Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Reduce the formation of nitrogen oxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

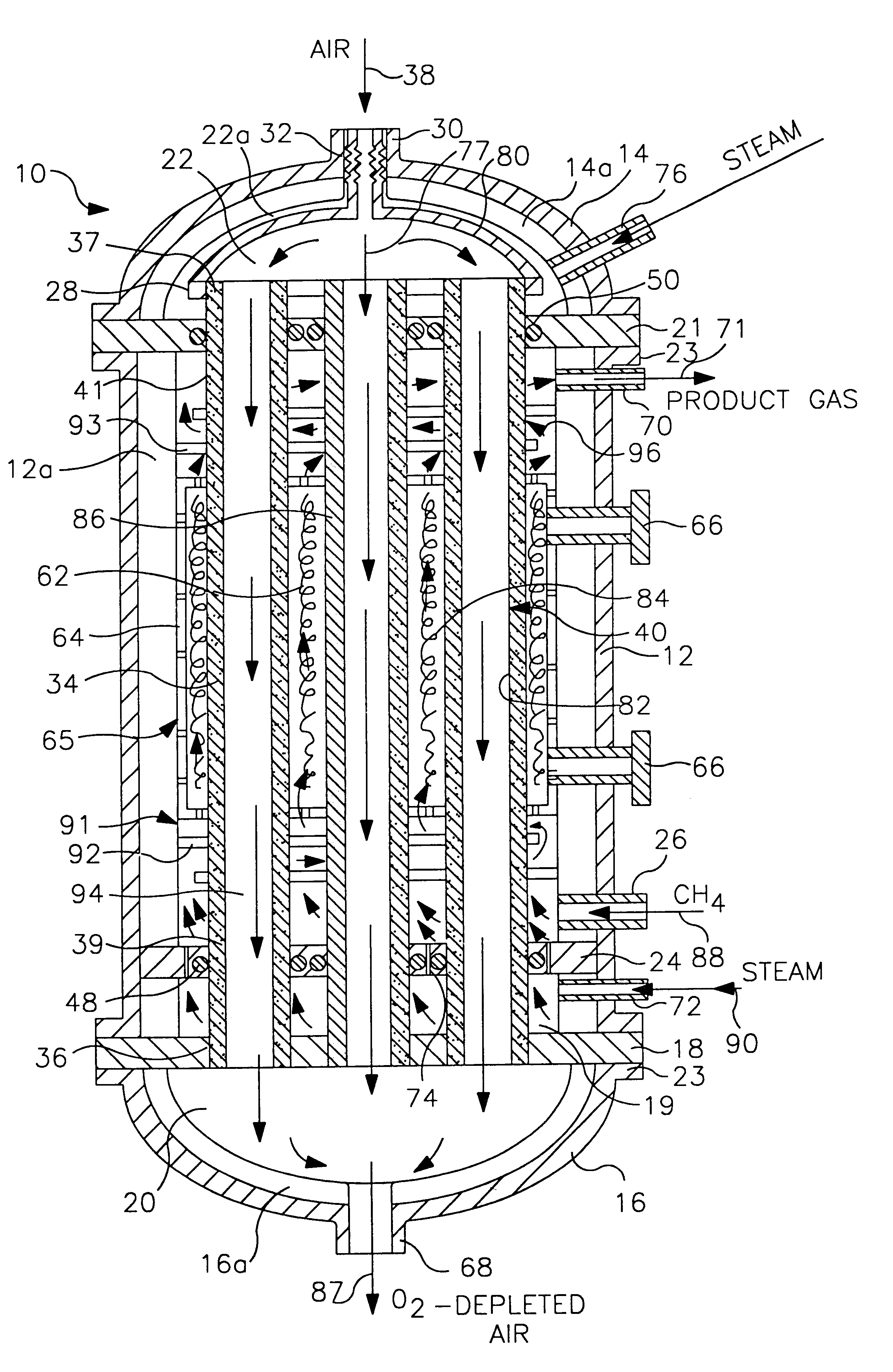

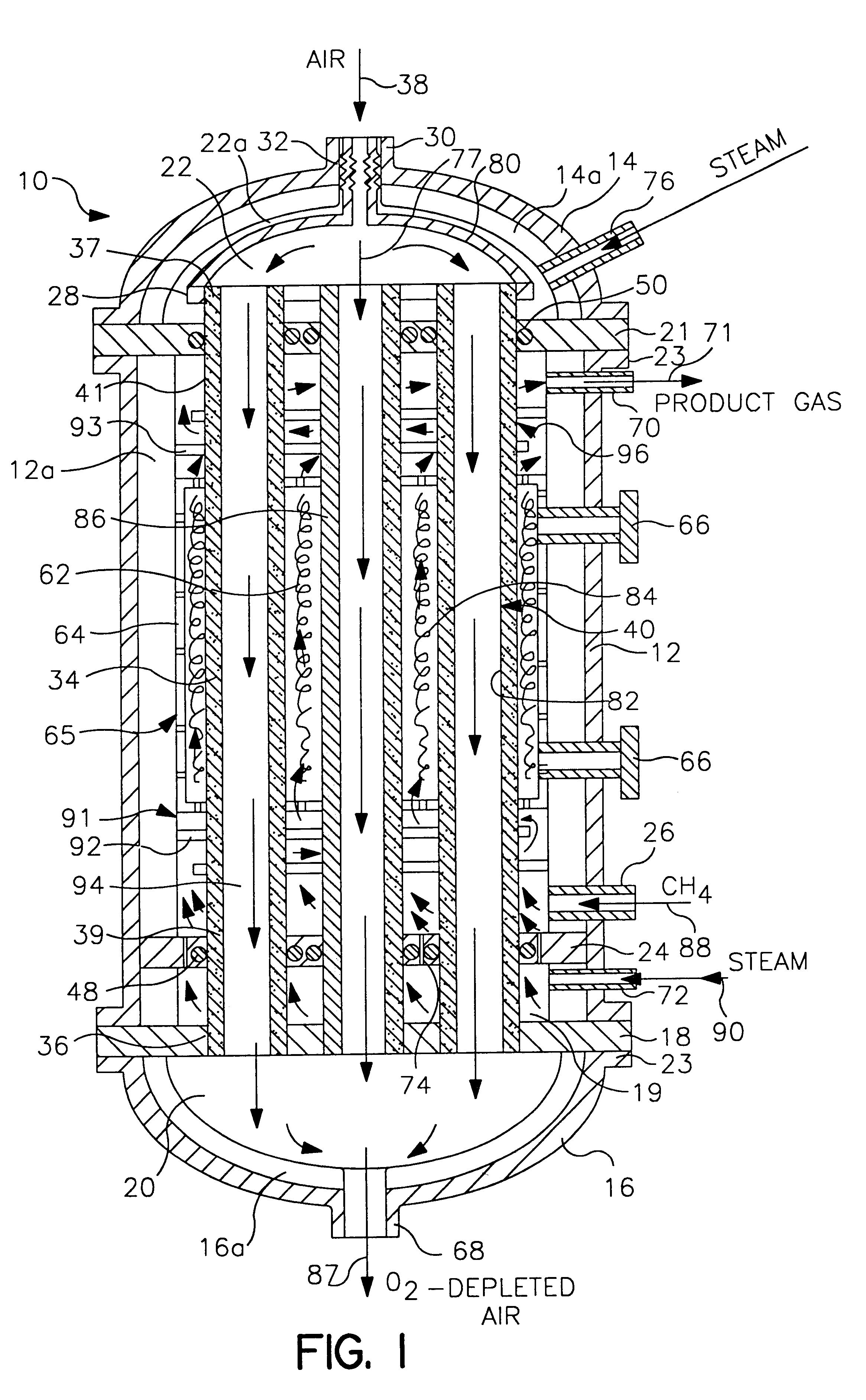

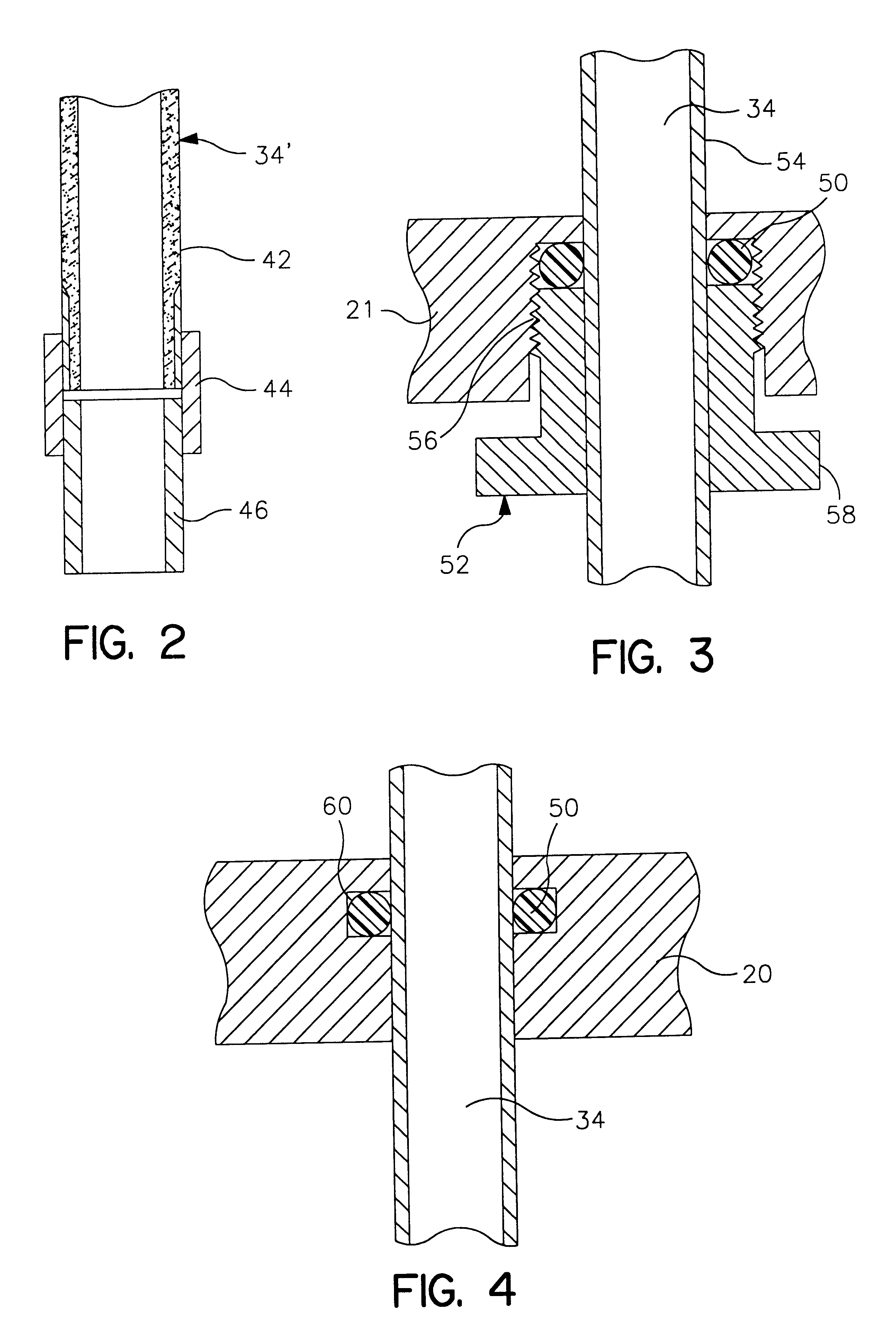

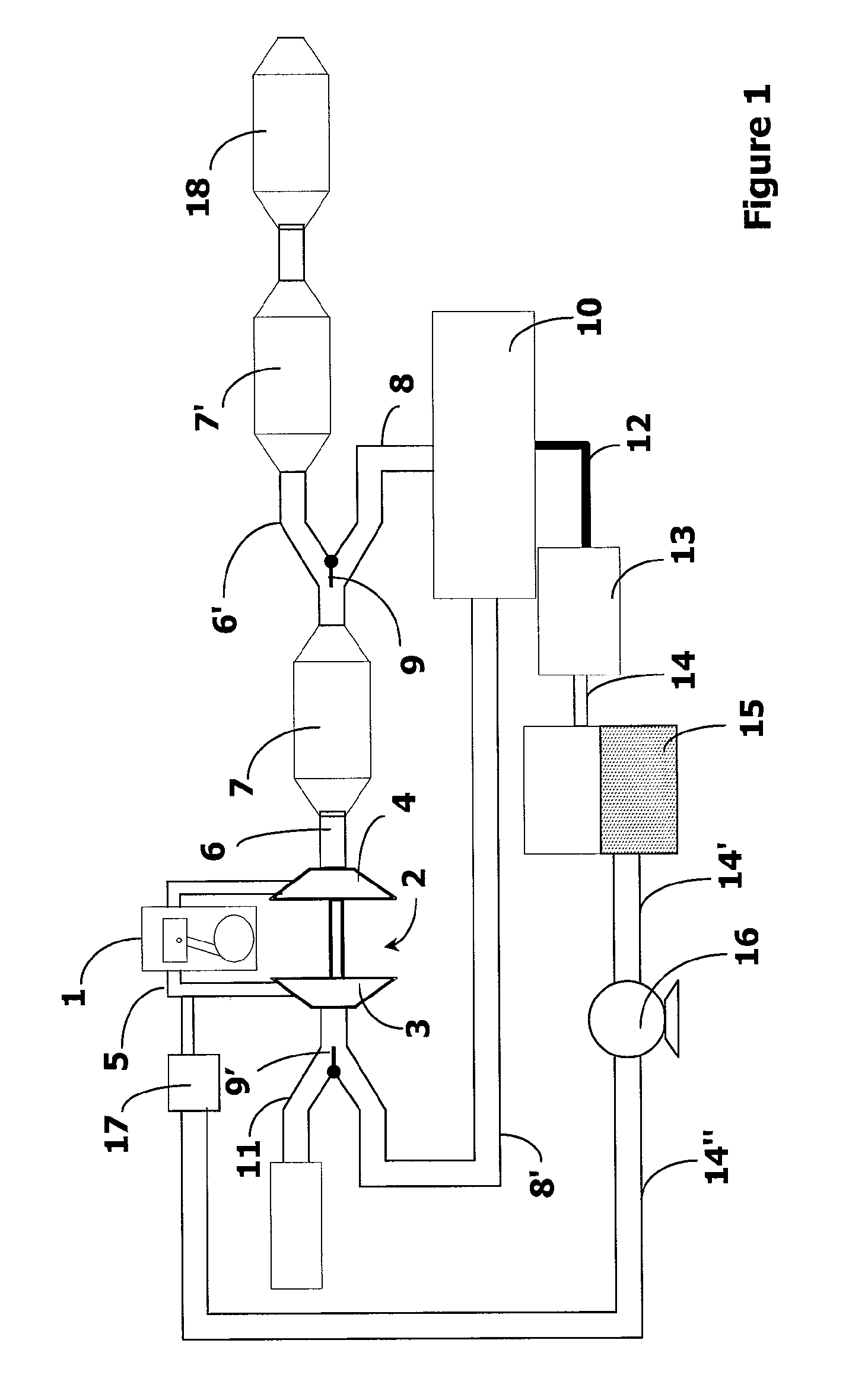

Process for producing a syngas

InactiveUS6402988B1Minimize the temperatures experienced by sealsMinimize pressure differenceCatalytic gas-gas reactionHydrogenSyngasReactor design

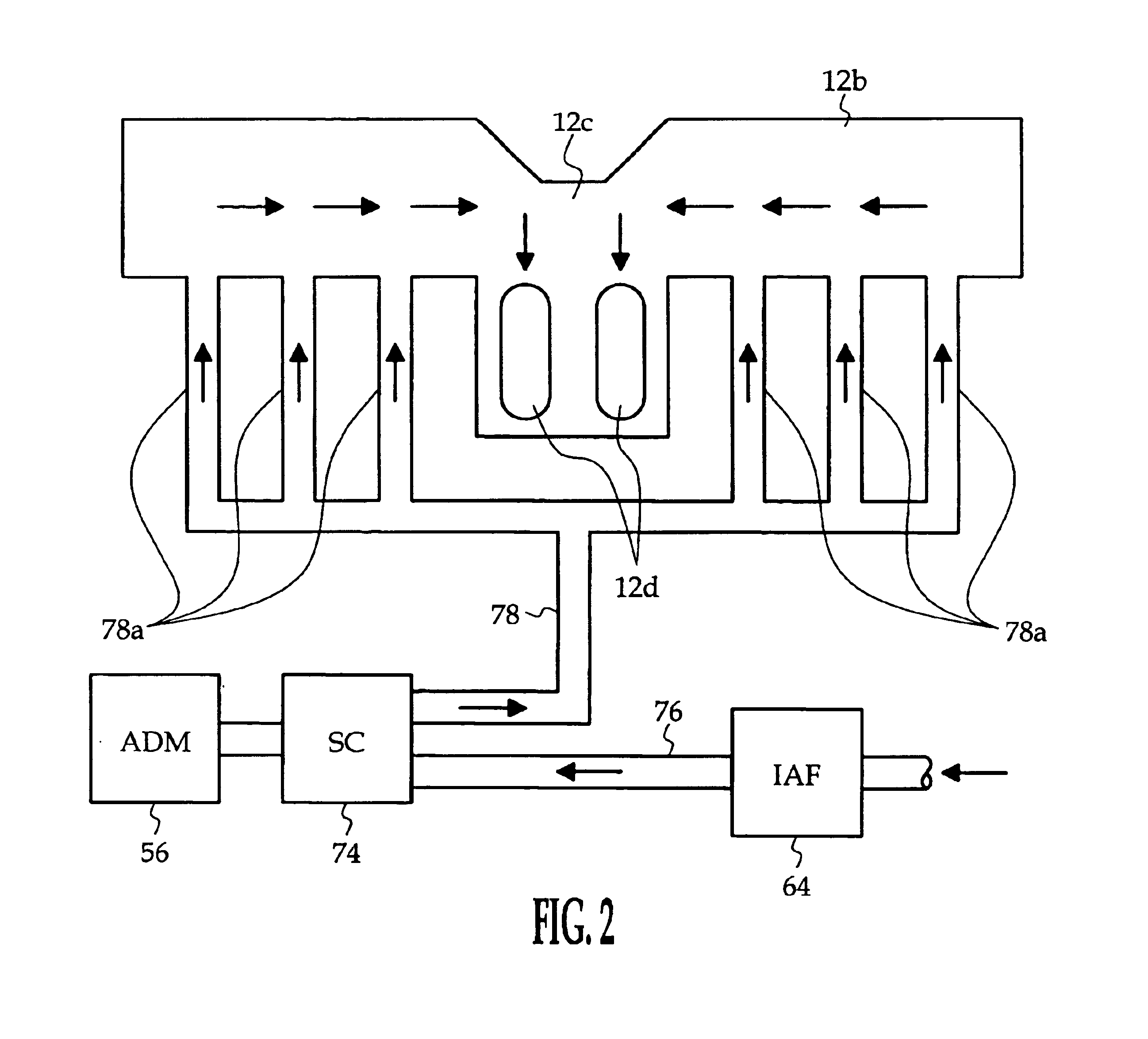

An exothermic reaction and an endothermic reaction are thermally combined in a reactor having at least one oxygen selective ion transport membrane that provides the exothermic reaction with oxygen from an oxygen-containing gas such as air. The thermal requirements of the endothermic reaction are satisfied by the exothermic reaction. Dependent on the reactor design employed, the exothermic and endothermic reactions may be gaseously combined.

Owner:PRAXAIR TECH INC +1

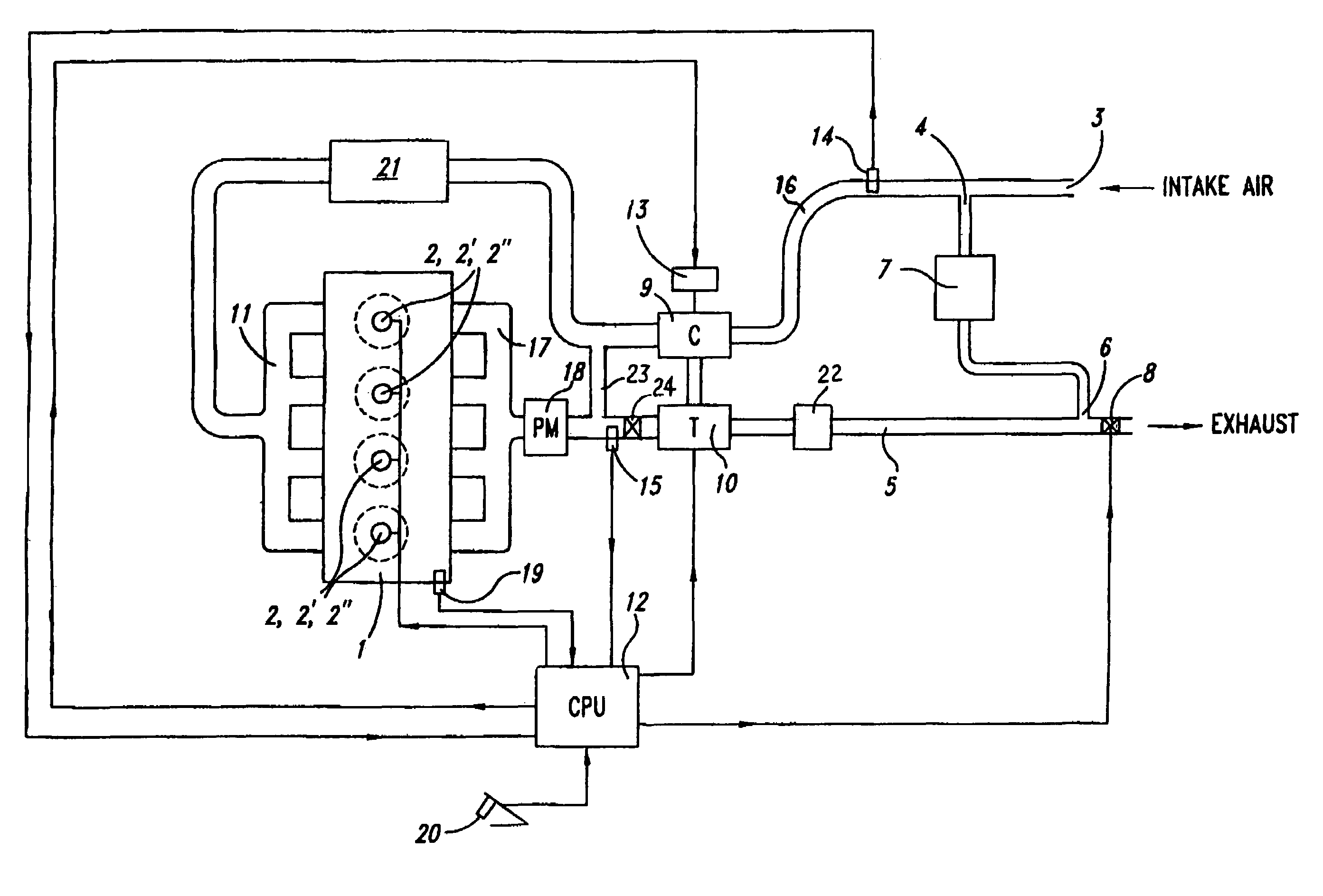

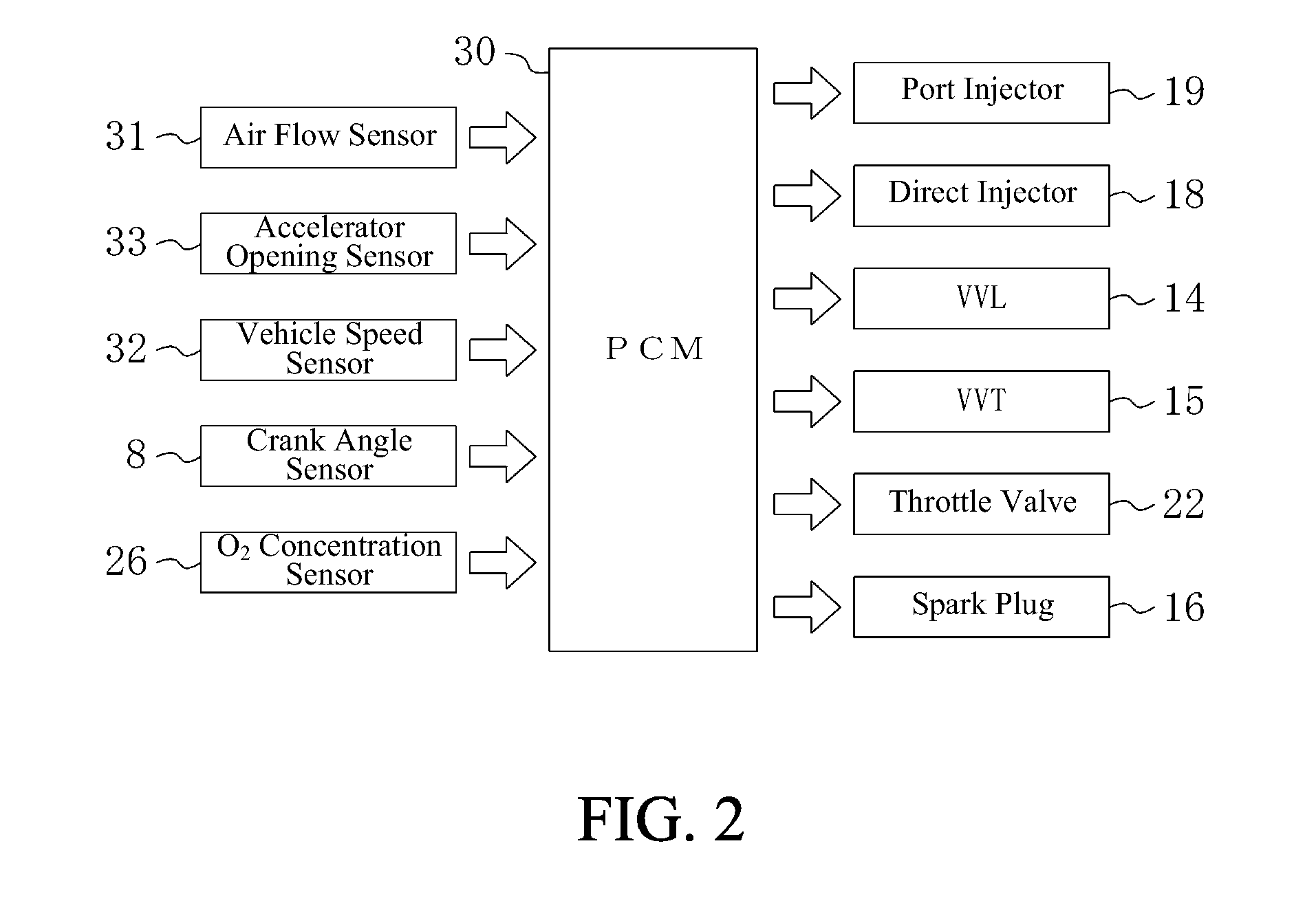

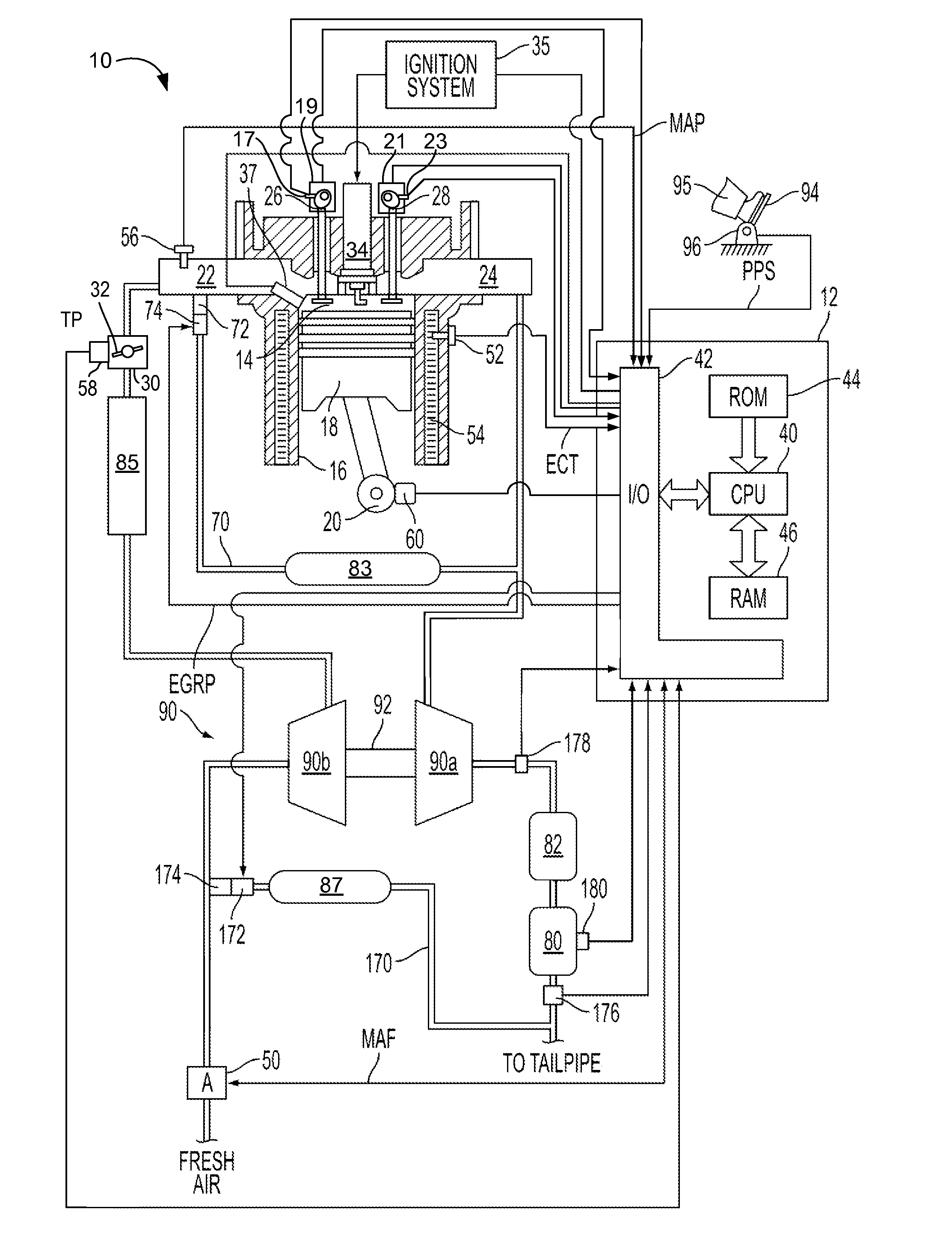

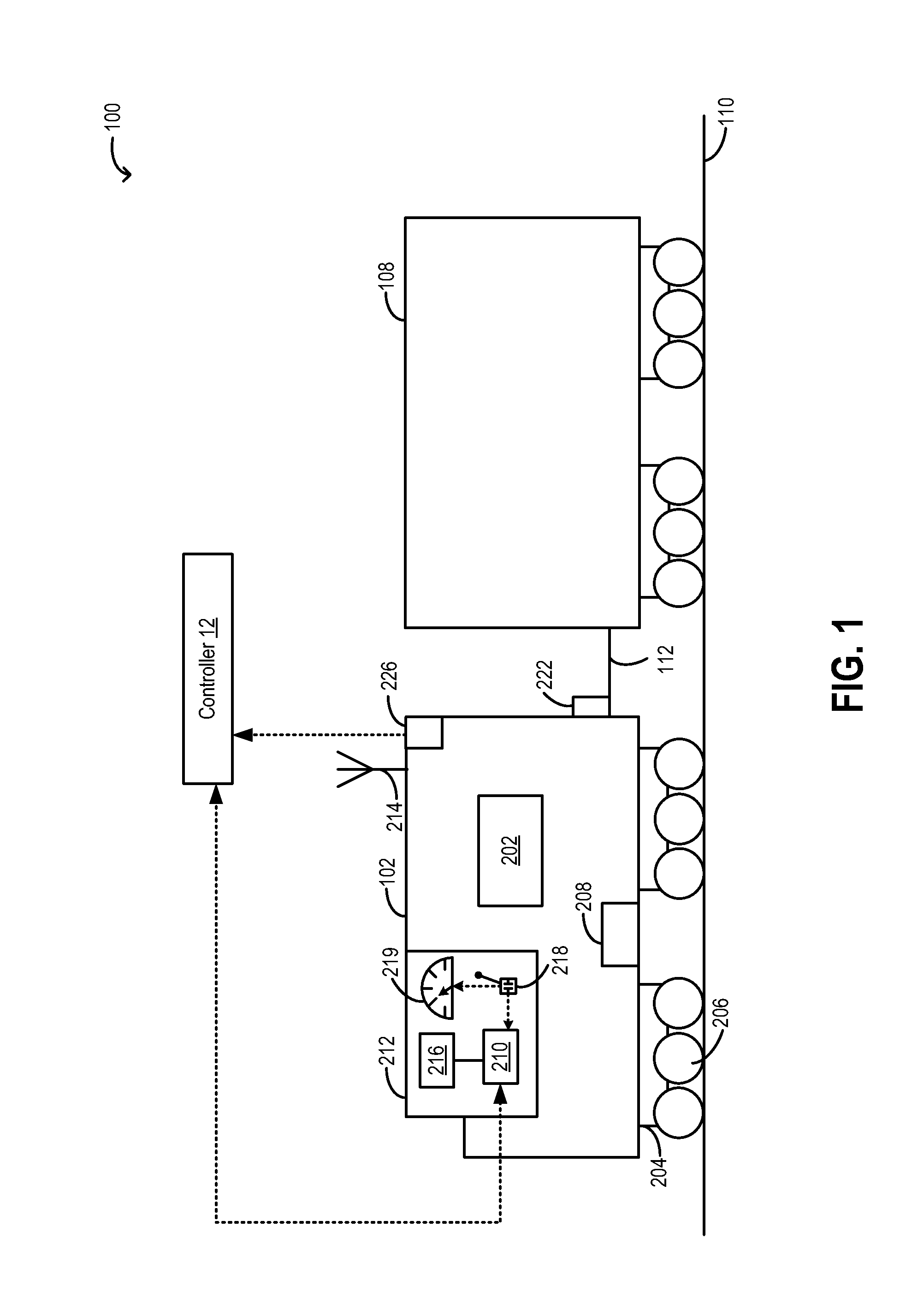

Control methods for low emission internal combustion system

InactiveUS7681394B2Cost-effectiveMaintaining NOx emissionsElectrical controlNon-fuel substance addition to fuelCombustion systemEngineering

Owner:US EPA OFFICE OF GENERAL COUNSEL UNITED STATES OF AMERICA THE

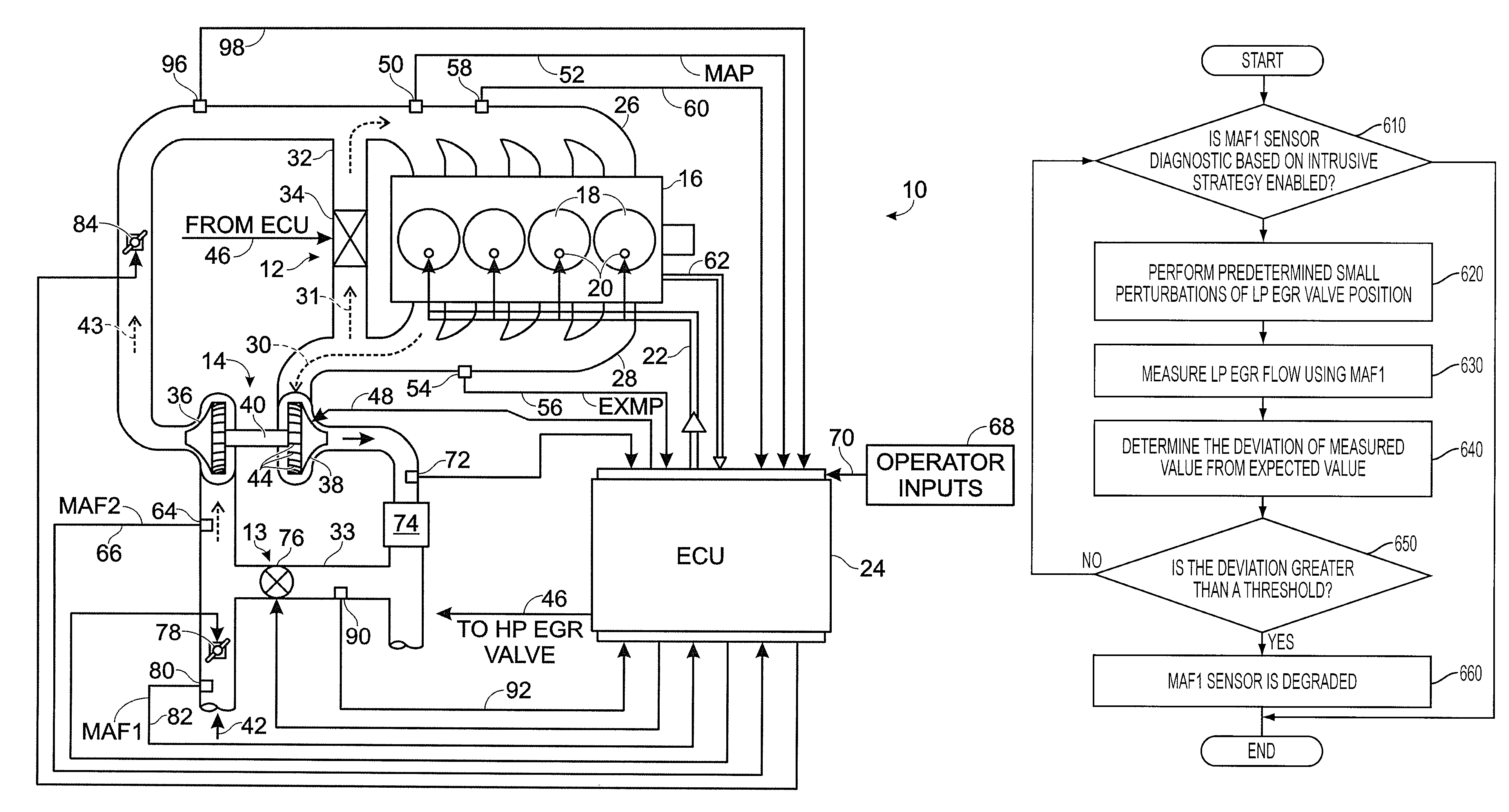

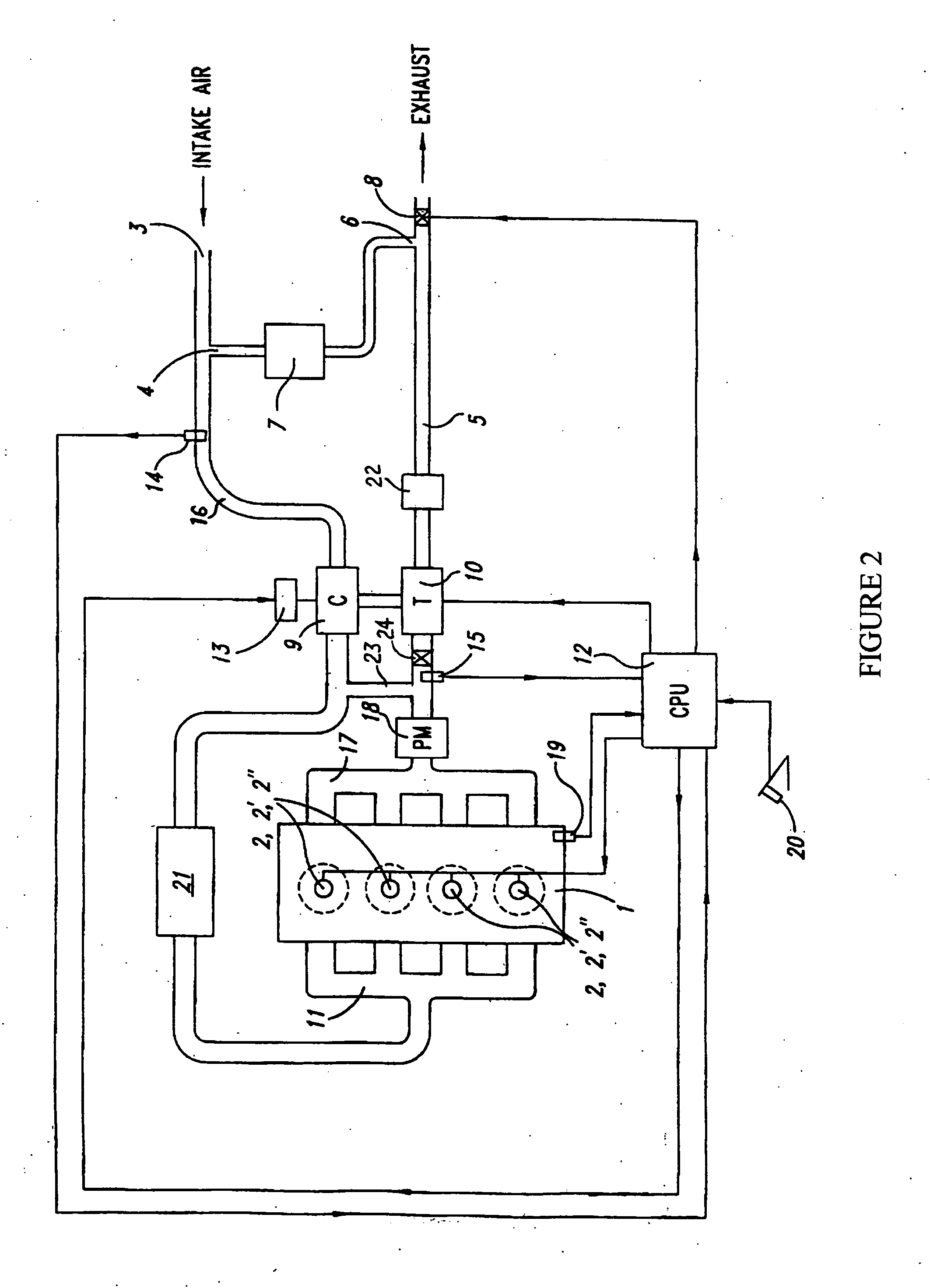

System and Method for Diagnostic of Low Pressure Exhaust Gas Recirculation System and Adapting of Measurement Devices

