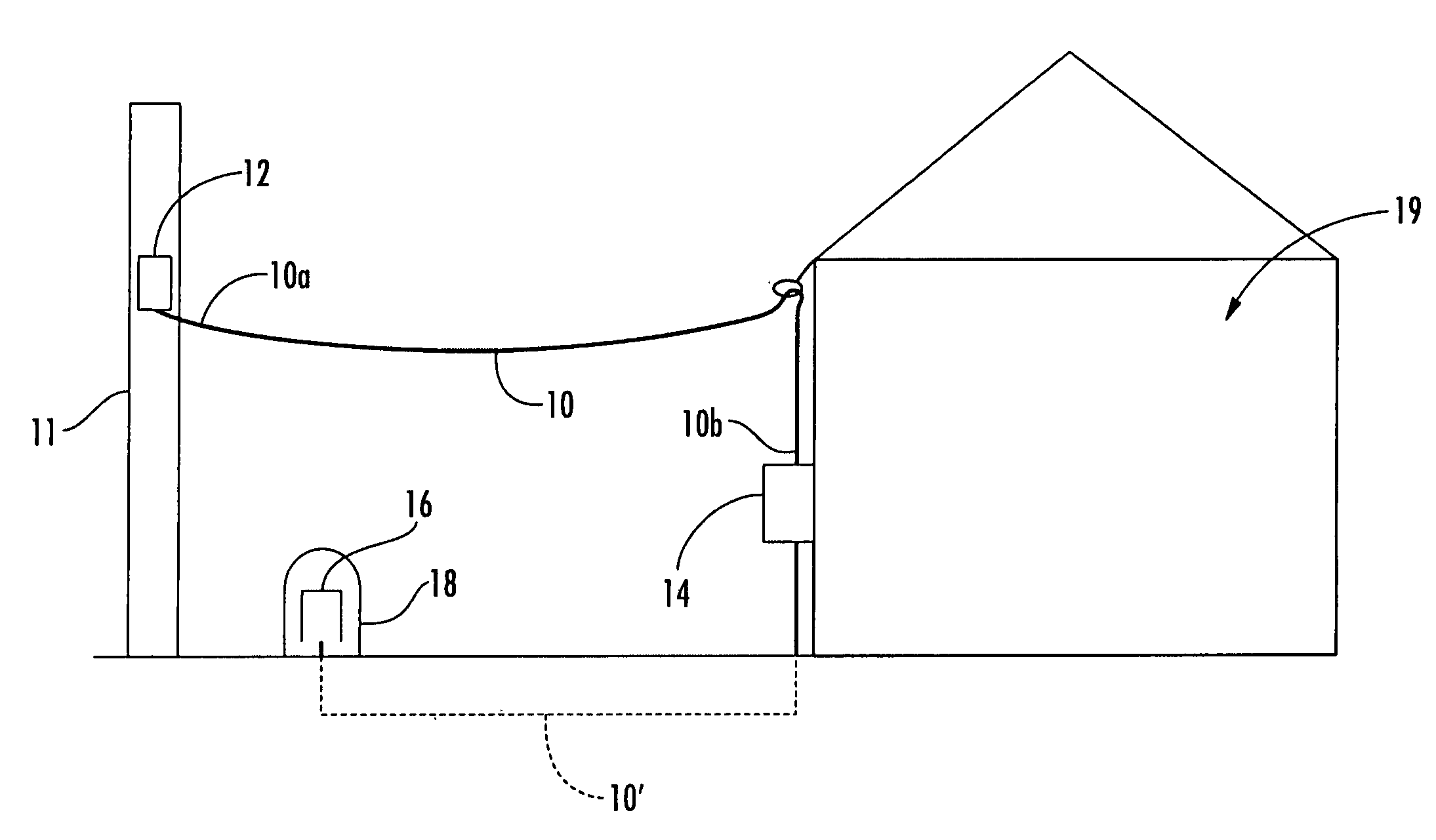

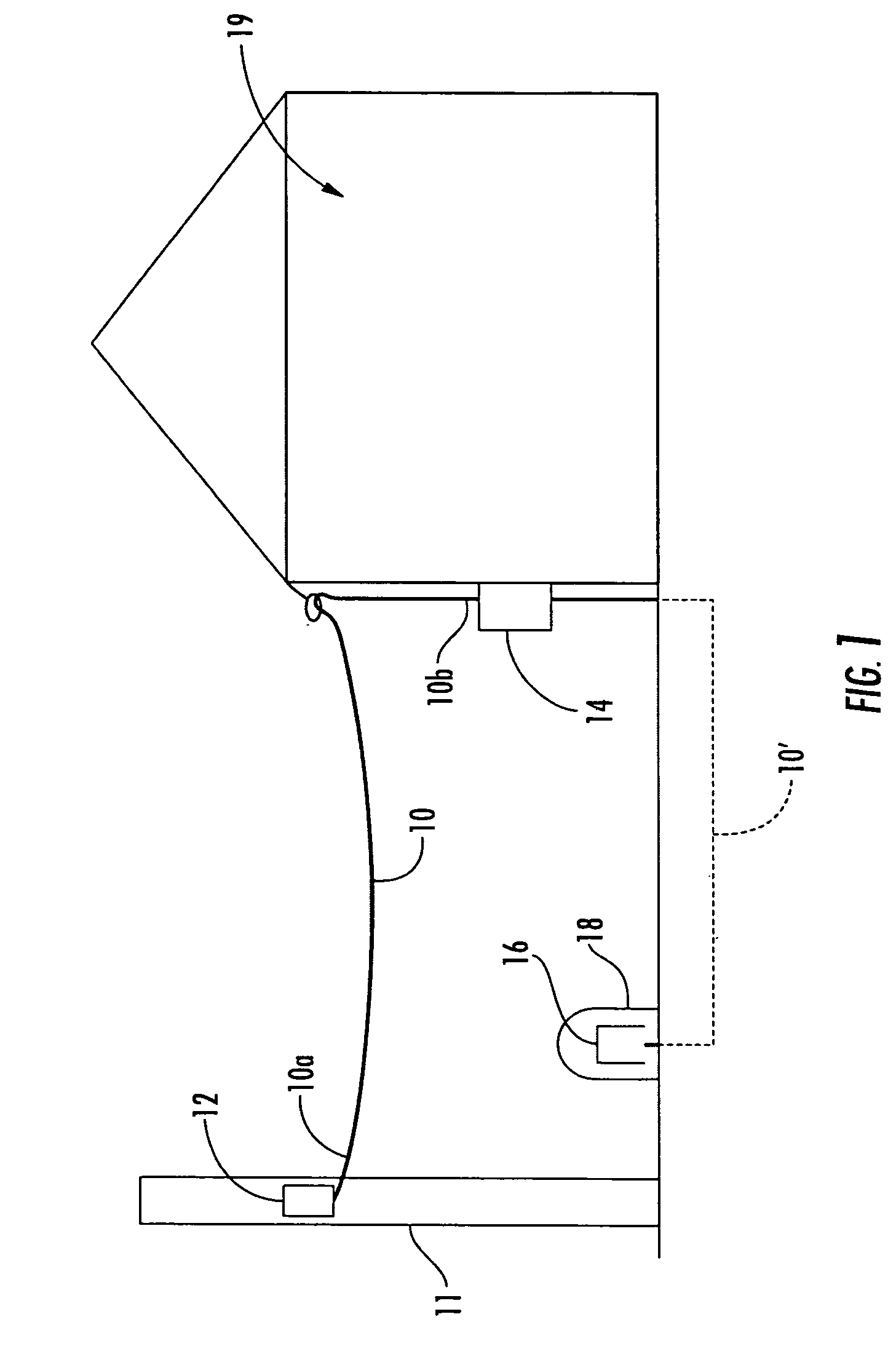

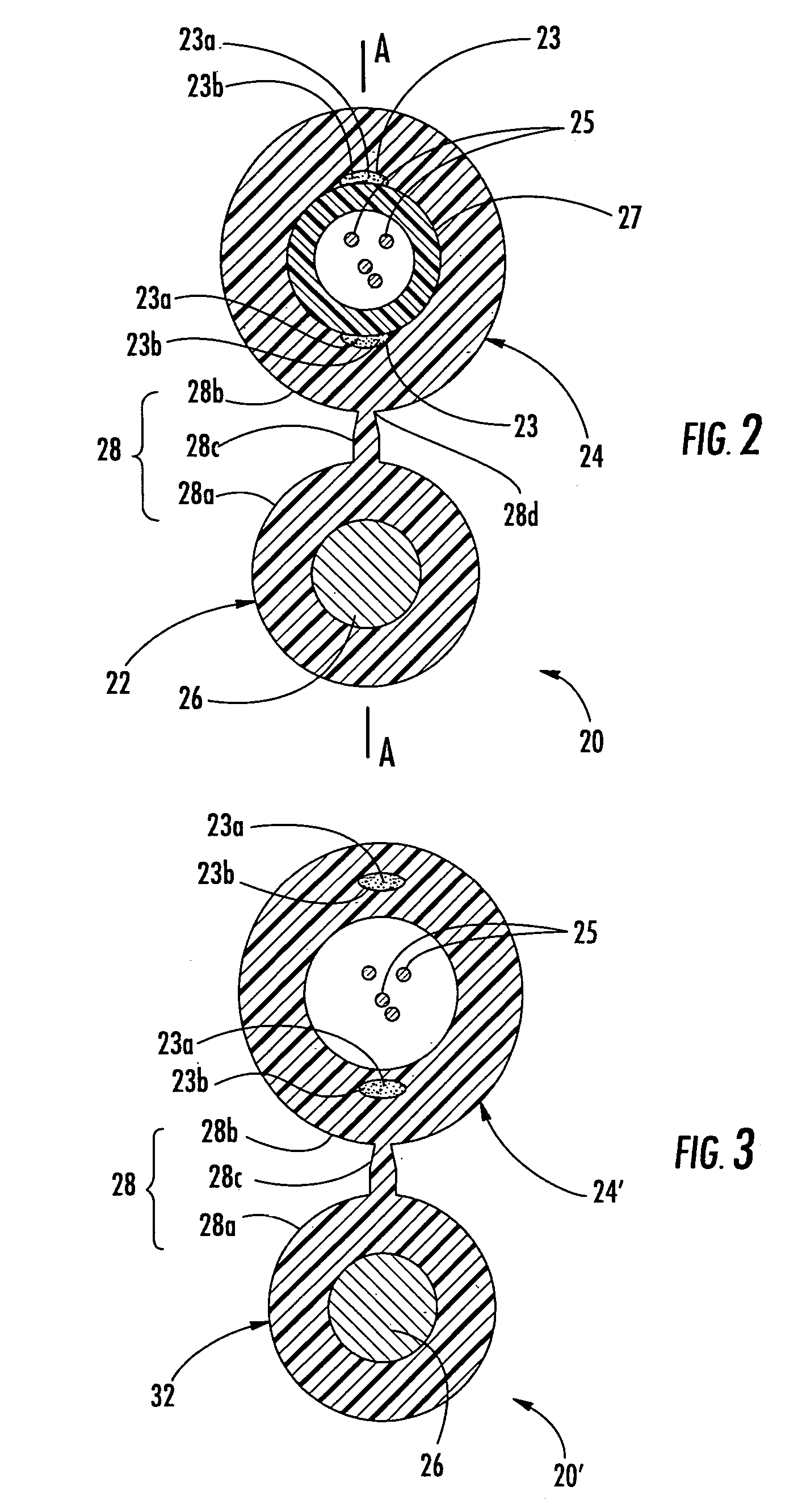

Fiber optic drop cables suitable for outdoor fiber to the subscriber applications

A fiber optic drop cable including at least one optical waveguide, at least one roving, and a cable jacket. In one embodiment, the at least one roving includes a resin matrix having a water-based acrylic composition that includes an ethylene-acrylic acid and a water-swellable component. The resin matrix has a percent by weight of about 10 percent or less of the flexible roving so that the at least of one roving is at least partially bonded with the cable jacket, thereby inhibiting buckling of the cable jacket. In another embodiment, a plurality of rovings are arranged in clusters in the cable for influencing the bonding between the rovings and cable jacket. Also, disclosed is a protective casing for protecting and routing optical fibers along with preconnectorized cable assemblies.

