Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about "Controlling mixing ratio of fluids with different temperatures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

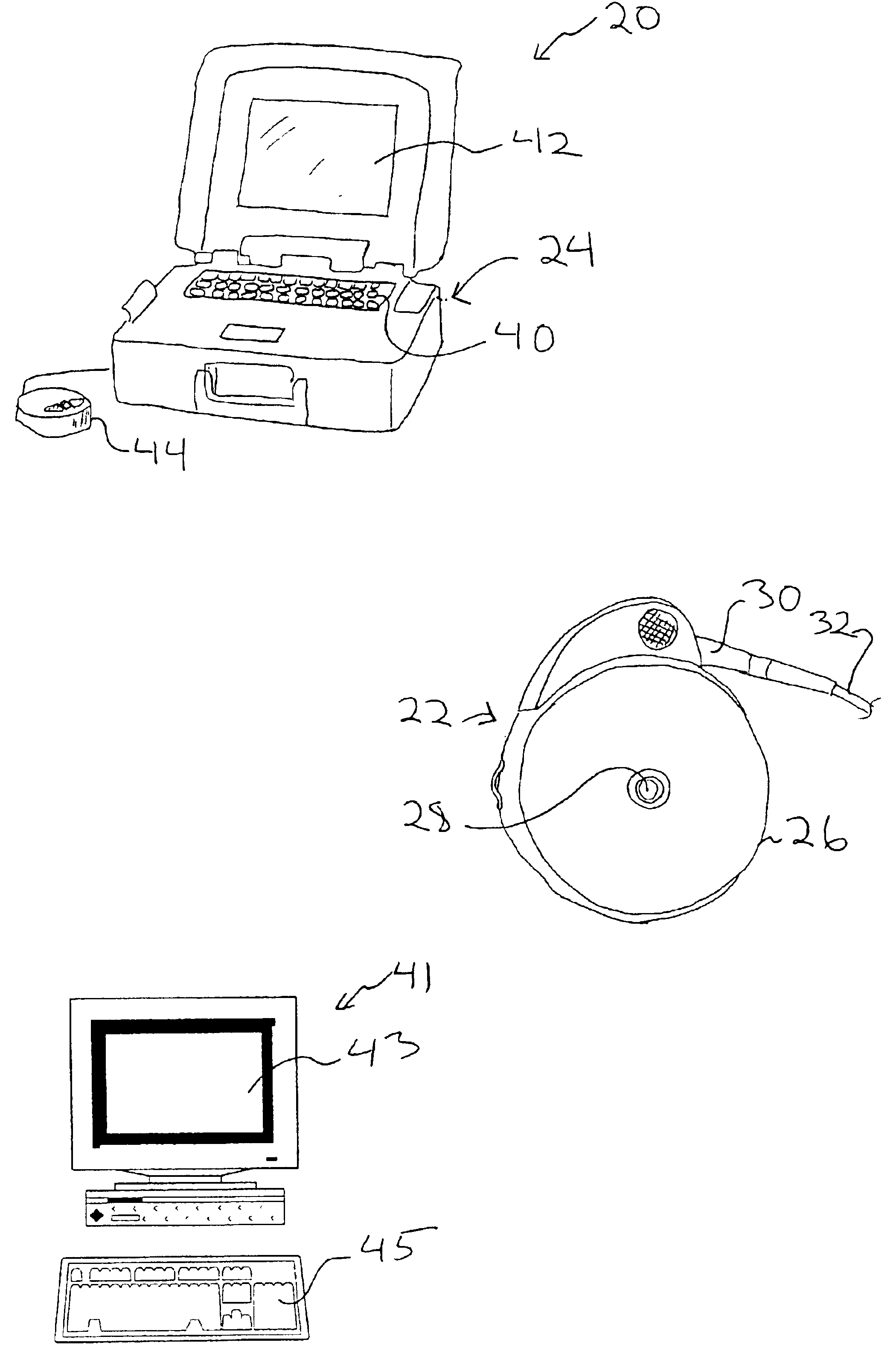

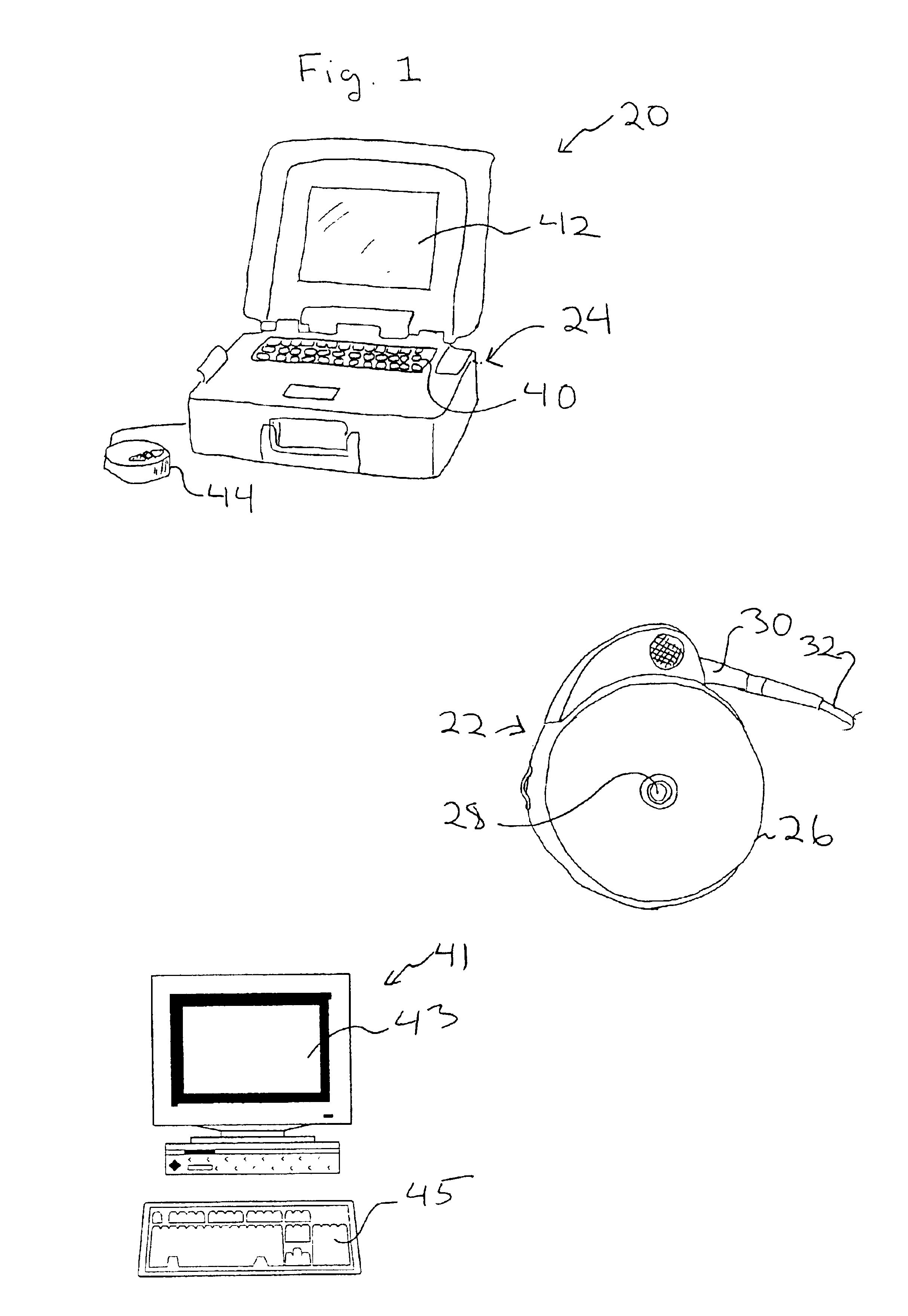

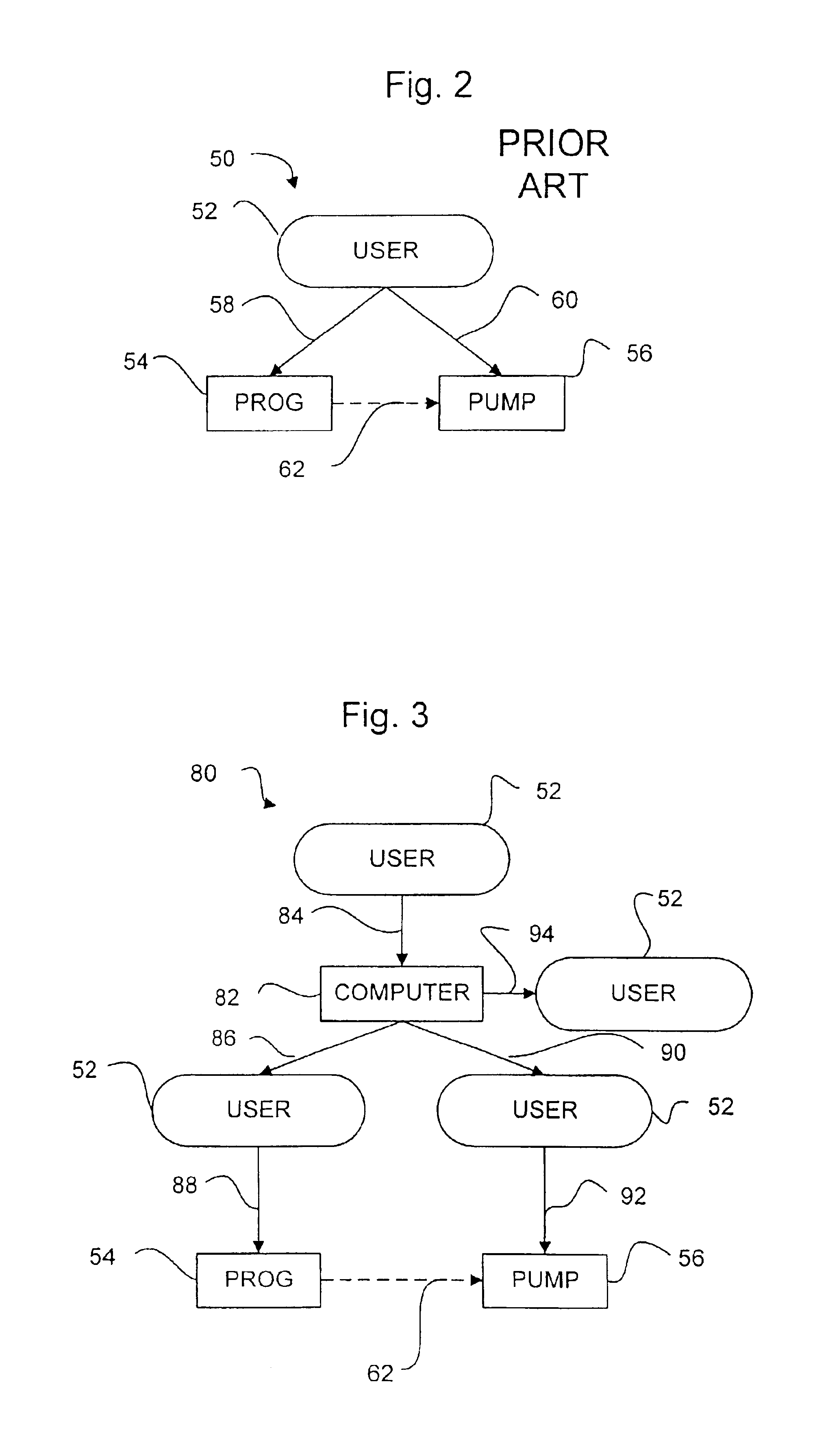

Decision information system for drug delivery devices

ActiveUS6928338B1Sampled-variable control systemsControlling ratio of multiple fluid flowsDoses rateGeneral purpose computer

Decision information systems, methods, and computer programs for better informing decisions to use multiple drugs in drug delivery devices, including implantable devices, for drug administration. Executable computer programs and logic embodying methods of the invention can calculate consistent multiple drug mixture amounts and drug delivery flow rates. One program accepts user input indicating a desired first drug dose rate, an initial first drug concentration, a desired second drug dose rate, an initial second drug concentration, and the reservoir size of the drug delivery device. The program method calculates a first drug amount and a second drug amount to combine in a mixture as well as a first drug true concentration in the mixture. The drugs can be mixed consistent with the physician's instructions using the program output. The first drug true concentration can be entered into a programmer device as the only drug concentration entered. Another program calculates a consistent first drug, second drug, and diluent amount to be added to a mixture for injection into a fixed flow rate, implantable drug delivery device. Methods preferably output true concentrations and dose rates for all drugs to be added and most preferably show all calculations used to arrive at the flow rate and mixture amount calculations. Yet another program receives a new desired drug dose rate for a previously filled device. The program accepts the existing mixture volume and true drug concentrations for a partially depleted device and calculates a new mixture flow rate to achieve the desired dose rate using the existing mixture. The methods can be implemented as executable computer programs in programmer devices, general purpose computers, servers, handheld computers, and personal digital assistants.

Owner:MEDTRONIC INC

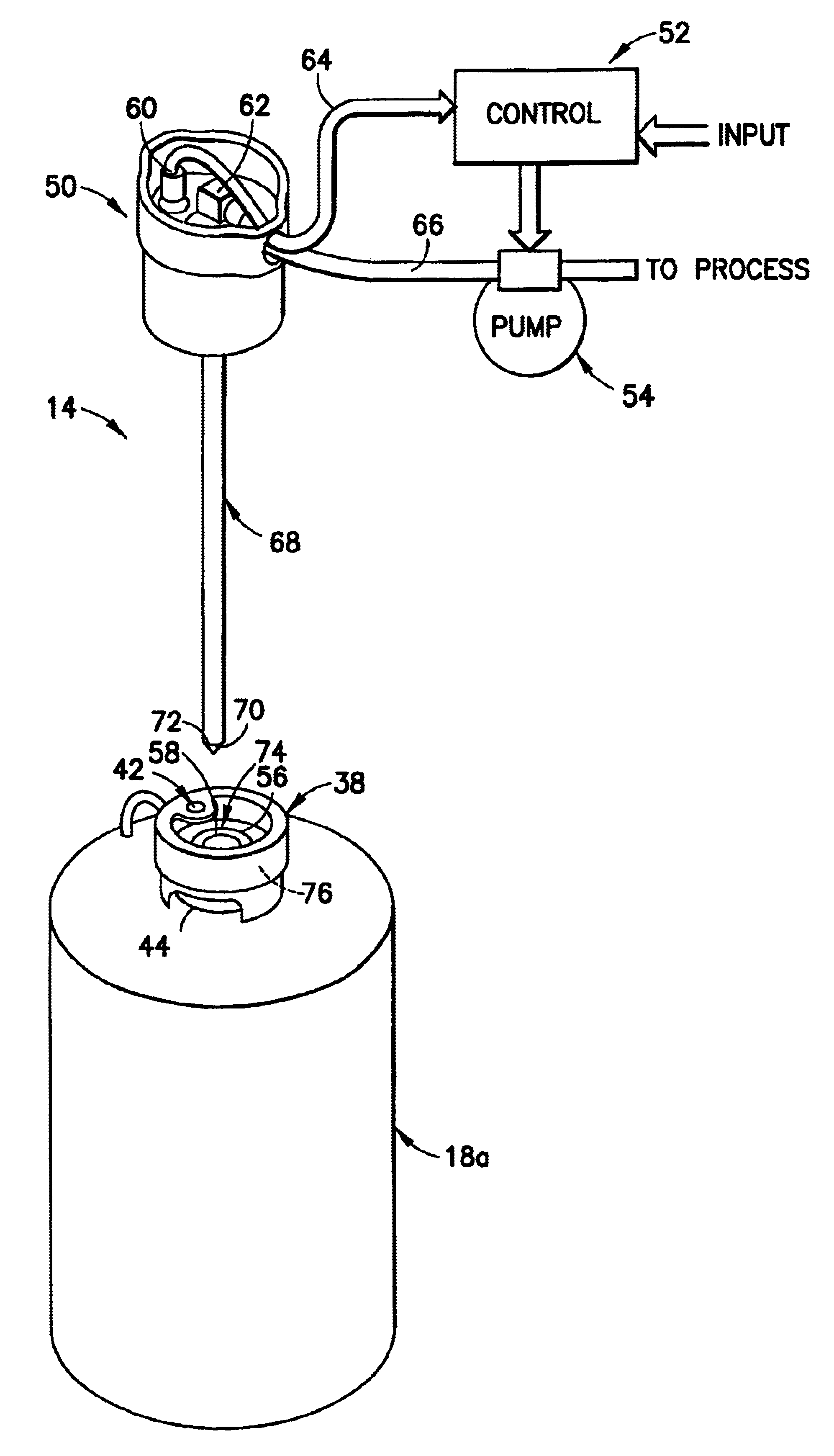

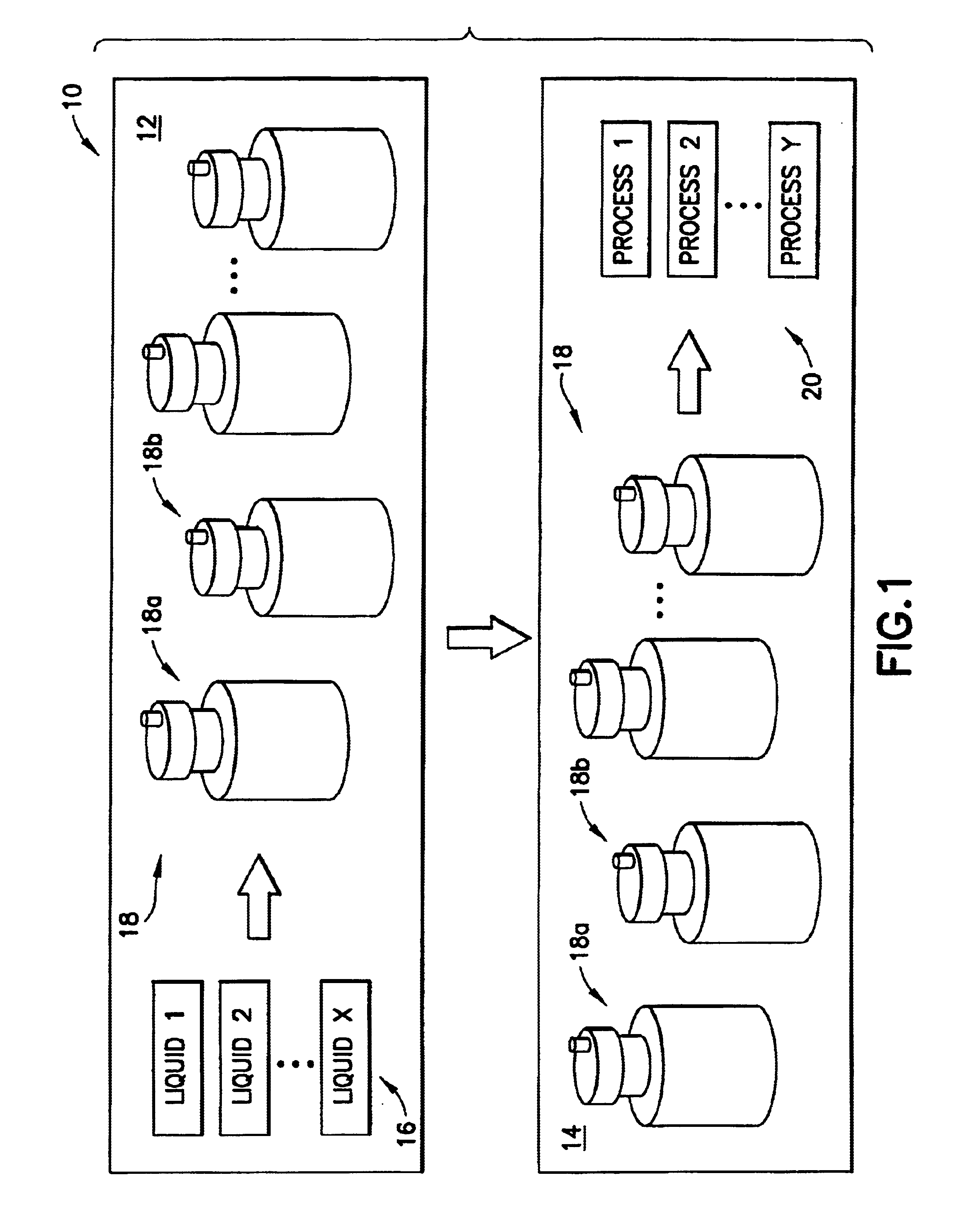

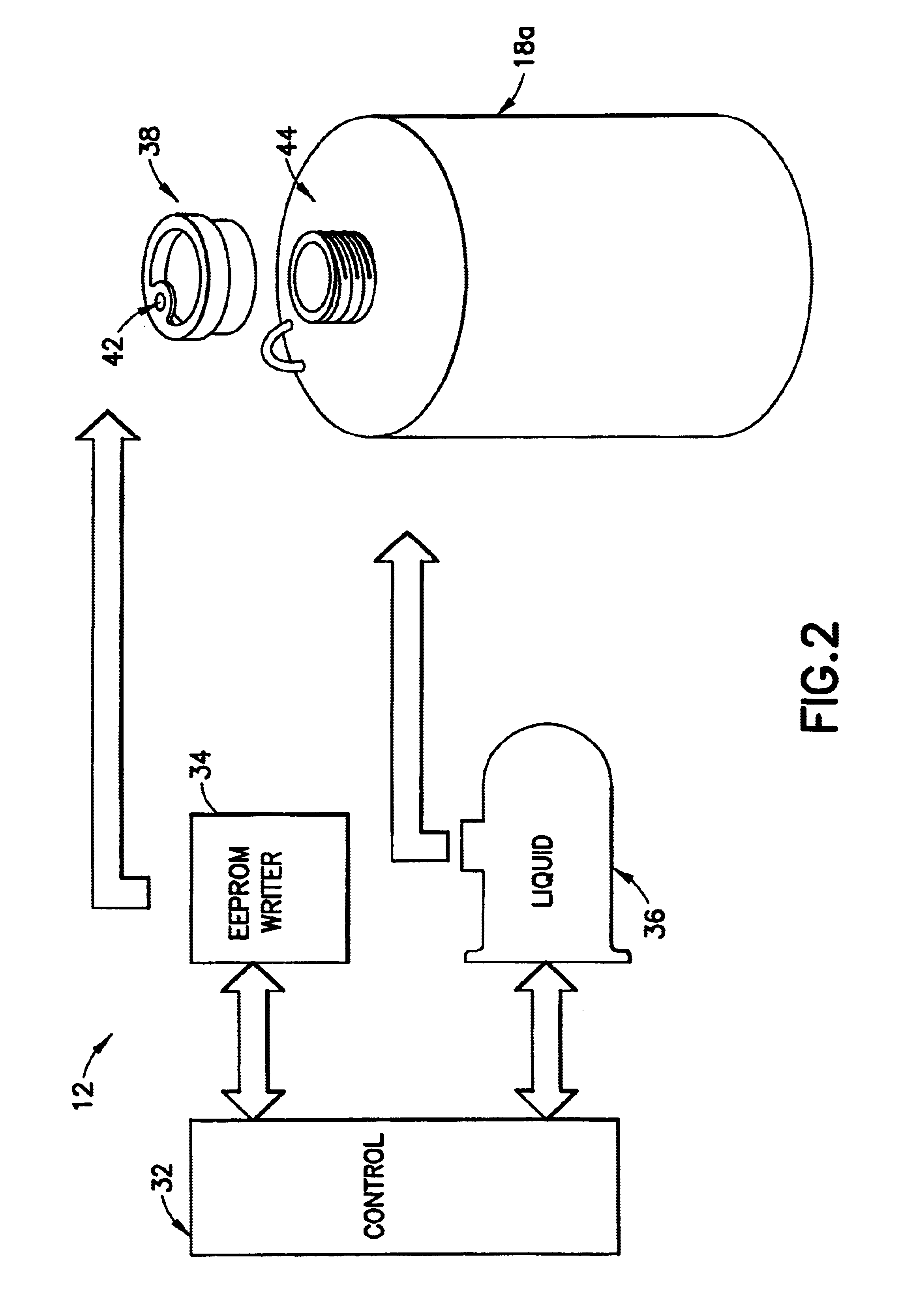

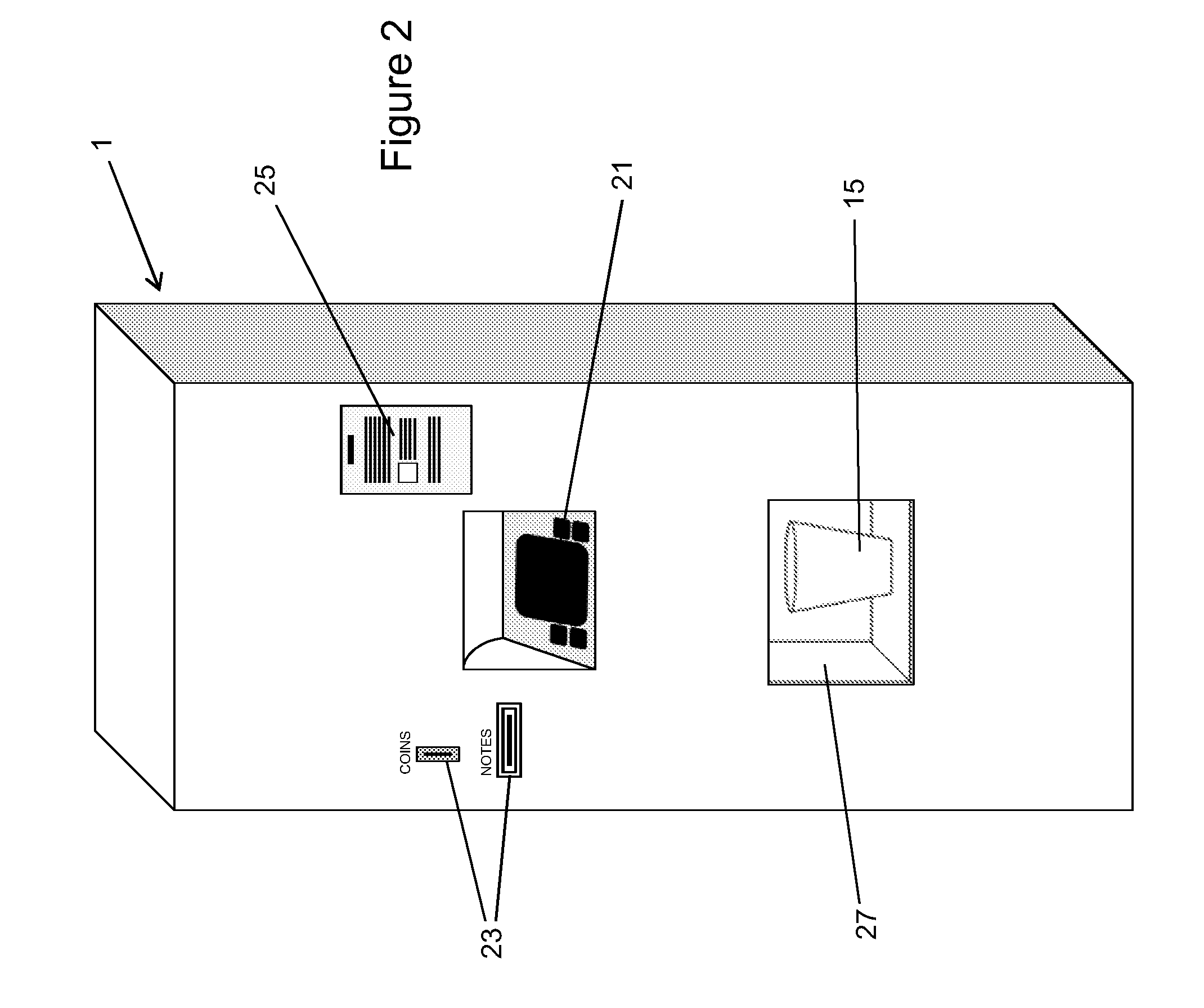

Liquid handling system with electronic information storage

The present invention is a system for handling liquid and a method for the same. The system has a container capable of holding a liquid. An electronic storage device is coupled with the container for electronically storing information relating to the liquid stored in the container. The system also has an antenna, for storing information to and reading information from the electronic storage device. Finally, the system has a microprocessor-based controller, coupled with the antenna, for controlling processing of the liquid based on information read from the electronic storage device by the antenna.