ActiveUS20080022677A1Reduce the formation of nitrogen oxidesImprove fuel economyVehicle testingElectrical controlMeasurement deviceTurbocharger

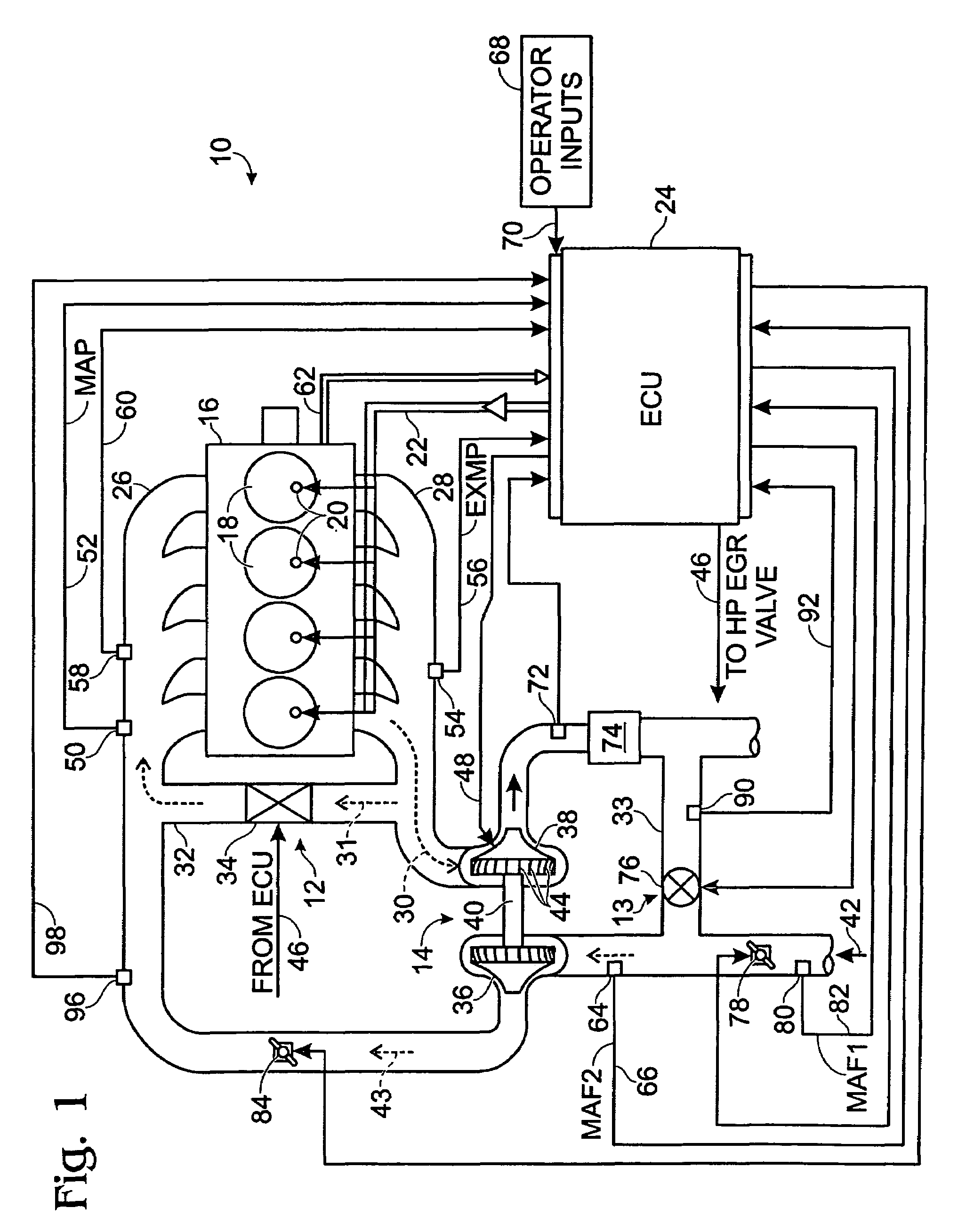

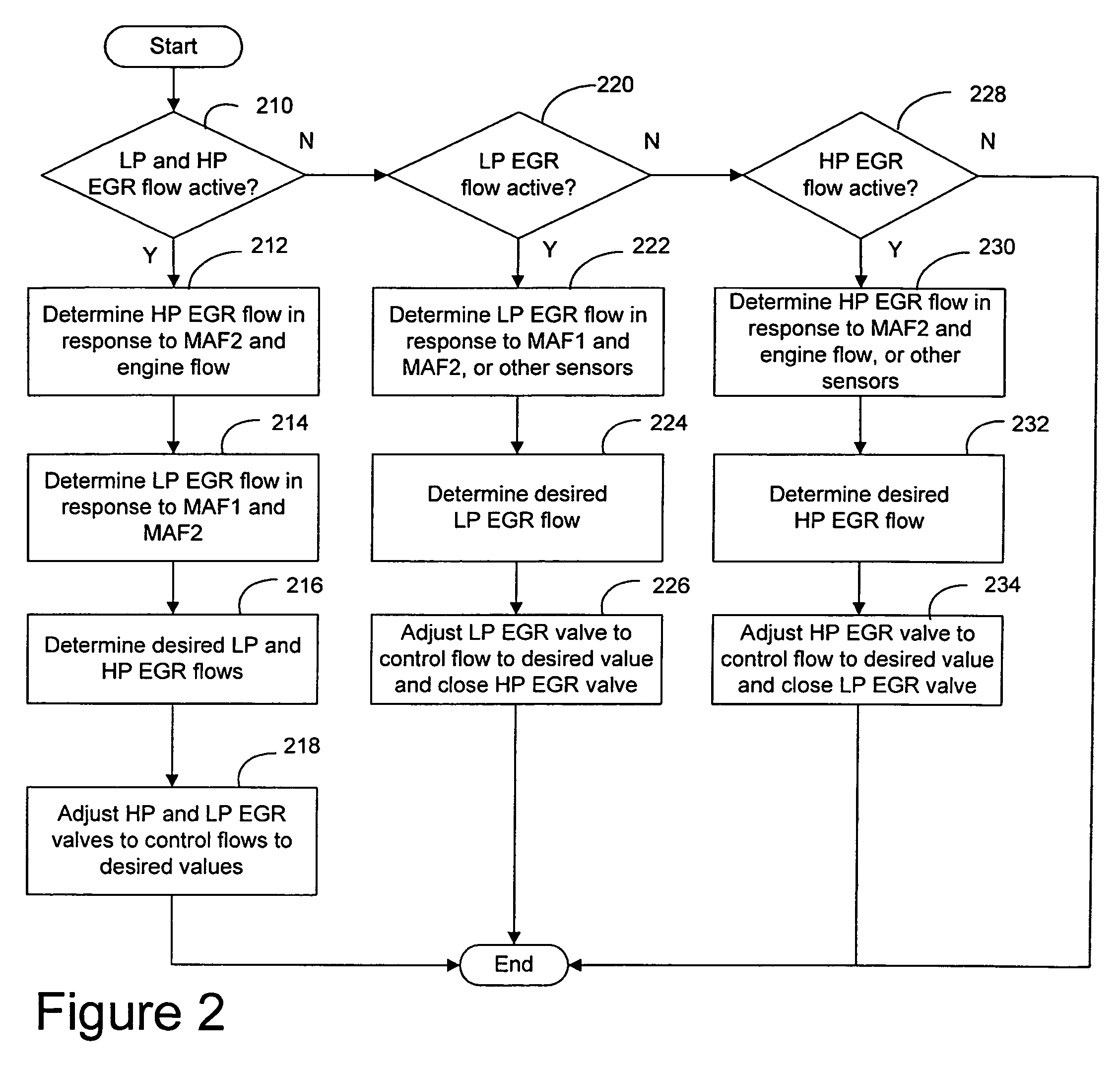

A system for a diesel engine having an intake manifold and an exhaust manifold, comprises a turbocharger between the intake and exhaust manifolds of the engine; a low pressure exhaust gas recirculation system with a first end coupled to the exhaust manifold downstream of the turbocharger and a second end couple to the intake manifold upstream of the turbocharger, said low pressure exhaust gas recirculation having a first valve coupled thereto for regulating flow; a high pressure exhaust gas recirculation system with a first end coupled to the exhaust manifold upstream of the turbocharger and a second end coupled to the intake manifold downstream of the turbocharger, said high pressure exhaust gas recirculation having a second valve coupled thereto for regulating flow; a first mass airflow sensor coupled in the engine intake manifold upstream of an inlet of said second end of said low pressure exhaust gas recirculation system; and a control system configured to diagnose the degradation of said first mass airflow sensor.

Owner:FORD GLOBAL TECH LLC

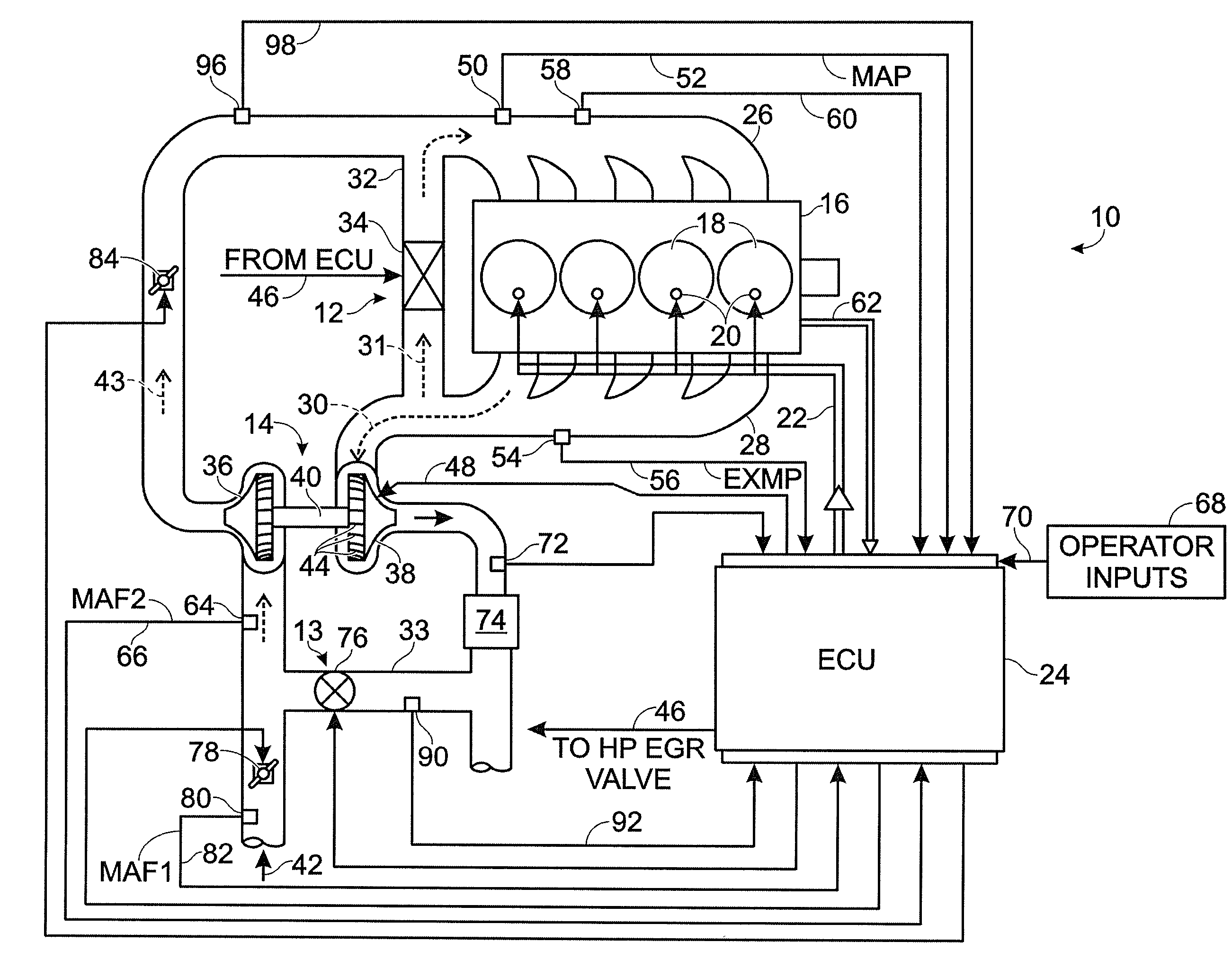

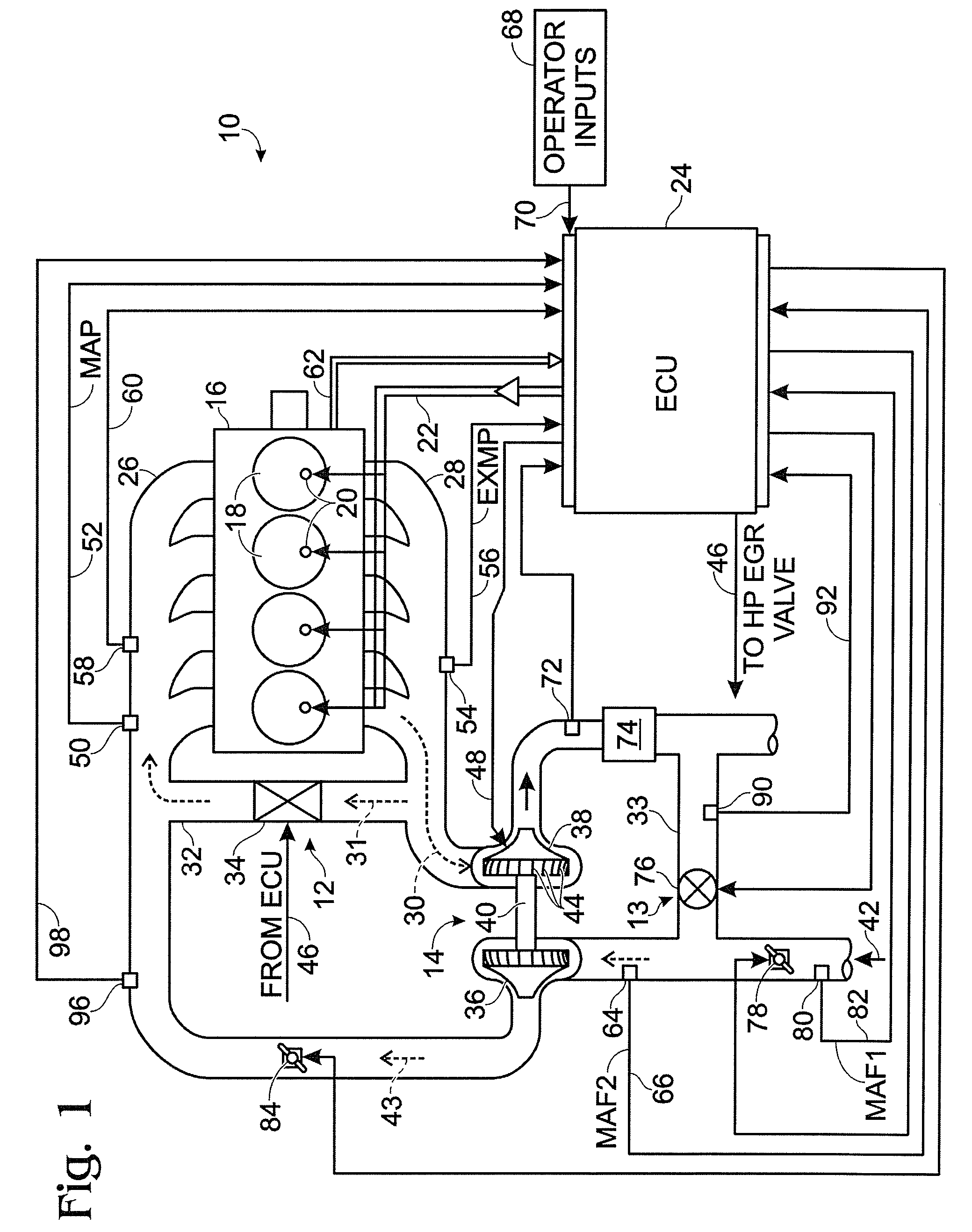

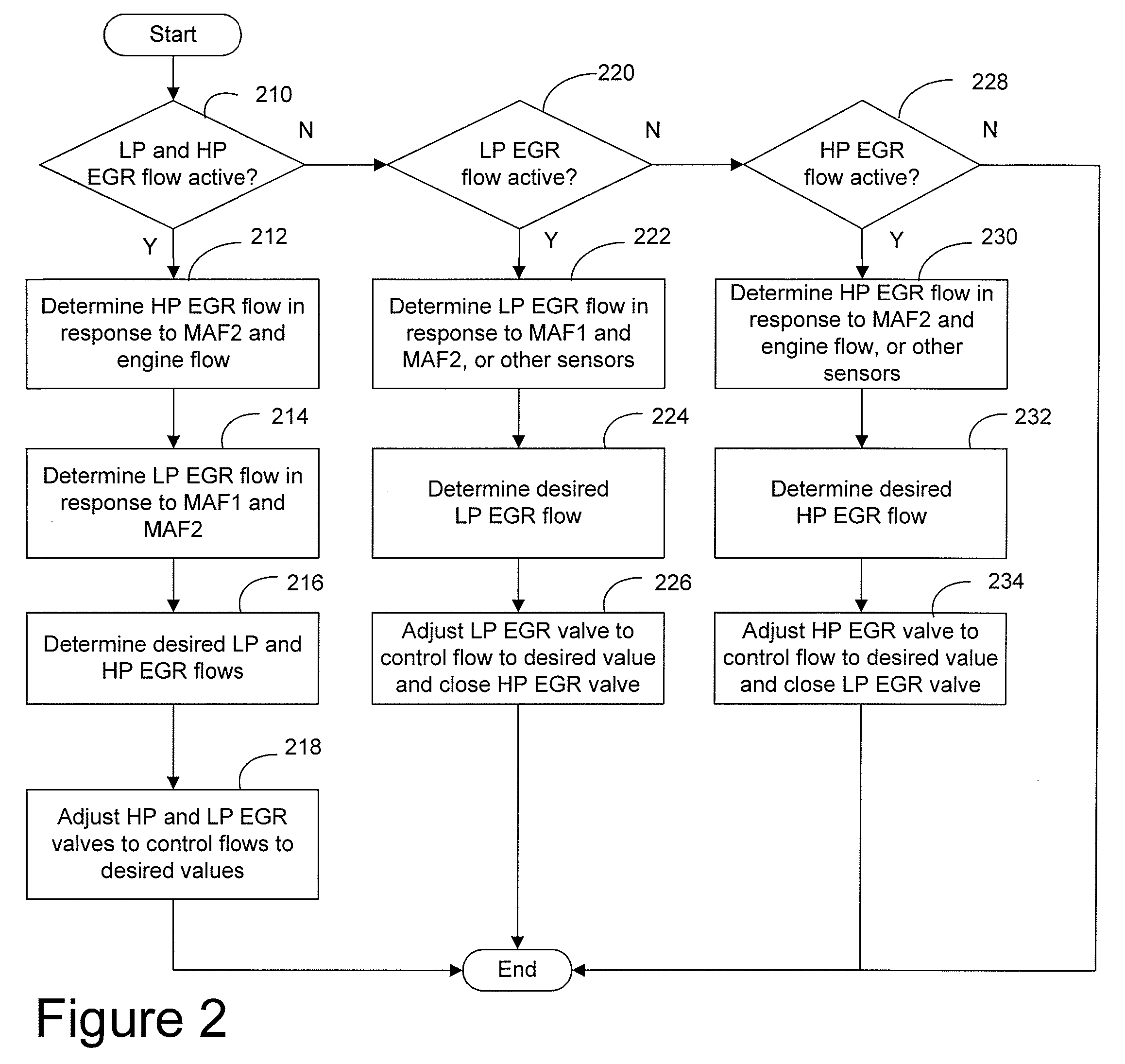

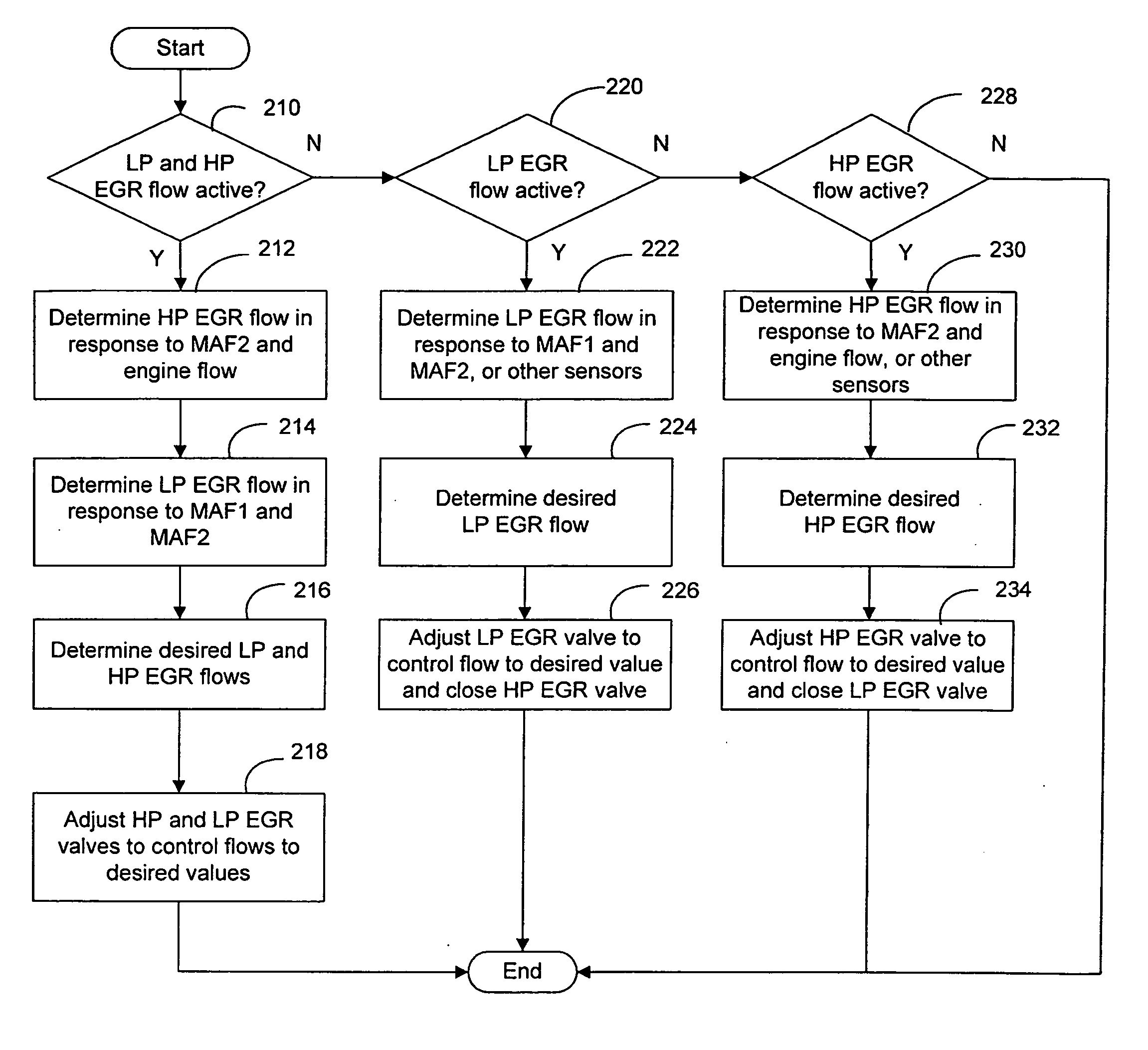

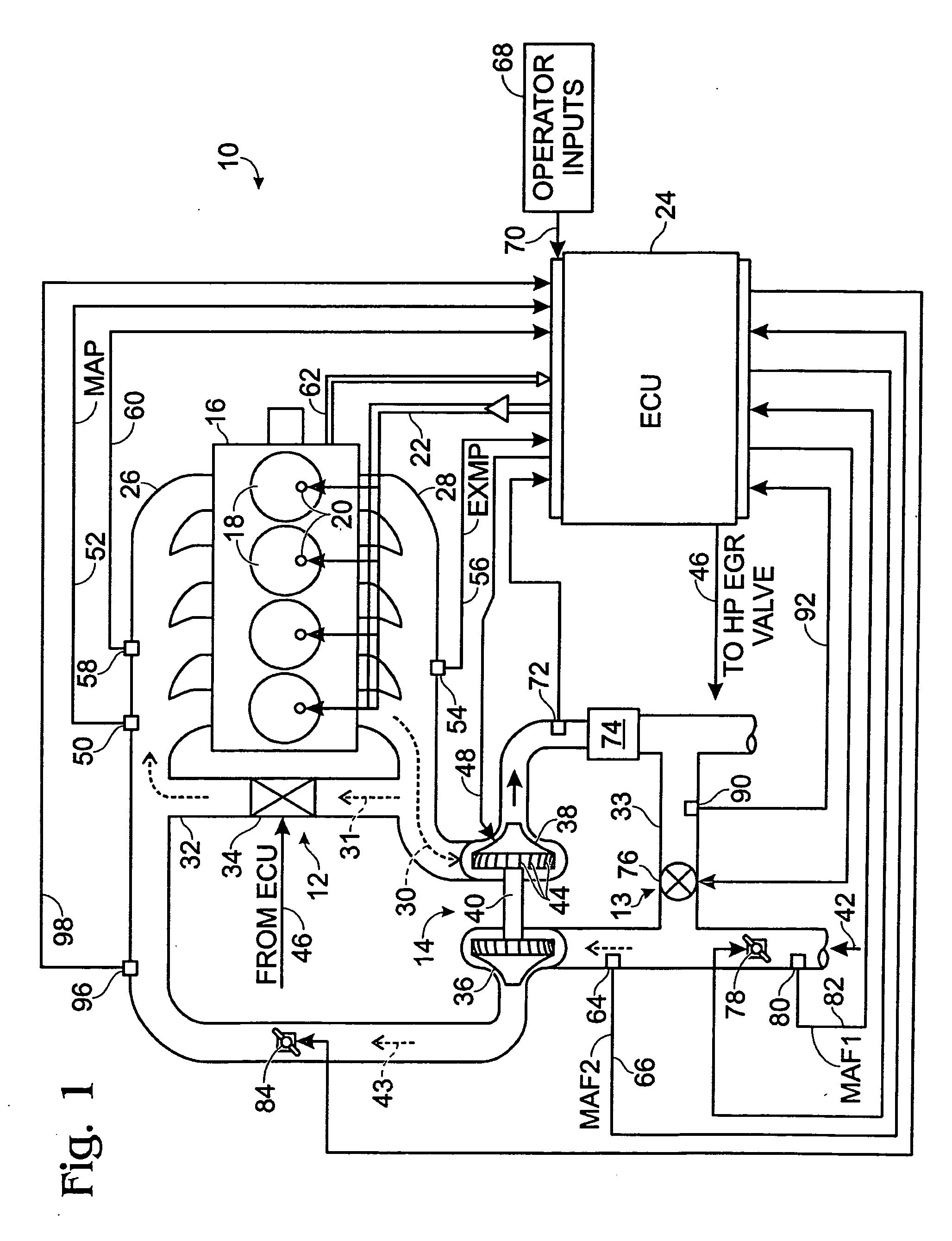

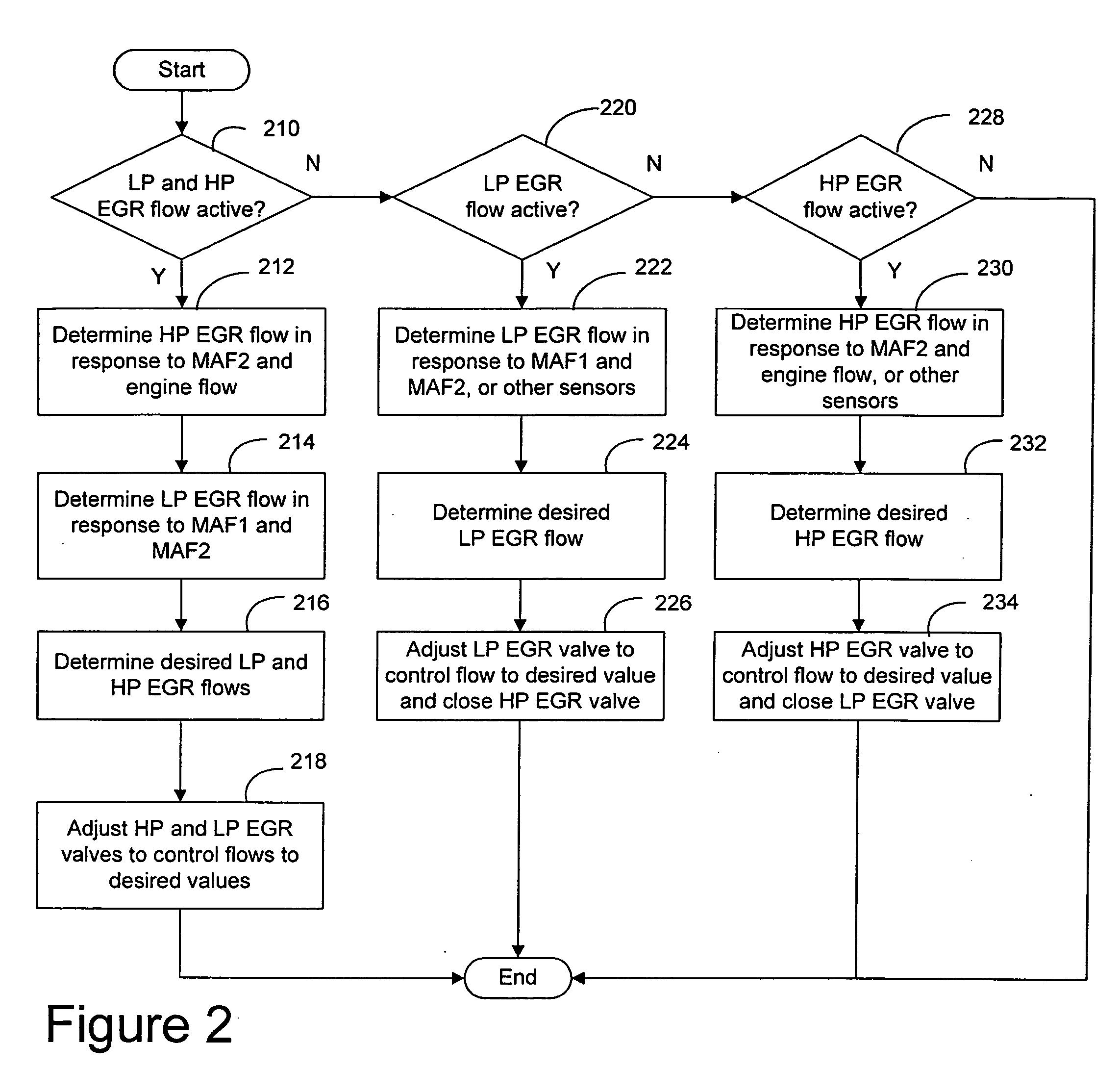

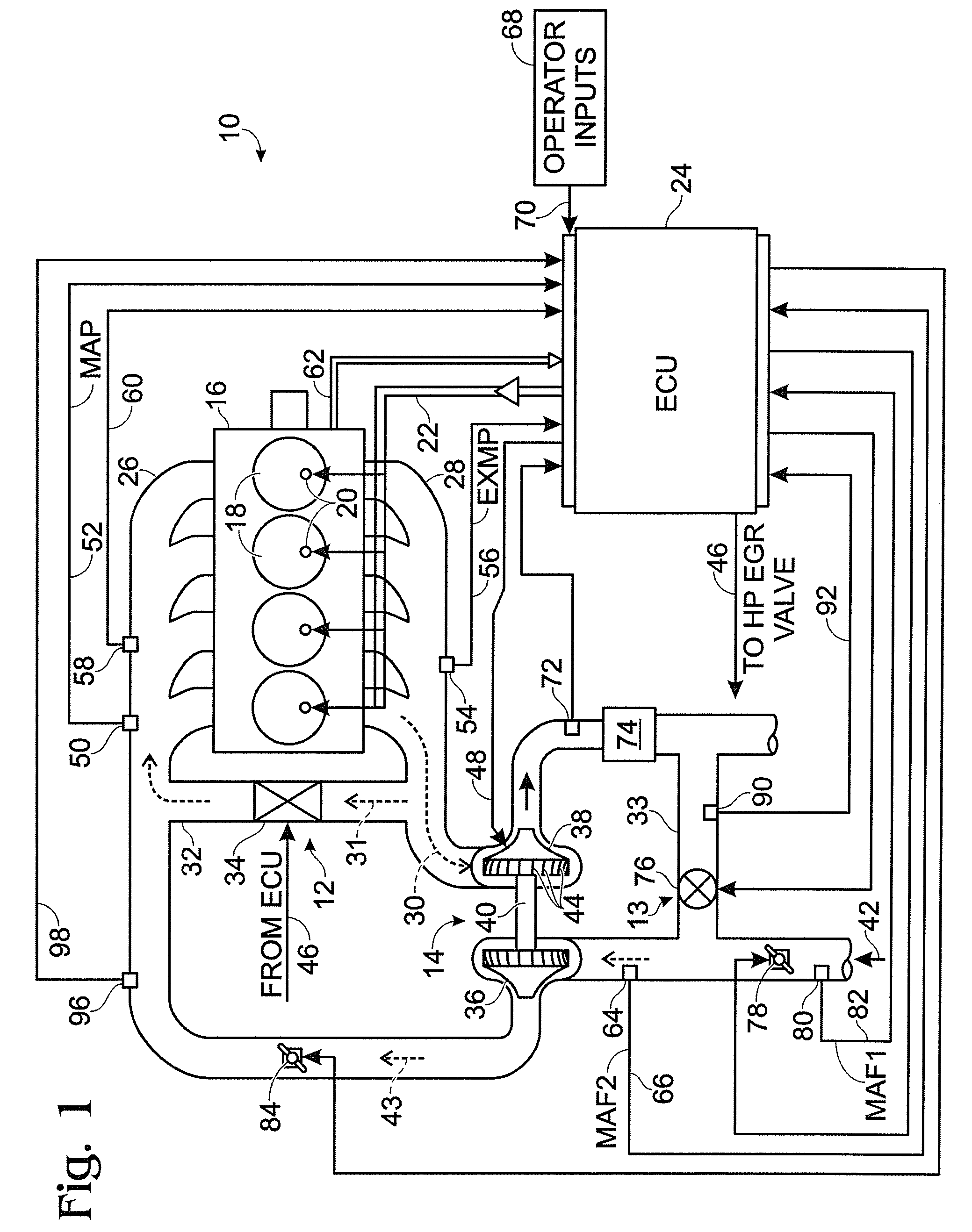

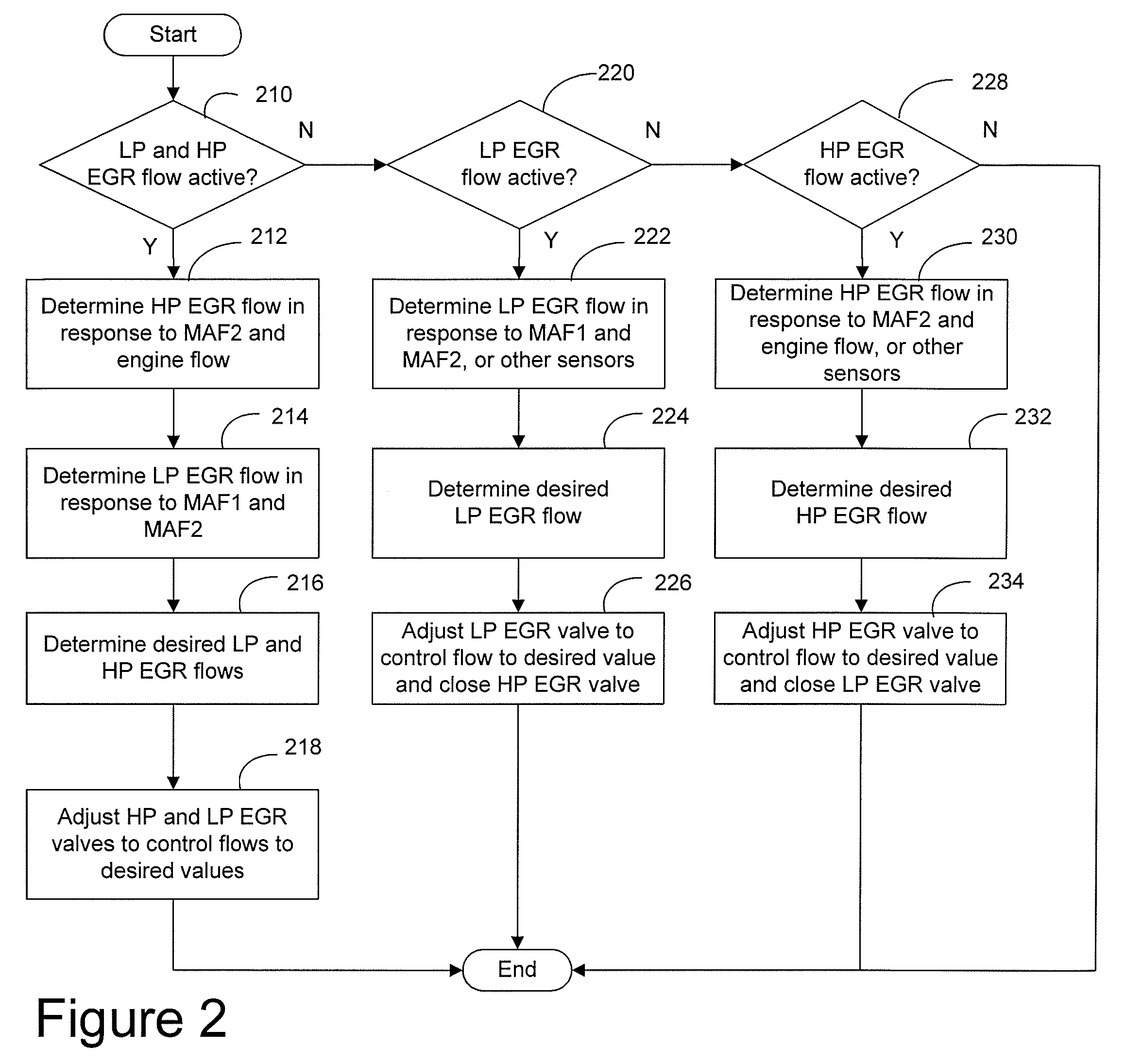

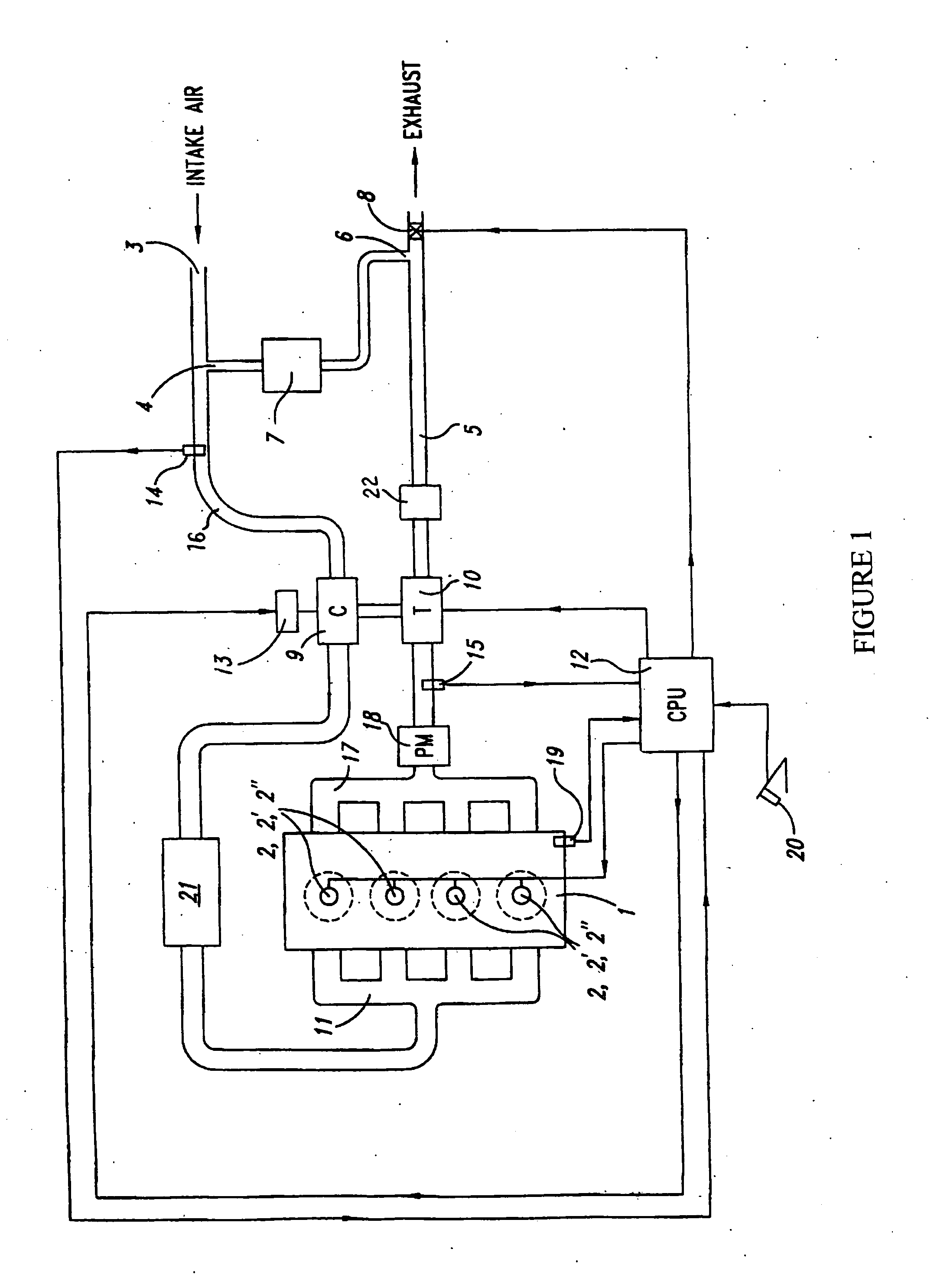

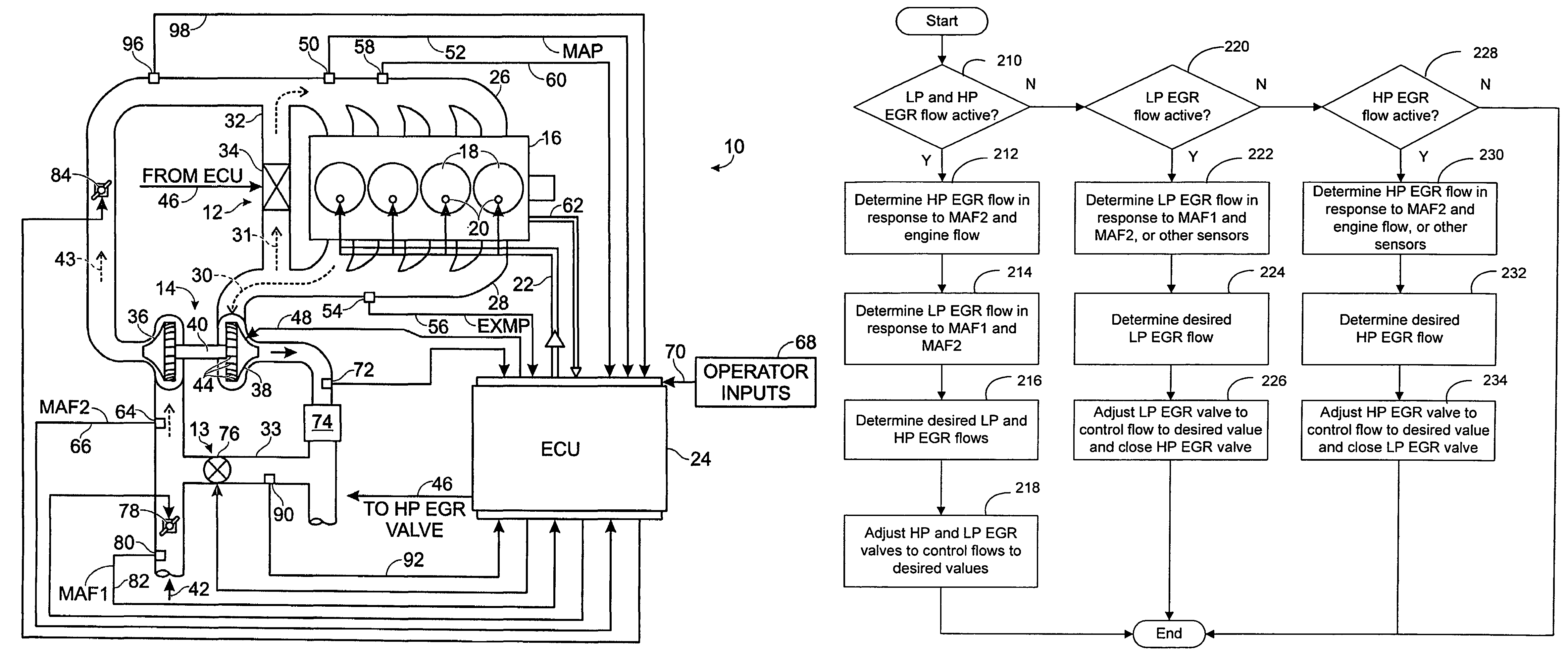

System and method for high pressure and low pressure exhaust gas recirculation control and estimation

