Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Multivariable predictive control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

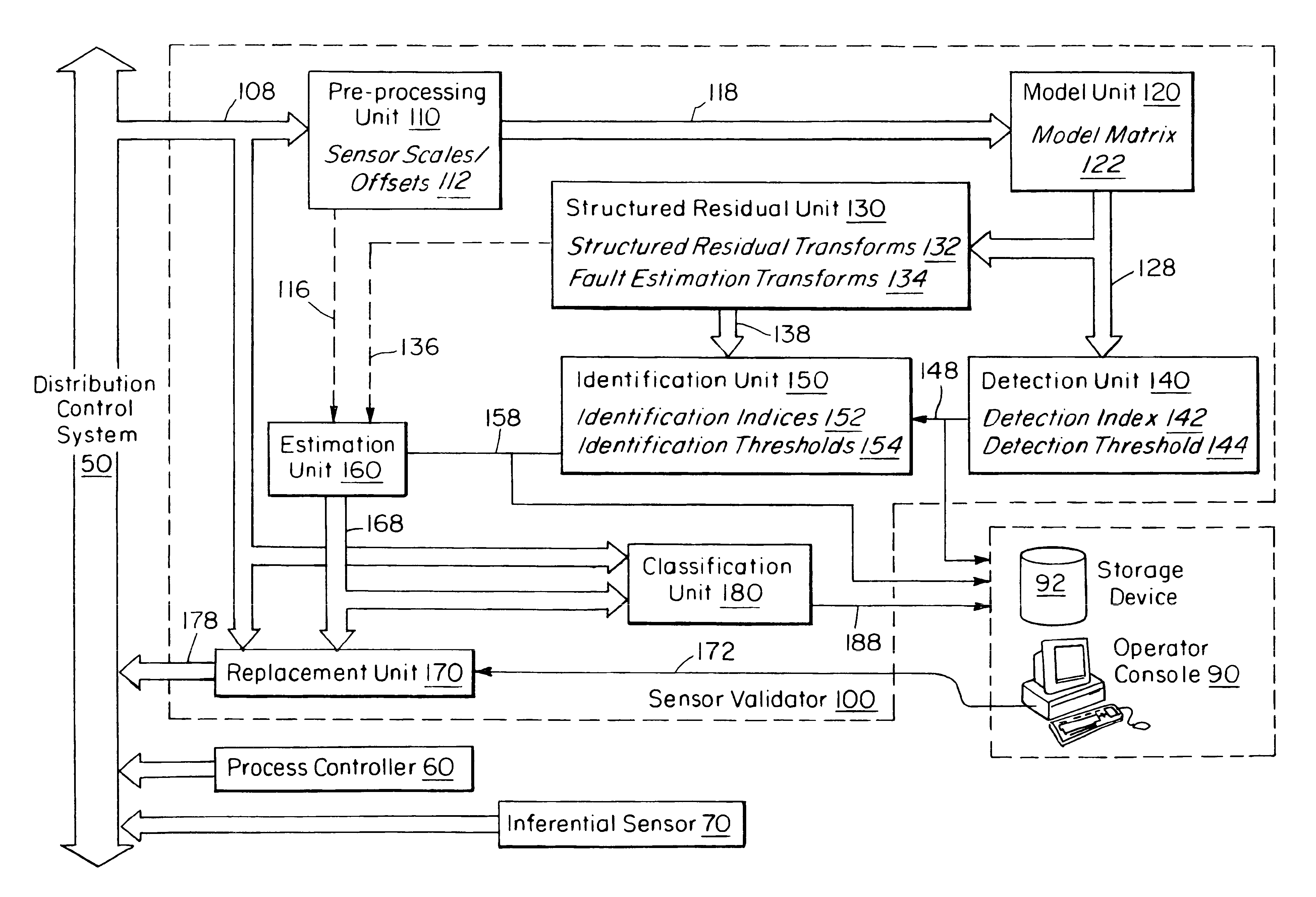

Sensor validation apparatus and method

An apparatus and method is disclosed for detecting, identifying, and classifying faults occurring in sensors measuring a process. A variety of process models can be used such as first principles models, dynamic multivariable predictive control models, from data using statistical methods such as partial least squares (PLS) or principal component analysis. If faults are identified in one or more sensors, the apparatus and method provide replacement values for the faulty sensors so that any process controllers and process monitoring systems that use these sensors can remain in operation during the fault period. The identification of faulty sensors is achieved through the use of a set of structured residual transforms that are uniquely designed to be insensitive to specific subsets of sensors, while being maximally sensitive to sensors not in the subset. Identified faults are classified into one of the types Complete Failure, Bias, Drift, Precision Loss, or Unknown.

Owner:ASPENTECH CORP

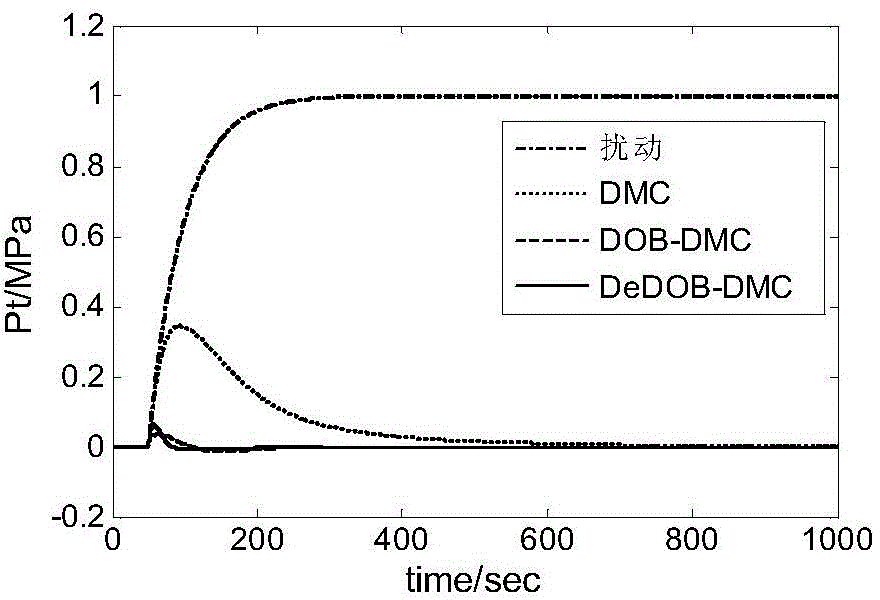

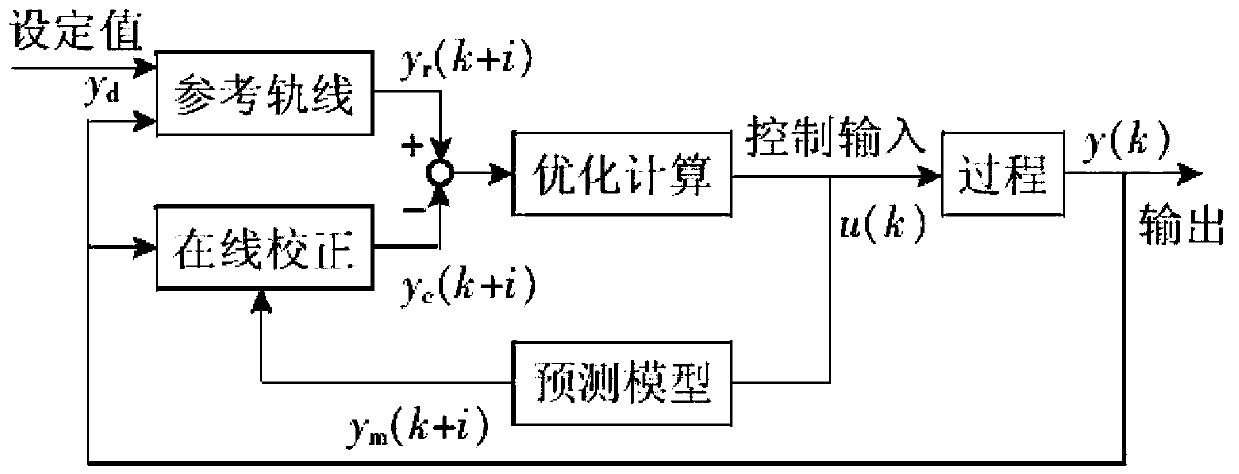

Predictive control method for supercritical set based on decoupling and disturbance observation

The invention discloses a predictive control method for a supercritical set based on decoupling and disturbance observation. According to the method, a supercritical thermal power generating set is adopted as a controlled object, the fuel amount, the water supply amount, and the openness of an adjusting valve of a steam turbine are adopted as inputs, the main steam pressure, the middle point temperature, and the loads of the set are adopted as outputs, the controlled object is enabled to be similar to decoupling through a feedforward compensator, and then disturbance is observed through disturbance observers which are respectively arranged at channels, so that the multivariate predictive control to the controlled object is realized, the problem of poor control effects caused by the disturbance influences of a coordinative control system of the supercritical set is solved, the external influence that the disturbance cannot be measured can be effectively inhibited, and besides, the internal disturbance caused by the coupling between input varies can be inhibited, so that the control property of the coordinative control system of the supercritical set is improved.