Owner:CORNING OPTICAL COMM LLC

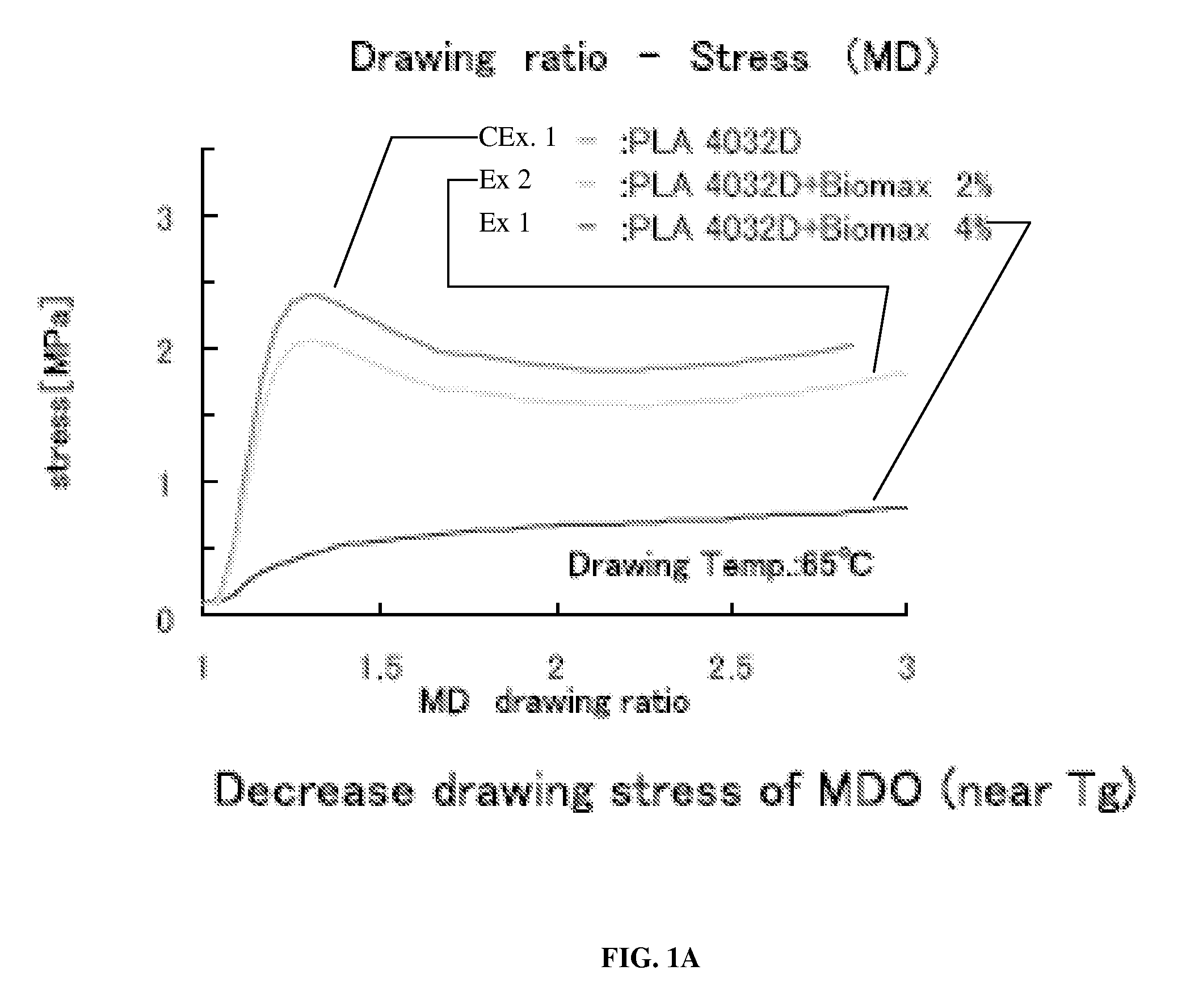

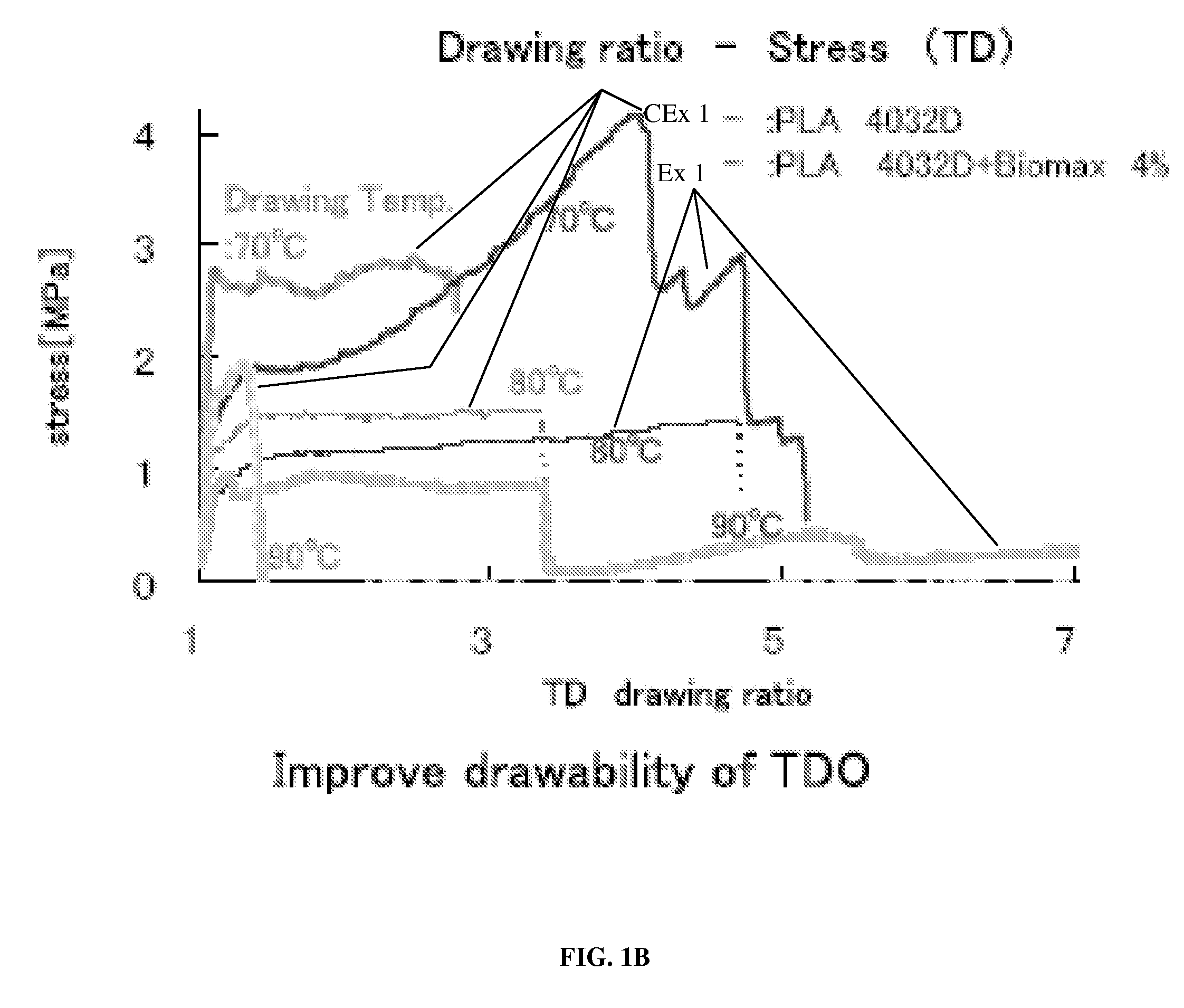

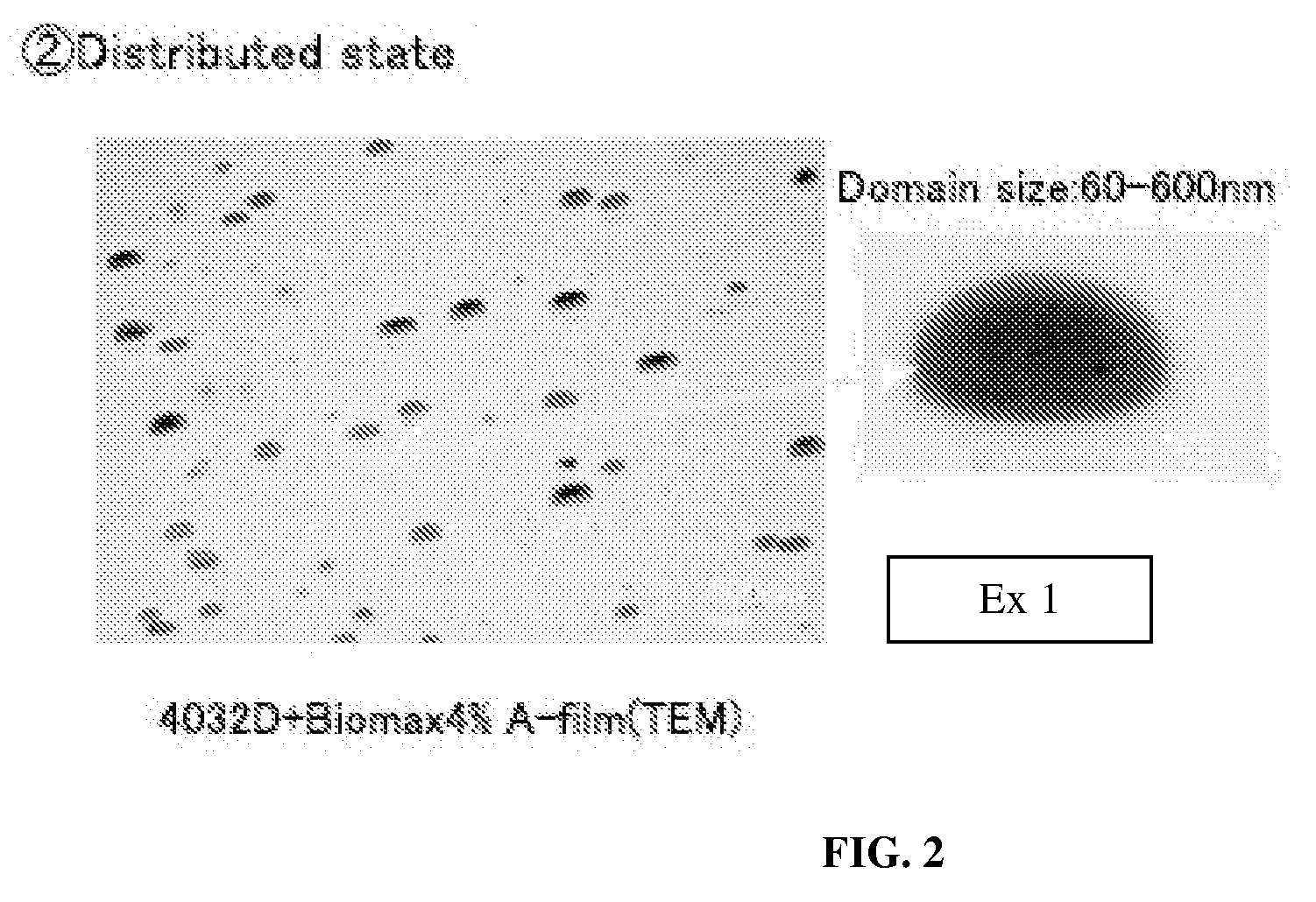

Process to produce biaxially oriented polylactic acid film at high transverse orientation rates

InactiveUS20090148715A1High rate of orientationEasy to stretchSynthetic resin layered productsDomestic articlesTransverse orientationEthylene

A biaxially oriented laminate film including a first amorphous polylactic acid polymer heat sealable resin layer and a second core layer including a blend of crystalline polylactic acid polymer and 2-10 wt % of the core layer of an ethylene-acrylate copolymer. The laminate film, exhibiting the property to be transverse oriented in excess of 6 times its original width, typically 8 to 10 times its original width with excellent operability and relatively low haze, is disclosed. The laminate film may further have additional layers such as a third polylactic acid resin-containing layer disposed on the side of the core layer opposite the heat sealable layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Foam compositions for selective recovery of oil spills and other applications

InactiveUS20110287929A1Improve oil absorption capacityOther chemical processesSeawater treatmentSaline waterSalt water

A polymer composition for use in the removal and recovery of oil slicks or spills floating on the surfaces of bodies of water or present on land, such as beaches comprising a foam of a blend of polyethylene and an ethylene-alkyl acrylate copolymer and a process for using such foams in the selective removal of oil from fresh water or salt water and the recovery of the absorbed oils from the foams is disclosed. The polymer composition is also for use in other applications in which absorption of liquids is desired.

Owner:OPFLEX TECH

Embossed tissue products

InactiveUS7842163B2Preserve strengthHigh strengthNatural cellulose pulp/paperMechanical working/deformationFiberCarboxylic acid

Owner:KIMBERLY-CLARK WORLDWIDE INC

Coating composition containing a low MFI ethylene acrylic acid copolymer

InactiveUS6852792B1Improve water resistanceLow sealing temperatureEmulsion paintsMelt flow indexSolvent

This invention is directed to the discovery that ethylene-acid copolymers that have low melt flow index MFI (namely less than 100 g / 10 min measured according to ASTM D1238 at 190° C., 2.16 kg) even with low acid content (such as less than 20 wt. %) can provide stable aqueous dispersions directly in aqueous media (i.e. free from any other solvent) with less than 1 wt. % non-dispersibles in single bases even at mild dispersion process conditions, at temperature less than 100°C., atmospheric pressure, and with low agitation speed.