ActiveUS20070079614A1Easy to operateReduce the formation of nitrogen oxidesElectrical controlInternal combustion piston enginesTurbochargerExhaust fumes

A system for a diesel engine having an intake manifold and an exhaust manifold, comprising a turbocharger coupled between the intake and exhaust manifolds of the engine; a low pressure exhaust gas recirculation system with a first end coupled to the exhaust manifold downstream of the turbocharger and a second end coupled to the intake manifold upstream of the turbocharger, said low pressure exhaust gas recirculation having a first valve coupled thereto for regulating flow; a high pressure exhaust gas recirculation system with a first end coupled to the exhaust manifold upstream of the turbocharger and a second end coupled to the intake manifold downstream of the turbocharger, said high pressure exhaust gas recirculation having a second valve coupled thereto for regulating flow; a first mass airflow sensor coupled in the engine intake manifold upstream of said second end of said low pressure exhaust gas recirculation system; a second mass airflow sensor coupled in the engine intake manifold downstream of said second end of said low pressure exhaust gas recirculation system and upstream of said second end of said high pressure exhaust gas recirculation system.

Owner:FORD GLOBAL TECH LLC

System and method for diagnostic of low pressure exhaust gas recirculation system and adapting of measurement devices

ActiveUS7367188B2Reduce the formation of nitrogen oxidesImprove fuel economyVehicle testingElectrical controlMeasurement deviceTurbocharger

A system for a diesel engine having an intake manifold and an exhaust manifold, comprises a turbocharger between the intake and exhaust manifolds; a low pressure exhaust gas recirculation system having a first valve coupled thereto for regulating flow; a high pressure exhaust gas recirculation system having a second valve coupled thereto for regulating flow; a first mass airflow sensor coupled in the engine intake manifold; and a control system configured to diagnose the degradation of the first mass airflow sensor.

Owner:FORD GLOBAL TECH LLC

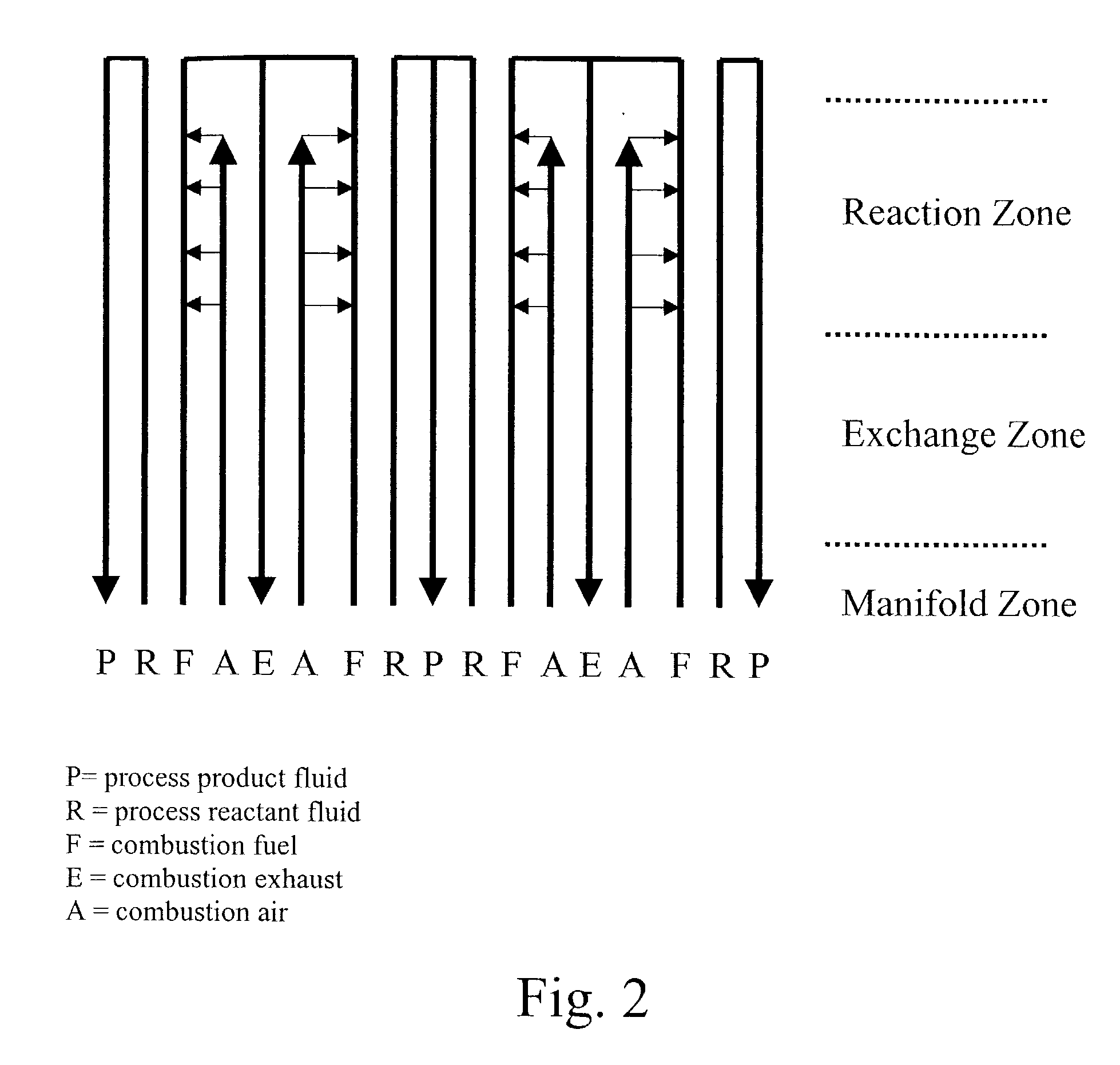

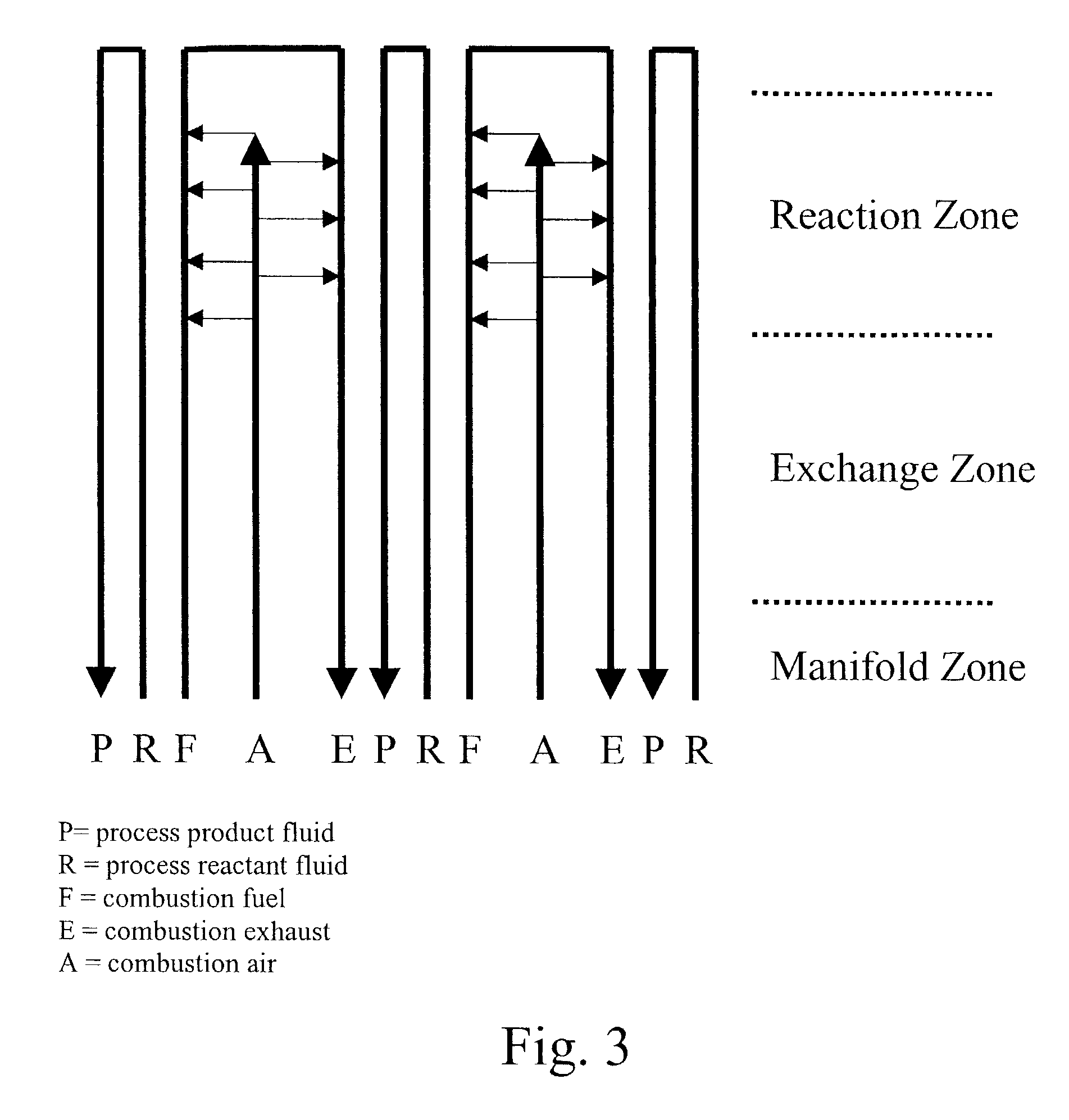

Methods of conducting simultaneous endothermic and exothermic reactions

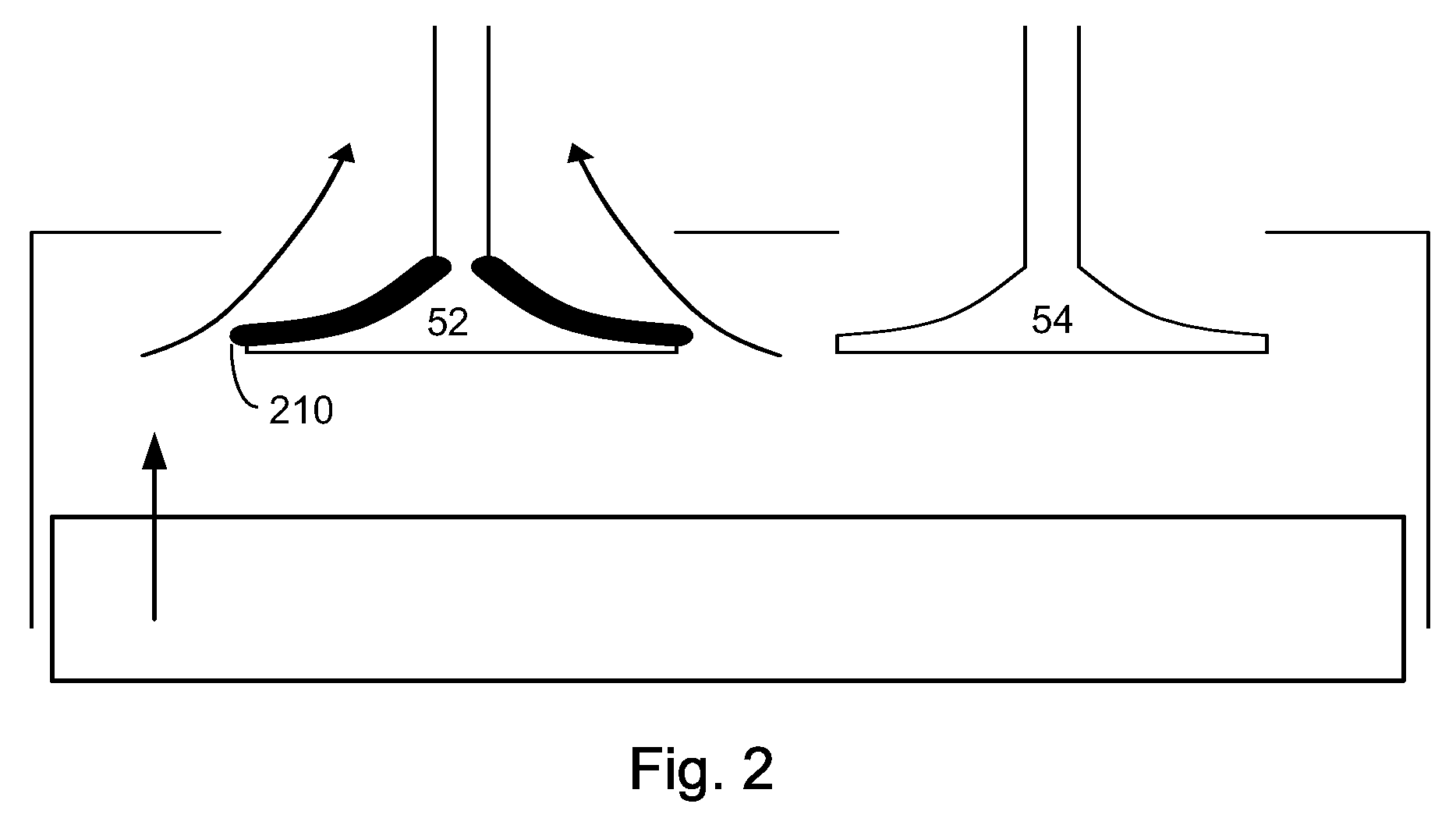

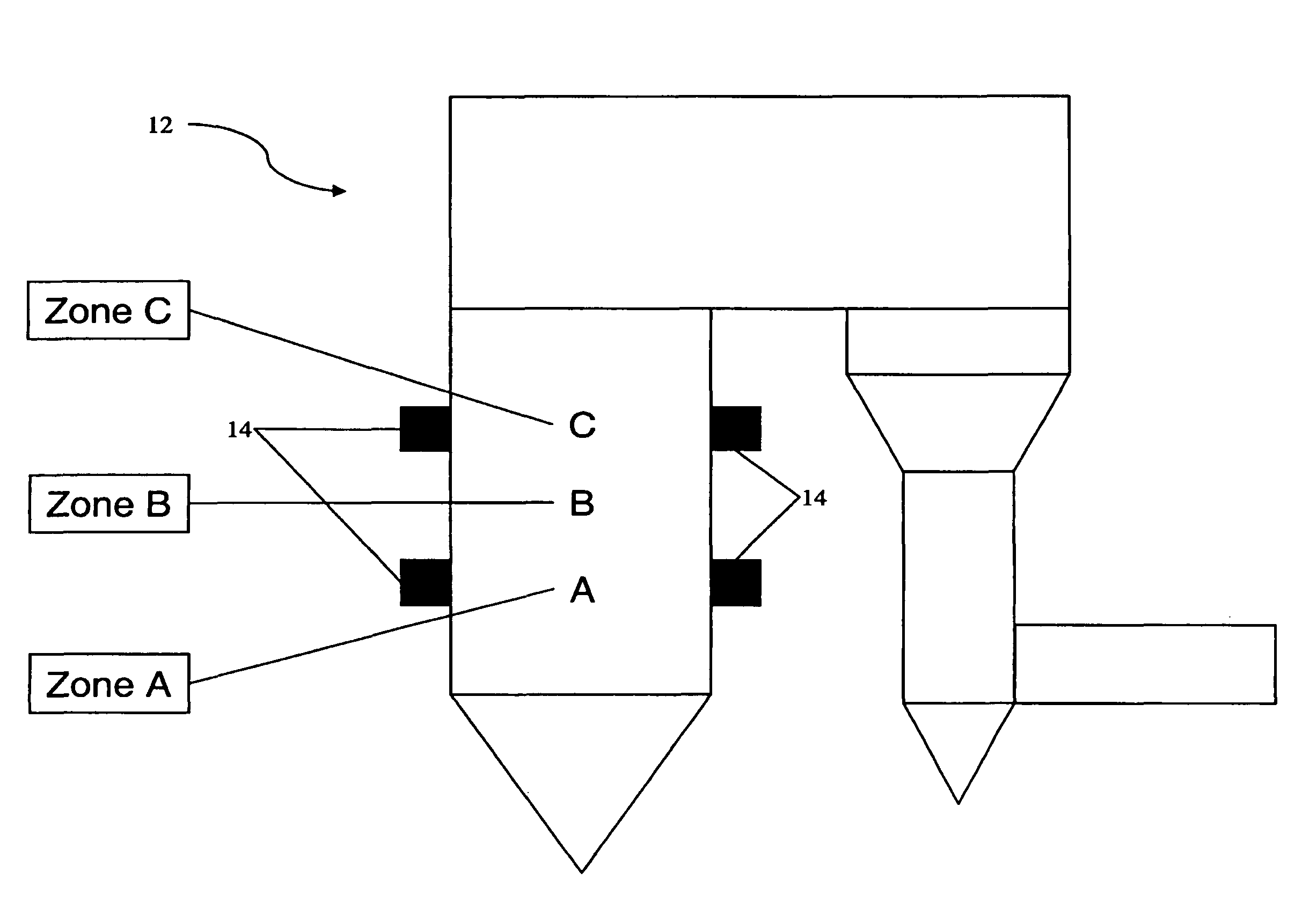

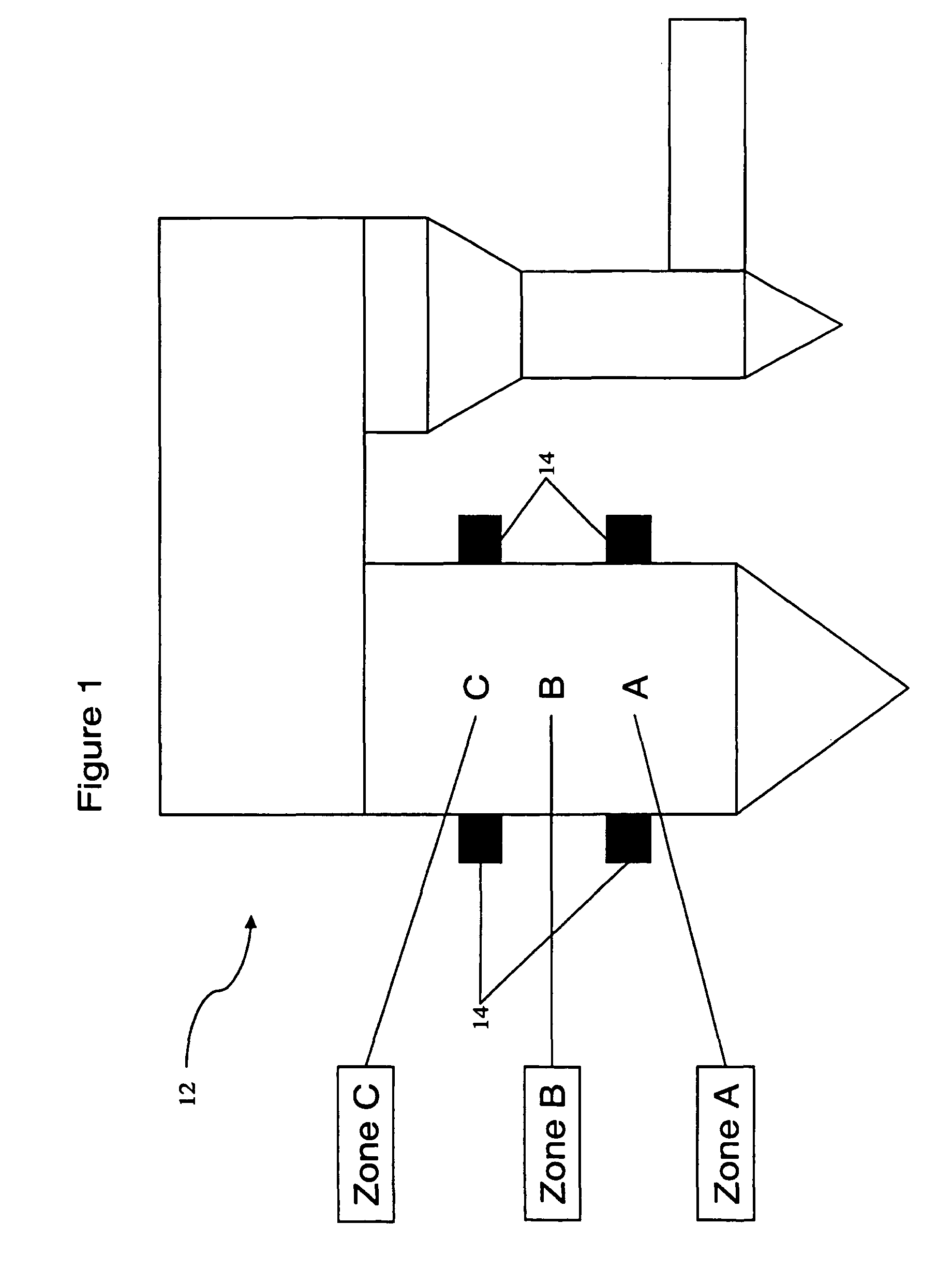

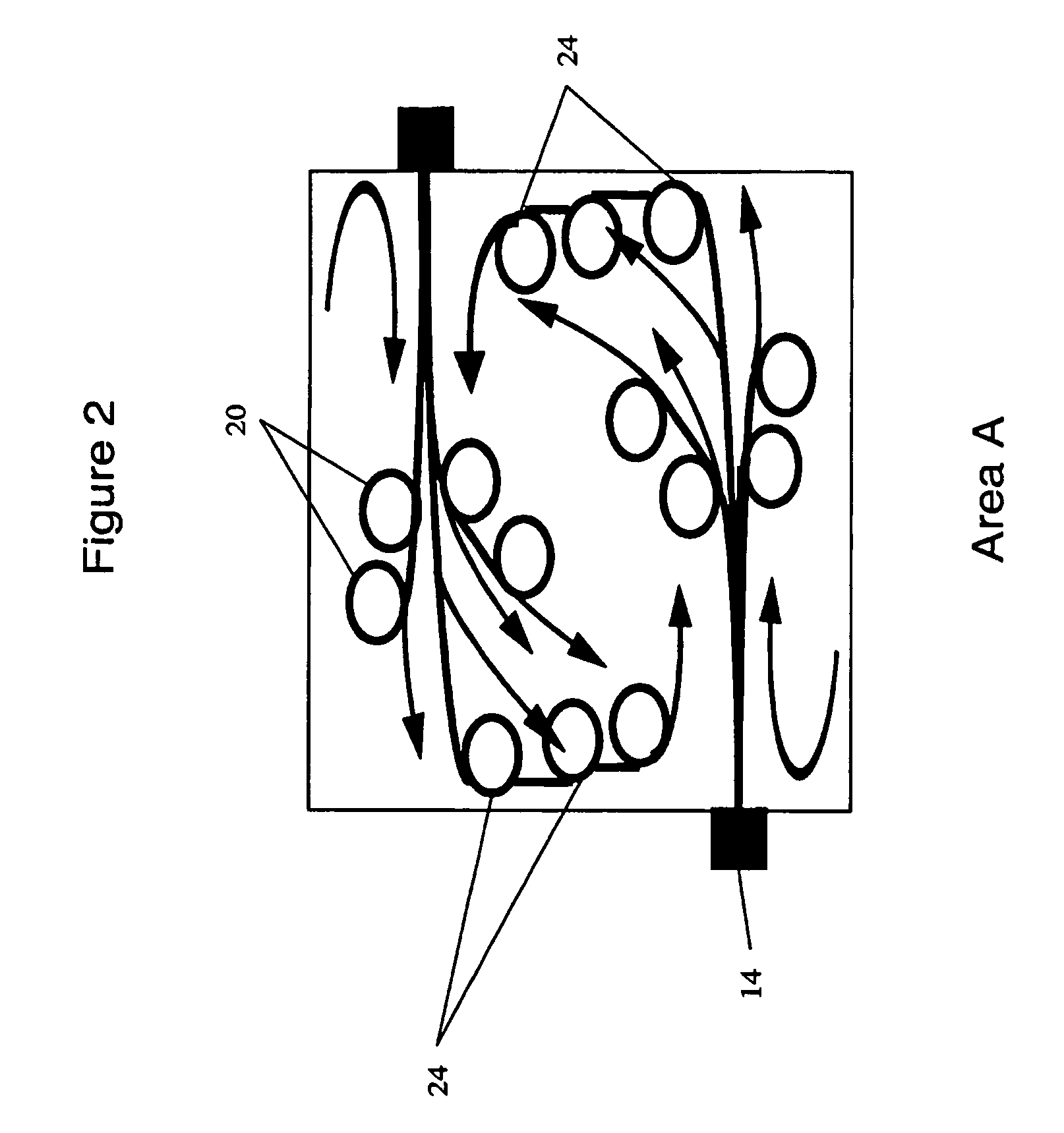

InactiveUS7250151B2Reduce the formation of nitrogen oxidesHigh thermal cycling durabilityFurnace componentsChemical/physical/physico-chemical microreactorsCombustion chamberProcess engineering

Integrated Combustion Reactors (ICRS) and methods of making ICRs are described in which combustion chambers (or channels) are in direct thermal contact to reaction chambers for an endothermic reaction. Particular reactor designs are also described. Processes of conducting reactions in integrated combustion reactors are described and results presented. Some of these processes are characterized by unexpected and superior results, and / or results that can not be achieved with any prior art devices.

Owner:VELOCYS CORPORATION

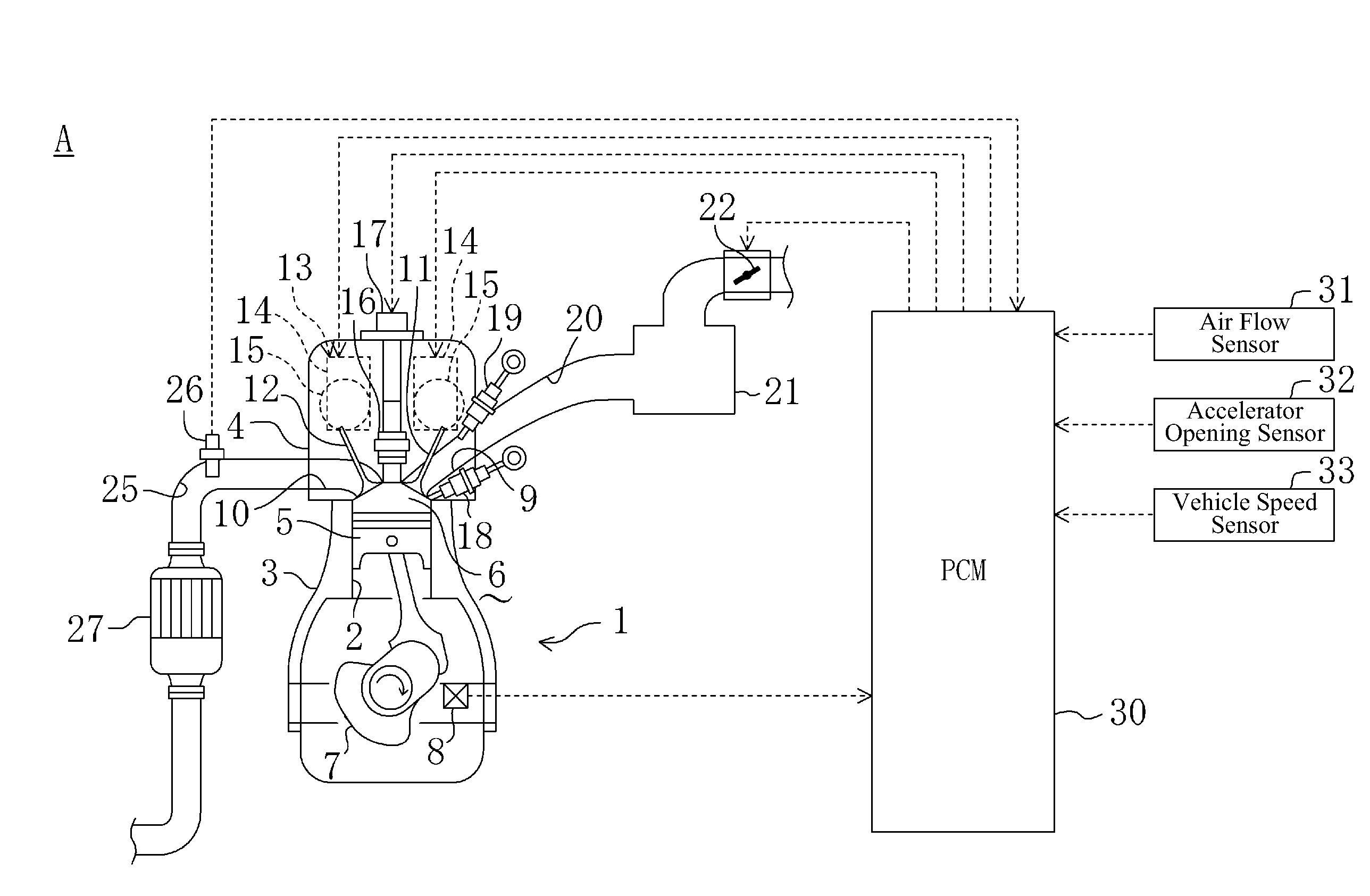

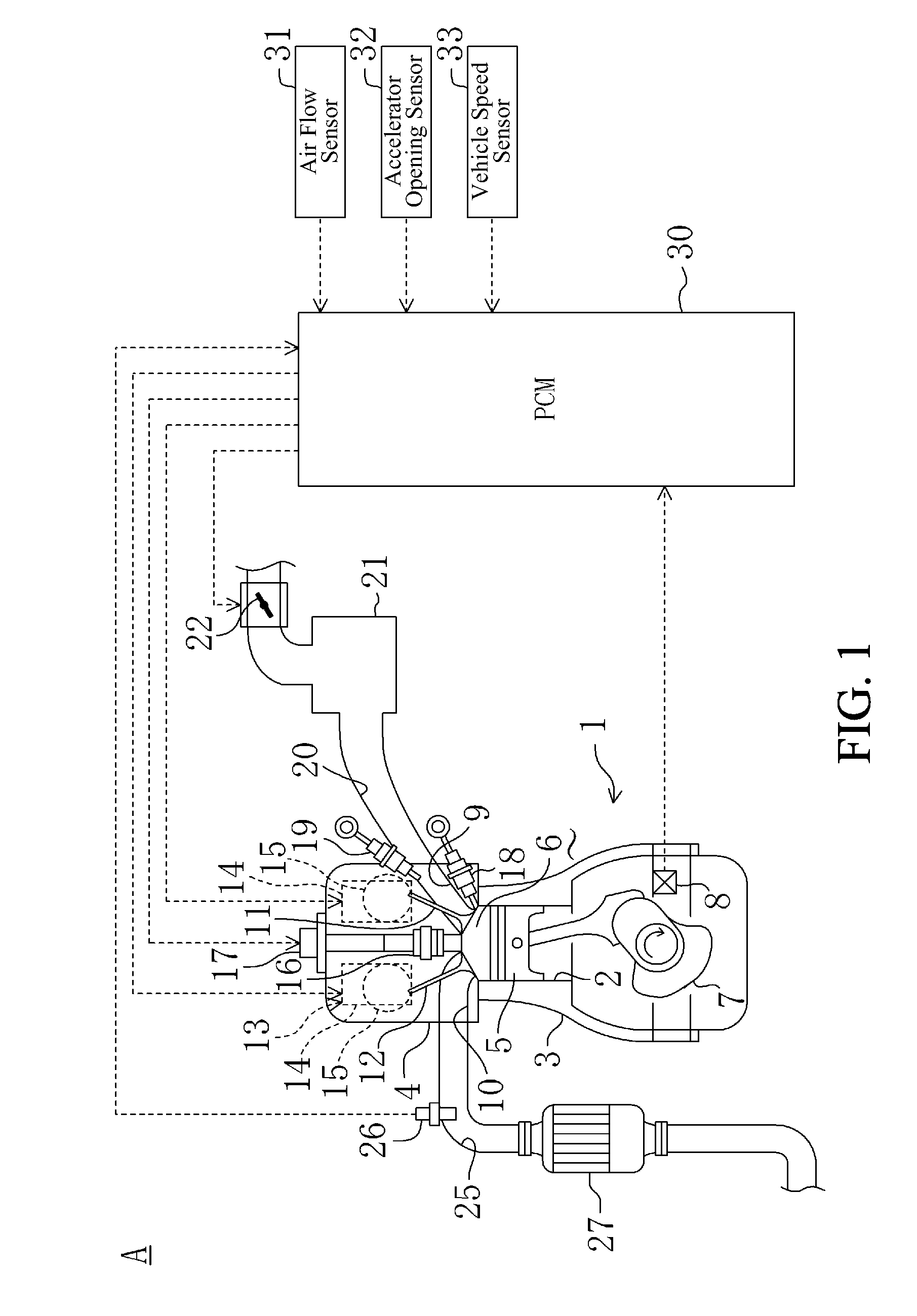

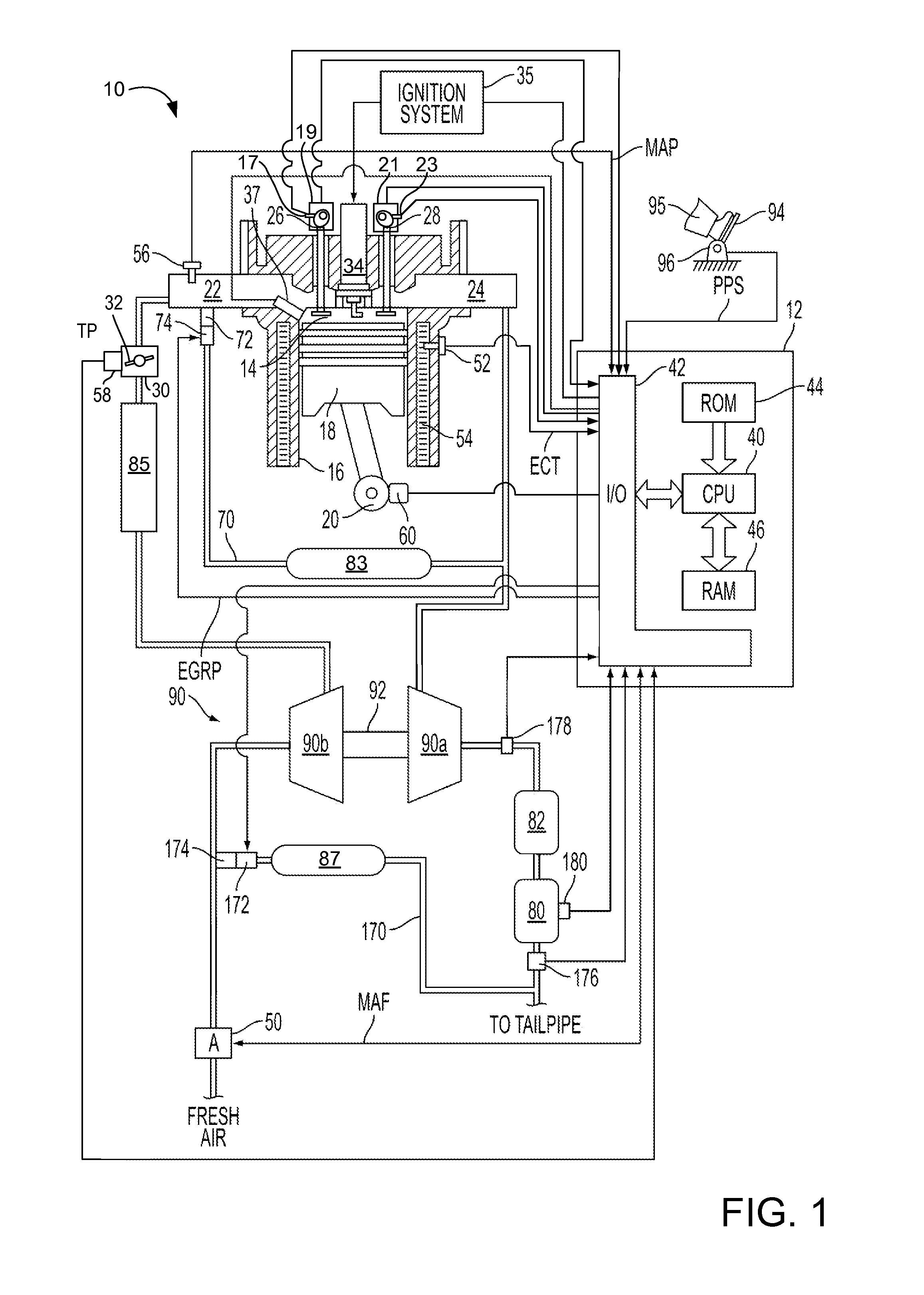

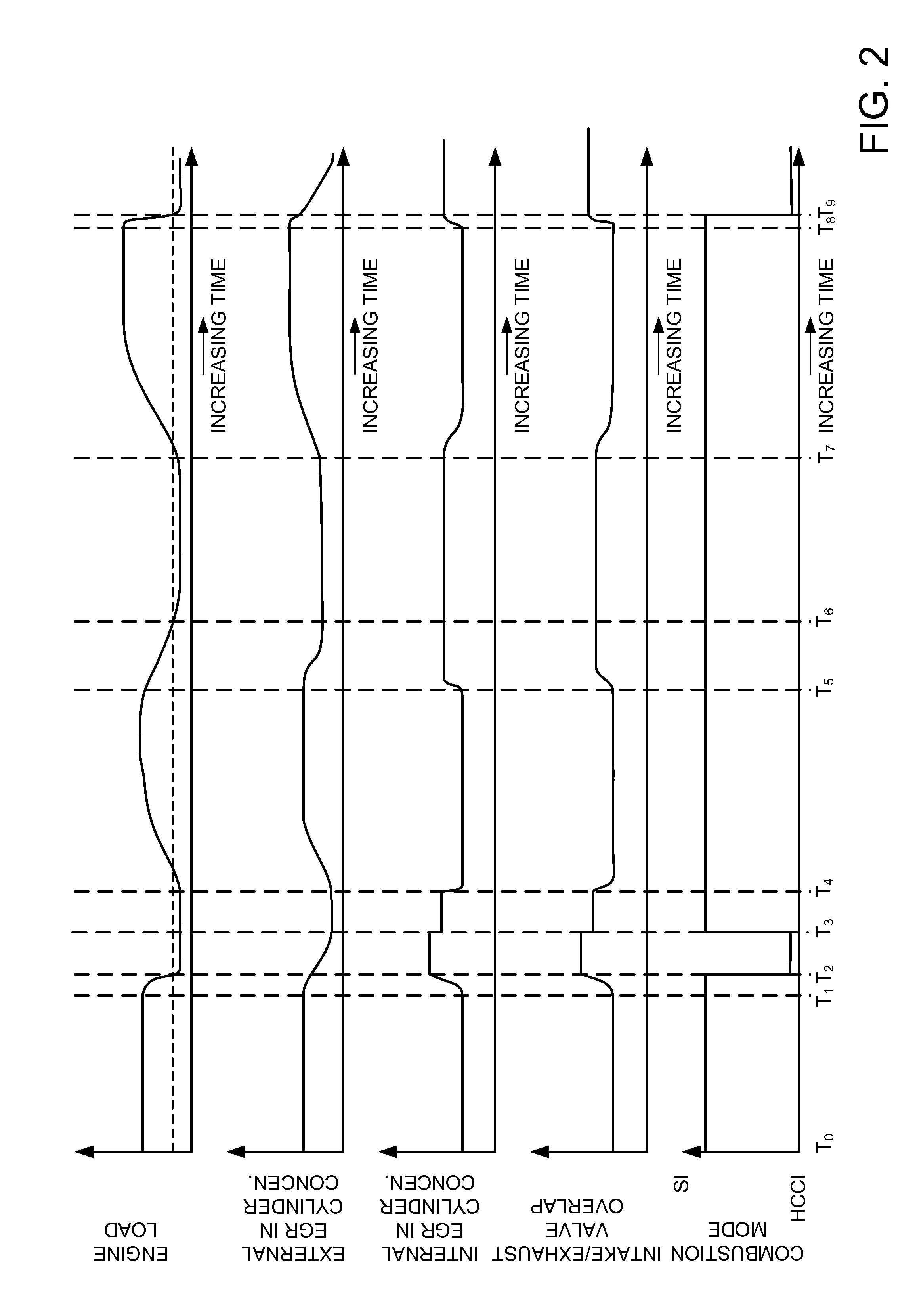

Method of operating an internal combustion engine

ActiveUS20080178836A1Overcome disadvantagesAccelerate emissionsValve arrangementsElectrical controlExternal combustion engineInternal combustion engine