Owner:SOUTHEAST UNIV

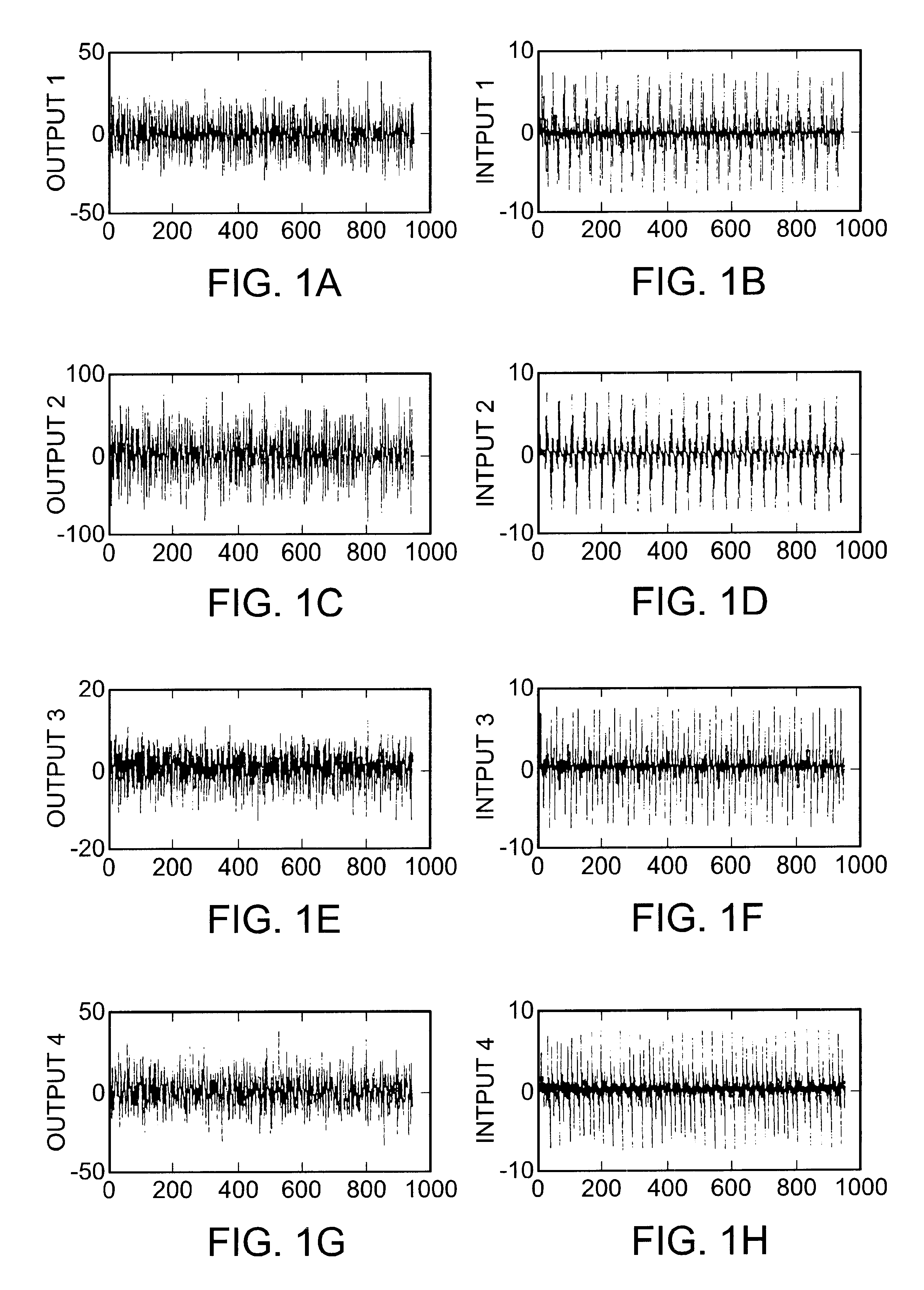

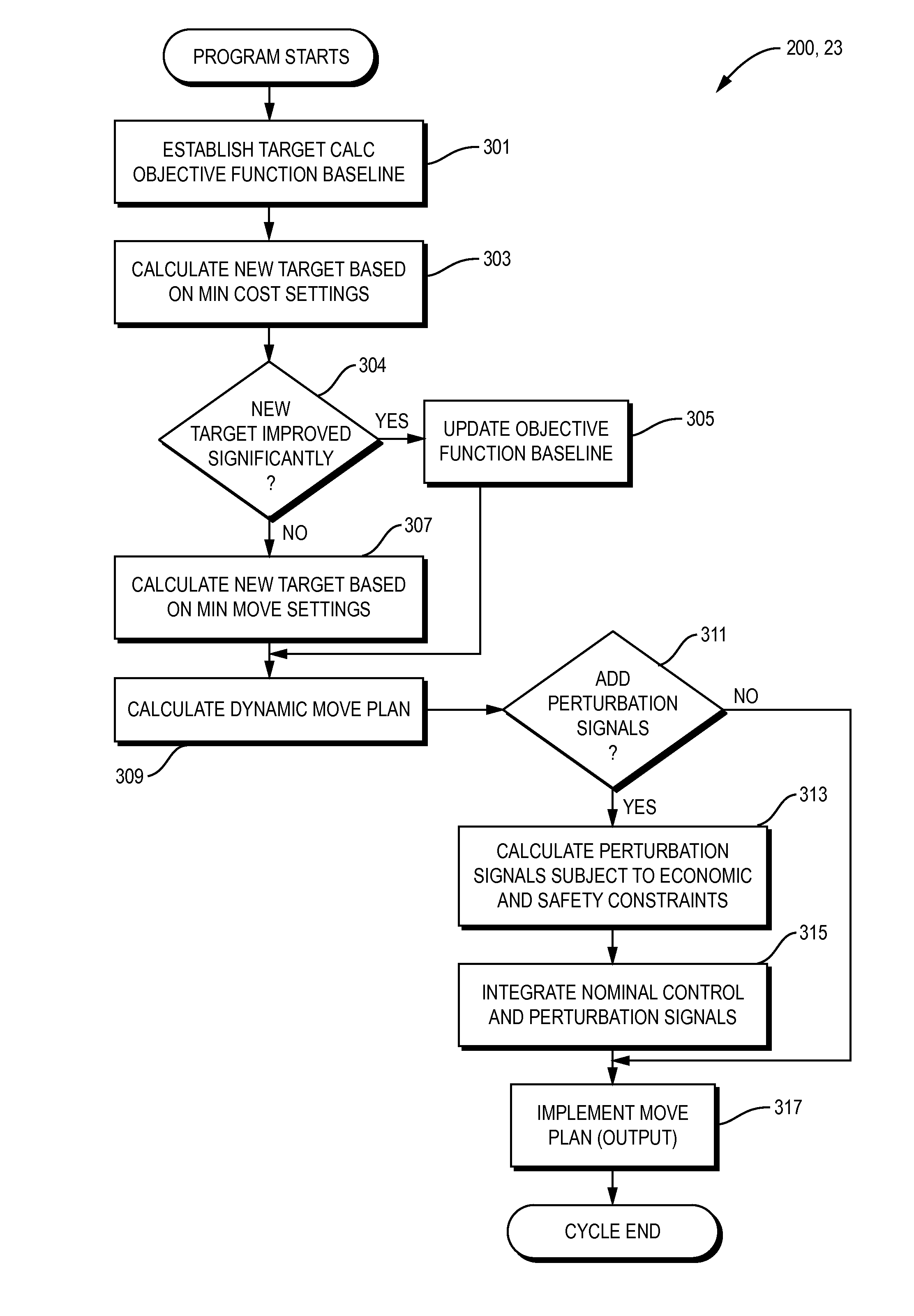

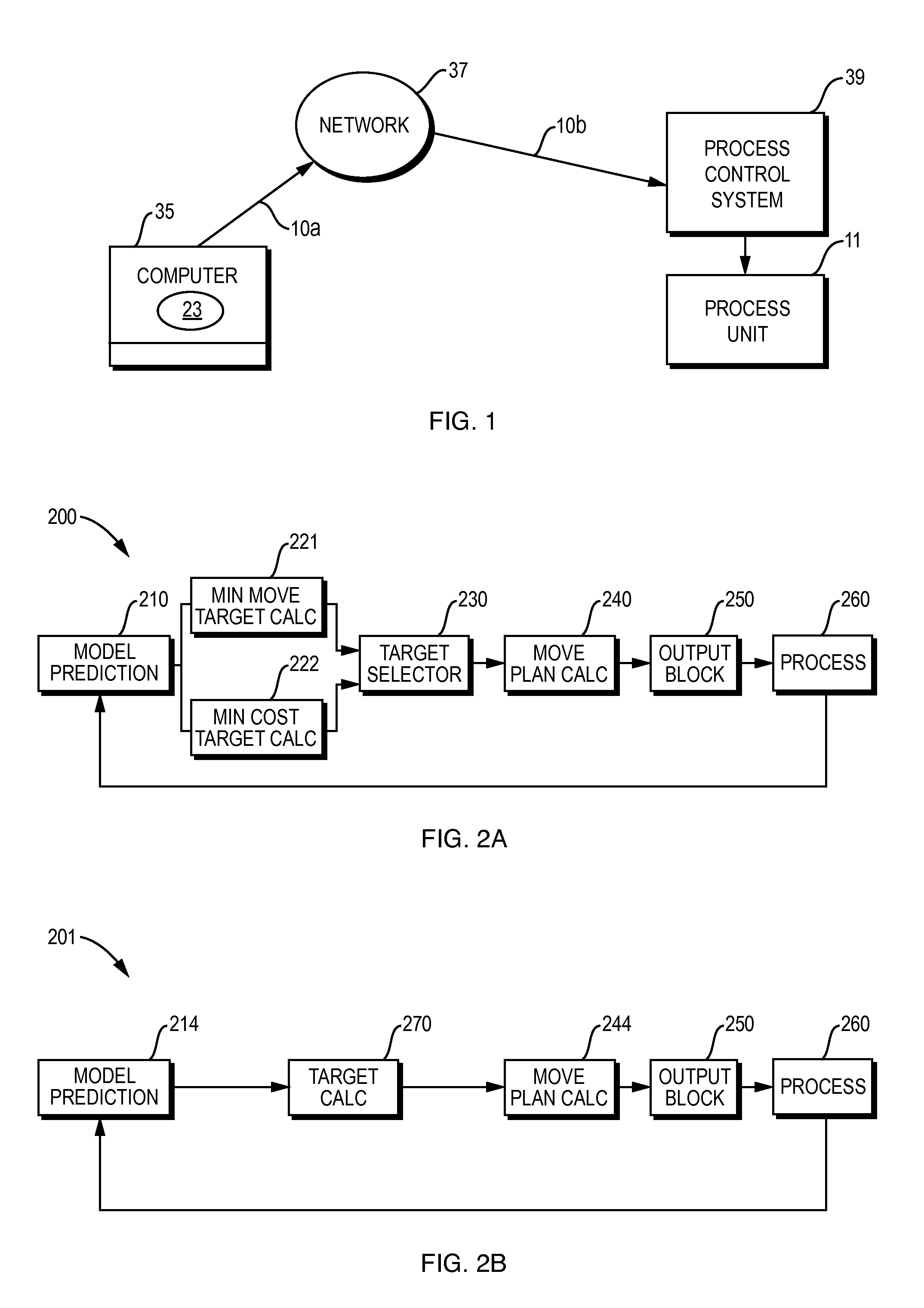

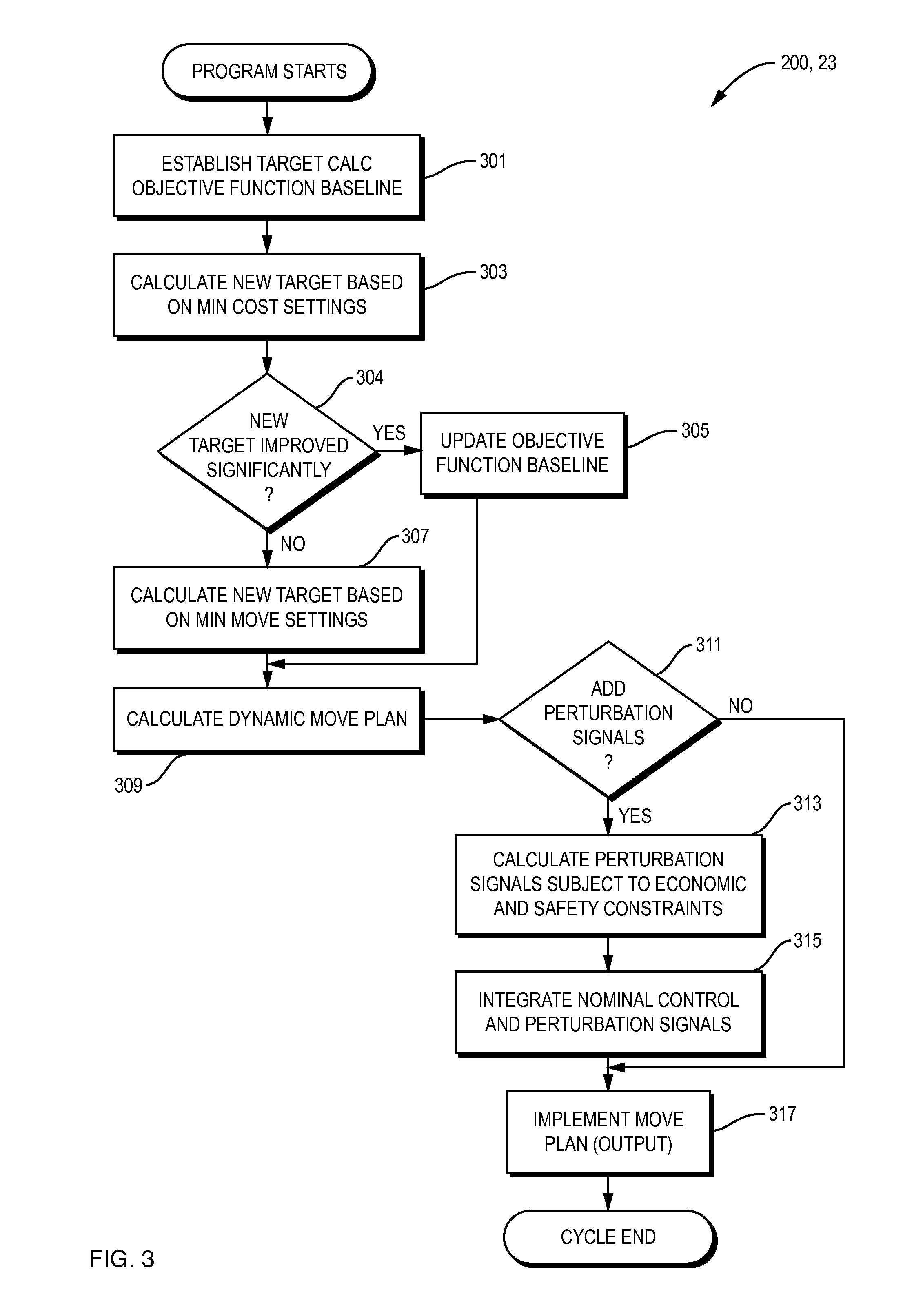

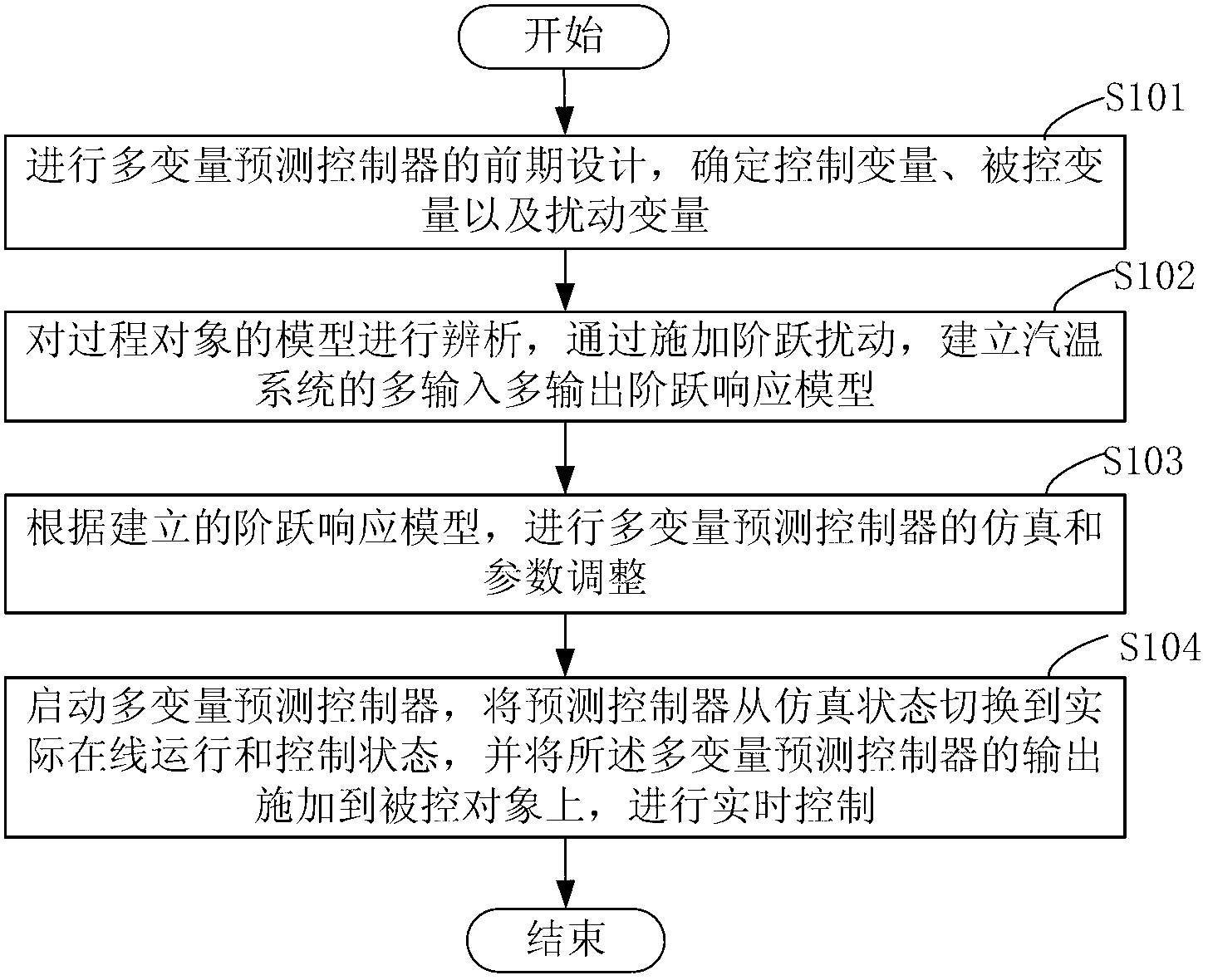

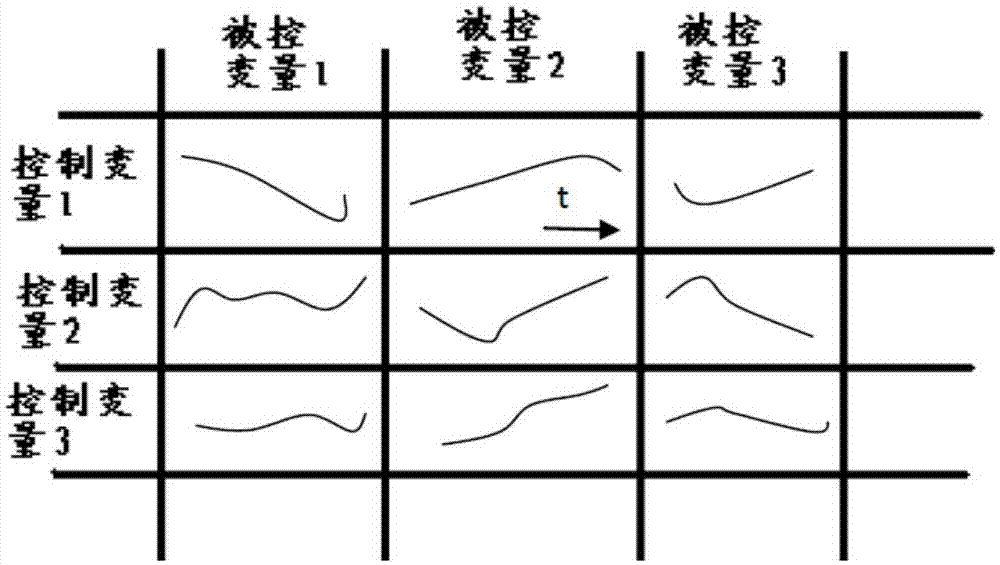

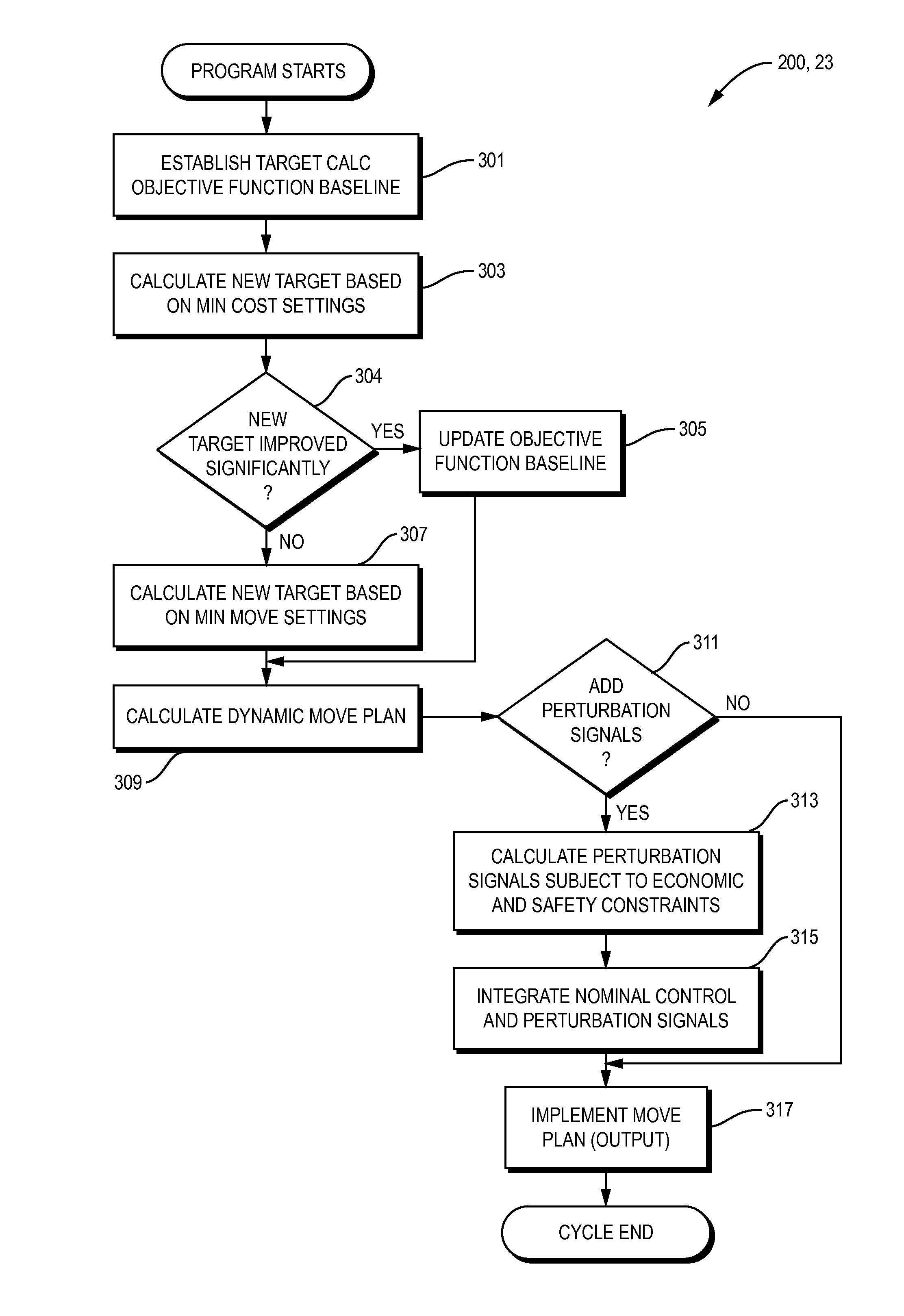

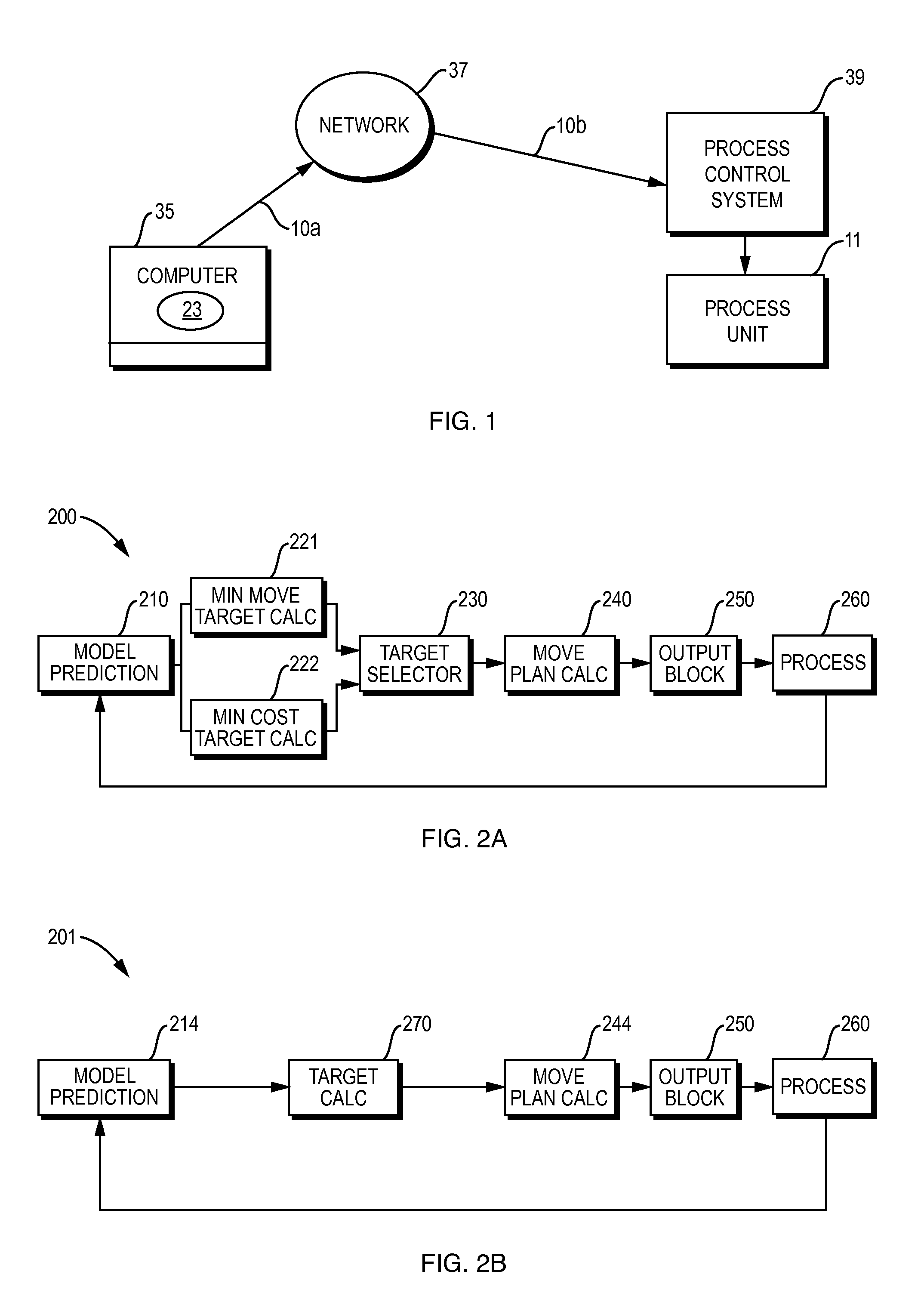

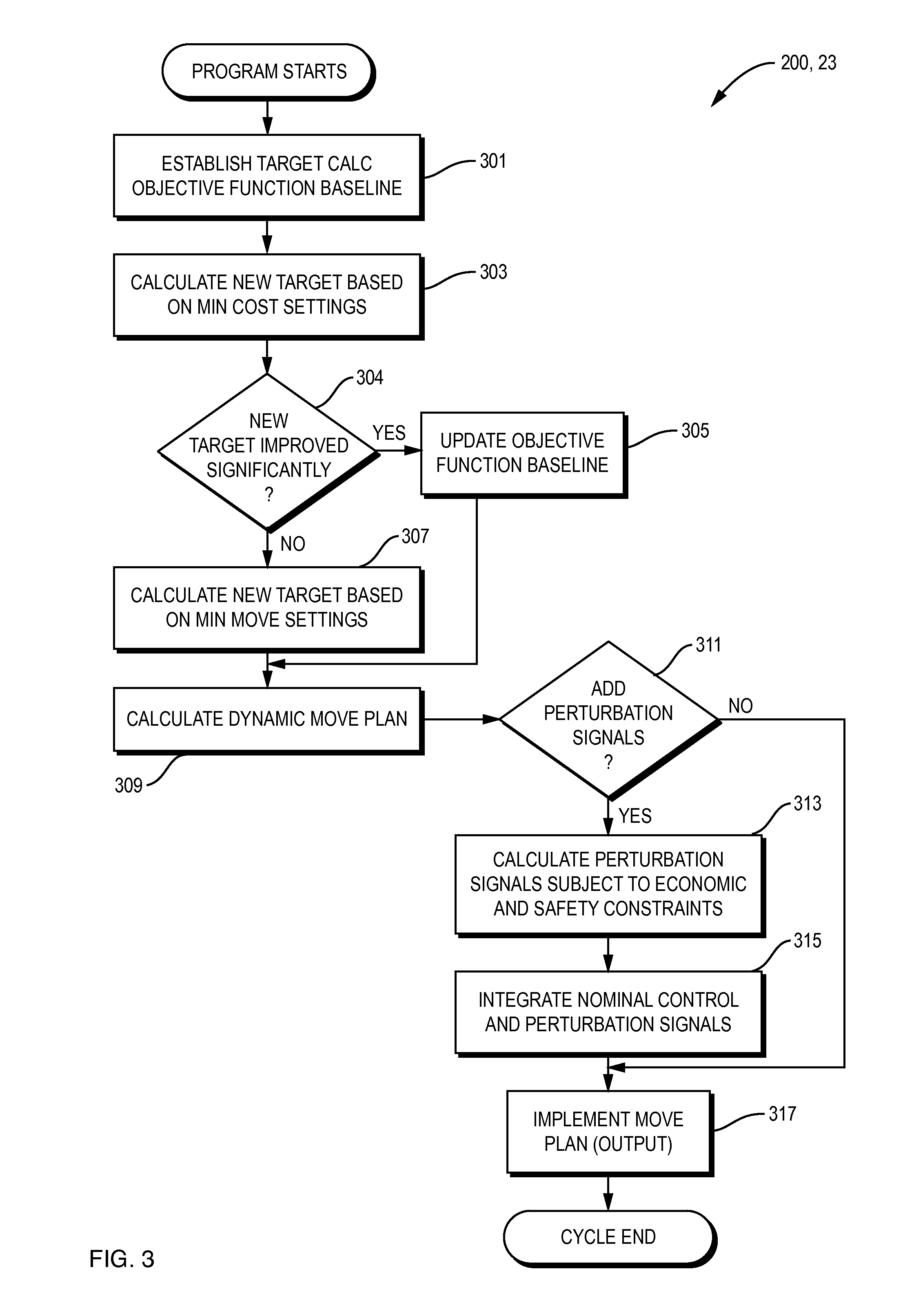

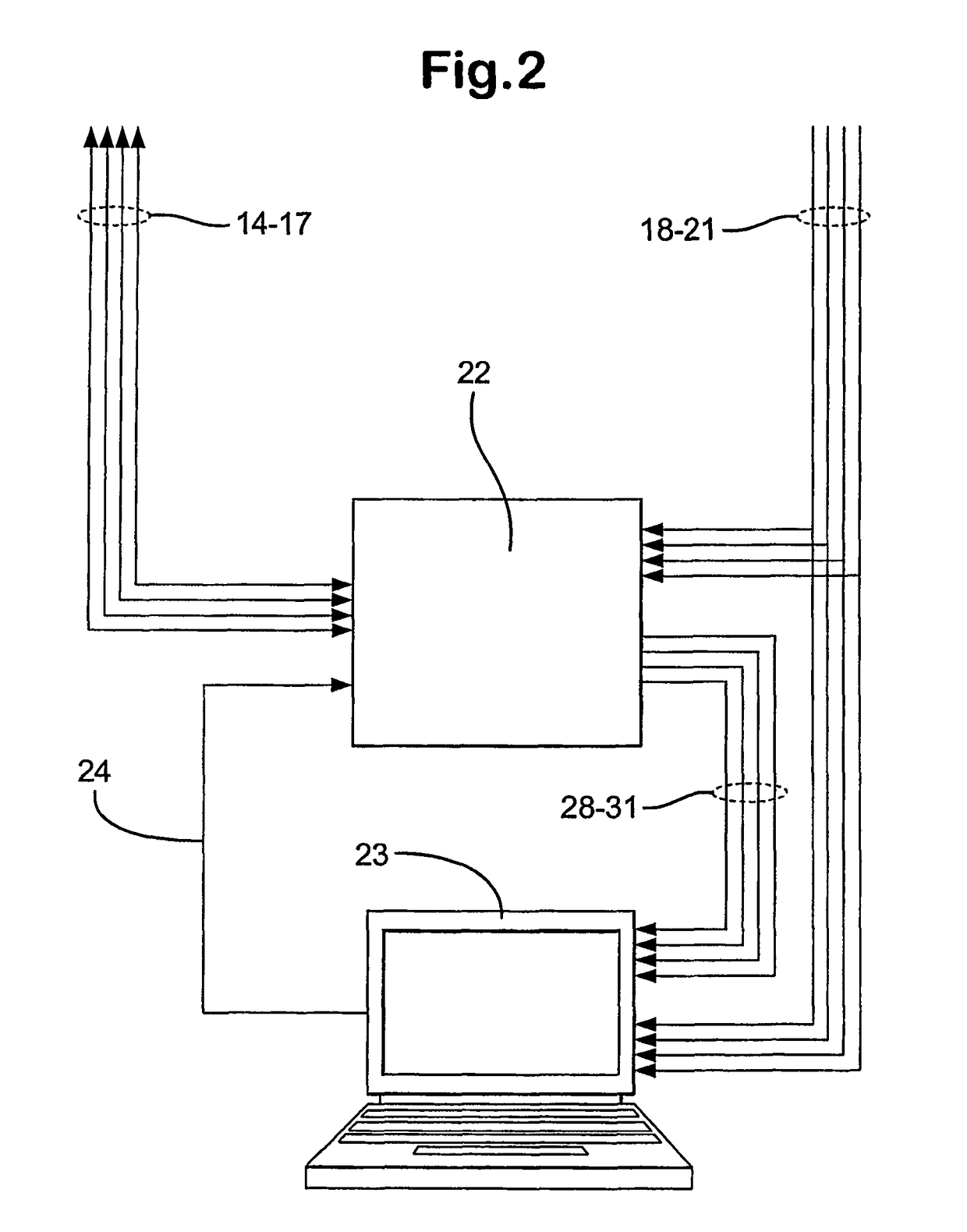

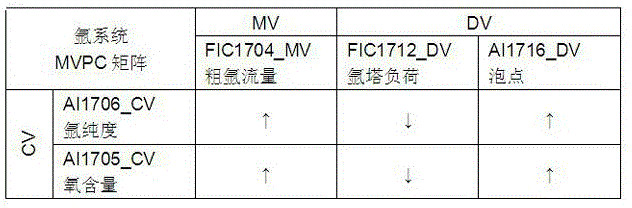

Apparatus and Methods for Non-Invasive Closed Loop Step Testing Using a Tunable Trade-Off Factor

An integrated multivariable predictive controller (MPC) and tester is disclosed. The invention system provides optimal control and step testing of a multivariable dynamic process using a small amplitude step for model identification purposes, without moving too far from optimal control targets. A tunable parameter specifies the trade-off between optimal process operation and minimum movement of process variables, establishing a middle ground between running a MPC on the Minimum Cost setting and the Minimum Move setting. Exploiting this middle ground, embodiments carry out low amplitude step testing near the optimal steady state solution, such that the data is suitable for modeling purposes. The new system decides when the MPC should run in optimization mode and when it can run in constrained step testing mode. The invention system determines when and how big the superimposed step testing signals can be, such that the temporary optimization give-away is constrained to an acceptable range.

Owner:ASPENTECH CORP

Supercritical machine set steam temperature control method and system based on multivariable predictive control

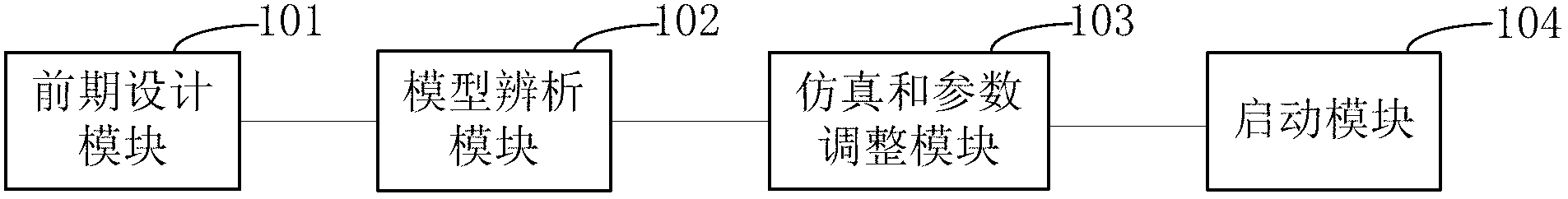

ActiveCN102707743AGuaranteed superheated steam temperatureSolve the problem of insufficient quality controlTemperature control using electric meansMulti inputPredictive controller

The invention provides a supercritical machine set steam temperature control method and system based on multivariable predictive control. The method includes the steps of: conducting pre-stage designing of a multivariable predictive controller to determine the control variables, the controlled variables and the disturbance variables, wherein the control variables include first stage temperature reducing water spray, second stage temperature reducing water spray, reheated temperature reducing water spray and the opening size of a fume gas baffle, and the controlled variables include main steam temperature and reheated steam temperature; discriminating a module of a process object and building a multi-input and multi-output step response model of the steam temperature system by applying step disturbance, simulating the multivariable predictive controller and adjusting the parameters of the multivariable predictive controller according to the built step response model; starting the multivariable predictive controller and switching the multivariable predictive controller from the simulated state to the actual online operation and control state and applying the output of the multivariable predictive controller to a controlled object to carry out real-time control. The supercritical machine set steam temperature control method and system can well ensure that the overheated steam temperature in a boiler is within the required range.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

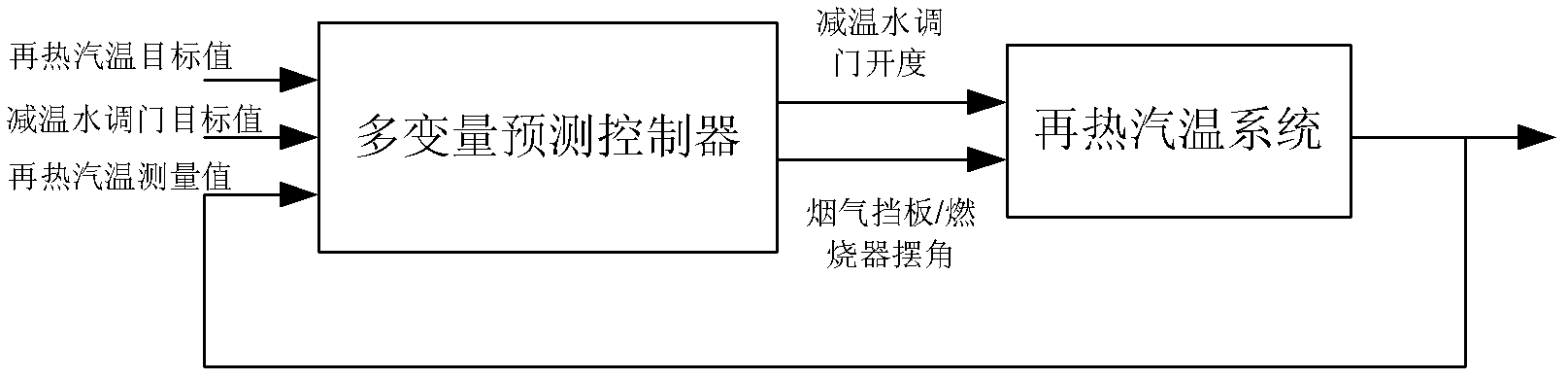

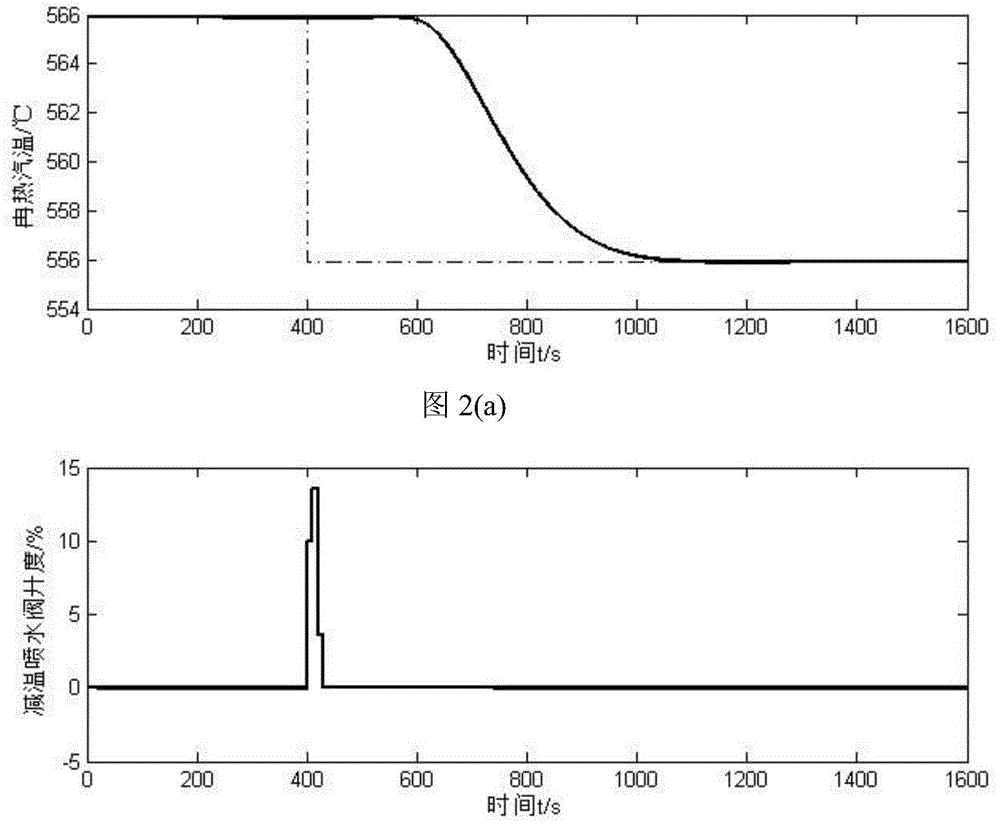

Reheated gas temperature optimization control method based on multi-variable predictive control

InactiveCN102401371AImprove economyDealing with large latency characteristicsSuperheating controlFlue gasPerformance index

The invention discloses a reheated gas temperature optimization control method based on multi-variable predictive control. According to the method, the whole hot steam temperature system is regarded as a two-in one-out multi-variable object, and the flow rate of reheated de-superheating jet water and the opening of a flue gas baffle plate are simultaneously controlled by adopting a multi-variable predictive control method; moreover, optimization of economical efficiency of the system is realized by adding a steady state target value of the opening of a reheated de-superheating jet water adjusting valve into optimization indexes of the conventional predictive control. By adopting the multi-variable predictive control method, coordination of side adjustment of flue gas and side adjustment of steam can be better realized, and the dynamic adjusting quality of the reheated steam temperature is further improved; and meanwhile, by adding the steady state target value of the de-superheating water adjusting valve into the conventional predictive control performance indexes, optimization of the de-superheating water jet quantity is realized, so that the circulating efficiency of a unit can be effectively improved.