Owner:PERFORMANCE MATERIALS NA INC +1

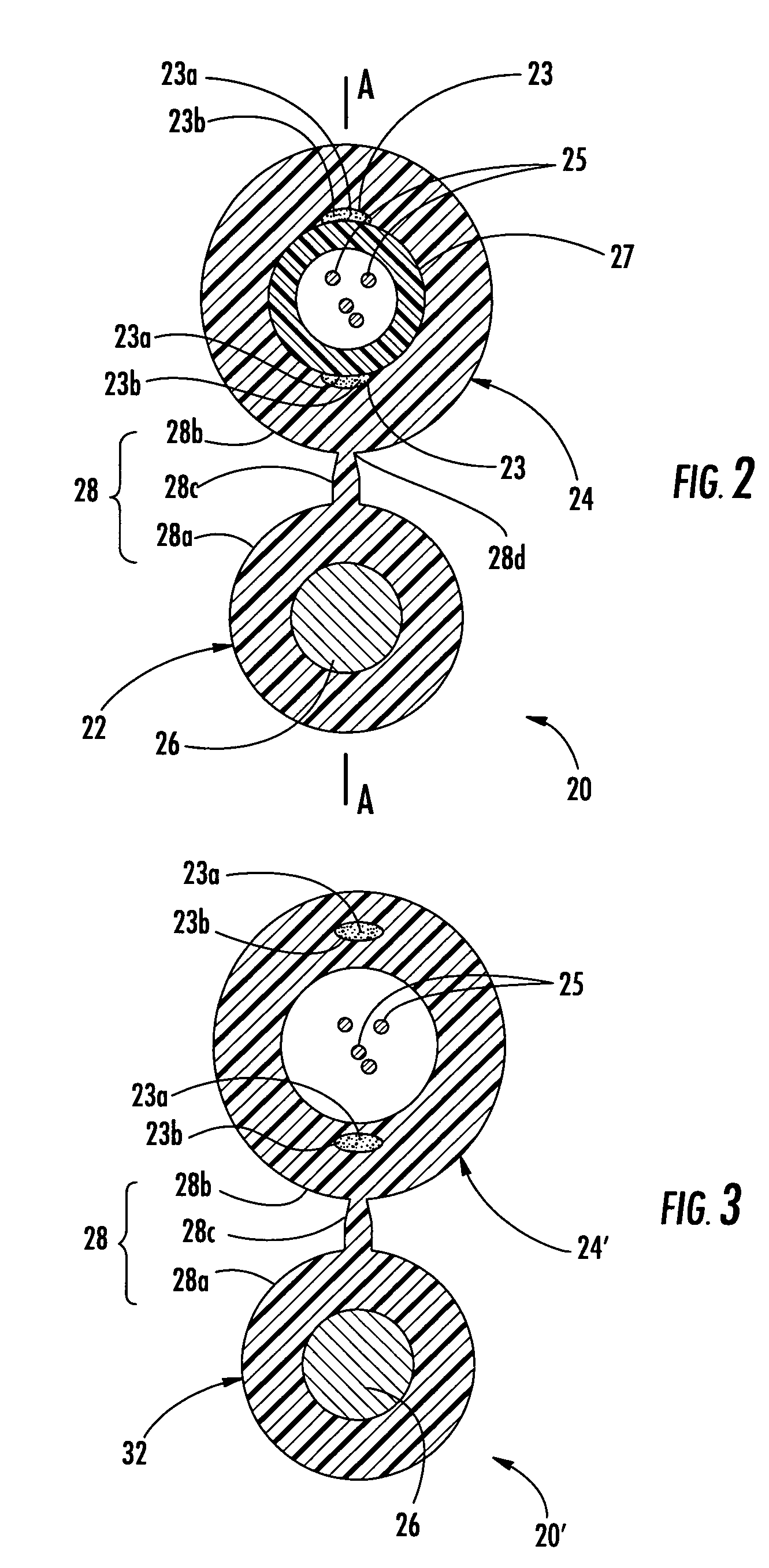

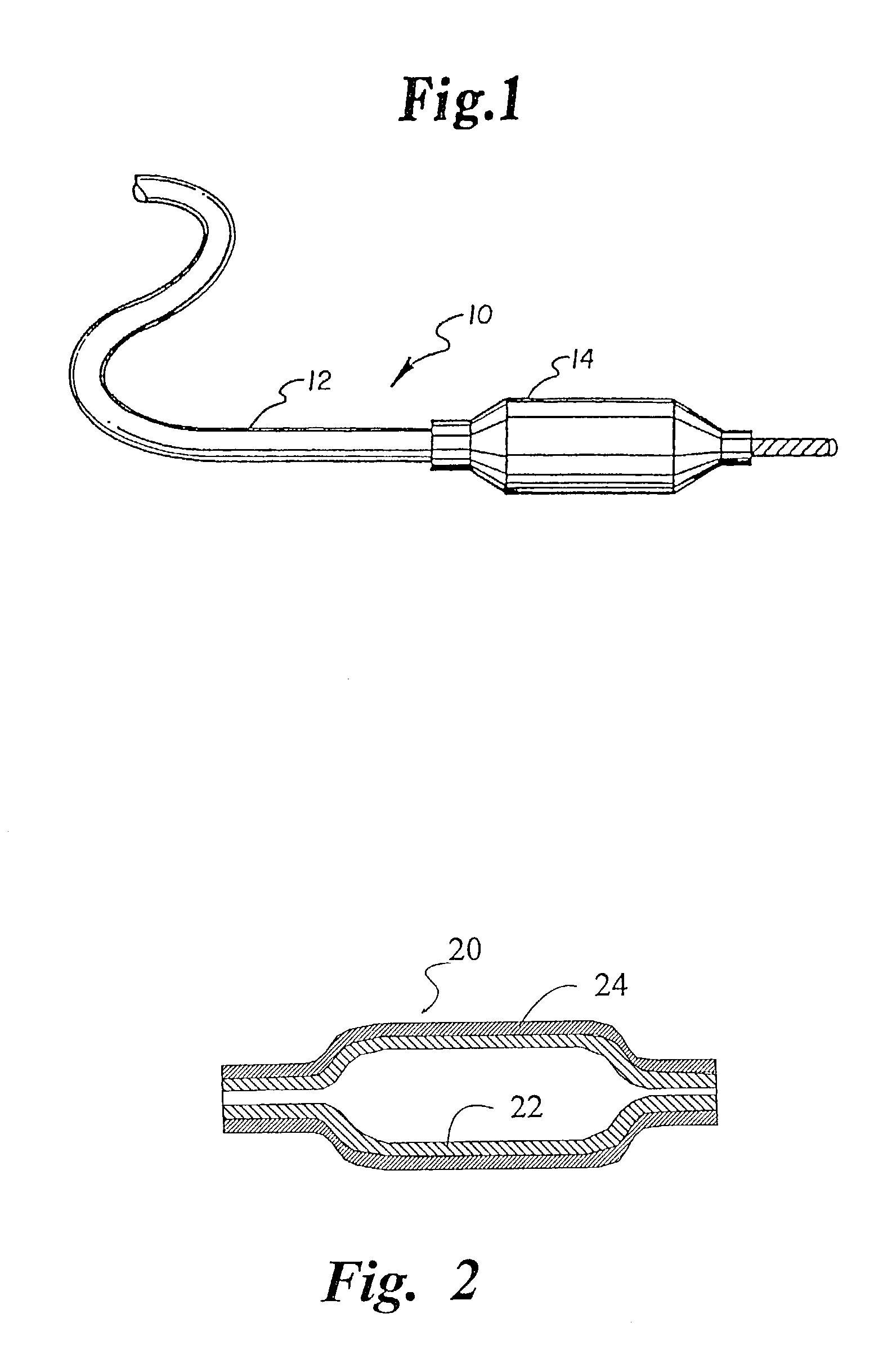

Balloons made from liquid crystal polymer blends

Balloons for use on medical devices such as catheter balloons are formed from polymer blend products which include a liquid crystal polymer (LCP), a crystallizable thermoplastic polymer, especially thermoplastic polyesters such as PET, and a compatabilizer. The compatabilizer may be an ethylene-maleic anhydride copolymer, an ethylene-methyl acrylate copolymer, an ethylene-methyl acrylate copolymer, an ethylene-methyl acrylate-maleic anhydride terpolymer, an ethylene-methyl-methacrylic acid terpolymer, an acrylic rubber, an ethylene-ethyl acrylate-glycidyl methacrylate terpolymer or a mixture of two or more such polymers.