Owner:ENTEGRIS INC

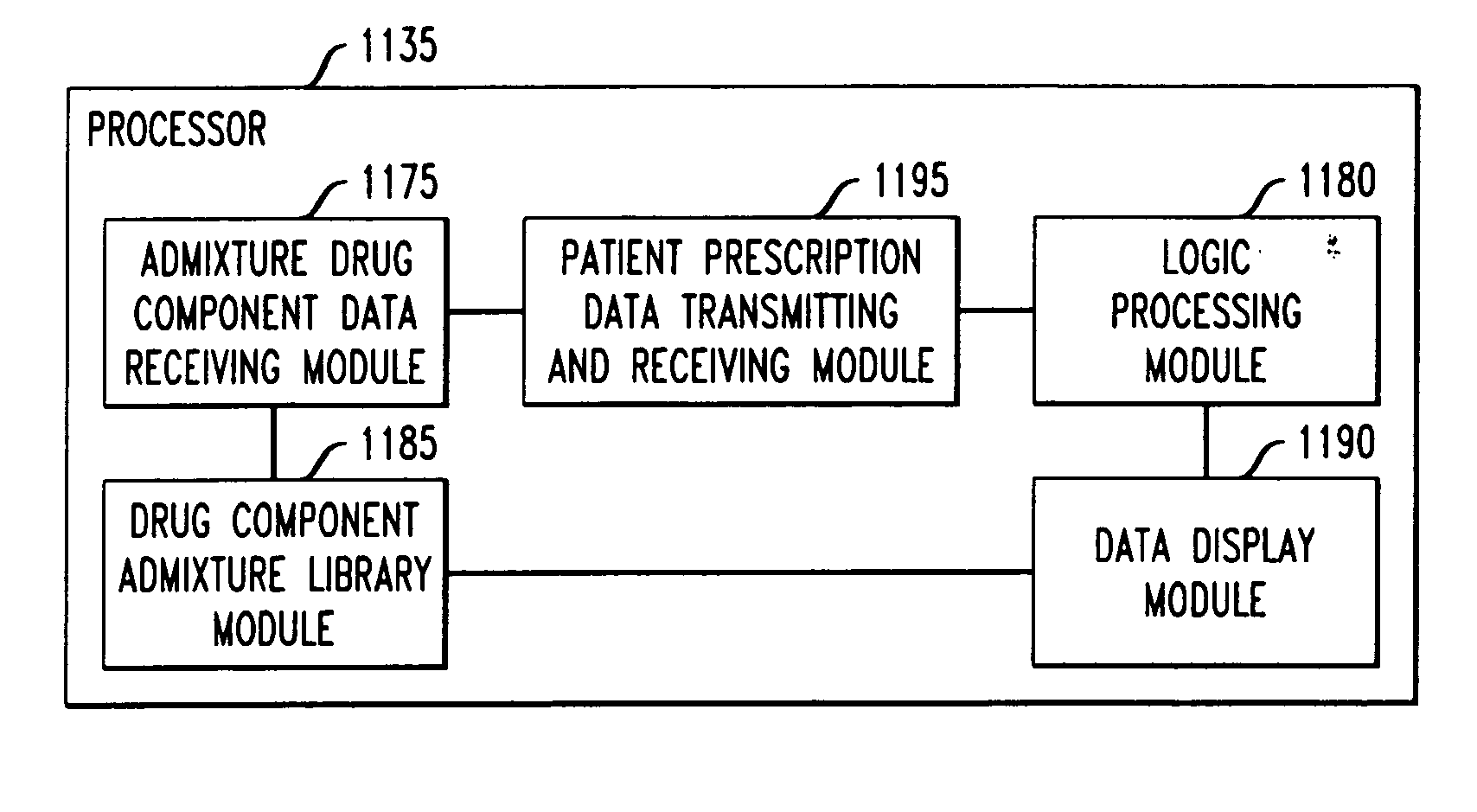

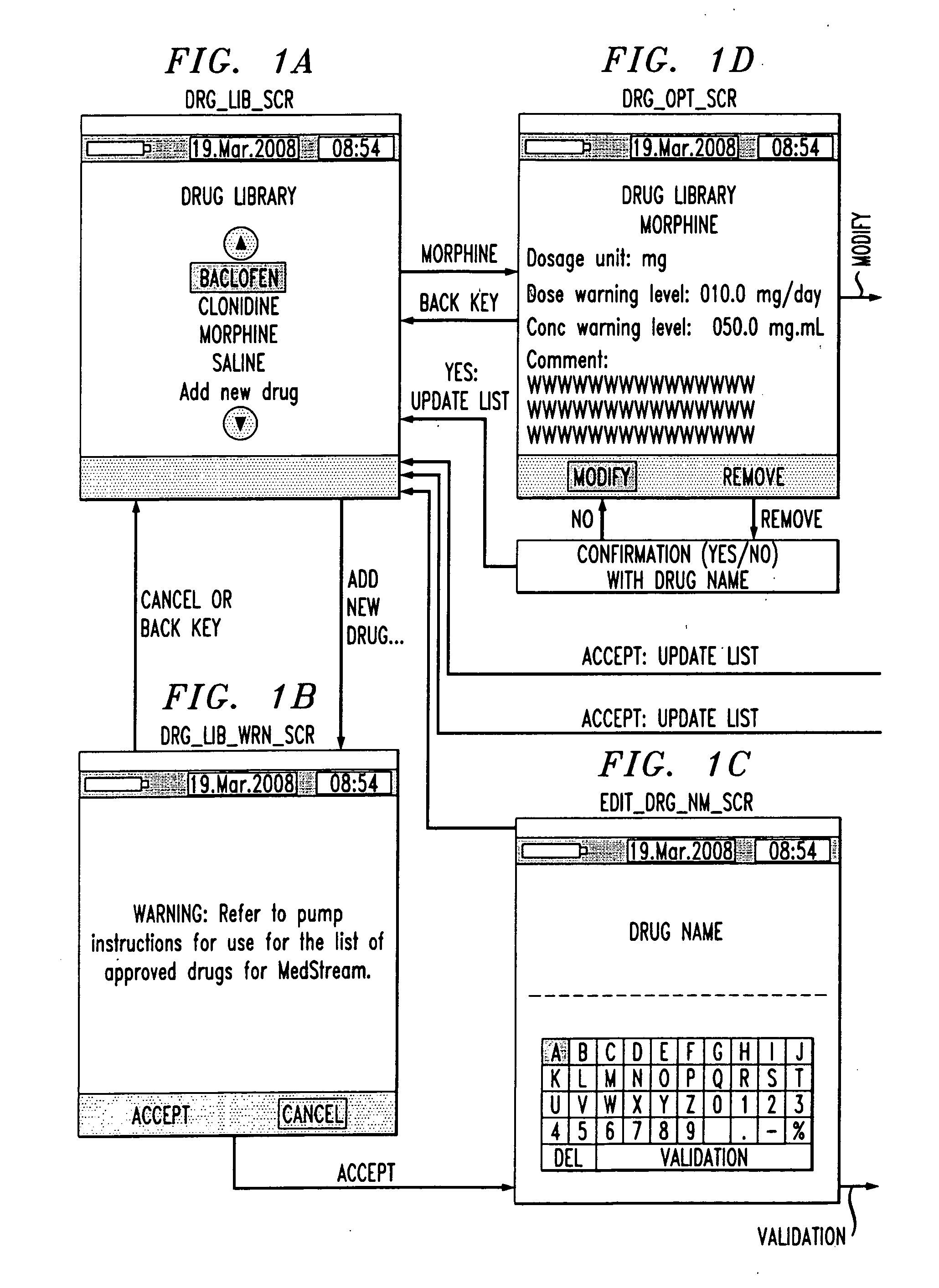

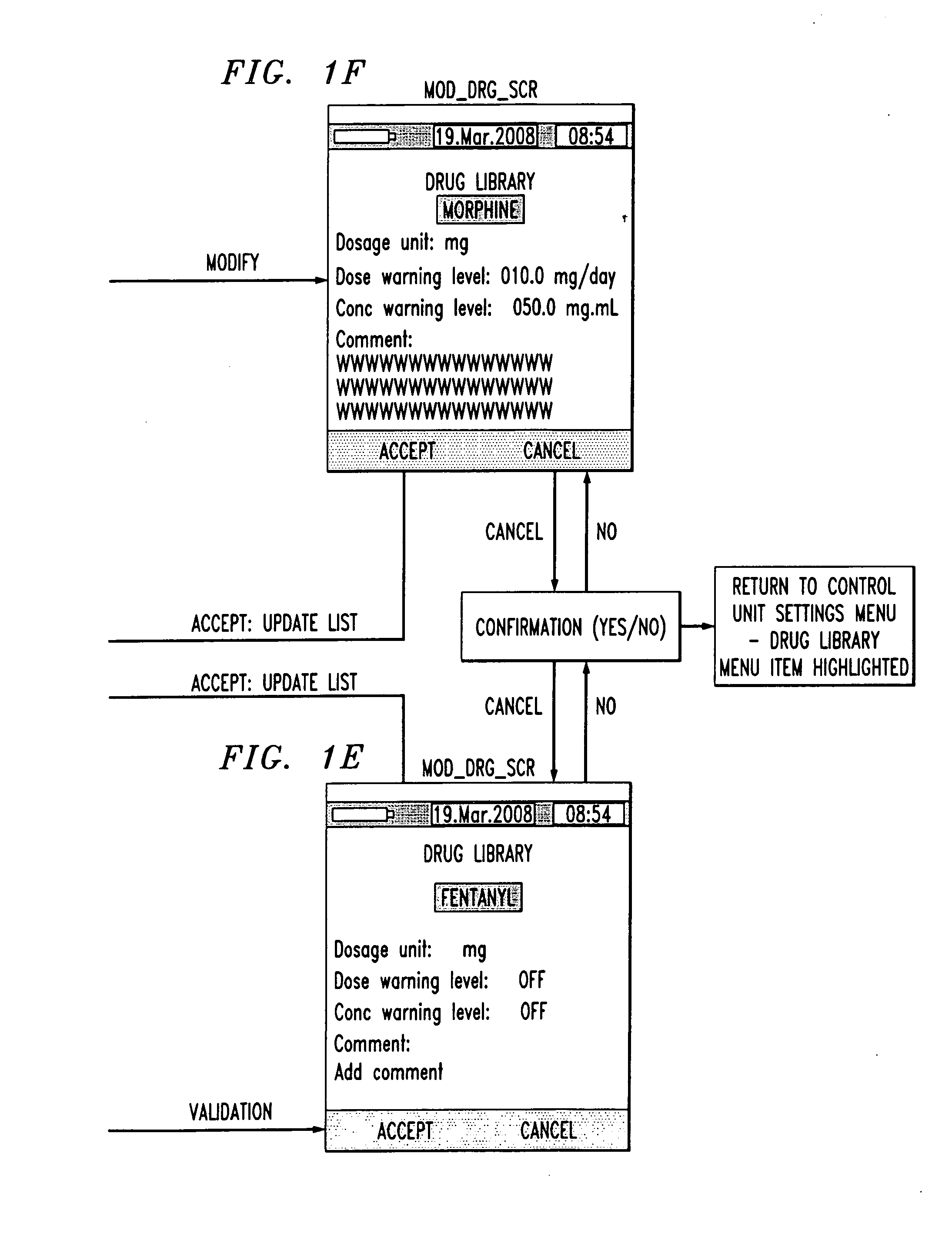

Drug component admixture library for a drug infusion delivery system

InactiveUS20110320049A1Shorten the timeReduce generationLevel controlControlling ratio of multiple fluid flowsDrugs infusionDelivery system

Minimizing improper dosage of a drug admixture (including a single primary drug component and at least one second drug component). For each drug component in the drug admixture, receiving a name of the drug component along with its dosage unit, a maximum dose warning level and a maximum concentration warning level. Receiving a concentration for each of the single primary drug component and the at least one secondary drug component; and a dose setting of only the primary drug component. Automatically calculating a dose of each of the at least one secondary drug component. Generating an alert when: (i) the received dose setting of the primary drug component or calculated dose setting of the at least one secondary drug component exceeds the dose warning level; or (ii) the received concentration of the primary drug component or the at least one secondary drug component exceeds the concentration warning level.

Owner:MEDOS INT SARL

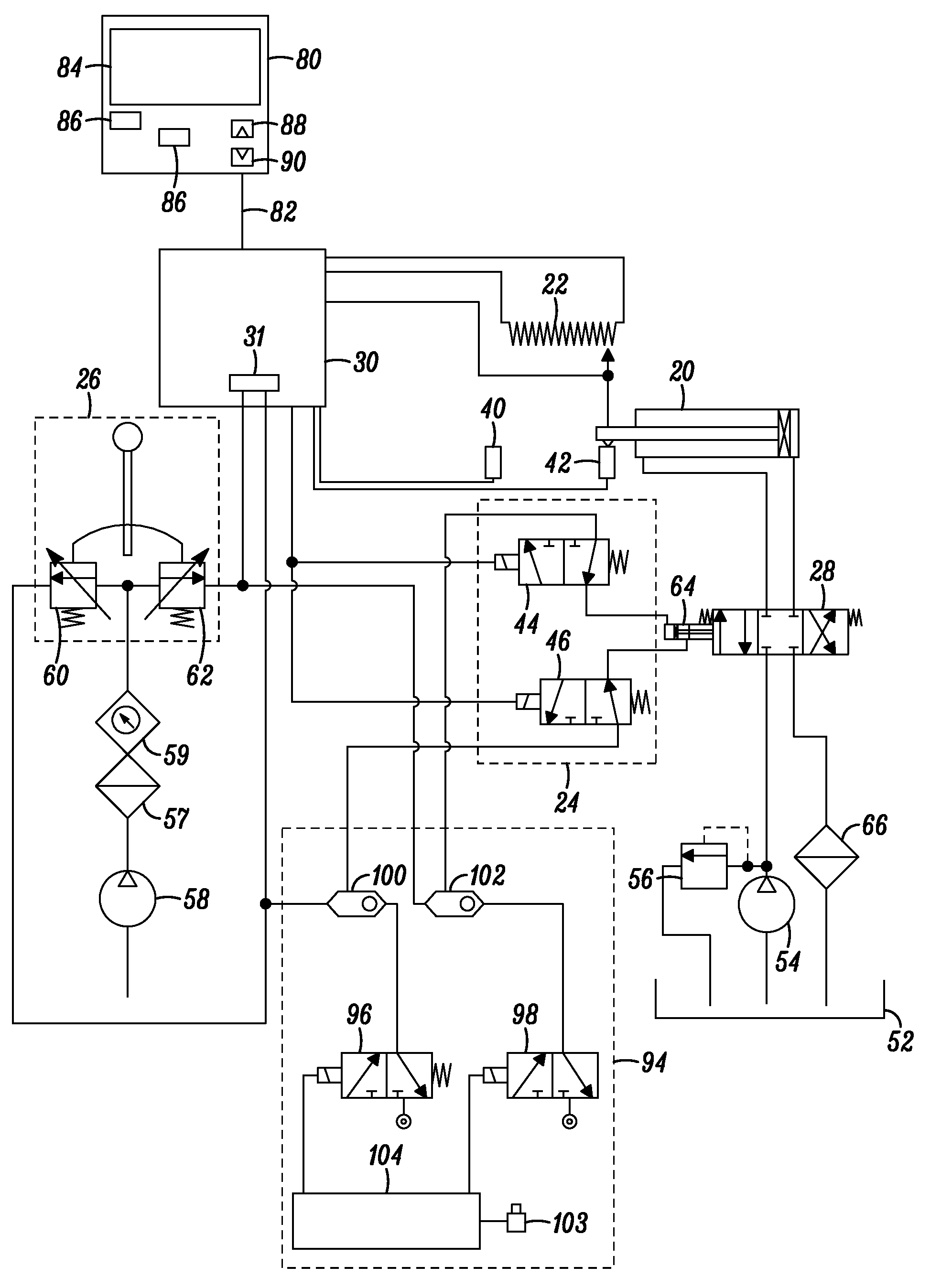

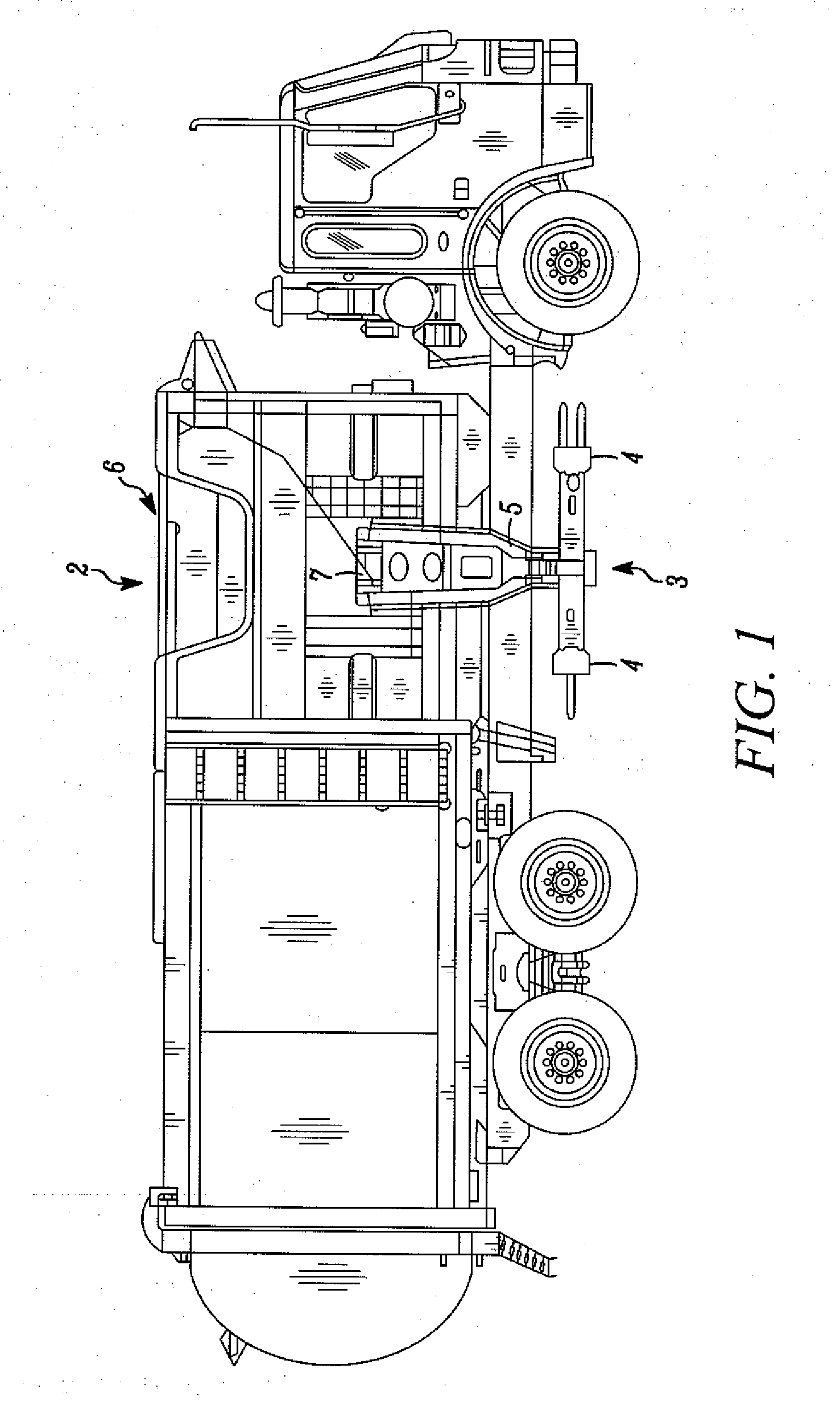

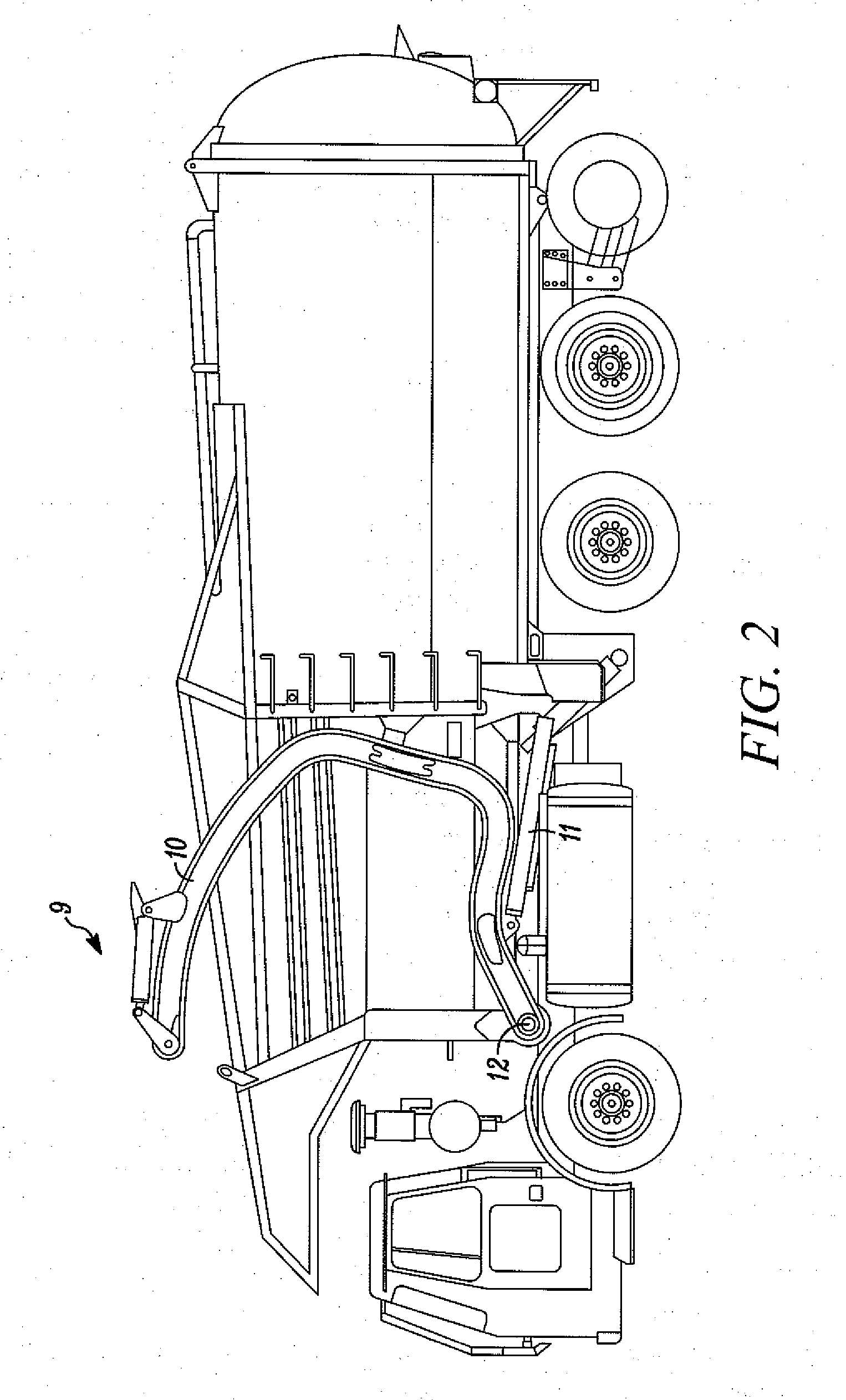

Hydraulic Actuator Control System

InactiveUS20080228323A1Slow motionFluid couplingsControlling ratio of multiple fluid flowsElectronic controllerControl signal

A system for controlling motion of a hydraulic actuator during a portion of its range of motion is described, including a sensor on the hydraulic actuator for providing a signal indicating that the actuator is near a portion of its range of motion, and a pneumatic control valve that is configured to selectively modify a pressurized air control signal to in turn restrict flow of pressurized hydraulic fluid to the hydraulic actuator. The hydraulic actuator control system further includes an electronic controller for controlling the pneumatic control valve in response to a signal from the sensor. The hydraulic actuator control system thereby slows the motion of the hydraulic actuator near the portion of its range of motion.

Owner:HARTFIEL AUTOMATION

Method and apparatus for flow control

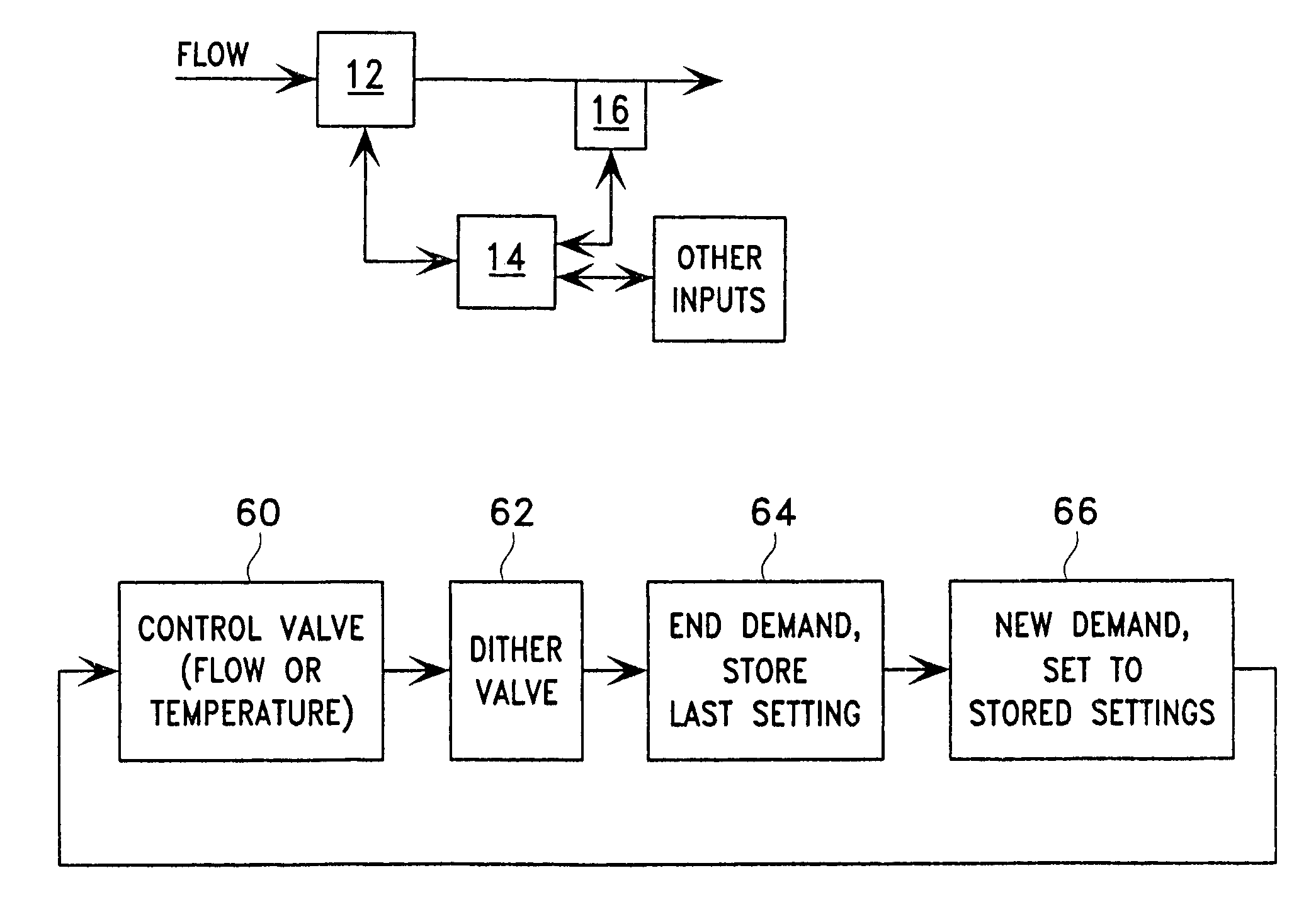

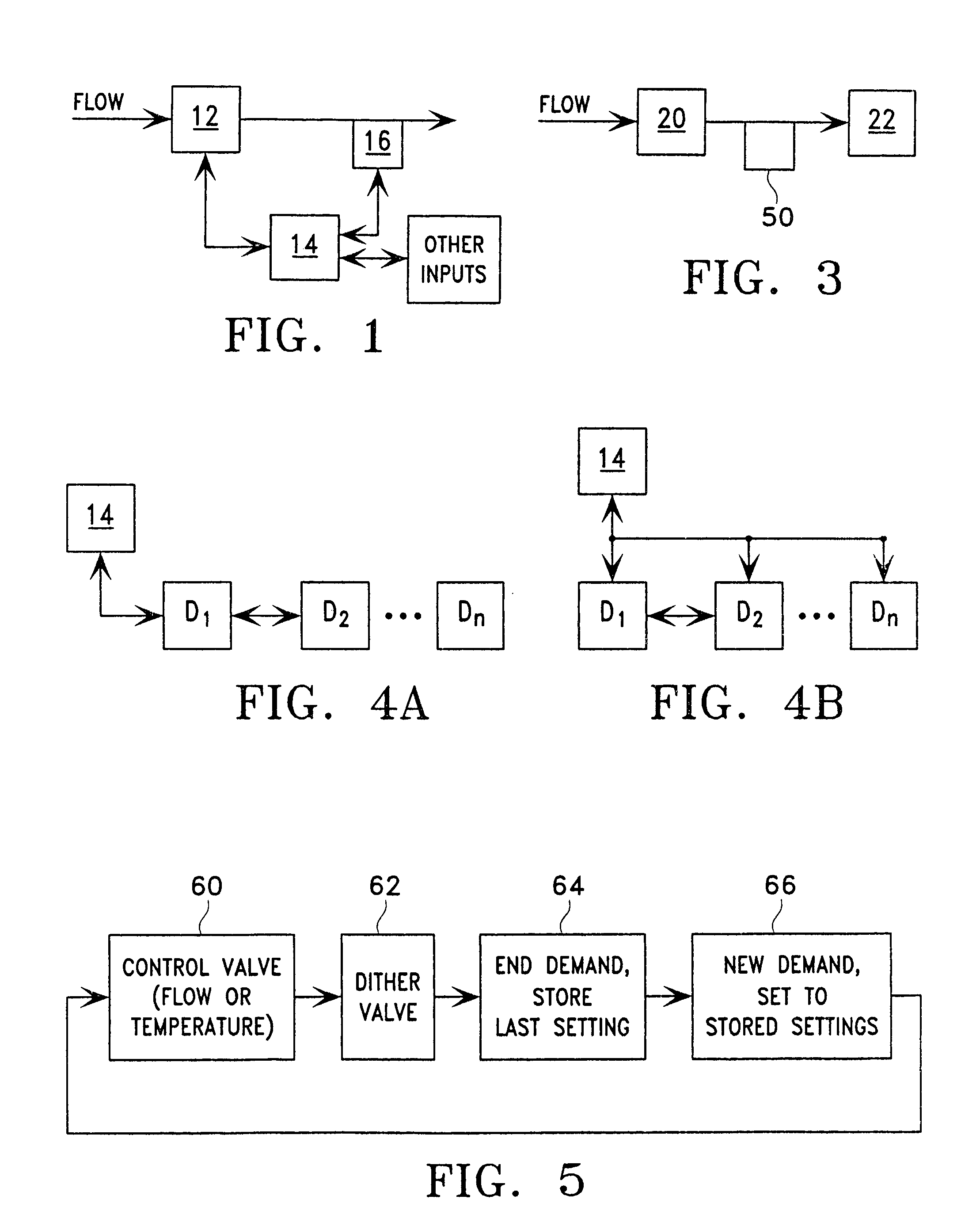

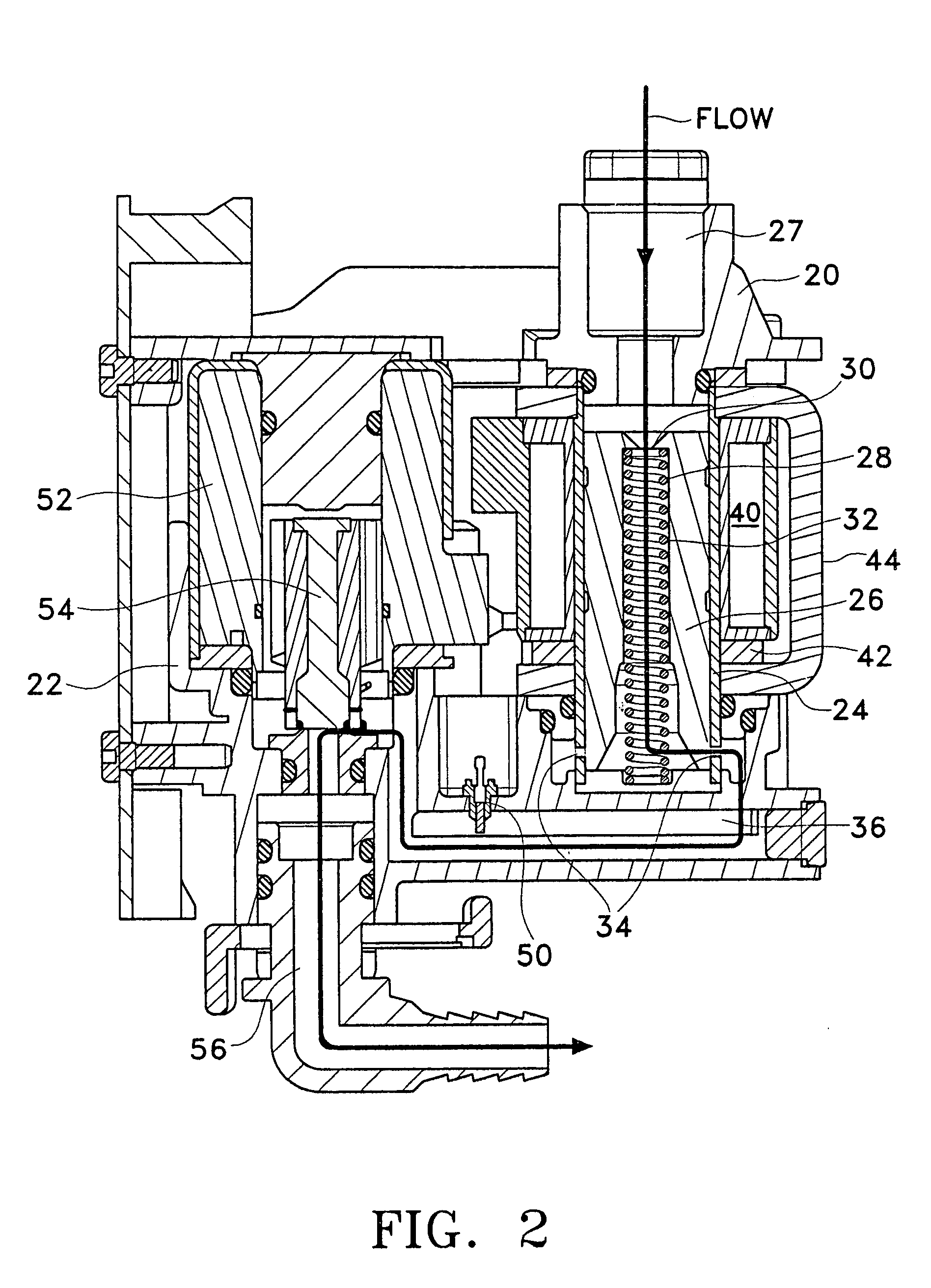

ActiveUS7156115B2Eliminate and substantially reduce problemControlling ratio of multiple fluid flowsFlow control using electric meansControl systemControl valves

A flow control system (10) is provided in which a flow control valve (12) is controlled by a control system (14). The control system (14) measures a flow rate or temperature of a fluid flowing through the flow control valve (12) and adjusts the flow control valve (12) to achieve a desired flow rate. The flow control valve (12) includes an electromagnetically adjustable spool (26).