Owner:SOUTHEAST UNIV

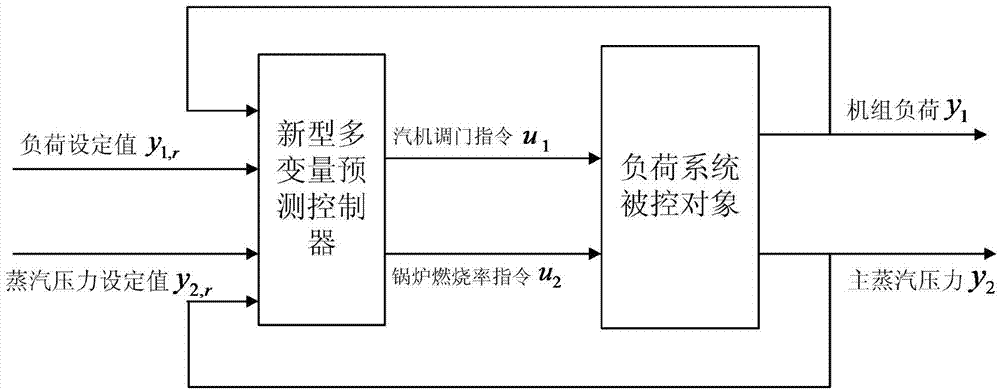

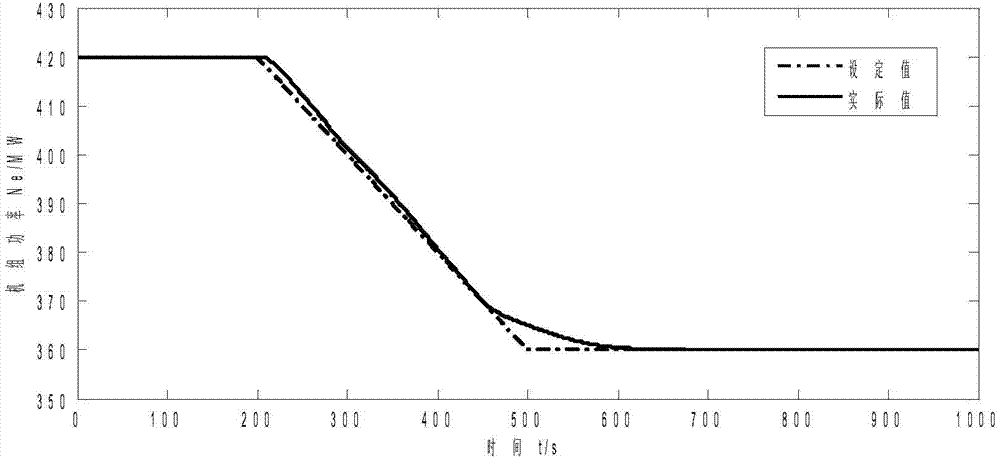

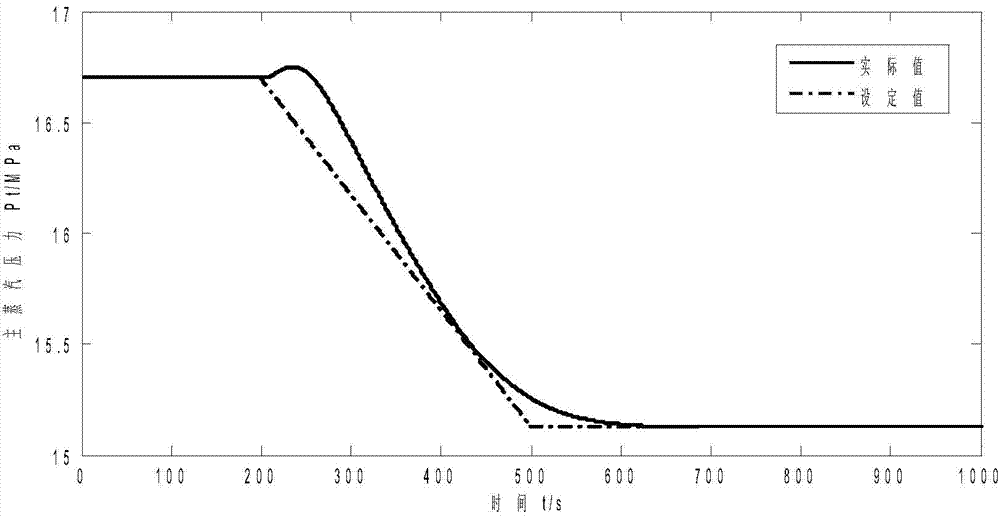

Novel thermal power generating unit load multivariable predictive control method

InactiveCN104122797AStable economic operationMeet real-time requirementsAdaptive controlSteam pressureControl system

The invention discloses a novel thermal power generating unit load multivariable predictive control method. According to the method, novel performance indexes are provided by being specific to characteristics of great inertia of a boiler, slow process response and the like, and a multivariable predictive control method of a unit load control system is designed according to the indexes. The performance indexes of the method are designed on the basis of the relation among unit output power, single-step predicted deviations of main steam pressure and deviation change rate. During process controlling, when demands of outside loads are changed, the valve opening degree of a turbine is adjusted to change inlet steam quantity of the turbine, the main steam pressure is changed to release stored heat of the boiler so that a unit can rapidly respond to the outside load demands, meanwhile, the boiler burning ratio is rapidly adjusted to meet the outside load demands and meanwhile, prevent the deviation between the main steam pressure and a set value from exceeding a limit, the set value can be tracked, stable operation of the unit can be maintained, and the stability of the load control system and the operating efficiency of the unit can be improved.

Owner:SOUTHEAST UNIV

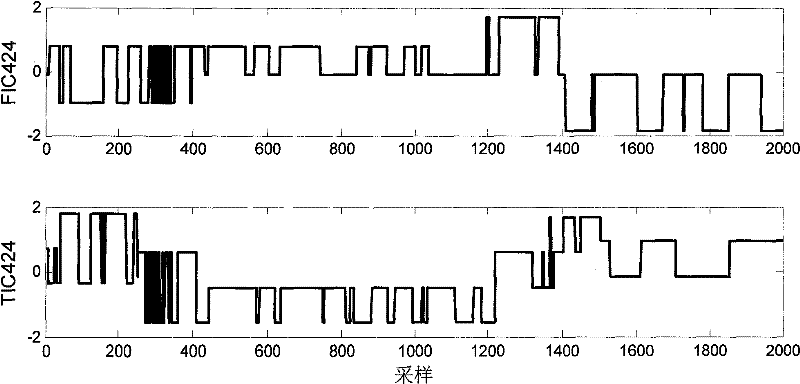

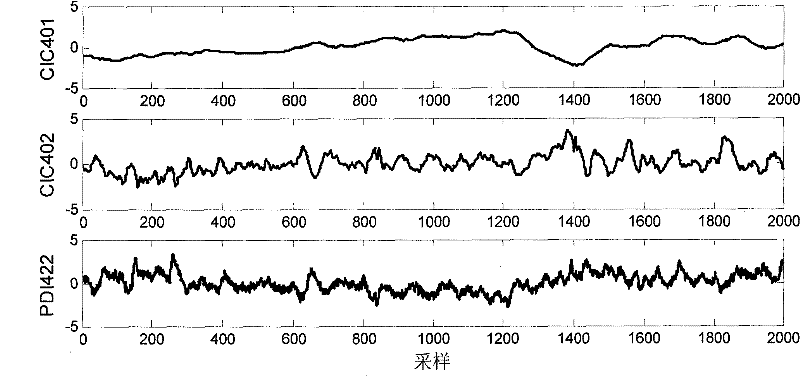

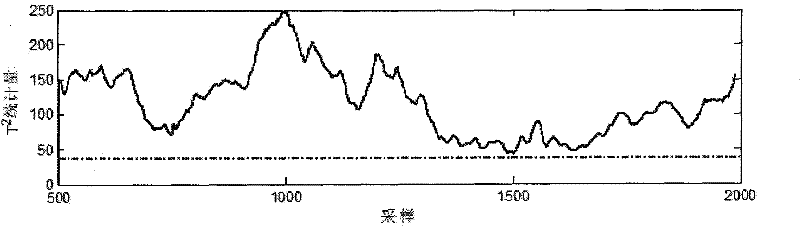

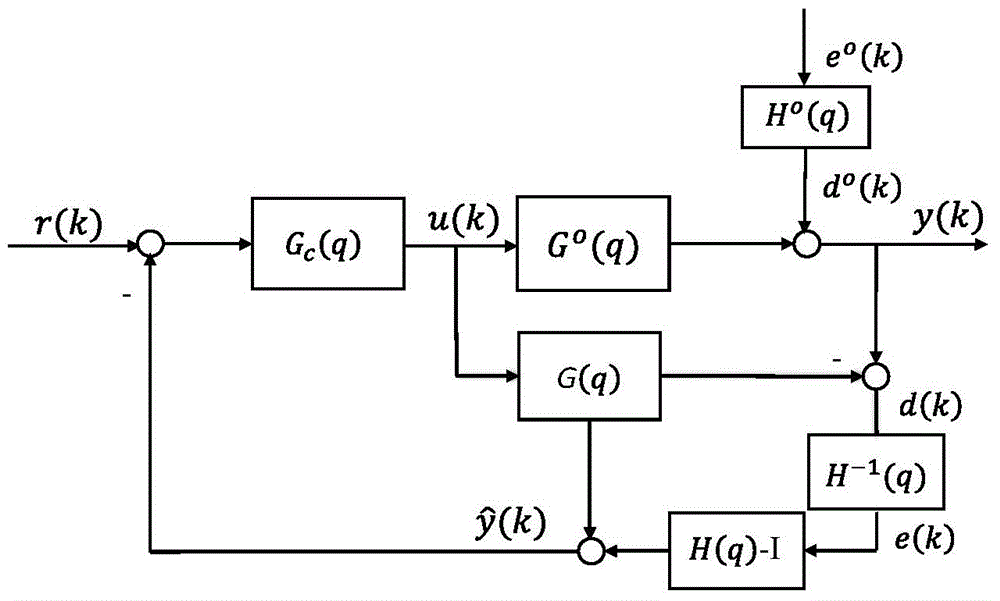

Method for model mismatching detection and positioning of multivariate predictive control system in chemical process

The invention discloses a method for model mismatching detection and positioning of a multivariate predictive control system in a chemical process. By aiming at the typical hierarchical control system in the traditional process industry, the model mismatching detection and positioning is carried out respectively on a multivariate system and all univariate subsystems in the multivariate system. The method comprises the steps of: acquiring residual errors of the multivariate system in a predicative control layer on the basis of an orthogonal projection method, constructing a monitoring statistic computing engine, and acquiring the residual errors, sensitive to process dynamic characteristic variation only, of the univariate system on the basis of an auxiliary variable identification method.In the invention, closed-loop operation data is adopted directly and additional information of the system is not needed; rapid detection and positioning can be made just by utilizing a small amount of data so that fewer disturbances are made to a working condition; and the mismatching information of process models of all univariate subsystems in the multivariate system can be positioned so as to eliminate the influence of the disturbances. By means of the method disclosed by the invention, the accurate model mismatching information can be obtained rapidly at lower cost, the maintenance cost of the predictive control system can be reduced, the service life of the predicative control system can be prolonged and the gain can be improved.

Owner:ZHEJIANG UNIV

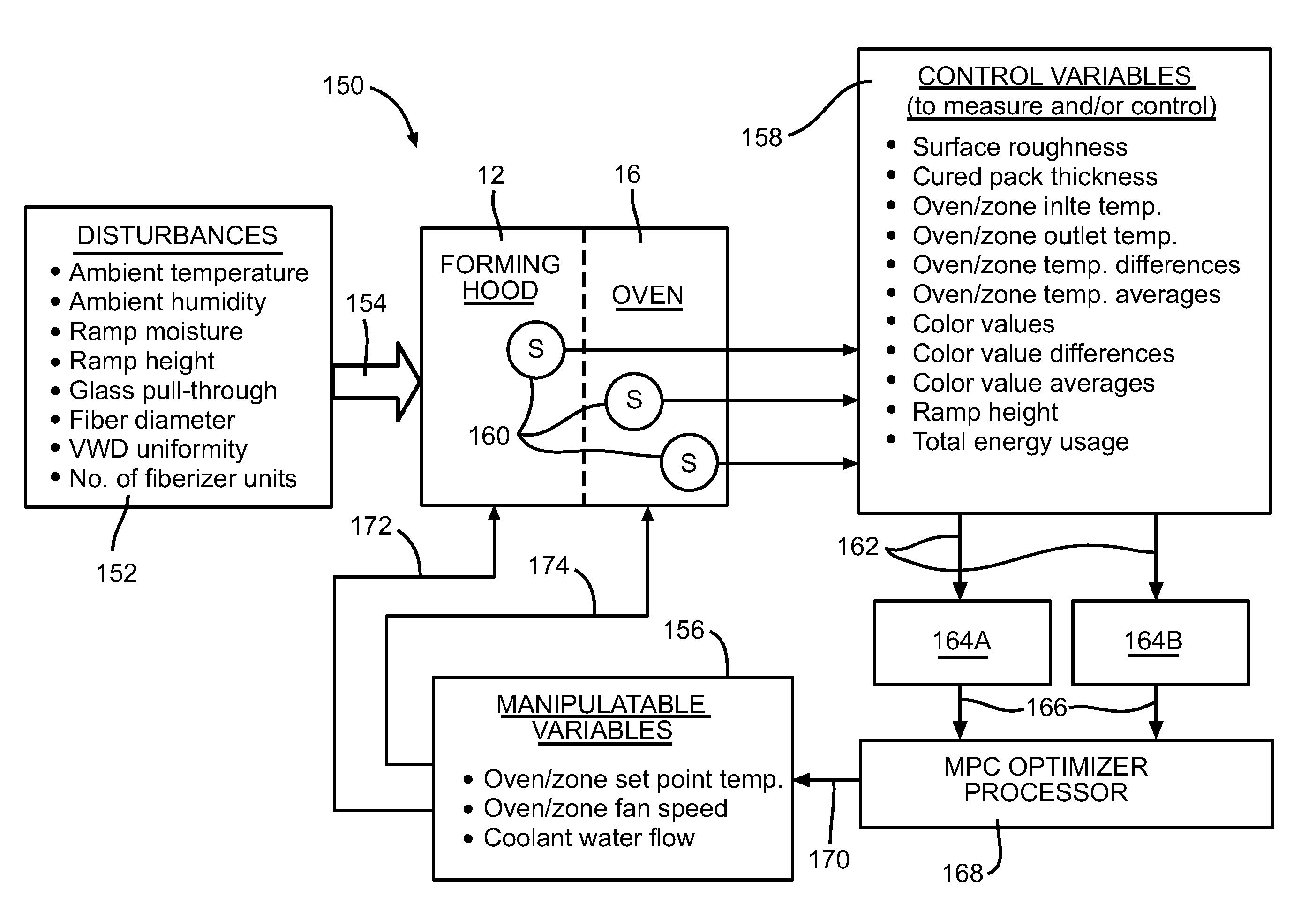

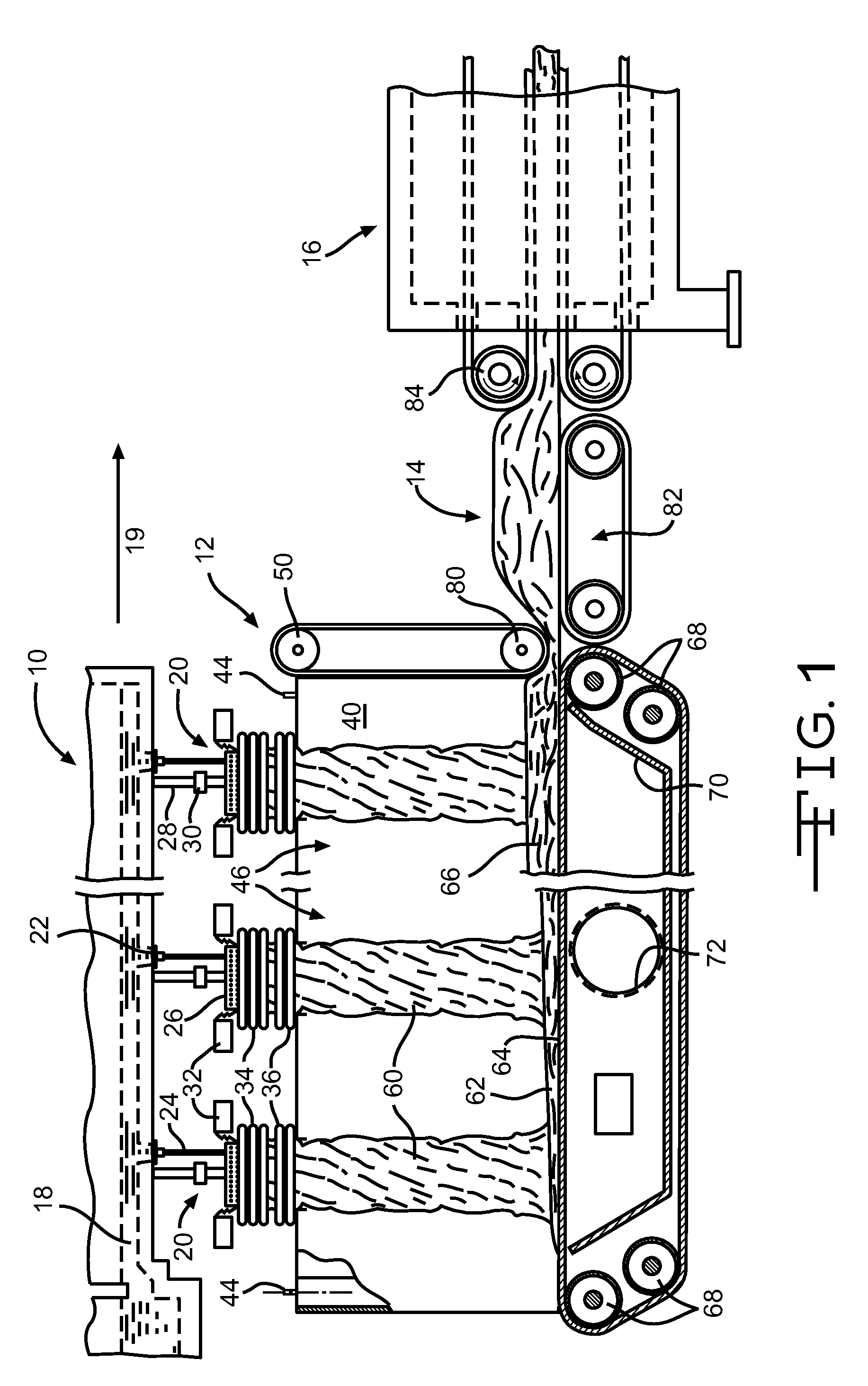

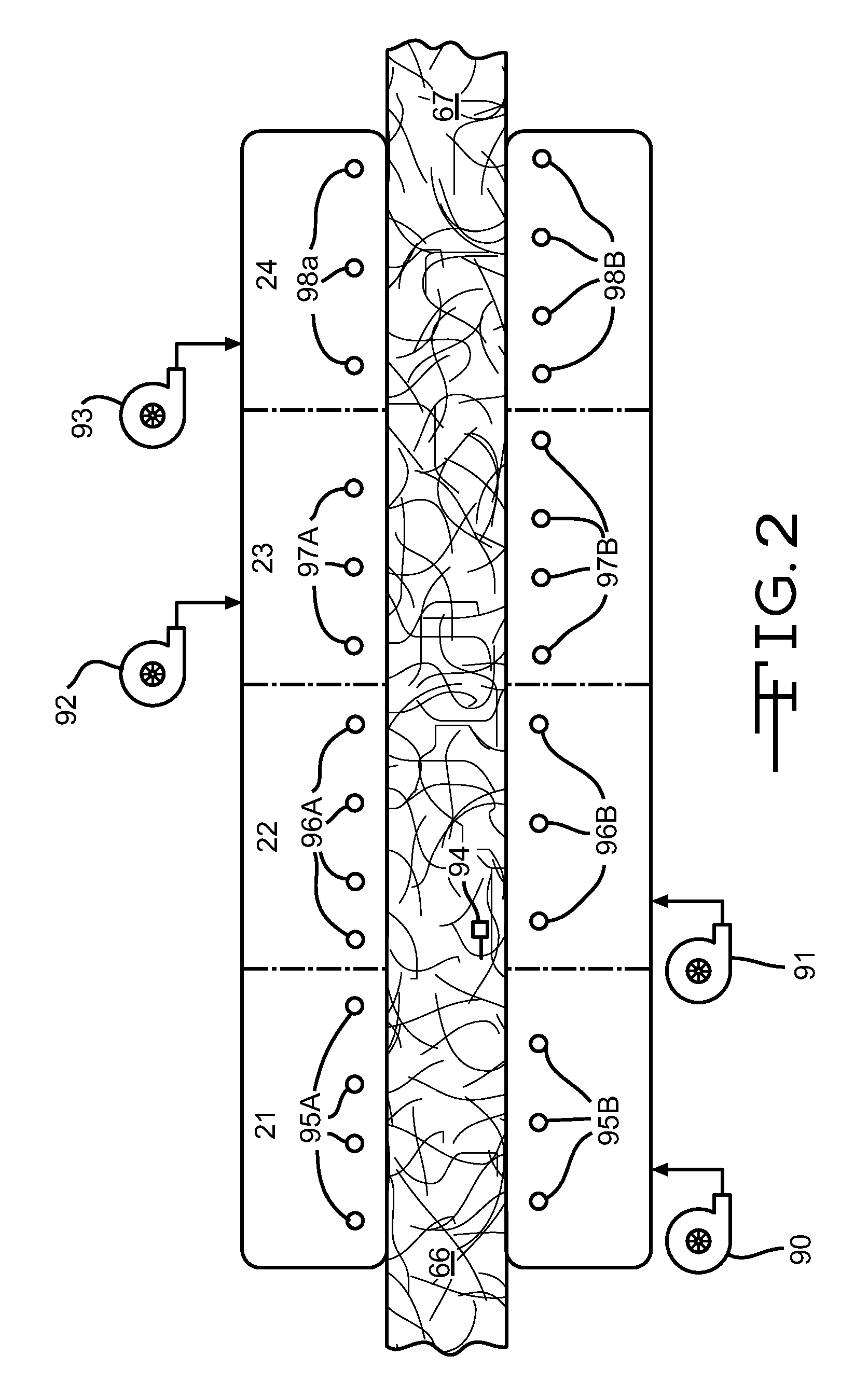

Multivariable predictive control optimizer for glass fiber forming operation

InactiveUS20120271445A1Keep full controlInvestigating moving fluids/granular solidsElectric controllersFiberGlass fiber

