Biaxial tension co-extrusion high-obstruct base material membrane and process for preparing the same

A technology of biaxial stretching and substrate film, which is applied in the field of plastic molding materials, can solve the problems of high manufacturing cost, achieve the effects of extended shelf life, good heat sealability, and resource protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

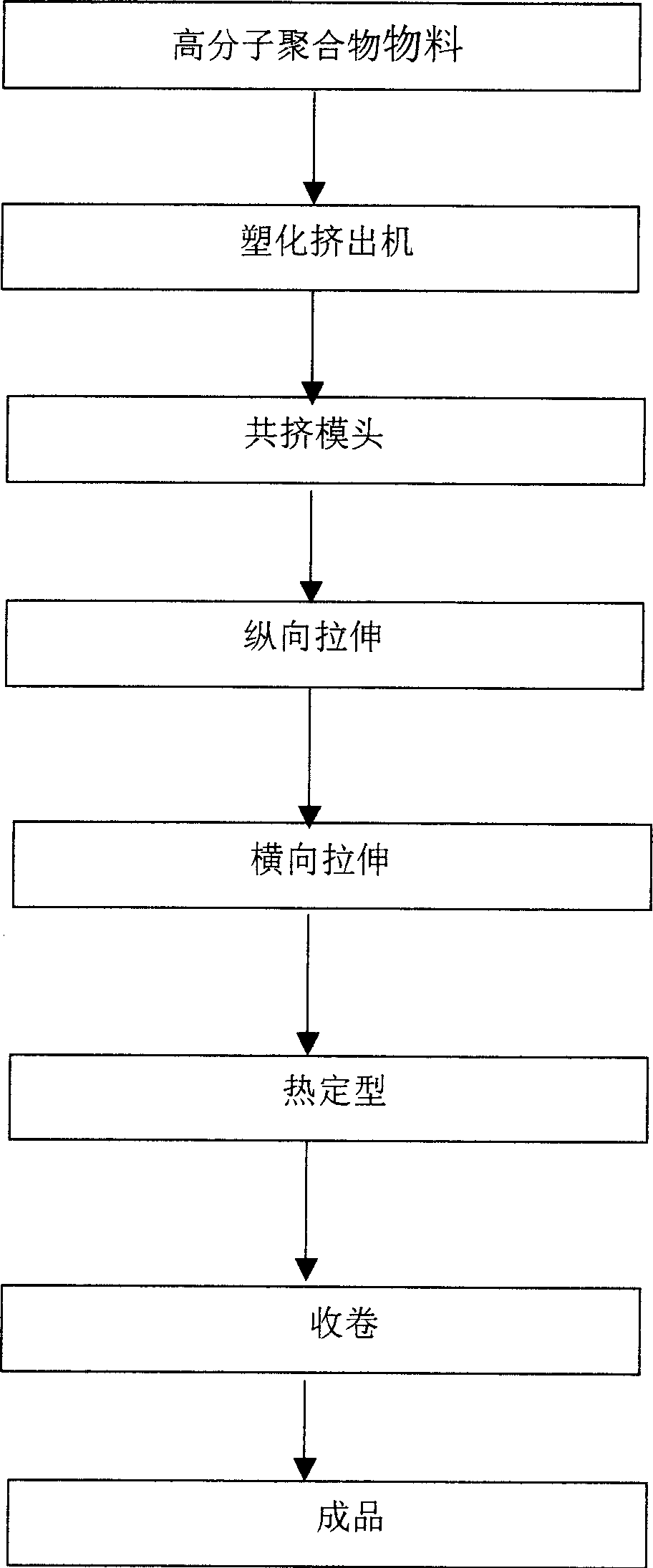

[0040] figure 1 It is a block diagram of the preparation method and process of the biaxially stretched multilayer co-extruded high-barrier substrate film of the present invention. Generally, more than three extruders extrude several different resins, enter the machine head for composite co-extrusion, and then Longitudinal and transverse stretching and heat setting are carried out separately or simultaneously to obtain the biaxially stretched multilayer co-extruded high-barrier substrate film of the present invention.