Owner:LANCER PARTNERSHIP

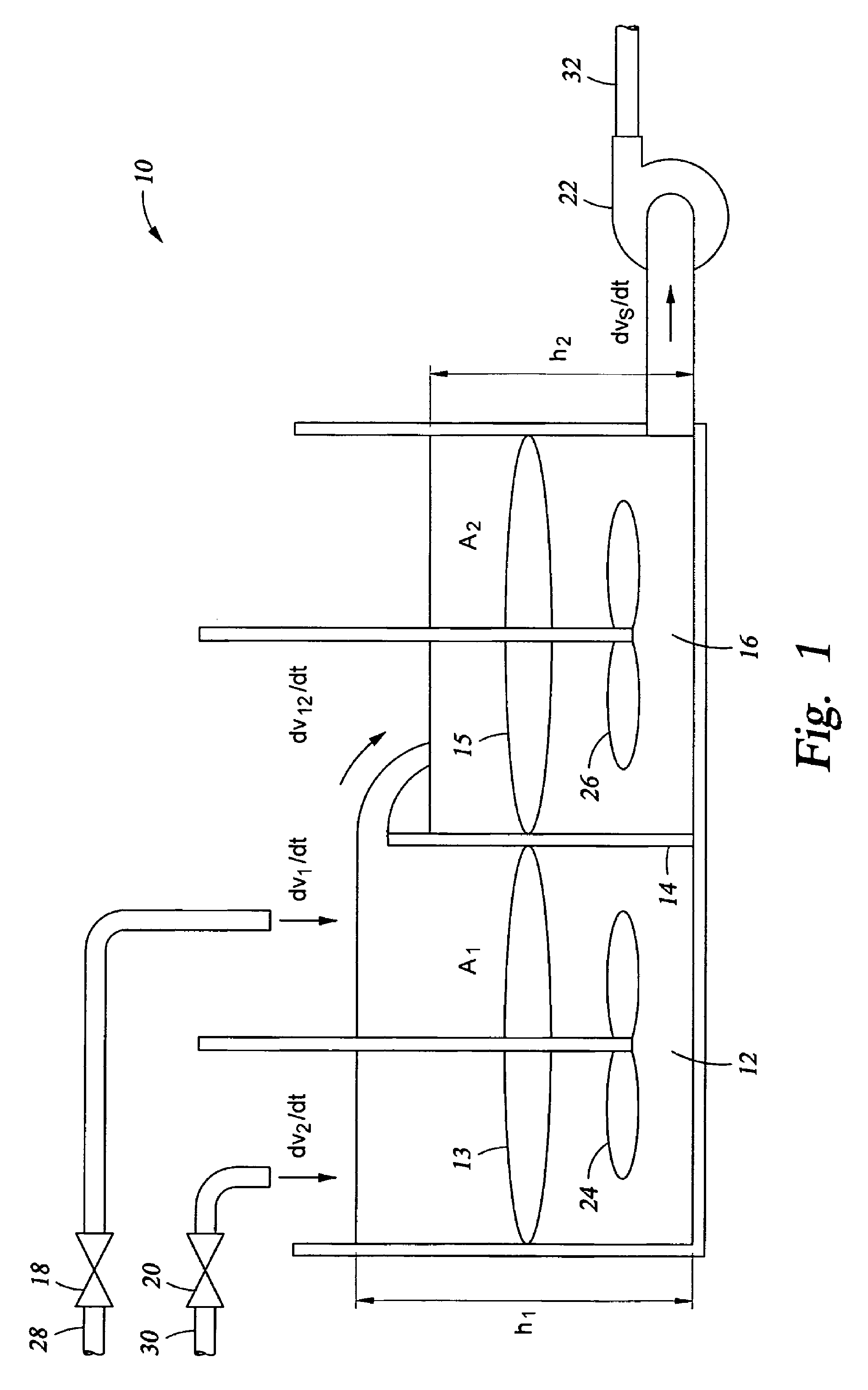

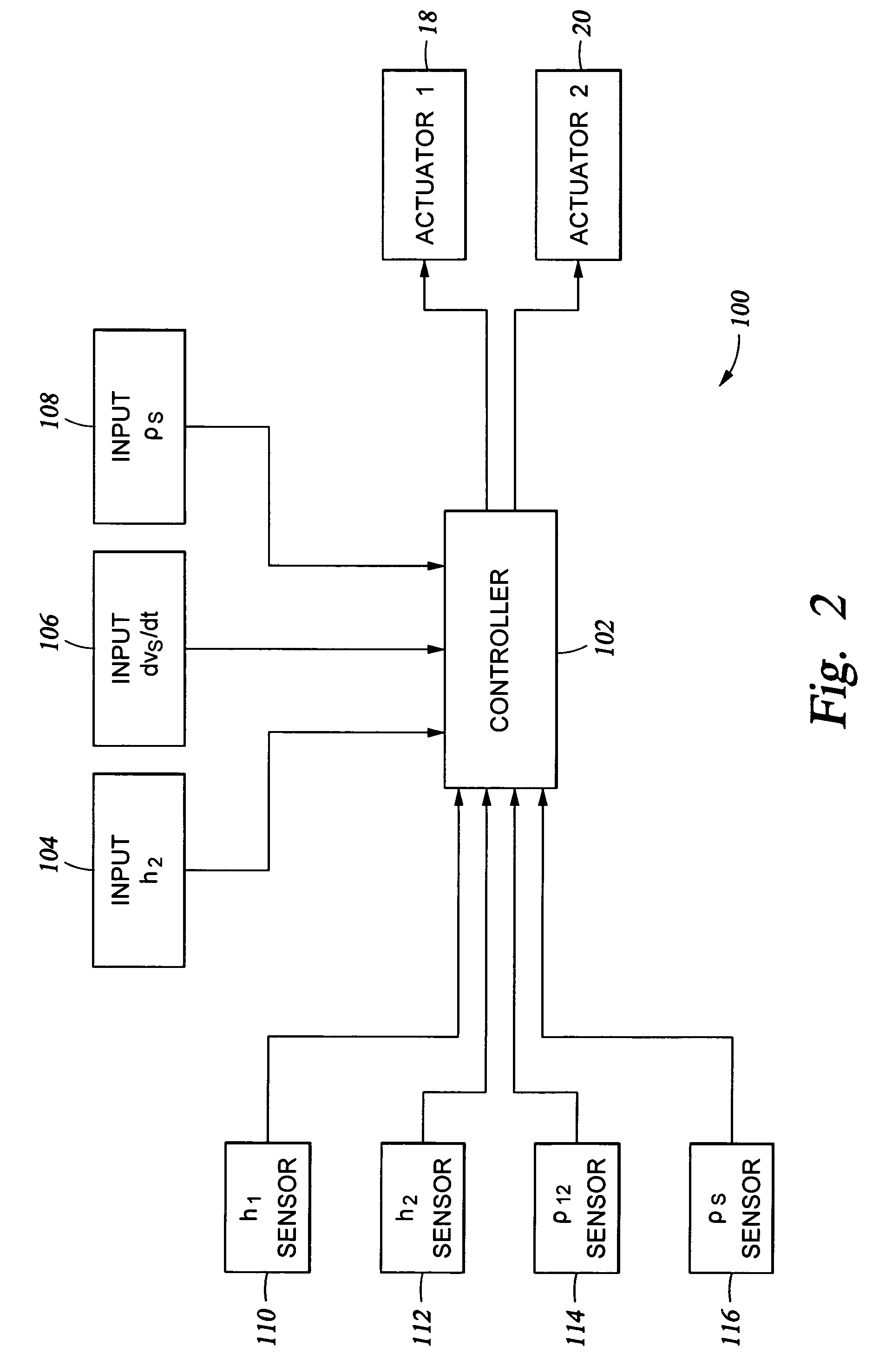

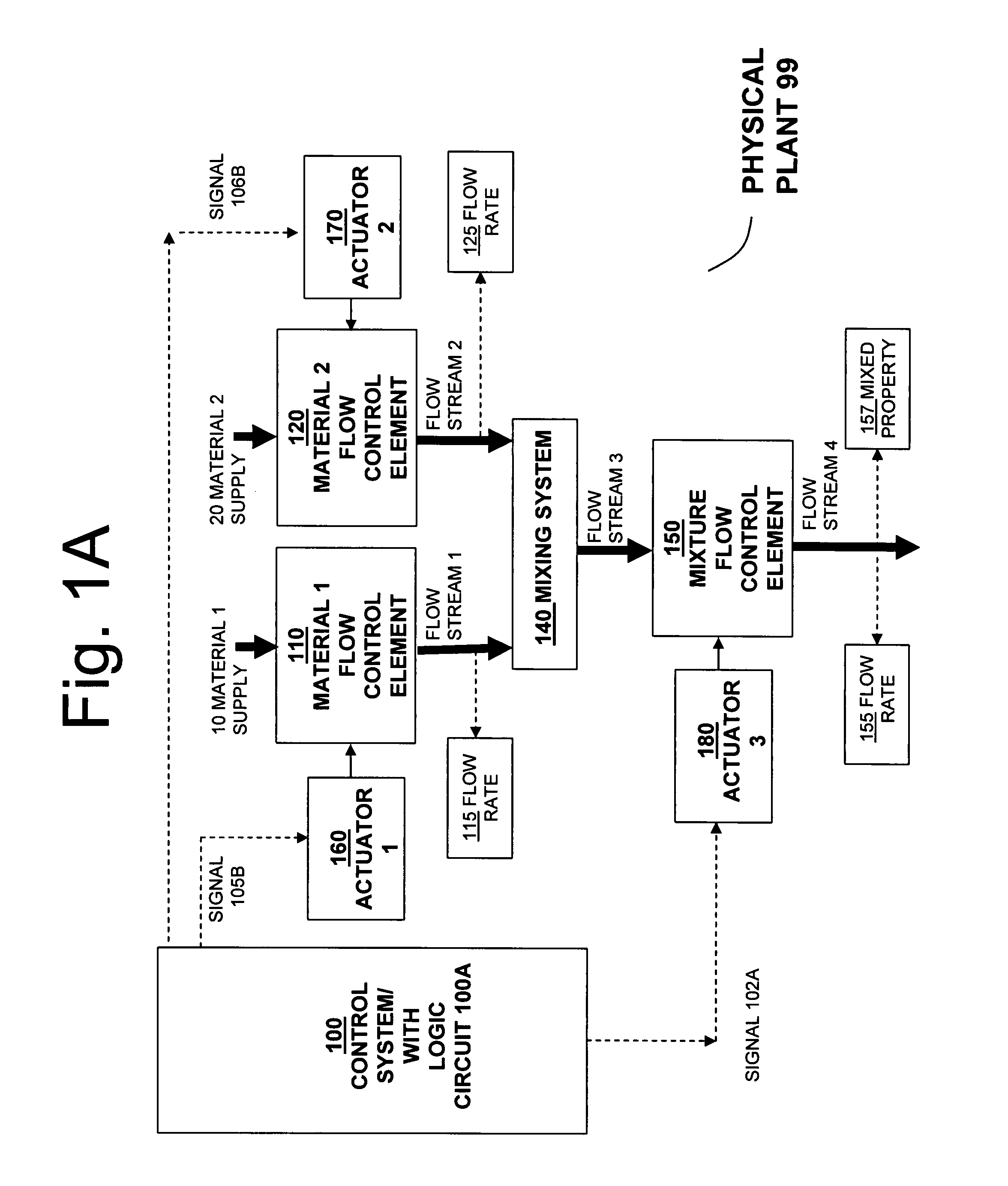

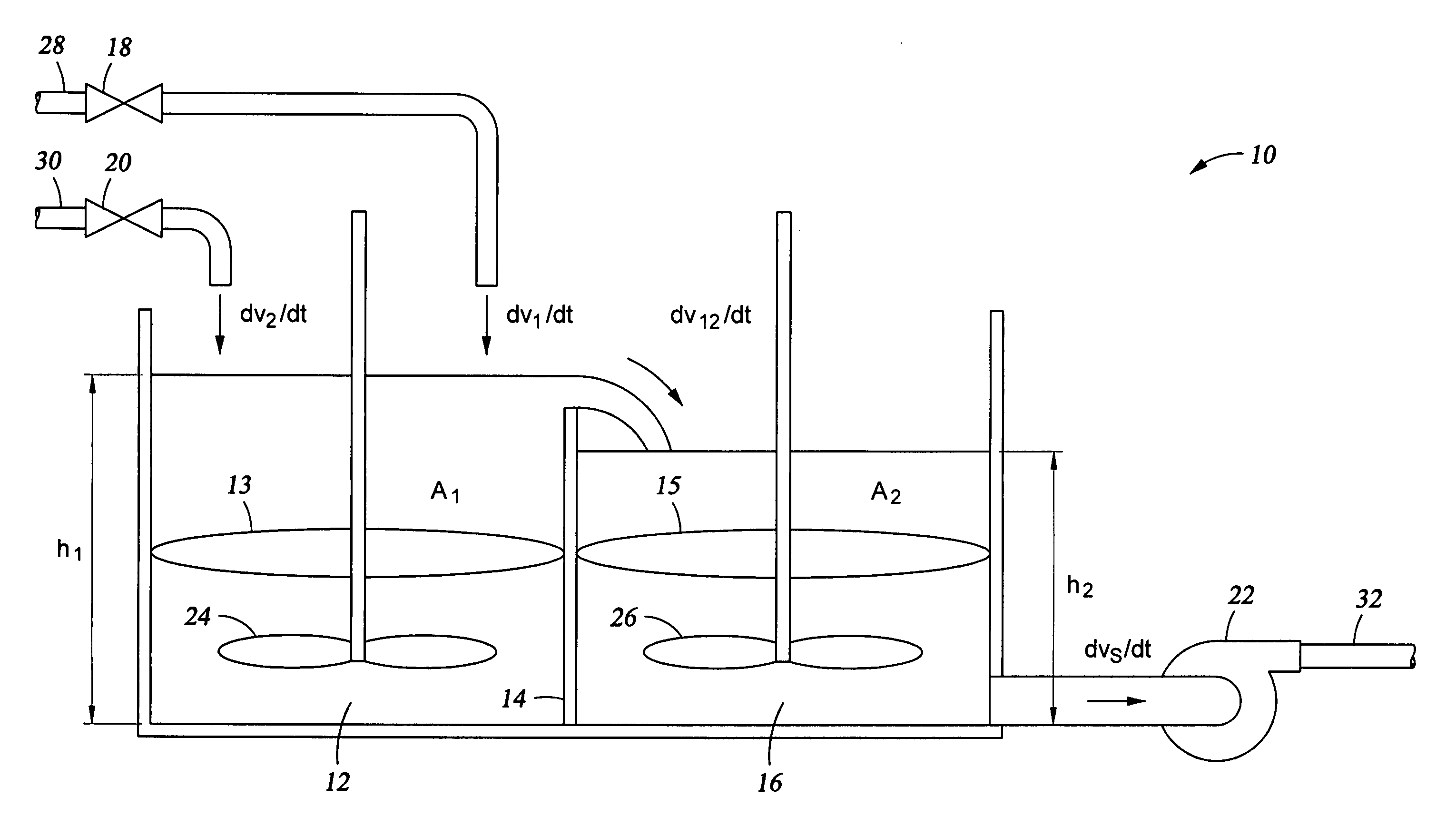

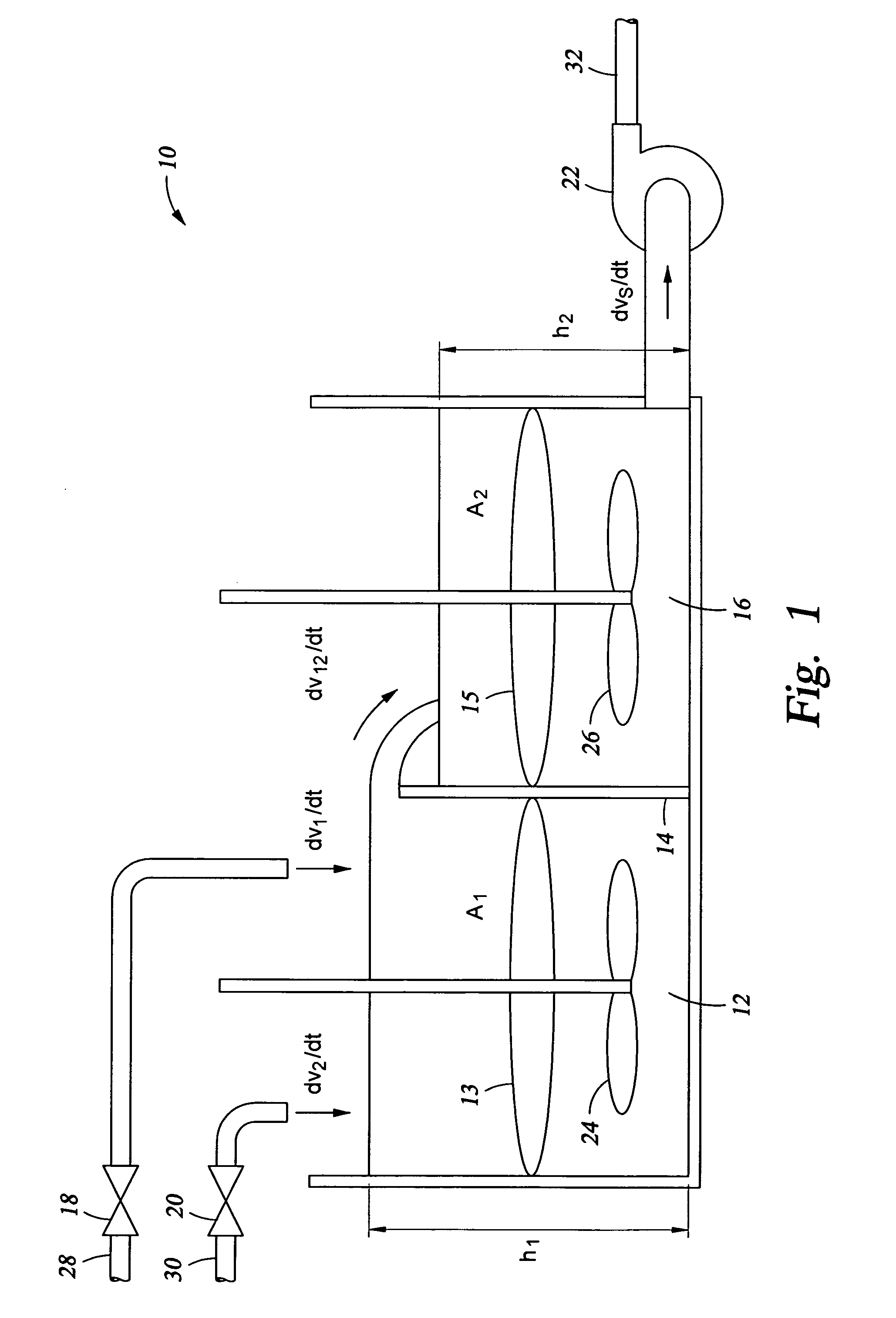

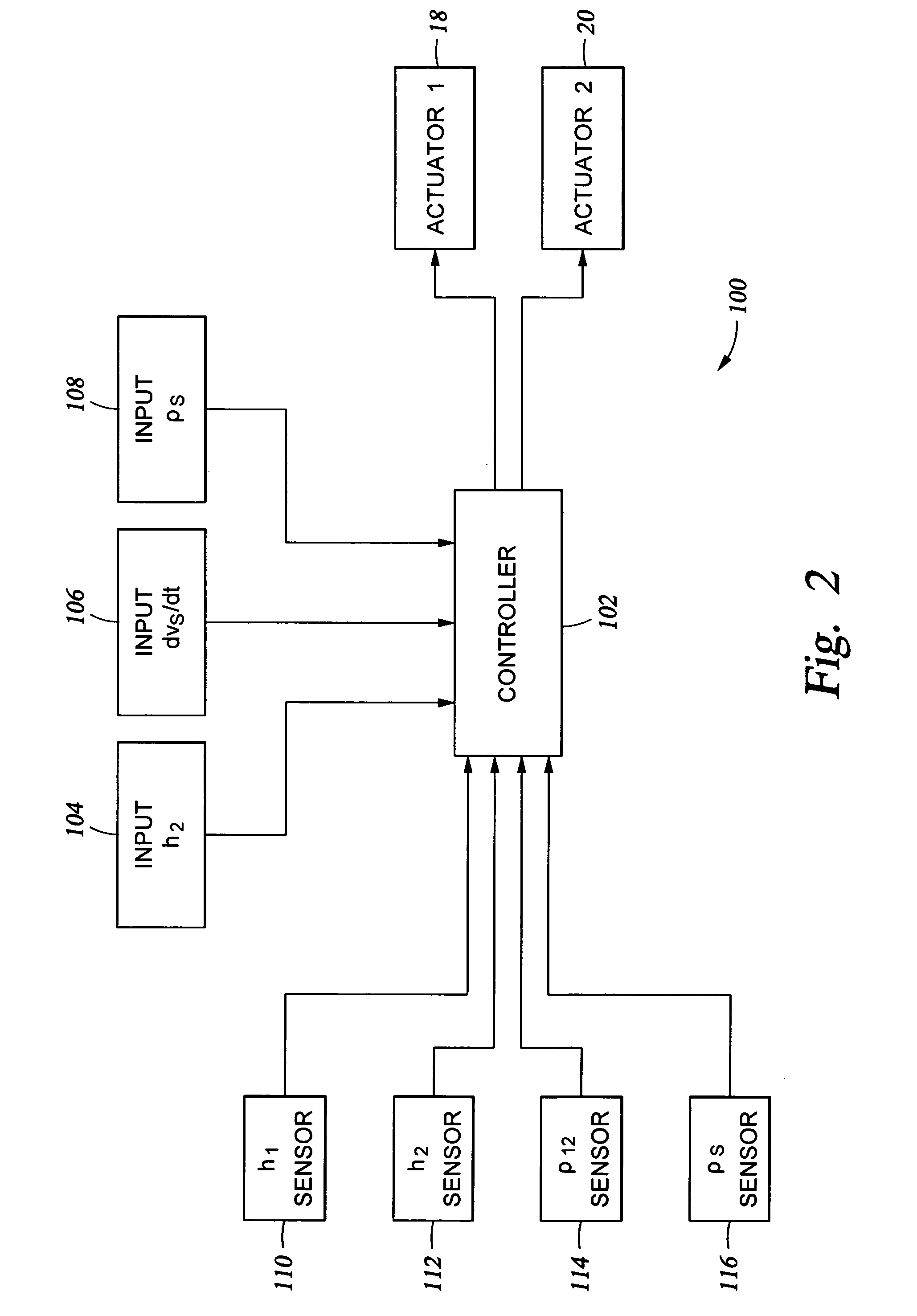

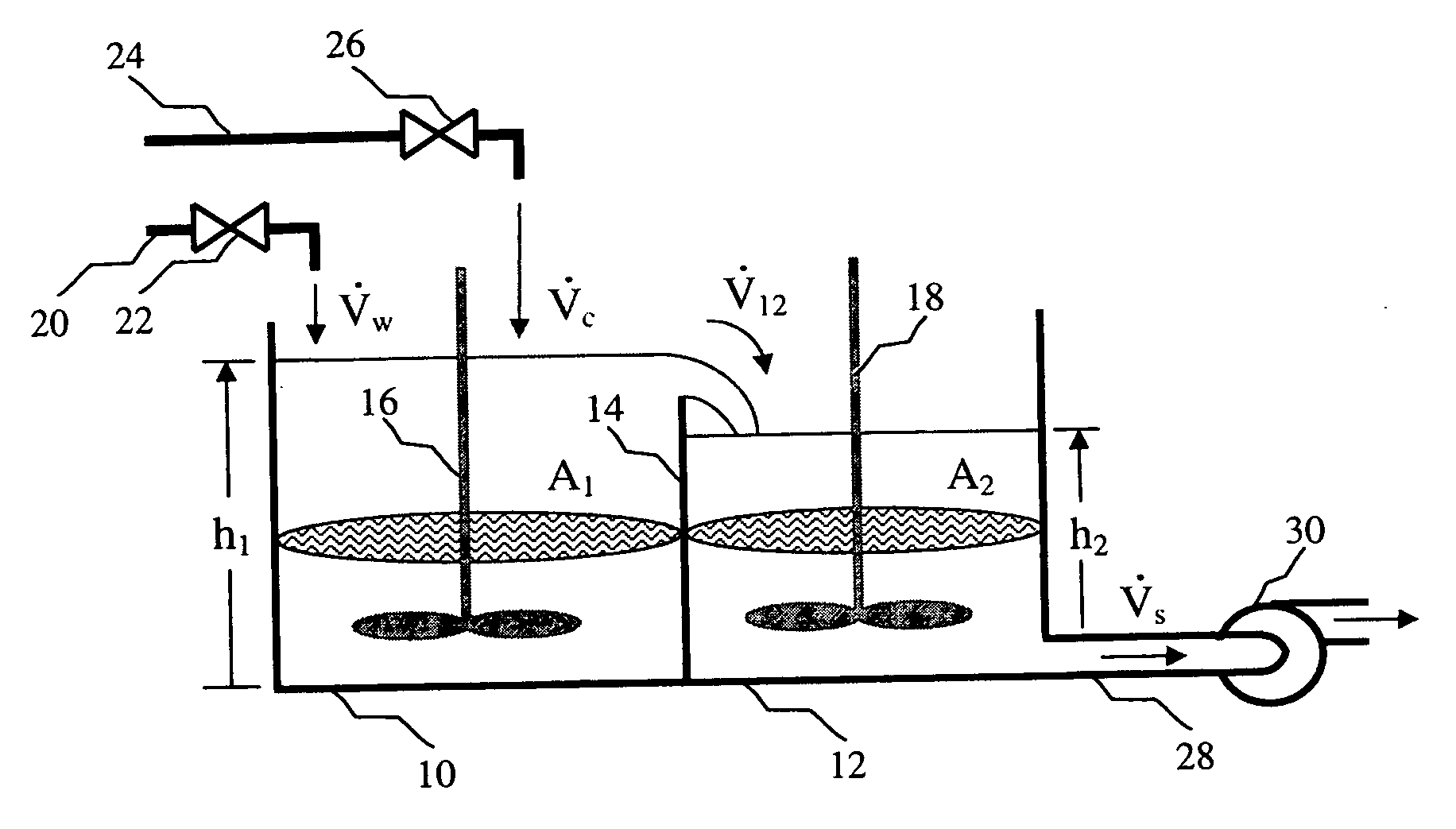

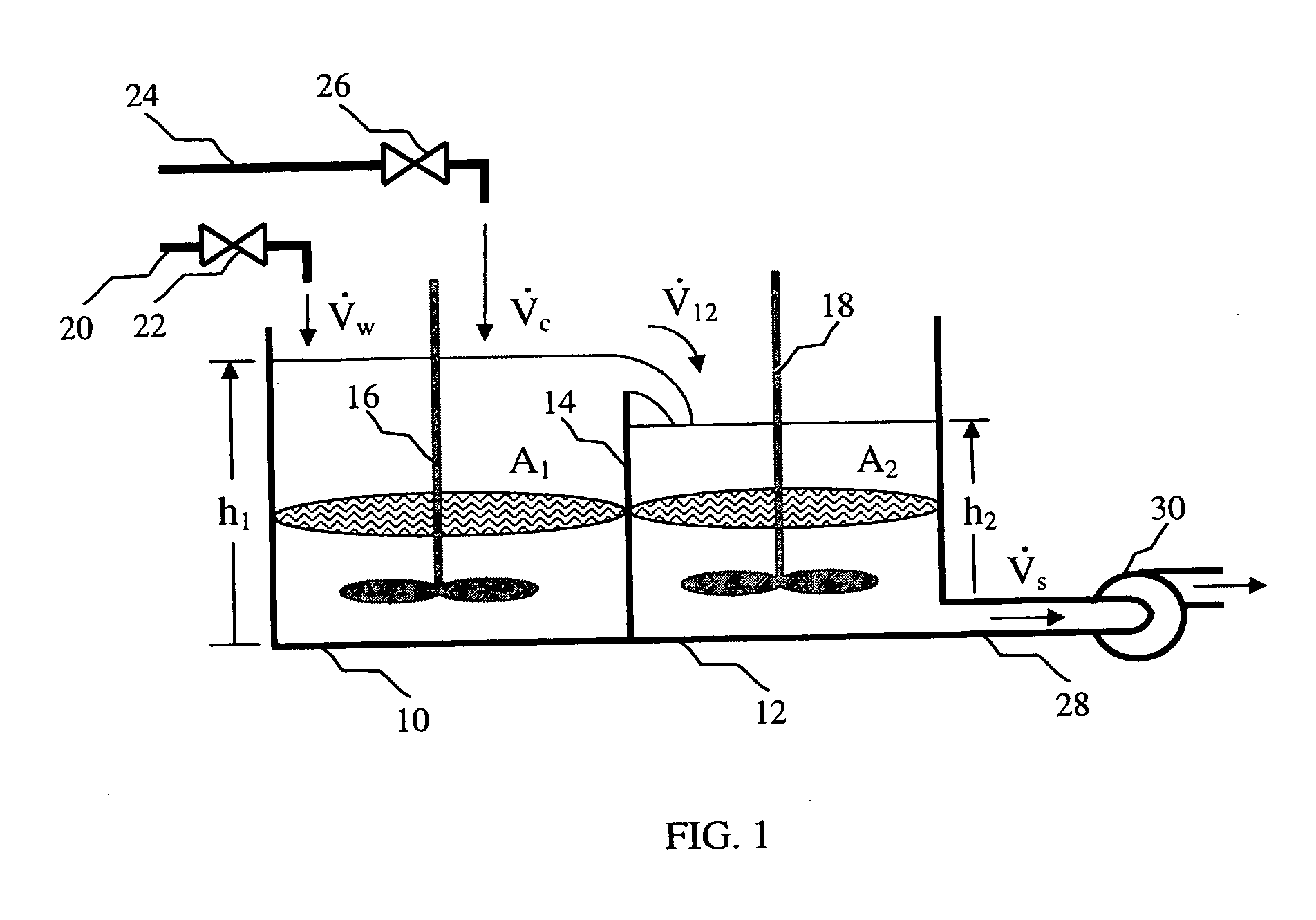

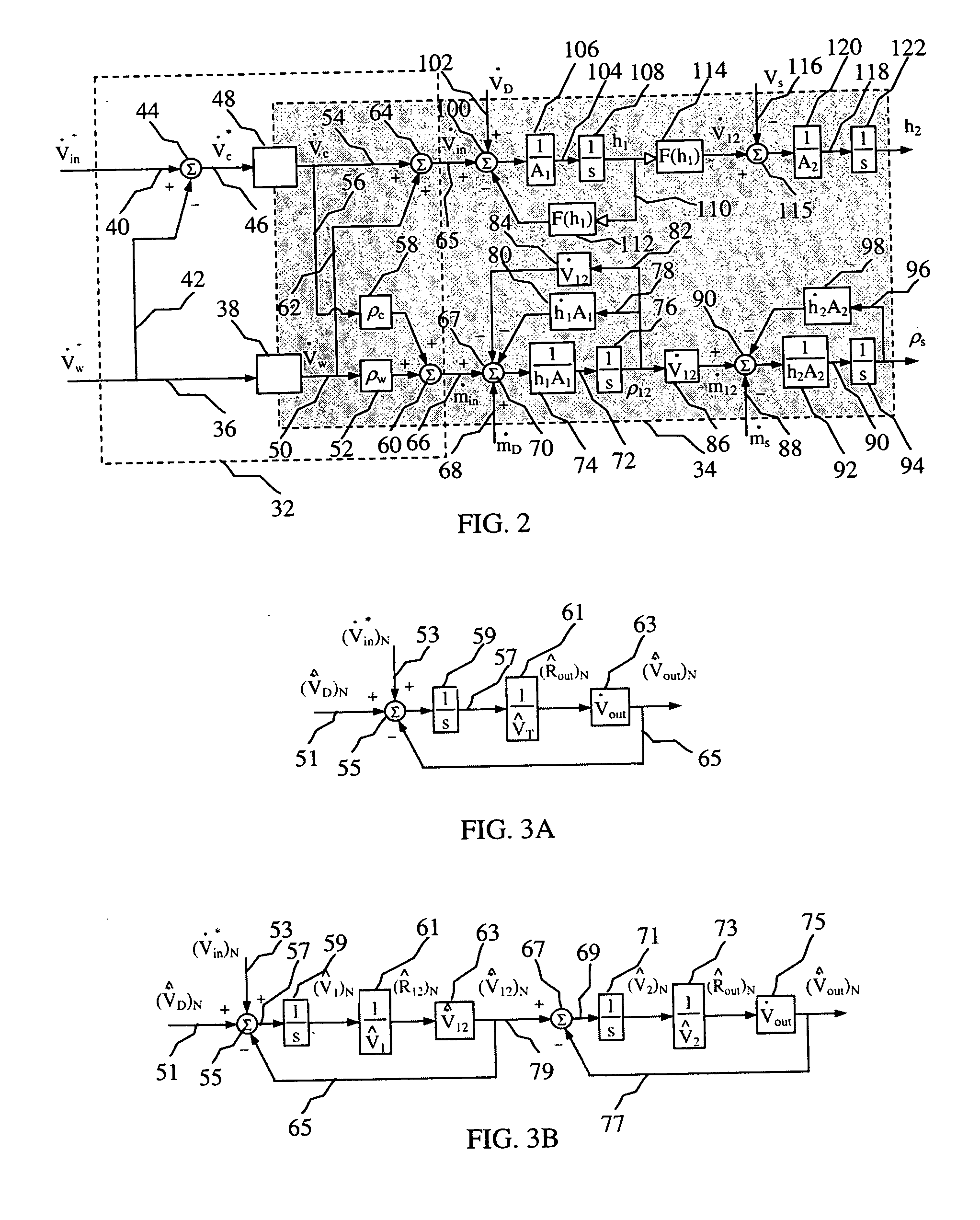

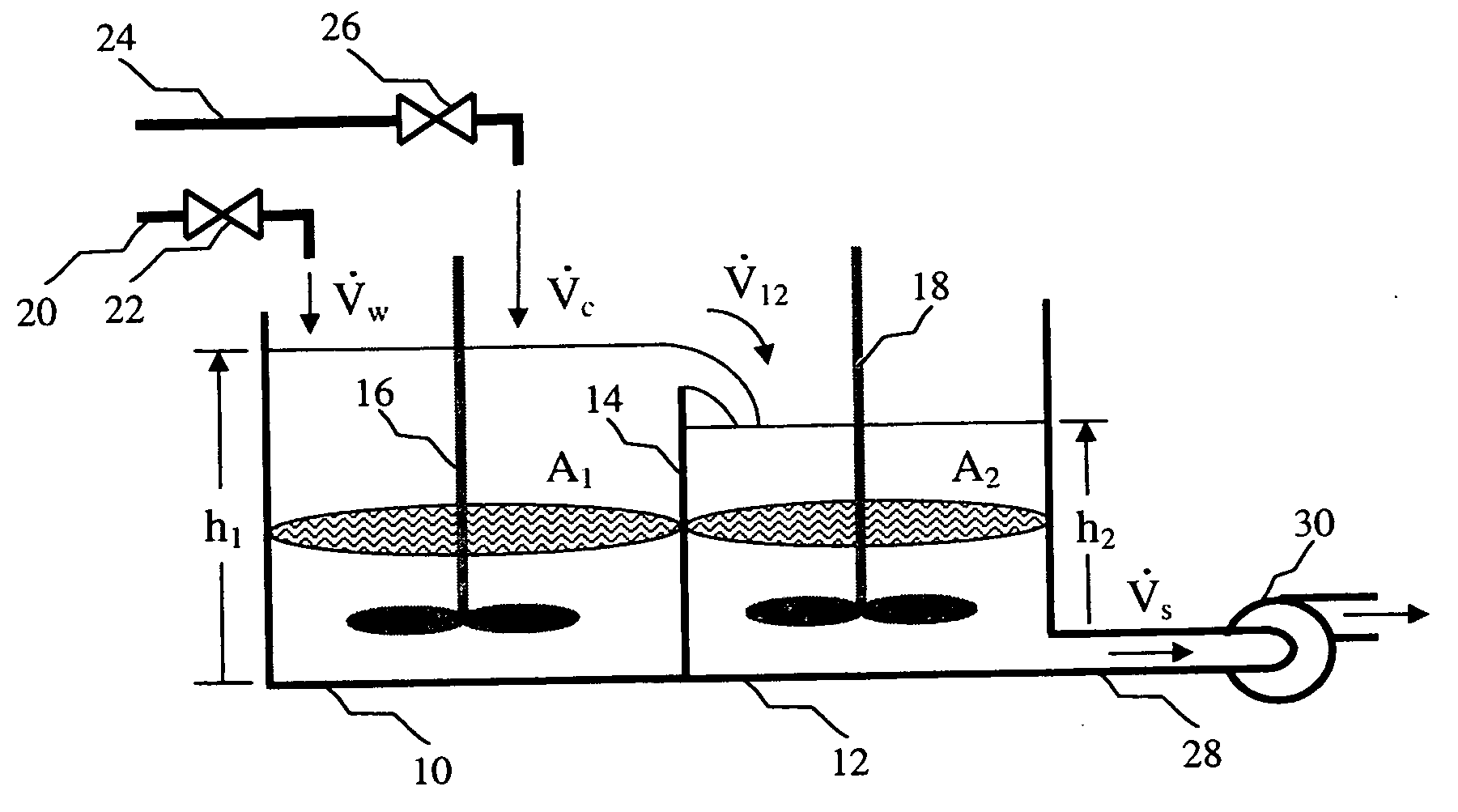

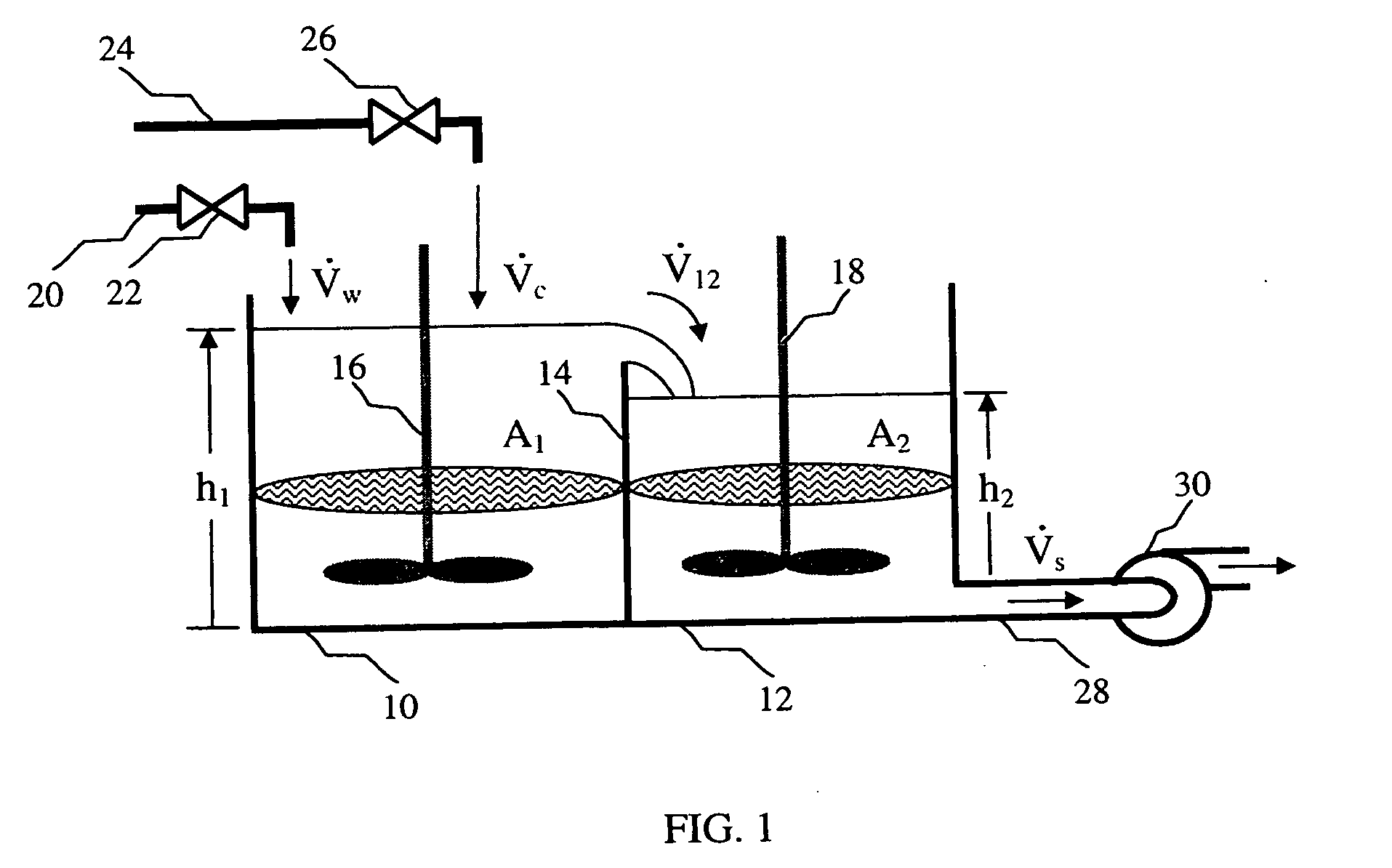

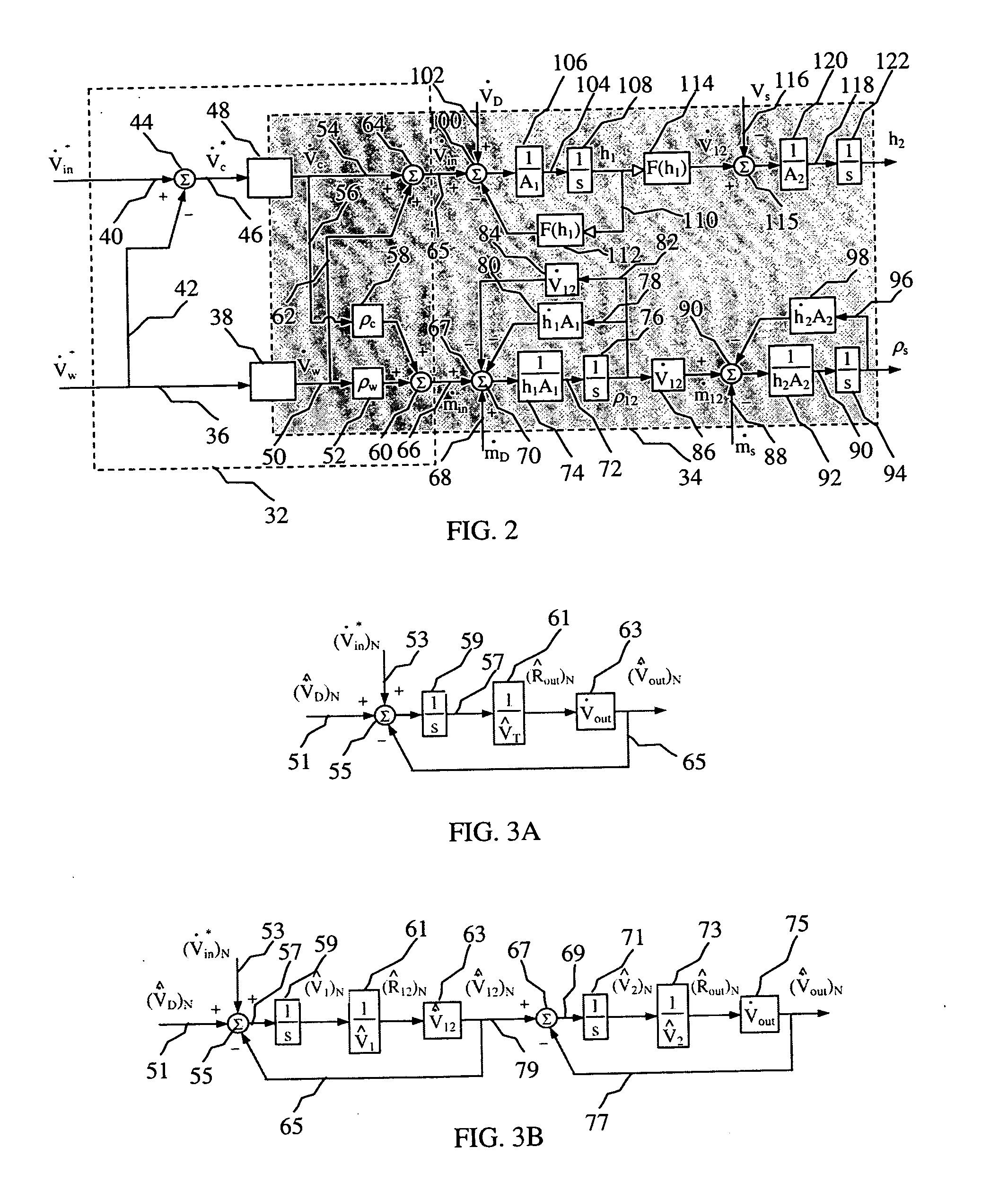

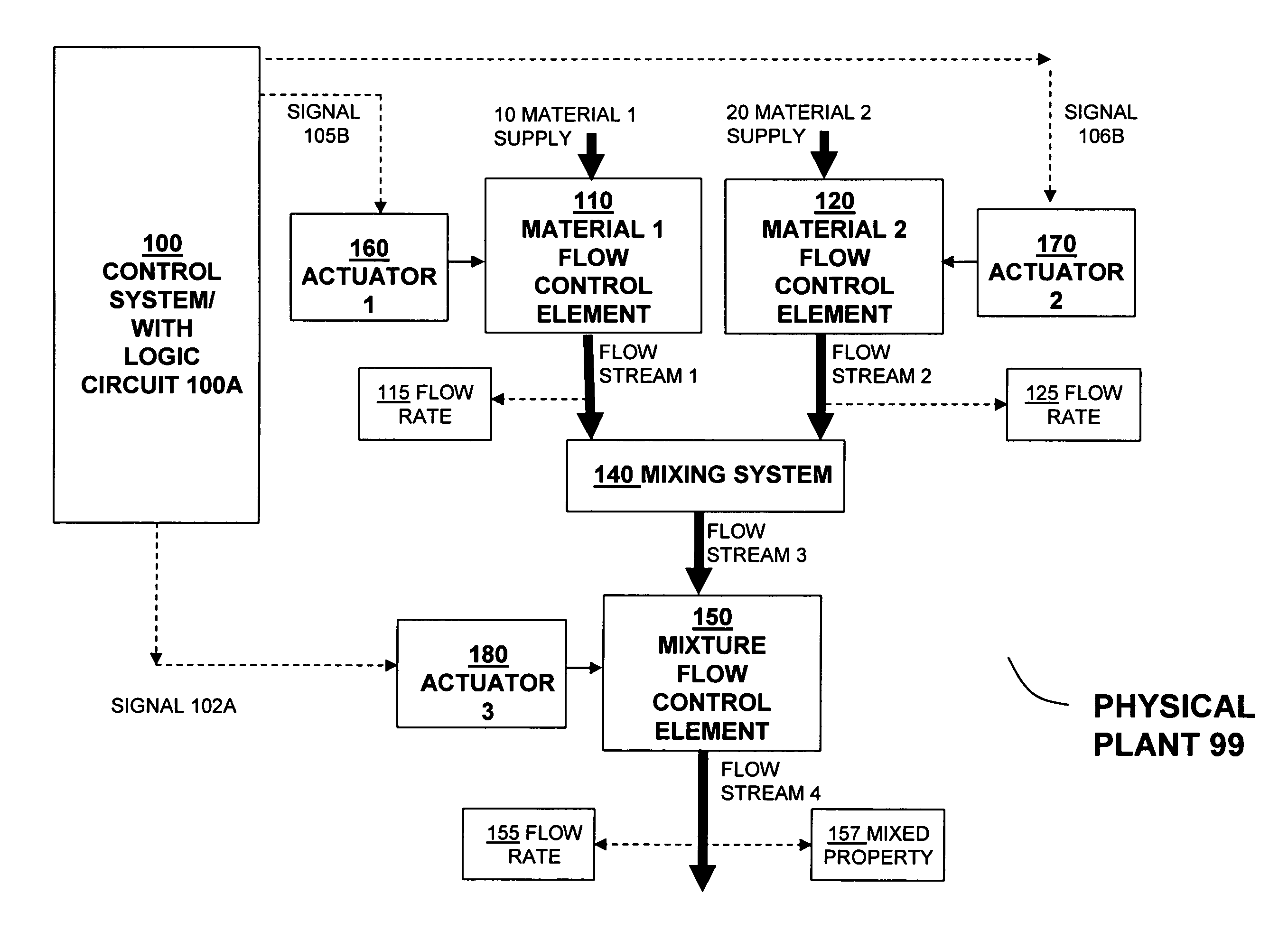

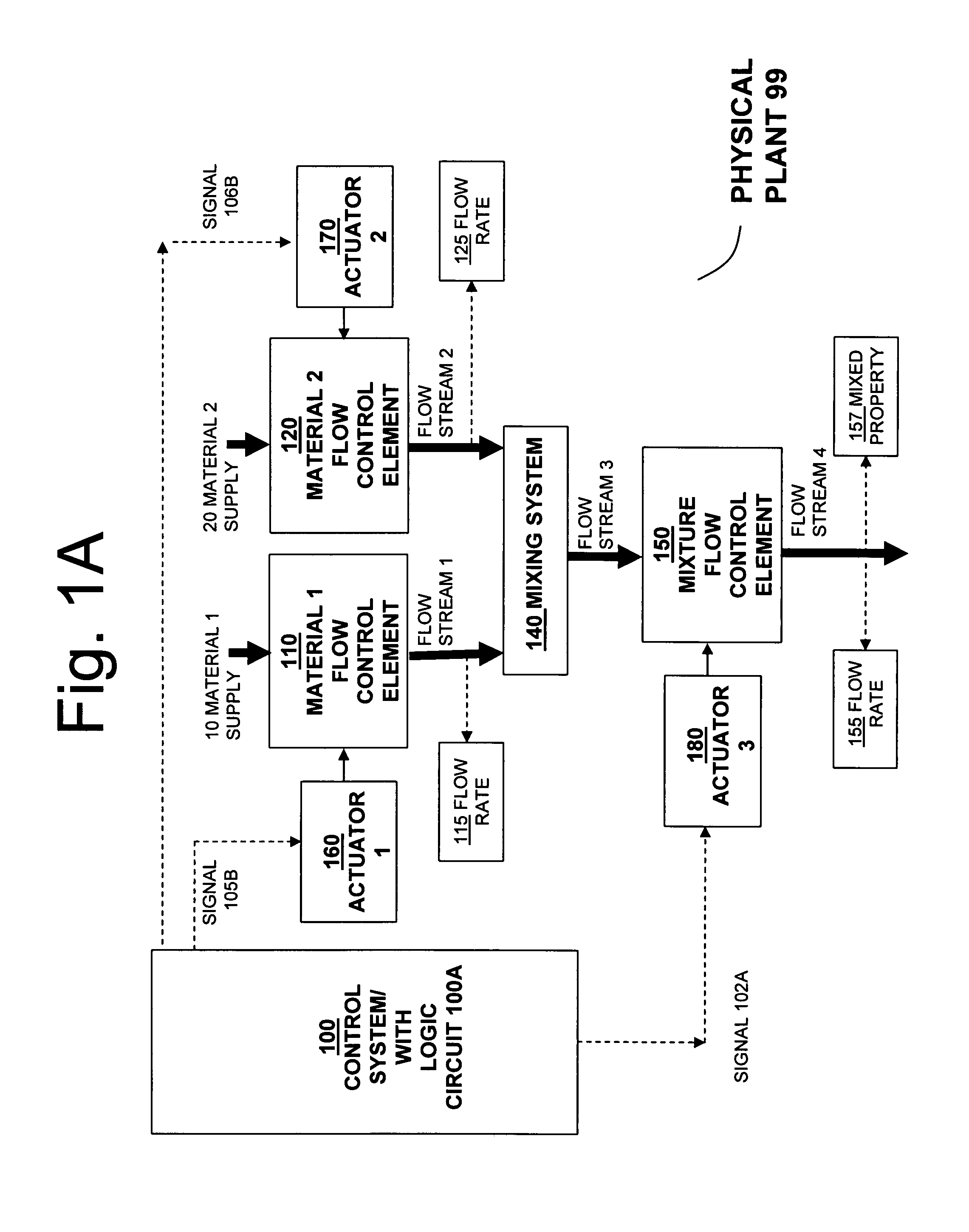

Control system design for a mixing system with multiple inputs

ActiveUS7494263B2Controlling ratio of multiple fluid flowsMixing operation control apparatusHybrid systemControl system design

A control system for mixing at least two materials in a physical system having two or more tanks comprises at least two actuators, each actuator being operable to introduce a material into a first tank to form a first mixture, the first mixture flowing into a second tank to form a second mixture and a controller operable, based on a commanded input, to control the at least two actuators to obtain a density of either the first mixture or the second mixture and a volume flow rate of the second mixture out of the second tank, wherein the density is controlled independently from the volume flow rate.