A system and method for determining and controlling for cure status of binder on a fibrous product are disclosed. Cure status is monitored by measuring one or more control variables and attempting to keep them within known control limits. Exemplary control variables include oven temperatures at various locations and color values of sections of the fibrous product. Sensors such as thermocouples and image capture systems sense these variables continuously online and provide input signals for a MPC processor-optimizer. The MPC optimizers balances the constraints according to a programmed optimization function and priority ranking of control variables and solves for optimal control setting on manipulatable variables, such as oven fan speed, oven setpoint temperatures and coolant water flow rate.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

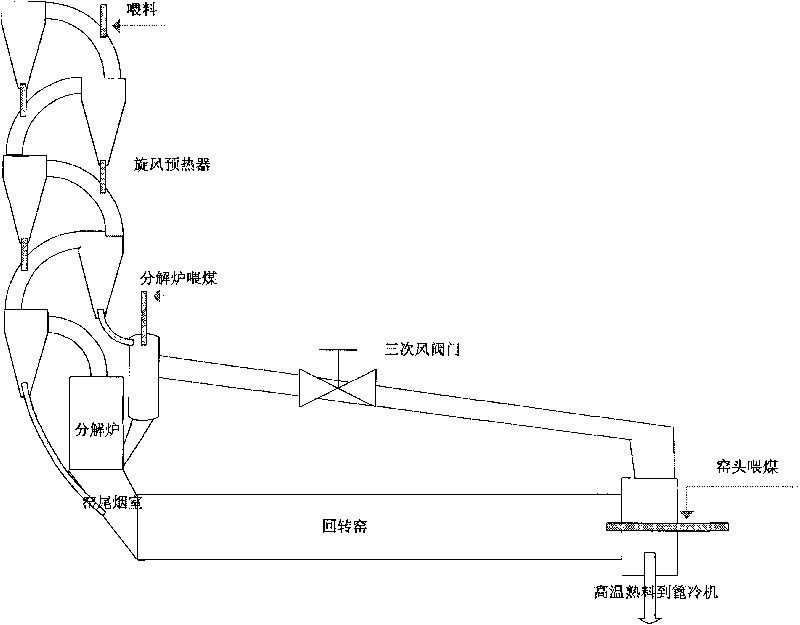

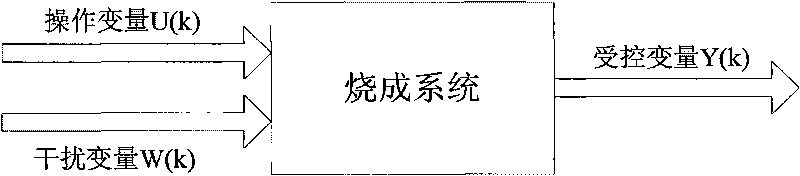

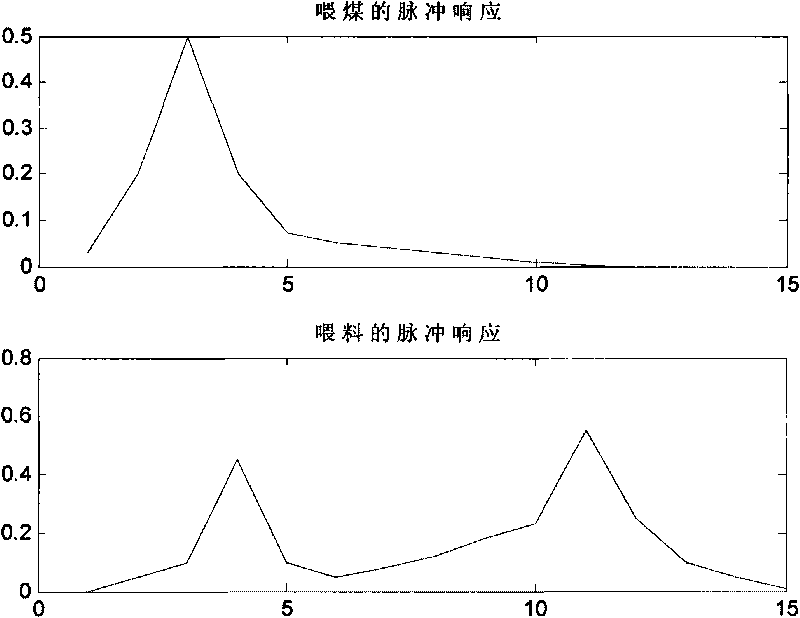

Multivariable predictive control method with firing system based on pulse response die

InactiveCN101750964ASimplify the modeling stepsImprove robustnessAdaptive controlAutomatic controlPrediction system

The present invention discloses a multivariable predictive control method with a firing system based on a pulse response die, which belongs to the field of industrial automatic control. The multivariable predictive control method with a firing system based on a pulse response die mainly comprises the steps of the building of the pulse response die and the design of a predictive control loop. The pulse response die based on a constrained least square method is built according to the on-site data and the system mechanism of the firing system. The future time output of the firing system is predicted by the pulse response die according to the current input and output of the firing system and the input of a future time system, and the better operating value of the current time of the firing system is obtained by solving a quadratic optimal problem according to a predictive control mechanism by combining set value output by the firing system and constrained conditions; after the better operating value is filtered, the better operating value is applied to the firing system to enable the firing system to work in the optimal state and finish one control circulation; the above step is repeated at the nest time to finish the rolling optimization of predictive control and ensure the stable and optimal running of the firing system in concrete production.

Owner:ZHEJIANG UNIV

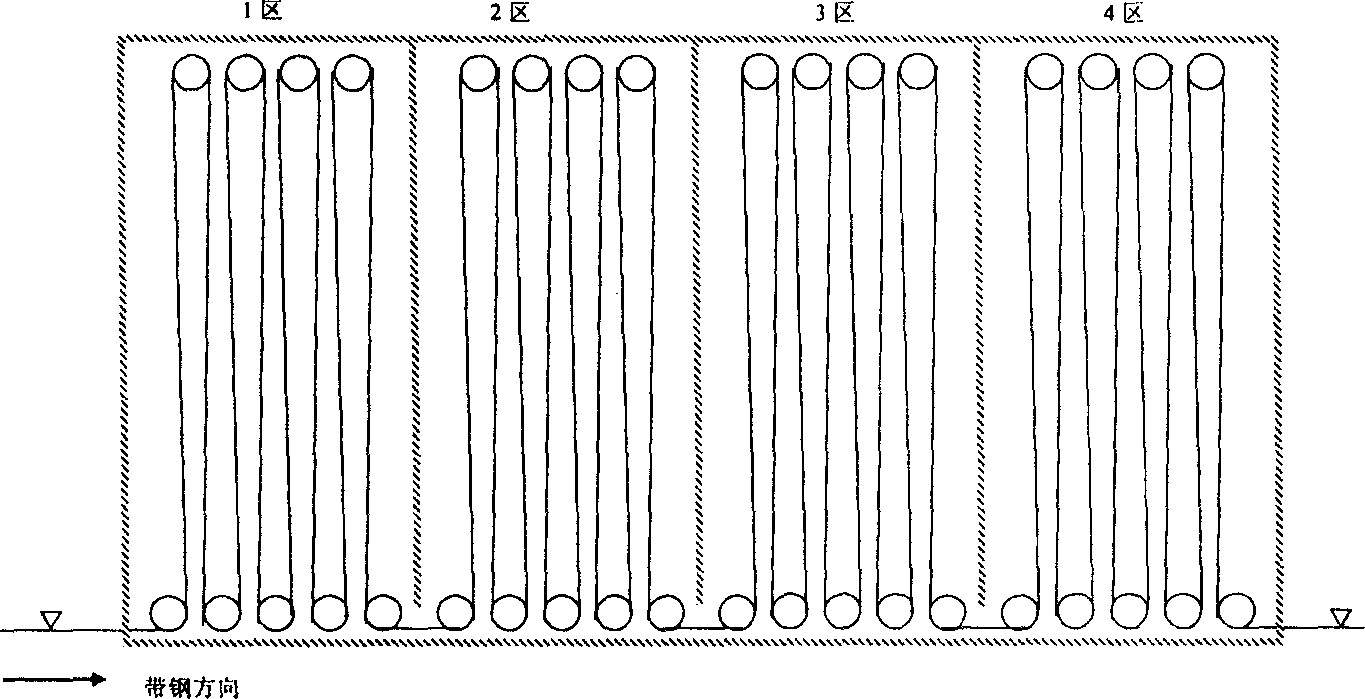

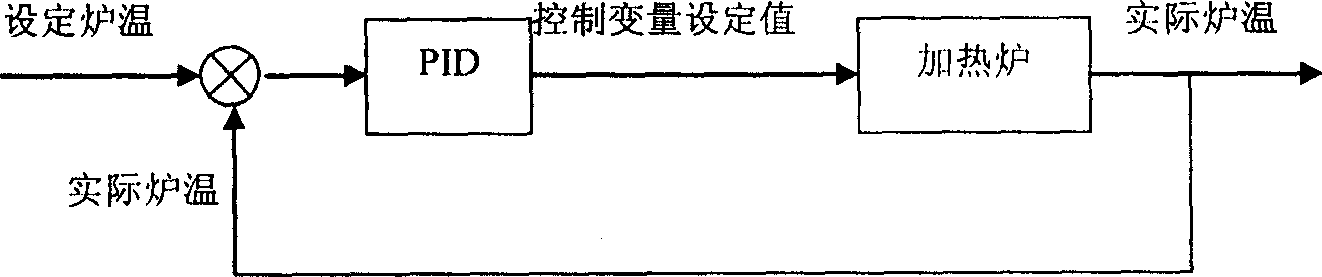

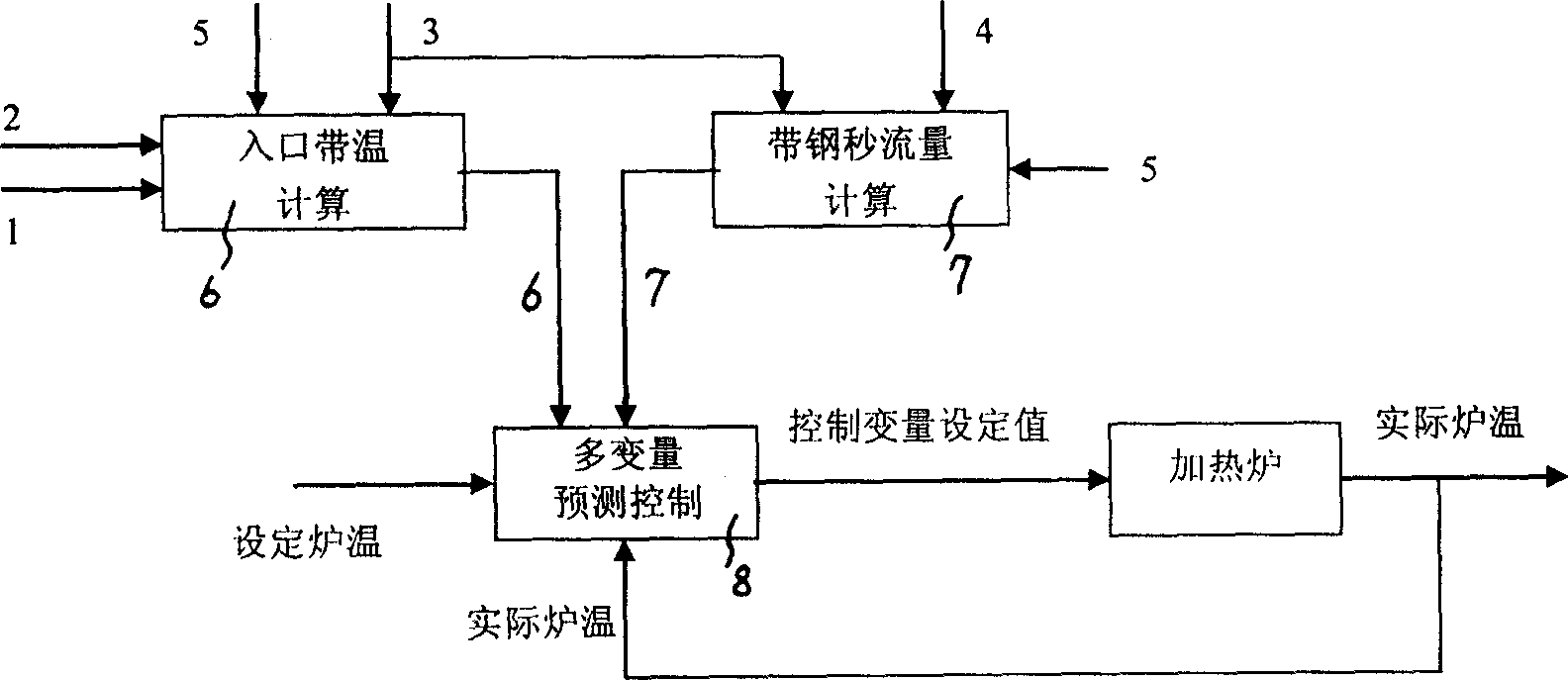

Method for controlling furnace temperature of heating furnace for continuous annealing

InactiveCN1873034AHigh precisionImprove dynamic response characteristicsFurnace typesHeat treatment process controlFurnace temperatureThermal energy

This invention relates to a method for controlling the temperature of continuous annealing heating oven. The entrance temperature of the oven, belt steel flow rate of a second and oven temperature are used as the input to calculate the optimal gas flow increase, and the oven temperature can be comtrolled by adjusting the gas flow increase. This invention considers the influences of belt steel thickness, width, flow rate and the entrance temperature to the oven temperature, and increases the accuracy and dynamic responsivity of the oven temperature control.

Owner:BAOSHAN IRON & STEEL CO LTD

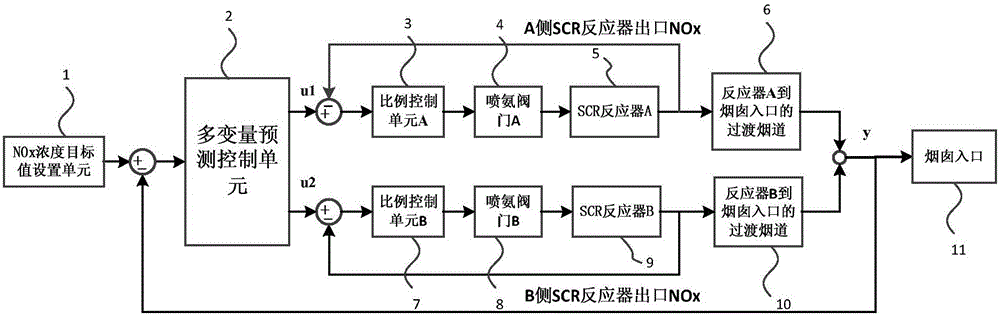

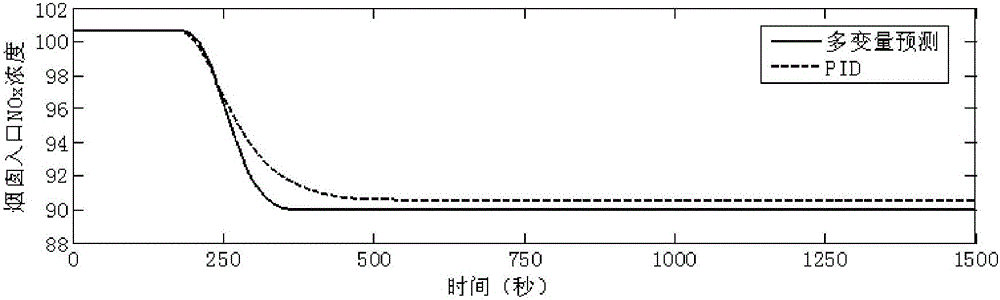

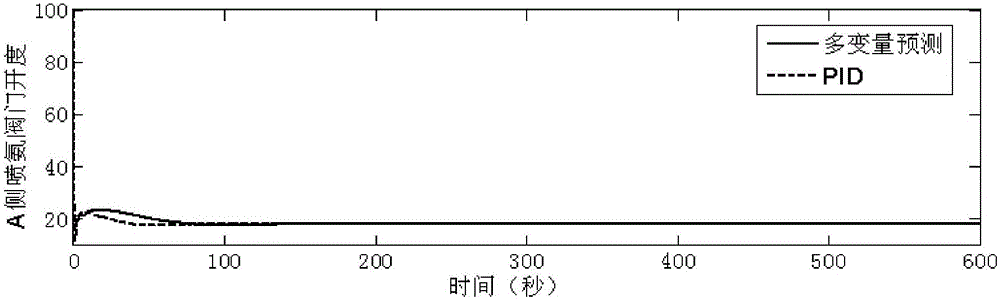

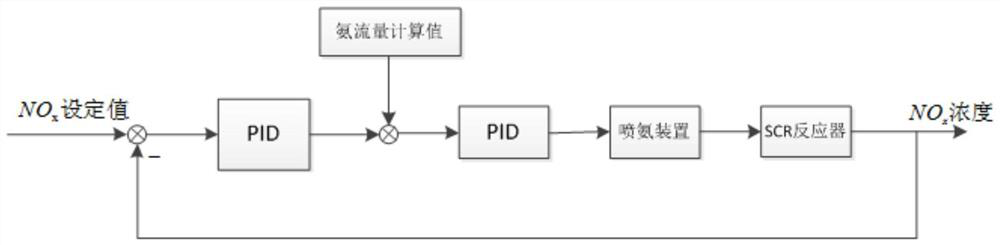

Multi-variable interval constrained estimation-based SCR denitration optimized control system and method

ActiveCN105700576AImprove economyQuick responseControlling mixing ratio of fluids with different temperaturesProportional controlActuator

The invention discloses a multi-variable interval constrained estimation-based SCR denitration optimized control system, which comprises an NOx concentration target value setting unit, a multi-variable predictive control unit, a proportional control unit A, an ammonia spraying valve A, an SCR reactor A, a transition flue between the reactor A to a chimney inlet, a proportional control unit B, an ammonia spraying valve B, an SCR reactor B, a flue between the reactor B and the chimney inlet, and the chimney inlet. The invention also discloses a control method of the above system. According to the technical scheme of the invention, the response speed of the ammonia spraying amount control to the unit load change is increased. Meanwhile, the influence on the performances of the system, caused by the saturation of an actuator, can be avoided. The actuating number of the actuator is reduced, and the service life thereof is prolonged. The economical efficiency of the denitration system is improved.

Owner:SOUTHEAST UNIV

Robust multivariable predicting control method based on uncertain color model

This invention relates to one dye machine module formula multi-variable prediction robust bar H infinity control method, which determines one dye machine mode formula multiple step prediction robust H infinity control method through data collection, process resolution, prediction control, robust H infinity control technique; using the control method to reduce uncertain factors color impact.

Owner:HANGZHOU DIANZI UNIV

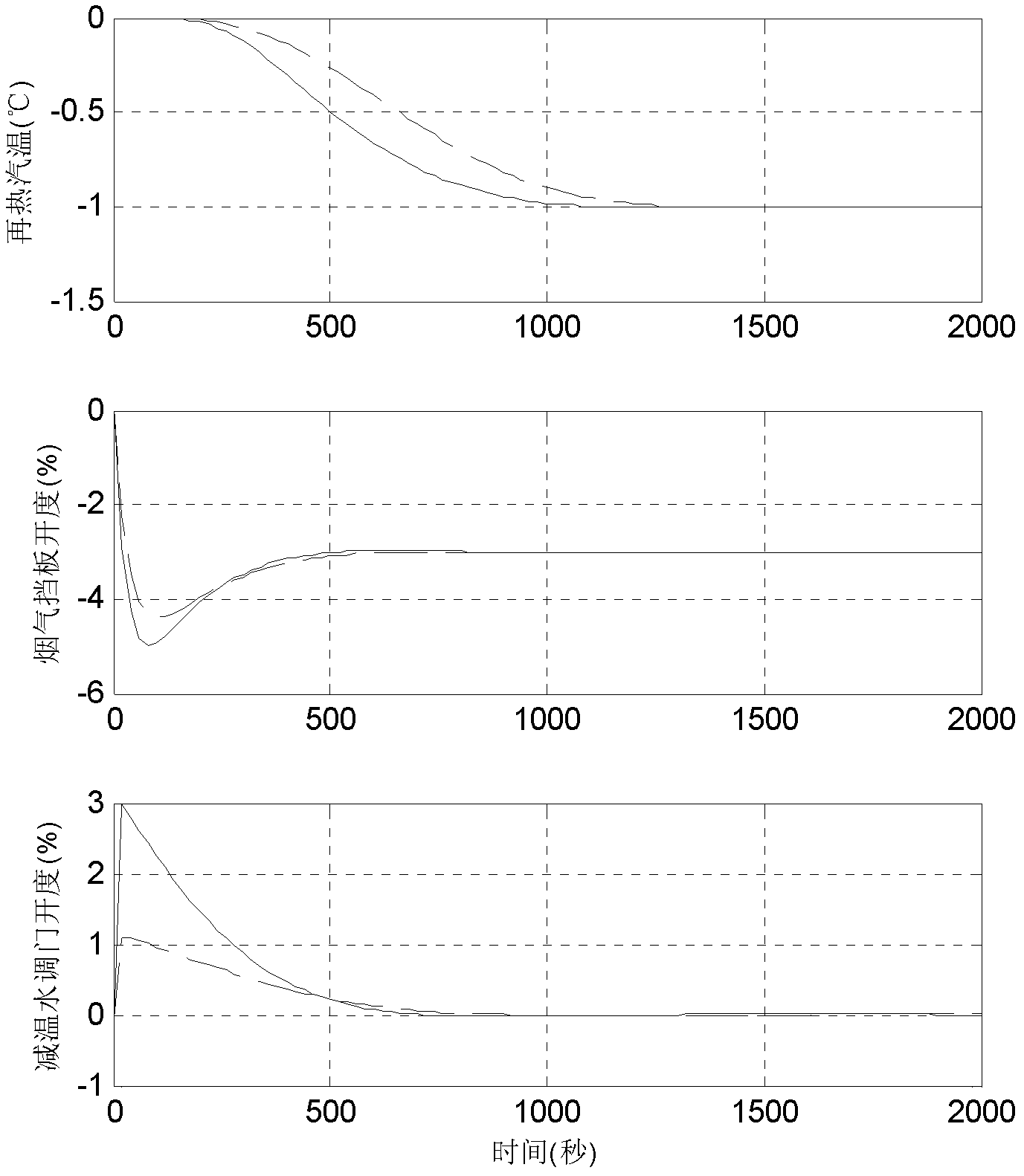

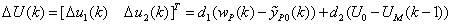

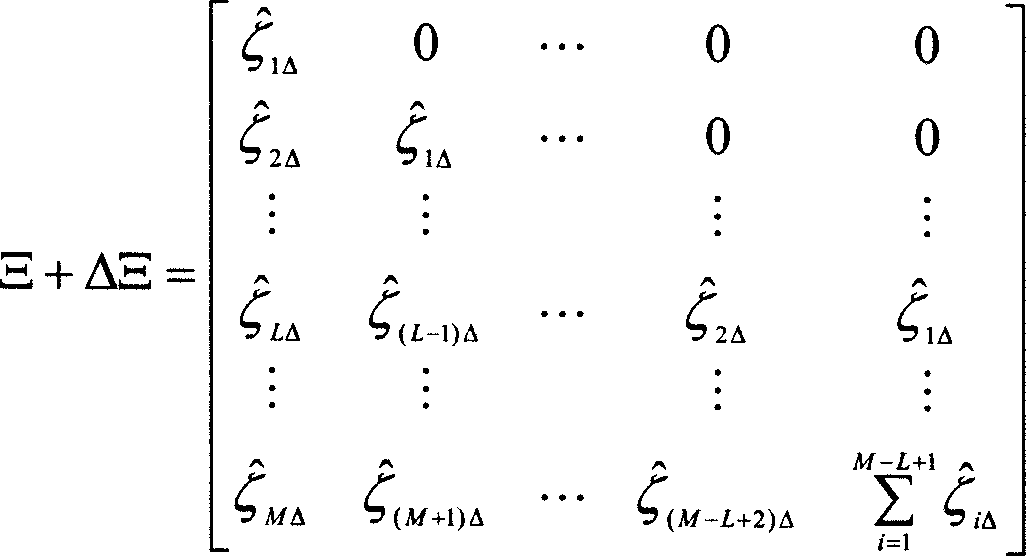

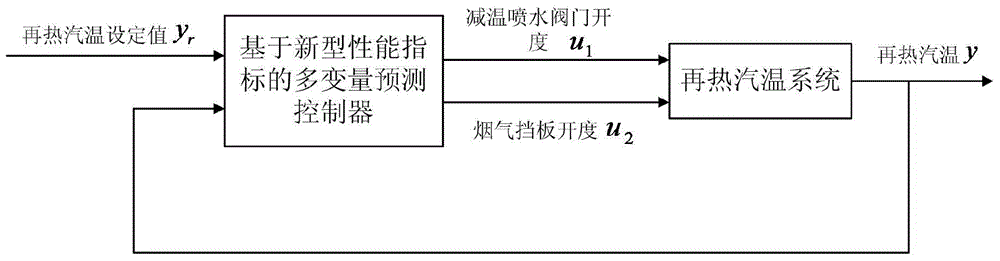

Method for realizing reheat steam temperature multivariable coordinate predictive control through performance indexes

InactiveCN104102134AStable controlGuaranteed dynamic coordinationTemperatue controlAdaptive controlControl systemPredictive controller

The invention discloses a method for realizing reheat steam temperature multivariable coordinate predictive control through performance indexes. According to the method, the reheat steam temperature system of a thermal power generating unit is regarded as a 2*1 multivariable system, a multivariable predictive controller is designed on the basis of novel performance indexes, and the opening degree of a reheat steam temperature reducing water-spray valve and the opening degree of a smoke baffle are controlled simultaneously. In the performance indexes, on one hand, an algorithm is simplified and rapid control is realized on the basis of requirements on a single-step prediction error and a prediction error change rate, and the control performance of a control system can also be effectively adjusted by adjusting a predictive length and a predictive error change rate weight; on the other hand, dynamic limit on the opening degree of the temperature reducing water-spray valve is added in the indexes, the part of the performance parameters is self-adaptive to changes during a control process, and the amount of temperature reducing water sprayed in reheat steam can be reduced while a reheat steam control quality is improved, thus effectively increasing the cycle efficiency of the unit.