Owner:BOSTON SCI SCIMED INC

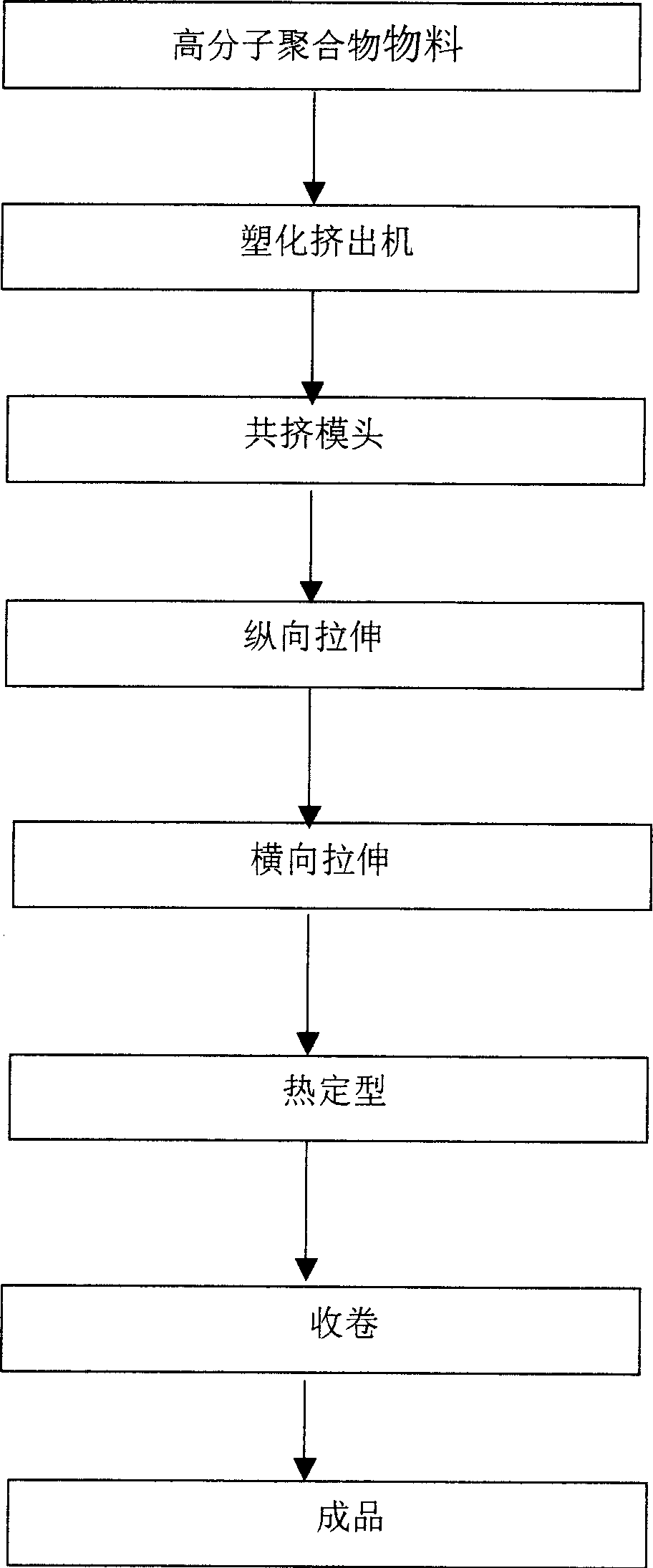

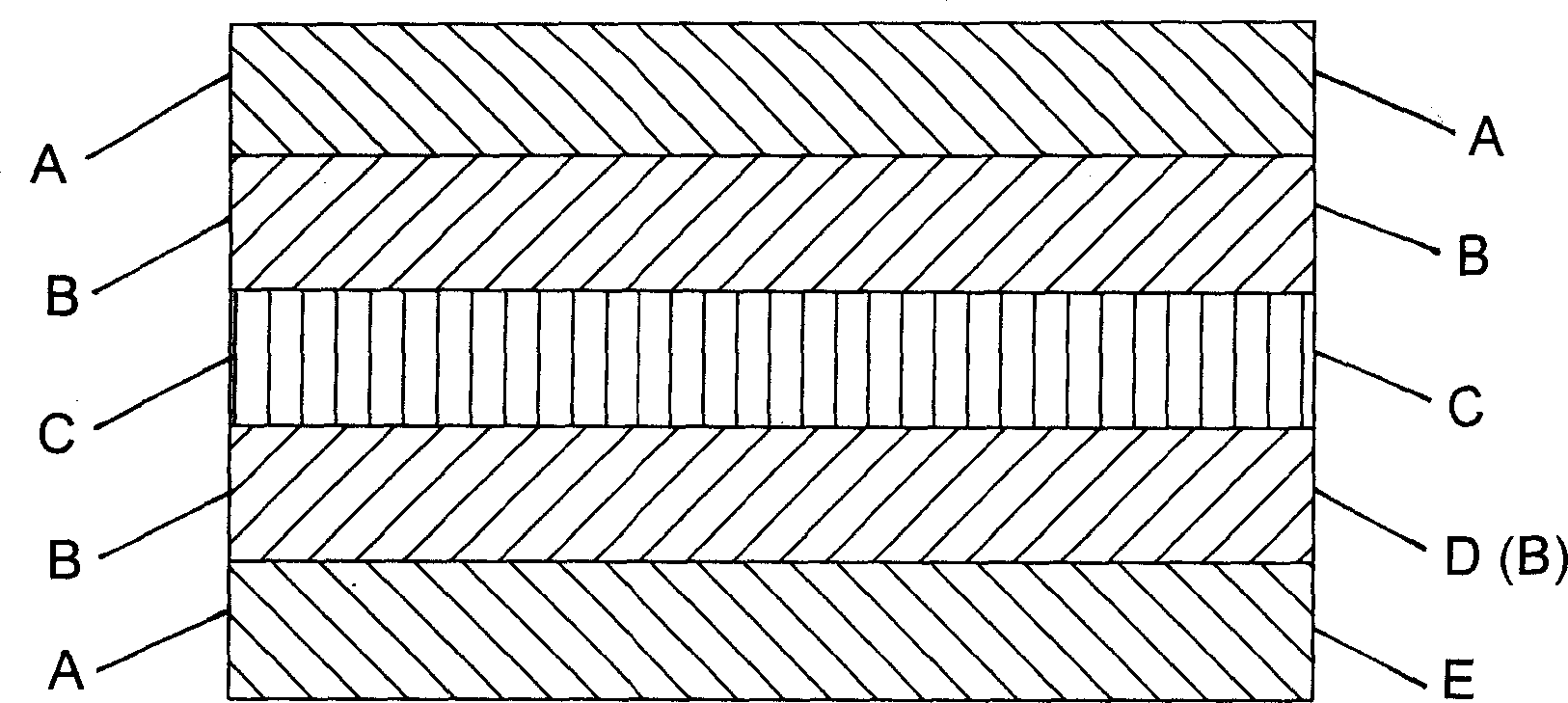

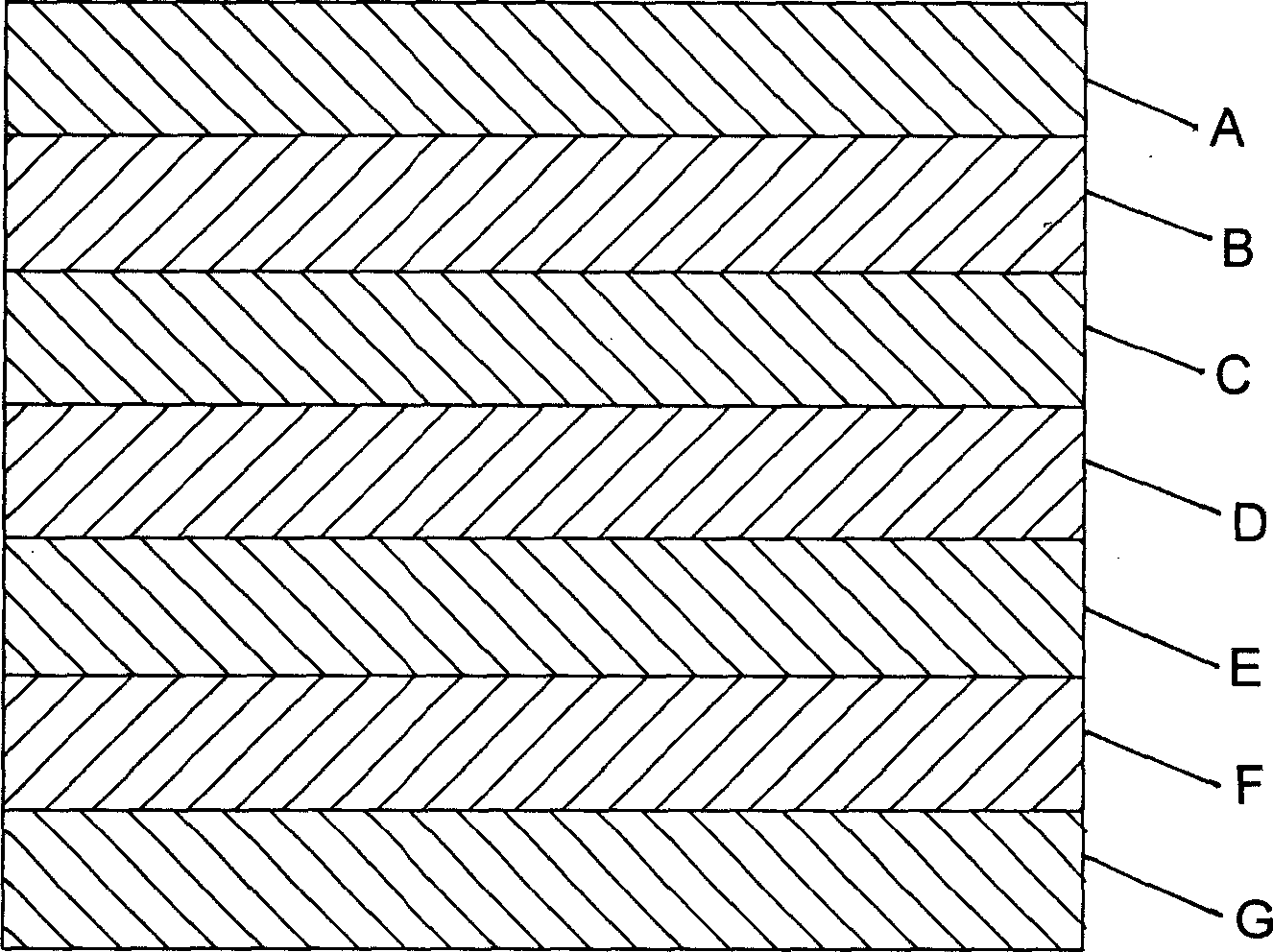

Biaxial tension co-extrusion high-obstruct base material membrane and process for preparing the same

InactiveCN1733397AImprove barrier propertiesImprove qualityTurning toolsHeat deflection temperaturePolyolefin

This invention provides biaxial tension coextrude resistive base material membrane and preparation method. Wherein, the membrane comprises at least a resistive layer that is at least one of PA, PVA, PVDC and MAD6, a splice layer belonged to EAA, EEA, ethylenemethacrylic acid copolymerized resin or polyolefin and neolyn resin that can combine the other tow layers, and a heat-sealing layer that is at least one of the polyolefin resin, EVA and PET; besides, there is nano inorganic material in resistive layer and or heat-sealing layer to improve performance. The product fits to package for all kinds goods.

Owner:朱春蕾 +4

Fiber optic drop cables suitable for outdoor fiber to the subscriber applications

A fiber optic drop cable including at least one optical waveguide, at least one roving, and a cable jacket. In one embodiment, the at least one roving includes a resin matrix having a water-based acrylic composition that includes an ethylene-acrylic acid and a water-swellable component. The resin matrix has a percent by weight of about 10 percent or less of the flexible roving so that the at least of one roving is at least partially bonded with the cable jacket, thereby inhibiting buckling of the cable jacket. In another embodiment, a plurality of rovings are arranged in clusters in the cable for influencing the bonding between the rovings and cable jacket. Also, disclosed is a protective casing for protecting and routing optical fibers along with preconnectorized cable assemblies.

Owner:CORNING OPTICAL COMM LLC

Filler masterbatch used for increasing polarity of polypropylene and preparation method thereof

The invention discloses a filler masterbatch used for increasing the polarity of polypropylene and a preparation method thereof. The filler masterbatch is characterized by comprising the following components by weight percent: 50%-79% of inorganic filler, 15%-30% of carrier, 5%-17% of polar additive and 1%-3% of processing additive; and the polar additive is one or more of thermoplastic polyurethane resin (TPU), maleic anhydride grafted polypropylene, epoxy resin, ethylene acrylate, ethylene vinyl acetate, polyether amine and polybutylene polyol. In the preparation method of the invention, the added carrier can not improve the polarity of polypropylene, the inorganic filler is used to increase the rigidity of the material; the key is to introduce the polar additive with high unipolarity, thus the filler masterbatch used for increasing the polarity of polypropylene can be prepared; when the filler masterbatch is combined with the polypropylene material for production, the surface polarity of the filled and modified polypropylene material can be increased, the surface energy of the filled and modified polypropylene can be reduced, the dimension stability can be increased, the modified polypropylene material can have good paint adhesion and the material can be used to form exterior trimming parts such as bumpers and interior trimming parts such instrument panels.

Owner:KINGFA SCI & TECH CO LTD +3

Tissue products containing a polymer dispersion

ActiveUS20070137809A1High strengthImprove propertiesNatural cellulose pulp/paperMechanical working/deformationFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

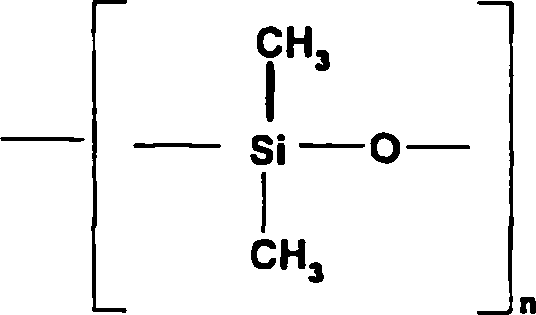

Thermoplastic elastomer composition, hose comprising thermoplastic elastomer composition and process of production thereof

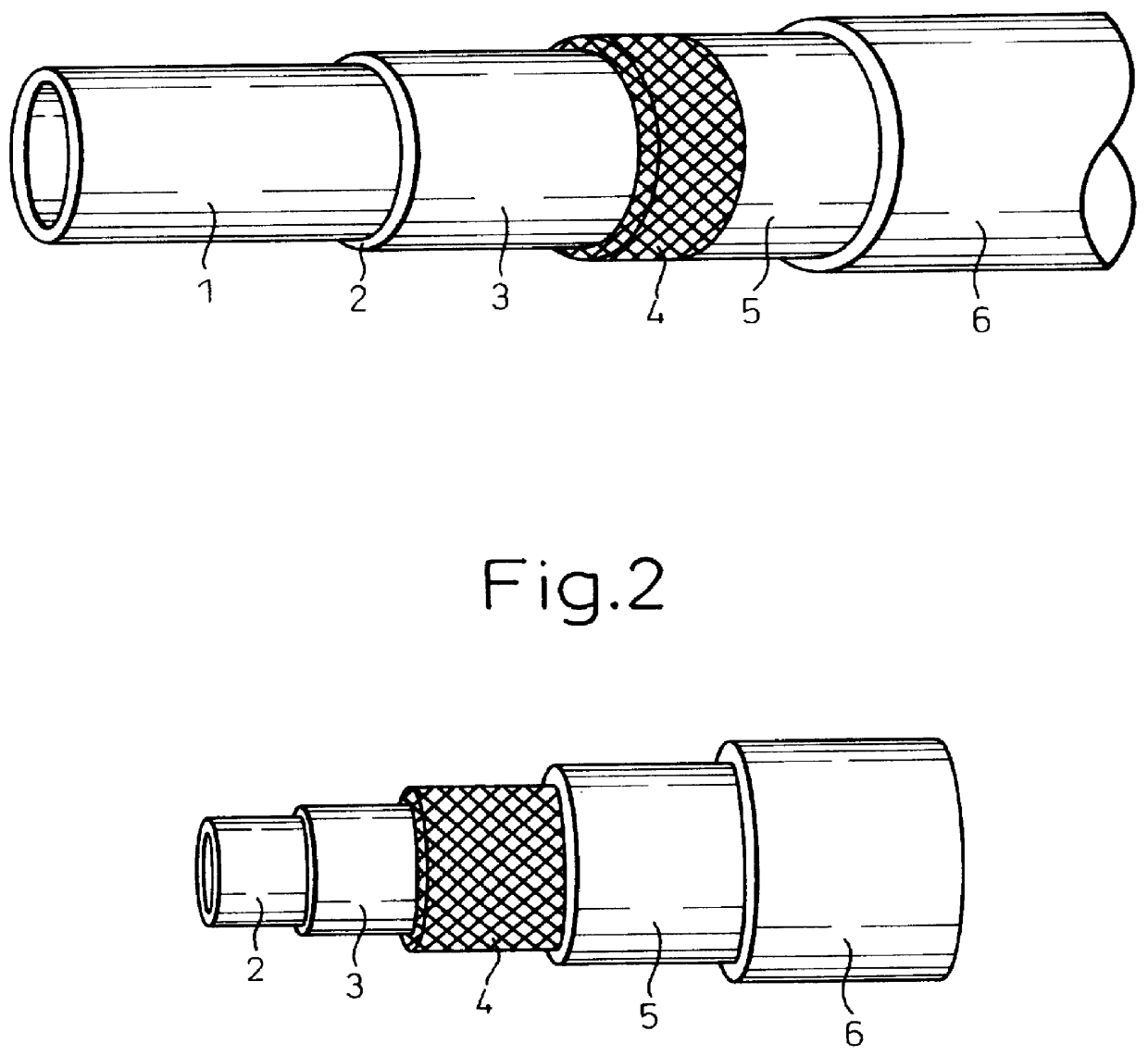

InactiveUS6166143AImprove compatibilitySolve the lack of flexibilityClosuresClosure using stoppersThermoplasticCross-link

PCT No. PCT / JP97 / 03987 Sec. 371 Date Jul. 2, 1998 Sec. 102(e) Date Jul. 2, 1998 PCT Filed Oct. 31, 1997 PCT Pub. No. WO98 / 20068 PCT Pub. Date May 14, 1998A thermoplastic elastomer composition containing a component (A) (thermoplastic polyolefin resin), component (B) (epoxy-group-containing ethylene acrylic ester copolymer rubber), and component (C) (acid-modified polyolefin resin) comprising a continuous phase of the component (A) in which the component (B) is dispersed as a dispersed phase and is cross-linked by a peroxide; a thermoplastic elastomer composition comprising a continuous phase of a thermoplastic polyolefin resin (A) and a dispersed phase of an epoxy-group-containing ethylene-acrylic ester copolymer rubber component (B) and acrylonitrile butadiene rubber component (C), which is dynamically cross-linked; and a hose having an inner tube, at least one reinforcing layer, and an outer cover, wherein the inner tube and the outer cover contain a thermoplastic elastomer composition comprised of a thermoplastic resin in which is blended an at least partially cross-linked elastomer component, the reinforcing layer is a brass-plated wire, and the reinforcing layer and inner tube and the reinforcing layer and outer cover have between them a maleic-acid-modified polyolefin thermoplastic resin.

Owner:YOKOHAMA RUBBER CO LTD

Protective casings for optical fibers

Owner:CORNING OPTICAL COMM LLC

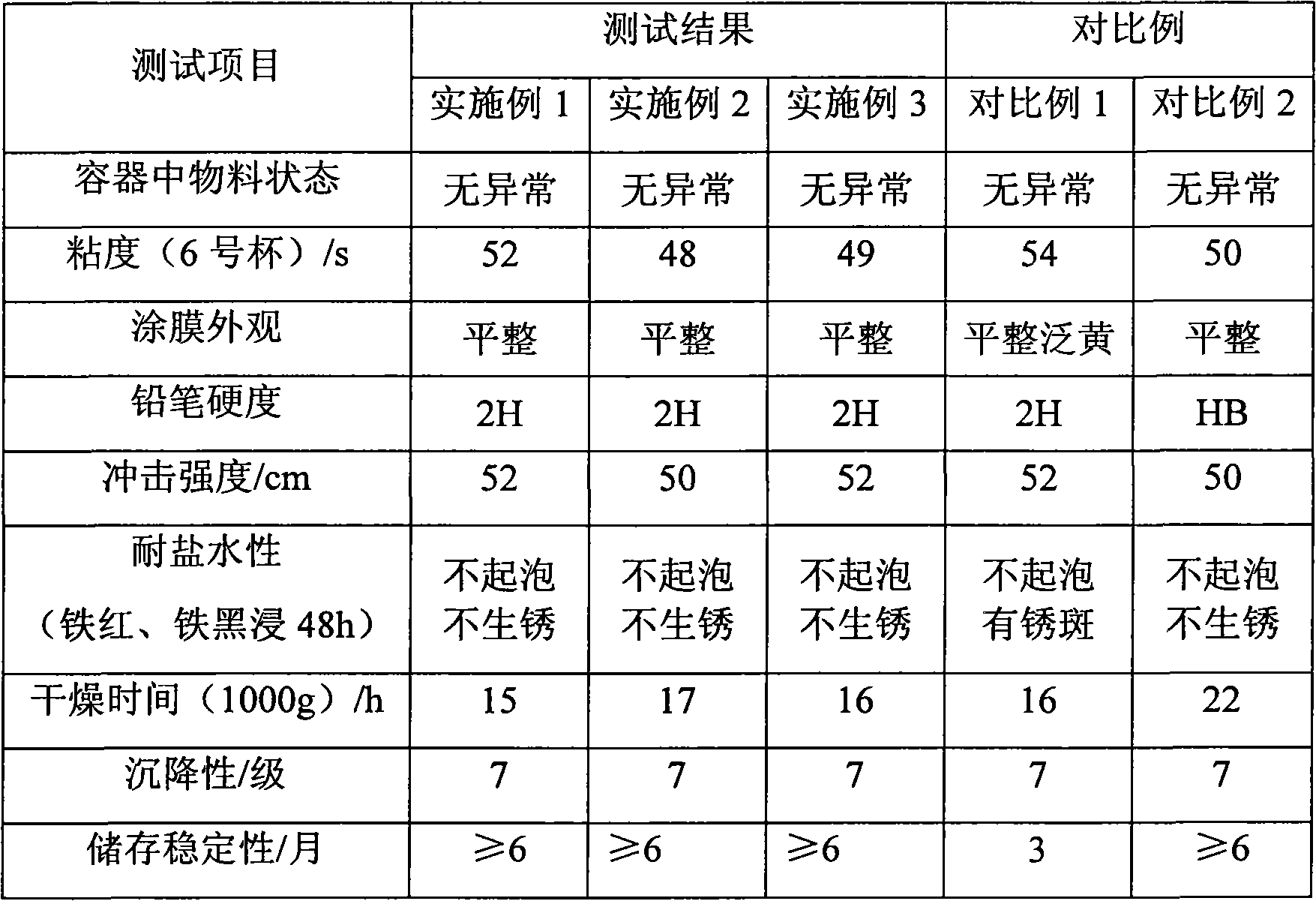

Water-borne epoxy ester modified alkyd resin emulsion and preparation method thereof