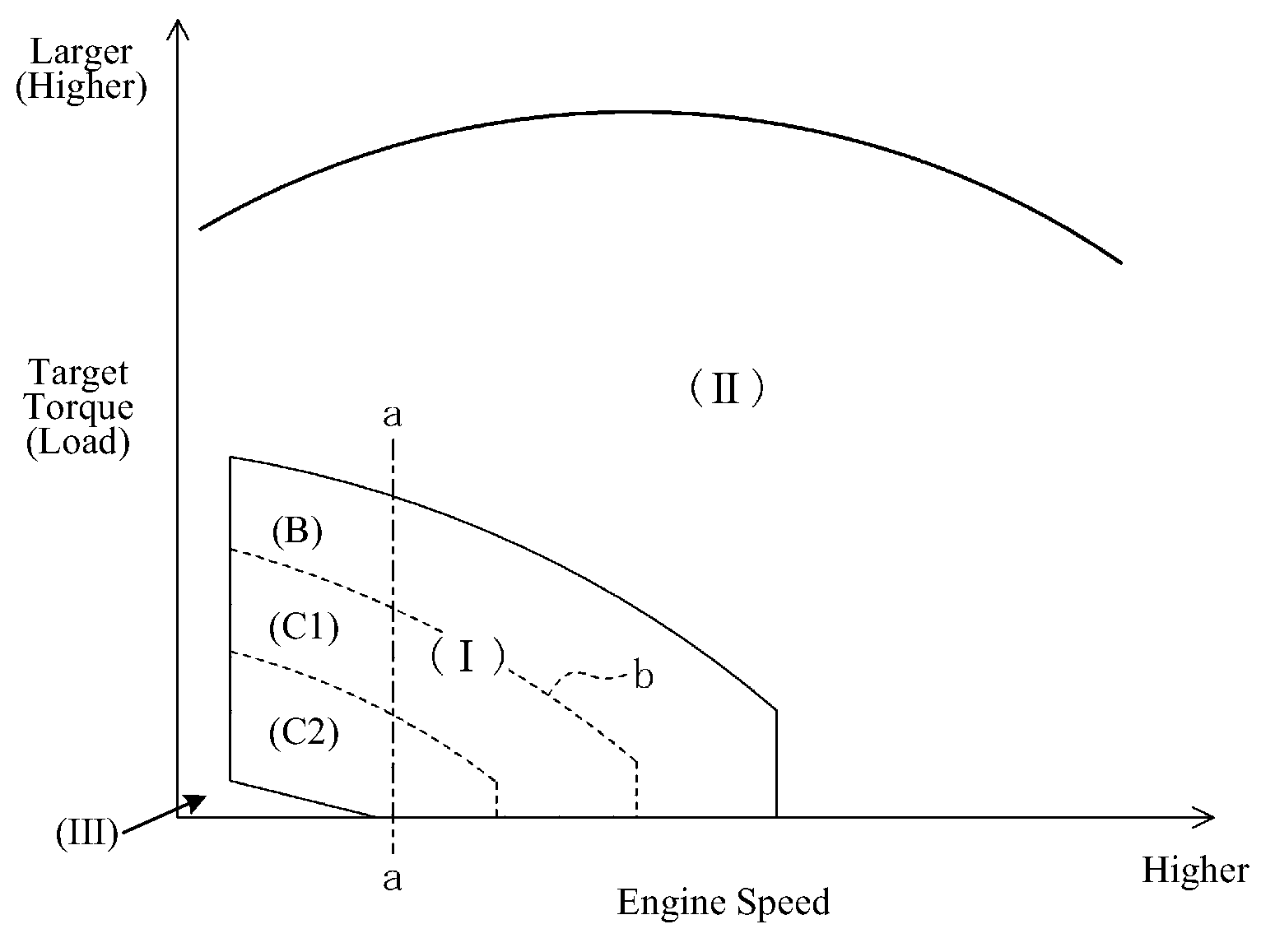

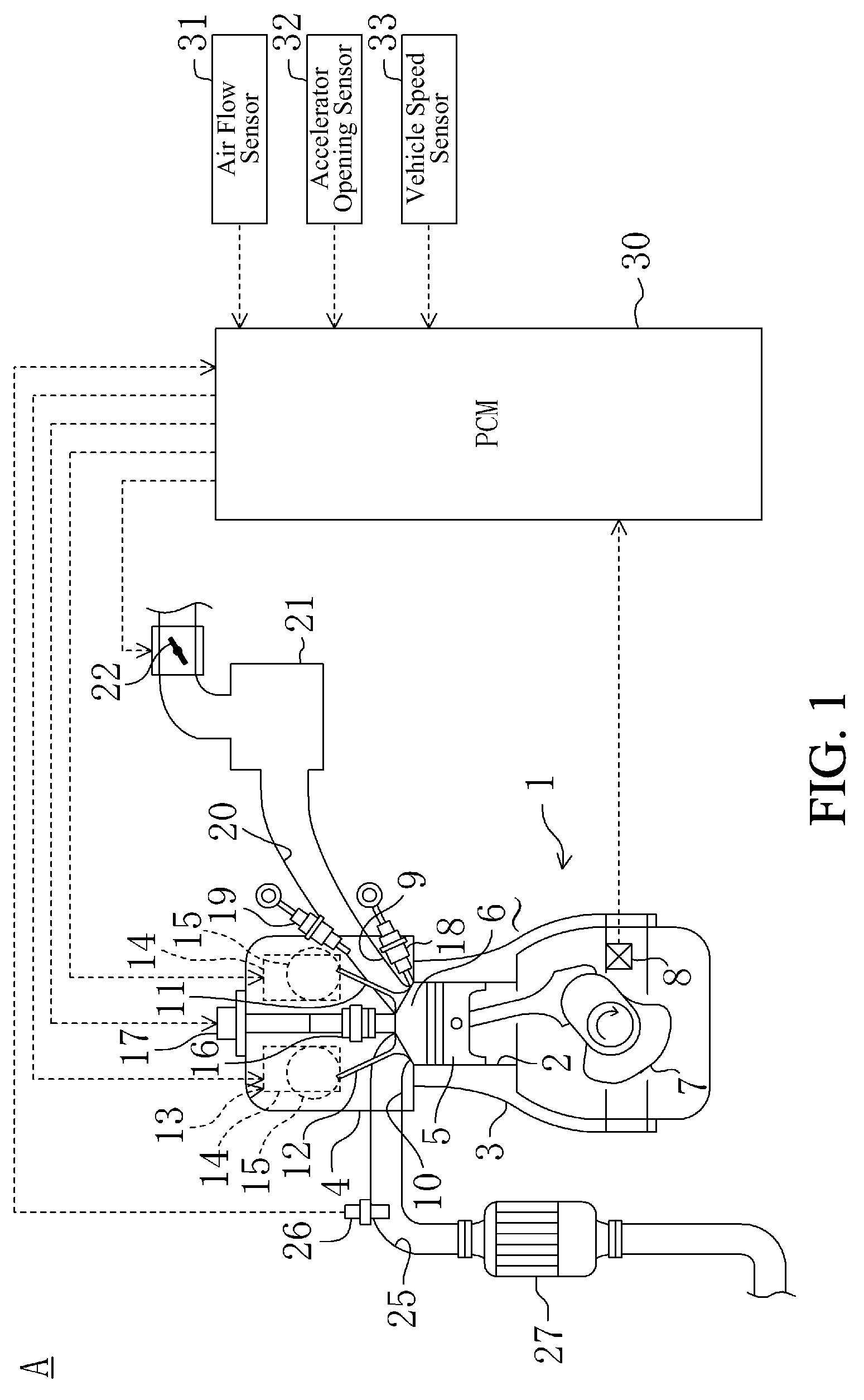

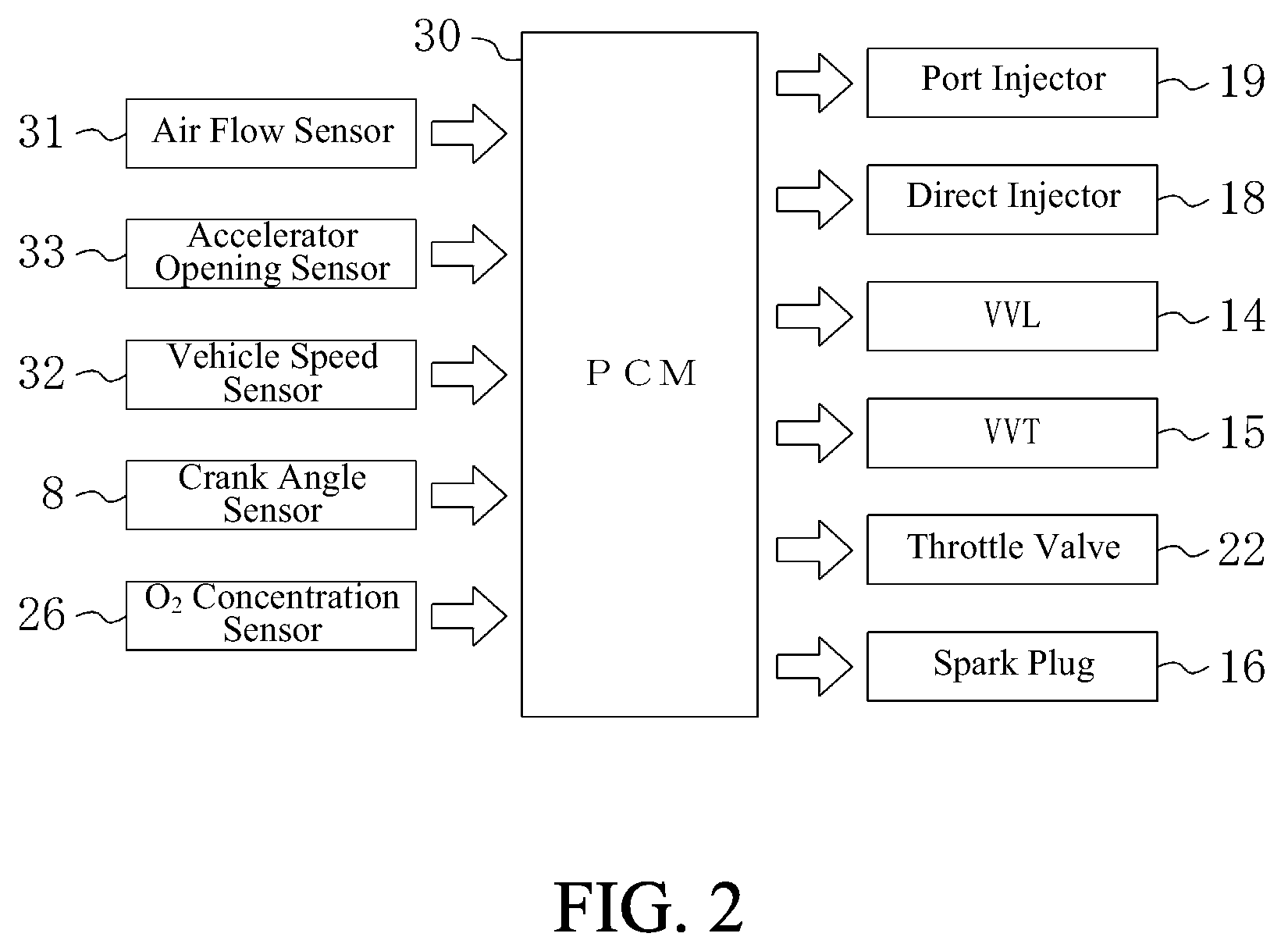

A method of operating an internal combustion engine having a combustion chamber with a piston and a spark plug, comprising during a first mode, bringing the temperature of the combustion chamber to auto-ignition temperature by adjusting engine operating conditions and producing auto-ignition in said combustion chamber without requiring spark from said spark plug; and during a second mode, bringing the temperature of the combustion chamber close to auto-ignition temperature by adjusting engine operating conditions, forming a small cloud of stratified air-fuel mixture near said spark plug, igniting said fuel cloud by a spark form said spark plug, and then causing cylinder pressure to rise, thereby producing auto-ignition at other sites in said combustion chamber wherein said first mode is implemented in a first operating range and said second mode is implemented only in a second operating range where engine speed and load are lower than said first operating range.

Owner:MAZDA MOTOR CORP

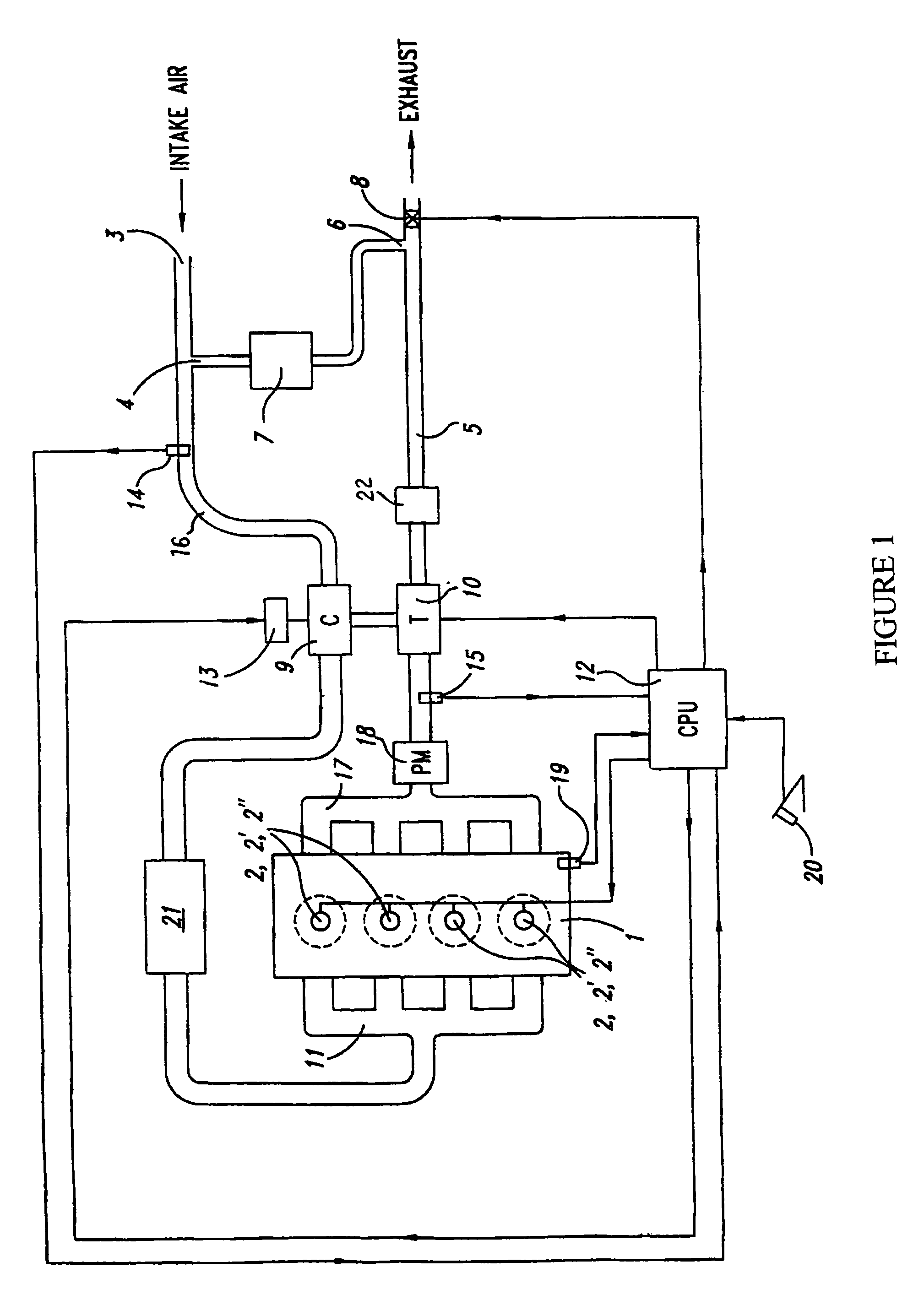

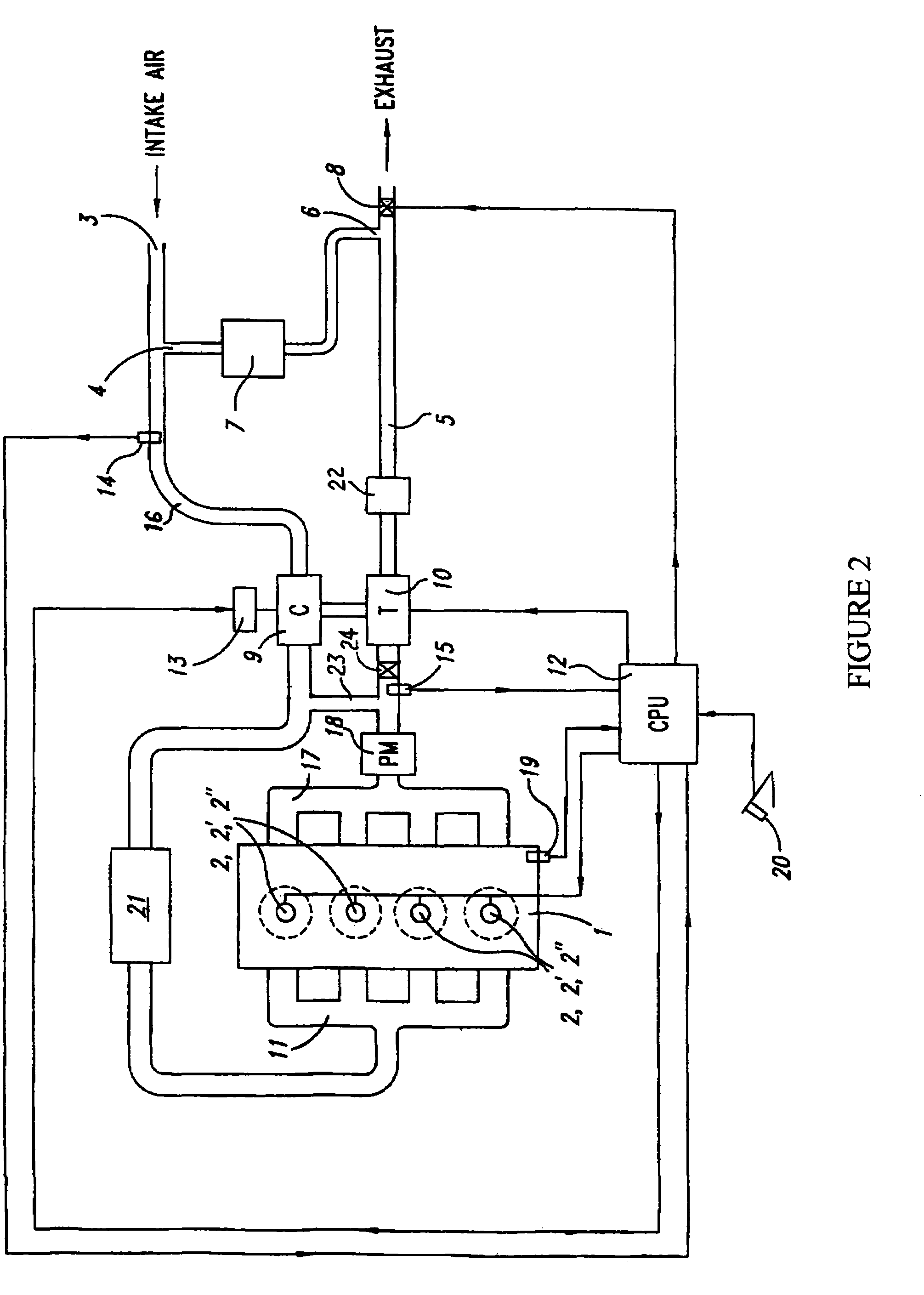

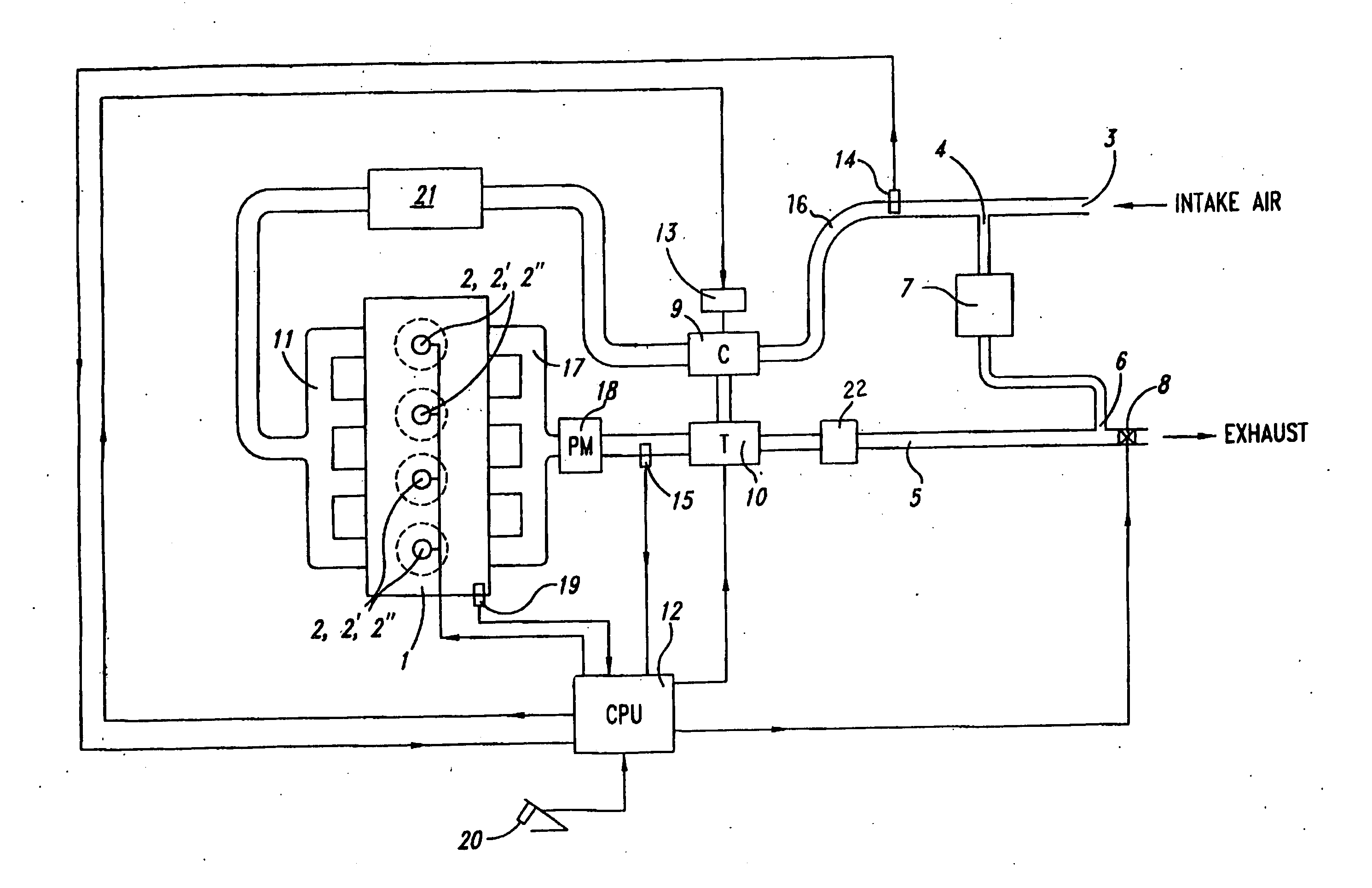

System for and methods of operating diesel engines to reduce harmful exhaust emissions and to improve engine lubrication

InactiveUS6892531B2Promote regenerationAnti-wear propertyInternal combustion piston enginesNon-fuel substance addition to fuelExhaust gas emissionsFuel tank

A Diesel engine anti-wear lubricant oil additive composition that includes organo-metallic compounds of Cu, Ce, etc., is used to catalytically burn-off diesel particulate matter (PM) collected by diesel particulate filter (DPF). A fuel borne catalyst (FBC) of Cu,Ce,Fe etc., required for regenerating the DPF is made by blending a predetermined quantity of used engine oil, removed from the engine crankcase oil system, with fuel in the fuel tank of a diesel engine equipped with DPF and EGR systems. A method of fumigating water and catalytic compounds of Cu, Fe, Ce, etc., into the air-intake system of a diesel engine in the EGR gases from the DPF or air, to reduce both PM and NOx emissions from a diesel engine, with improved engine lubrication performance, is also disclosed.

Owner:RIM JULIUS J

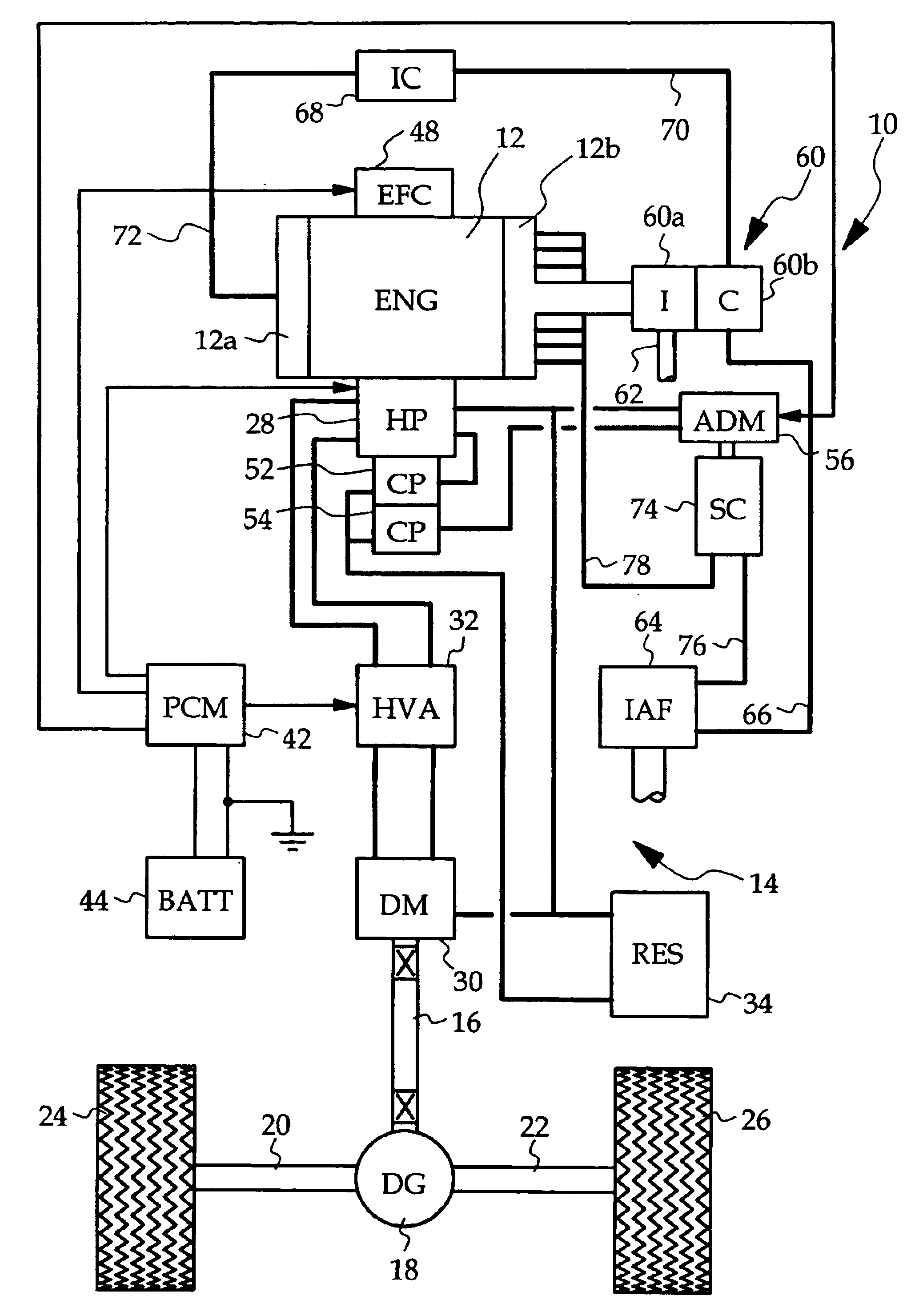

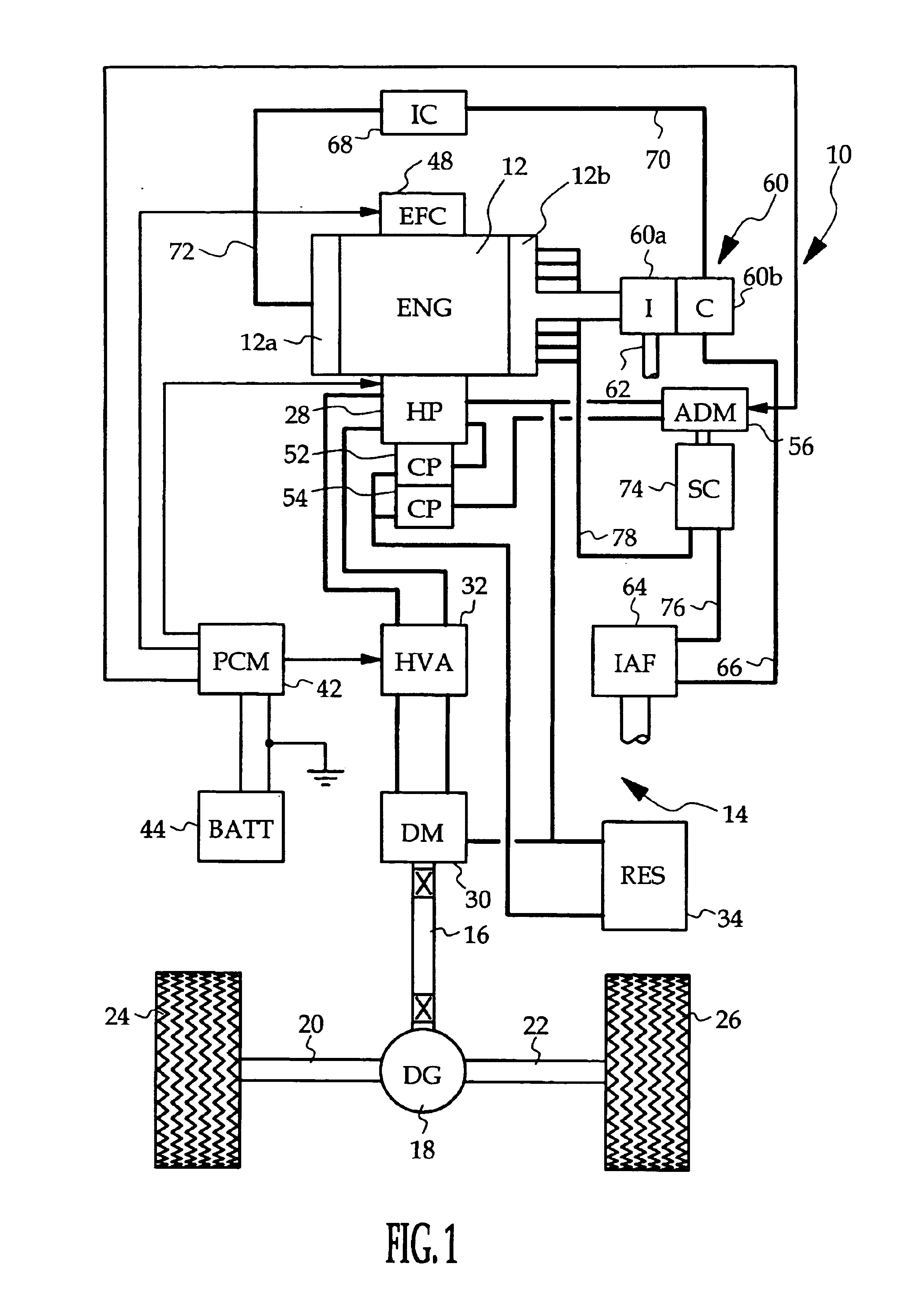

Control methods for low emission internal combustion system

InactiveUS20070220864A1Reduce the formation of nitrogen oxidesImprove transient response timeElectrical controlInternal combustion piston enginesCombustion systemEngineering

Improved transient response times are obtained while maintaining low emissions with a low pressure EGR system through methods for quickly obtaining a desired oxygen concentration for charge-air to be used for combustion. Under a first method, fuel quantity in the main combustion event is controlled in the combustion process to produce exhaust around a relatively constant target exhaust oxygen concentration value. By keeping the exhaust oxygen concentration levels at a relatively constant value, lag time in waiting for low pressure EGR valve adjustments during transients may be avoided, and the system's air handling response to meet transients may be paced solely by adjusting the mass of air to be supplied (i.e. boost response). Under a second method, a multiple-stage combustion process is utilized, in which fuel feed is controlled in a small, preliminary HCCI-type combustion event in order to produce a target oxygen concentration of charge-air to be used for the second, main combustion event. Under a third method, exhaust rebreathing is used to produce a target oxygen concentration of charge-air to be used for combustion.

Owner:US EPA OFFICE OF GENERAL COUNSEL UNITED STATES OF AMERICA THE

System and method for high pressure and low pressure exhaust gas recirculation control and estimation

ActiveUS7380400B2Reduce the formation of nitrogen oxidesImprove fuel economyElectrical controlInternal combustion piston enginesTurbochargerExhaust fumes

A system for a diesel engine having an intake manifold and an exhaust manifold is described. The system may include both a high pressure and low pressure exhaust gas recirculation system, as well as a turbocharger. Further, in one example, the system may include two mass airflow sensors appropriately placed to enable improved control of both the high and low pressure exhaust gas recirculation systems.

