Main-steam-flow-based steam turbine sliding pressure optimization control method

A technology of main steam flow and control method, which is applied in the control field of steam turbine sliding pressure optimization, can solve the problems of large error in main steam flow and difficult practical application, and achieves the effect of improving operating economy and tapping energy-saving potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

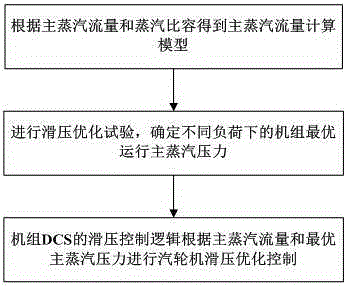

Method used

Image

Examples

Embodiment 1

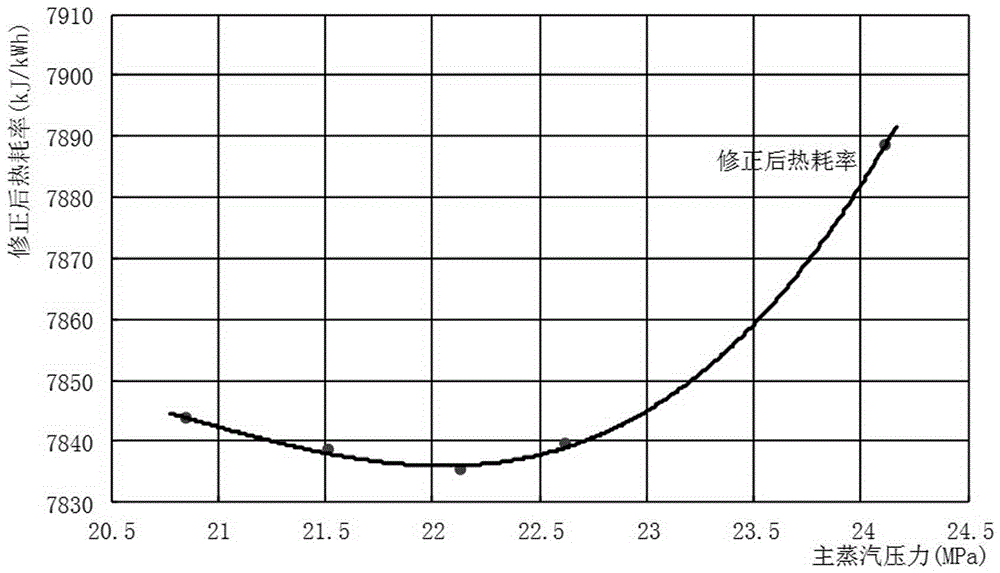

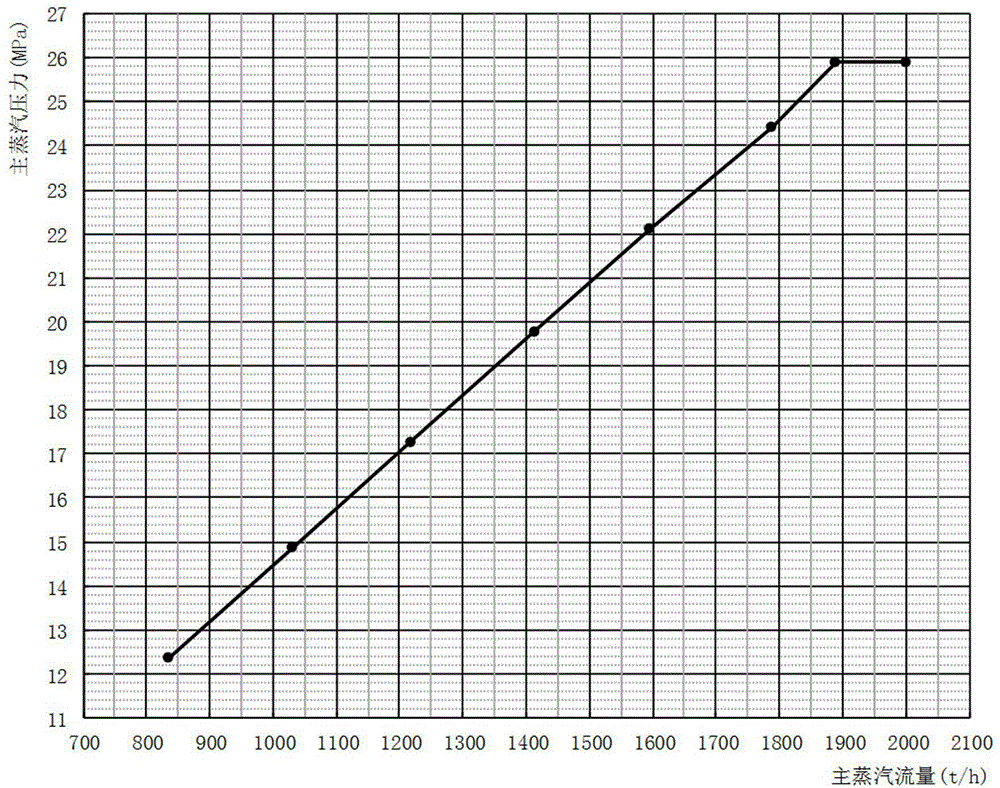

[0063] Combine below figure 2 , image 3 This embodiment will be specifically described.

[0064] The process of applying this method to a 600MW supercritical steam turbine unit to obtain the main steam flow calculation formula and sliding pressure optimization curve is as follows:

[0065] Under the rated load of 600MW, the steam turbine heat rate test is carried out according to the ASME standard. According to the test data, the main steam flow calculation formula is obtained as:

[0066] G = 1251.089 × p 1 2 - p 2 2 0.01324 × P d × t d - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com