InactiveCN101942063AStrong adhesionImprove performanceDyeing processCoatingsEnvironmental resistanceEpoxy

The invention provides water-borne epoxy ester modified alkyd resin emulsion and a preparation method thereof. The method comprises the following steps: allowing unsaturated fatty oil, polyalcohol, epoxy resin and the like to carry out alcoholysis reaction by using triphenylphosphine and an alcoholysis catalyst; adding polyacid for esterification; dropwise adding crylic acid monomers such as methacrylic acid, phenylethylene, butyl acrylate and the like and a silane coupling agent for copolymerization under initiation of benzoyl peroxide; adding amine to the obtained copolymer for neutralizing to form salt; and dispersing with water to obtain the high-performance water-borne epoxy ester modified alkyd resin emulsion. The emulsion maintains self-drying property, flexibility and other excellent properties of alkyd resin, has excellent adhesive property of the epoxy resin as well as excellent adhesion force, excellent physical and mechanical properties and strong water resistance, strong salt fog resistance, strong acid and alkali resistance and other properties; and the emulsion has the advantages of possessing good stability and being nontoxic and harmless, thus meeting the environmental friendly requirement.

Owner:SOUTH CHINA UNIV OF TECH

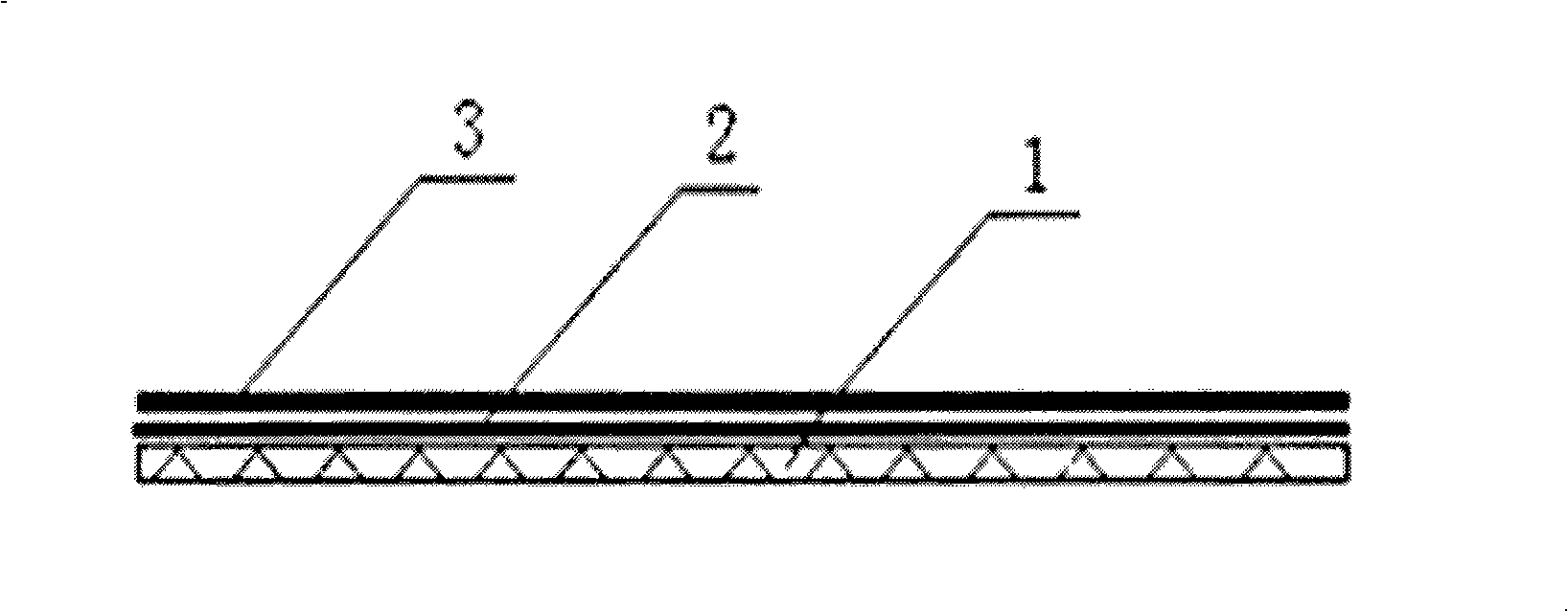

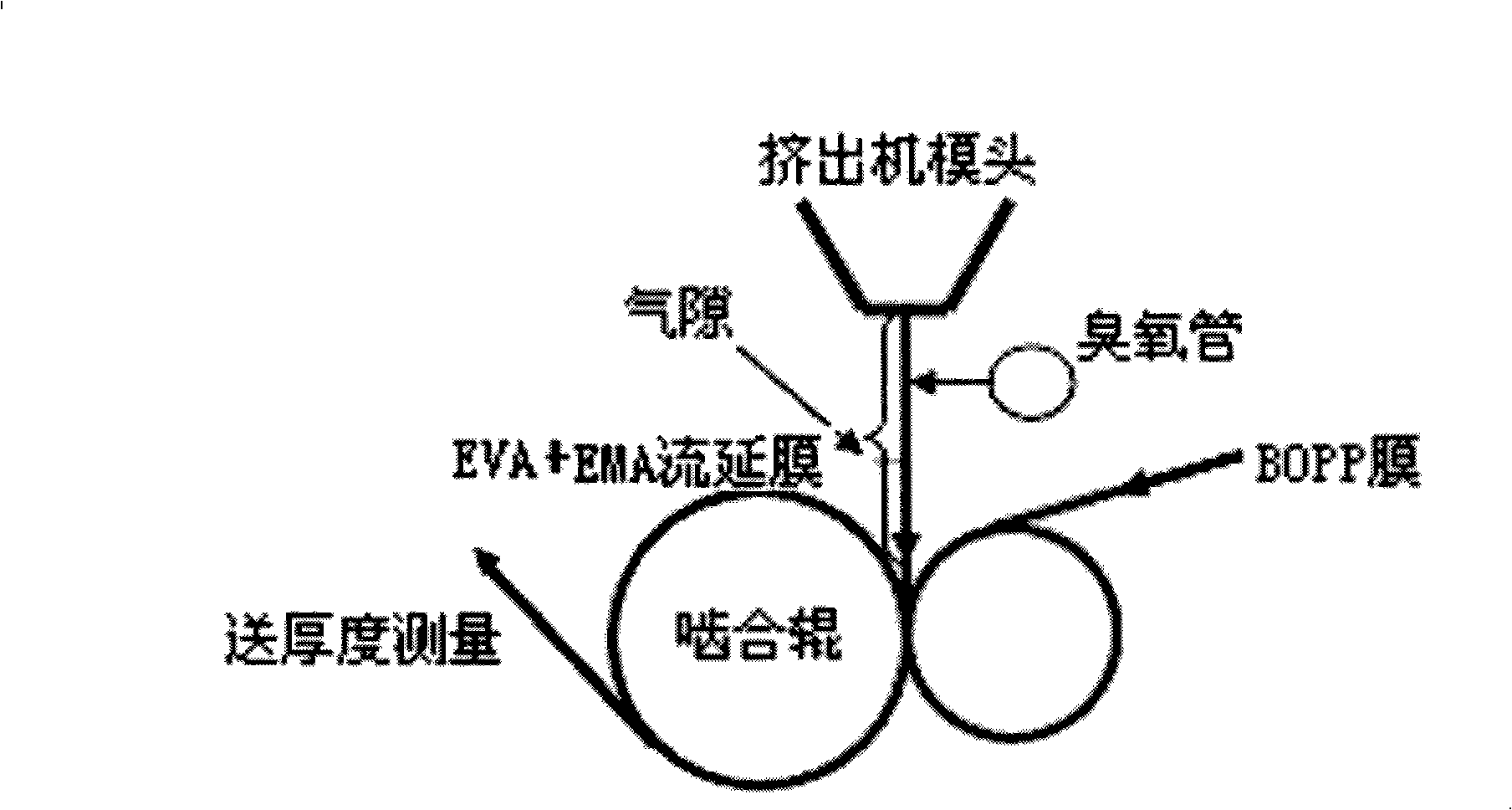

Viscosity-increasing precoating film of biaxial tension

ActiveCN101402269AFill the gap in the marketImprove adhesionLamination ancillary operationsSynthetic resin layered productsChemistryPolypropylene

The invention relates to a bidirectional stretched precoating film with increased viscosity and a processing technology thereof. The precoating film comprises a base material, a middle layer and a hot melt adhesive layer, and is characterized in that the base material is a bidirectional stretched polyester (BOPET) film or a bidirectional stretched polypropylene (BOPP) film, the middle layer is made from polyethylene imine (PEI), and the hot melt adhesive layer is a mixture consisting of ethylene-vinyl acetate (EVA) and ethylene-methyl acrylate copolymer (EMA). The bidirectional stretched precoating film with the increased viscosity is obtained by using an extruded compound production line to evenly coat and clad the middle layer and the hot melt adhesive layer on one surface of the base material in turn. Because the resin adopted by the hot melt adhesive layer of the precoating film is the mixture consisting of the ethylene-vinyl acetate (EVA) and the ethylene-methyl acrylate copolymer (EMA), the precoating film has far larger cohesive force to printed matters than the precoating film of which the hot melt adhesive is pure EVA, and can remarkably show the high cohesive force particularly to the printed matters containing silicone oil ink or the printed matters containing water-based ink.