Owner:FORD GLOBAL TECH LLC

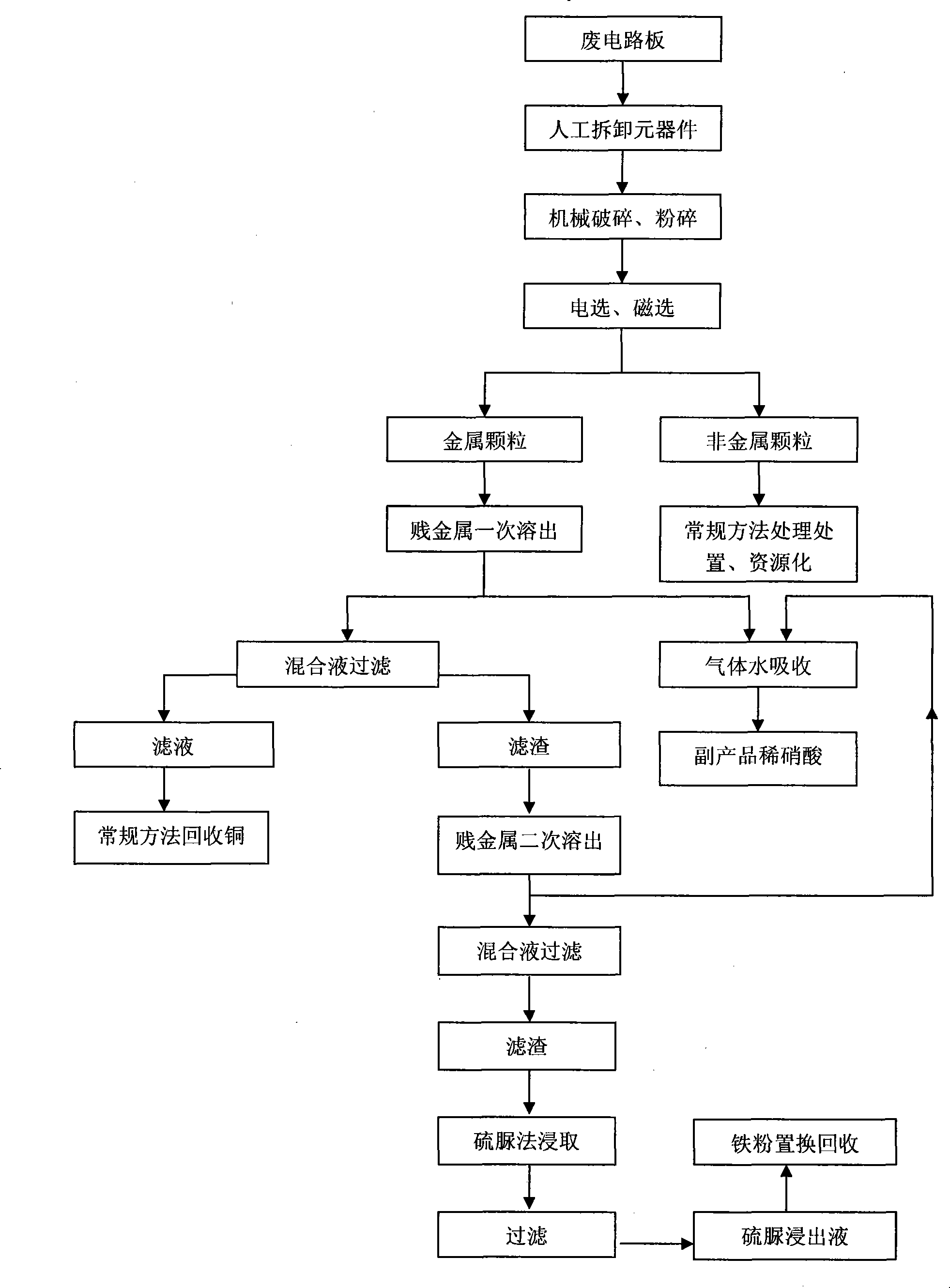

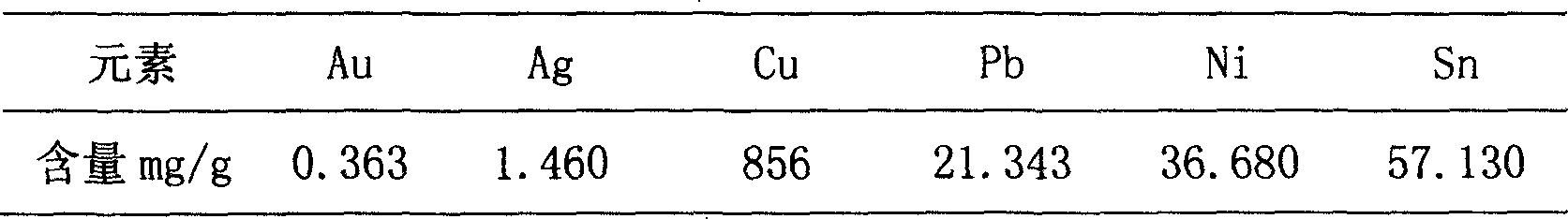

Method for extracting gold from waste circuit boards

InactiveCN101230421ALow cost of reagentsReduce the formation of nitrogen oxidesProcess efficiency improvementNitrogen oxidesPre treatment

The invention relates to a method by which gold can be extracted form waste circuit boards. Secondary acid dipping can be used for pre-processing metal particles of waste circuit boards. A first leaching uses mixed acid solution of nitric acid and sulphuric acid to leach out base metals which mainly is copper and can be used for wrapping gold in circuit boards. The diluted nitric acid solution can be used for dissolving out base metals secondarily to create favorite condition for the following gold extracting. A little nitrogen oxides can be absorbed by water, and then non-cyanogen complexing agent thiourea can be used for selectively leaching out gold and silver; finally, base-metal ferrous powder can be used for displacing gold and silver form the leaching solution, thereby realizing the source recycling of gold and silver. With simple equipment and convenient operation, the method has great potential in industrial promotion. The invention recycles copper and silver when gold is extracted form waste circuit boards, thereby having considerable economic, social and environmental benefits.

Owner:DONGHUA UNIV

Method and arrangement for exhaust-gas recirculation in an internal combustion engine

ActiveUS8104456B2Reduce risk of damagePrevent buildupElectrical controlNon-fuel substance addition to fuelTurbochargerExternal combustion engine

Owner:FORD GLOBAL TECH LLC

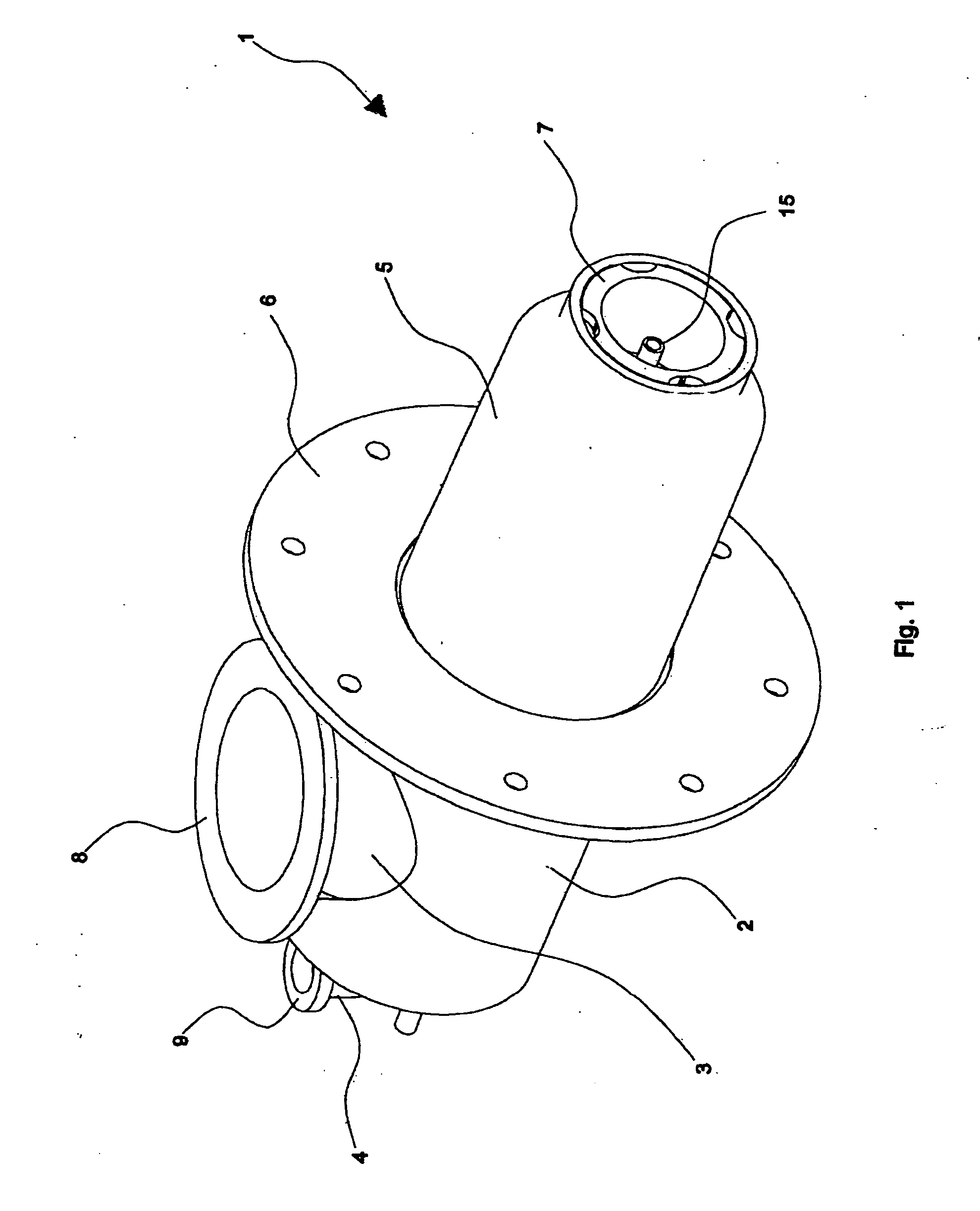

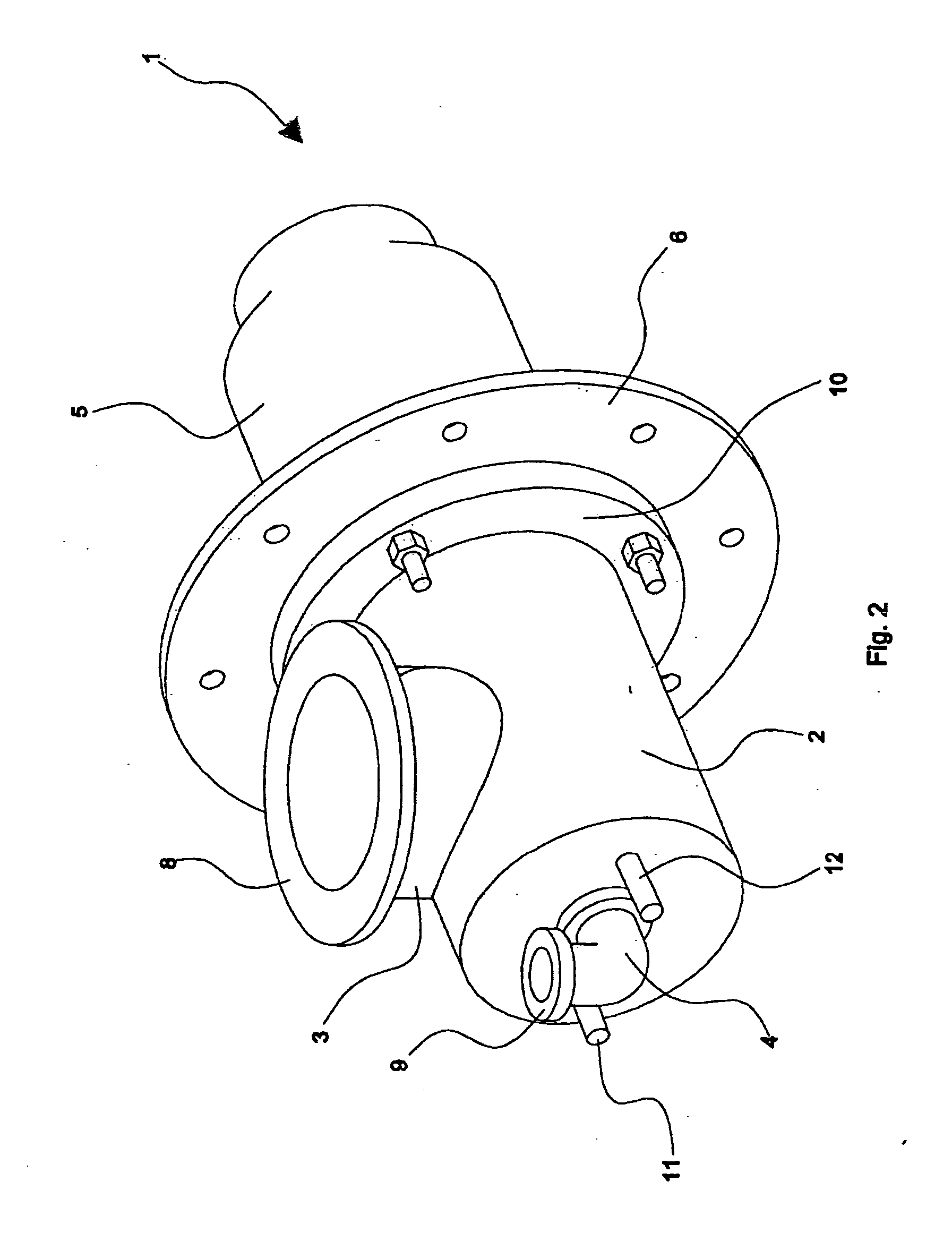

Air injection apparatus for a turbocharged diesel engine

InactiveUS6862885B1Improves turbocharger boostReduce the formation of nitrogen oxidesInternal combustion piston enginesExhaust apparatusLow speedCombustion

A supercharger injects air into the engine exhaust manifold of an engine to dramatically improve turbocharger boost at low engine speeds, while cooling the gases in the exhaust manifold to reduce NOx formation. The injected air additionally reduces other exhaust emissions through secondary combustion, allowing the air / fuel ratio to be controlled closer to the stoichiometric ratio for improved thermodynamic efficiency. The engine is particularly well suited to high torque, low speed applications, such as a vehicle hydrostatic drive in which the engine is connected to drive a variable capacity hydrostatic pump at a low and substantially constant speed.

Owner:SUPERDRIVE

Method of operating an internal combustion engine

ActiveUS7669578B2Improve fuel economy and emissionReduce the formation of nitrogen oxidesValve arrangementsElectrical controlExternal combustion engineEngineering

A method of operating an internal combustion engine having a combustion chamber with a piston and a spark plug, comprising during a first mode, bringing the temperature of the combustion chamber to auto-ignition temperature by adjusting engine operating conditions and producing auto-ignition in said combustion chamber without requiring spark from said spark plug; and during a second mode, bringing the temperature of the combustion chamber close to auto-ignition temperature by adjusting engine operating conditions, forming a small cloud of stratified air-fuel mixture near said spark plug, igniting said fuel cloud by a spark form said spark plug, and then causing cylinder pressure to rise, thereby producing auto-ignition at other sites in said combustion chamber wherein said first mode is implemented in a first operating range and said second mode is implemented only in a second operating range where engine speed and load are lower than said first operating range.

Owner:MAZDA MOTOR CORP

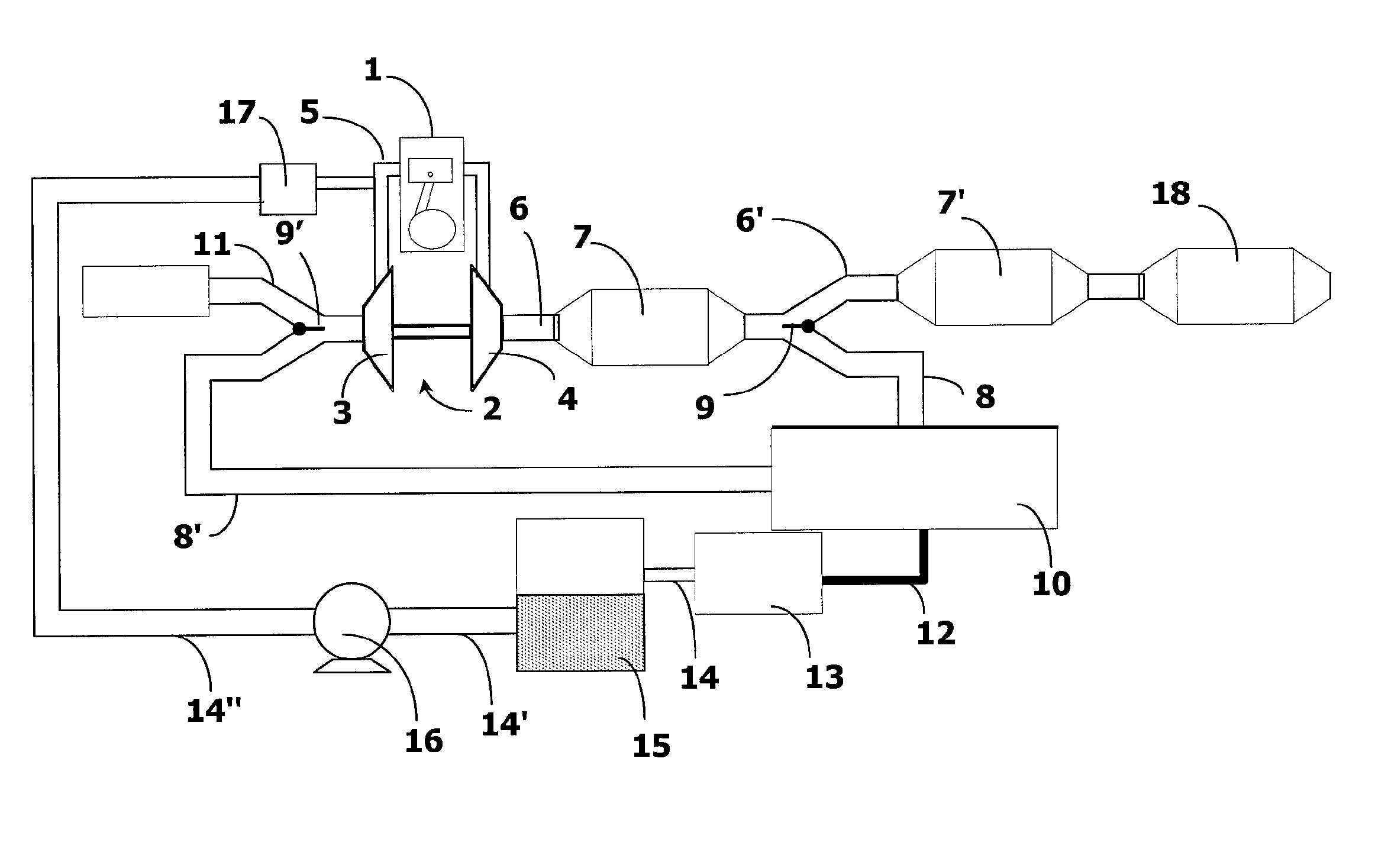

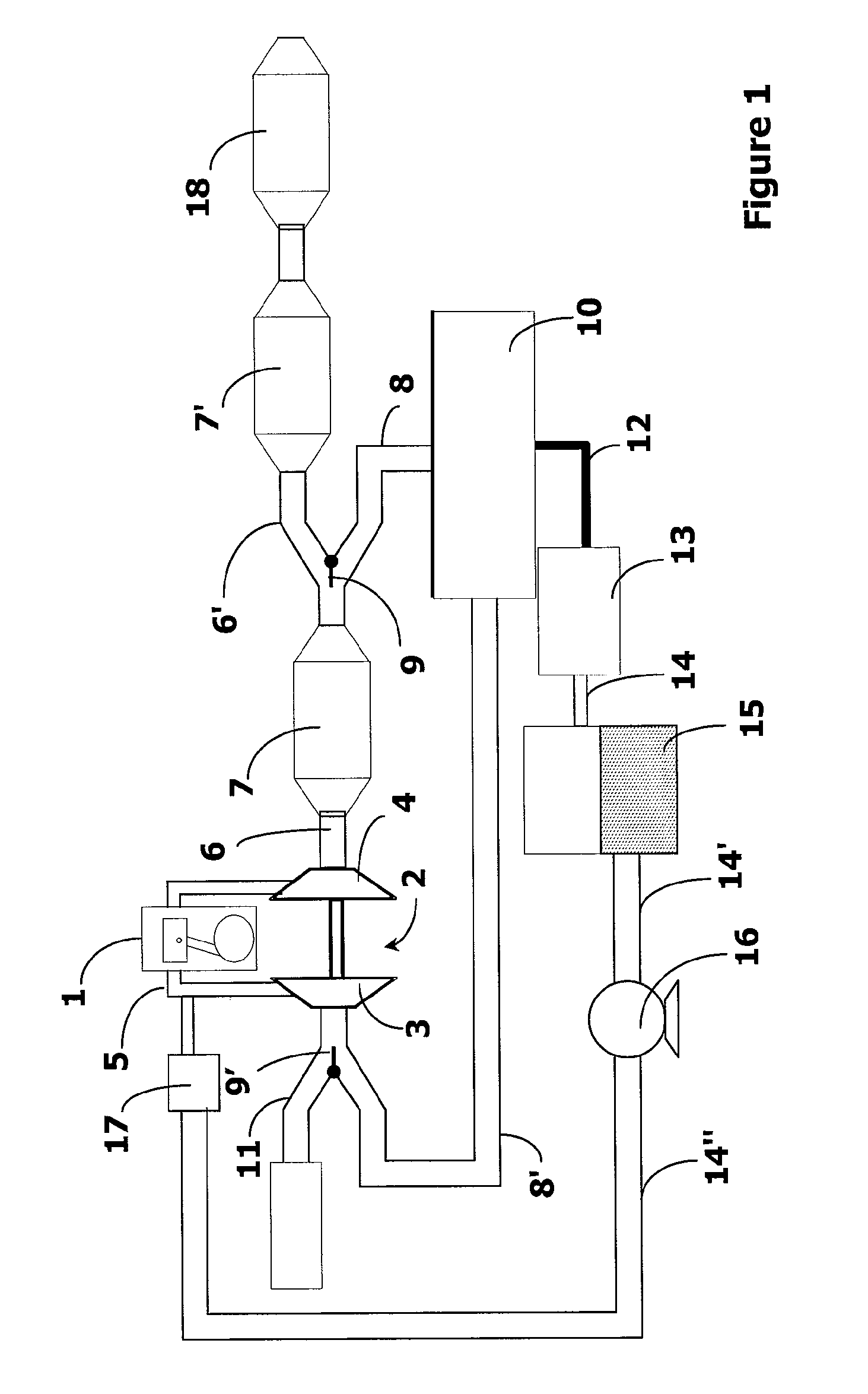

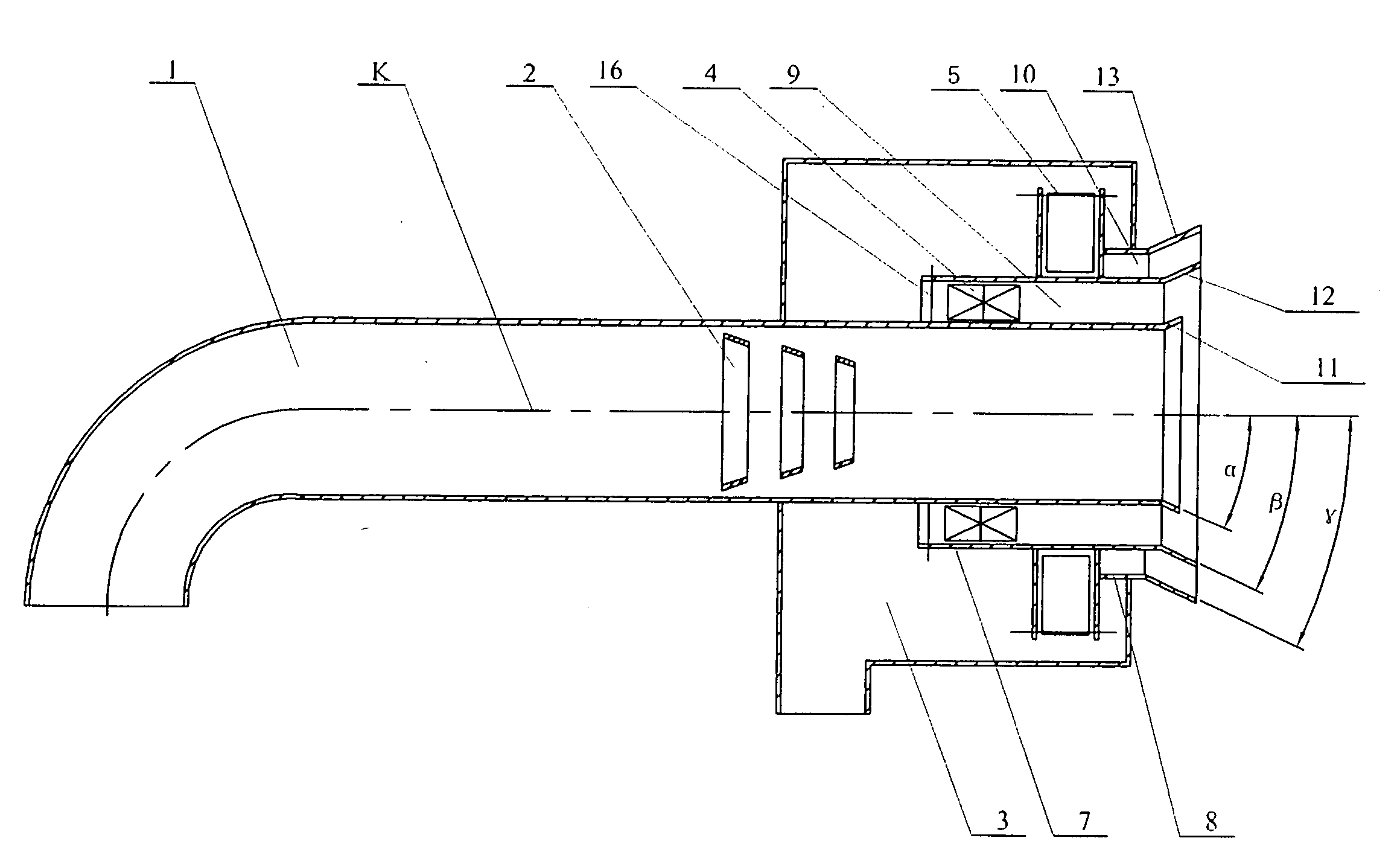

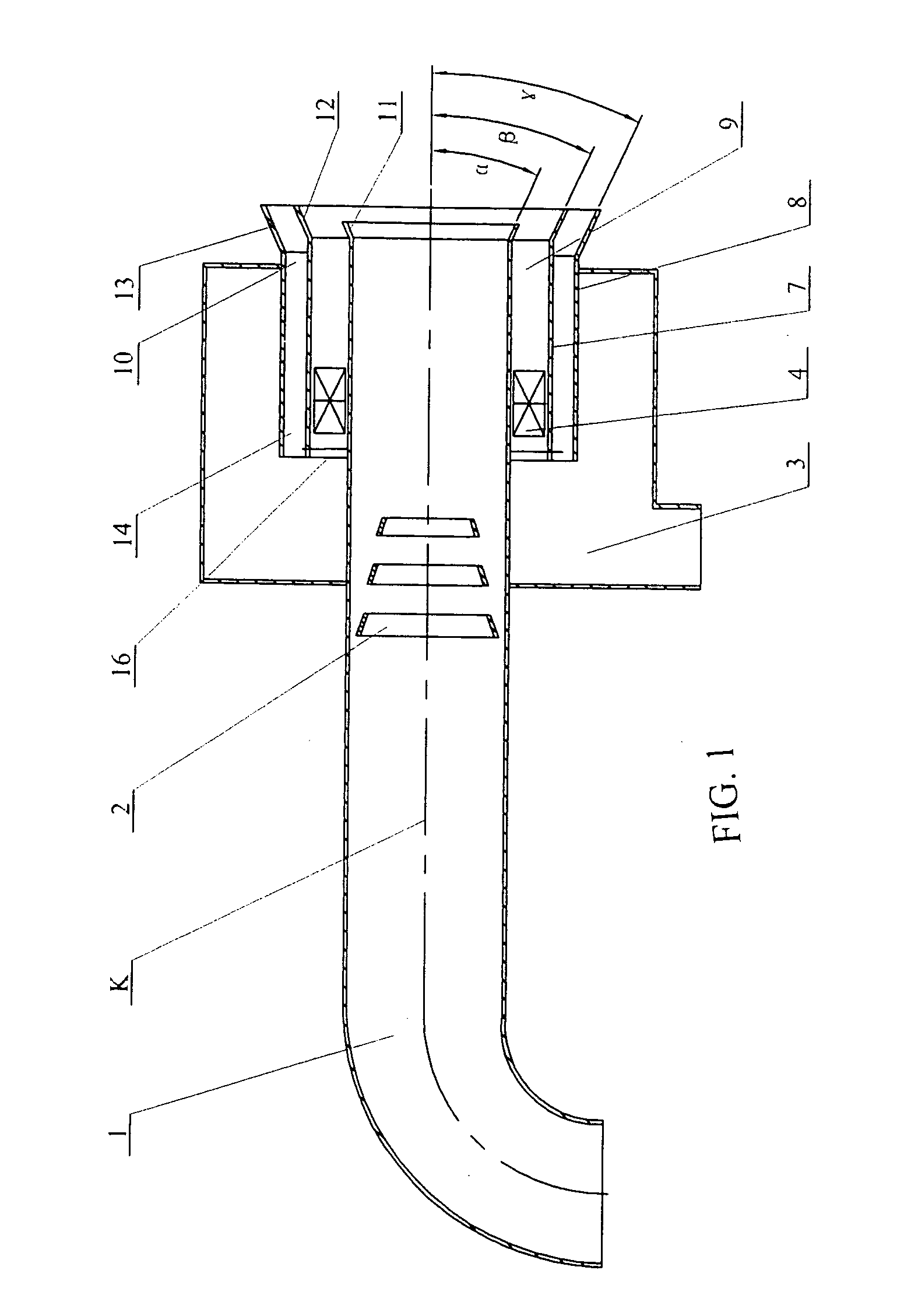

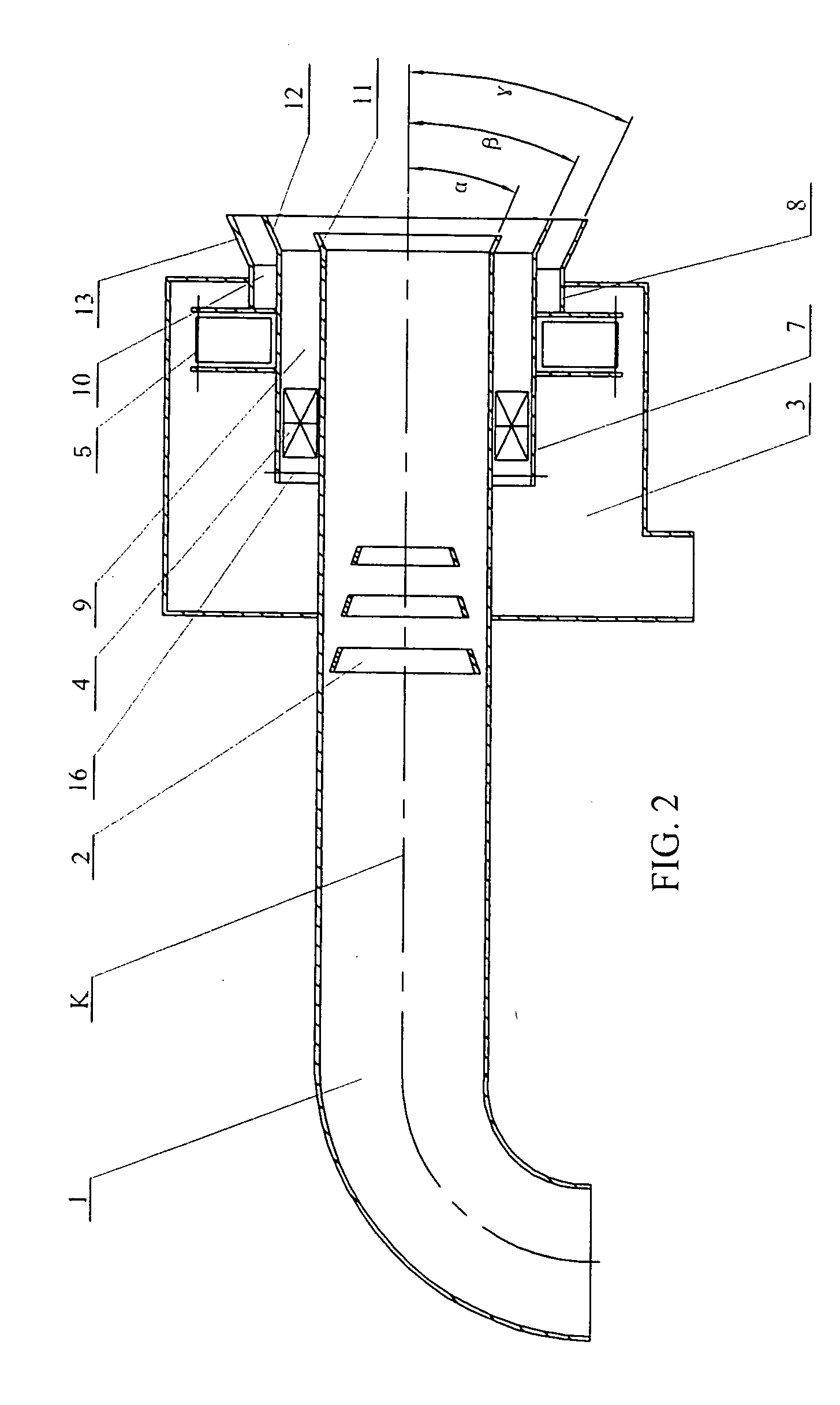

Low Nox Swirl Coal Combustion Burner

InactiveUS20100018445A1Low NOxIncrease volumeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCoalNOx

A burner includes a primary air-coal mixture duct coaxially extended through a secondary air wind box, a pulverized coal separator supported within the primary air-coal mixture duct, a secondary air duct including an inner secondary air duct and an outer secondary air duct coaxially formed around the primary air-coal mixture duct, a primary air-coal mixture conical outlet coupled with the outlet of the primary air-coal mixture duct, and inner secondary air and outer conical outlets coupled with the outlets of the inner secondary air and outer secondary air ducts respectively. The conical outlets are arranged to delay the mixing time of the primary air-coal mixture and secondary air flows through the primary air-coal mixture and secondary air ducts and to prolong the residence time in the center recirculation zone under the reduction ability so as to effectively reduce the formation of NOx.

Owner:HARBIN INST OF TECH

Method and arrangement for exhaust-gas recirculation in an internal combustion engine

ActiveUS20110100341A1Prevent excessive condensate quantityEfficient reductionElectrical controlInternal combustion piston enginesTurbochargerExternal combustion engine

A system and method are disclosed for providing exhaust-gas recirculation in an internal combustion engine that has an exhaust-gas turbocharger. The exhaust gas to be recirculated is collected from the exhaust line downstream of a turbine of the turbocharger, passed through a condensate separator, and supplied into the intake line upstream of the compressor. The condensate is filtered, collected in a reservoir, and pumped to an injection device coupled to the engine intake at a location downstream of the compressor.

Owner:FORD GLOBAL TECH LLC

System and method for operating an engine

InactiveUS20140352670A1Improve engine operationReduce engine emissionsNon-fuel substance addition to fuelExhaust gas recirculationHigh concentrationAutomotive engineering

