Method for re-circulating combustion of flue gas of pulverized coal fired boiler

A flue gas recirculation and pulverized coal boiler technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of poor burnout and low thermal efficiency, achieve enhanced convective heat transfer, increase boiler steam temperature, Effect of reducing capture and collection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

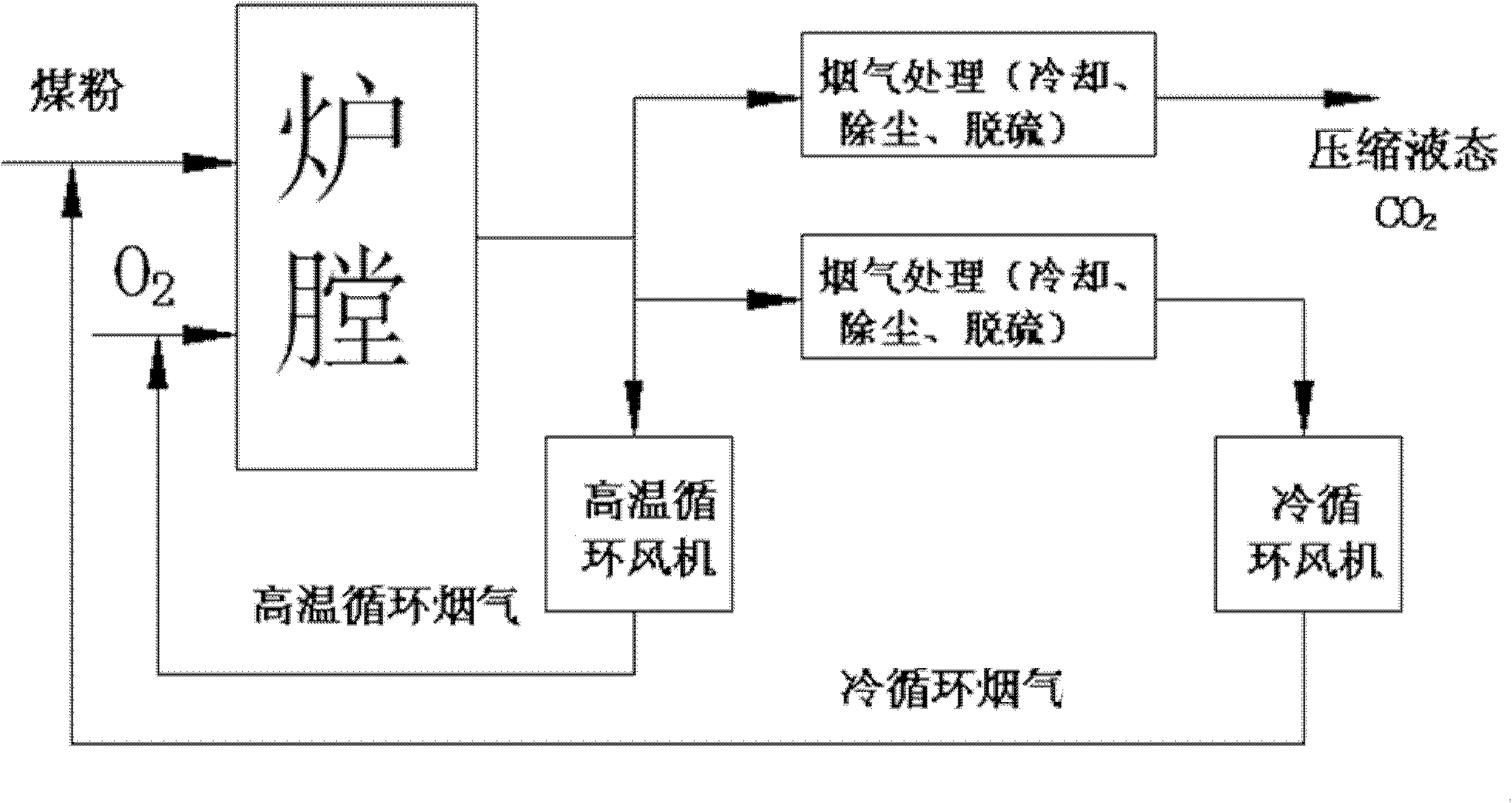

[0021] Ignition and combustion step: use the circulating flue gas to transport pulverized coal to the furnace, and at the same time, separate the air to obtain O 2 into the furnace, ignited and burned;

[0022] Flue gas circulation steps: the high-temperature flue gas produced by the combustion of pulverized coal in the furnace is divided into two parts. The first part of high-temperature flue gas accounts for 30% of the total high-temperature flue gas volume. After cooling, dust removal and desulfurization, it is compressed into liquid CO 2 ;The second part of high-temperature flue gas accounts for 70% of the volume of all high-temperature flue gas, which is used as circulating flue gas;

[0023] The second part of high-temperature flue gas is further divided into two paths: the first path of high-temperature flue gas accounts for 60% of the volume of circulating flue gas. Income O 2 Enter the furnace after mixing, after mixing O 2 The volume accounts for 30% of the volume...