Owner:SOUTHEAST UNIV

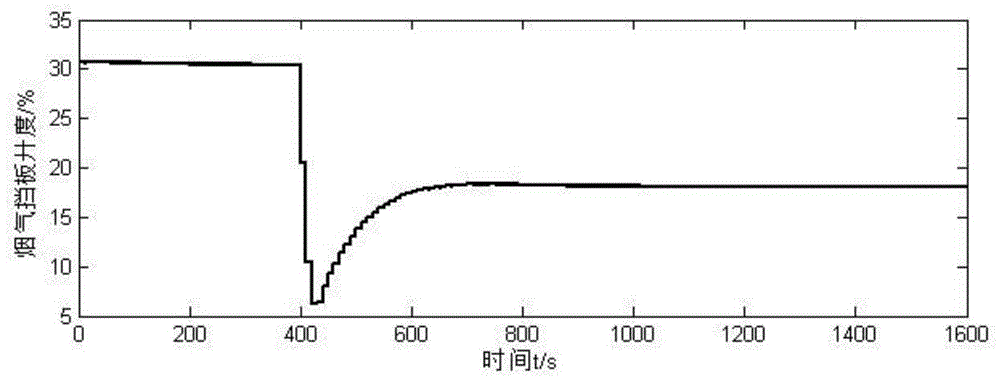

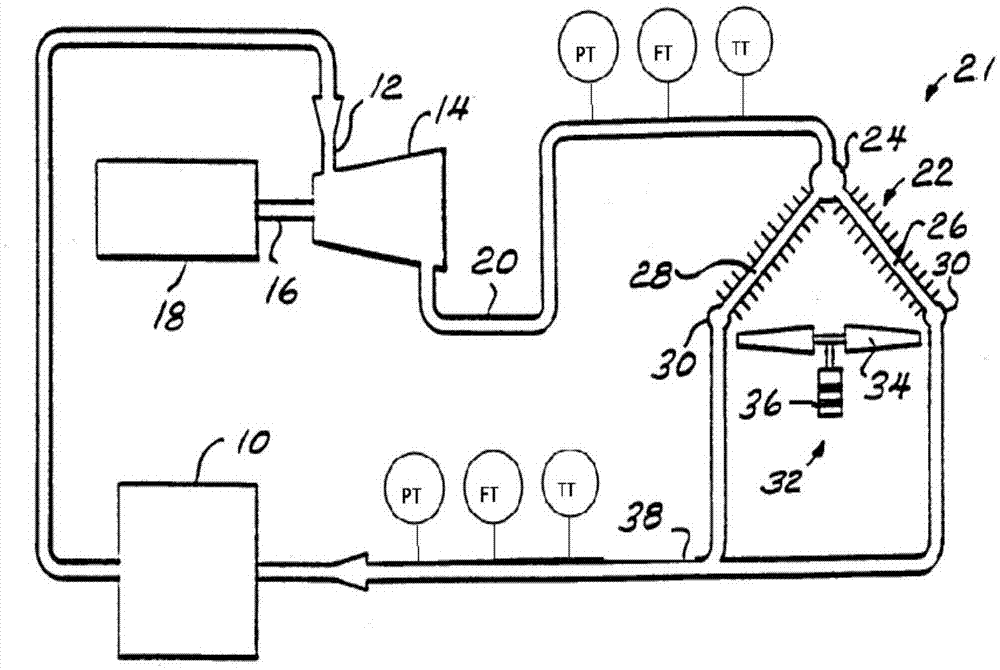

Air cooled condenser unit with optimized operation

InactiveCN106855365AReal-time controlUninterrupted controlSteam/vapor condensersPredictive controllerEngineering

The invention relates to an air-cooled condenser unit with optimized operation, comprising: an air-cooled condenser, which has a heat exchange tube bundle and fan equipment, the heat exchange tube bundle is configured to receive exhaust steam from a steam turbine, and the fan equipment is matched with the heat exchange tube bundle arranged to cool the exhaust steam flowing in the heat exchange tube bank into condensed water; a data measurement and acquisition system configured to measure and acquire at least part of the controlled variables and disturbance variables of the air-cooled condenser; a multivariable predictive controller, It is based on pre-set modular units, and automatically controls the control variables of the fan equipment according to the values of at least part of the controlled variables and disturbance variables from the data measurement and acquisition system to optimize the performance of the air-cooled condenser while preventing the back pressure of the steam turbine from being lower than the set value The range of pressure protection limits and prevent the condensate temperature from falling below the predetermined limit of condensate temperature.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

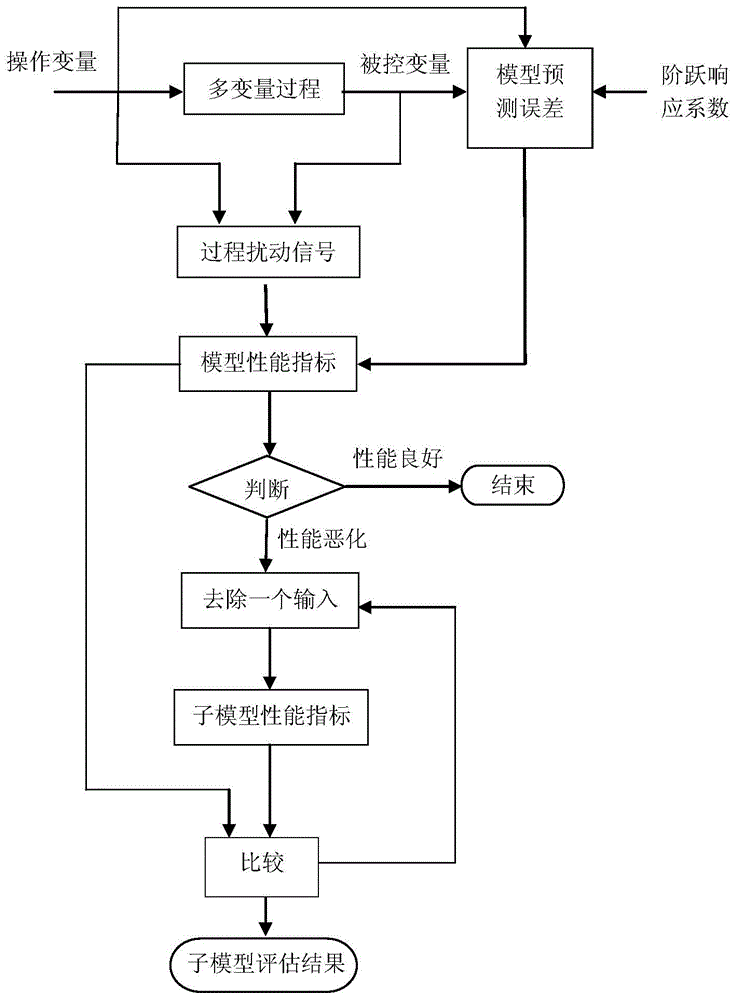

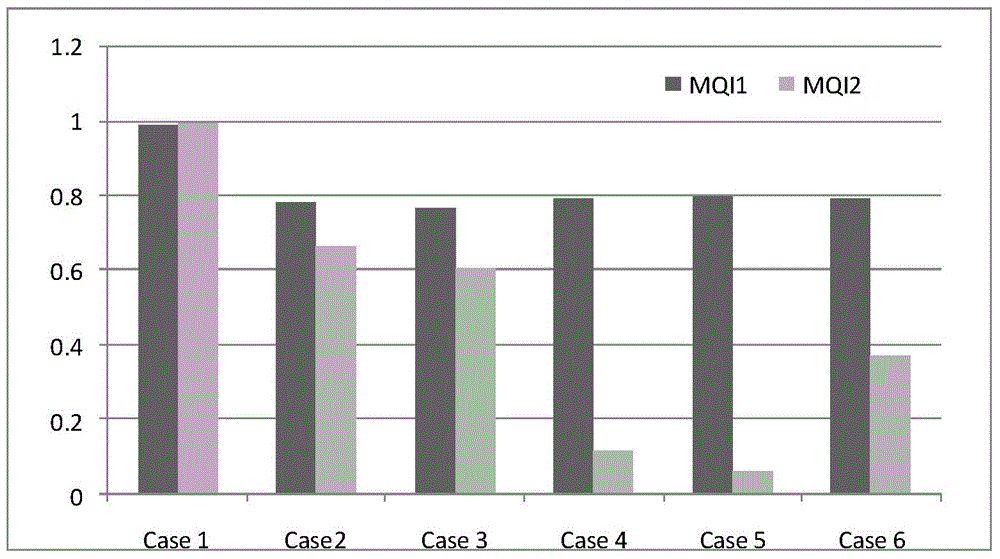

Deep diagnostic method of performance reduction of predictive control model

InactiveCN104698976AReduce performanceSave on remodeling costsProgramme controlComputer controlComputational modelPredictive controller

The invention discloses a deep diagnostic method of performance reduction of a predictive control model. The deep diagnostic method of the performance reduction of the predictive control model includes: using a production run data calculation process disturbance signal, and then using production data and a step response coefficient of a design stage of a predicting controller to calculate model prediction error, and judging overall performance advantages and disadvantages of the predictive control model through a model performance index built through the production data and the step response coefficient of the design stage of the predicting controller. The deep diagnostic method of the performance reduction of the predictive control model further includes: for the model deteriorative in performance, using a method of removing input variables one by one to calculate a new model performance index, judging sub model performance corresponding the removed input variables through model performance index change situations, and thereby achieving monitoring for the performance of each sub module. The deep diagnostic method of the performance reduction of the predictive control model only uses the production process data and design data, and thereby not only can evaluate the overall performance of the multivariable predictive control model, but also can further evaluate the performance of all the sub modules corresponding to the input variables, provides a suggestion for an engineer to maintain a control system, and can substantially reduce maintenance cost of the predictive controller.

Owner:NANJING UNIV OF TECH

Apparatus and methods for non-invasive closed loop step testing using a tunable trade-off factor

ActiveUS9513610B2Minimize negative impactSimple modelAdaptive controlSmall amplitudePredictive controller

An integrated multivariable predictive controller (MPC) and tester is disclosed. The invention system provides optimal control and step testing of a multivariable dynamic process using a small amplitude step for model identification purposes, without moving too far from optimal control targets. A tunable parameter specifies the trade-off between optimal process operation and minimum movement of process variables, establishing a middle ground between running a MPC on the Minimum Cost setting and the Minimum Move setting. Exploiting this middle ground, embodiments carry out low amplitude step testing near the optimal steady state solution, such that the data is suitable for modeling purposes. The new system decides when the MPC should run in optimization mode and when it can run in constrained step testing mode. The invention system determines when and how big the superimposed step testing signals can be, such that the temporary optimization give-away is constrained to an acceptable range.

Owner:ASPENTECH CORP

Double-layer-structure predication control method applicable to middle-discharging type cement raw material mil system

InactiveCN103350023AIncrease load levelAvoid the effects of mutual couplingGrain treatmentsLoad optimizationEngineering

For the characteristics that a middle-discharging type cement raw material mill system is provided with two control loops of a coarse powder bin and a fine powder bin, the coupling action exists between the coarse powder bin and the fine powder bin and the load of the two bins needs to be coordinated and optimized, the invention adopts a double-layer-structure predication control method with two layers of optimization and control to carry out independent optimization and control on a control system. A steady optimization layer realizes the load optimization on the coarse powder bin and the fine powder bin according to the economic optimization index; a dynamic control layer selects milling noise and the negative pressure of an inlet of the fine powder bin as output variables, selects the feeding amount and the openness of a distributing valve as input variables, and selects the rotating speed of a powder selecting machine as a feed-forward variable so as to form a two-input two-output one-feed-forward multi-variable predication control system. The double-layer-structure predication control method has the advantages that the total load level of a raw material mill is effectively improved, the mutual coupling action when the coarse powder bin and the fine powder bin are respectively controlled is avoided, the influence of lagging of the feeding amount is reduced, the disturbance action of quality adjustment on a product on the control system is inhibited, the automation degree is improved, the yield of raw materials is increased, the continuous operation rate of the control system is increased and the economic benefit is increased for enterprises.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

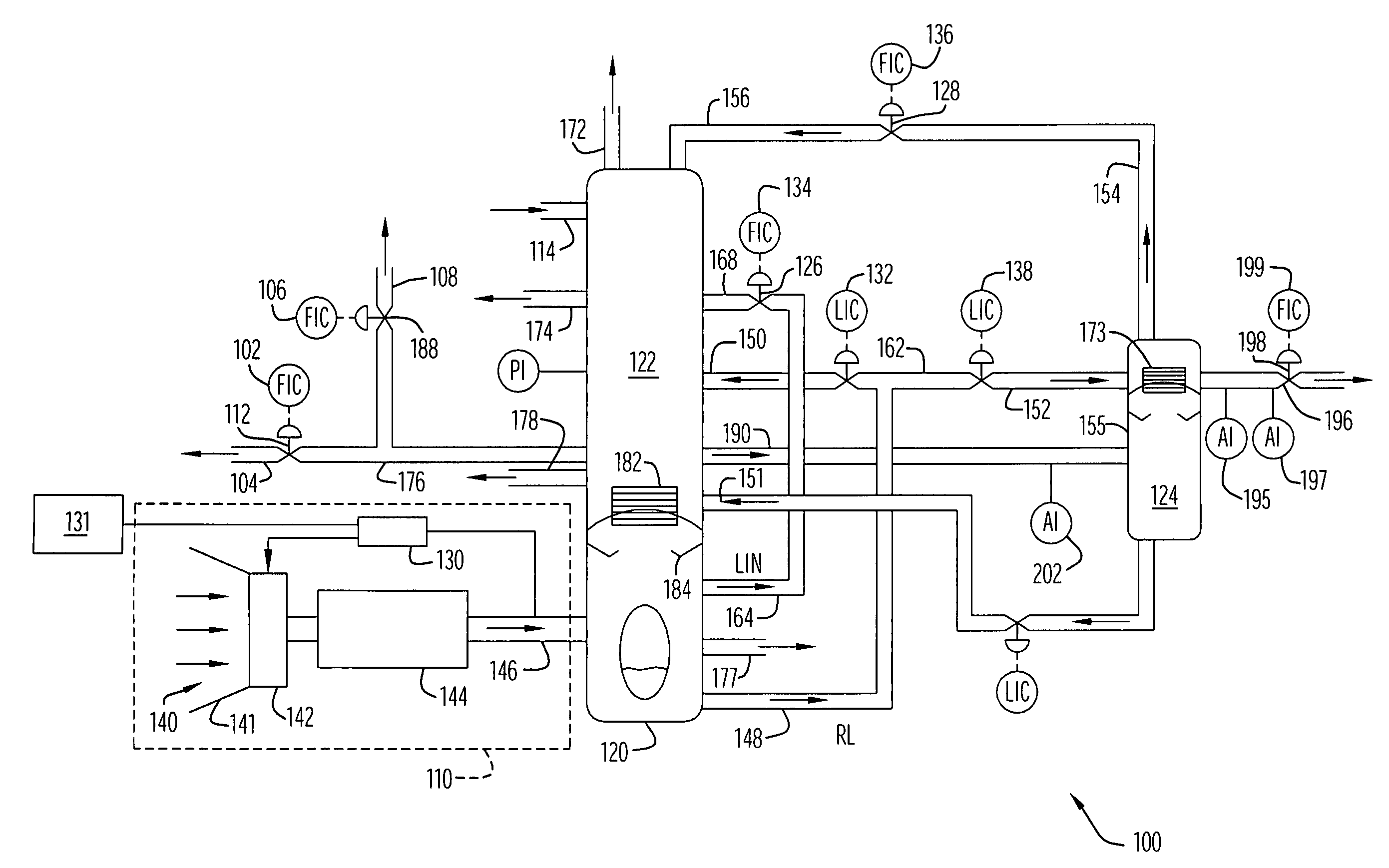

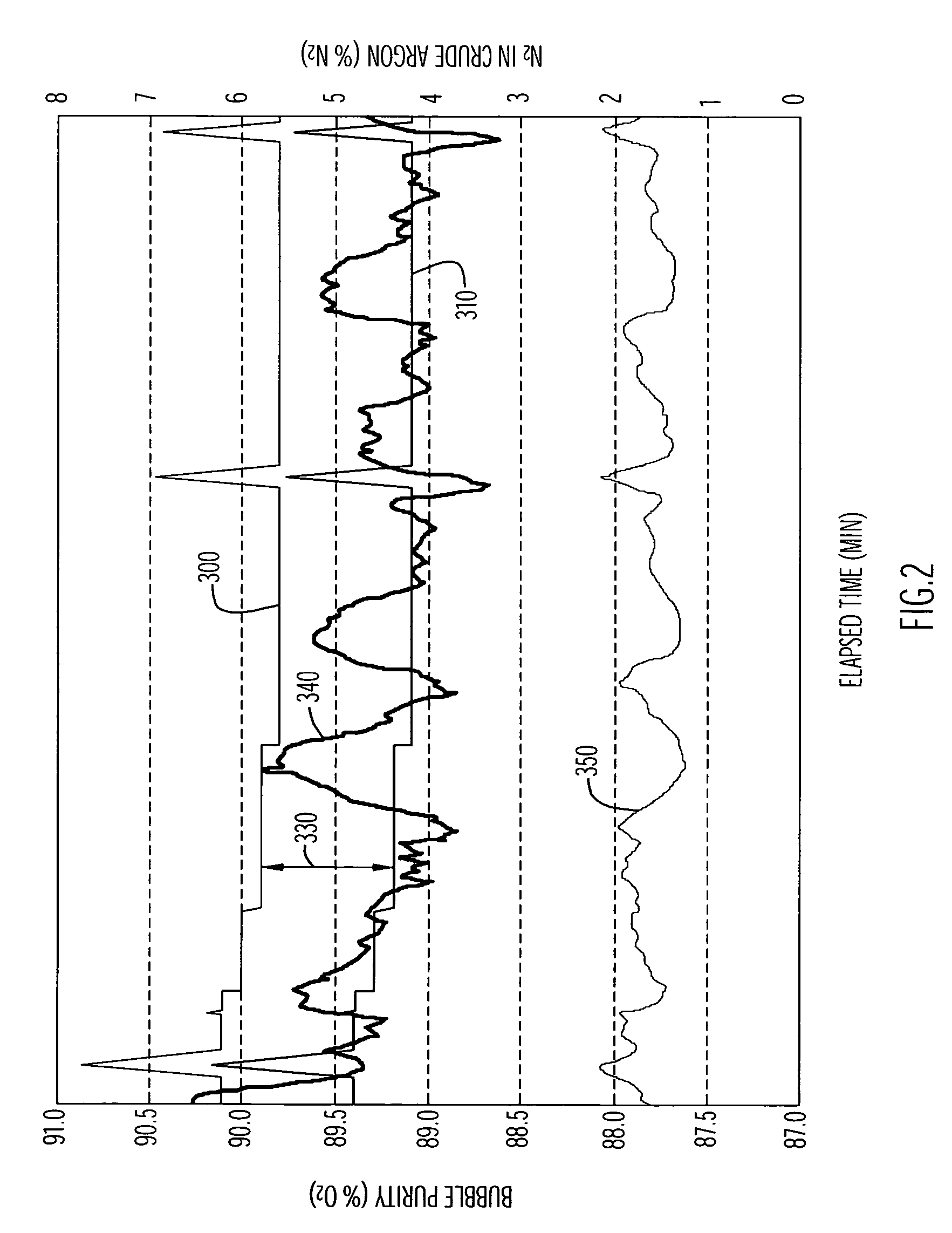

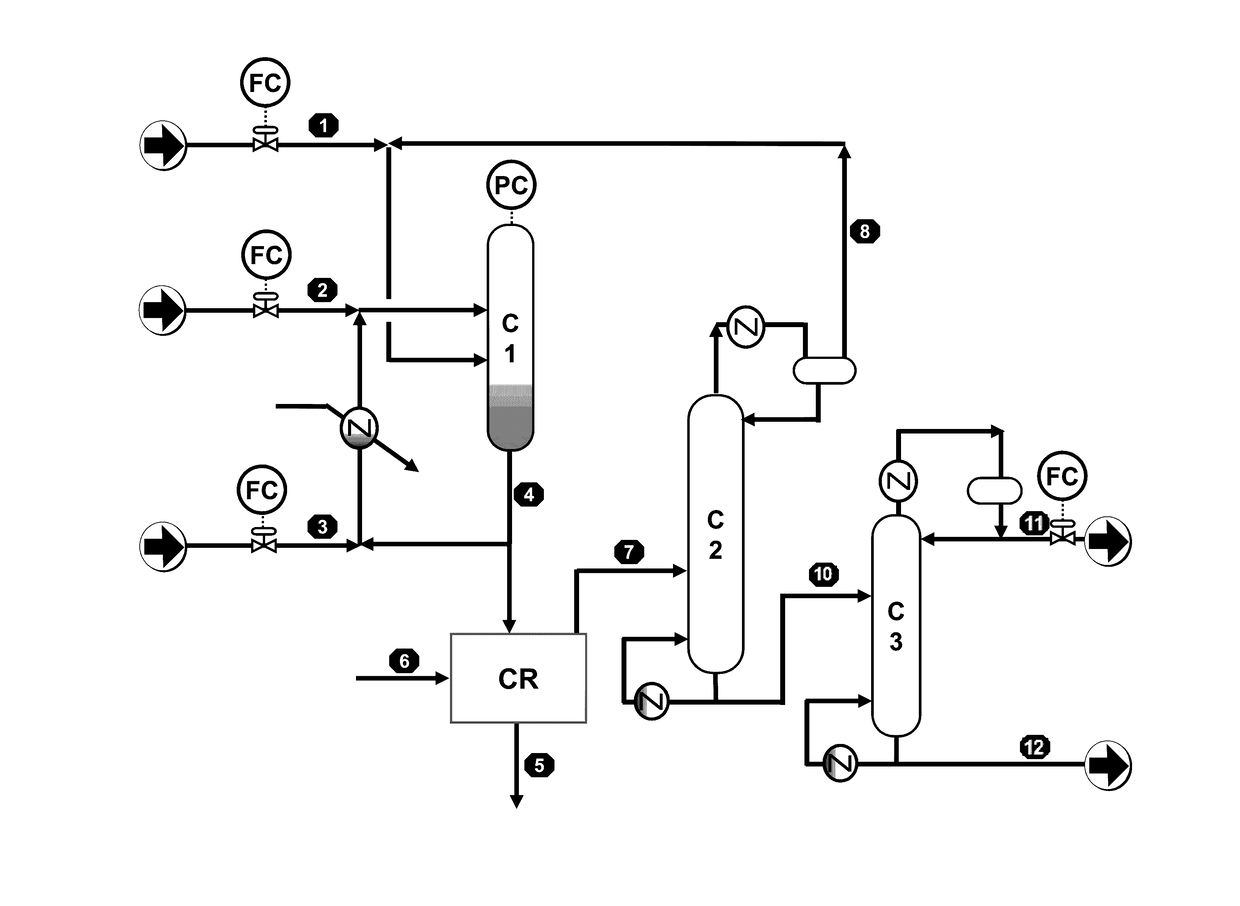

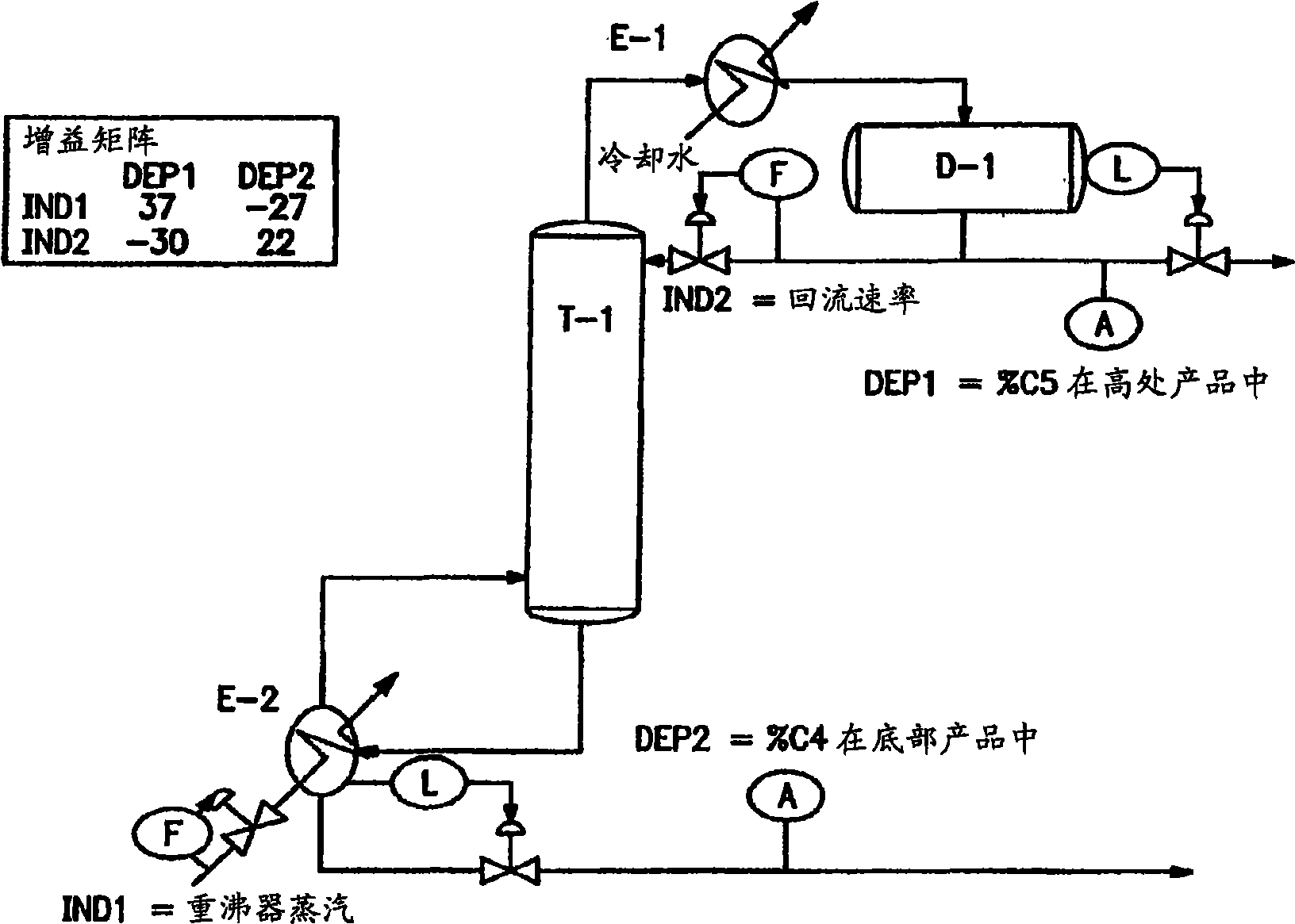

Methods and systems for optimizing argon recovery in an air separation unit

ActiveUS20050072187A1Maximum argon recoveryMaximize flowSolidificationLiquefactionDistillationNitrogen

A cryogenic air separation system that optimizes the recovery of argon includes an air intake, a high-pressure distillation column, a low-pressure distillation column, a crude argon distillation column, and a controller that automatically controls the composition of the raw argon stream to decrease the concentration of oxygen in the stream while preventing the concentration of nitrogen in the crude argon stream from exceeding a selected value. In addition, the controller also controls the composition of the crude argon stream until an oxygen concentration of the crude argon stream reaches a selected value. The controller may include a multivariable predictive controller.