Owner:KANGDE XIN COMPOSITE MATERIAL CO LTD

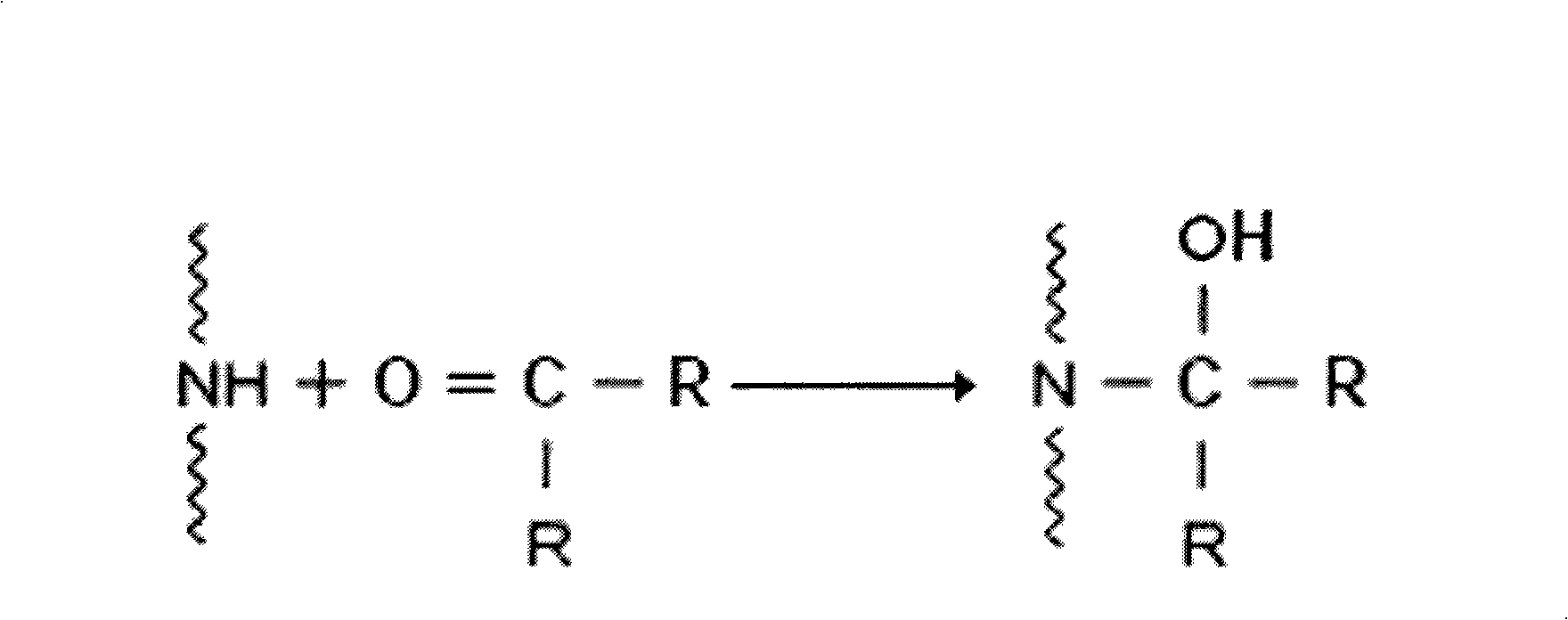

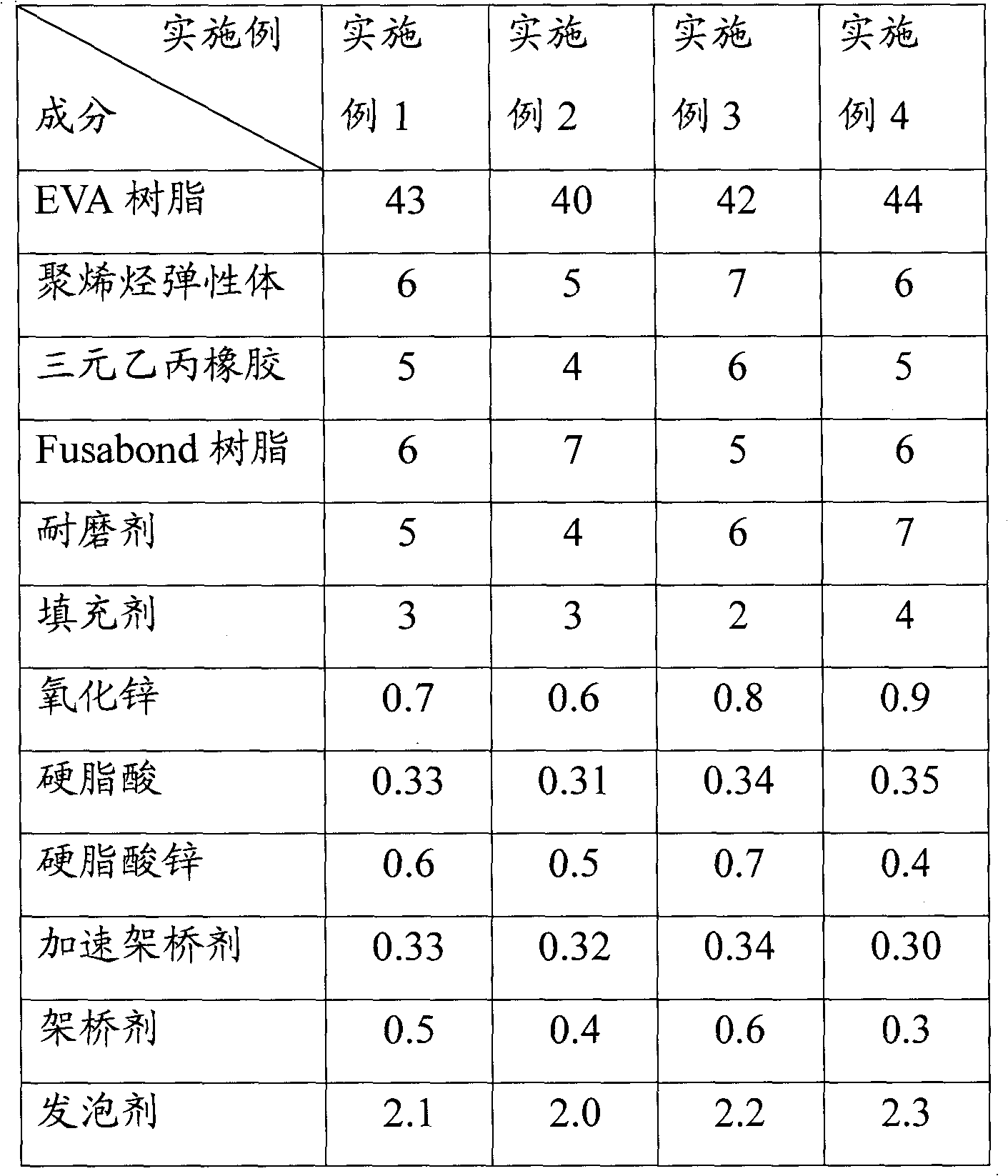

Plastic foam for sport shoe sole

The invention discloses a plastic foam for a sport shoe sole, which comprises the following components in part by weight: 70-74 parts of ethylene-vinyl acetate copolymer, 8-12 parts of ethylene-octylene copolymer, 6-10 parts of ethylene propylene ethylene-propylene-diene monomer, 8-12 parts of ethylene-acrylic acid copolymer, 8-9 parts of wear-resisting agent, 4-6 parts of filler, 1.0 -1.2 parts of zinc oxide, 0.5-0.6 part of stearic acid, 0.8-1.0 part of zinc stearate, 0.5-0.7 part of accelerate bridging agent, 0.8-0.9 part of bridging agent and 3.2-3.8 parts of foaming agent, wherein the ethylene propylene ethylene-propylene-diene monomeris a terpolymer of ethylene-propylene and non-conjugate diolefin. The plastic shoe sole of the sport shoe has the light weight performance, wear resistant performance and comfortable performance which are superior to those of a foam plastic formula injected by common IP, greatly reduces the physical consumption of athletes and has a plurality of performances such as durable comfort, durable buffer resistant performance and the like.

Owner:ANTA CHINA

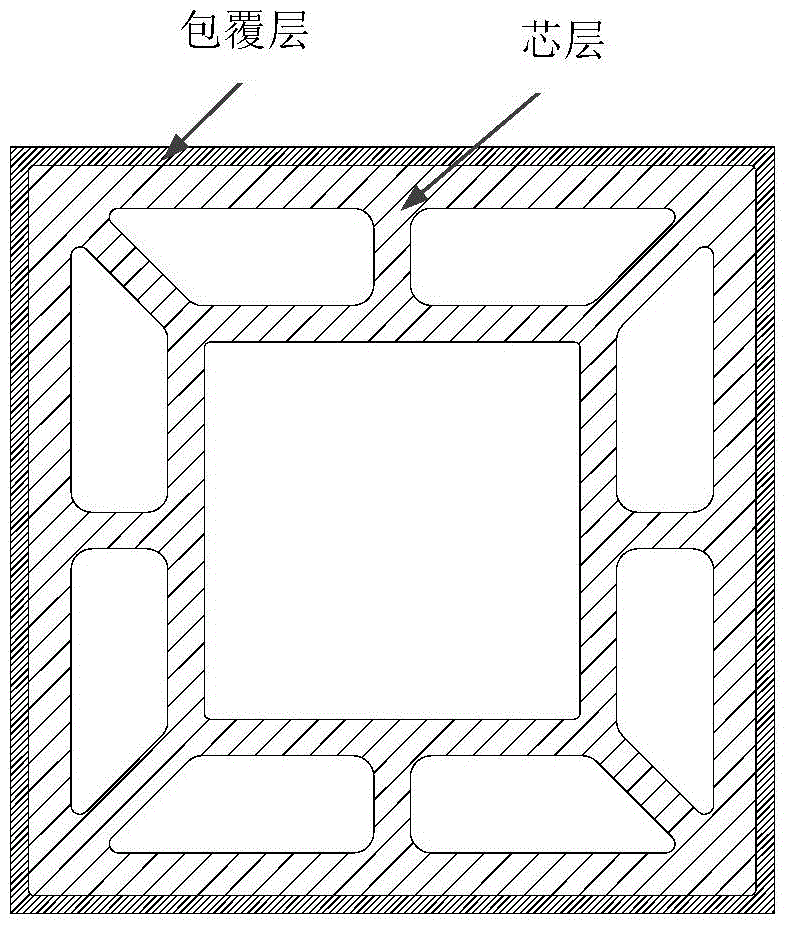

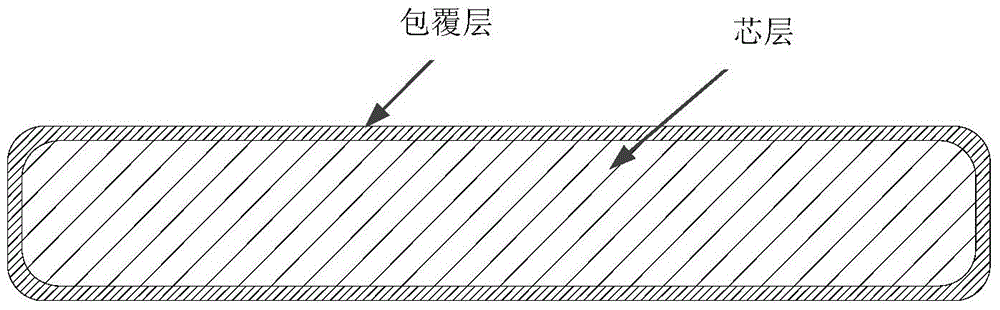

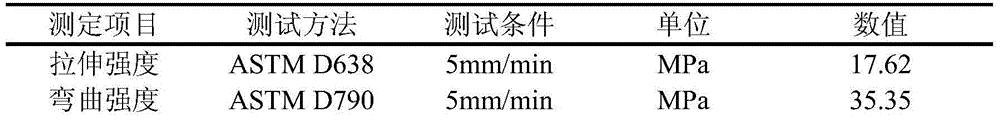

High strength wood-plastic coated coextruded composite material and preparation method thereof

InactiveCN105644074APlay the role of "filling"Improve mechanical propertiesSynthetic resin layered productsLaminationFiberDiameter ratio

The invention provides a high strength wood-plastic coated coextruded composite material. The material is composed of a core layer and a coating layer. The coating layer coats the surface of the core layer through a co-extrusion technology, biomass powder in the core layer is improved to a biomass fiber material, because of a large length-diameter ratio, the biomass fiber material not only plays a "filling" role in a wood-plastic composite material, but also plays a "reinforcing" role, greatly improves the mechanical properties of the composite material, especially improves the impact resistance, creep resistance and other properties, thereby broadening the application scope of the wood-plastic composite material. In addition, the coating layer involved in the invention preferably contains ethylene-methyl acrylate copolymer resin, ethylene-vinyl alcohol copolymer resin and high strength fiber, thus being conducive to further enhancing the mechanical properties of the composite material and the binding force with the core layer.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Adhesive and sealant systems

Adhesive and sealant systems based on epoxy resins, polyurethane, silane-terminated polymers, silicones, unsaturated polyester resins, vinyl ester resins, acrylates, polyvinyl acetate, polyvinyl alcohol, polyvinyl ether, ethylene vinyl acetate, ethylene-acrylic acid copolymers, polyvinyl acetates, polystyrene, polyvinyl chloride, styrene-butadiene rubber, chloroprene rubber, nitrile rubber, butyl rubber, polysulfide, polyethylene, polypropylene, fluorinated hydrocarbons, polyamides, saturated polyesters and copolyesters, phenol-formaldehyde resins, cresol- / resorcinol-formaldehyde resins, urea-formaldehyde resins, melamine-formaldehyde resins, polyimides, polybenzimidazoles, polysulfones, which contain 1 wt.% to 15 wt.% of a compacted, hydrophobic pyrogenic silica.