Owner:FORD GLOBAL TECH LLC

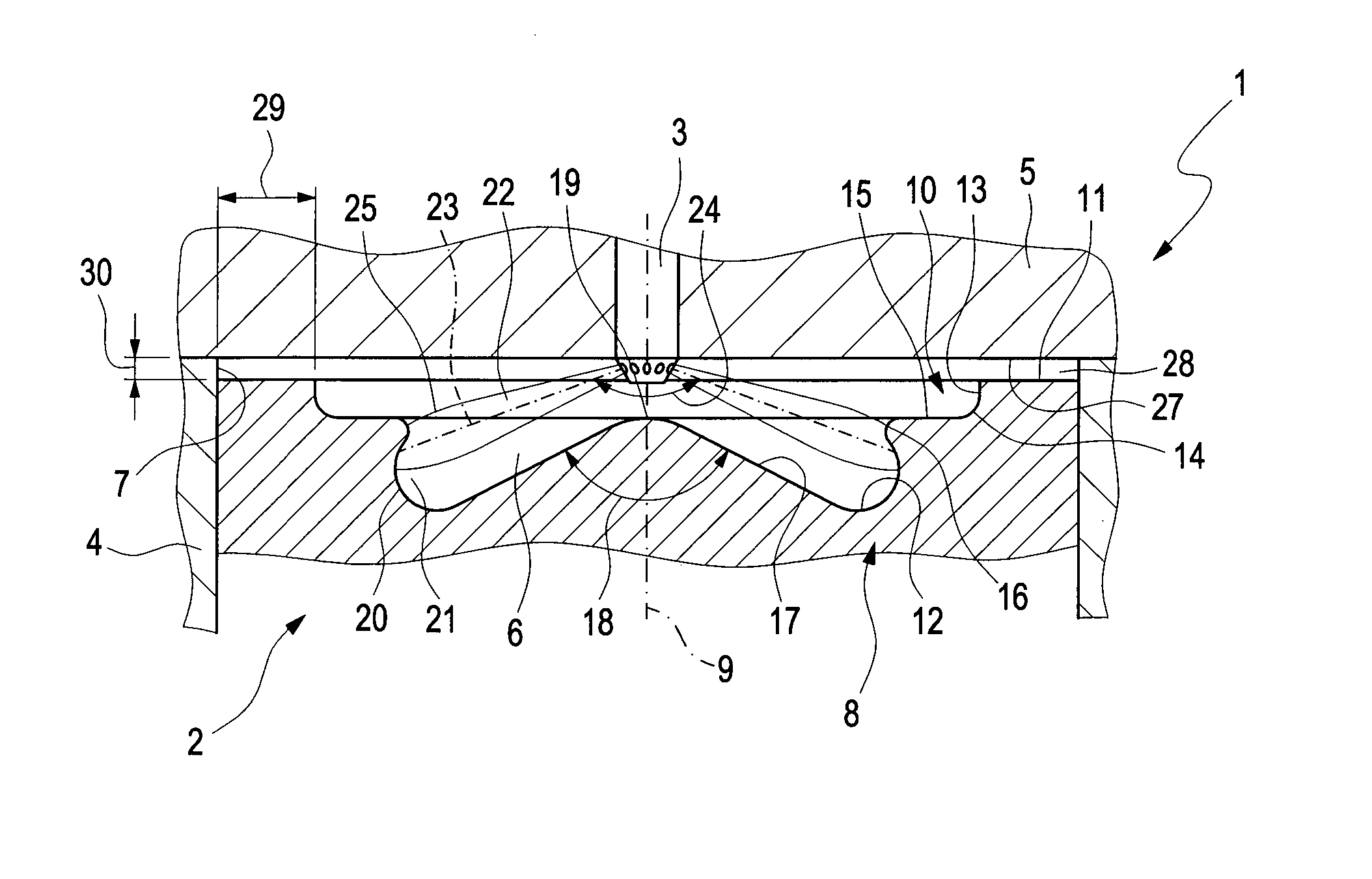

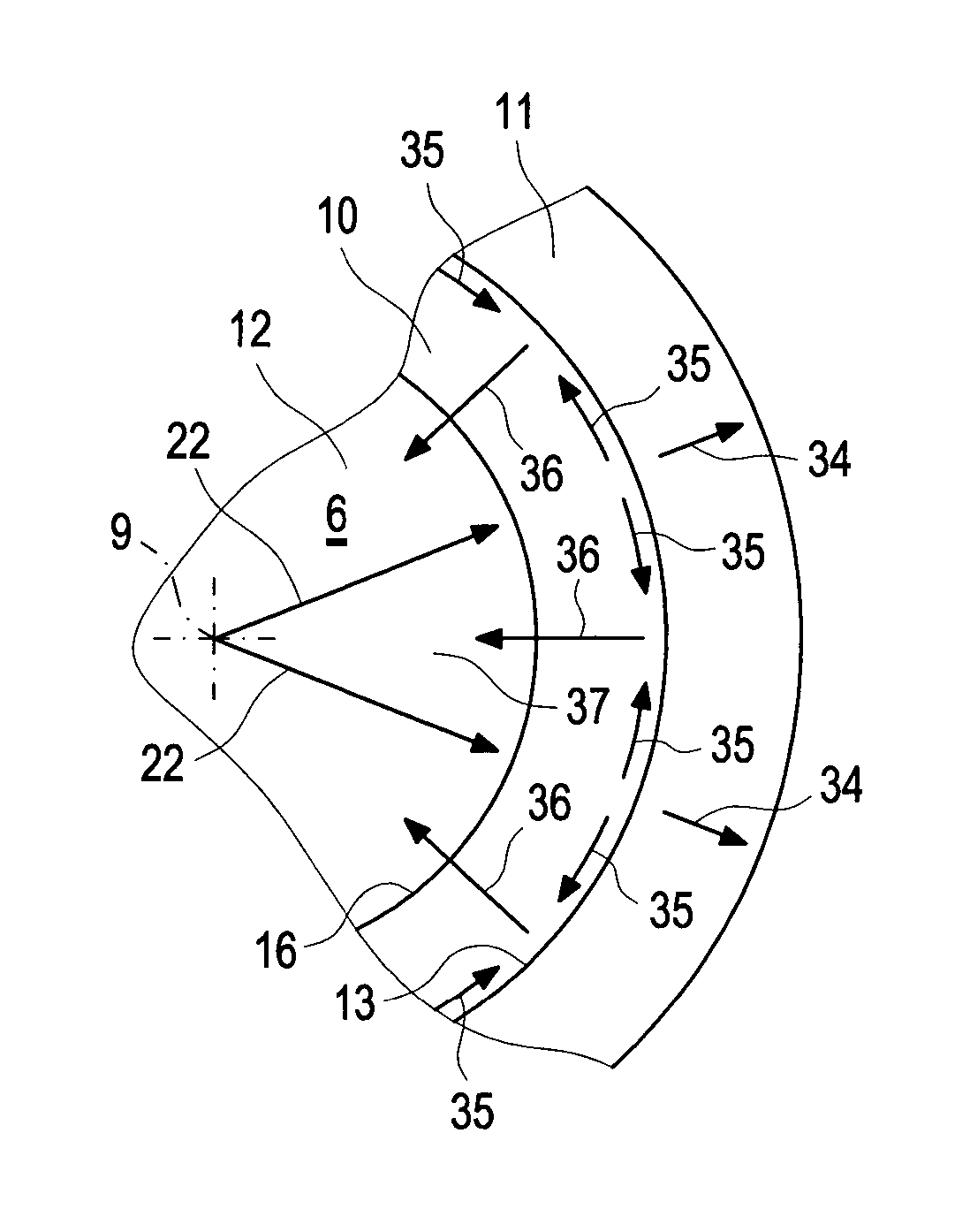

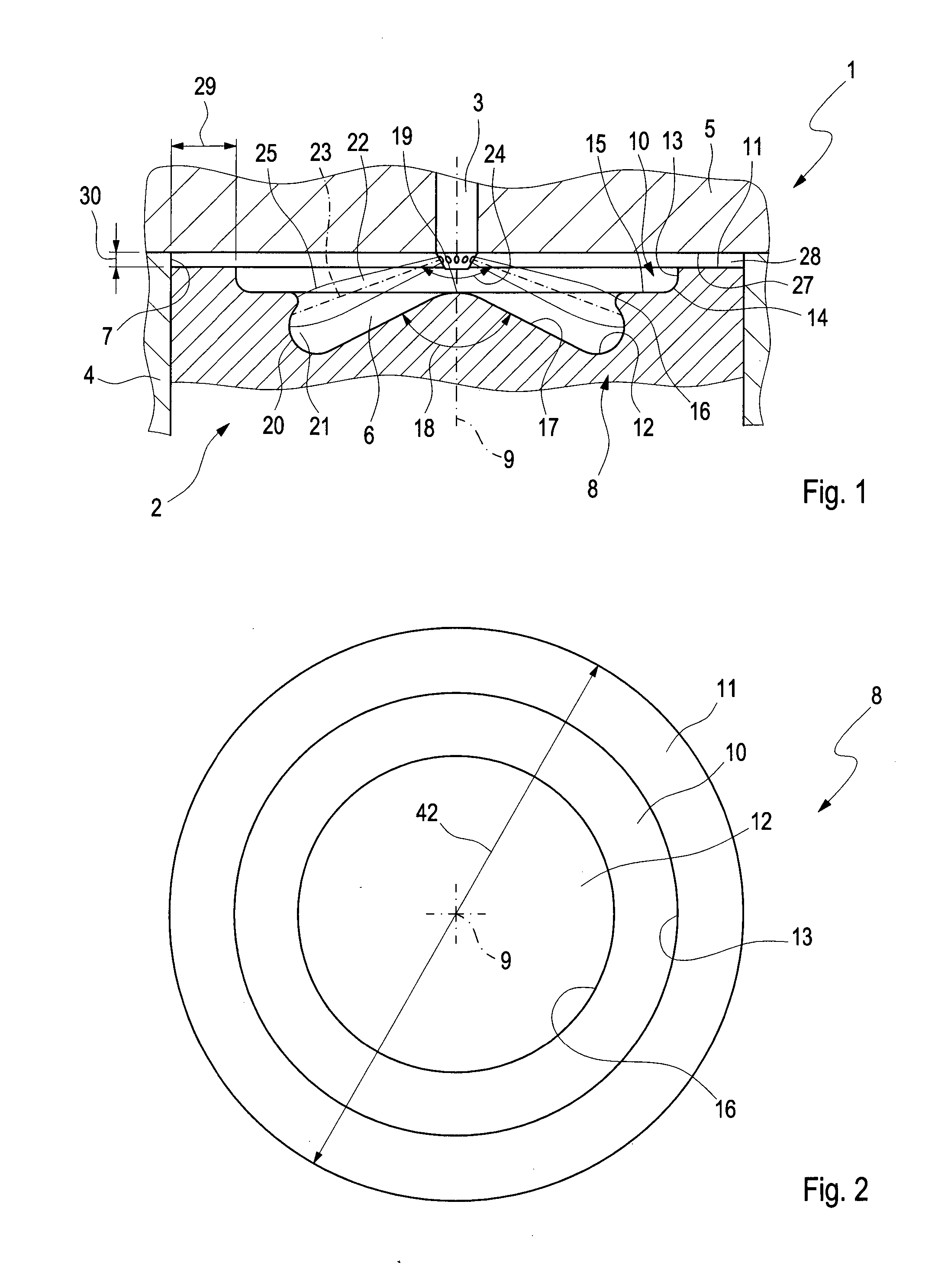

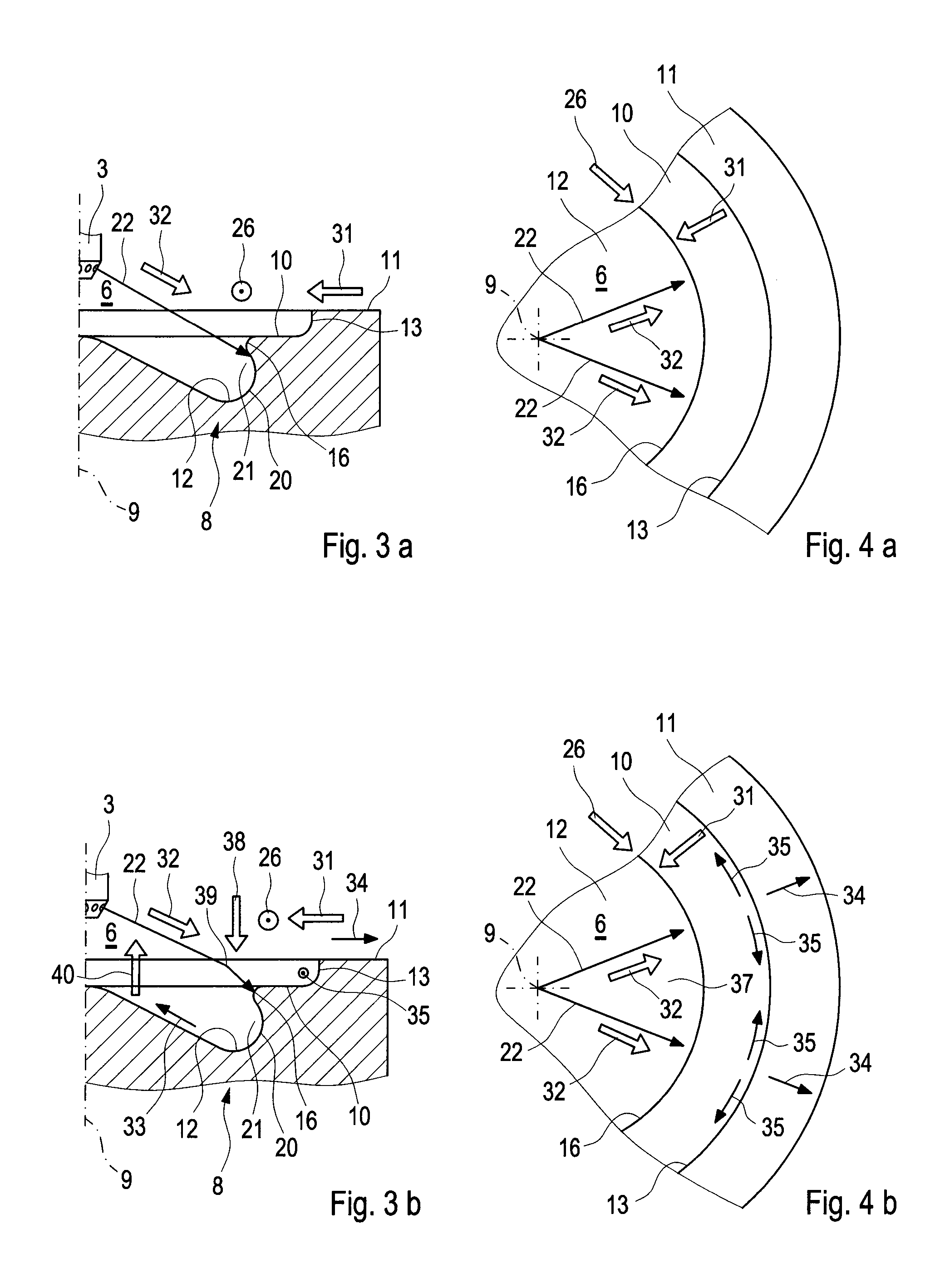

Combustion Method and Internal Combustion Engine

ActiveUS20140305402A1Reduce formationReduce the temperatureInternal combustion piston enginesJet flowCylinder head

A combustion process with auto-ignition for direct-injection internal combustion engines involves dividing injection jets at a jet divider contour into a first partial quantity, a second partial quantity, and third partial quantities. The first partial quantity enters into the piston cavity, the second partial quantity enters via the piston step into a region between the piston crown and the cylinder head, and the third partial quantities, starting from the respective injection jet, spread out on both sides in the peripheral direction in opposite directions along the piston step, and the respective third partial quantities collide with one another between two adjacent injection jets within the piston step and are deflected radially inwardly. The first partial quantity and the second partial quantity form a first combustion front and a second combustion front, and the partial quantities which in each case are jointly deflected inwardly form a third combustion front radially inwardly into a gap between the injection jets. The injection jets are deflected upstream from the jet divider contour in the direction of the piston by means of a resultant flow formed essentially from a swirl, a squish gap flow, and a jet flow.

Owner:DAIMLER AG

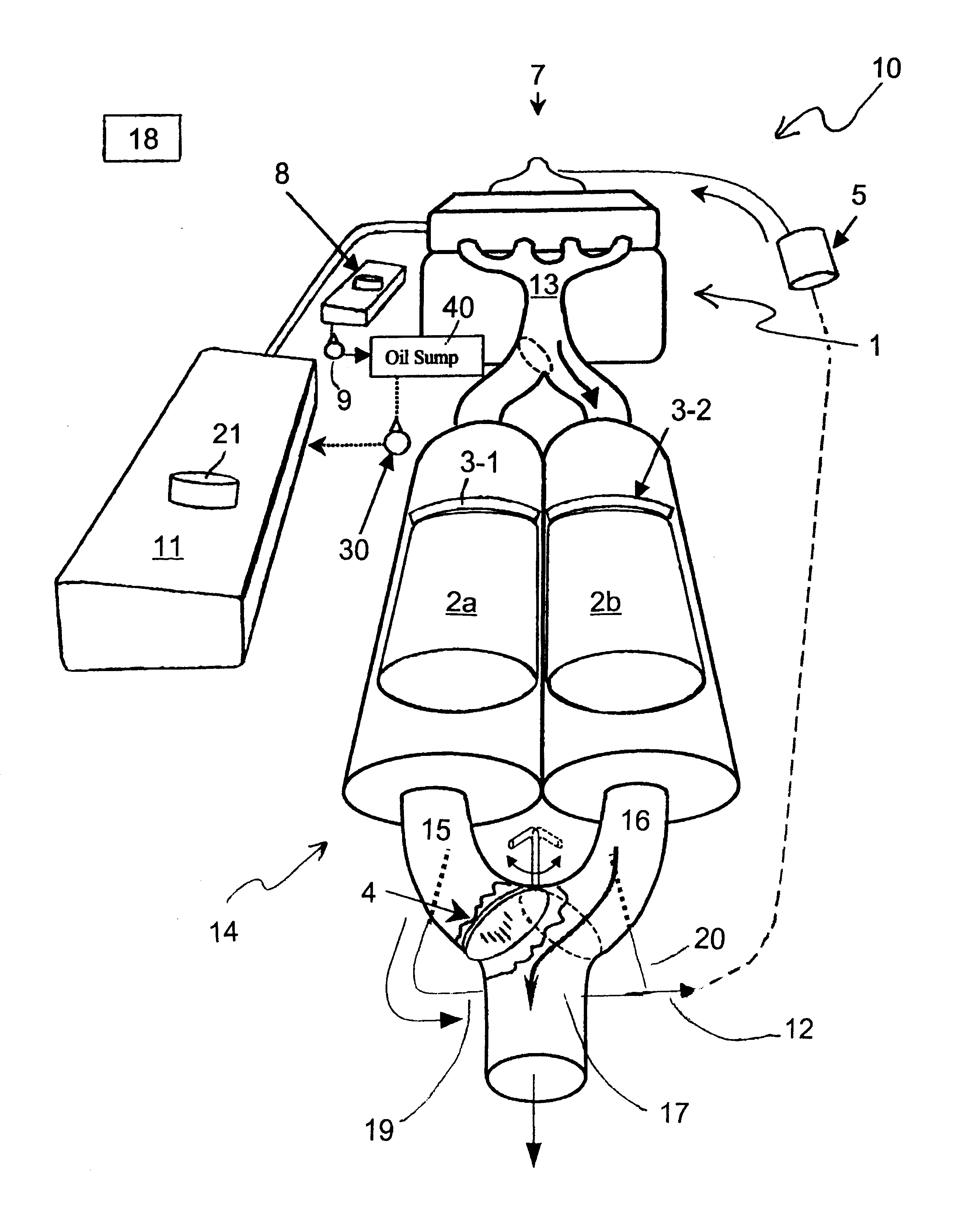

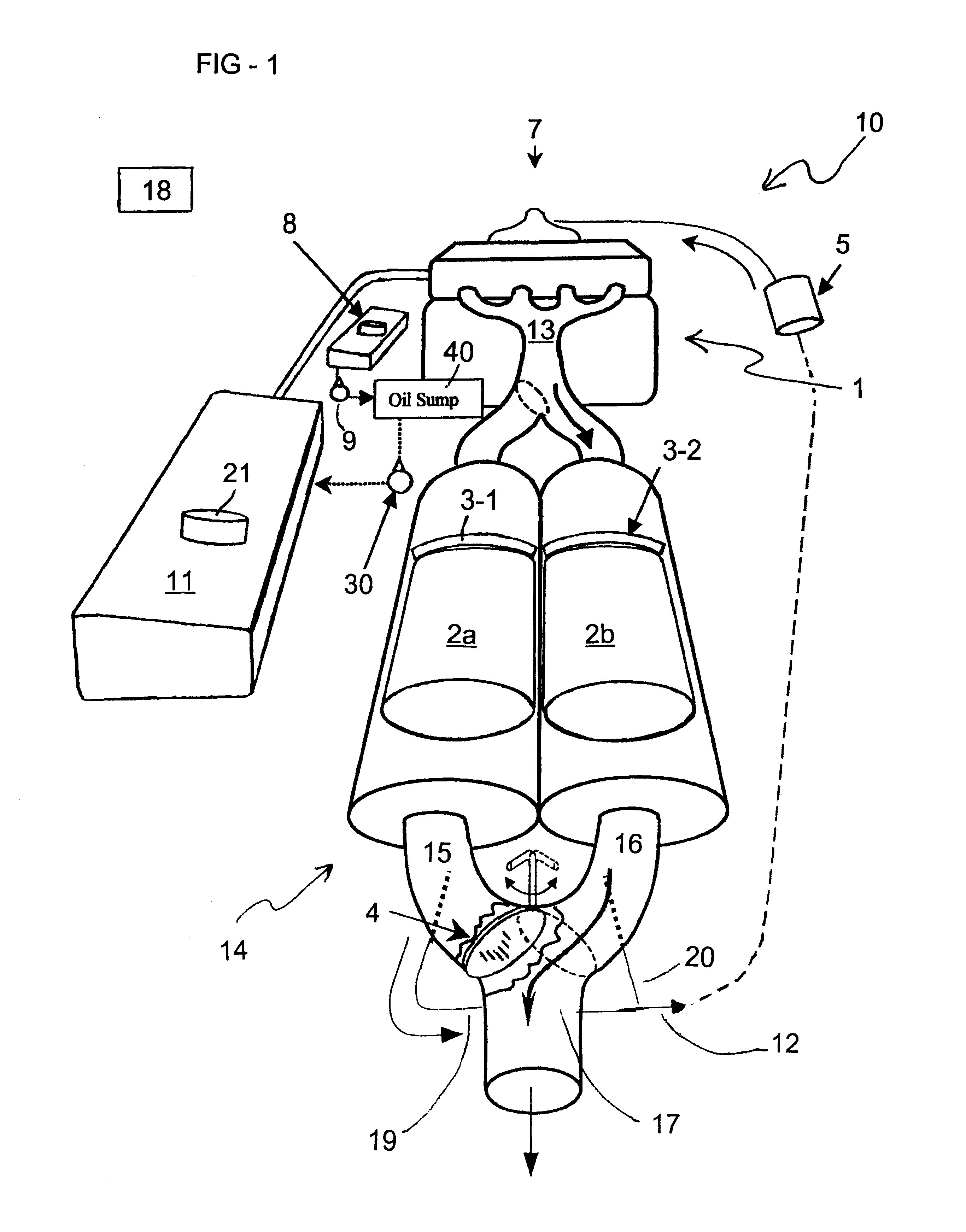

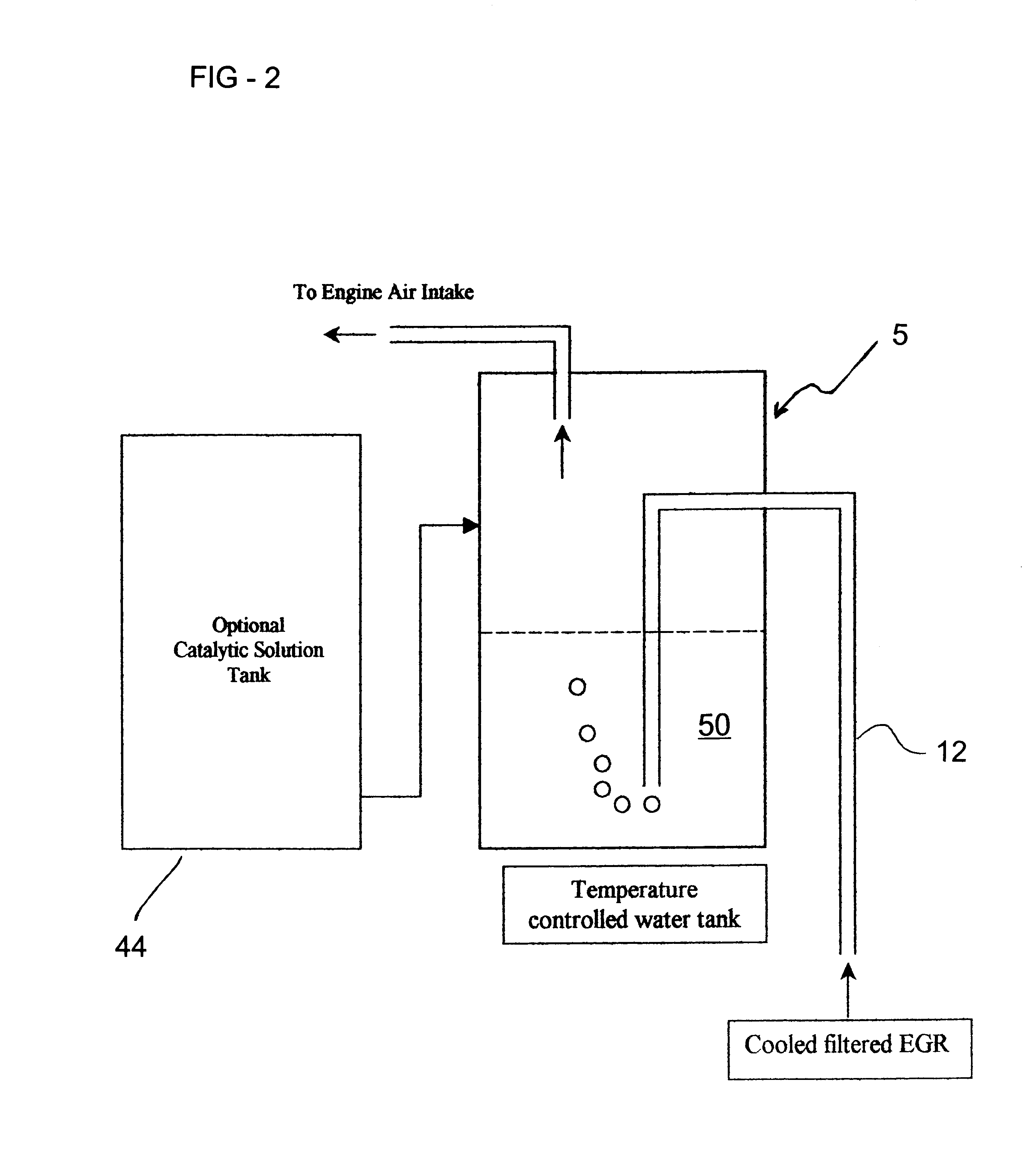

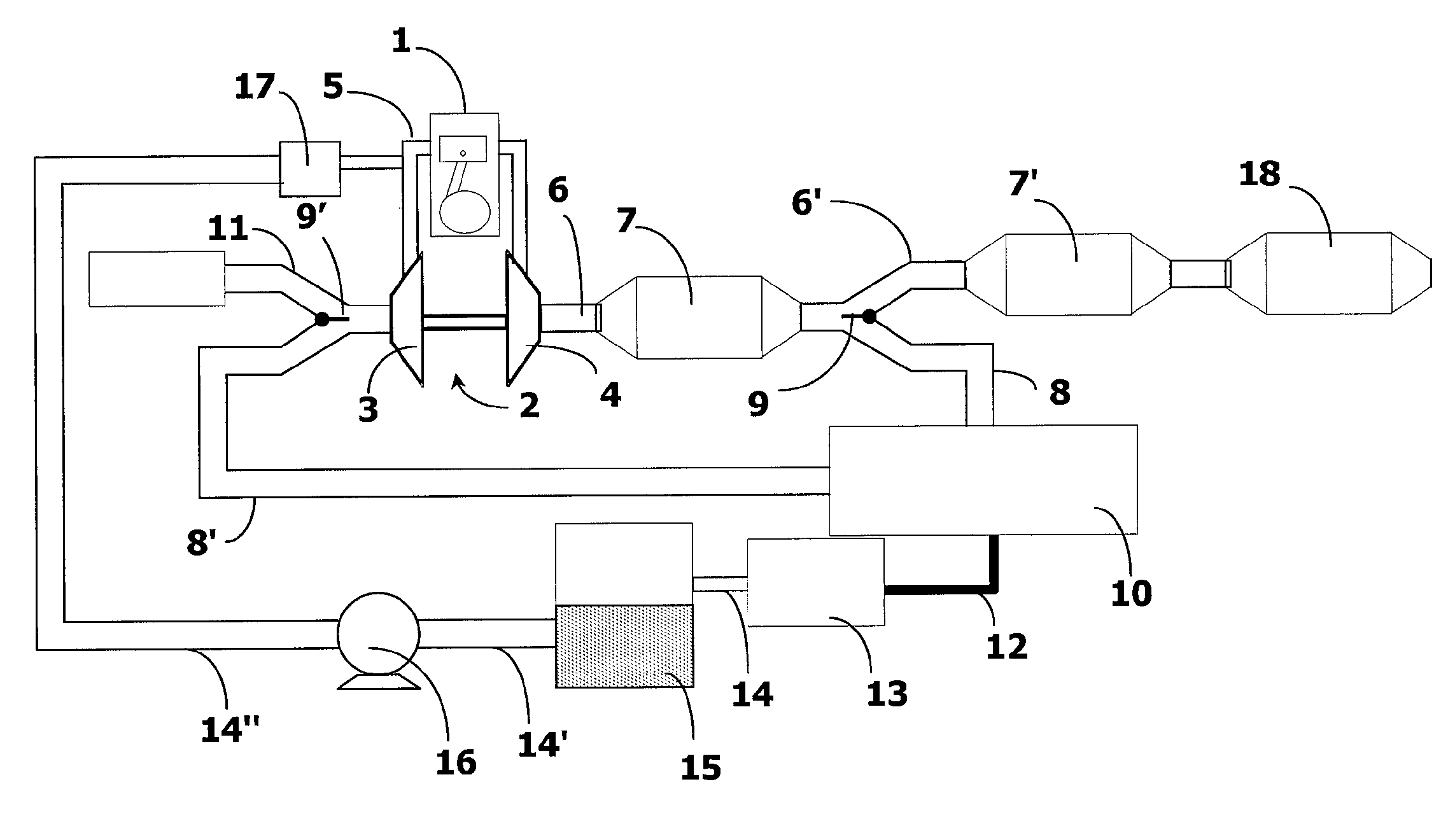

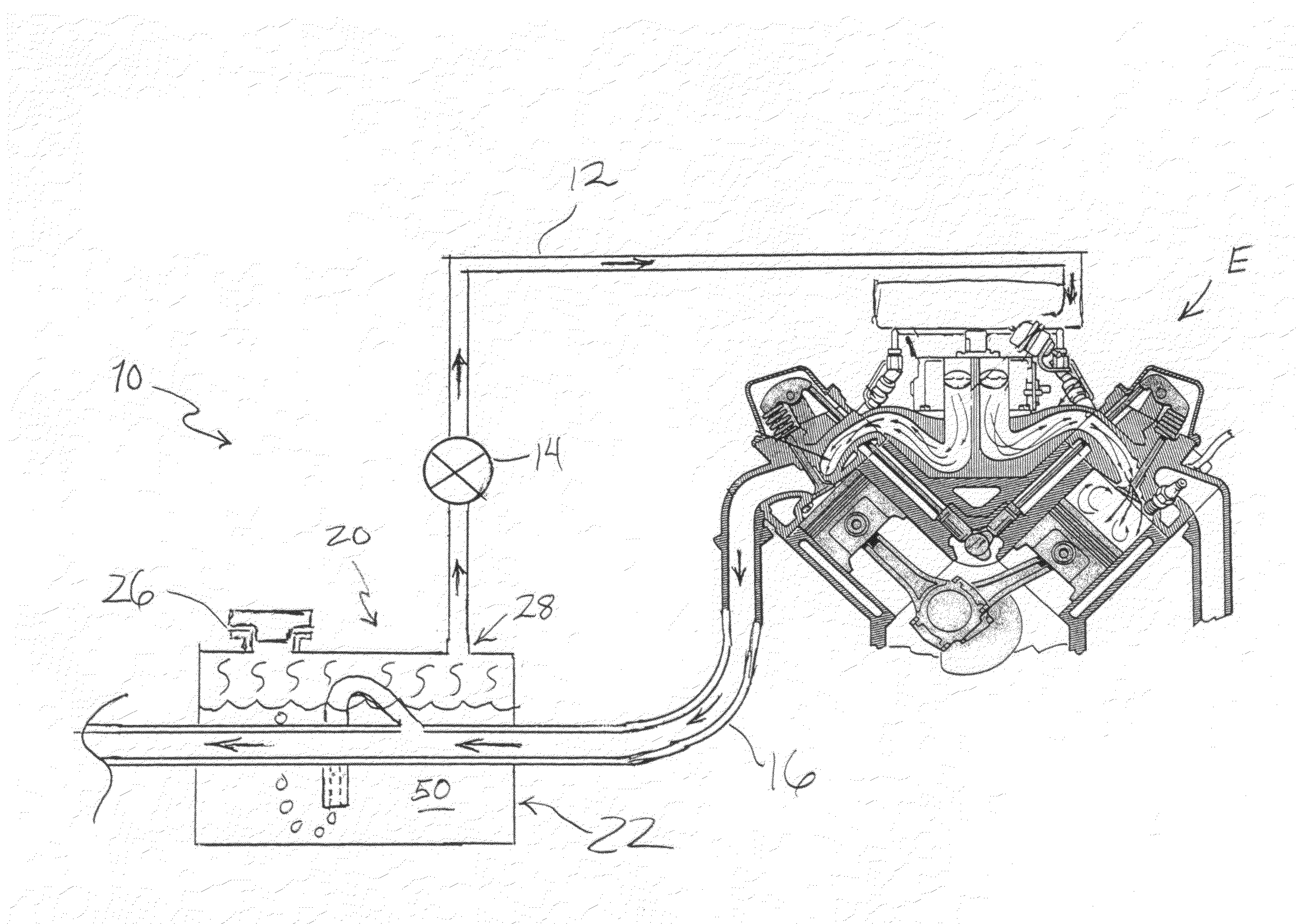

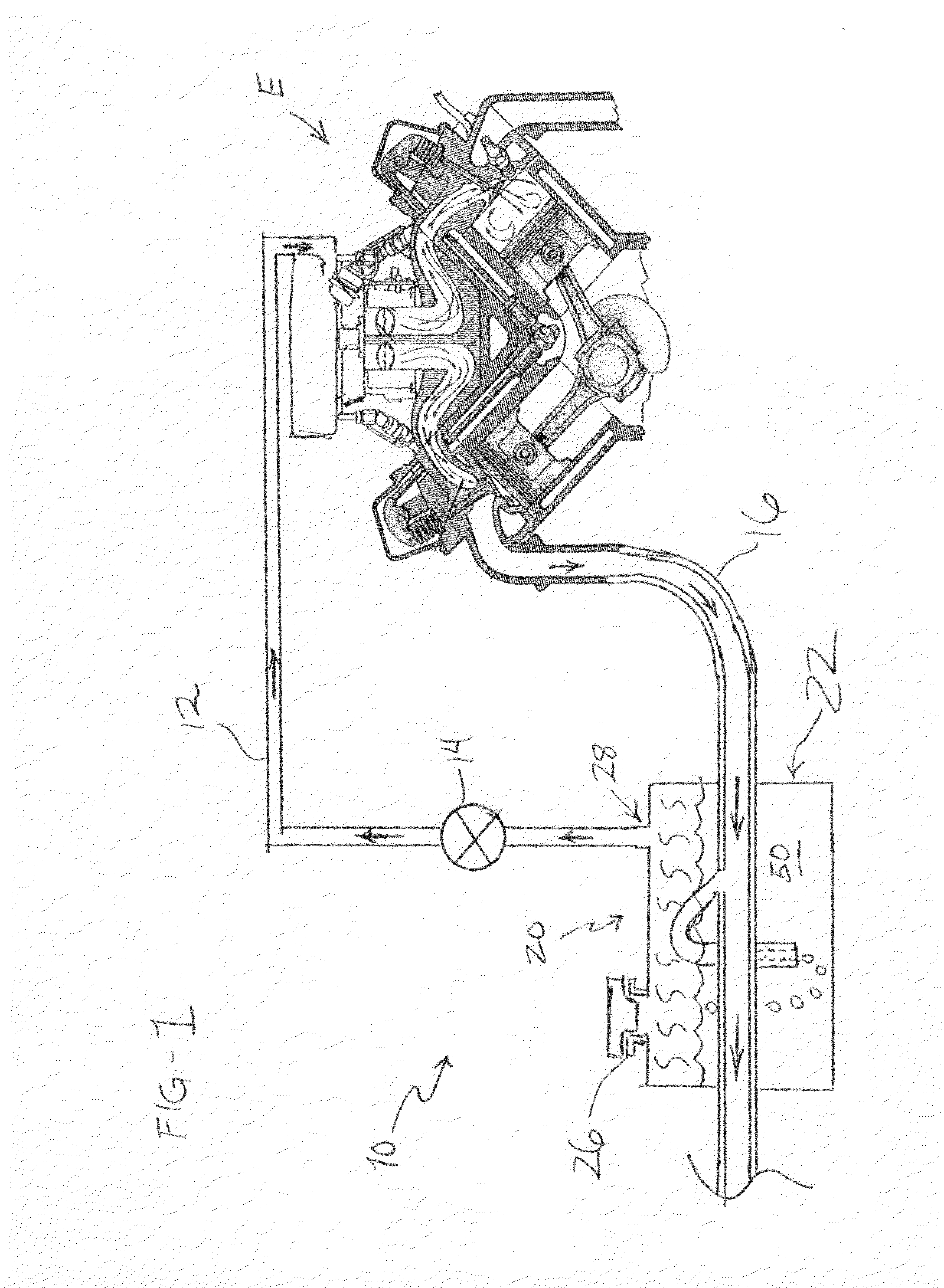

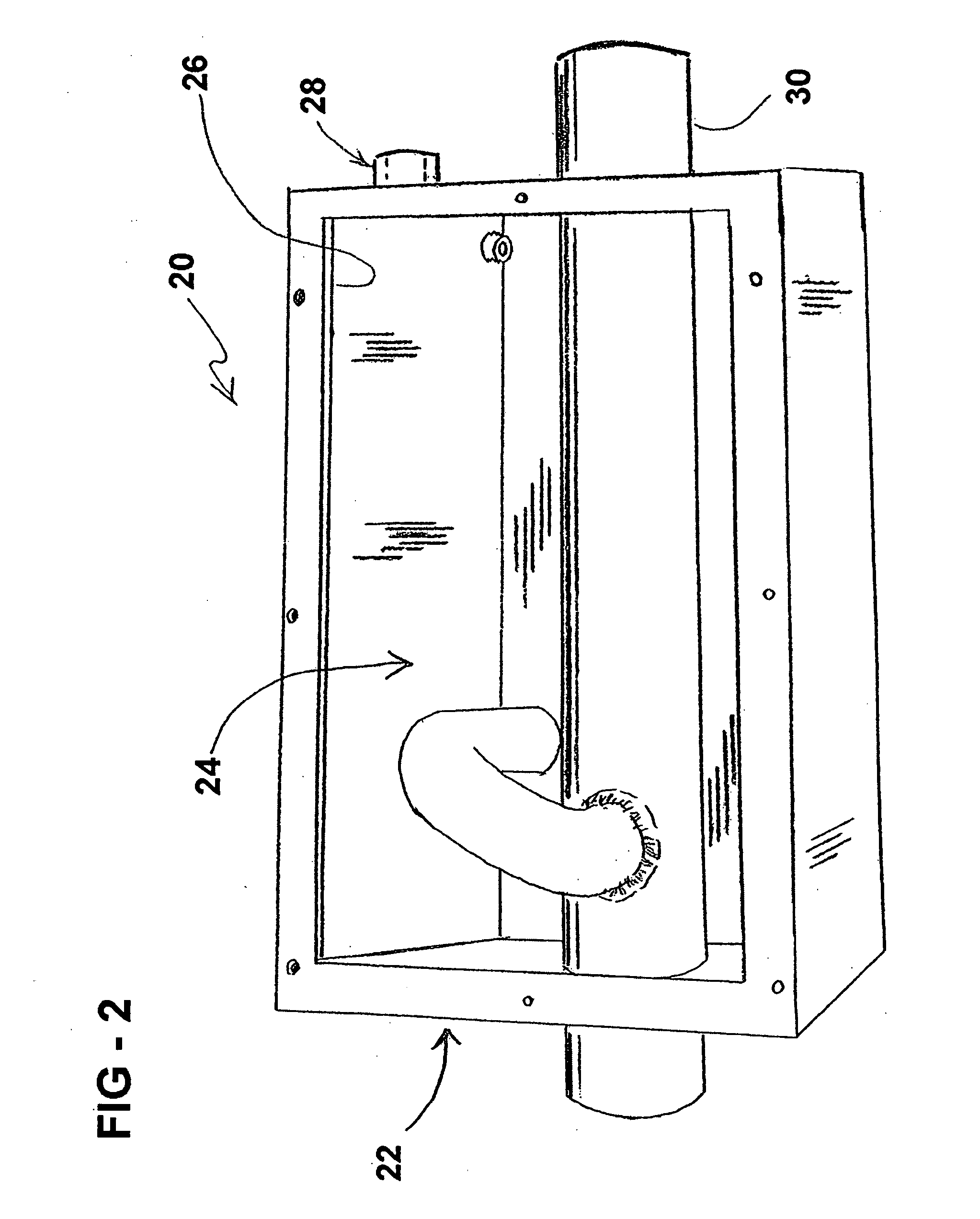

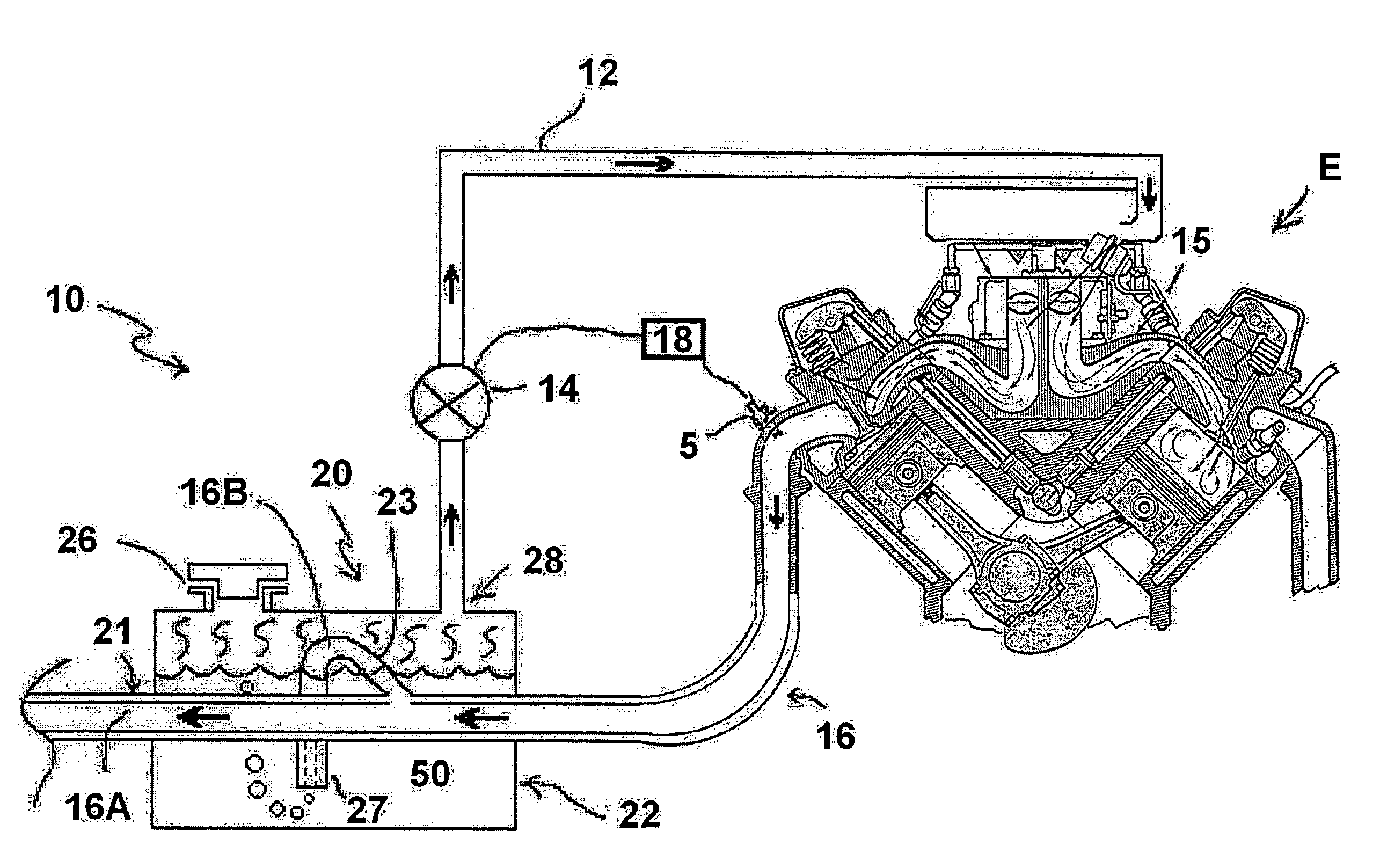

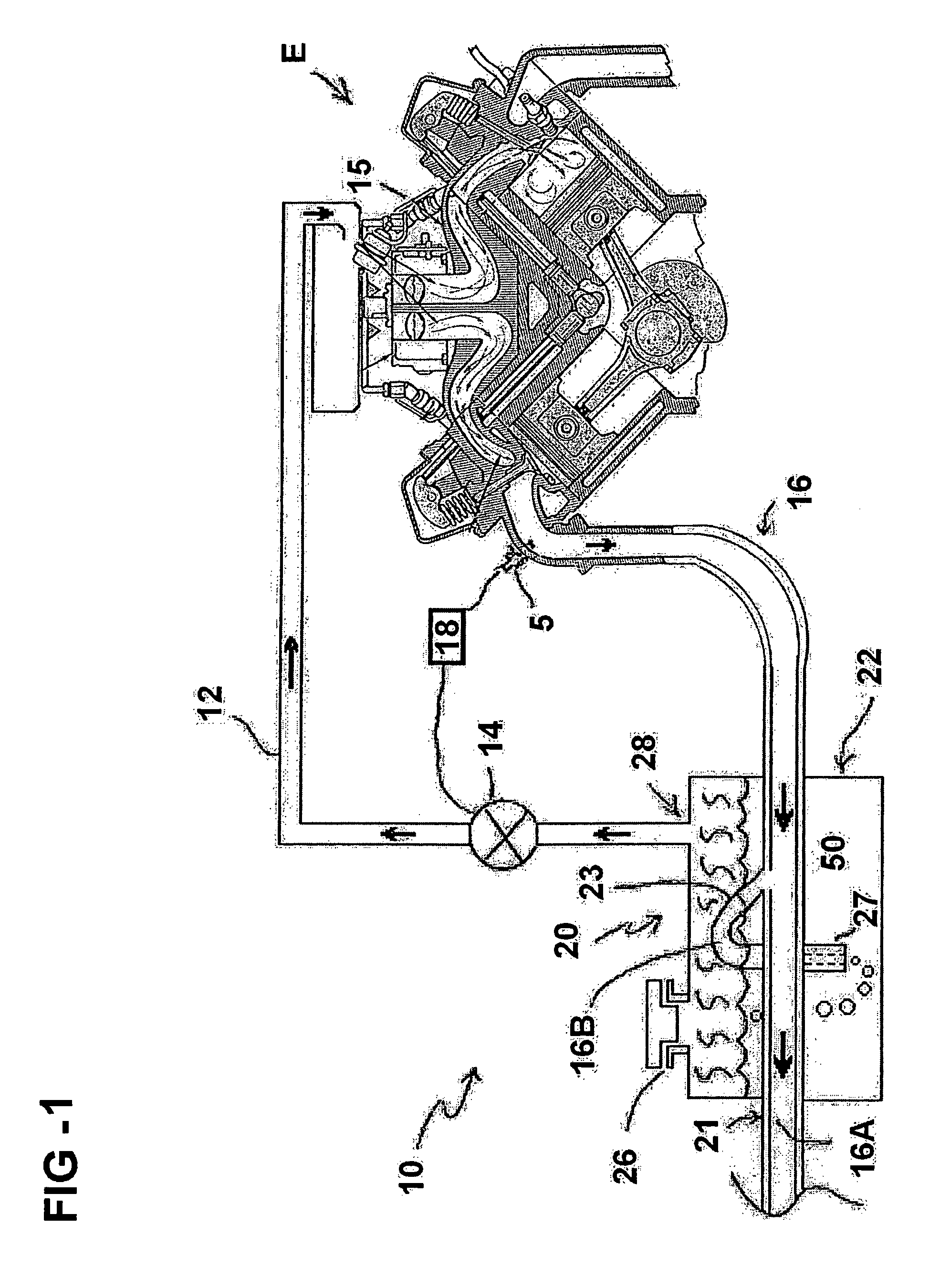

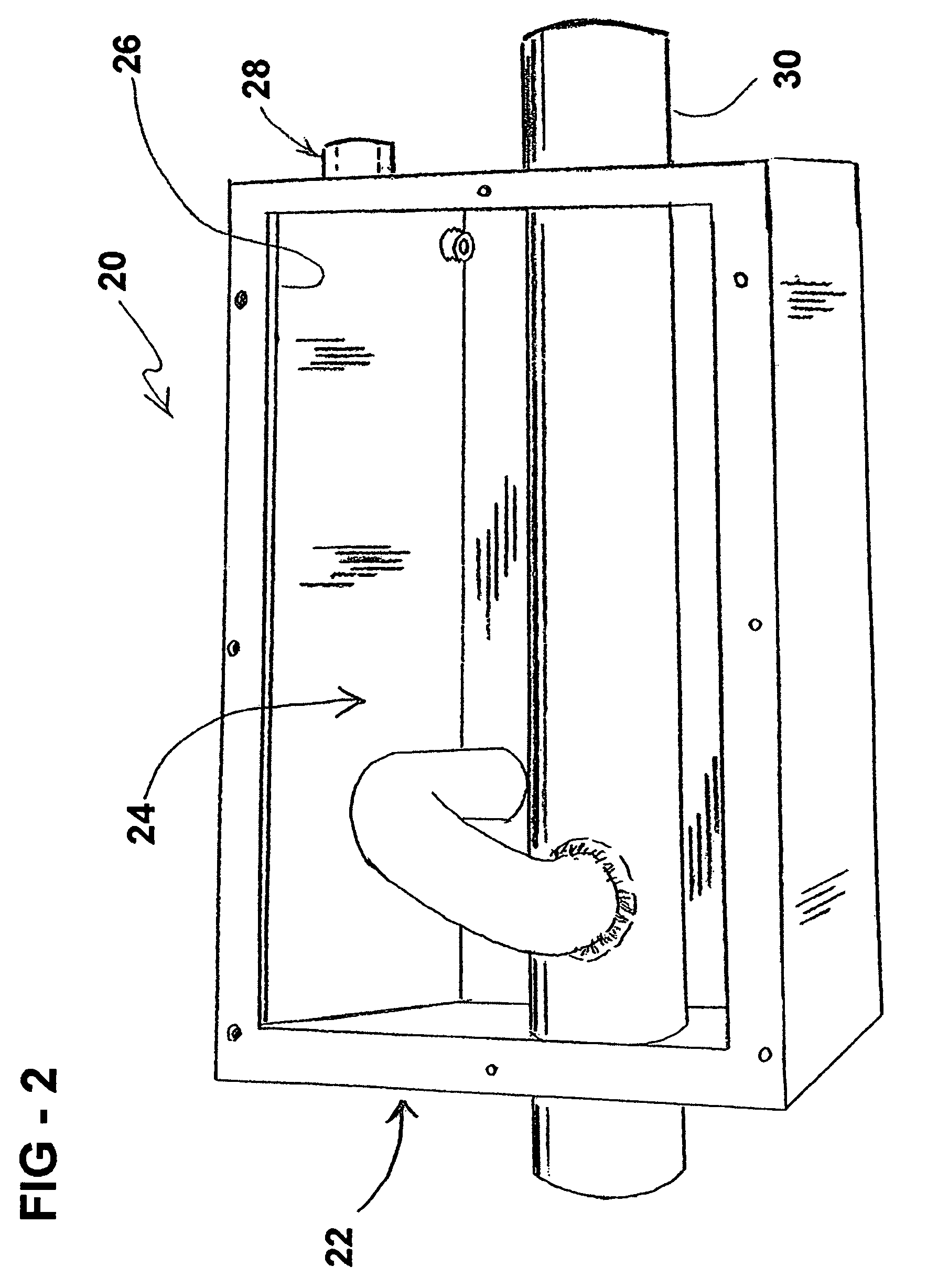

Hydrated EGR system, method and apparatus for reducing harmful exhaust emissions and improving fuel economy

ActiveUS20090032000A1Reduce harmful exhaust emissionsImprove engine performanceInternal combustion piston enginesNon-fuel substance addition to fuelWater vaporExhaust fumes

A hydrated EGR system, method and apparatus for a vehicle, in which heat from an exhaust pipe is used to heat an aqueous fluid solution in a water tank. A portion of the hot exhaust gas is diverted from the main exhaust flow, and the diverted portion is bubbled through the heated aqueous fluid solution to form a hydrated EGR mixture containing water vapor. The hydrated EGR mixture is then fed back to an intake portion of the engine, is mixed with an incoming fuel / air mixture, and is burned with the fuel air mixture inside the engine. The use of the hydrated EGR mixture, including heated water vapor, as part of the intake charge simultaneously reduces harmful exhaust emissions, improves engine performance, and improves fuel economy of the vehicle.