Owner:HALLIBURTON ENERGY SERVICES INC

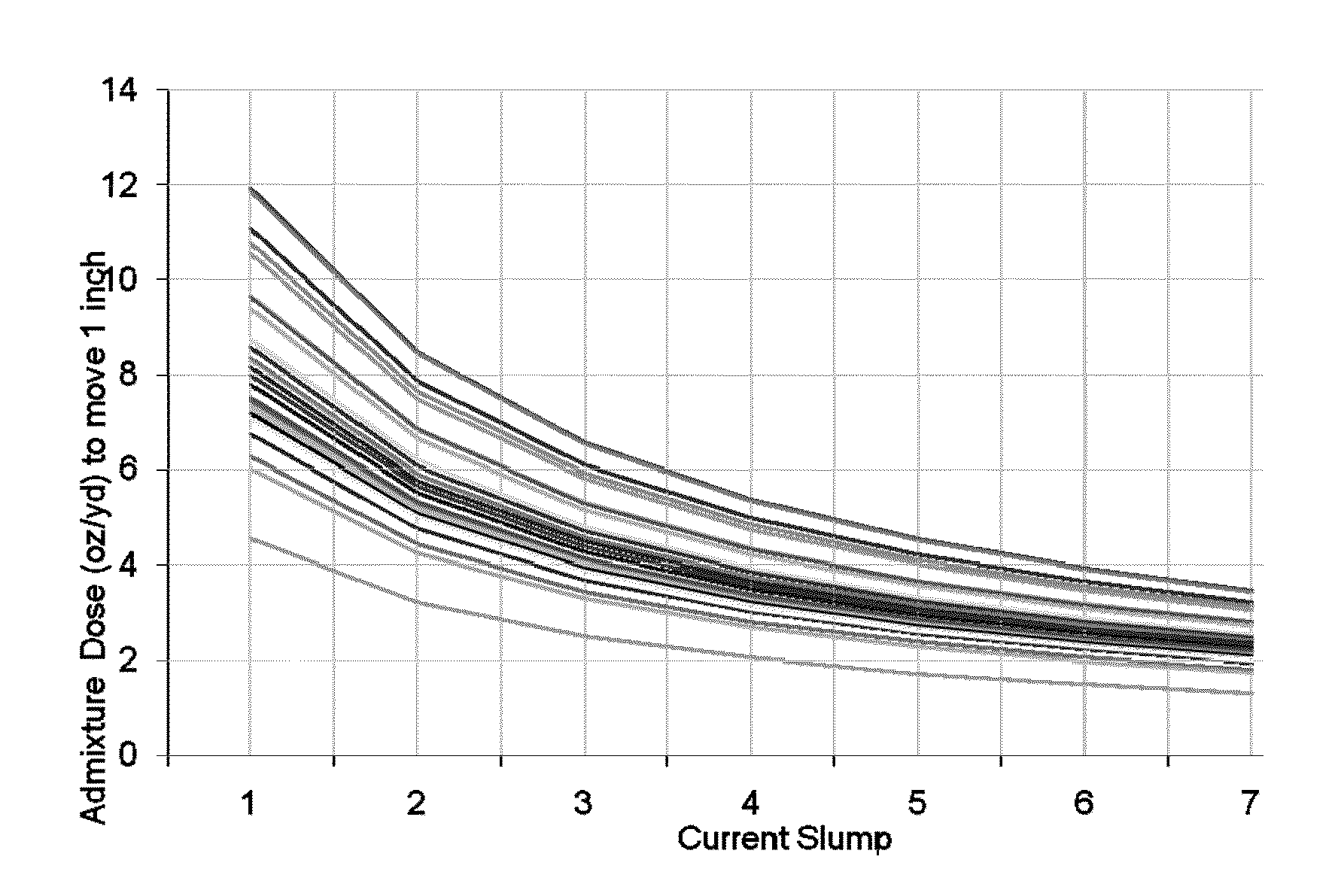

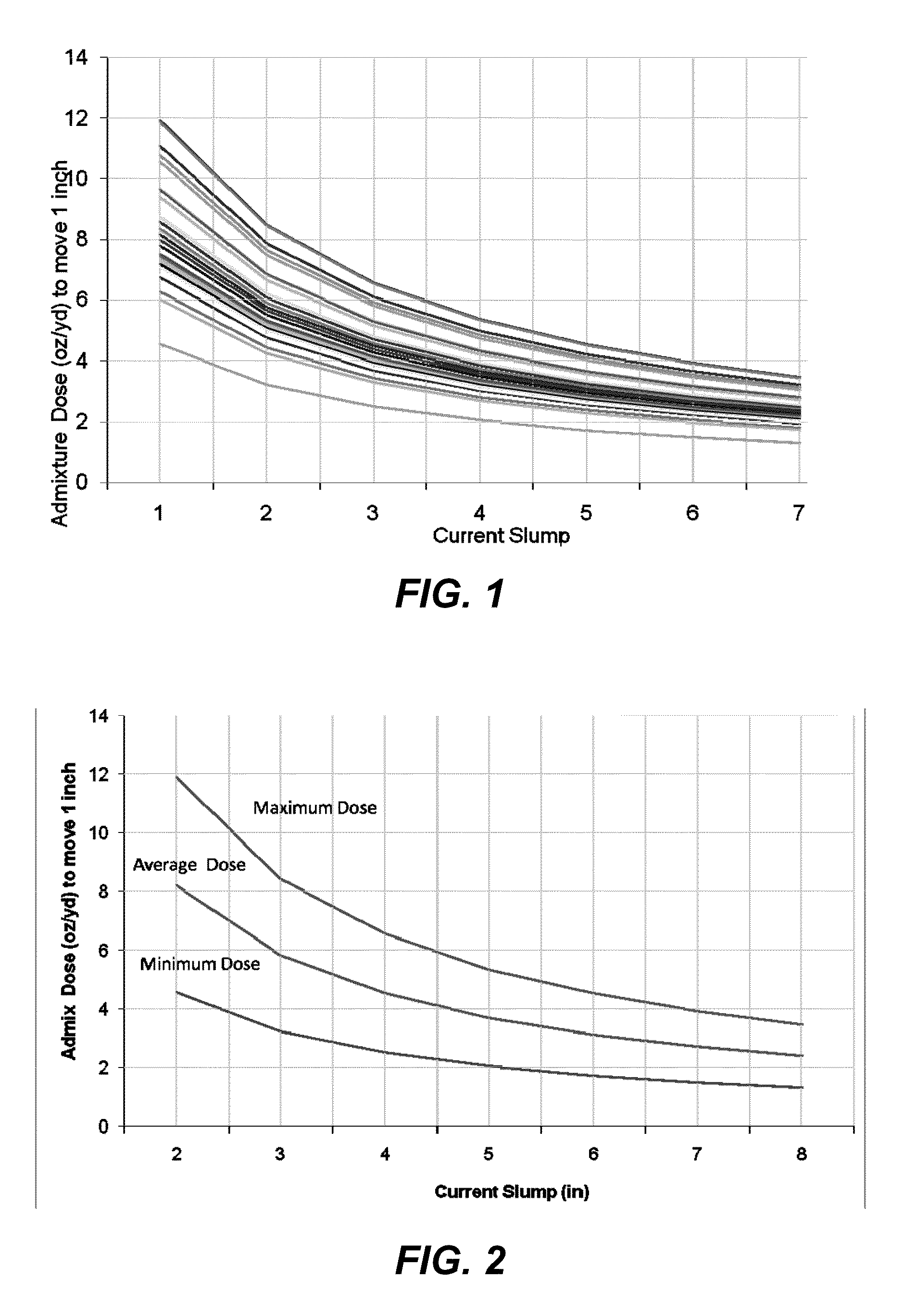

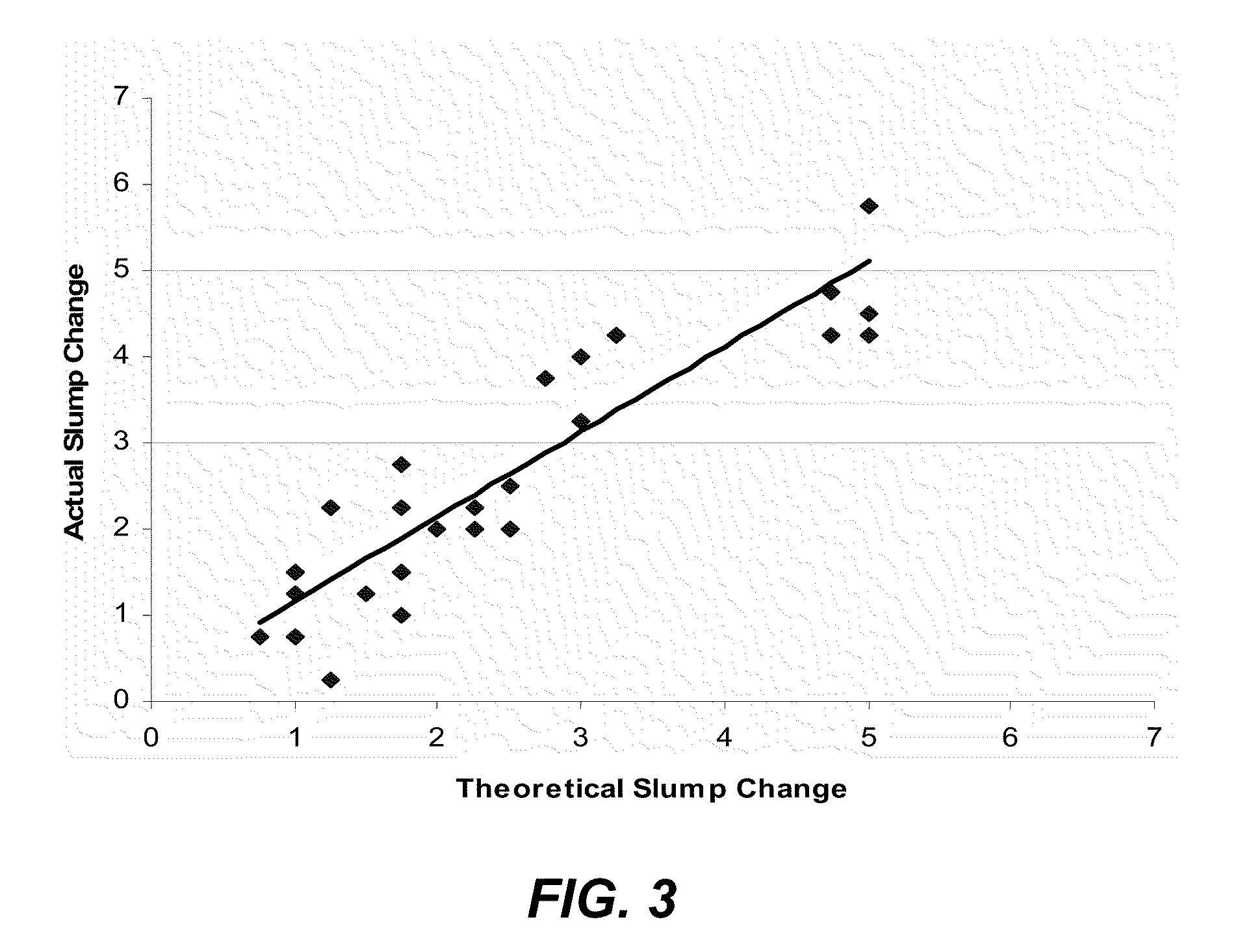

Method for adjusting concrete rheology based upon nominal dose-response profile

ActiveUS8311678B2Increased complexityAvoid overdoseSampled-variable control systemsControlling ratio of multiple fluid flowsEngineeringLookup table

The invention relates to a method for adjusting concrete rheology requiring only that load size and target rheology value be selected initially rather than requiring inputs into and consultation of a lookup table of parameters such as water and hydration levels, mix components, temperature, humidity, aggregate components, and others. Dosage of particular rheology-modifying agent or combination of rheology-modifying agents is calculated based on a percentage of a nominal dose calculated with reference to a nominal dose response (“NDR”) curve or profile. The NDR profile is based on a correlation between a rheology value (e.g., slump, slump flow, yield stress) and the rheology-modifying agent(s) dose required to change rheology value by one unit (e.g., slump change from 2 to 3 inches) such that exemplary methods can employ corrective dosing based on the NDR and the measured deviation by the system.

Owner:VERIFI INC

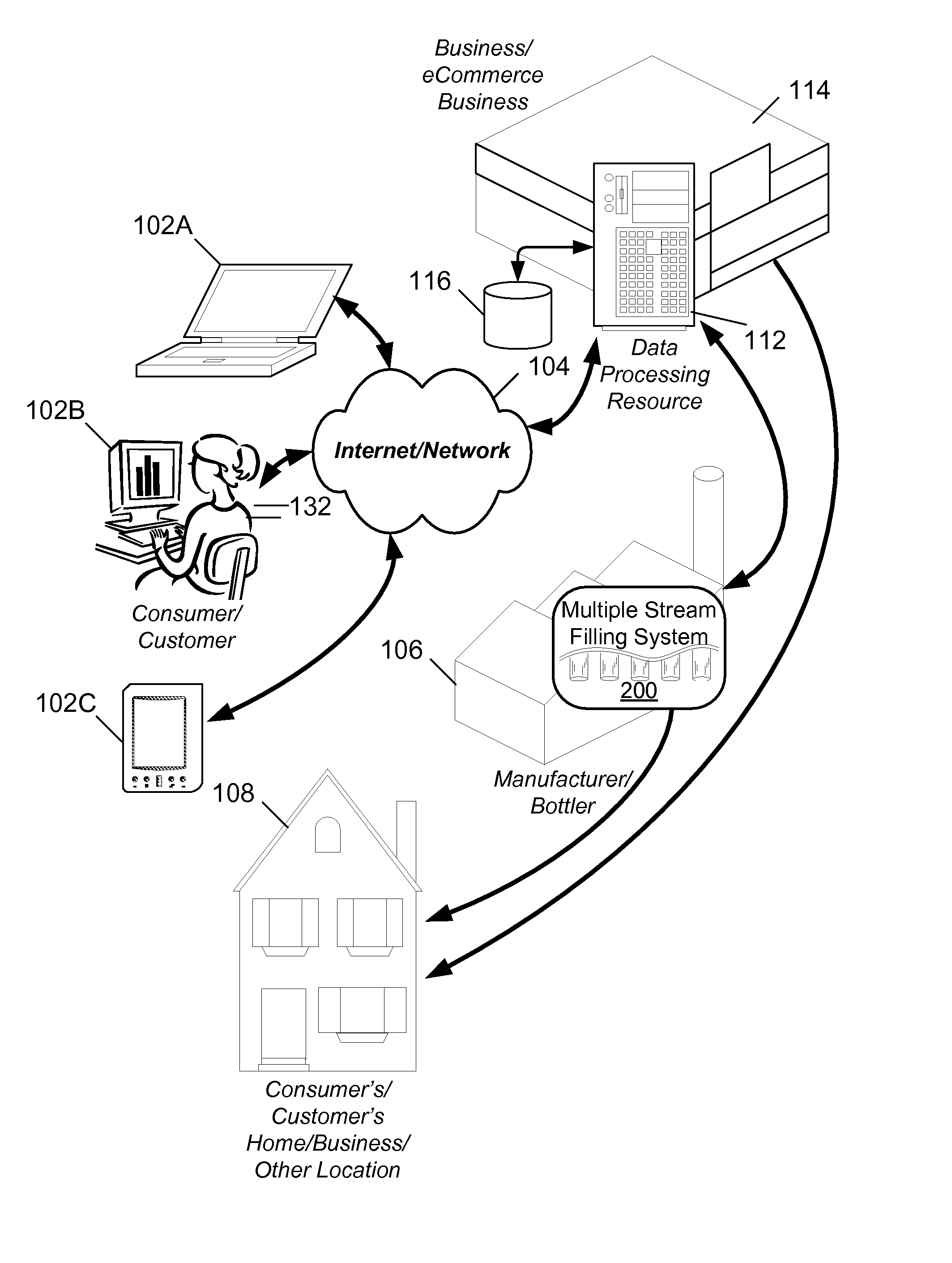

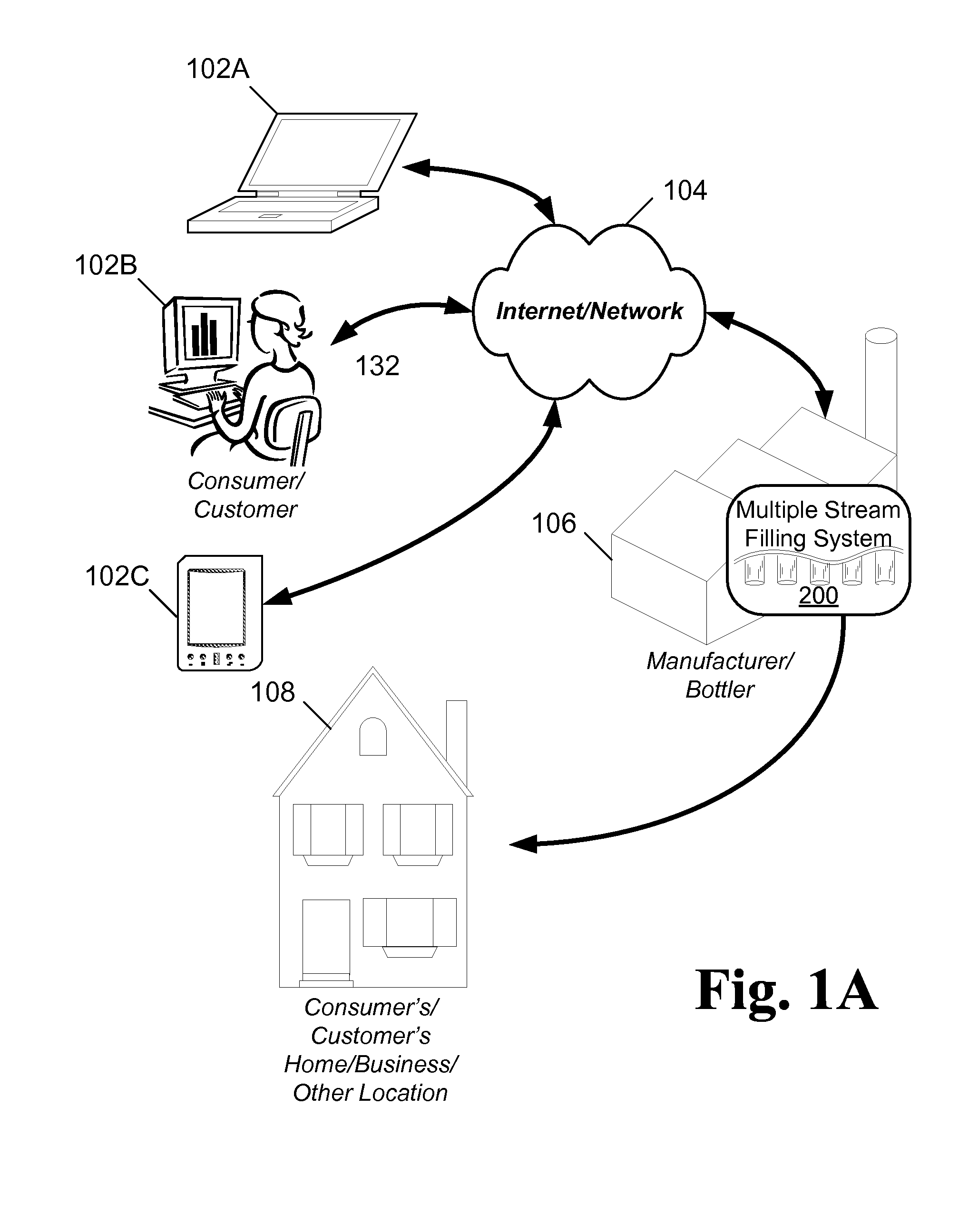

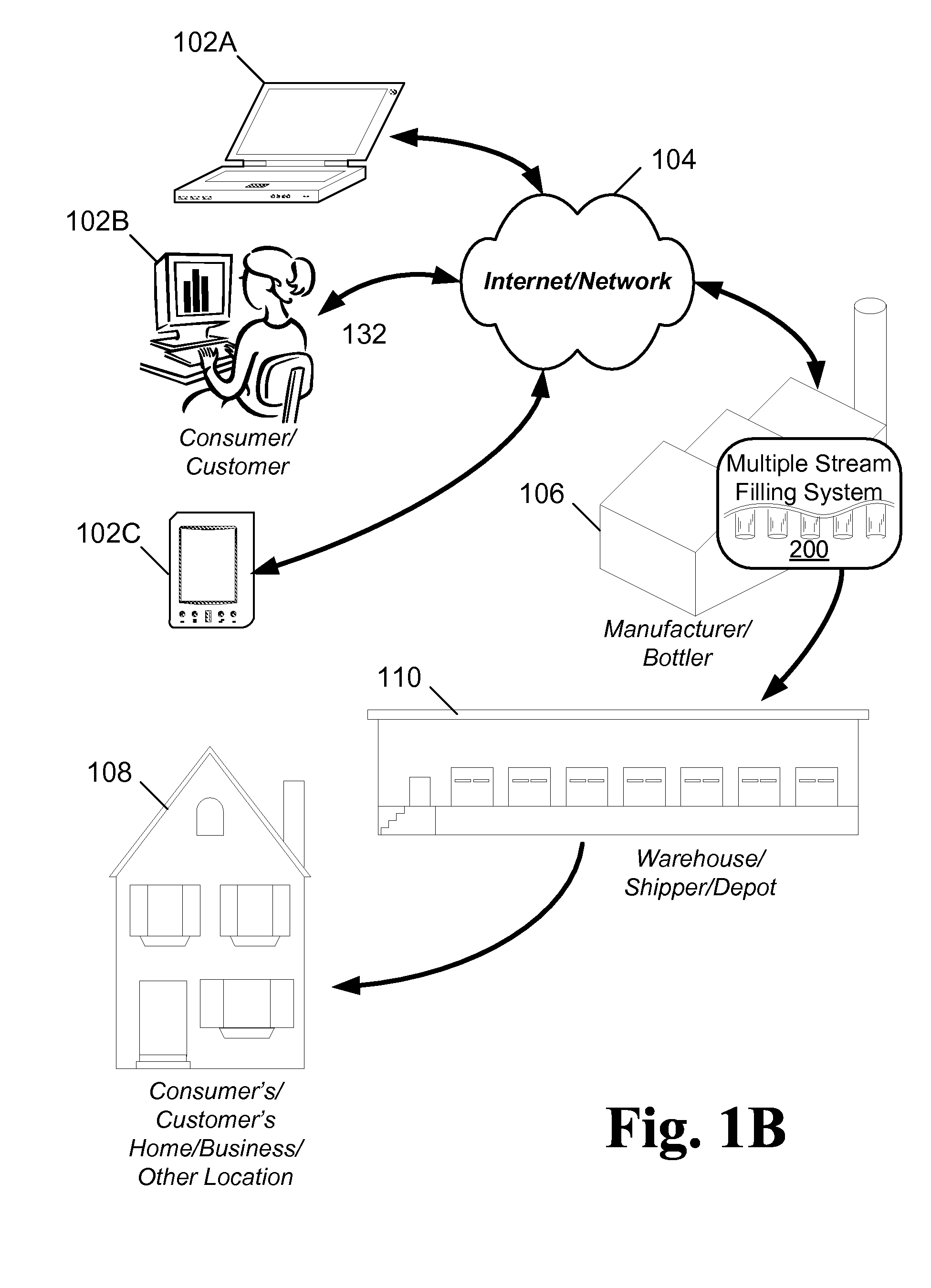

Methods of creating customized beverage products

ActiveUS20100030355A1Reduce pollutionControlling ratio of multiple fluid flowsFlow control using electric meansAdditive ingredientOrder form

A method of creating customized beverage products includes providing a multiple stream filing system suited for producing an array of beverage products. The method also includes receiving an order for a customized beverage product from the array of beverage products. The order indicates at least one characteristic of the customized beverage product. The at least one characteristic comprises one or more of the following: a beverage formulation, a beverage additive, a package size, a package shape, or label content. The method further includes instructing the multiple stream filling system to produce the customized beverage product. The multiple stream filing system produces the customized beverage product without performing an operation to reduce contamination of the customized beverage product with ingredients from a previously produced beverage product.

Owner:THE COCA-COLA CO

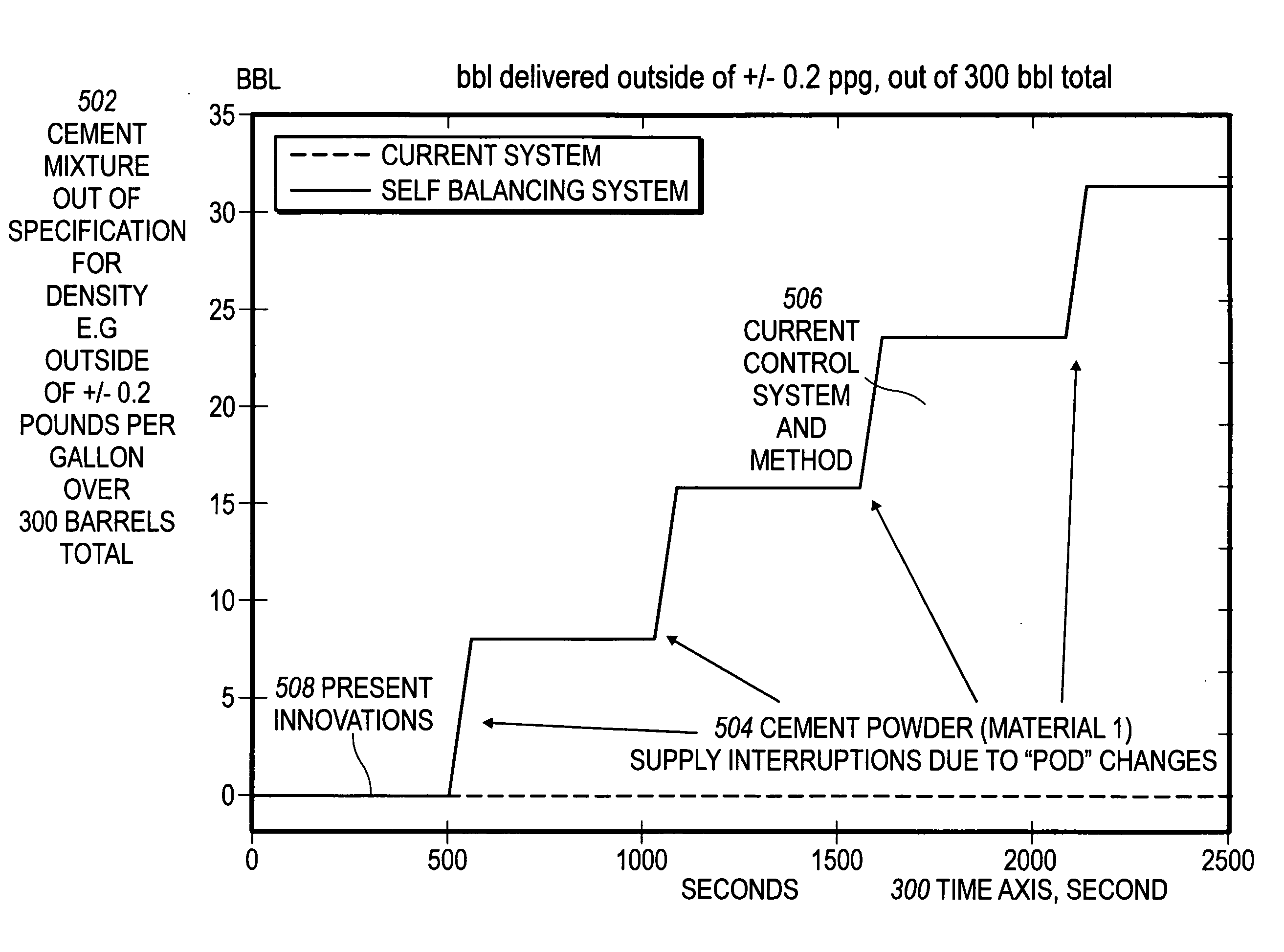

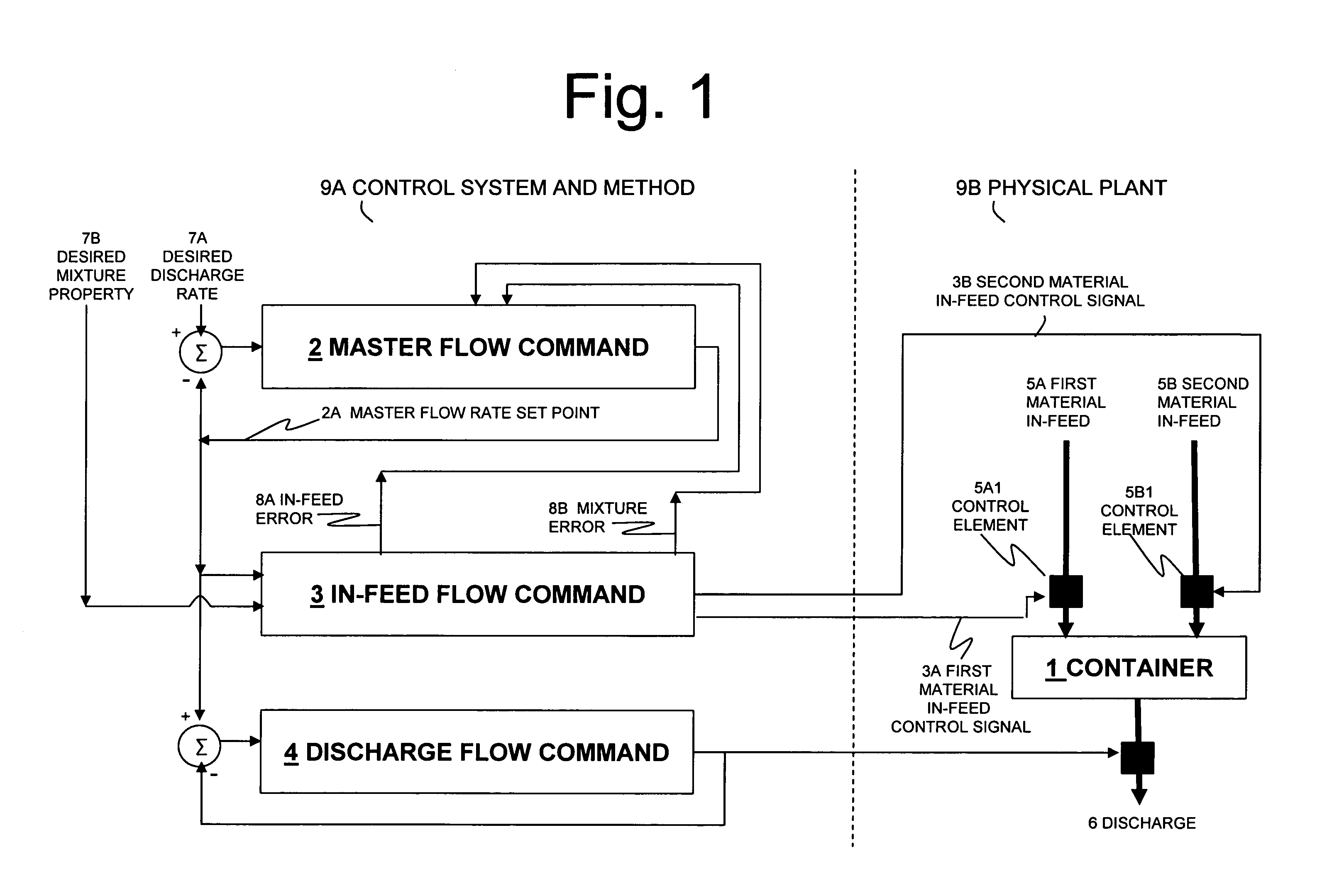

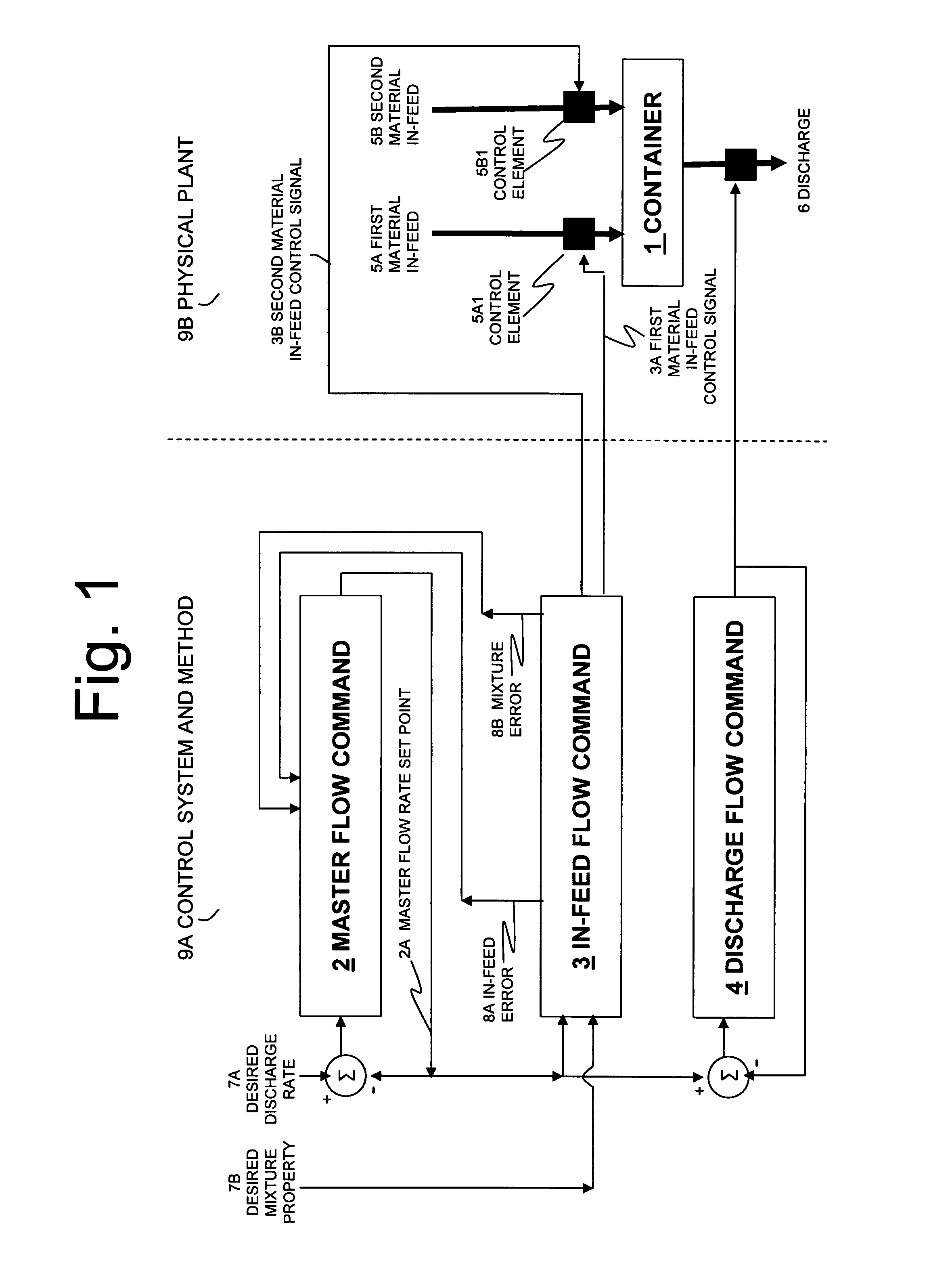

Systems for self-balancing control of mixing and pumping

ActiveUS20080165613A1Reduce needImprove consistencySampled-variable control systemsControlling ratio of multiple fluid flowsControl signalControl system

Systems for controlling the in-feed and discharge rates of materials flowing into and out of a mixing process where one priority is to achieve a target mixture flow rate from the mixing process and another priority can be to achieve a target value for a mixture property. Actuators can be operated to control material in-feed rates, the mixture composition, and discharge rate, and can maintain a hold-up of the mixture in the mixing process. A total flow rate controller provides a control signal to a controller acting on the discharge rate and a controller acting on the in-feed rates. The mixture discharge flow rate can be automatically reduced from its desired target when the commanded rate of at least one of the materials exceeds its available supply rate as inferred from an inability to maintain the targeted value for the mixture property.