Owner:DEGUSSA AG

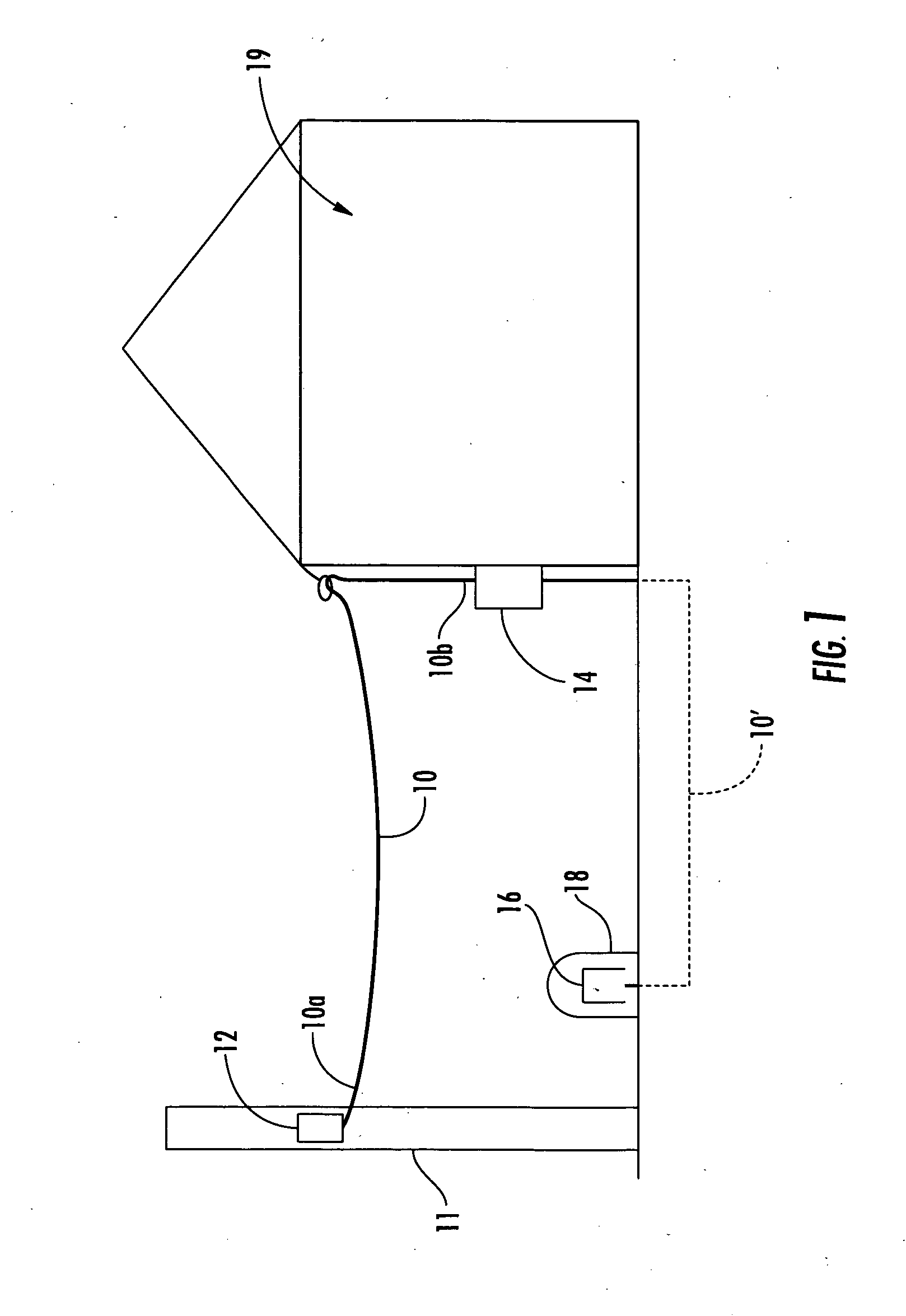

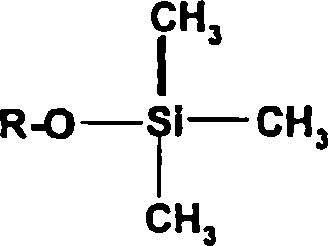

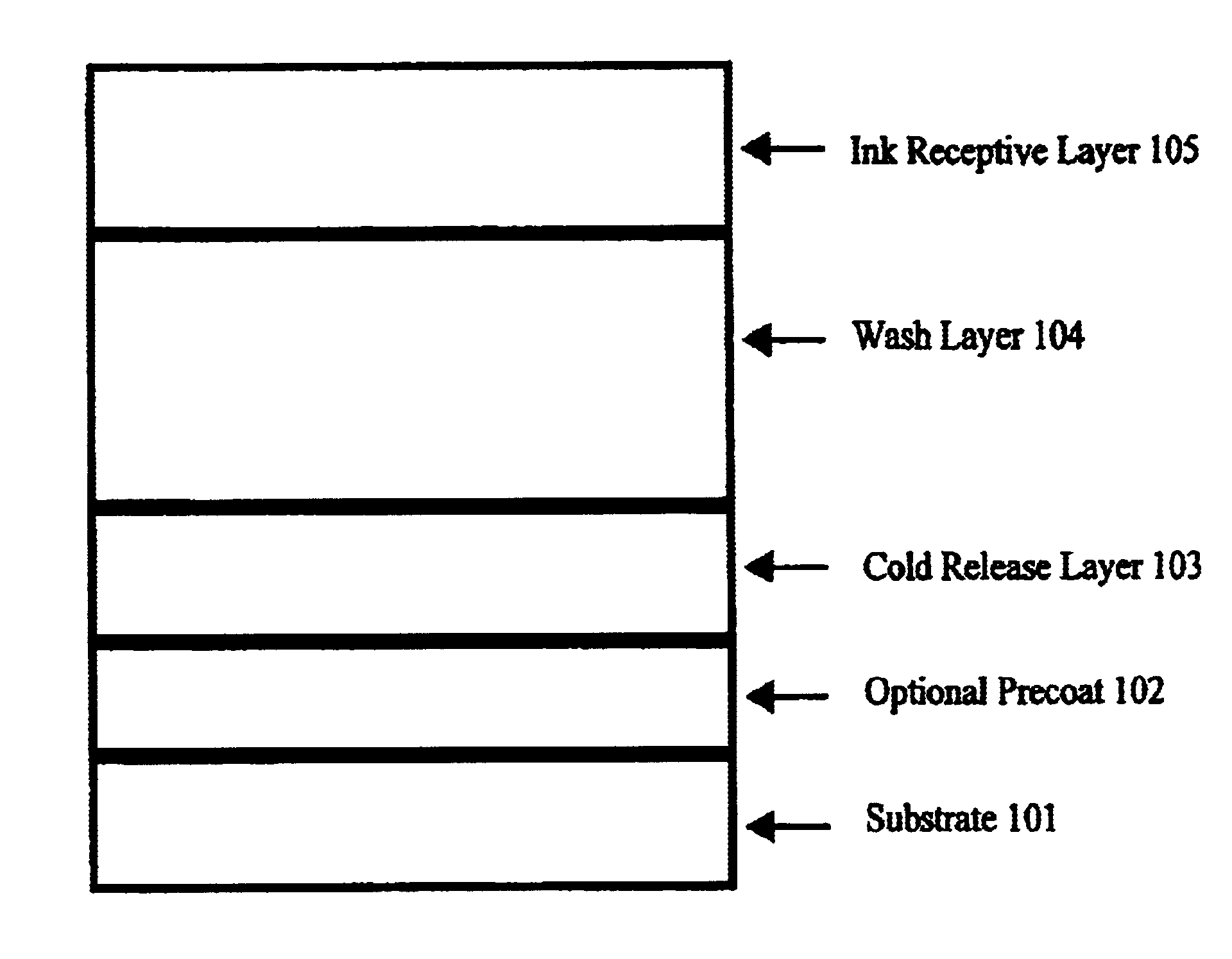

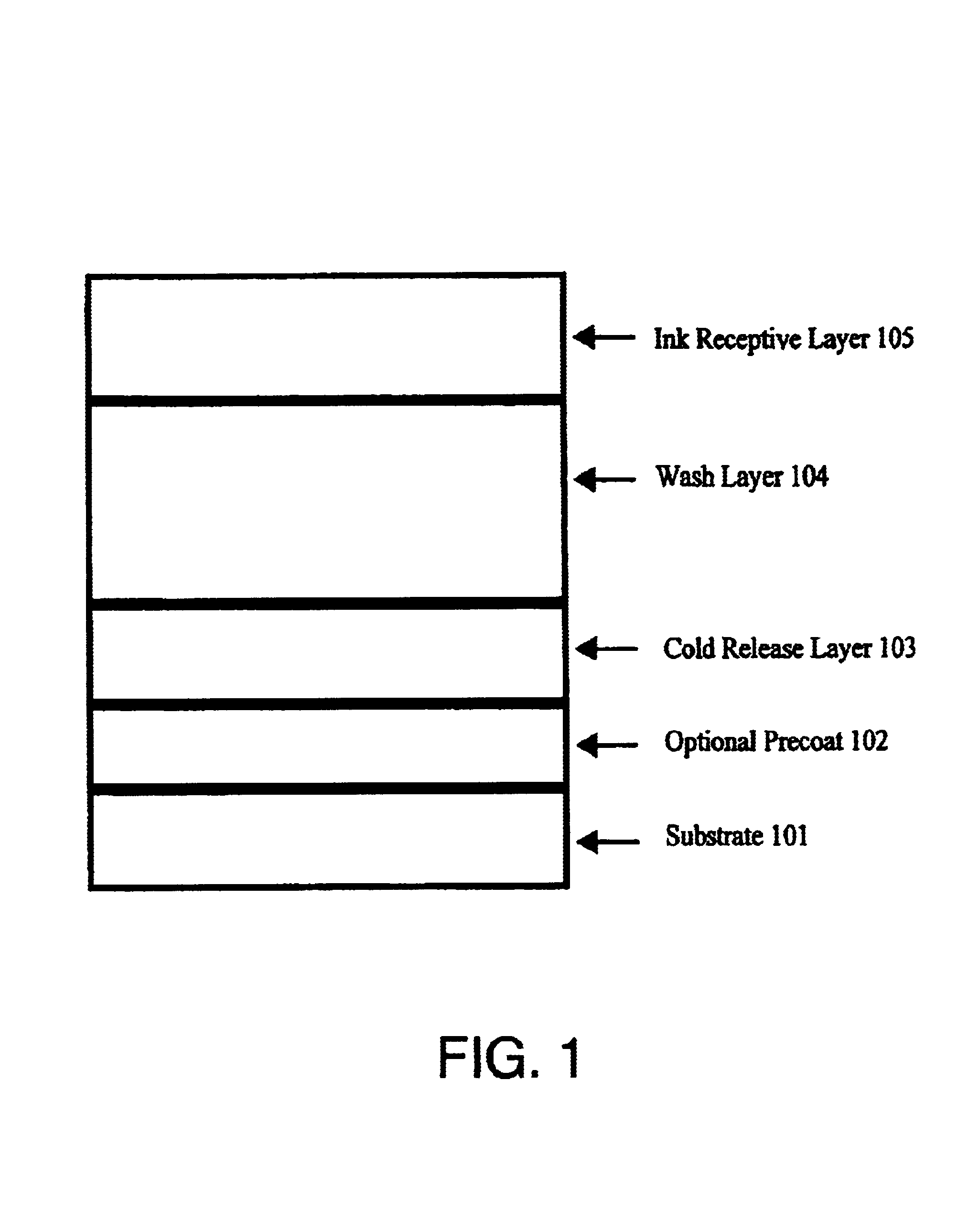

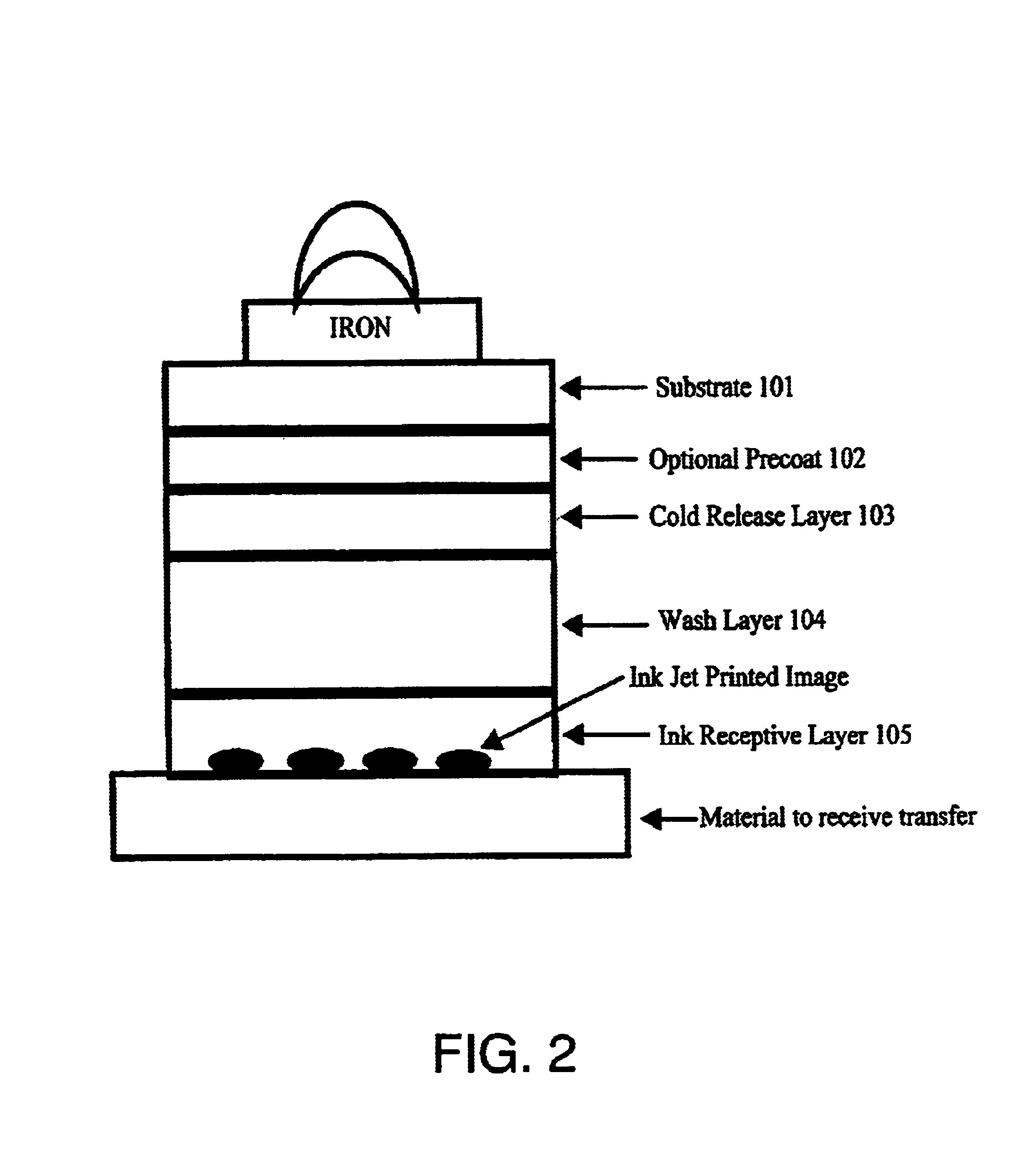

Ink jet printable heat transfer paper

InactiveUS6951671B2Quality improvementAbrasion excellentDecorative surface effectsTransfer printing processThermoplasticAntioxidant

This patent describes an ink jet printable heat transfer material with cold release properties. The invention consists of multiple layers of coatings applied to a suitable substrate, typically paper. The first optional layer coating consists typically of a pigmented coating bound together with a synthetic or natural binder and is applied in sufficient quantity to level and densify the surface of a given substrate. The second coating is applied over the first and consists of a silicone coating with a controlled surface energy. The surface energy must be such that the subsequent aqueous coatings can be applied over top with good wetting and adhesion, but low enough for an easy removal from the heat transfer after cooling. A third or wash layer is applied over the silicone release layer. This layer must easily wet and adhere to the silicone release layer so the coating does not come off during subsequent coating passes and during handling by the user. The wash layer consists of one or more thermoplastic polymers including ethylene acrylic acid, waxes, and other polymers along with dispersions of non-water soluble plasticizers and antioxidants. An ink receptive layer consists of a low binder thermoplastic organic pigmented coating containing non-water soluble plasticizers and antioxidants along with water soluble and insoluble cationic polymers and / or cationic inorganic pigments. The non-water soluble cationic materials, either organic or inorganic, aid in the retention of the dyes and reduce the wet bleed and wash out of the dyes when the transfers get wet.

Owner:P H GLATFEITER +1

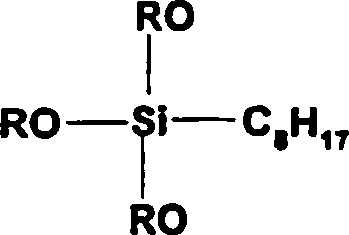

Interpolymer latex of polystyrene and acrylic ester in hud polymerization type, and preparation method

This invention relates to a core-shell polystyrene-acrylate copolymer emulsion, which comprises: emulsifiers 0.2-1.5 wt.%, monomers 45-55 wt.%, initiator 0.1-0.3 wt.%,, pH regulator 0.1-0.2 wt.%, and deionized water as balance. The emulsifiers are two or three of anionic emulsifier, nonionic emulsifier and functional allyloxy hydroxypropyl sulfonate emulsifier. The monomers are soft monomer, hard monomer and functional silane monomer containing epoxy groups and oxy groups. The solid content of the emulsion is 48-52%, the glass transition temperature of the core is 25-35 deg.C, and the glass transition temperature of the shell is (-5)-5 deg.C. The emulsion has such advantages as high wet adhesivness of the coating film and high washing resistance of the coating film.