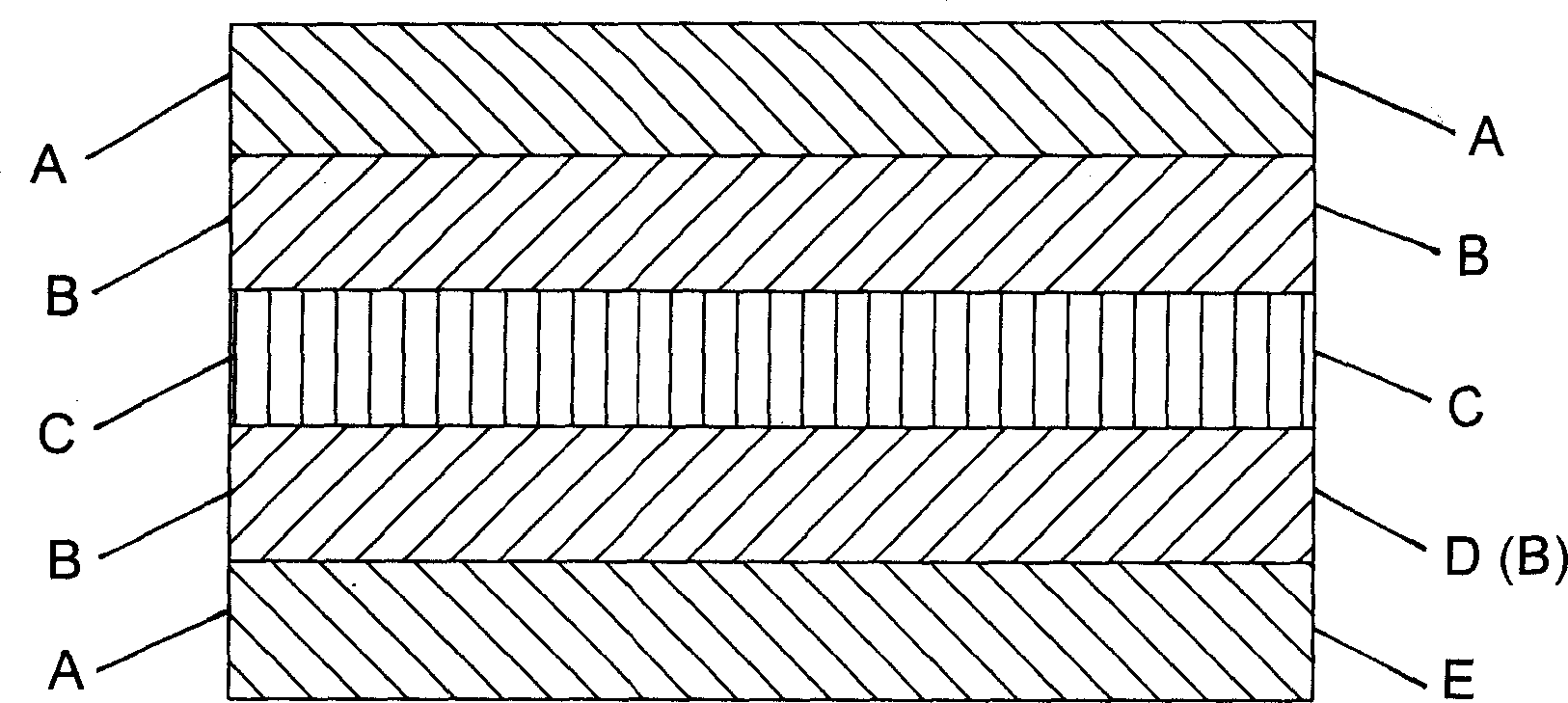

[0041] see figure 2 Left label, cross-sectional view of the five-layer structure of the present invention, the two outer layers (layer A) are heat-sealing layers, which are made of LLDPE resin of 1018CA brand of Exxon Company of the United States, and the barrier layer C is made of nylon PA6 / 66 resin, made by BASF of Germany The brand produced by the company is C35EN, or 5034FDX40 of Ube, Japan, and the two layers of adhesive resin layer B adopts the ethylene-...

Embodiment 2

[0047] The same is a 5-layer structure, and the substrate film of the present invention can also be an asymmetric structure, see figure 2 The label on the right side, layer A is the first heat-sealing layer, the resin is made of PP resin with brand name HF400 of South Korea’s Samsung Company, the barrier layer C is made of German BASF C35FN or Japan’s Kuraly Company’s EVOH resin, brand G156B, and the adhesive resin is made of Japan’s Mitsui & Co. The adhesive resin produced, the second heat-sealing layer E is LDPE with the brand name FN810 of South Korea’s Samsung Company, and the film structure of the barrier substrate is an asymmetric A / B / C / D / E layered structure, wherein the materials of B and D are The production is the same, that is, the film is formed according to the structure of the material PP-HF400 / 571 / G156B (or C35FN) / 571 / N810LDPE, and the ratio of various materials is 10-25wt% / 5-10wt% / 5-45wt% / 5-10wt % / 10-25wt%, this ratio can also be thickness. See Example 1 for s...