Owner:HALLIBURTON ENERGY SERVICES INC

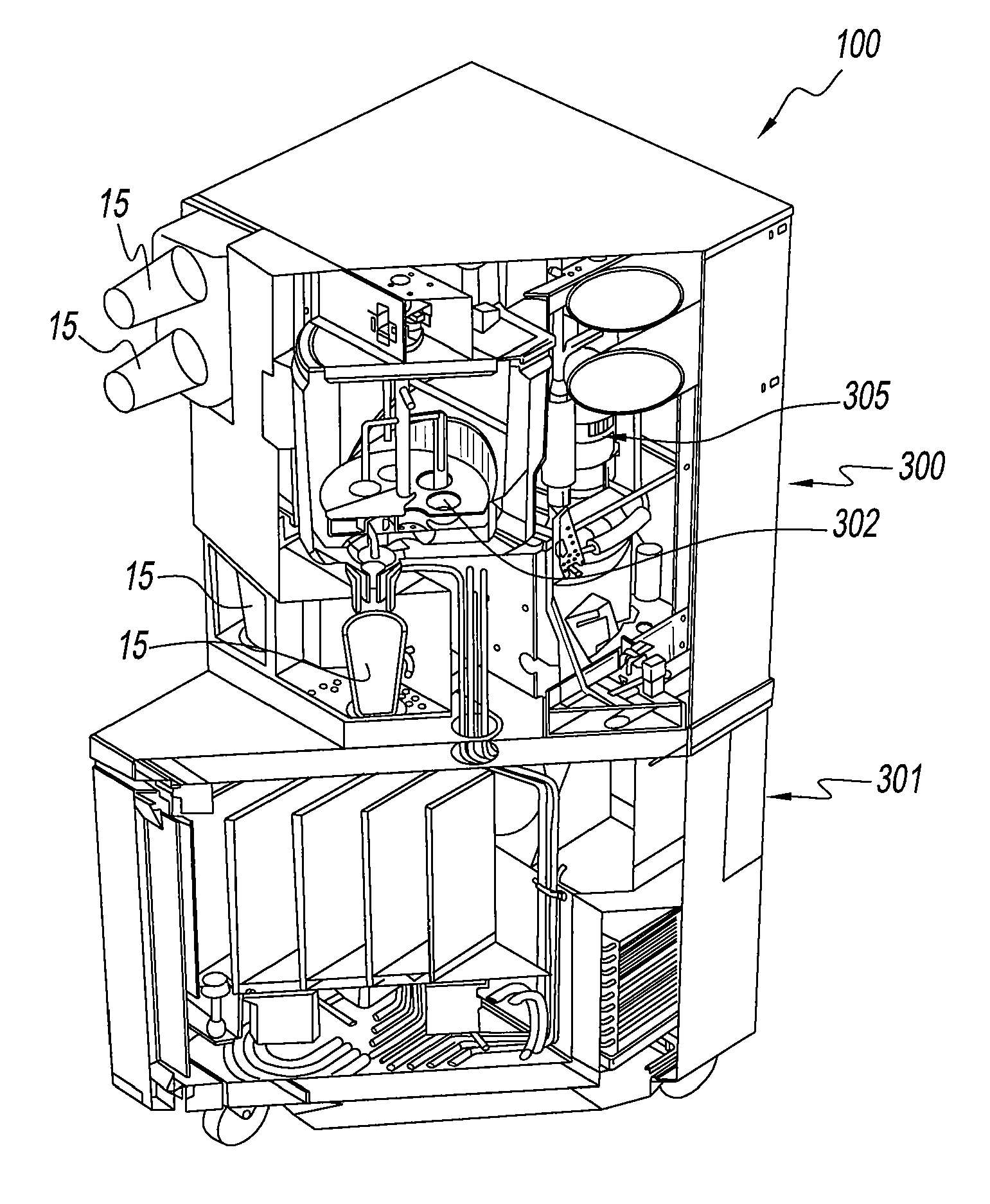

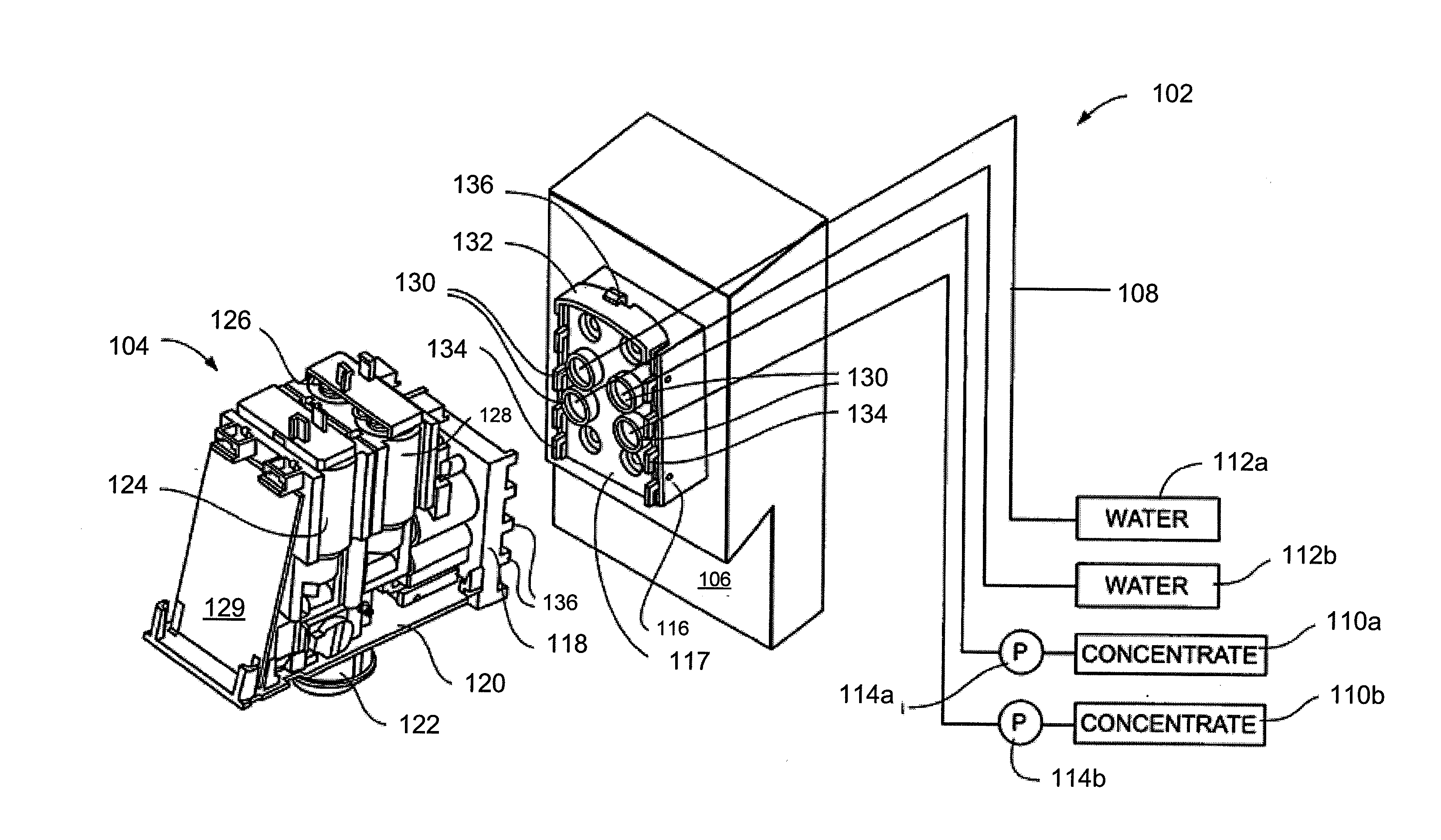

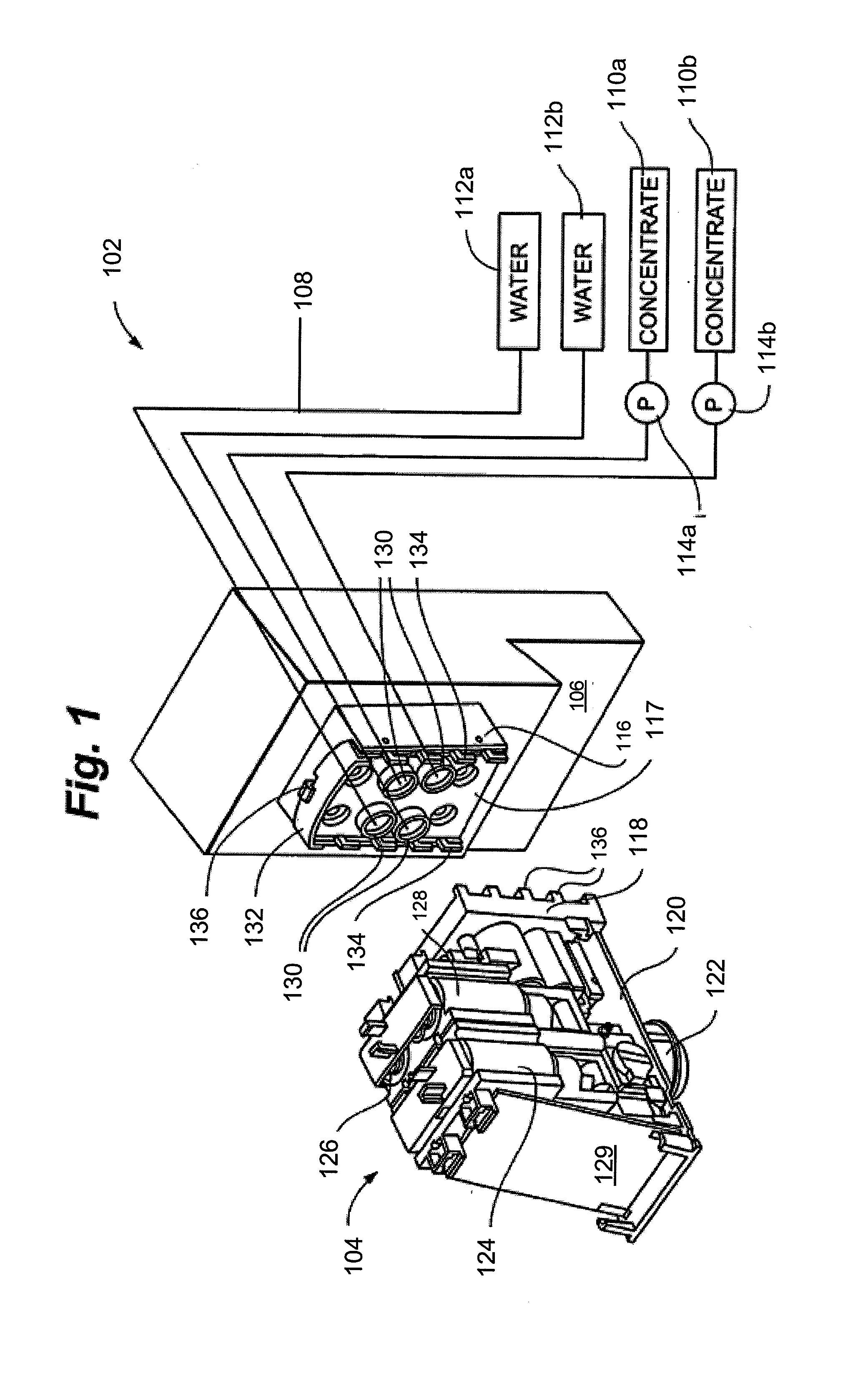

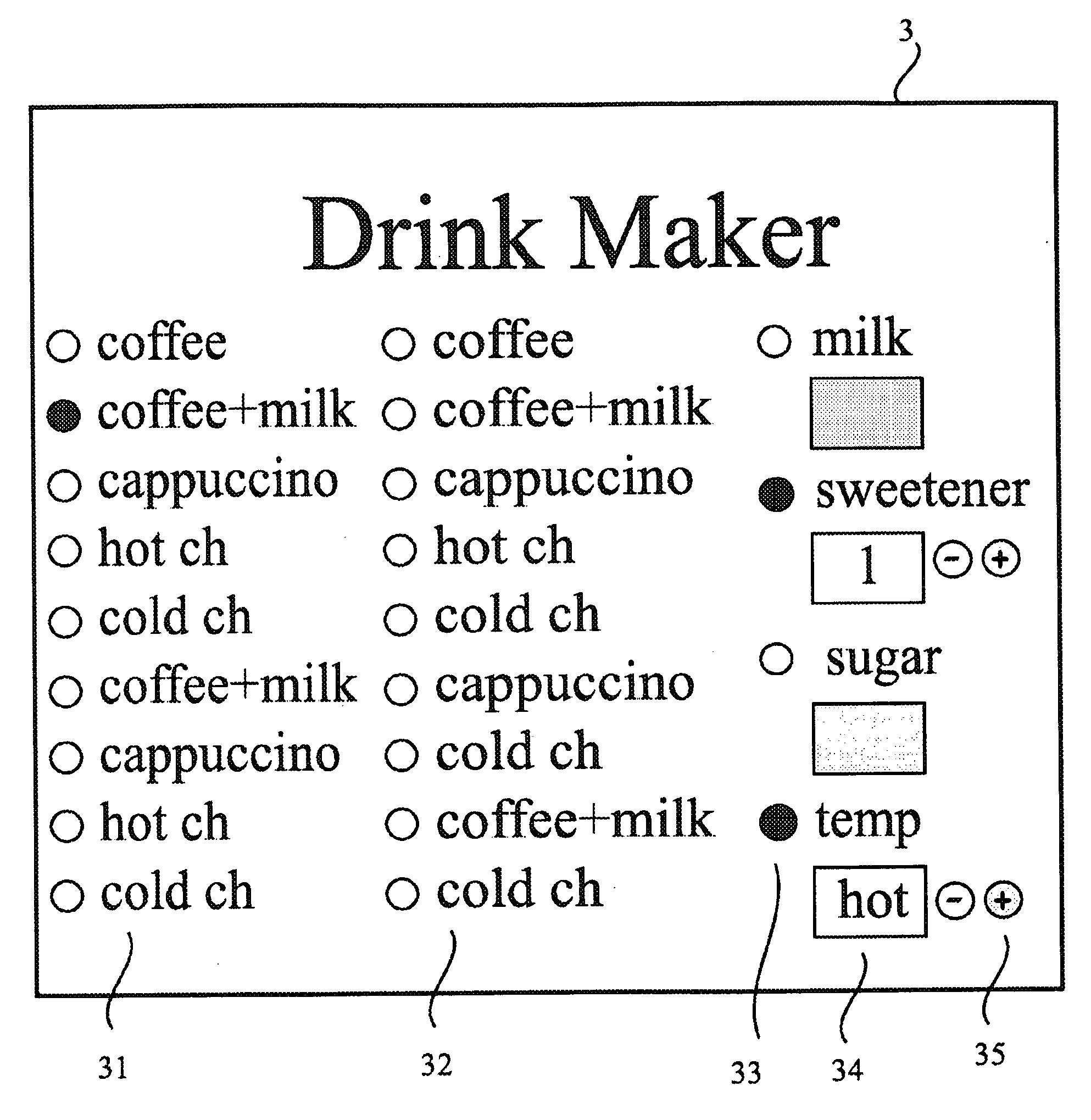

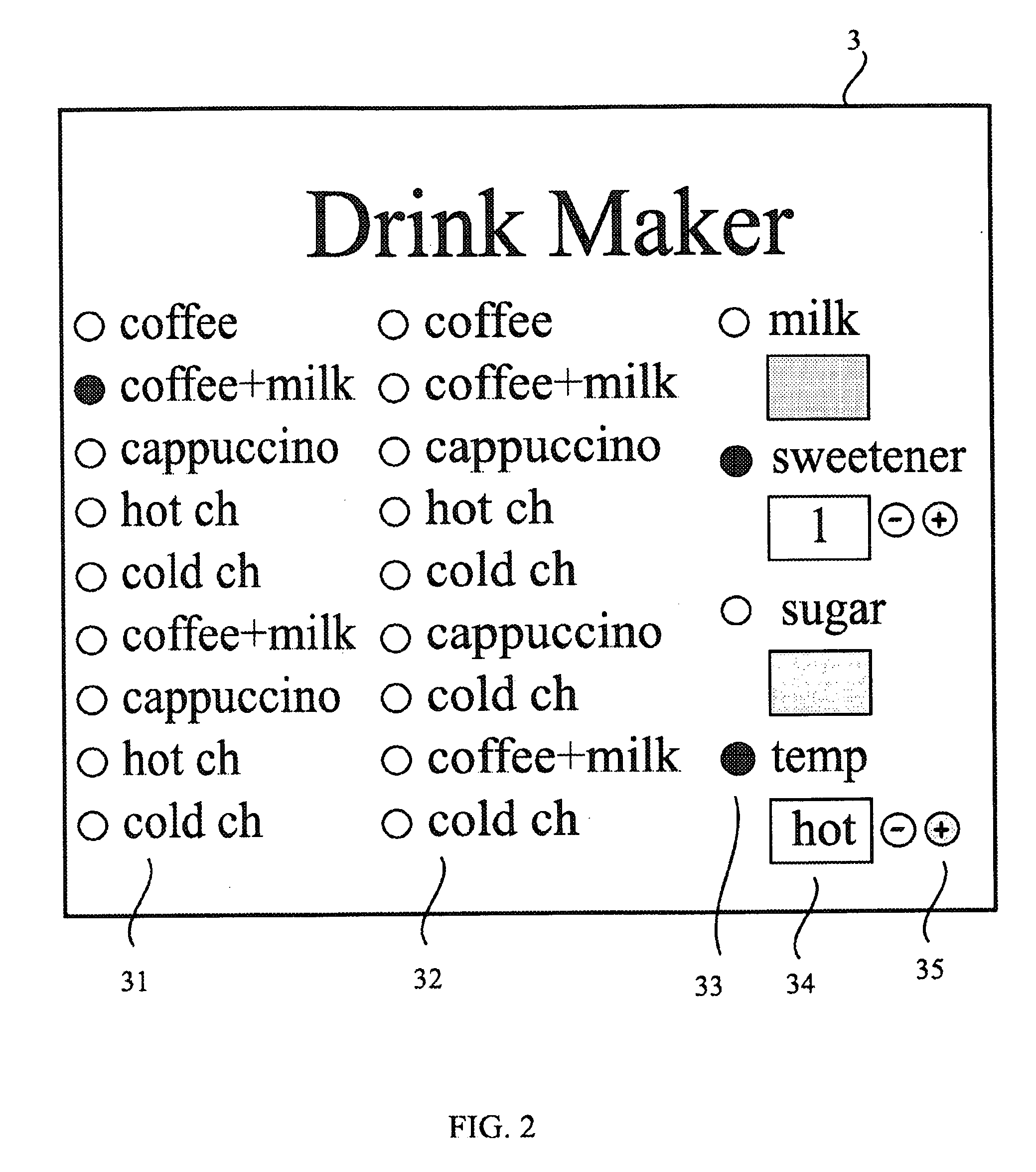

Device and method of creating a beverage recipe for an integrated system for dispensing and blending/mixing beverage ingredients

ActiveUS20100145522A1Sampled-variable control systemsControlling ratio of multiple fluid flowsHybrid systemAdditive ingredient

A method and device for creating a beverage recipe for an integrated beverage blending system includes a dispenser and at least one blending / mixing / cleaning module. The method creates the beverage recipe with recipe program running on a computer interactively with a user making recipe entry parameters for the dispensing, blending and mixing operations. The recipe can be stored on a portable memory and inserted into a user interface controller of the integrated system or into an associated point of sale device.