Owner:CHANGZHOU GUANGHUI CHEM +1

Composite materials

InactiveUS20070082172A1Acceptable sound-absorbent propertyReduce usageSynthetic resin layered productsLaminationFiberWater based

A noise reducing composite material for use in automotive applications, and methods for preparing the material, are disclosed. The composite includes a carpet layer and a noise reducing layer. The carpet layer can be a tufted carpet layer that includes a primary backing in which to position tufts of yarn, and a latex layer to lock in the tufts of yarn, or a nonwoven carpet layer with a coating of latex to lock in the fibers. The noise reducing layer is adhered to the carpet layer. The latex layer includes, as an additive, an adhesive of sufficient type and quantity to adhere the noise reducing layer to the carpet layer. Latex dispersions including such additives, which can be used to form the latex layer in the composite material, are also disclosed. Examples of noise reducing layers include heavily filled EVA, shoddy, and foam layers. For adhering shoddy and / or foam layers, the additive in the latex layer is a polyolefin, such as polyethylene. For adhering filled EVA layers, the additive in the latex layer is a water-based adhesive such as an ethylene acrylic acid ammoniated dispersion. The composite carpet materials described herein represent an improvement over the existing carpet materials, in that they can be manufactured using wet steps, without the need for organic solvents, and reduce the number of process steps by eliminating the need for an extruded polyethylene layer.

Owner:MALLARD CREEK POLYMERS

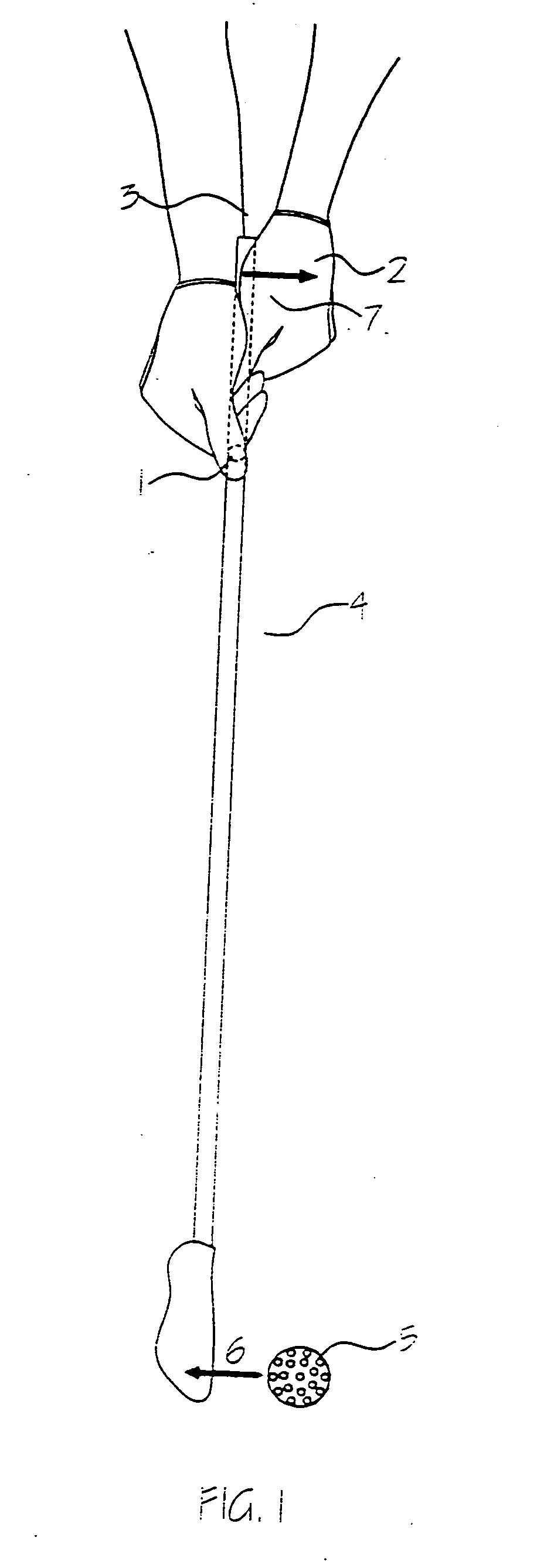

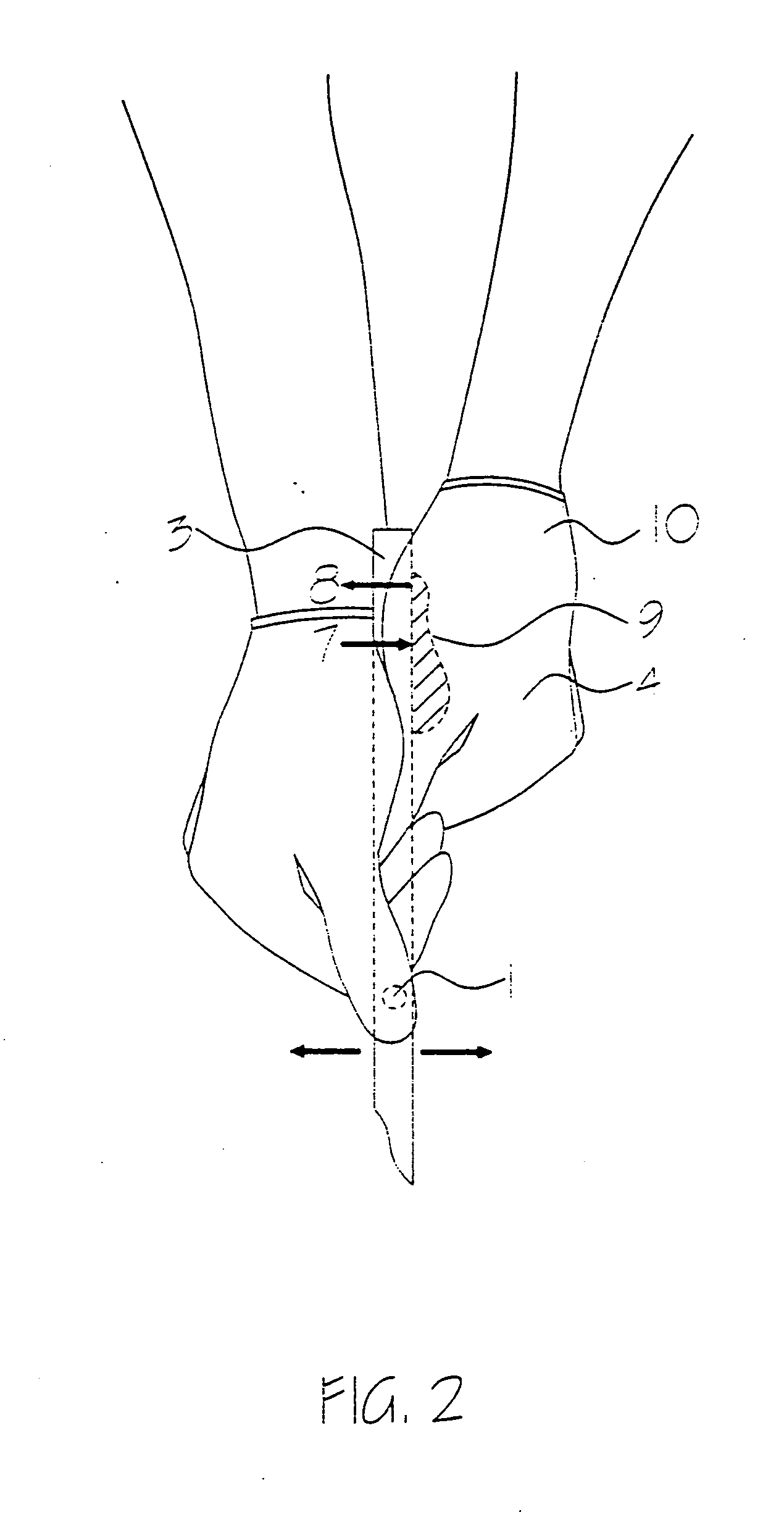

Golf glove with action/anti-action device

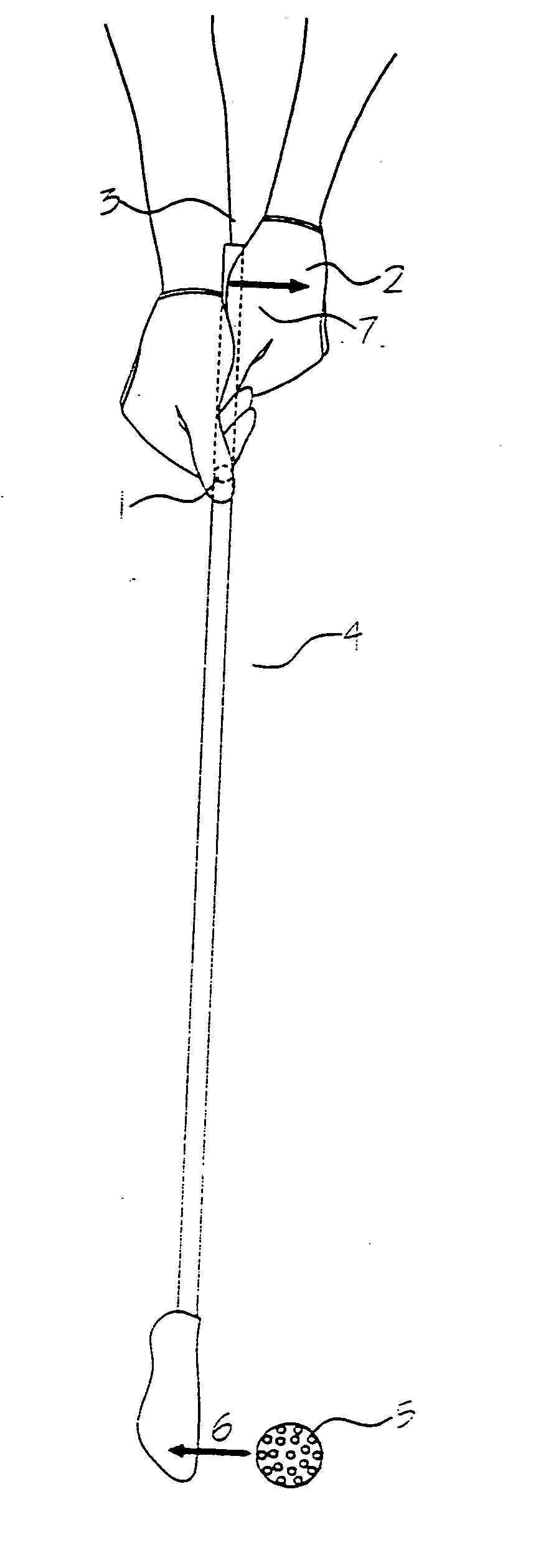

InactiveUS20050229285A1Flying distance can be improvedIncrease distanceGlovesSport apparatusElastomerRepulsion force

A golf glove for increasing the flying distance of golf ball has an insert that provide a repulsion forces to the grip of a golf club when the head of the club impacts a golf ball. The insert is made of synthetic elastomer such as polyurethane, silicon rubber, EVA (Ethylene Vinyl Acetate copolymer, EMA (Ethylene Methyl Acetate copolymer), or EAA (Ethylene Acrylic Acetate copolymer). The insert has a planar shape that fits to the concave inner surface of human palm. The insert is firmly attached to the inner surface of the palm side of a golf glove.

Owner:CHUNG PAUL HOON

Environmentally-friendly photocatalyst air freshening inner wall coating and preparation method thereof

InactiveCN102329544AEfficient antibacterial and antibacterialTo achieve the purpose of anti-pollution and easy cleaningCoatingsPollutionAnatase

The invention discloses an environmentally-friendly photocatalyst air freshening inner wall coating and a preparation method thereof. The coating comprises the following raw materials in percentage by weight: 20-40 percent of silicone-acrylic emulsion or ethylene-acrylic acid copolymer emulsion, 1-5 percent of anatase-phase nano-titanium dioxide, 2-2.5 percent of negative ion generating material, 1-2 percent of wetting agent, 0.5-1 percent of dispersing agent, 1 percent of preservative, 1 percent of pH regulating agent, 1-2 percent of anti-freezing agent, 1-2.5 percent of diatomite, 1-2 percent of film forming aid, 1-2 percent of thickening agent and the balance of water. In the coating, a photocatalysis material and the negative ion generating material are used, so that indoor air pollution can be eliminated effectively, and the coating has the advantages of stable lasting effect and avoidance of secondary pollution.

Owner:ANHUI MEIJIA NEW MATERIAL

Preparation of neutralized ethylene-acrylic acid polymer dispersions and use in printing media for improvement of digital toner adhesion

ActiveUS7279513B2Improve adhesionLayered productsTransportation and packagingOrganic chemistryAqueous dispersion

Aqueous dispersions comprising one or more ethylene-acrylic acid polymers and an effective dispersing amount of one or more N,N-dialkylalkanolamines are useful for preparing substrates for use in electrophotographic or digital offset printing processes.

Owner:ECOLAB USA INC

Blends of Styrene Butadiene Copolymers with Ethylene Acrylate Copolymers and Ethylene Based Wax for Asphalt Modification

The present invention is a polymer-modified asphalt composition comprising an elastomeric polymer blend, a low molecular weight plastomer and an un-modified asphalt. Asphalt compositions of the present invention demonstrate improved elasticity and stiffness compared to conventional polymer-modified asphalt compositions.

Owner:PERFORMANCE MATERIALS NA INC

Stress/Thermal Cracking Resistant Cable Sheath Material

InactiveUS20100101822A1Improve the immunityPlastic/resin/waxes insulatorsInsulated cablesCrazingEthyl acetate

A composition useful as a wire or cable insulation or sheathing layer, the composition comprising (i) an inorganic flame retardant, e.g., aluminum trihydroxide (ATH), (ii) ethylene ethyl acetate (EEA) or ethylene butyl acrylate (EBA), (iii) a homogeneous polyethylene, (iv) an ethylenic resin modified with an organo-functional group, e.g., maleic anhydride (MAH) grafted polyethylene, (v) a silicone polymer, and optionally, (vi) a smoke suppressant. The insulation or sheathing layer comprising the composition of this invention exhibits good resistance to stress and / or thermal cracking.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com