Owner:RIM JULIUS J

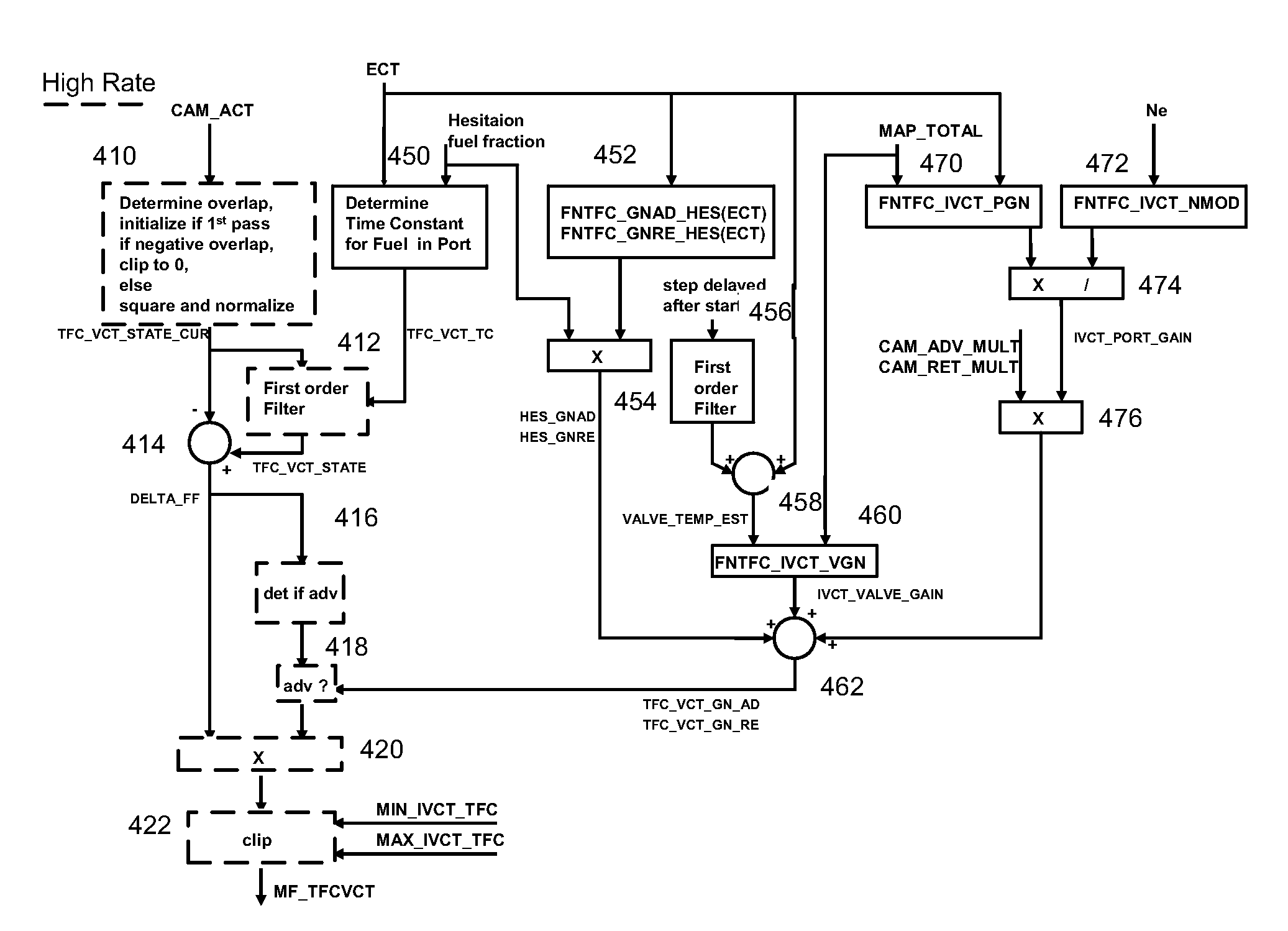

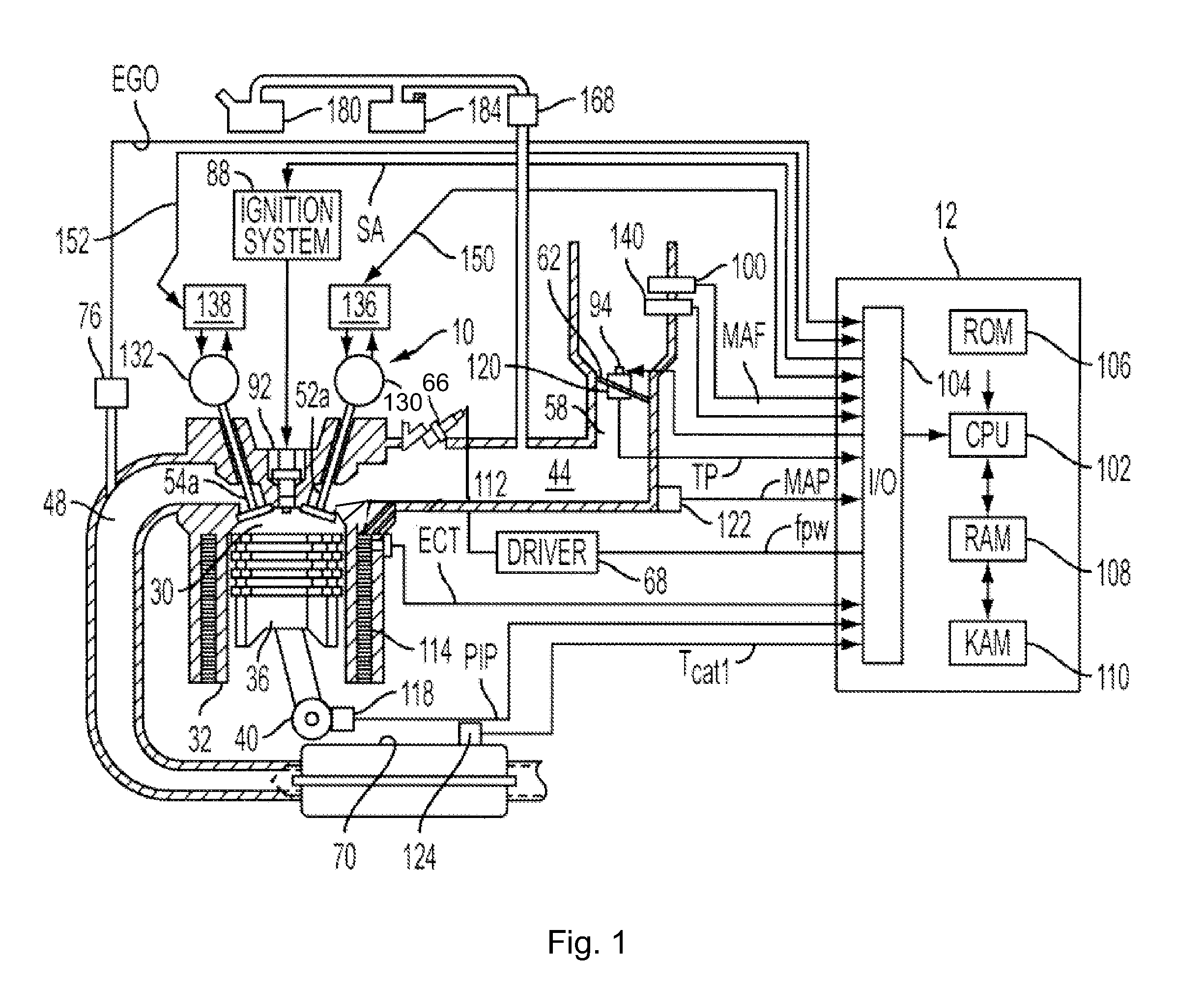

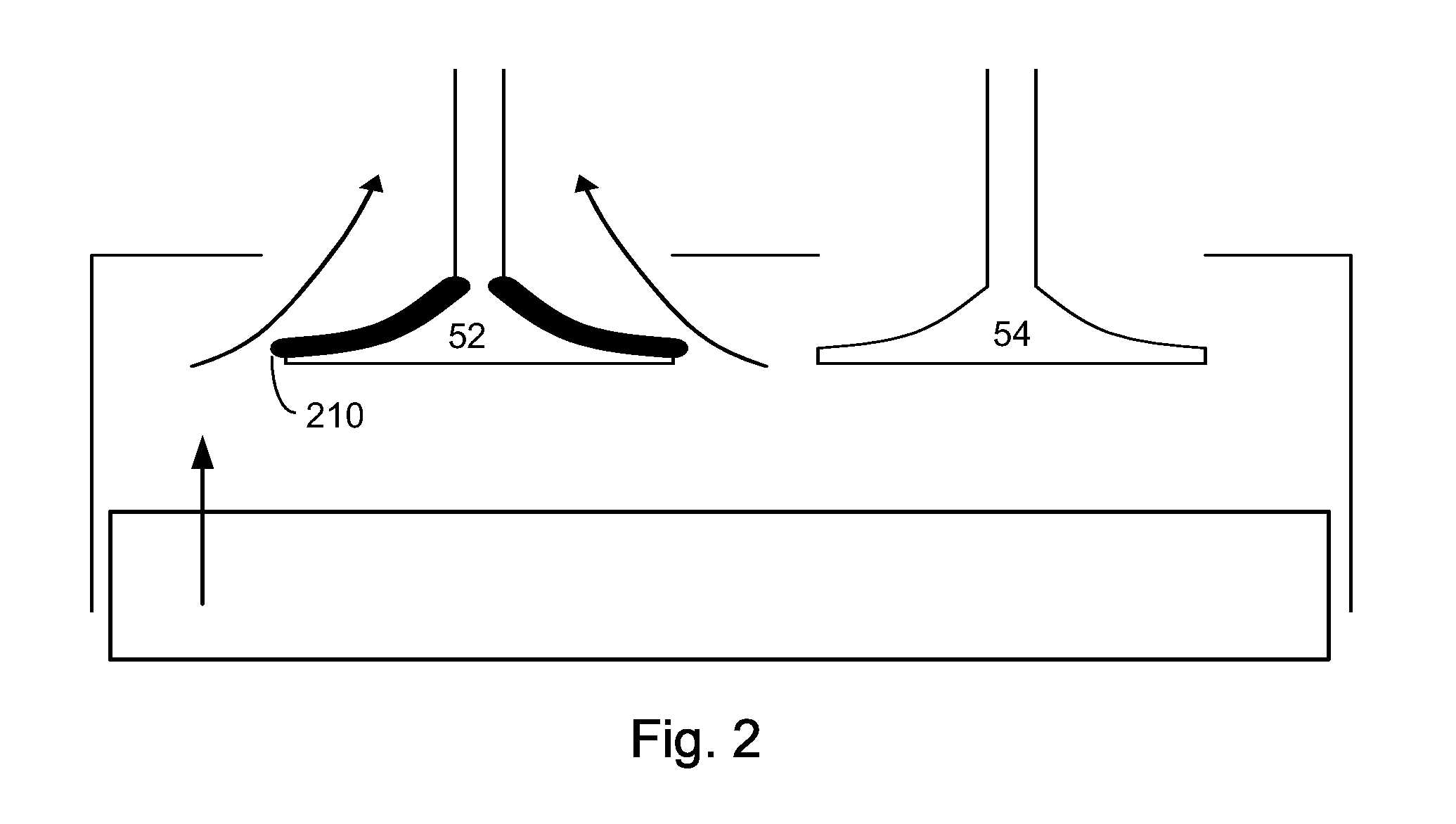

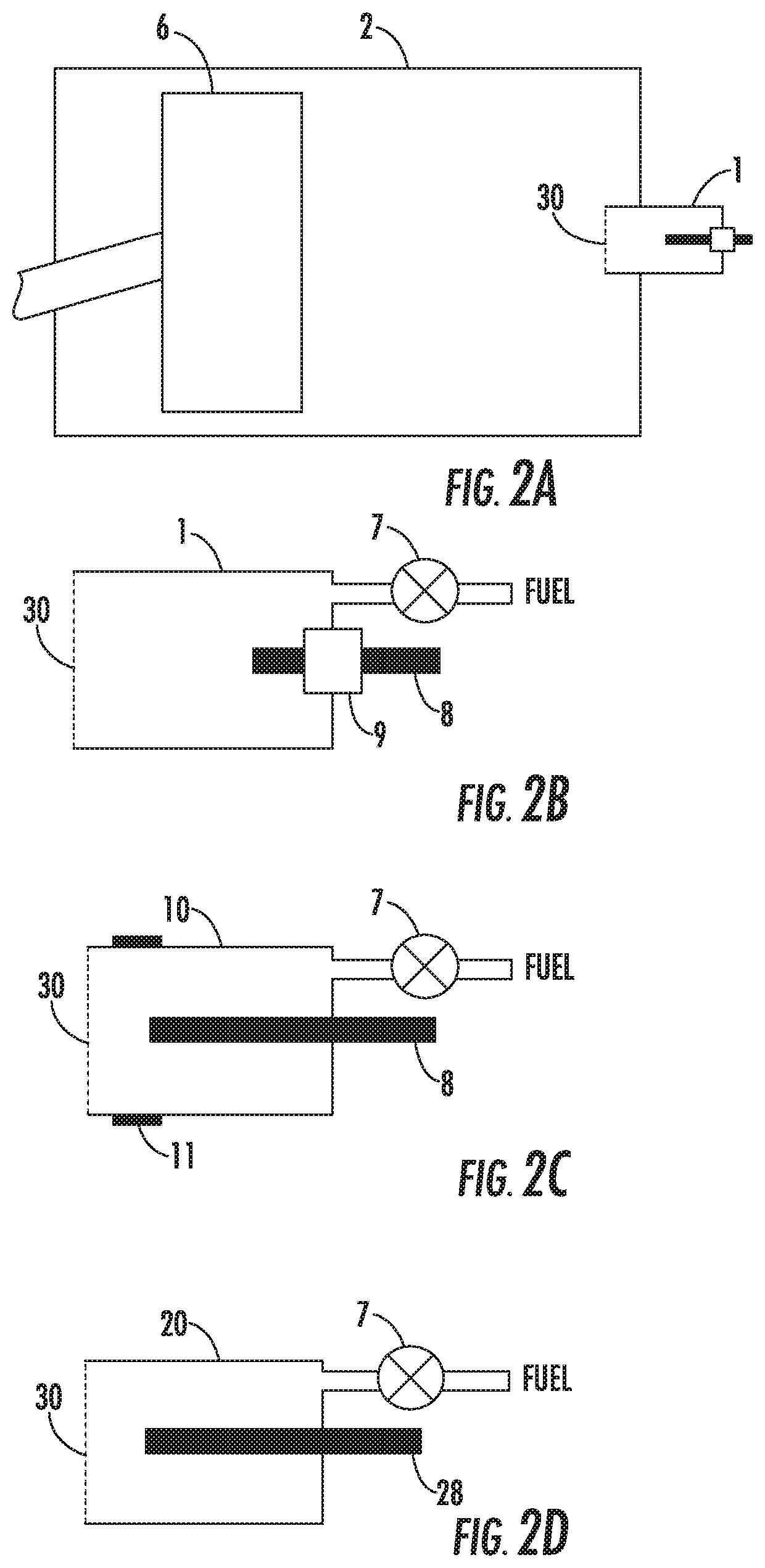

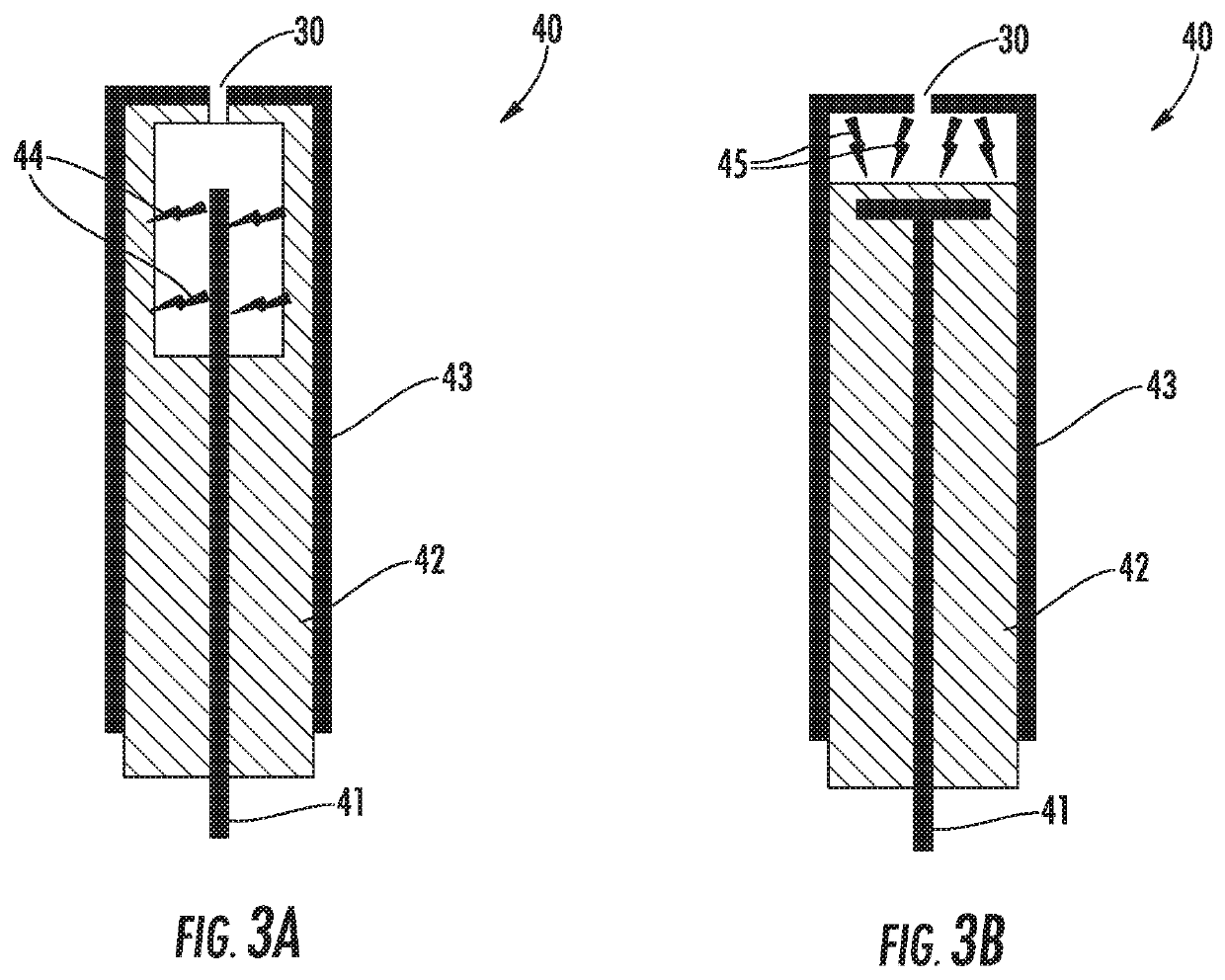

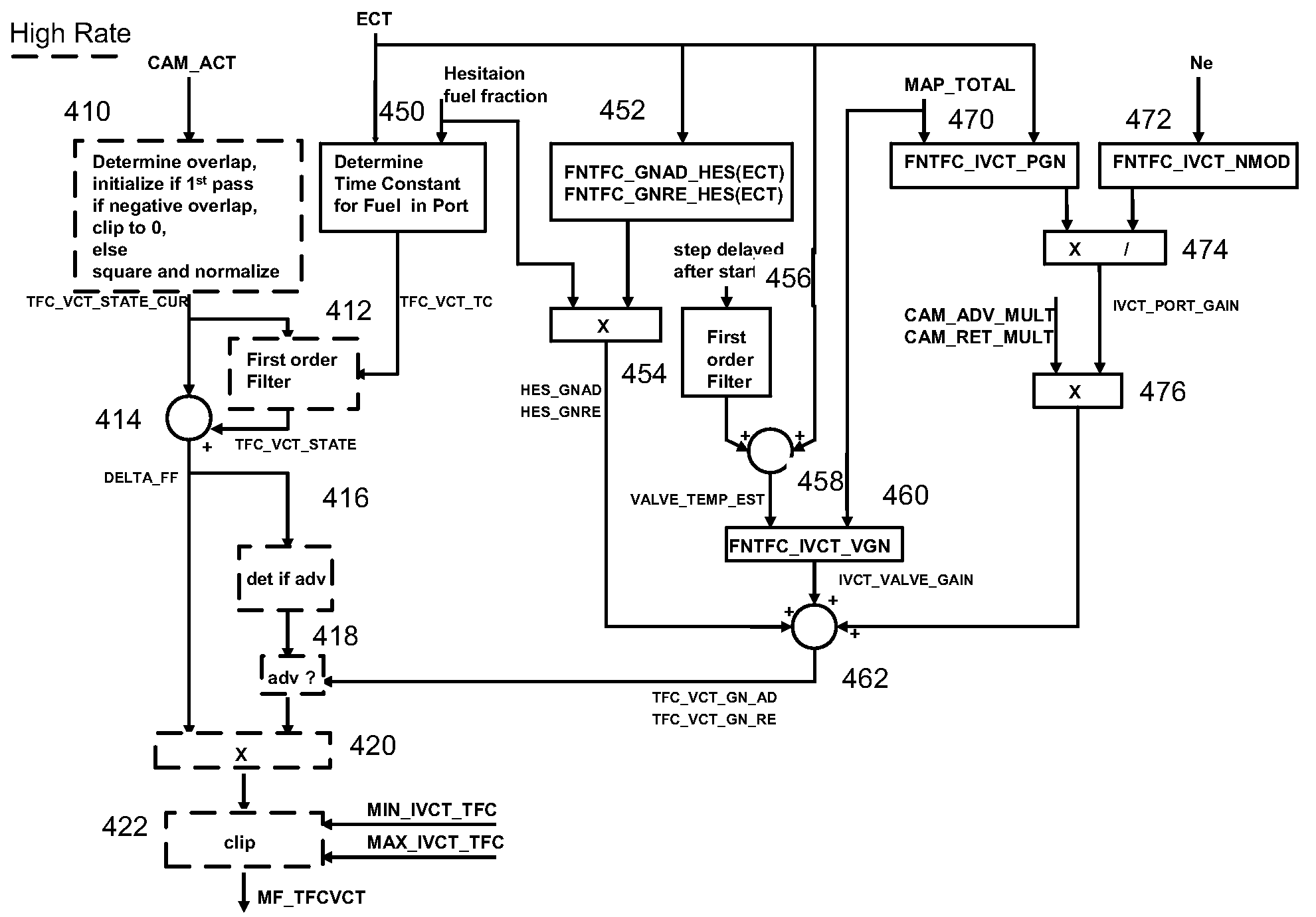

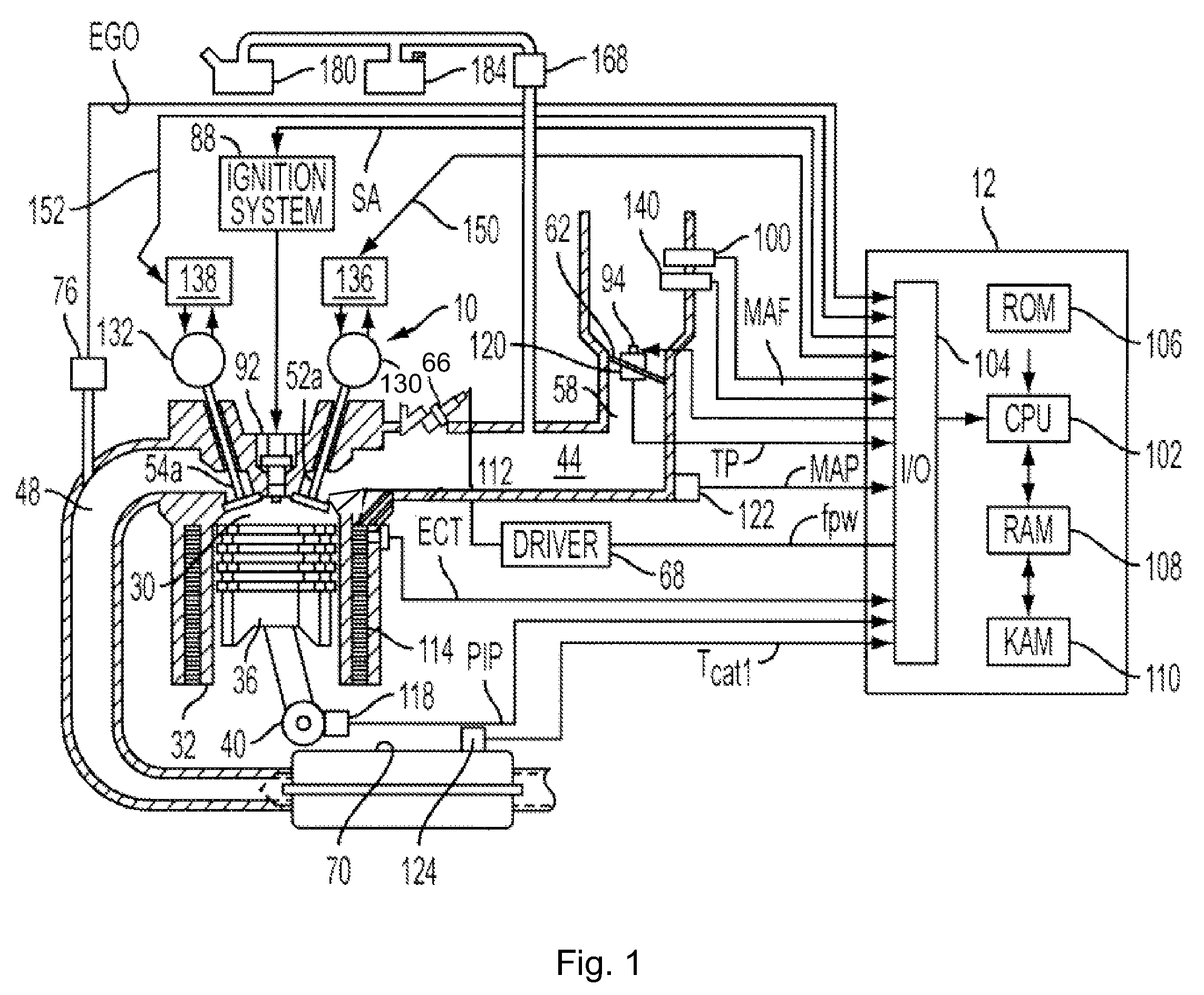

System and Method of Controlling Fuel Delivery During Positive Valve Overlap Operation of an Engine Start

ActiveUS20070283933A1Improve fuel economyIncrease output of engineValve arrangementsElectrical controlEvaporationMechanical engineering

An approach is provided for compensating engine fueling during starting conditions in which positive valve overlap is enabled early in the start. In one example, the valve timing is adjusted to increase positive overlap during cold starting conditions, and fuel adjustments are provided to compensate for the evaporation effects of the increased residual push-back.

Owner:FORD GLOBAL TECH LLC

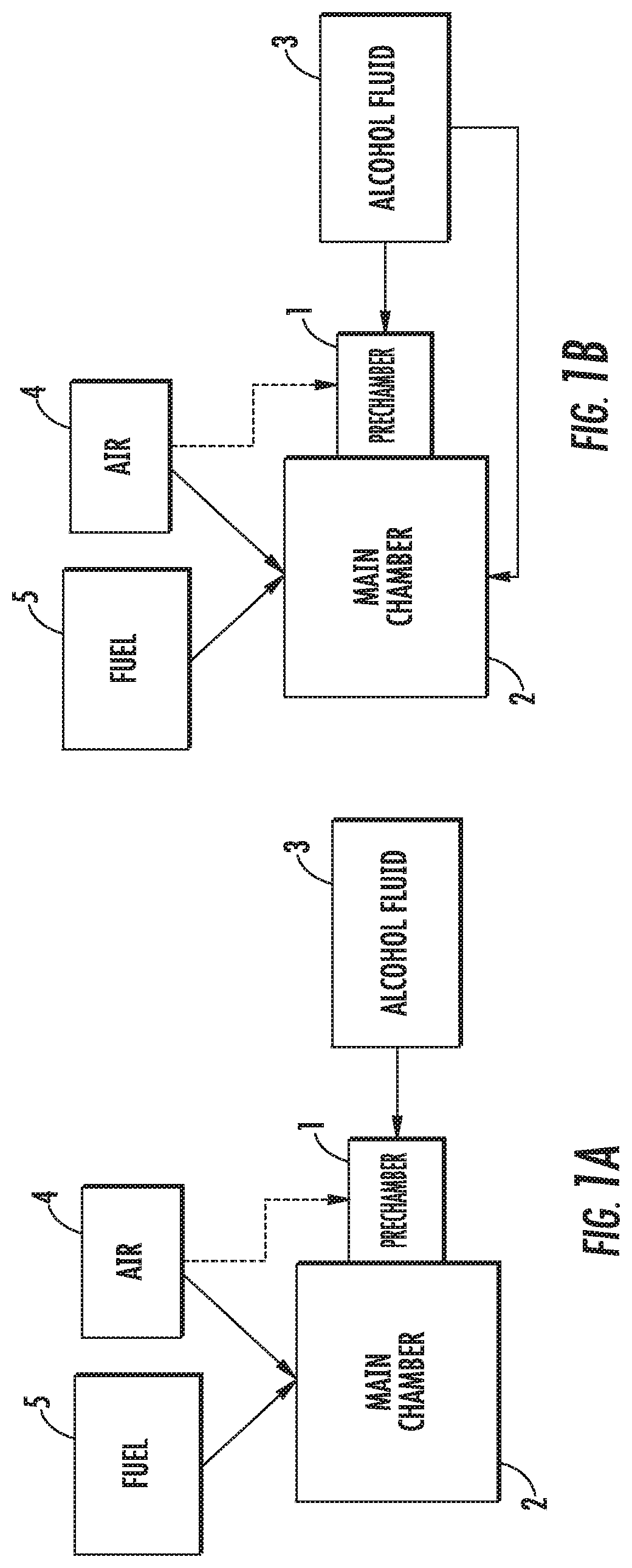

Alcohol And Plasma Enhanced Prechambers For Higher Efficiency, Lower Emissions Gasoline Engines

InactiveUS20210131337A1Emission reductionLow costCombustion enginesEngine operationsAlcohol fuelIn vehicle

Optimized alcohol and plasma enhanced prechambers for engines powered by gasoline and other fuels are used to increase the range of prechamber operation and to reduce soot. The increased prechamber capability is employed to extend the limit of lean operation of the engines. It can also be used to extend the limit of heavy EGR operation and to enable higher RPM operation. The amount of alcohol used in the prechamber is preferably less than 2% of the fuel that is used in the engine cylinder. The alcohol for the prechamber can be entirely provided by onboard separation from a gasoline-alcohol fuel mixture.

Owner:MASSACHUSETTS INST OF TECH

System and method of controlling fuel delivery during positive valve overlap operation of an engine start

ActiveUS7607410B2Improve fuel economyHigh outputValve arrangementsElectrical controlEvaporationEngineering

An approach is provided for compensating engine fueling during starting conditions in which positive valve overlap is enabled early in the start. In one example, the valve timing is adjusted to increase positive overlap during cold starting conditions, and fuel adjustments are provided to compensate for the evaporation effects of the increased residual push-back.