Embodiment 3

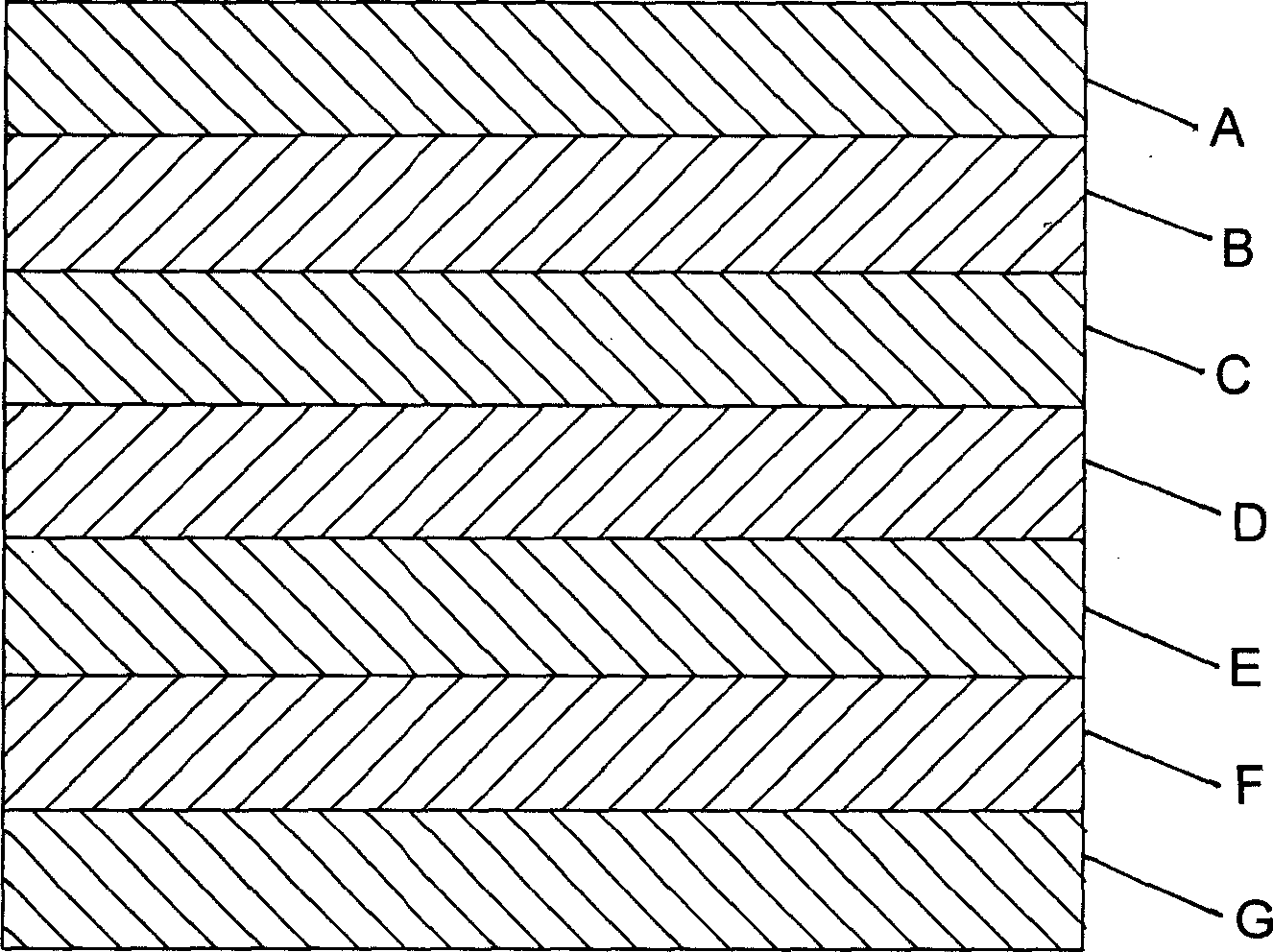

[0050] Resin selection is the same as Example 1 or Example 2, the structure is three-layer barrier layer PA6 / 66 / adhesive layer ethylene-ethyl acrylate copolymer resin / heat-sealing layer LLDPE, the ratio of each layer is 20-60% / 5-15% / 20 -60%. Such as Figure 4 shown. Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Stretch ratio | aaaaa | aaaaa |

| Longitudinal stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com