Owner:ENODIS

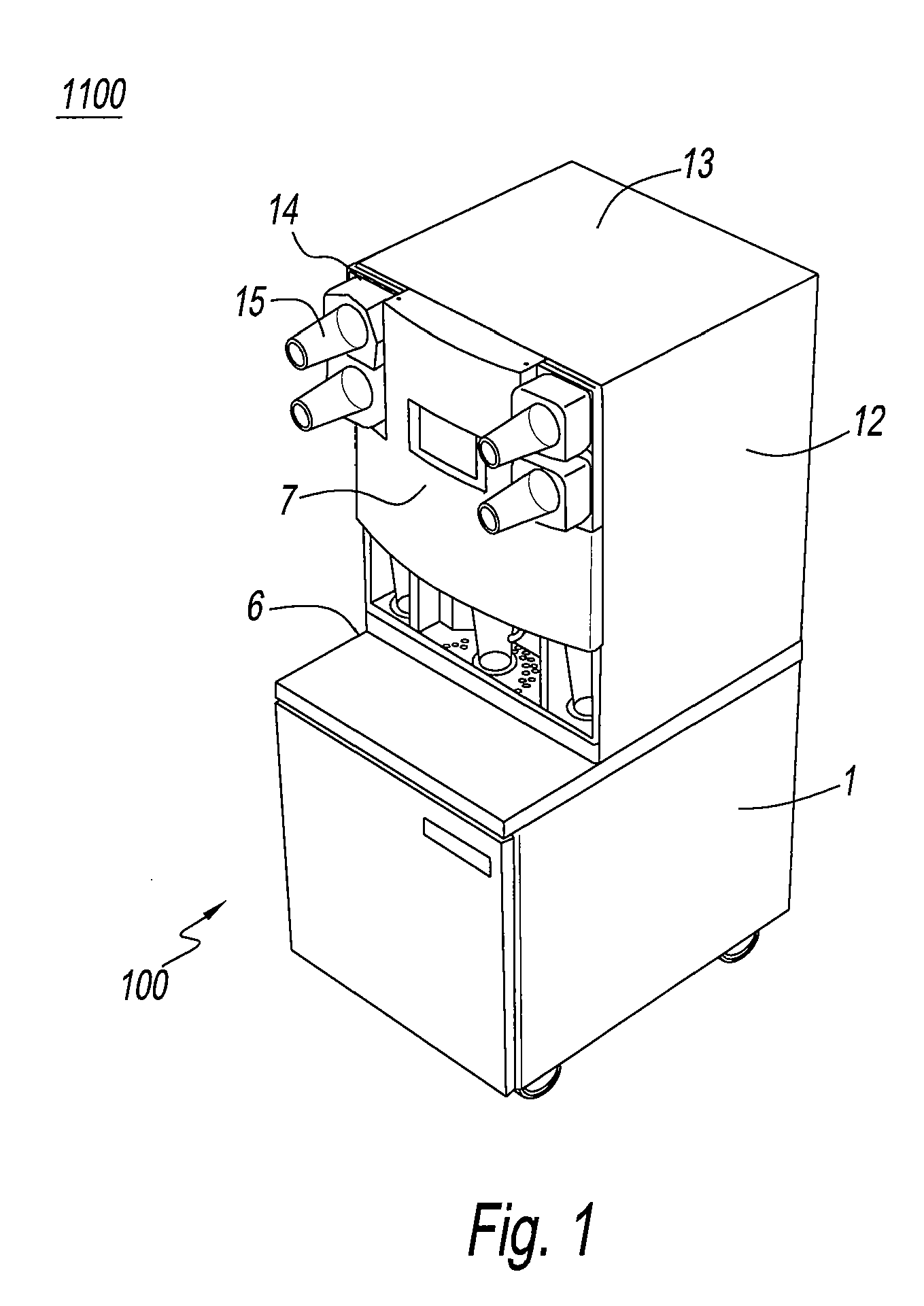

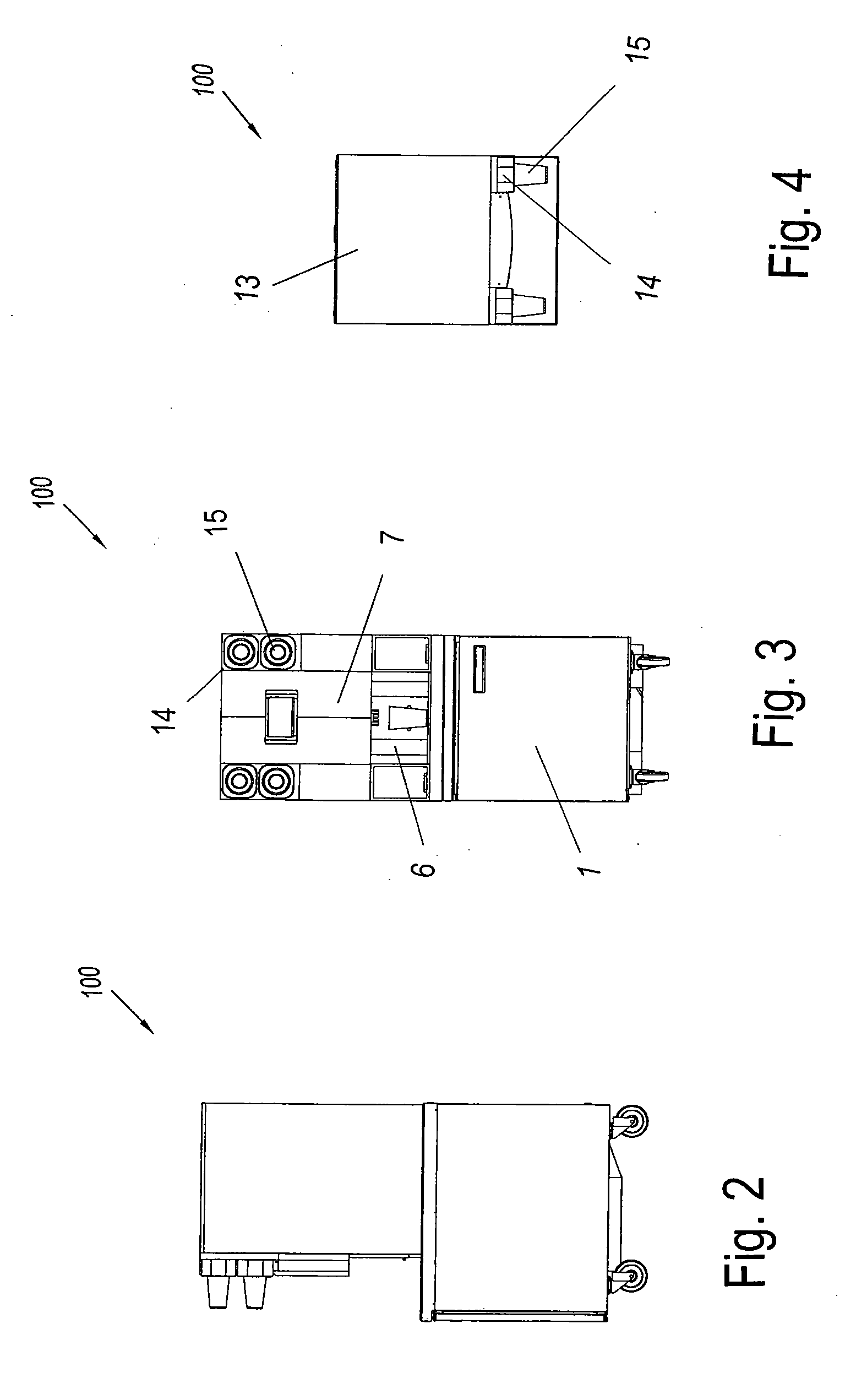

Beverage dispensing device

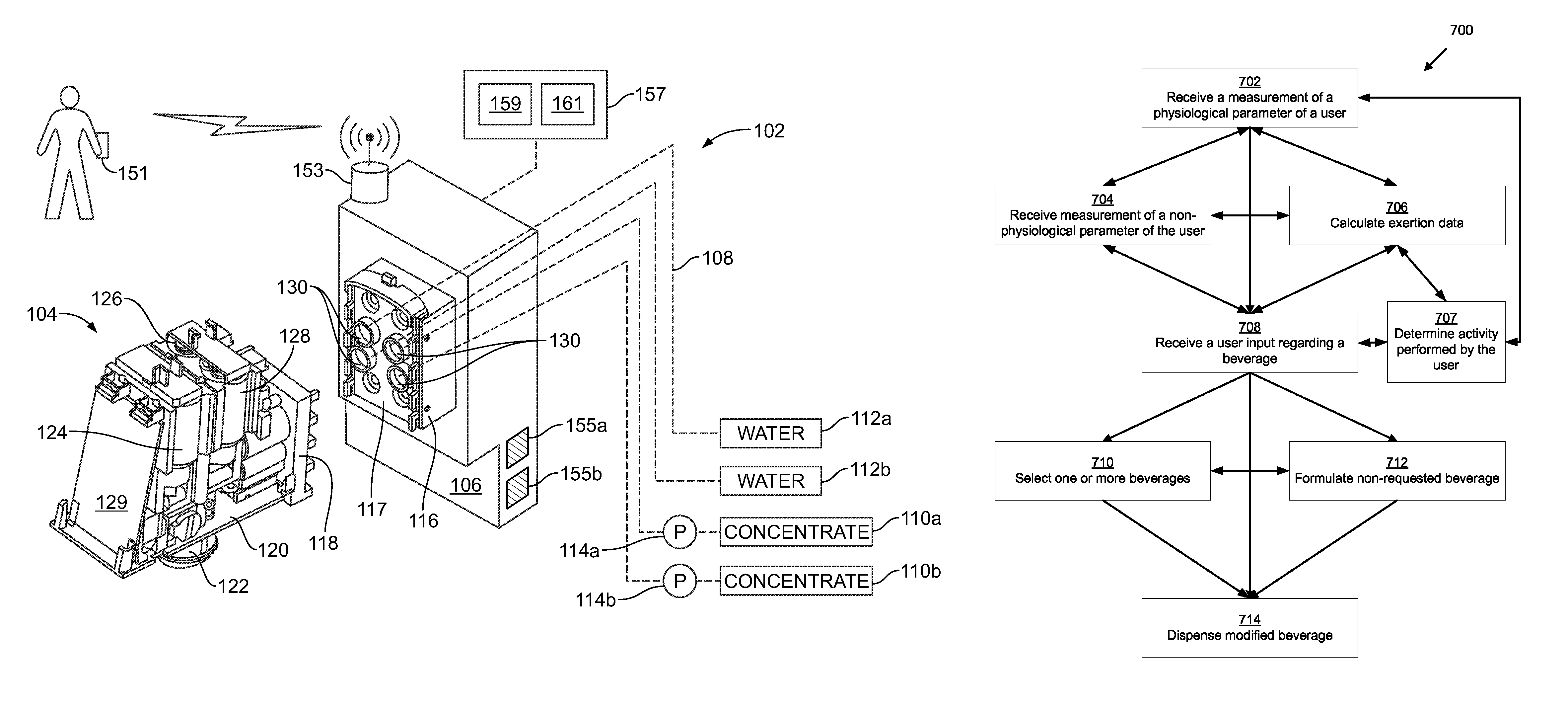

ActiveUS20110121032A1Accurate assessmentLow costLighting and heating apparatusFlow controlEngineeringExertion

Novel systems and methods for dispensing compositions, such as beverages, are provided. Novel beverage dispensers may be configured to receive one or more physiological parameters regarding a user, and in response, formulate at least one beverage recipe for dispensing. A beverage dispenser may wirelessly receive data from a biosensor. In certain embodiments, data from the biosensor may be used to alter the recipe to another existing beverage or a custom beverage. Non-physiological data may also be considered. In one embodiment, environmental and / or biographical data may be utilized. In another embodiment, exertion data may be calculated. The calculation of exertion data may receive inputs regarding at least one physiological parameter and / or non-physiological parameters to derive a second physiological parameter not being measured. Novel systems and methods may reduce costs associated with extra sensors and / or allow more accurate assessment of the user's exertion level.

Owner:PEPSICO INC

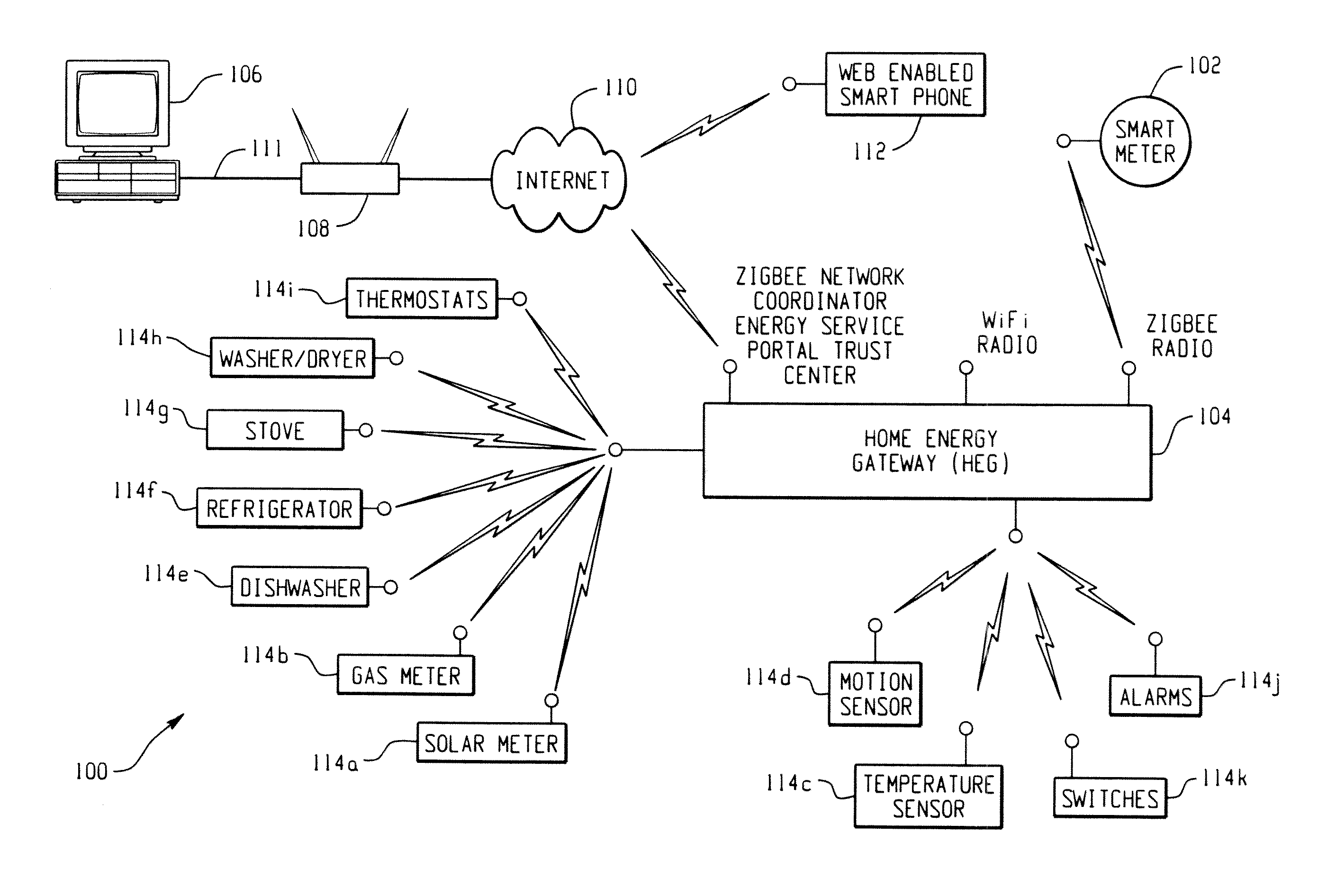

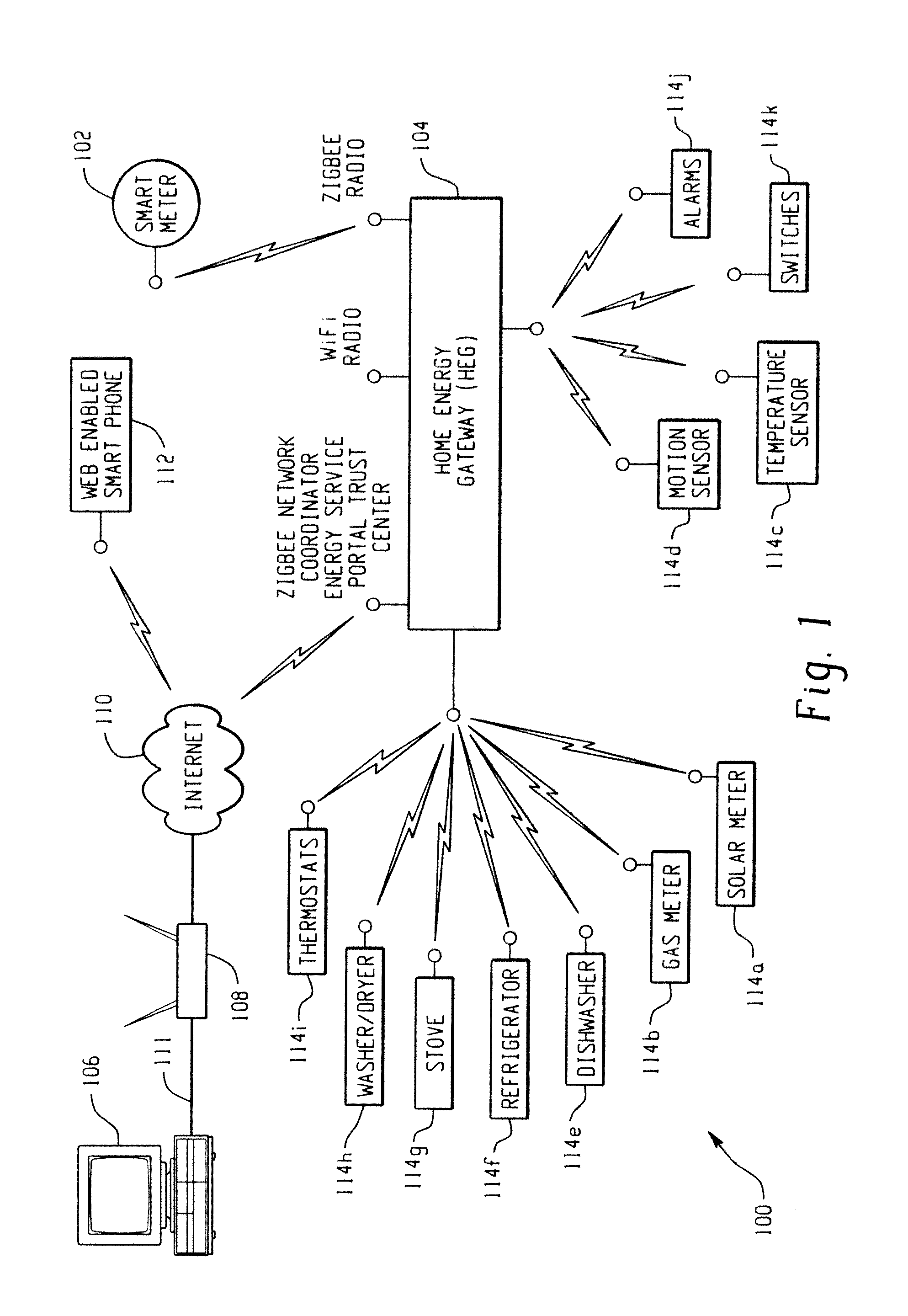

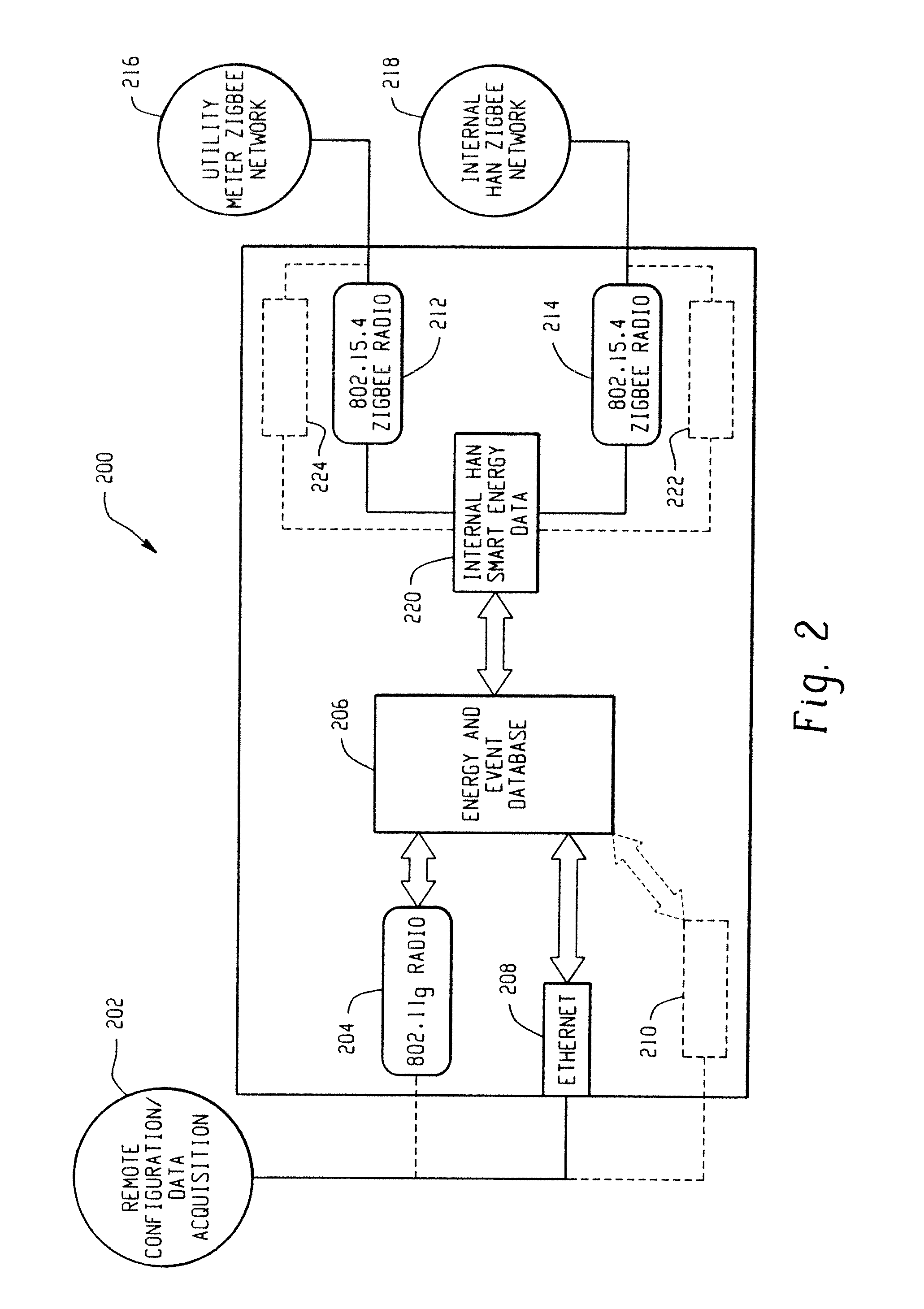

Low cost and flexible energy management system and method for transmitting messages among a plurality of communication networks

A system and method of operating an energy data management and control system has a first communication network to transmit and receive data to and from a user interface, a second communication network to transmit and receive data to and from a Utility company, and a third communication network to access data from and provide data to accessories within a home. The system reformats the data from any of the first, second and third communication networks for communication with another of the first, second and third communication networks, wherein at least one of the communication networks operate on a protocol different from another one of the communications networks. The data defines various operations of the system.

Owner:HAIER US APPLIANCE SOLUTIONS INC

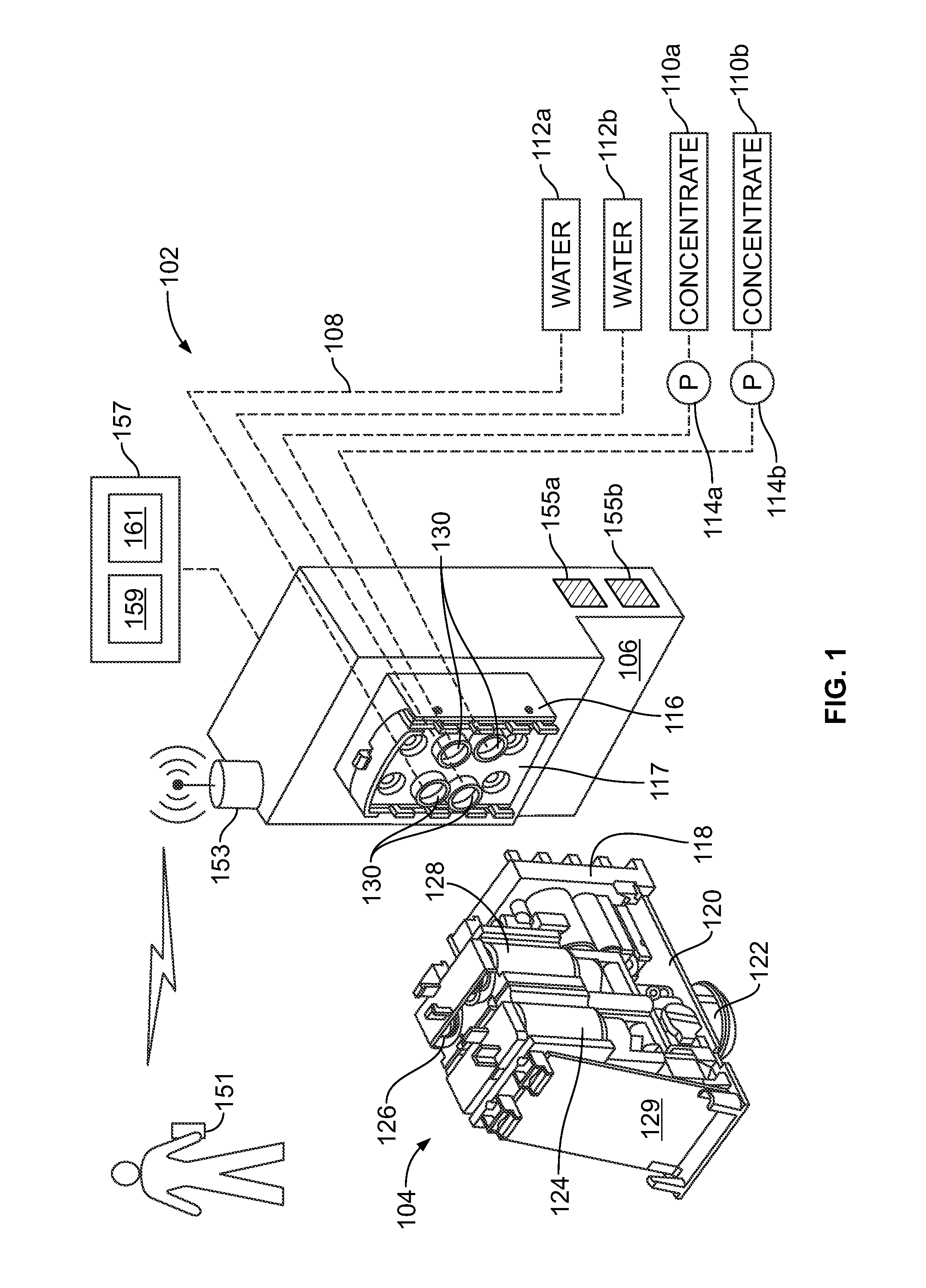

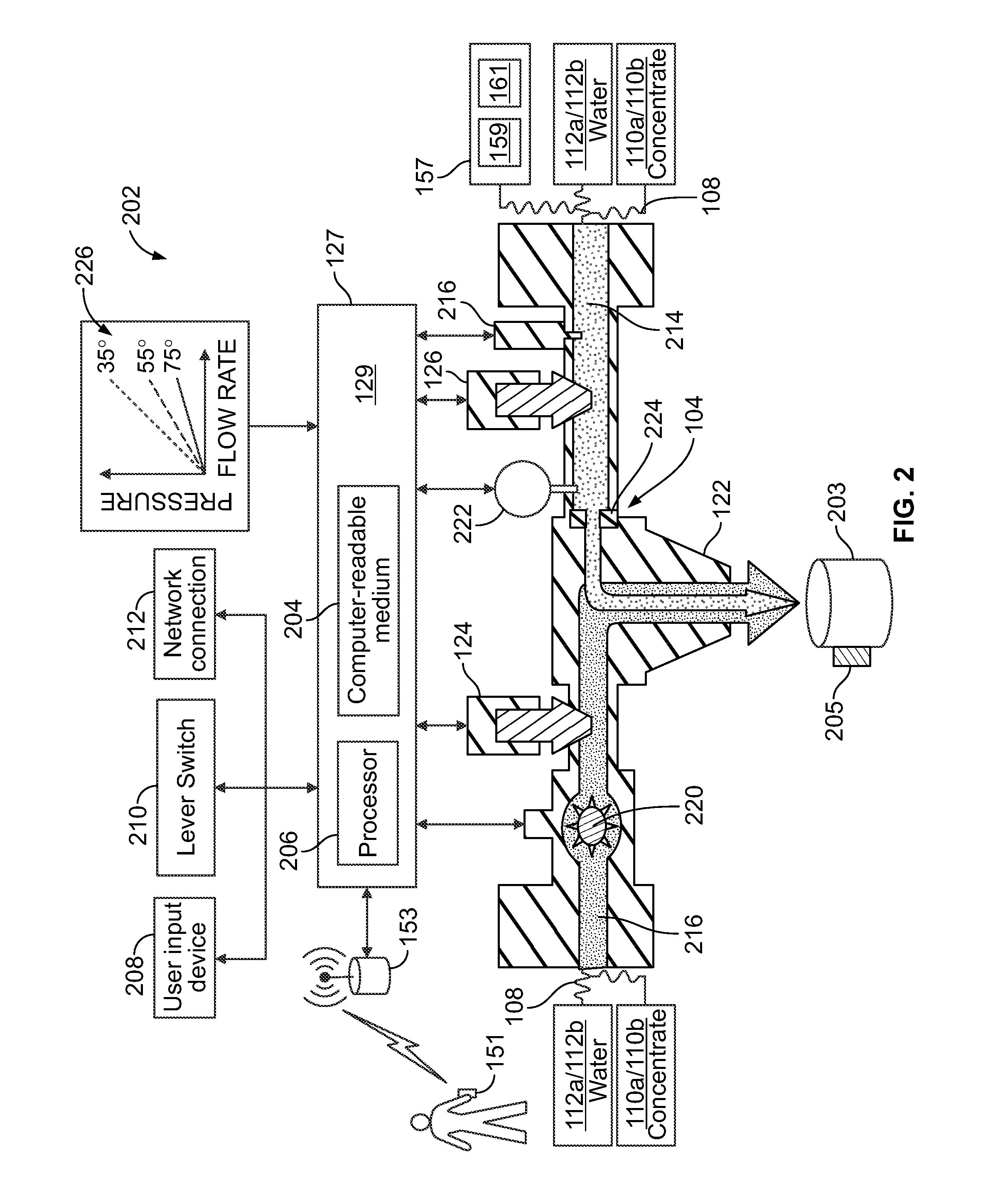

Personalized beverage dispensing device

ActiveUS8490829B2Accurate assessmentLow costLighting and heating apparatusFlow controlPersonalizationExertion

Owner:PEPSICO INC

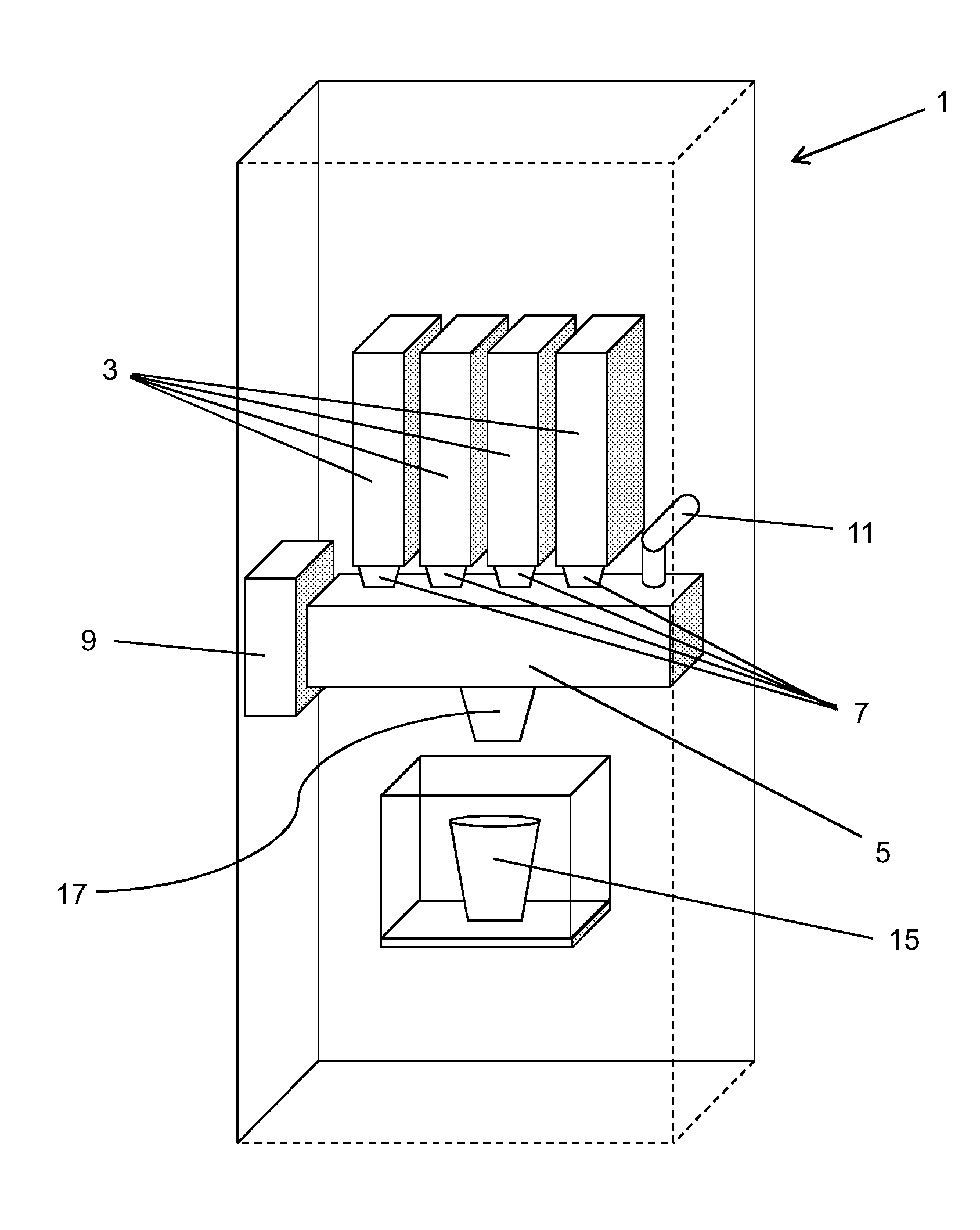

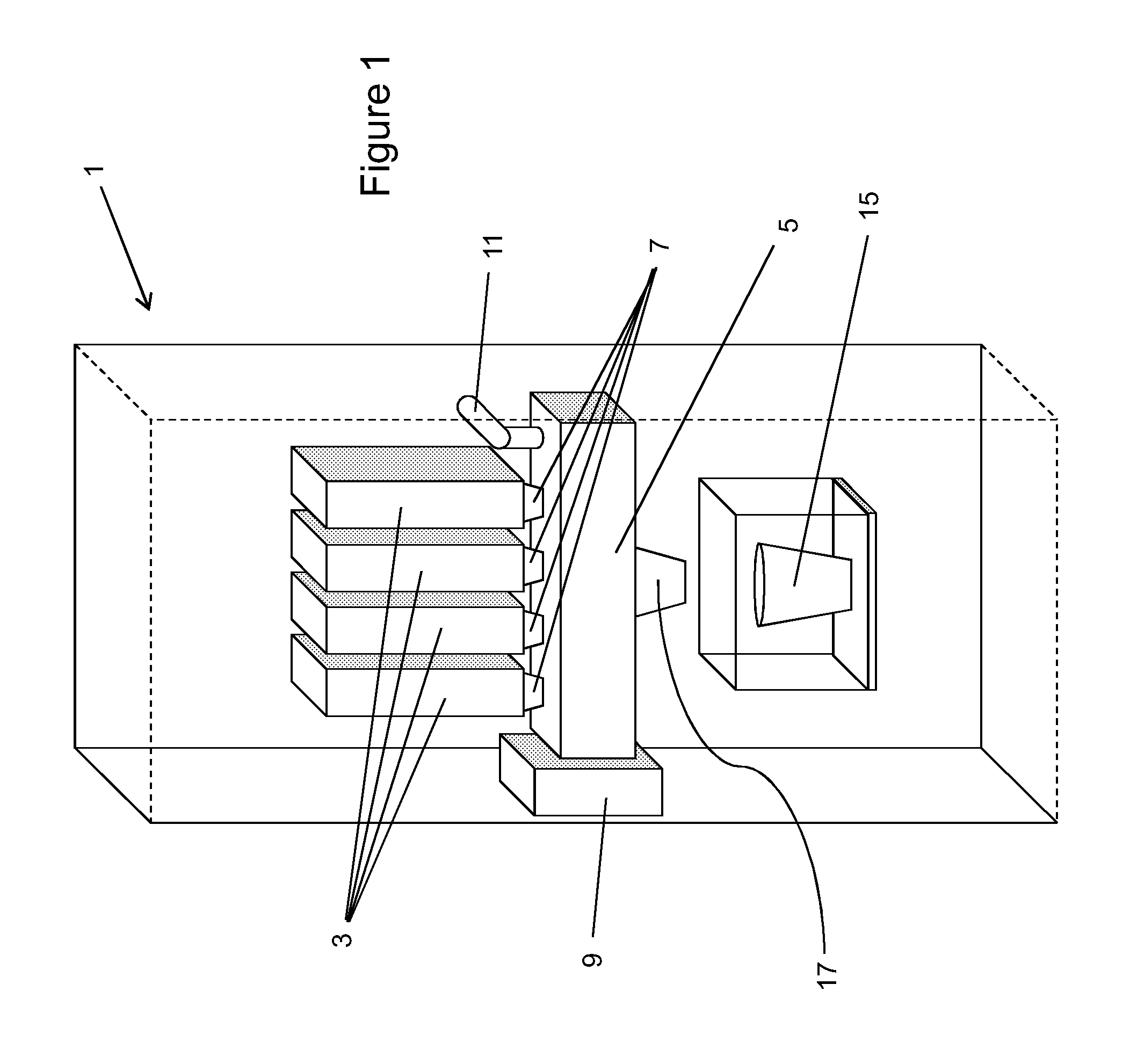

Nutritional product dispenser

InactiveUS20110052764A1Reduces and removes for to clogReduce consumptionControlling ratio of multiple fluid flowsBeverage vesselsUser inputControl system

An apparatus for dispensing nutritional products including a number of storage hoppers for powdered ingredients, a controllable outlet connected to each storage hopper and operable to release controlled amounts of the powdered ingredients, a controllable liquid supply, a mixer, and a control system including a user interface for capturing data from a user. The control system uses the data that the user inputs to determine the quantity of each powdered ingredient and the quantity of liquid to be released to create a nutritional product, and sends signals to the liquid supply and the outlets to release the determined quantity of liquid and each powdered ingredient into the mixer to be mixed before being dispensed into a container.