Owner:AIR LIQUIDE LARGE INDS U S LP

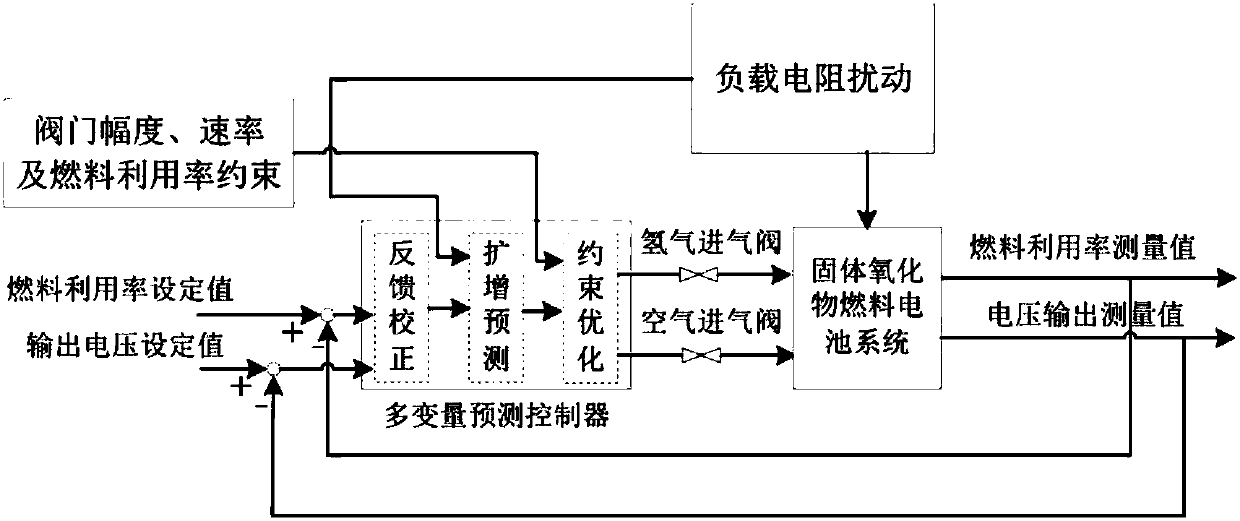

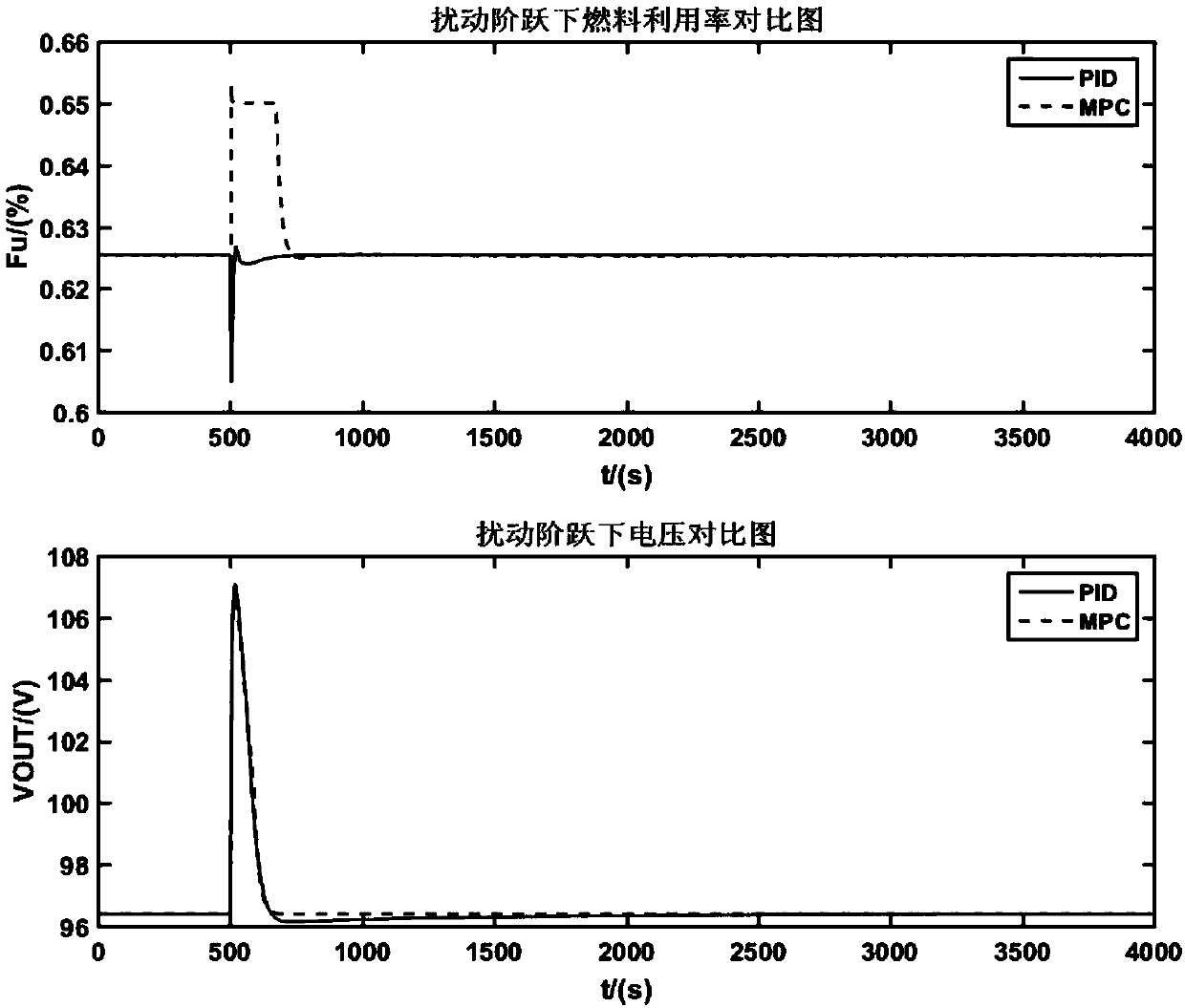

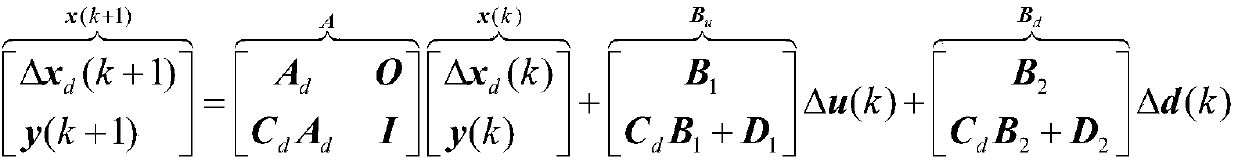

Fuel cell anti-interference control method with high speed, good safety and good decoupling performance

The invention discloses a fuel cell anti-interference control method with high speed, good safety and good decoupling performance. According to the characteristics that solid oxide fuel cells experience frequent load interferences and a system has low response speed and great coupling performance, and optimal control for the solid oxide fuel cells is achieved through extension state observation, operational restraint setting and multi-variant prediction control algorithm. By amplifying a prediction model in disturbed form, the issue with low load interference response of the fuel cells is solved; by setting amplitude limit speed for an intake valve and operation restraints on reasonable fuel usage, failure of the valve and battery gas shortage are effectively avoided; according to the characteristic of great coupling of fuel usage ratio and output voltage, a multi-variant prediction control algorithm is used to achieve decoupling during dynamic optimizing. The fuel cell anti-interference control method provided herein has the advantages that hydrogen and air intake volumes are precisely optimized, the influence of load disturbances upon output voltage is quickly inhibited, fuel usage ratio is increased, and operational safety of the valve and the fuel cells are guaranteed.

Owner:SOUTHEAST UNIV

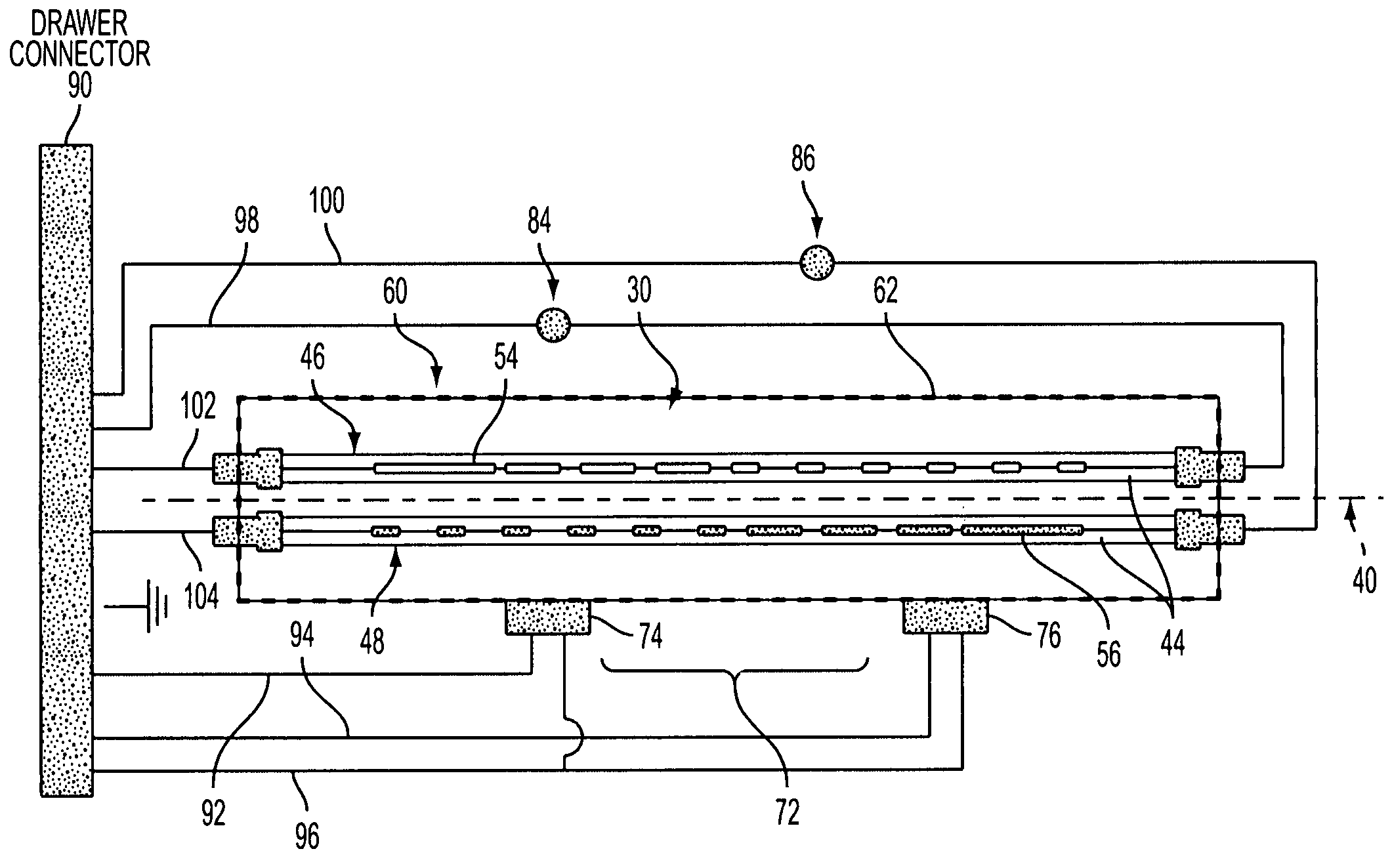

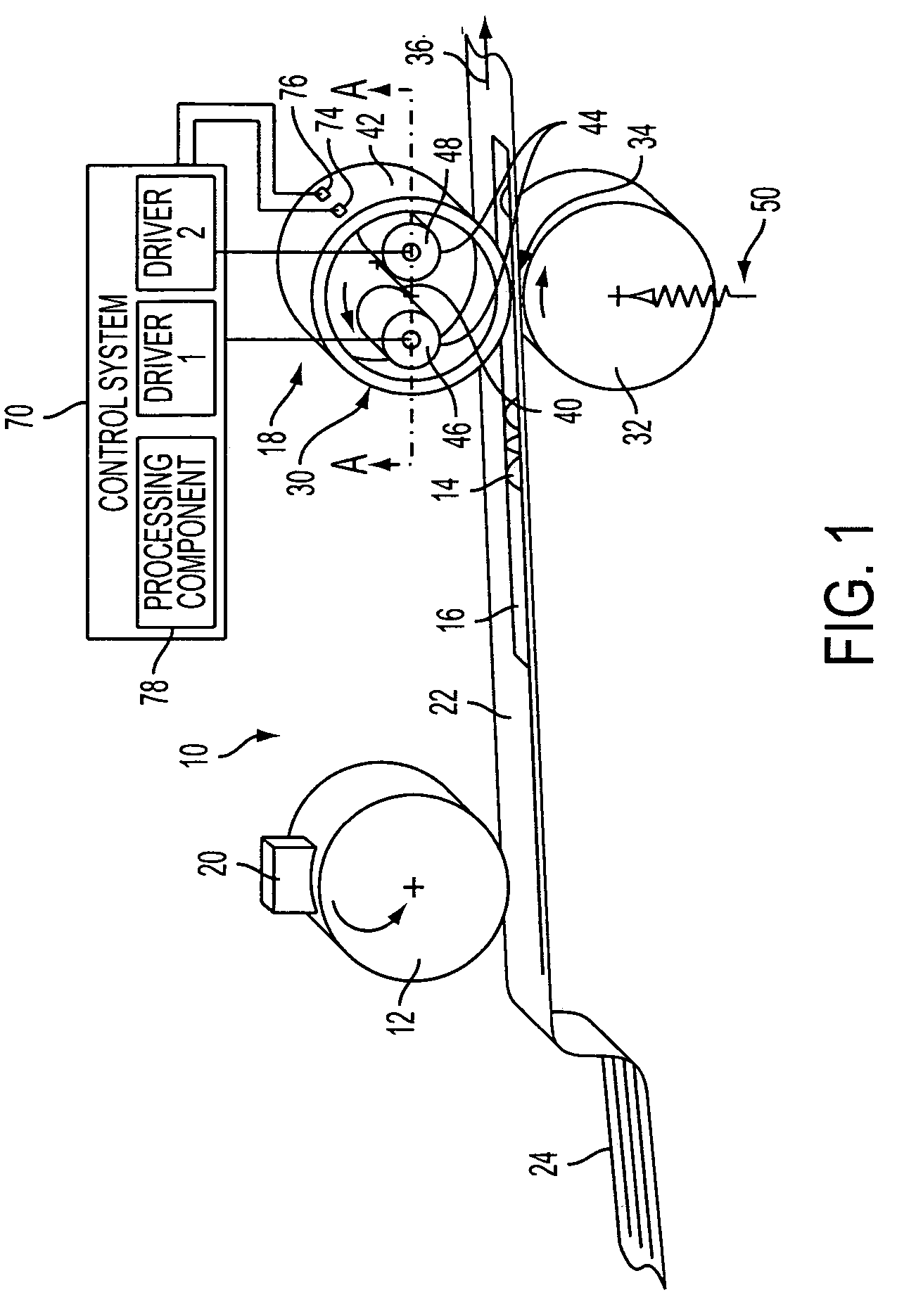

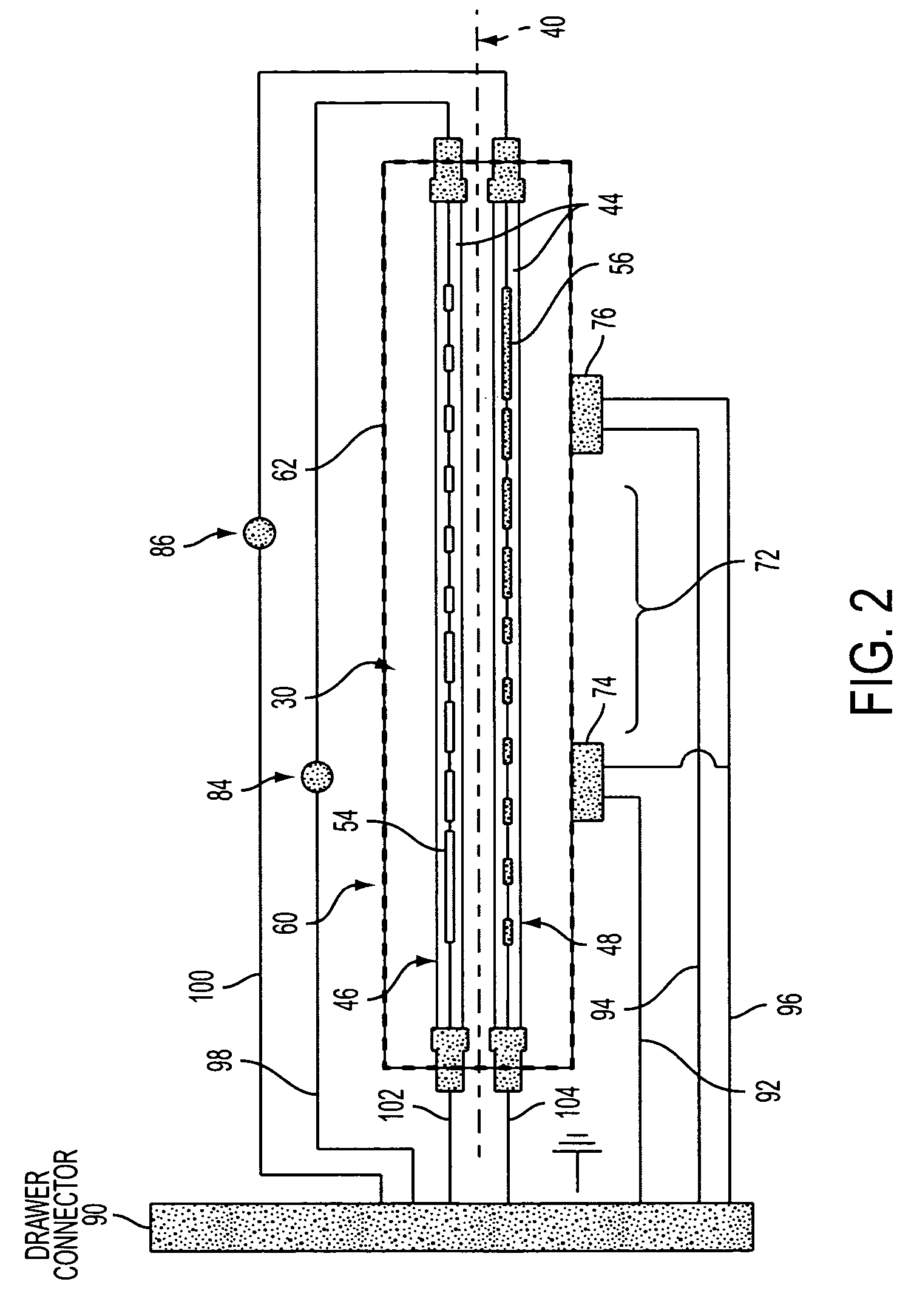

Multivariate predictive control of fuser temperatures

A fusing apparatus includes a fuser roll and a pressure roll which define a nip therebetween. Two heating elements heat the fuser roll. One of the heating elements is configured for heating a first portion of the fuser roll while a second of the heating elements is configured for heating a second portion of the fuser roll. The second portion of the fuser roll is axially spaced from the first portion. A temperature sensing system monitors a temperature of the fuser roll in a first location and monitors a temperature of the fuser roll in a second location which is axially spaced from the first location. A control system determines an amount of power to supply to the first heating element as a function of the monitored temperatures at the first and second axially spaced locations and determines an amount of power to supply to the second heating element as a function of the monitored temperatures at the first and second axially spaced locations.