Embodiment 2

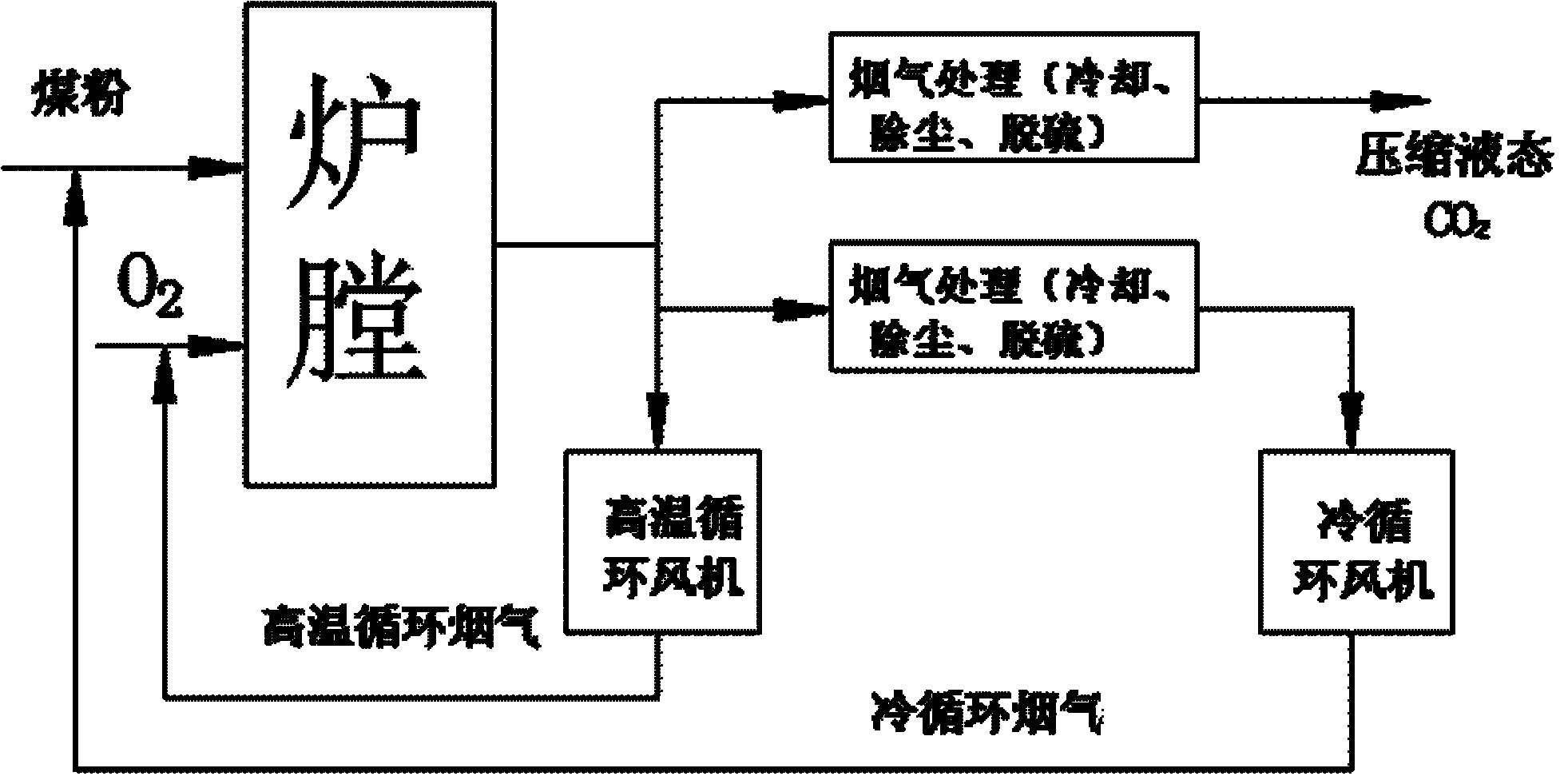

[0025] Ignition and combustion step: use the circulating flue gas to transport pulverized coal to the furnace, and at the same time, separate the air to obtain O 2 sent into the furnace, ignited and burned;

[0026] Flue gas circulation steps: the high-temperature flue gas produced by the combustion of pulverized coal in the furnace is divided into two parts. The first part of high-temperature flue gas accounts for 30% of the total high-temperature flue gas volume. After cooling, dust removal and desulfurization, it is compressed into liquid CO 2 ;The second part of high-temperature flue gas accounts for 70% of the volume of all high-temperature flue gas, which is used as circulating flue gas;

[0027] The second part of high-temperature flue gas is further divided into two paths: the first path of high-temperature flue gas accounts for 80% of the volume of circulating flue gas. Income O 2 Enter the furnace after mixing, after mixing O 2 The volume accounts for 30% of the m...

Embodiment 3

[0029] Ignition and combustion step: use the circulating flue gas to transport pulverized coal to the furnace, and at the same time, separate the air to obtain O 2 sent into the furnace, ignited and burned;

[0030] Flue gas circulation steps: the high-temperature flue gas produced by the combustion of pulverized coal in the furnace is divided into two parts. The first part of high-temperature flue gas accounts for 60% of the total high-temperature flue gas volume. After cooling, dust removal and desulfurization, it is compressed into liquid CO 2 ;The second part of high-temperature flue gas accounts for 40% of the volume of all high-temperature flue gas, which is used as circulating flue gas;

[0031] The second part of high-temperature flue gas is further divided into two paths: the first path of high-temperature flue gas accounts for 60% of the volume of circulating flue gas. Income O 2 Enter the furnace after mixing, after mixing O 2 The volume accounts for 28% of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com