Owner:FORD GLOBAL TECH LLC

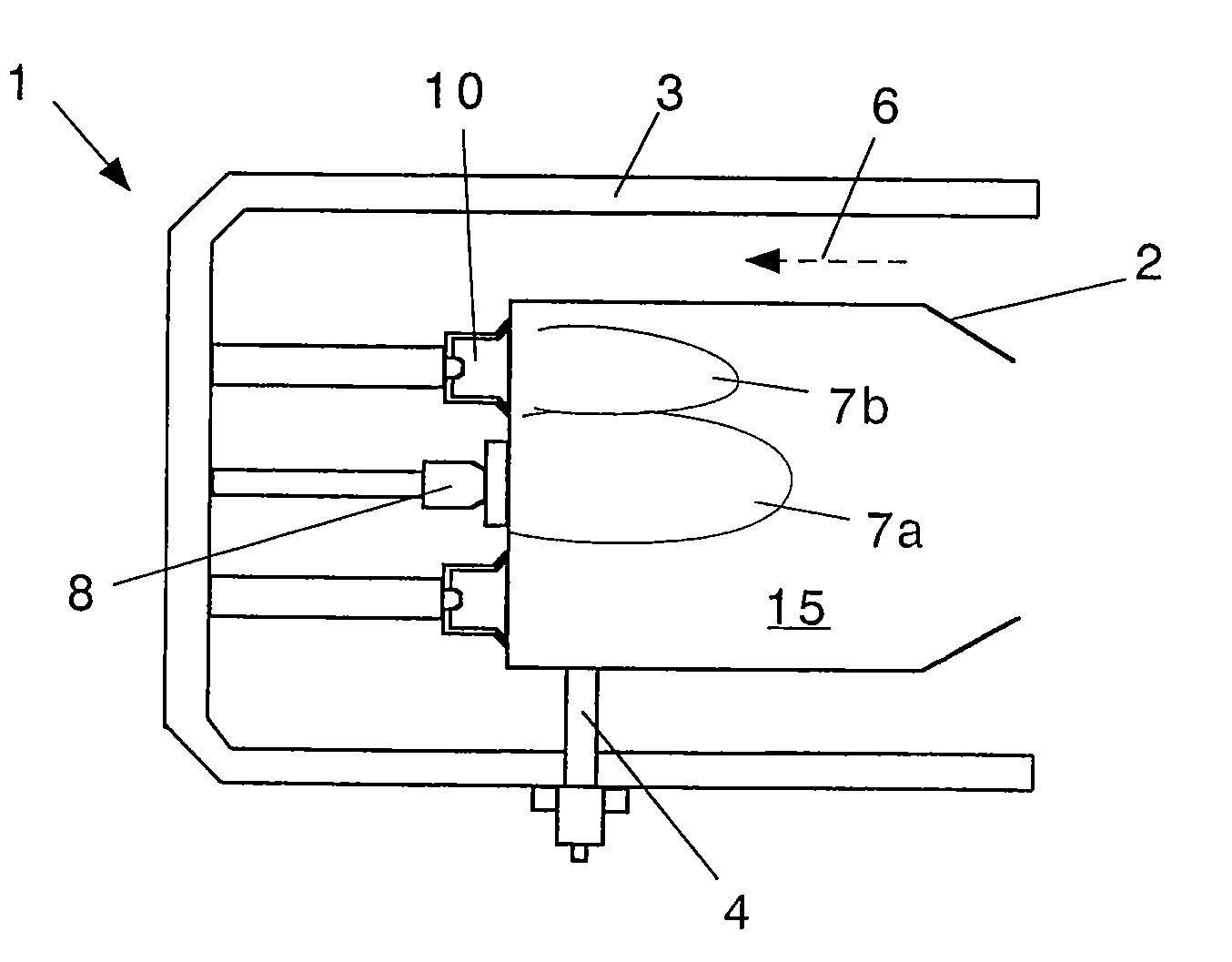

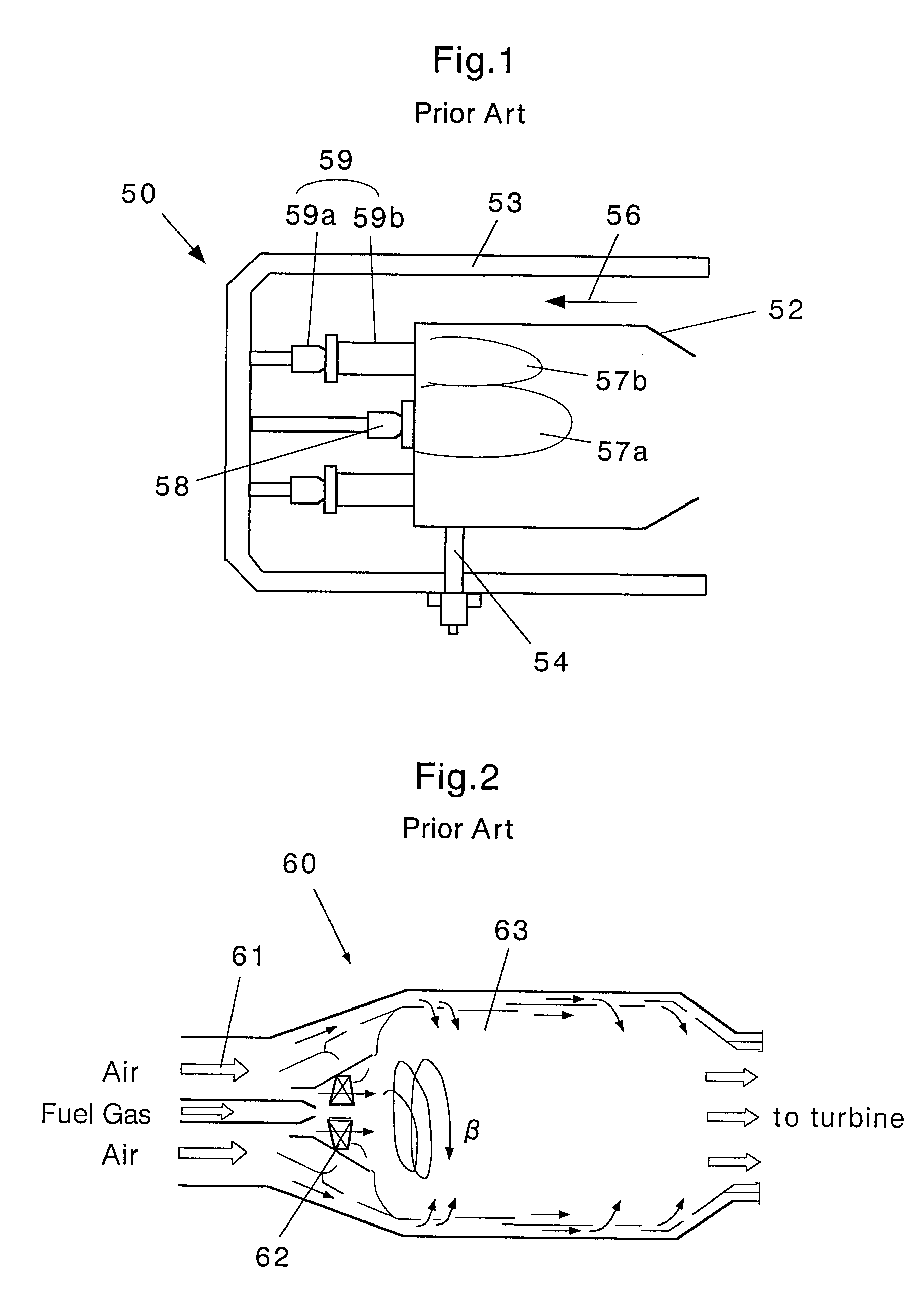

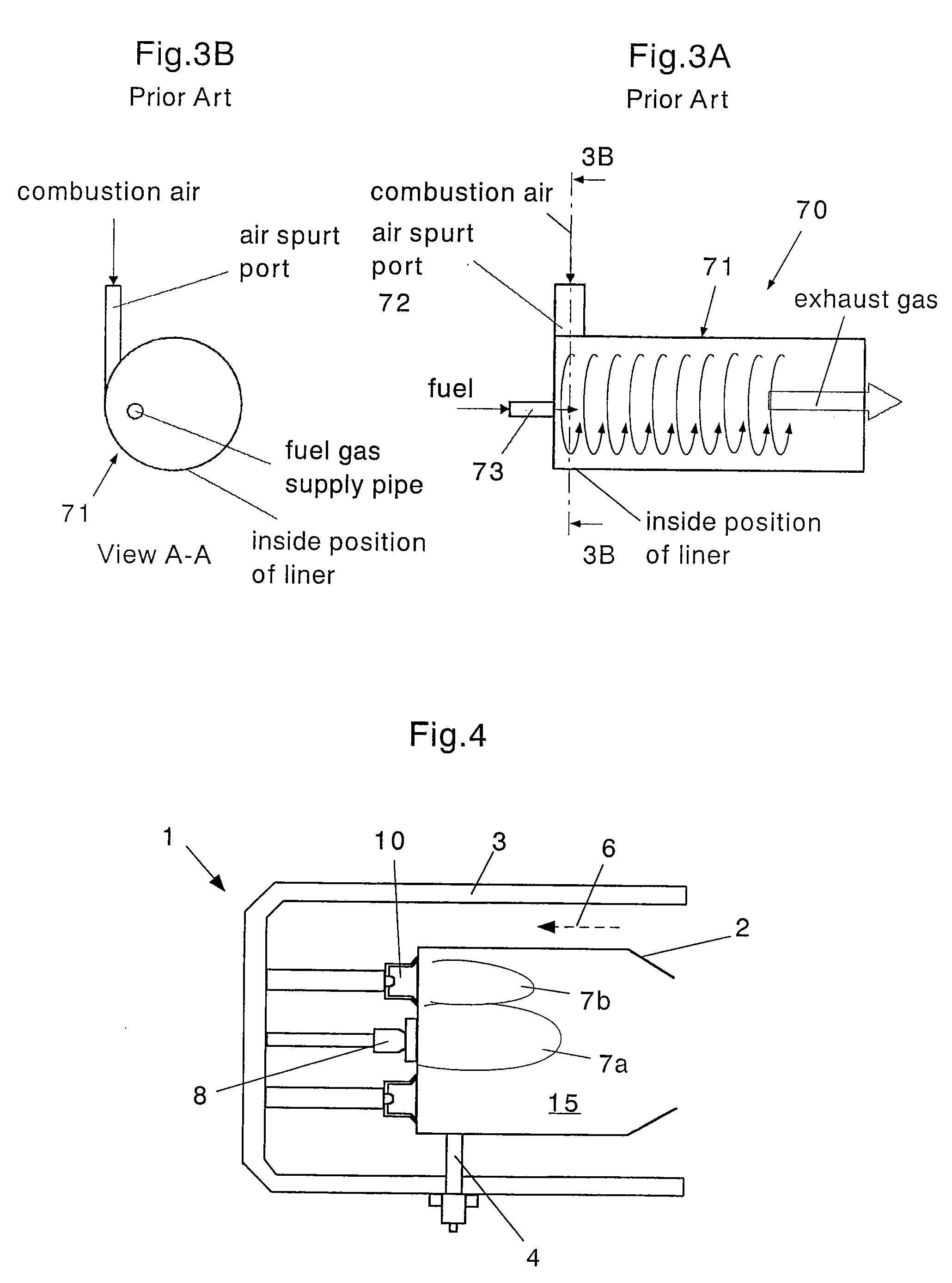

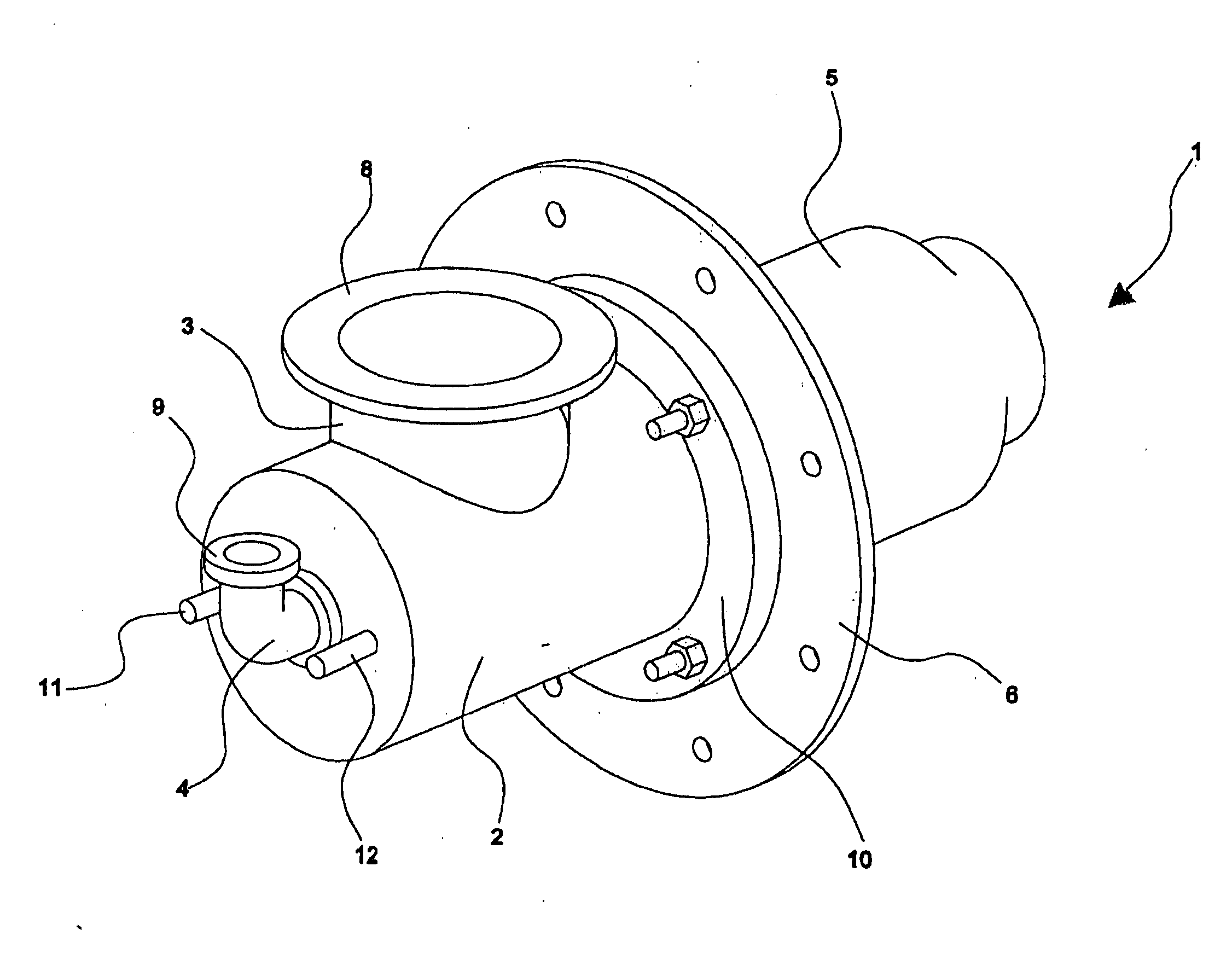

Fuel injection valve, combustor using the fuel injection valve, and fuel injection method for the fuel injection valve

InactiveUS20090031729A1Prevent burnoutLow NOx generationContinuous combustion chamberTurbine/propulsion fuel valvesEngineeringInjection air

A fuel injection valve is provided with a cylindrical injection valve main body in which one end is closed, and a fuel nozzle arranged on a center line of the main body and injecting a fuel. The main body has a plurality of air injection ports for injecting an air to an inner side in a tangential direction and forming a whirl flow in an inner portion in a circumferential direction of a cylinder portion of the main body, and the fuel nozzle has a fuel injection port injecting the fuel toward an inner peripheral surface of the main body.

Owner:IHI CORP

Urea-based mixing process for increasing combustion efficiency and reduction of nitrogen oxides (NOx)

InactiveUS8449288B2Reduce the formation of nitrogen oxidesNitrogen compoundsUsing liquid separation agentNitrogen oxidesEngineering

Owner:THE POWER IND GRP

Gas measurement module for use in therapeutic settings comprising reflective scanning microspectrometer

ActiveUS20120242980A1Reduce the formation of nitrogen oxidesLean and compactRespiratory organ evaluationColor/spectral properties measurementsCombustorCombustible gas

A high speed burner having very low polluting emissions, suitable for the process for heat treatment furnaces of a load in free atmosphere. The burner is capable of creating a compact and lean flame with the peculiarity of keeping the NOx emissions at very low levels at any chamber temperature and at any excess combustion air. The burner requires a single inlet for the comburent air and a single inlet for the combustible gas.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Combustion method and internal combustion engine

ActiveUS9476346B2Reduce formationReduce the temperatureInternal combustion piston enginesPistonsCylinder headExternal combustion engine

A combustion process with auto-ignition for direct-injection internal combustion engines involves dividing injection jets at a jet divider contour into a first partial quantity, a second partial quantity, and third partial quantities. The first partial quantity enters into the piston cavity, the second partial quantity enters via the piston step into a region between the piston crown and the cylinder head, and the third partial quantities, starting from the respective injection jet, spread out on both sides in the peripheral direction in opposite directions along the piston step, and the respective third partial quantities collide with one another between two adjacent injection jets within the piston step and are deflected radially inwardly. The first partial quantity and the second partial quantity form a first combustion front and a second combustion front, and the partial quantities which in each case are jointly deflected inwardly form a third combustion front radially inwardly into a gap between the injection jets. The injection jets are deflected upstream from the jet divider contour in the direction of the piston by means of a resultant flow formed essentially from a swirl, a squish gap flow, and a jet flow.

Owner:DAIMLER AG

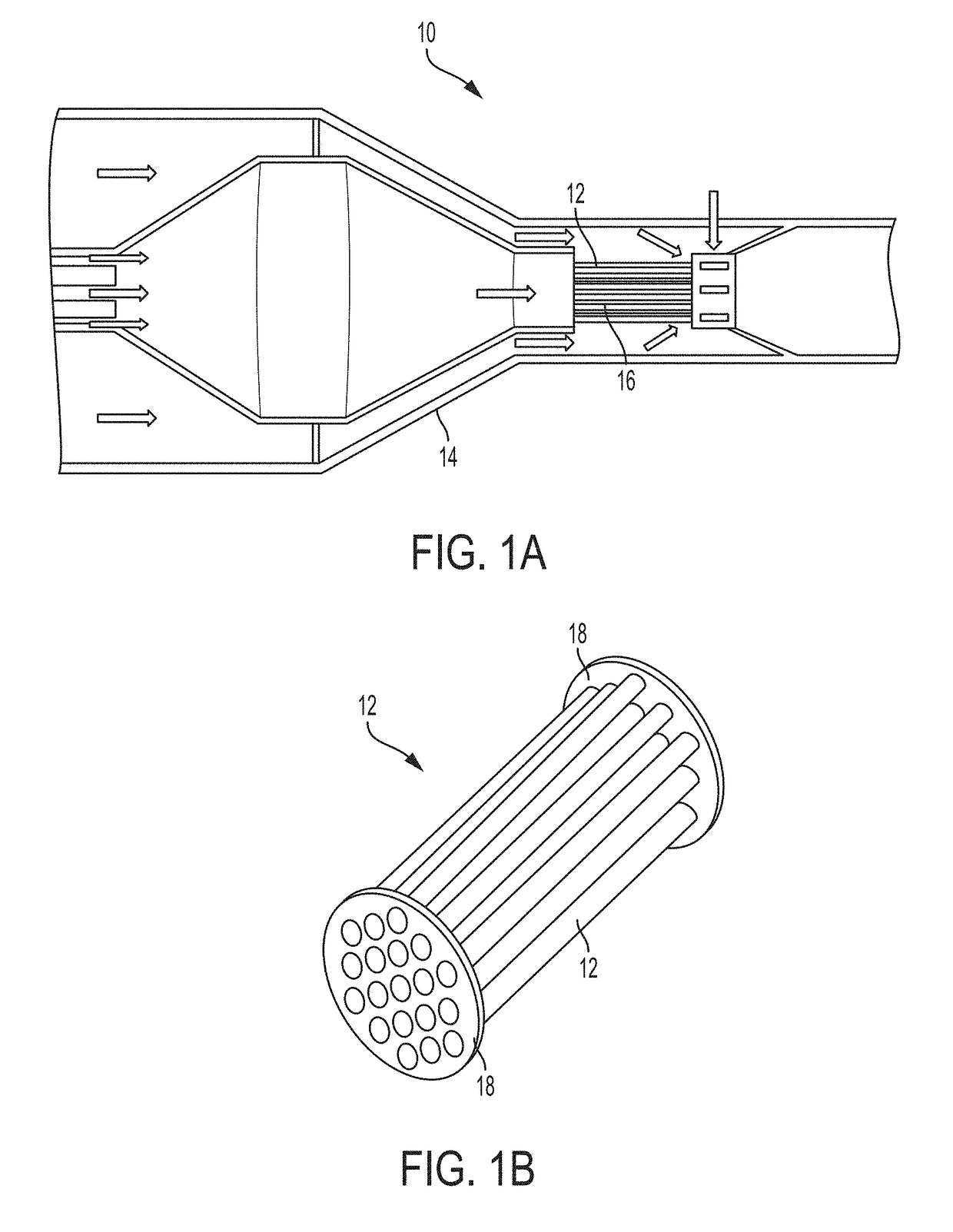

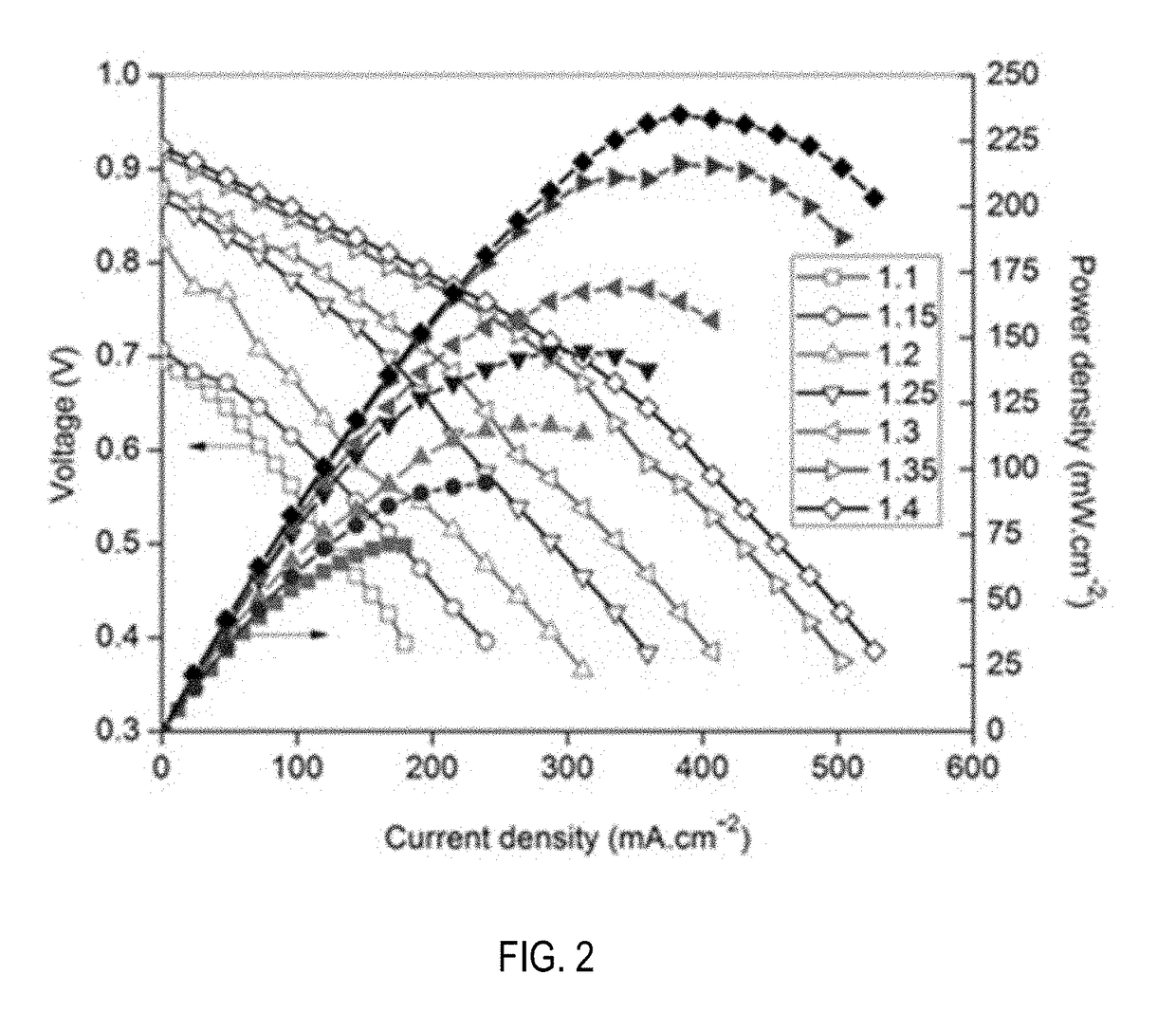

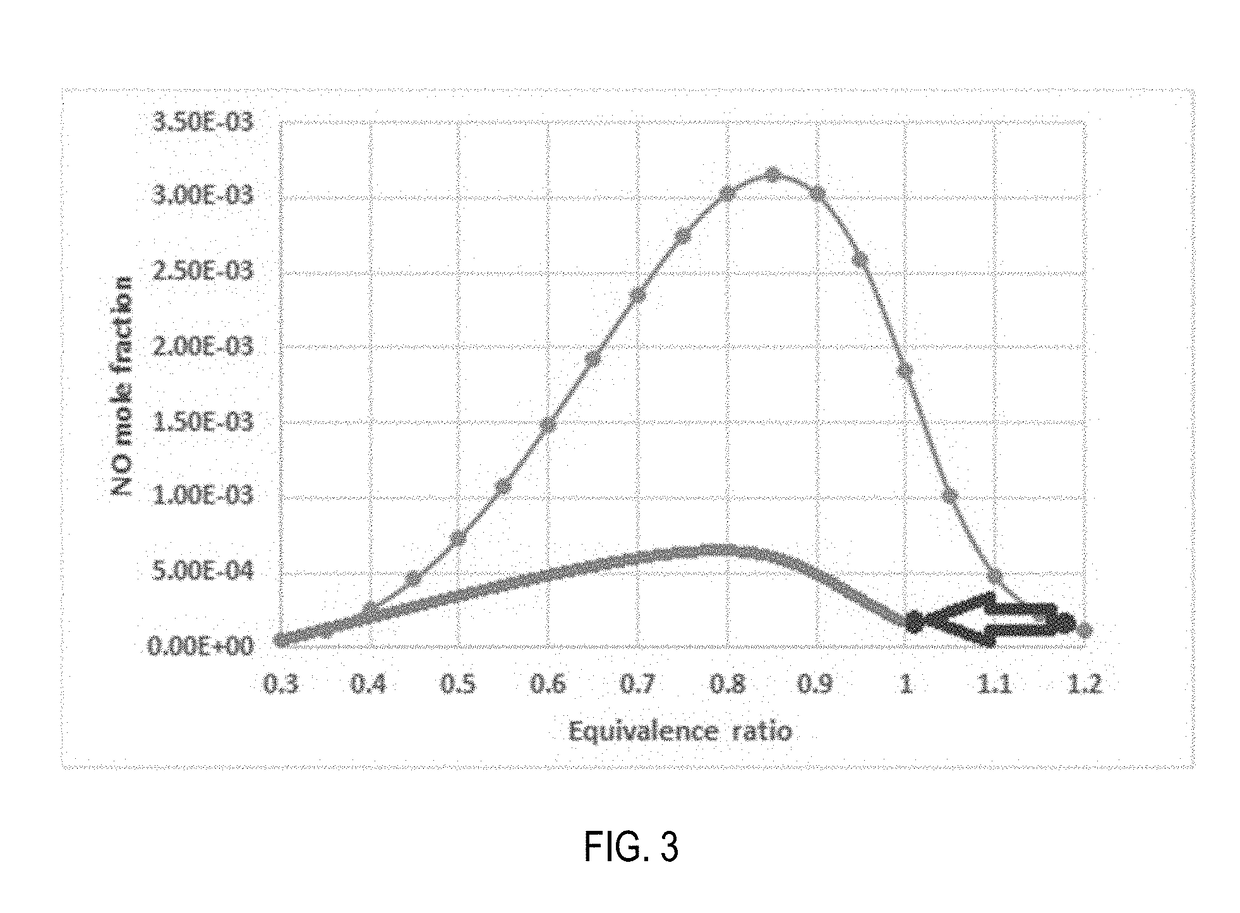

FLAME-ASSISTED FUEL CELL INTEGRATED RICH BURN, QUICK MIX, LEAN BURN COMBUSTION FOR REDUCED NOx

ActiveUS20190063283A1Reduce the formation of nitrogen oxidesReactant parameters controlExhaust apparatusCombustorFuel cells

A micro-tubular flame assisted fuel cell (mT FFC) integrated with a rich-burn, quick-mix, lean-burn (RQL) combustor for reduced NOx. Fuel and oxidant pass into a first-stage, fuel-rich combustion chamber. The exhaust products pass to the fuel cell for electrochemical conversion. Any remaining fuel is quickly mixed in a jet of oxidant to reduce temperature gradients and NOx formation in a second stage, fuel-lean combustion chamber. Preheating of the fuel, and different oxidant streams, is possible via heat exchangers in the fuel-rich and fuel-lean combustion chambers.

Owner:SYRACUSE UNIVERSITY

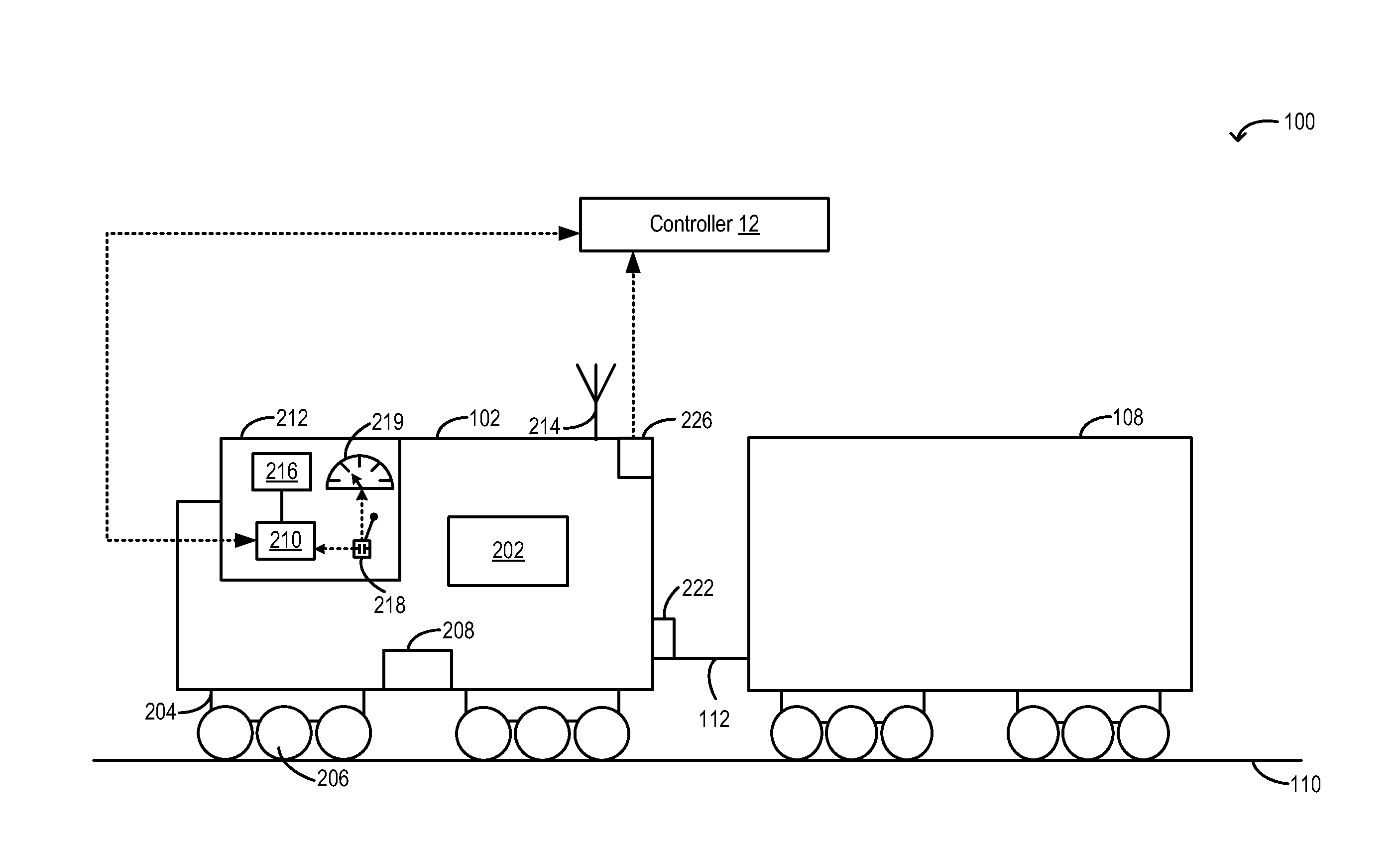

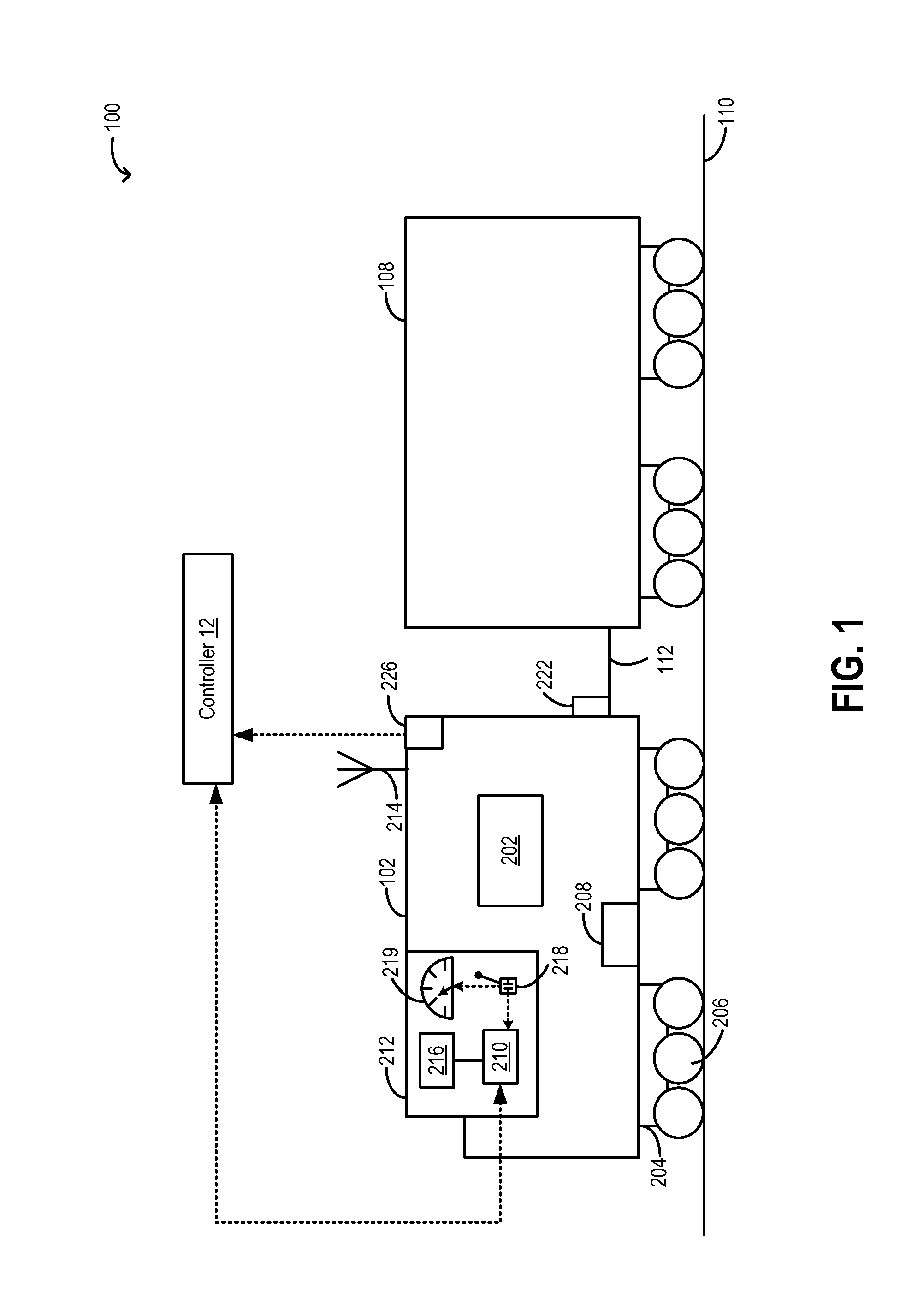

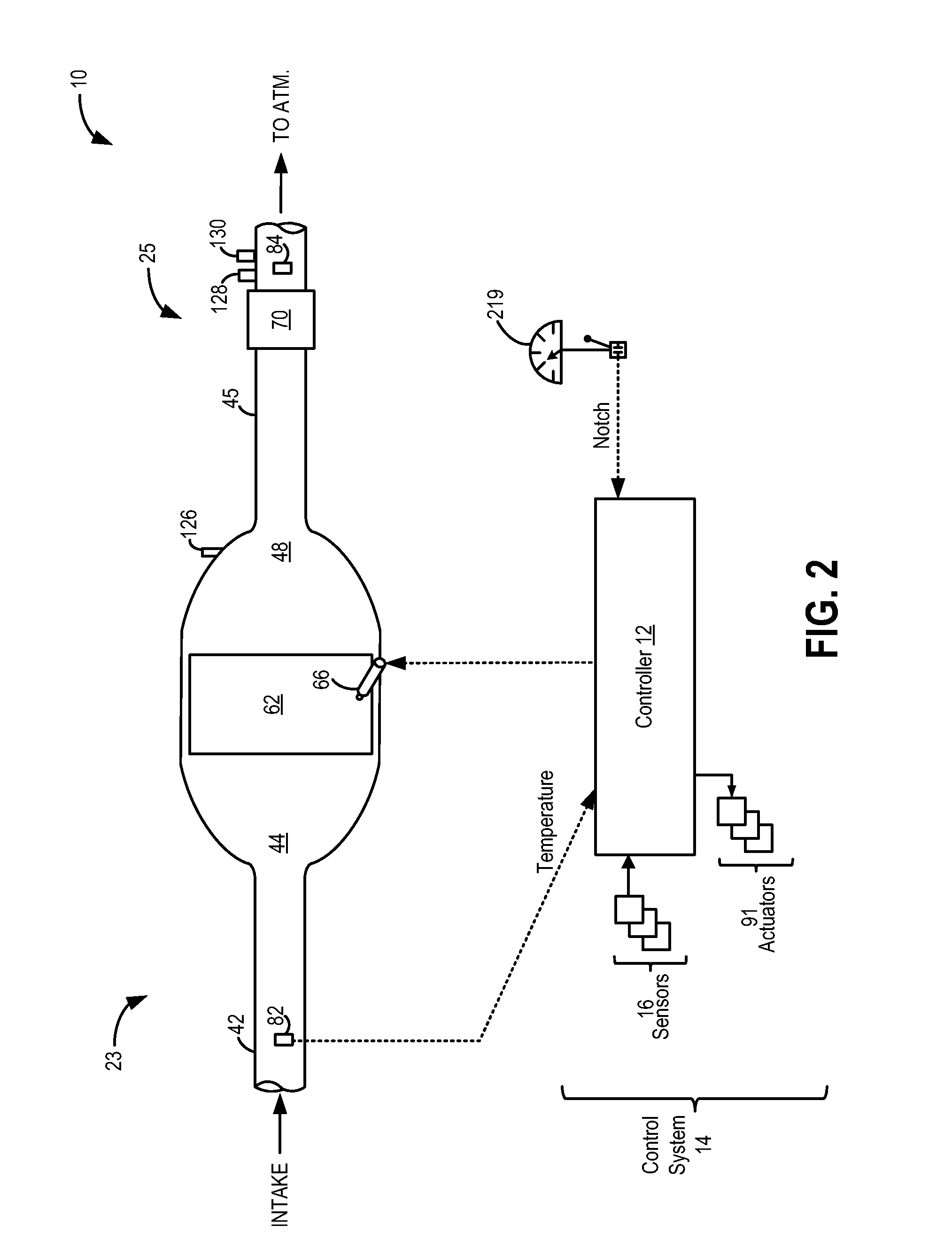

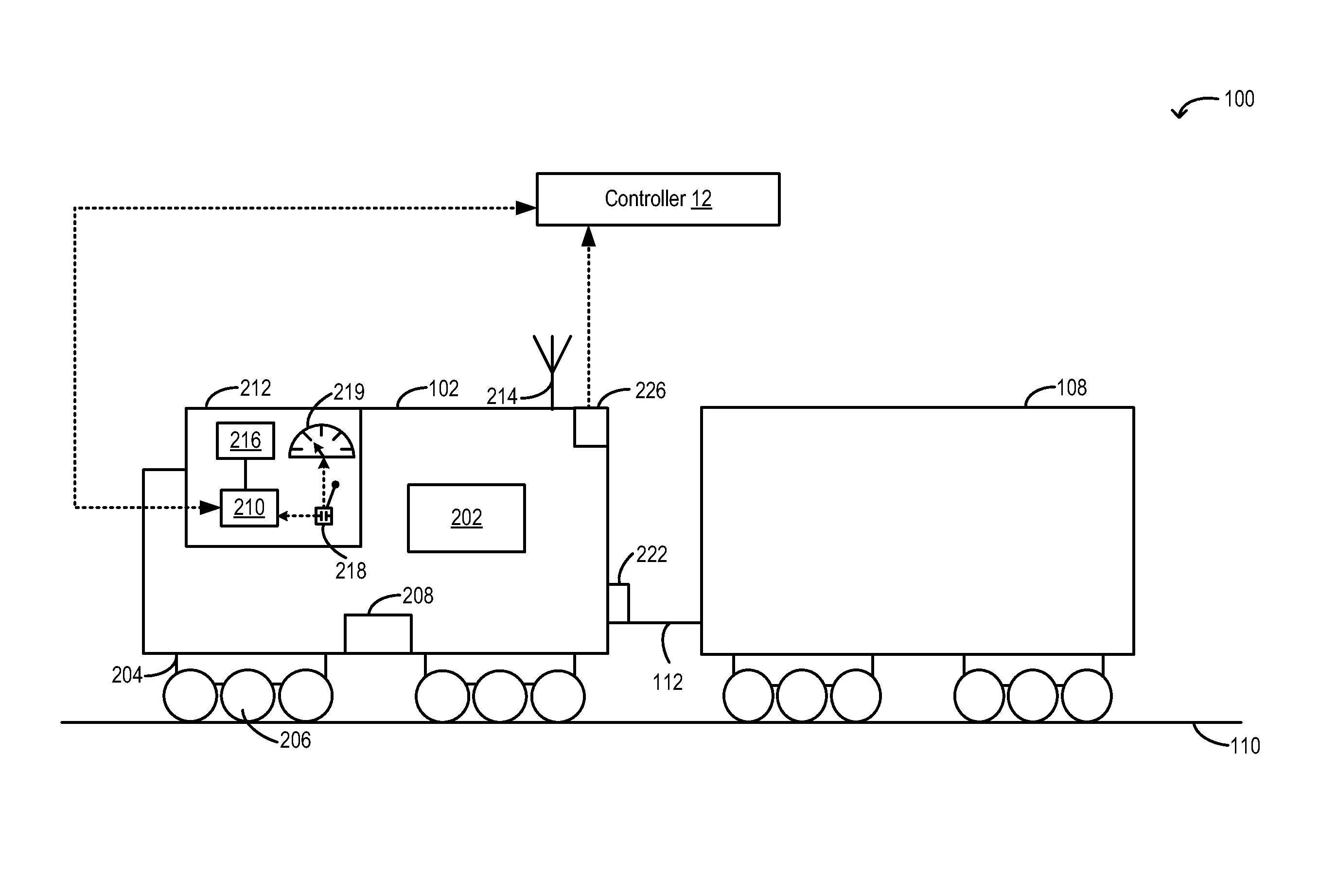

Method and system for engine emission control

ActiveUS20120123662A1Offset increased emissionEmission reductionAnalogue computers for vehiclesElectrical controlIncrease temperatureAutomotive engineering

Owner:GE GLOBAL SOURCING LLC

Method and system for engine emission control

ActiveUS8560211B2Accelerate emissionsEmission reductionAnalogue computers for vehiclesElectrical controlIncrease temperatureAutomotive engineering

Owner:GE GLOBAL SOURCING LLC

Hydrated EGR system, method and apparatus for reducing harmful exhaust emissions and improving fuel economy

ActiveUS7530349B2Improve engine performanceHarmful exhaust emissionInternal combustion piston enginesNon-fuel substance addition to fuelWater vaporExhaust gas emissions

A hydrated EGR system, method and apparatus for a vehicle, in which heat from an exhaust pipe is used to heat an aqueous fluid solution in a water tank. A portion of the hot exhaust gas is diverted from the main exhaust flow, and the diverted portion is bubbled through the heated aqueous fluid solution to form a hydrated EGR mixture containing water vapor. The hydrated EGR mixture is then fed back to an intake portion of the engine, is mixed with an incoming fuel / air mixture, and is burned with the fuel air mixture inside the engine. The use of the hydrated EGR mixture, including heated water vapor, as part of the intake charge simultaneously reduces harmful exhaust emissions, improves engine performance, and improves fuel economy of the vehicle.

Owner:RIM JULIUS J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com