Owner:XEROX CORP

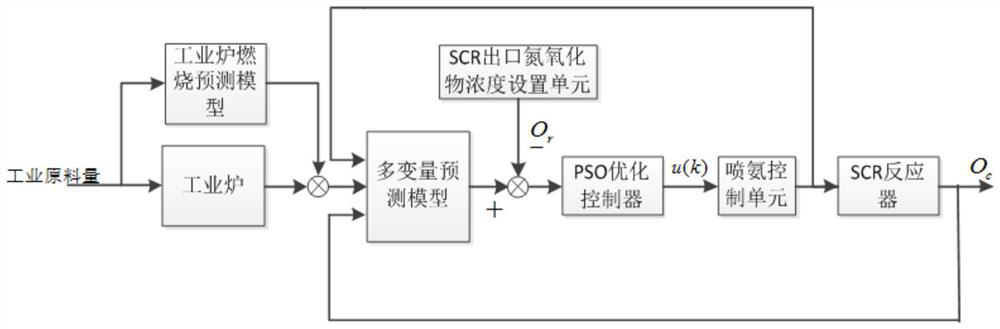

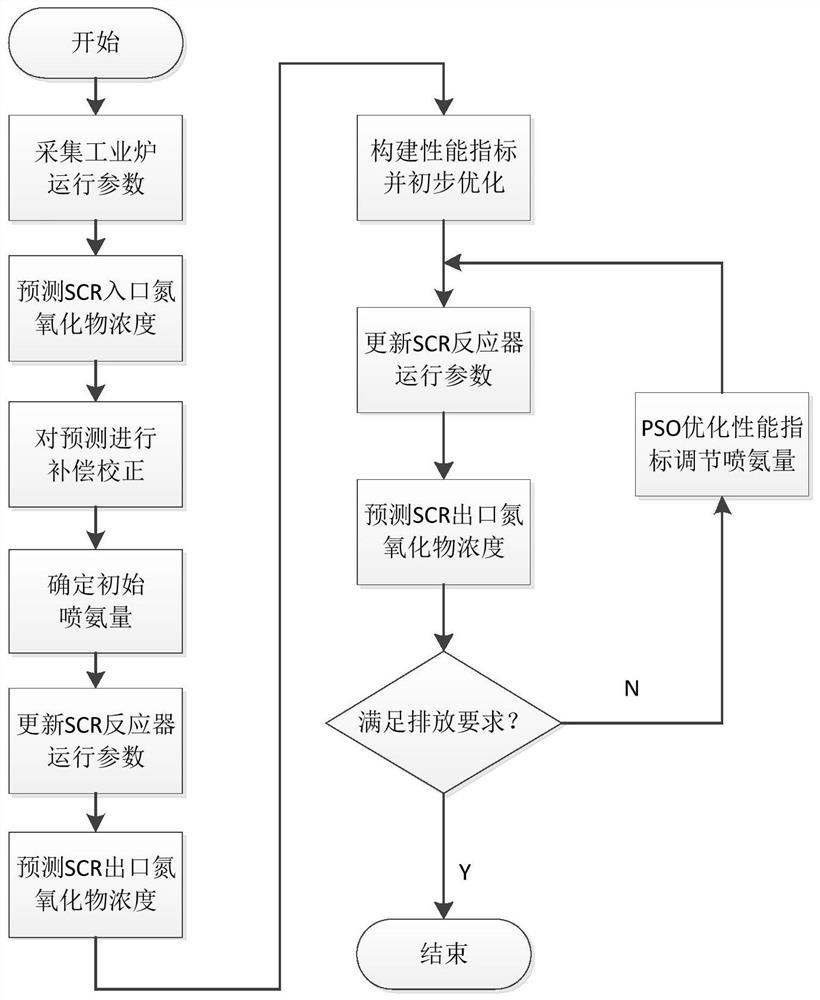

SCR denitration device ammonia injection flow adjusting method based on model prediction

ActiveCN111897373ASolve the problem of large measurement delayAvoid delayDispersed particle separationFlow control using electric meansNitrogen oxidesPhysical chemistry

An SCR denitration device ammonia injection flow adjusting method based on model prediction comprises: firstly, training and obtaining an industrial furnace combustion prediction model and a multivariable prediction control model, then obtaining a predicted value of the nitrogen oxide concentration of an inlet of an SCR reactor through prediction, and then determining the initial ammonia injectionamount; then, according to the corrected prediction value of the concentration of the nitrogen oxide at the inlet of the SCR reactor, multivariable parameters of the SCR reactor and the multivariableprediction control model, predicting the concentration of nitric oxide at the outlet of the SCR reactor, constructing a performance index function according to the predicted value, the measured value, the set value and the ammonia spraying amount of the concentration of nitric oxide at the outlet of the SCR reactor, and then conducting preliminary optimization of the ammonia spraying amount; andfinally, updating the actual ammonia injection amount of the SCR reactor by using the preliminary optimization result of the ammonia injection amount, taking the actual ammonia injection amount as theoptimal position initial value of the next PSO algorithm, predicting the concentration of nitrogen oxide at the outlet of the SCR reactor, returning to the step 7, continuing to optimize the performance index by using the PSO algorithm, and repeating the iteration in this way.

Owner:海南创实科技有限公司

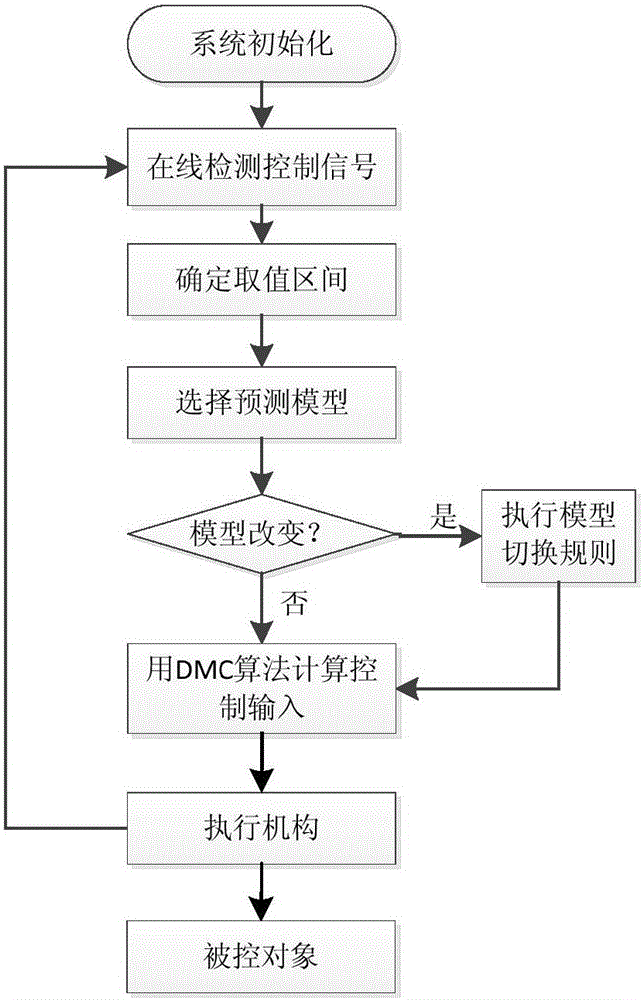

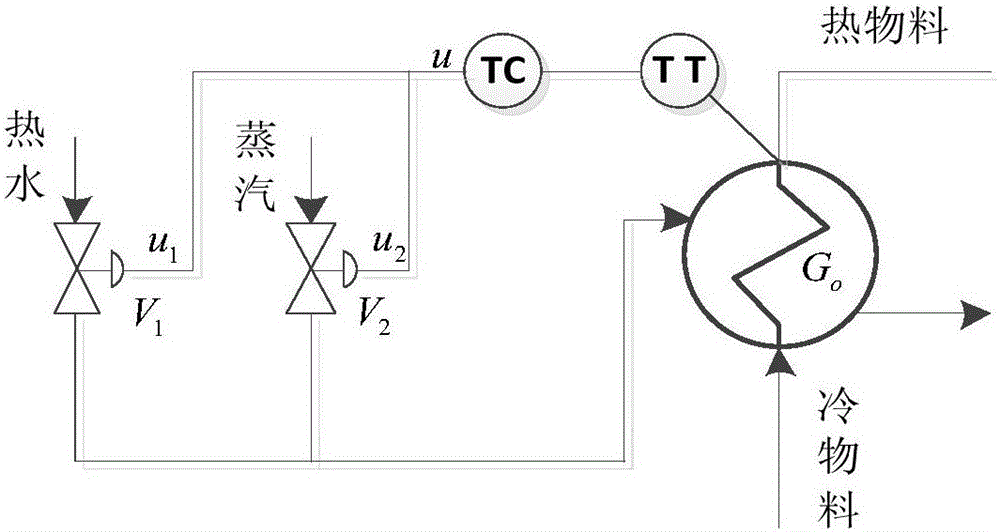

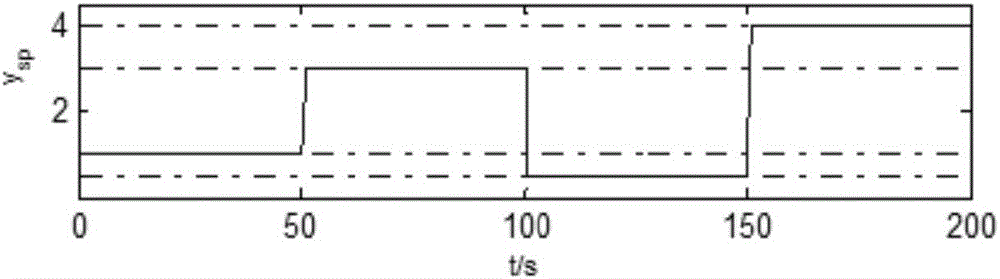

Split-ranging control realization method for multi-variable model predictive control

ActiveCN107179685ASolve the control problem of split-range control functionLarge adjustment rangeAdaptive controlMulti inputControl signal

The invention relates to a split-ranging control realization method for multi-variable model predictive control. The method comprises: carrying out off-line initialization on a multi-input and multi-output control system; and carrying out on-line split-ranging controlling on the system based on a model prediction algorithm. Prediction models are established according to different action combinations of all execution mechanisms in all linear intervals in split-ranging control; during each control period, a prediction model is selected by comparing an output control signal value of a controller with a corresponding intermediate threshold; and a control increment is calculated by using a dynamic matrix control algorithm and the calculated control increment is applied to the corresponding execution mechanism for action implementation. Therefore, a design problem of a multi-variable model predictive controller for a split-ranging control need during a control process can be solved; and thus the application range of the prediction controller can be extended.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Methods and systems for optimizing argon recovery in an air separation unit

A cryogenic air separation system that optimizes the recovery of argon includes an air intake, a high-pressure distillation column, a low-pressure distillation column, a crude argon distillation column, and a controller that automatically controls the composition of the raw argon stream to decrease the concentration of oxygen in the stream while preventing the concentration of nitrogen in the crude argon stream from exceeding a selected value. In addition, the controller also controls the composition of the crude argon stream until an oxygen concentration of the crude argon stream reaches a selected value. The controller may include a multivariable predictive controller.

Owner:AIR LIQUIDE LARGE INDS U S LP

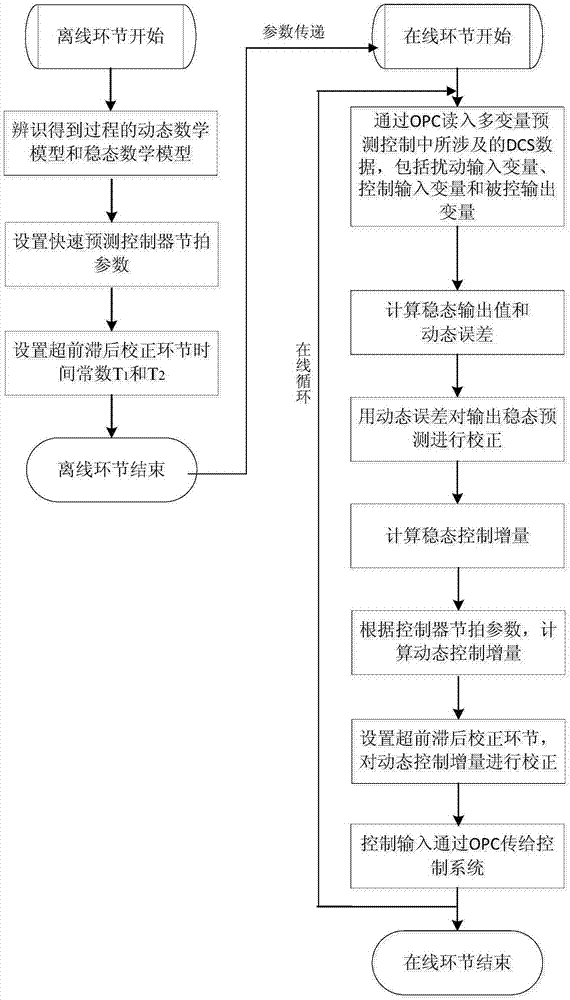

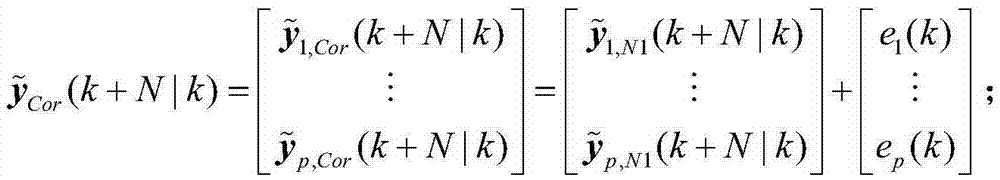

Quick multivariable predication control method for ethylene cracking furnace

ActiveCN106873395AQuick solveEasy to solveSimulator controlStatic optimizationComputation complexity

The invention relates to a quick multivariable predication control method for an ethylene cracking furnace. The method has an offline link and an online link. In the offline link, a dynamic mathematic model and a static mathematic model of a production process of the ethylene cracking furnace are obtained through an analysis or recognition method and control parameters are set. In the online link, a prediction value is calculated and output according to a measurement value of an ethylene cracking furnace control system (DCS), a predication error is calculated based on the difference between the predication value and the measurement value and accordingly a static output predication value is corrected; and then a static control input predication value is calculated through static optimization or a direct inversion method; and finally a control input value of a current moment is calculated according to a given control parameter, the dynamic performance of the control input value is corrected through a lead-lag link and the corrected value is then transmitted to the DCS. According to the invention, the calculation complexity for multivariable prediction control is simplified and the control period of multivariable prediction control is reduced distinctively, and control problems in quick reaction processes of the ethylene cracking furnace and the like can be solved effectively.

Owner:MICROCYBER CORP

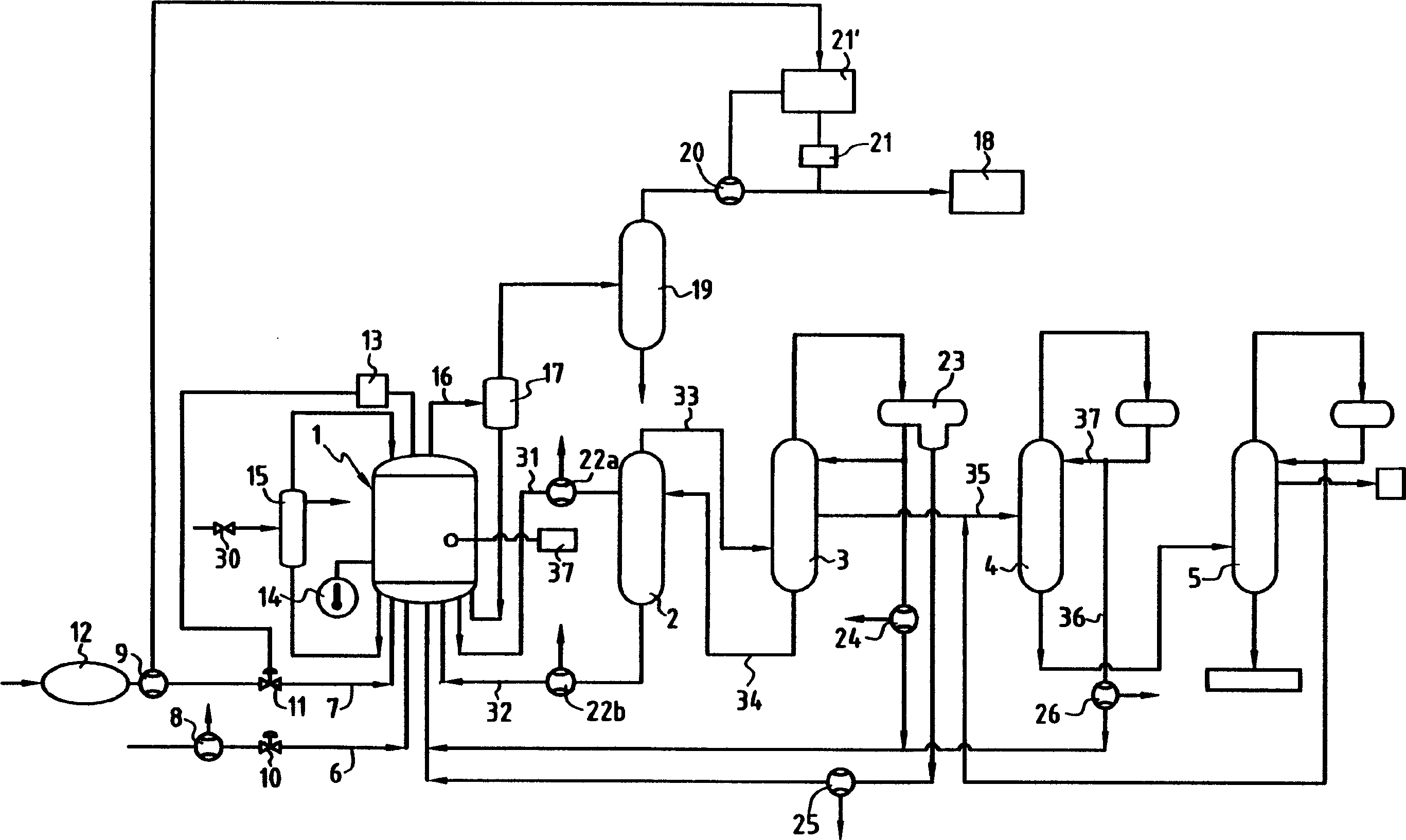

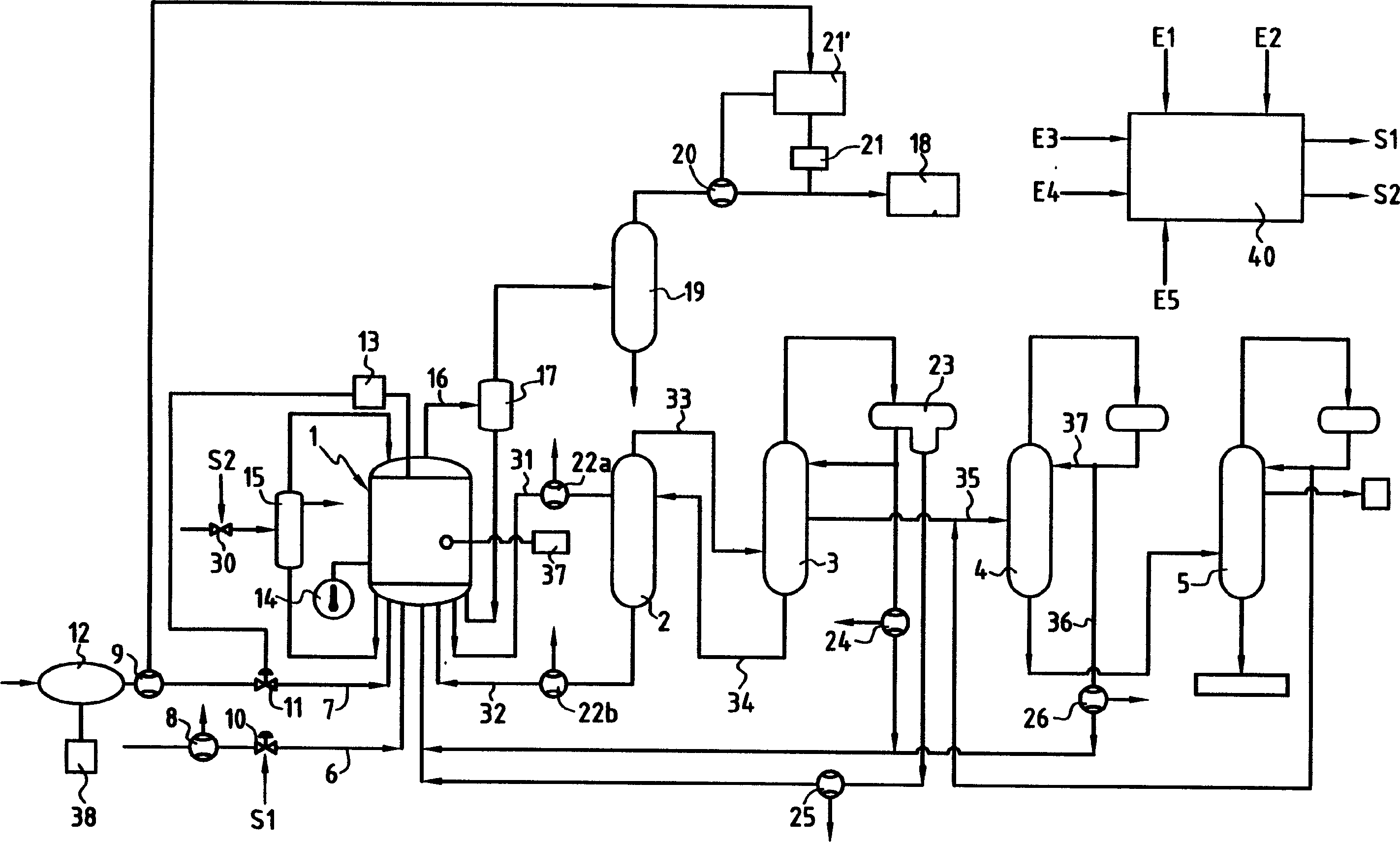

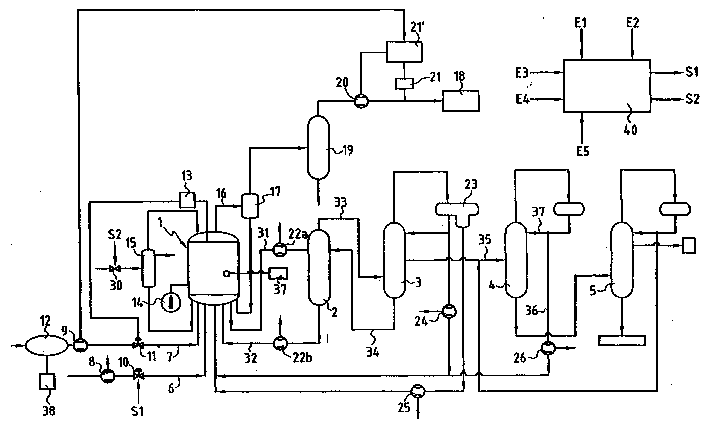

Improvement to methods for continuous production of acetic acid and/or methyl acetate

InactiveCN1538947AControl concentrationControl moisture contentOrganic compound preparationOrganic chemistry methodsAutomatic controlMethyl acetate

The invention relates to a method for the continuous preparation of acetic acid and / or methyl acetate by carbonylation using carbon monoxide, methanol or a methanol derivative that can be carbonylated, in liquid phase, in the presence of water and a catalytic system. According to the invention, in order to improve the production of acetic acid and / or methyl acetate, the temperature of the reactor and the inlet flow of methanol, or the methanol derivative that can be carbonylated, into said reactor are controlled by the inlet flow of carbon monoxide and by at least one of the parameters that define the composition of the reaction medium and / or events, said automatic control being performed preferably by means of a predictive multi-variable regulator. The inventive method is suitable for use in Monsanto-type preparation methods and low water content methods.

Owner:ACETEX CHEM

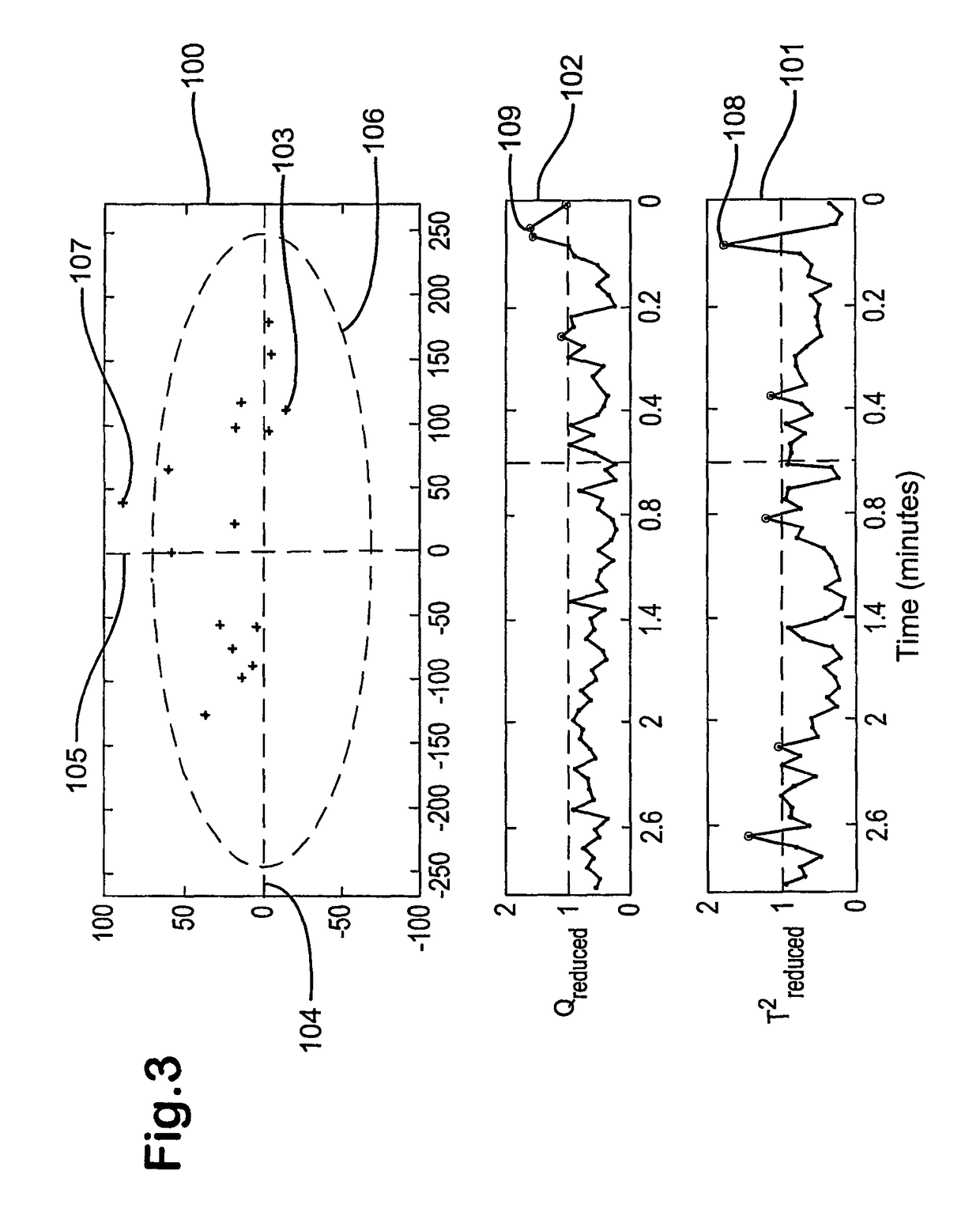

Abnormal event detection using principal component analysis

InactiveUS8121817B2Amount of timeLess timeSampled-variable control systemsTesting/monitoring control systemsKernel principal component analysisControl system

Process control system for detecting abnormal events in a process having one or more independent variables and one or more dependent variables. The system includes a device for measuring values of the one or more independent and dependent variables, a process controller having a predictive model for calculating predicted values of the one or more dependent variables from the measured values of the one or more independent variables, a calculator for calculating residual values for the one or more dependent variables from the difference between the predicted and measured values of the one or more dependent variables, and an analyzer for performing a principal component analysis on the residual values. The process controller is a multivariable predictive control means and the principal component analysis results in the output of one or more scores values, T2 values and Q values.

Owner:BP OIL INT LTD

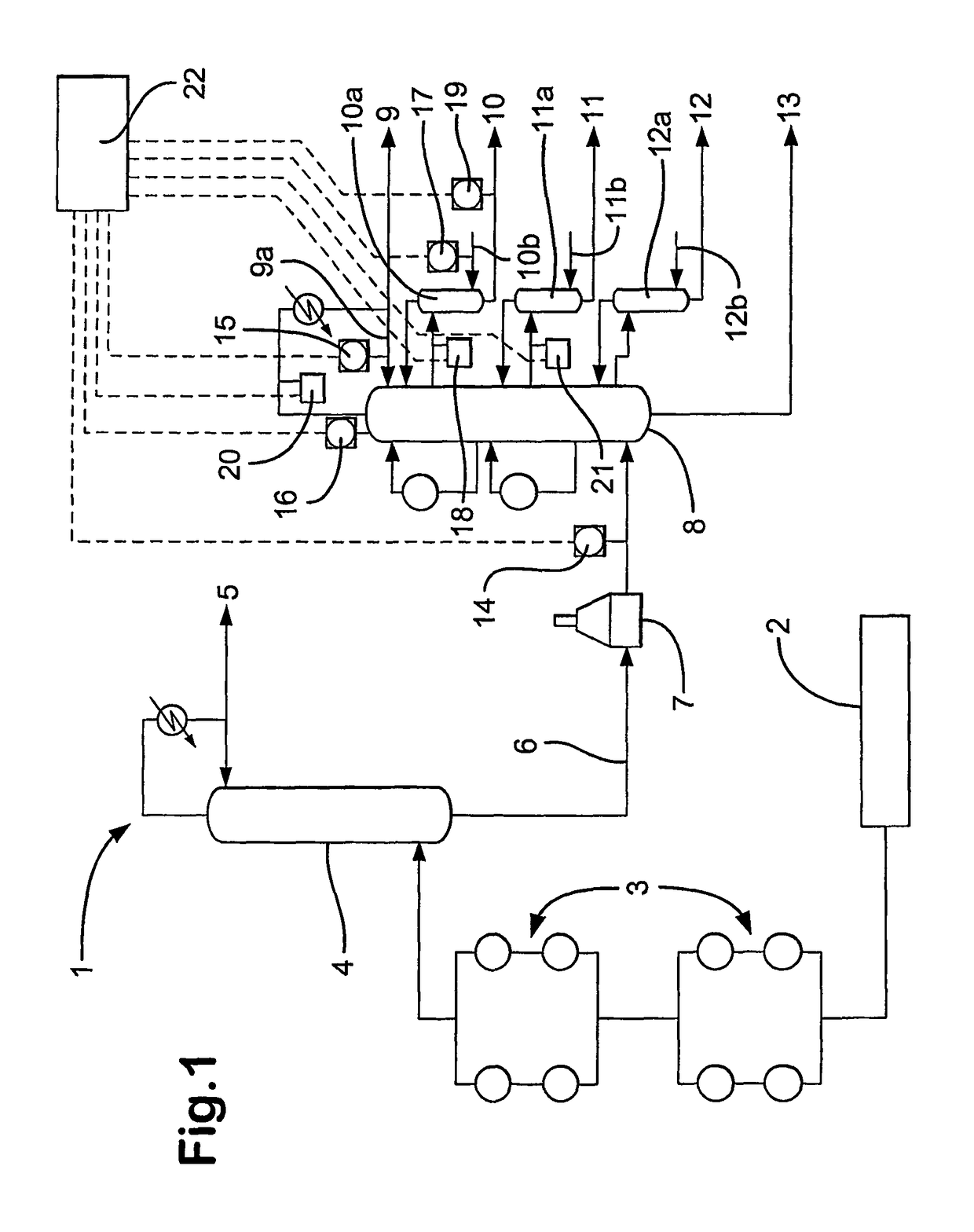

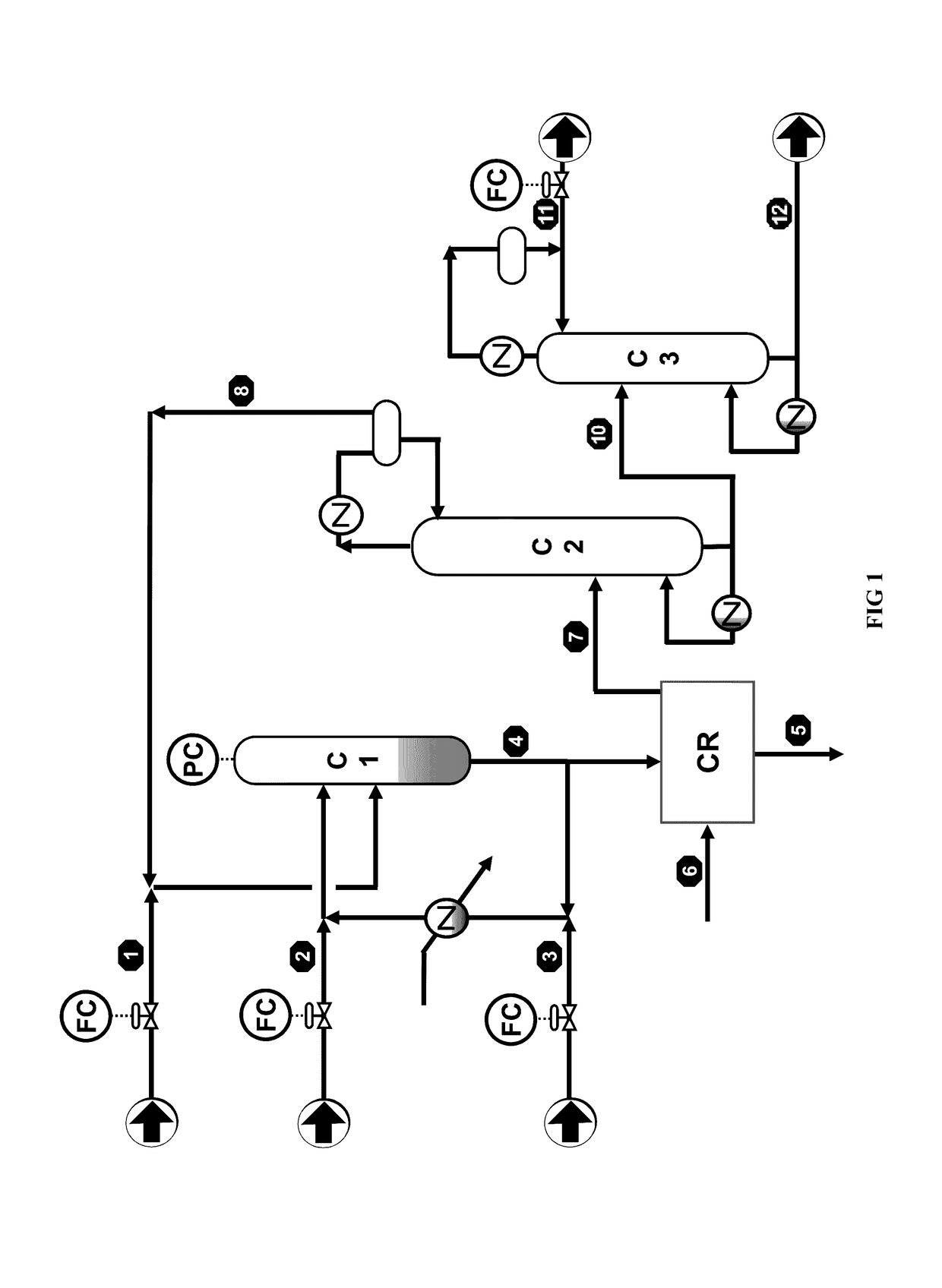

Use of an advanced multivariable controller to control alphabutol units

ActiveUS20170158581A1Increase production capacityFluid pressure control using electric meansChemical/physical/physico-chemical processesControl systemPredictive controller

The present invention describes a control system for units for the production of 1-butene by the oligomerization of ethylene in the presence of a homogeneous catalyst, in the liquid phase and at the bubble point, which uses a multivariable predictive controller and provides the units with better stability.

Owner:AXENS SA

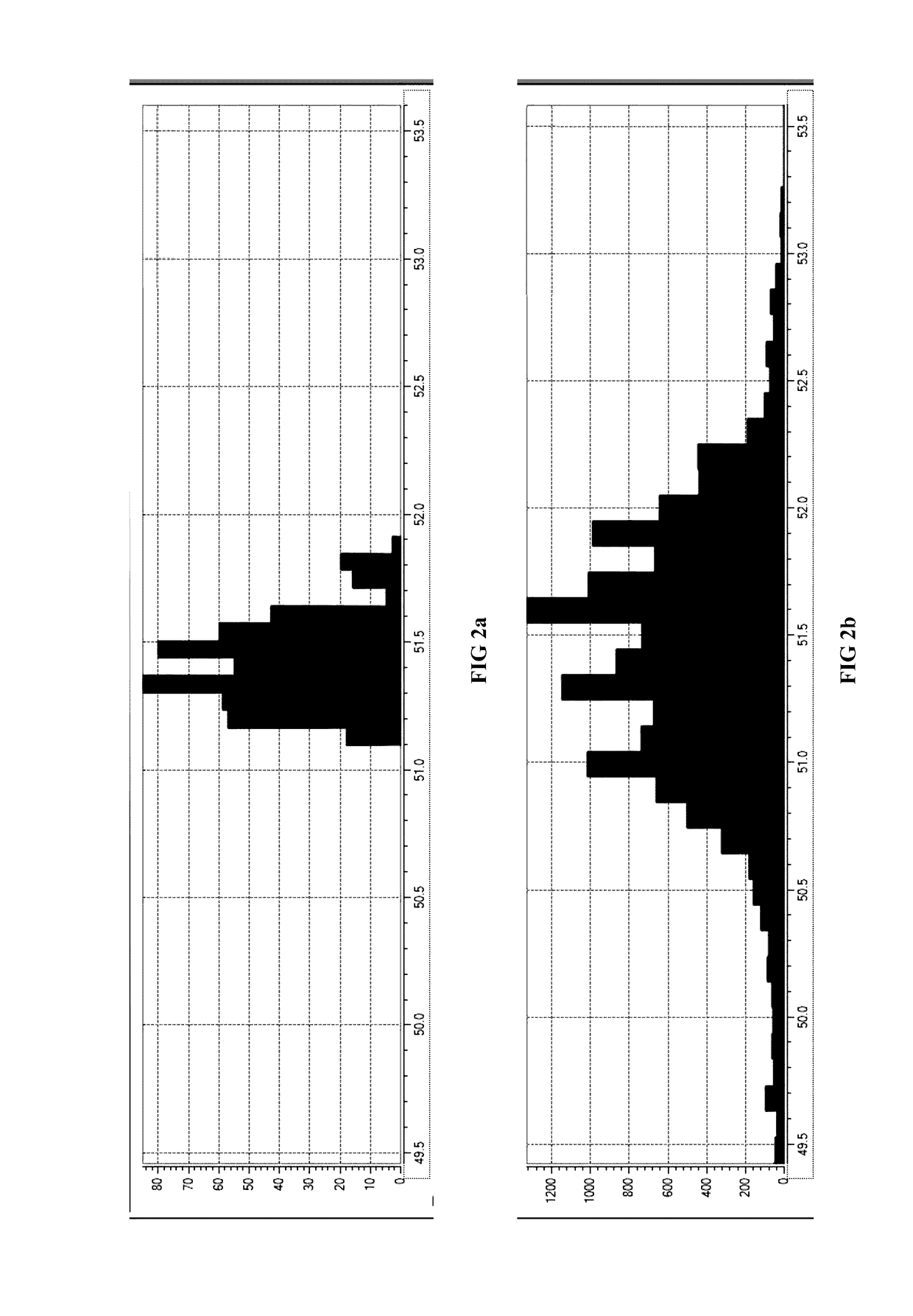

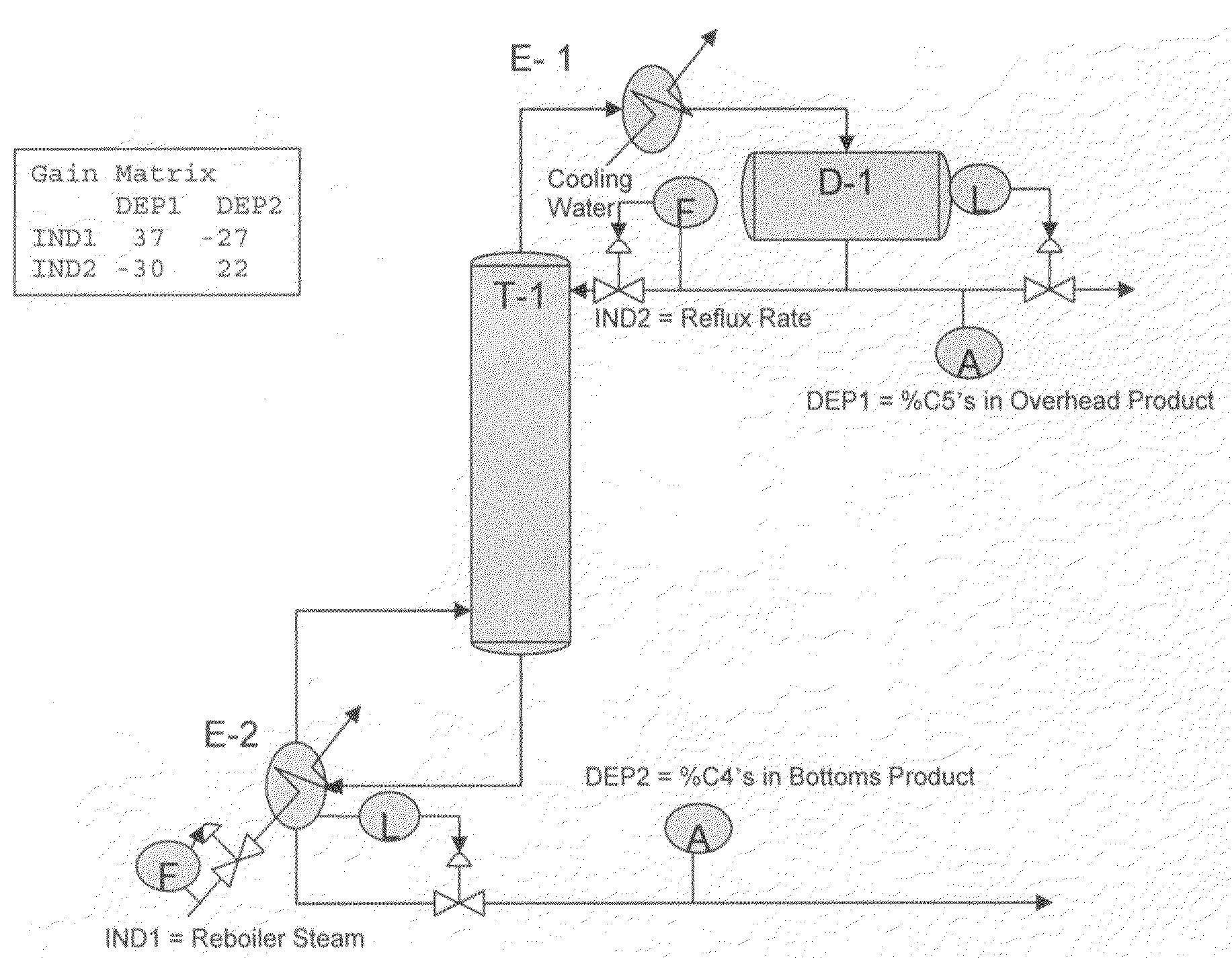

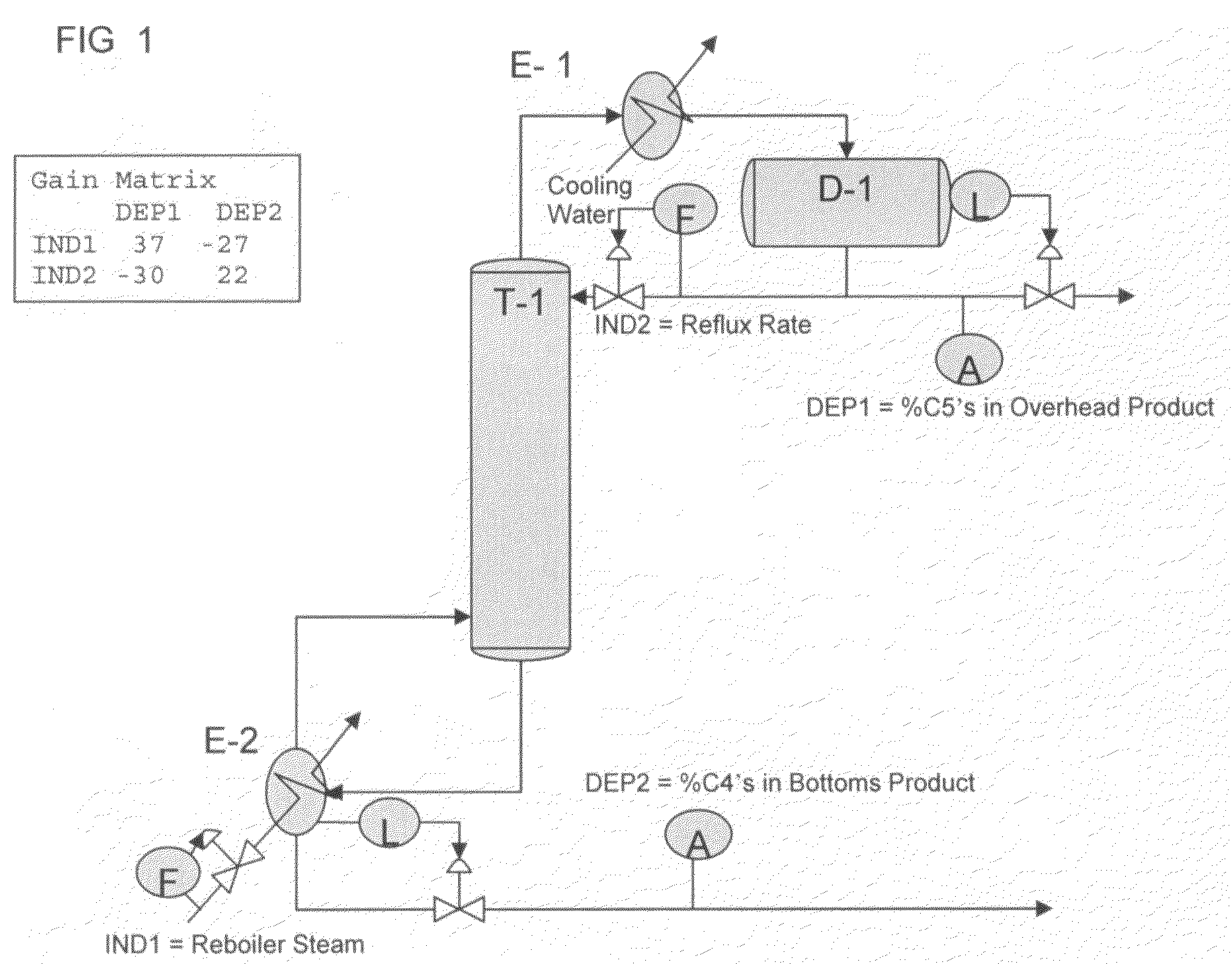

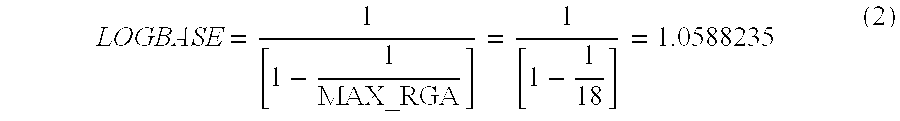

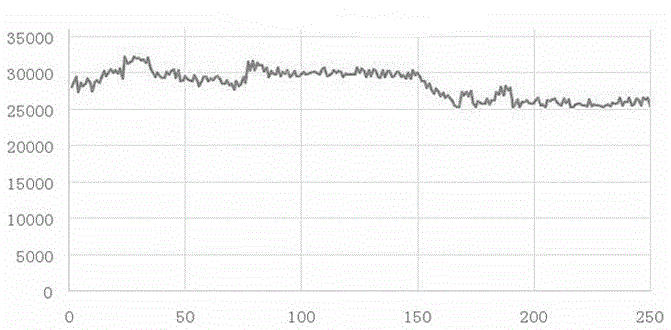

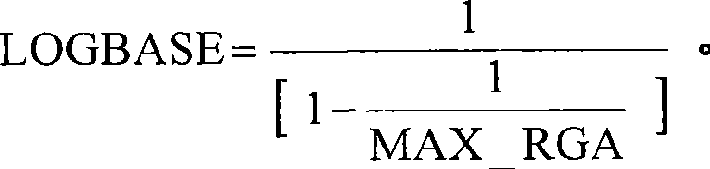

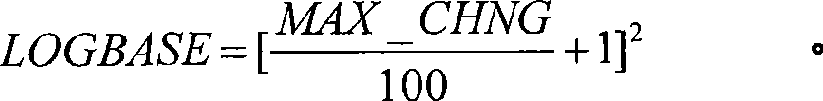

Method for model gain matrix modification

ActiveUS7797063B2Easy to modifyImprove propertiesComputation using non-denominational number representationDigital function generatorsModel selectionEngineering

A method is presented for adjusting the steady-state gains of a multivariable predictive control, planning or optimization model with uncertainty. The user selects a desired matrix relative gain criteria for the predictive model or sub-model. This is used to calculate a base number. Model gains are extracted from the predictive model and the magnitudes are modified to be rounded number powers of the calculated base number.

Owner:EXXON RES & ENG CO

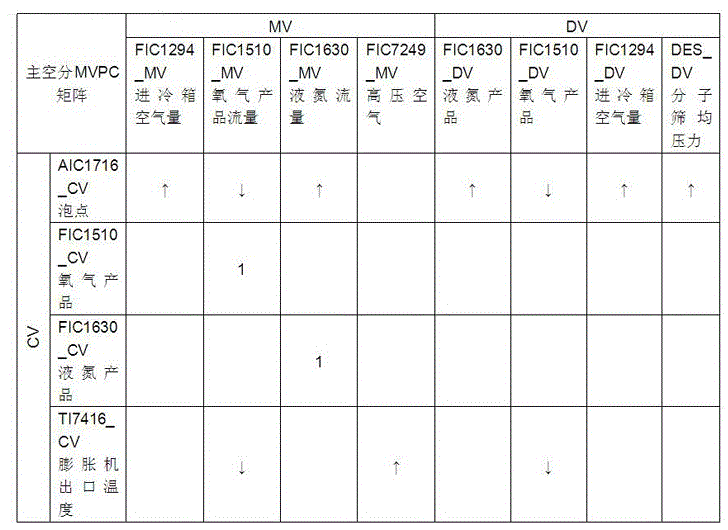

Multivariable predictive control method for air separation device

ActiveCN107525348AHigh extraction rateReduce the dissipation rateSolidificationLiquefactionAutomatic controlDelayed time

Disclosed is a multivariable predictive control method for an air separation device. The multivariate predictive control method comprises the steps that (a) an upper computer is additionally arranged on a DCS system local area network of the air separation device for creating an MVPC server of the air separation device; (b) variables are determined, specifically, according to the technological process optimizing target of the air separation device, the controlled variable (CV), the manipulating variable (MV) and the disturbance variable (DV) are determined; (c) the establishment principles of the size of an MVPC matrix are that key parameters are selected, the variables are controlled as less as possible, the valve opening degree, namely corresponding to the output of a PID controller under conventional control, is adjusted through the MV of an MVPC, when the MVPC works, the PID controller corresponding to the MV of the MVPC is in cascade control, the output of the PID controller tracks the MV of the MVPC, and when the MVPC does not work, the PID controller corresponding to the MV of the MVPC is in automatic control, and the MV of the MVPC tracks the output of the PID controller; (d) a model is built, specifically, an MVPC controller model is built in the air separation device, or independent MVPC controller models are built in different work sections in the air separation device; (e) the models are trained and adjusted, specifically, the gain K, the time constant Tau and the delay time Tdelay in the models are preliminarily set, and after the models are put into use, the optimized gain, time constant and delay time are provided by a system automatically; and (f) the models are put into use.

Owner:盈德气体工程(浙江)有限公司

Method for model gain matrix modification

InactiveCN101506743AImproved RGA characteristicsShorten the timeAdaptive controlModel selectionBase Number

A method is presented for adjusting the steady-state gains of a multivariable predictive control, planning or optimization model with uncertainty. The user selects a desired matrix relative gain criteria for the predictive model or sub-model. This is used to calculate a base number. Model gains are extracted from the predictive model and the magnitudes are modified to be rounded number powers of the calculated base number.

Owner:EXXON RES & ENG CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com