Owner:BIOSAUCE HLDG

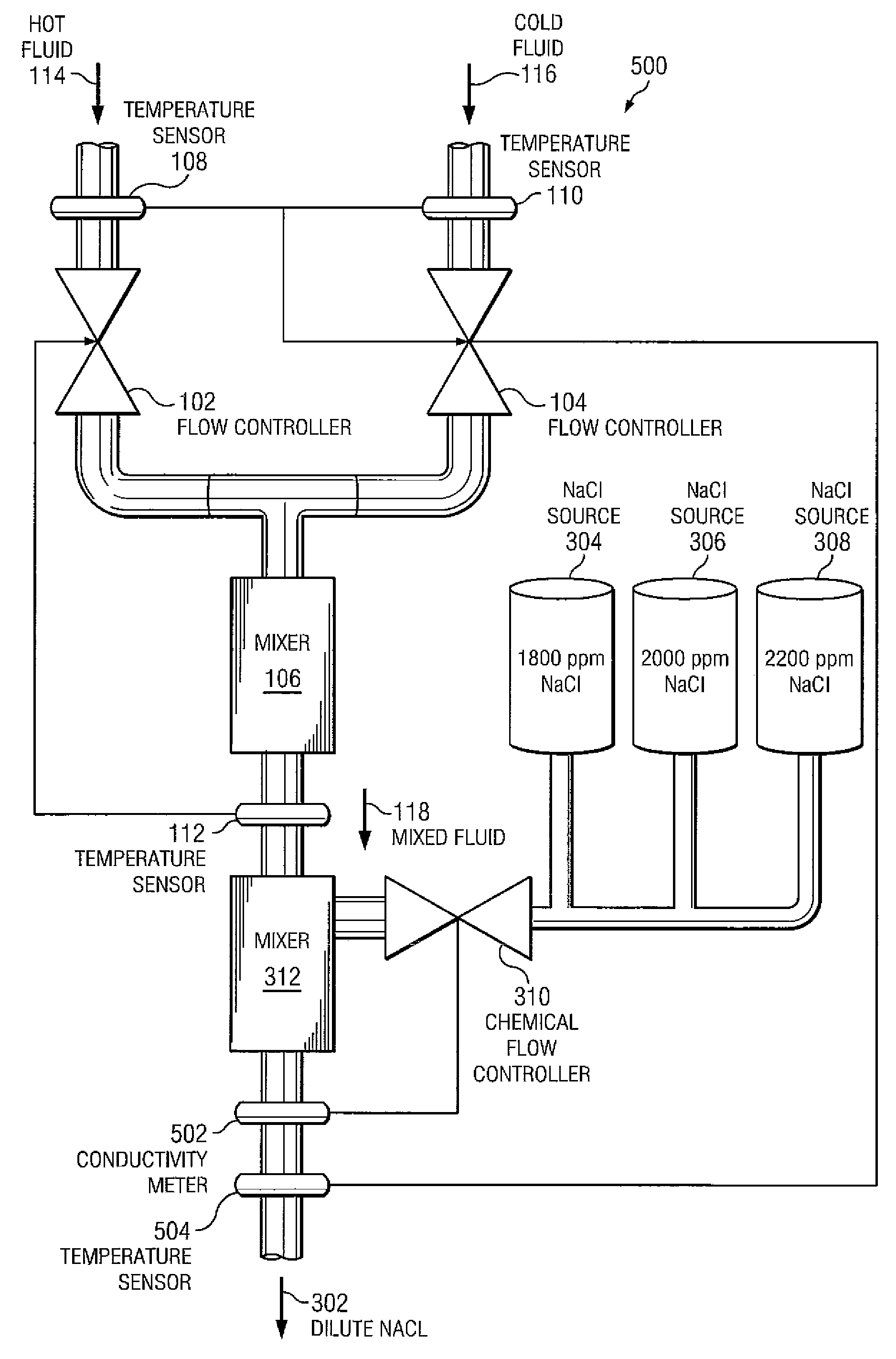

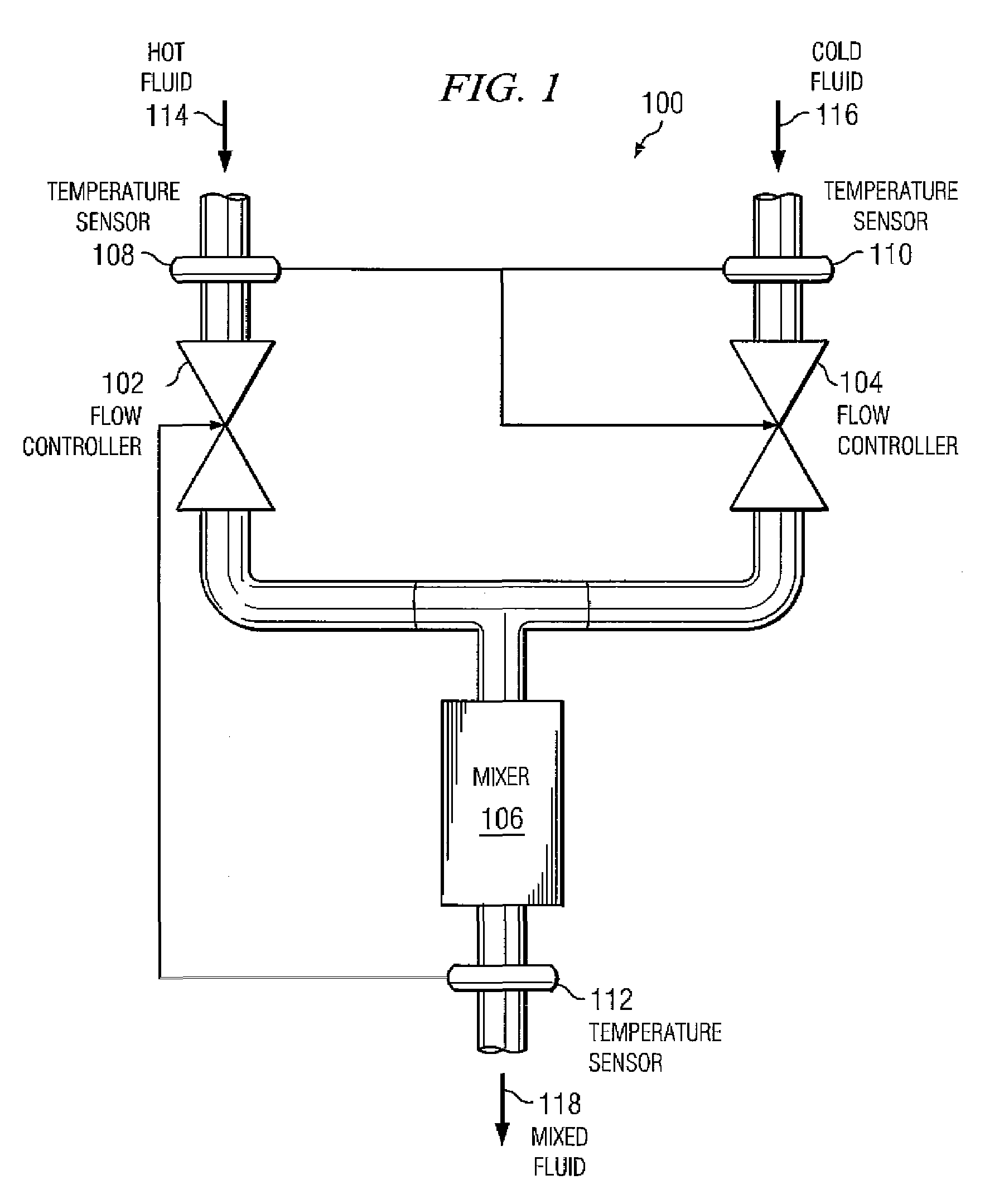

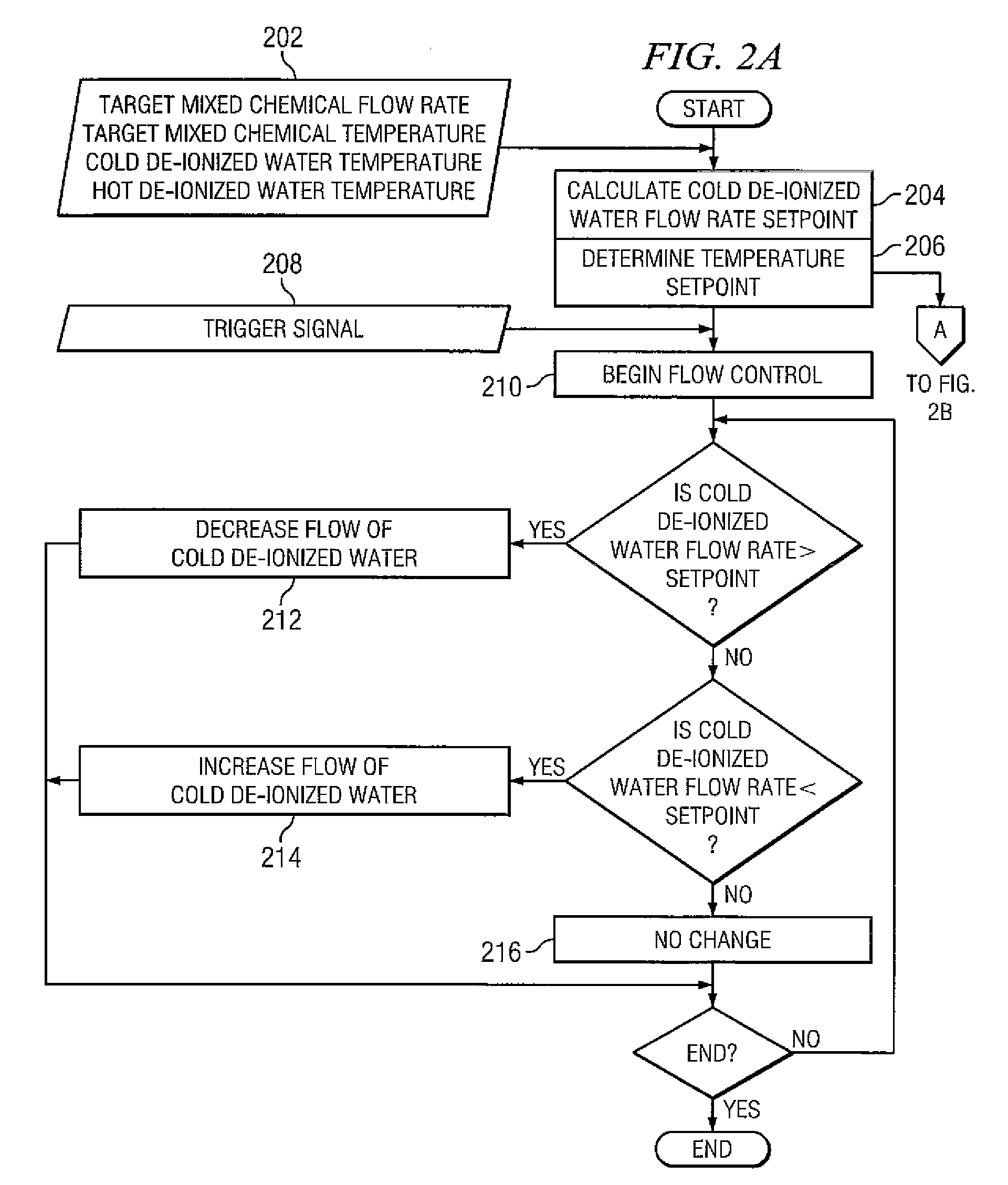

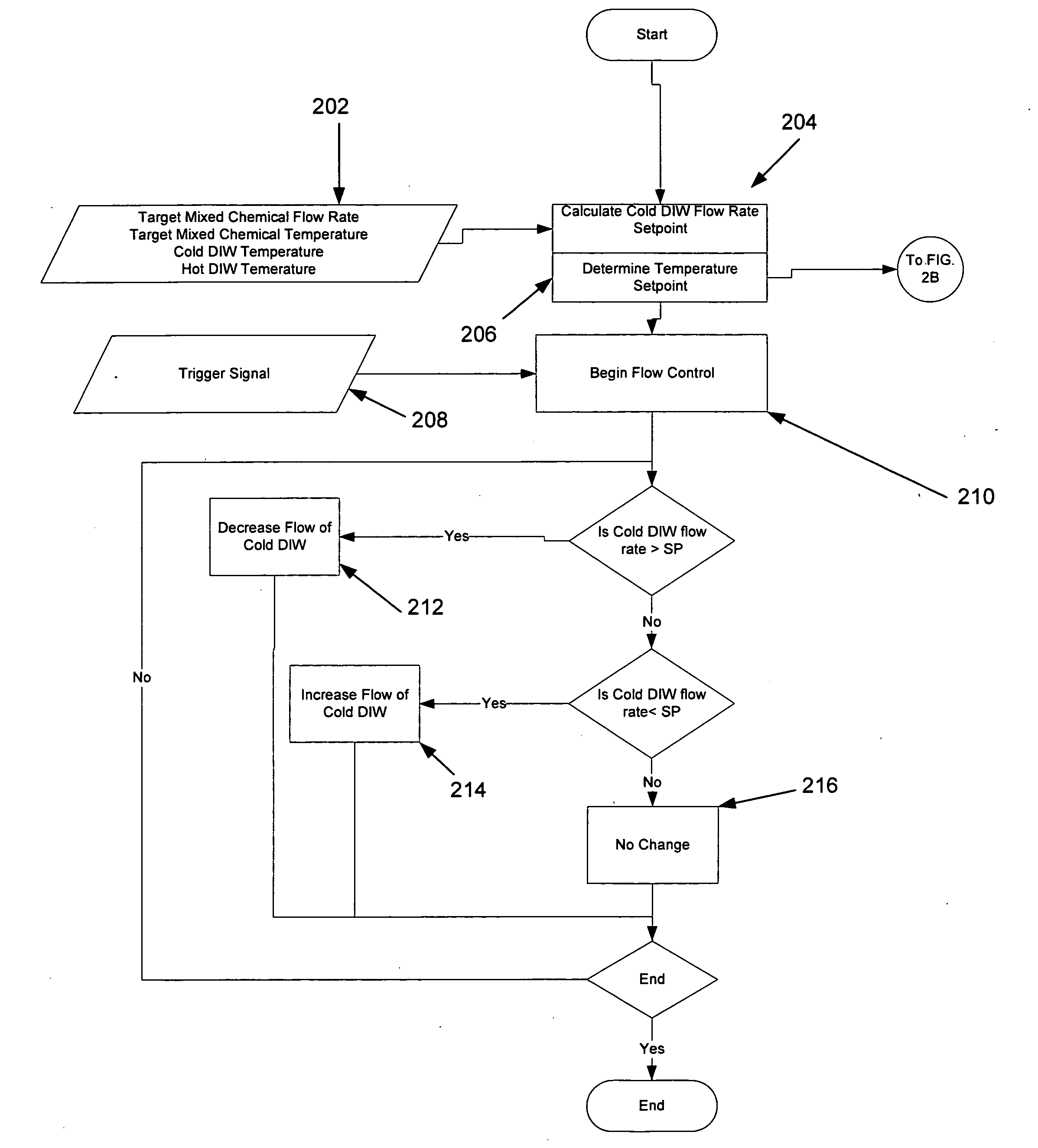

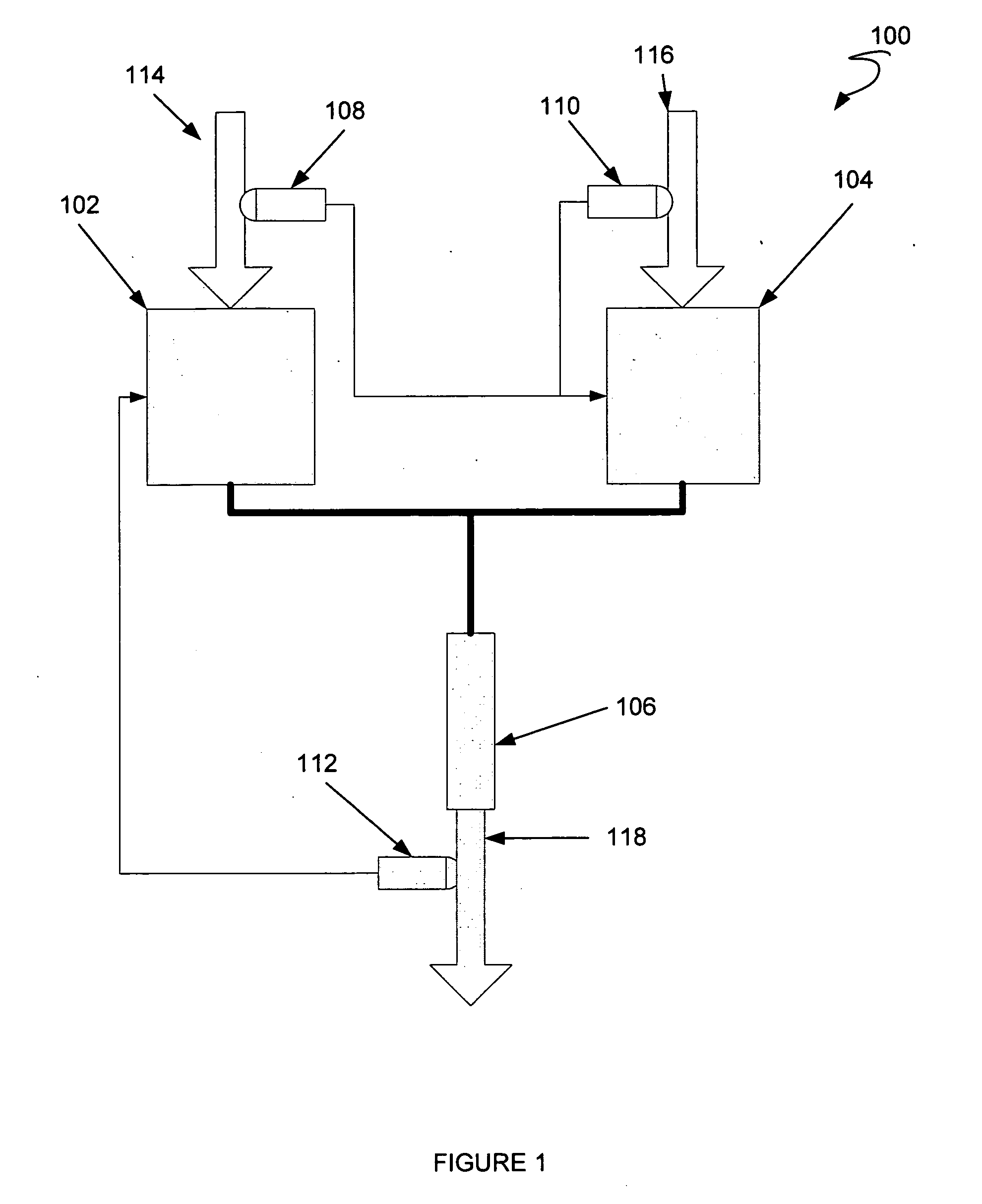

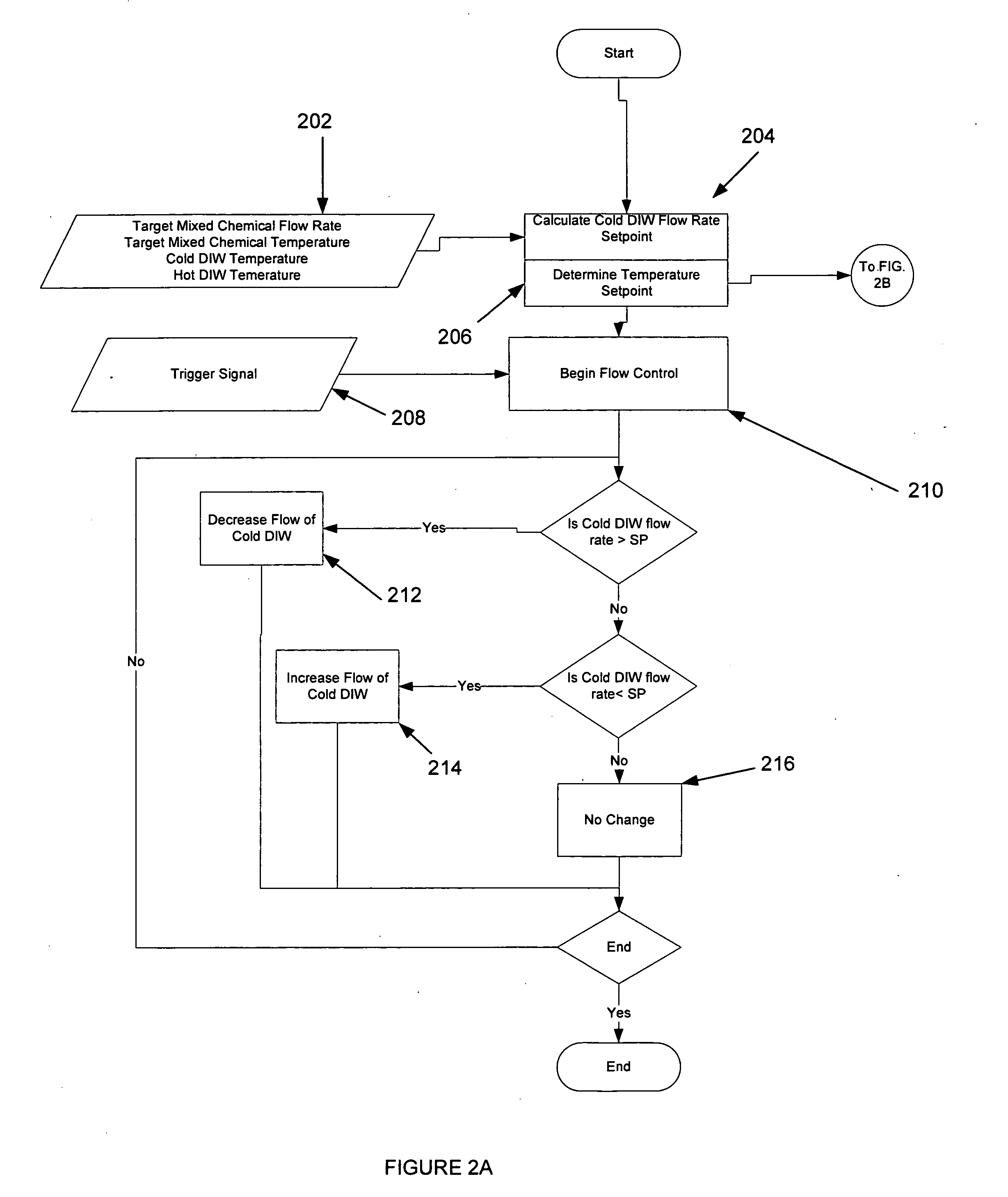

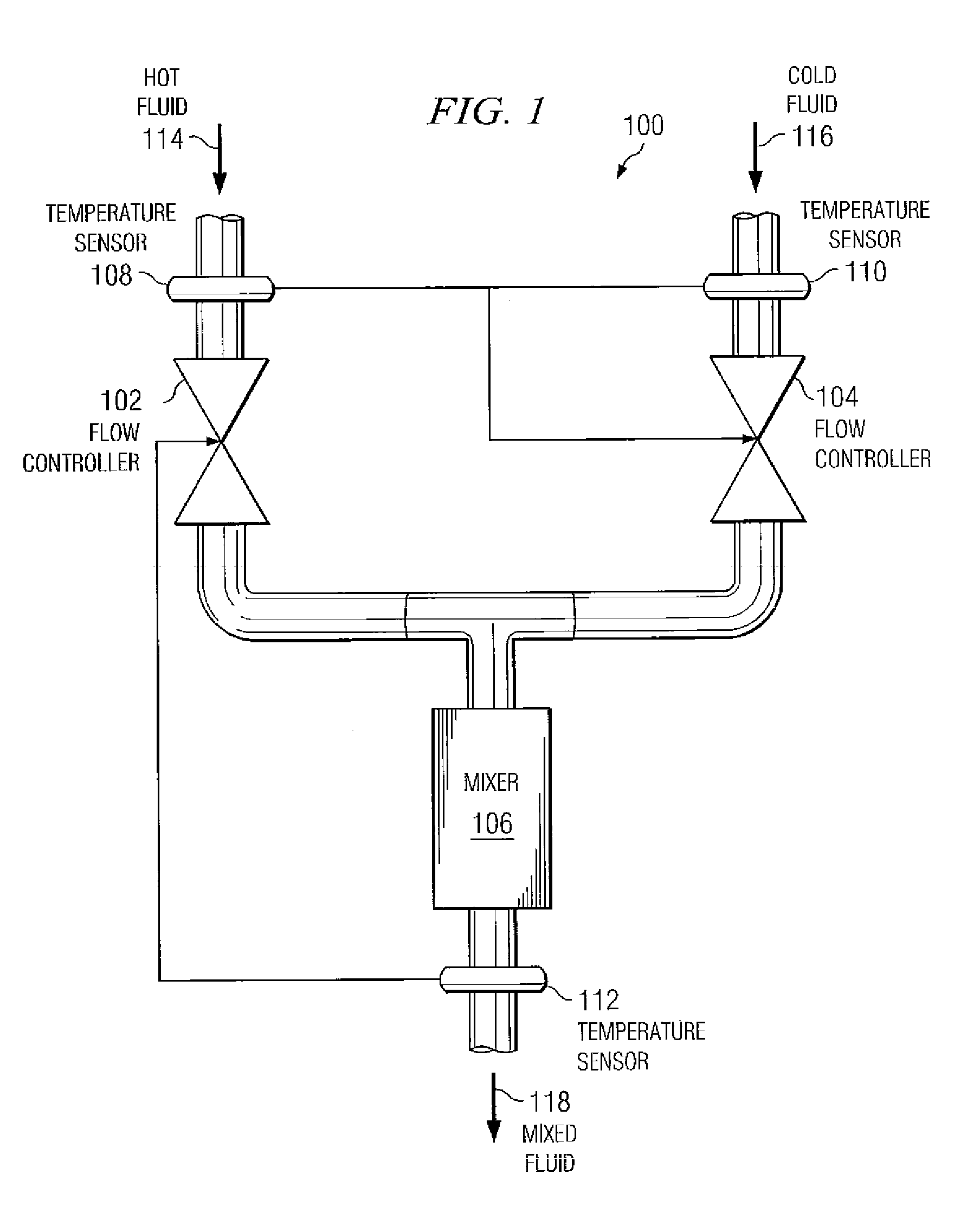

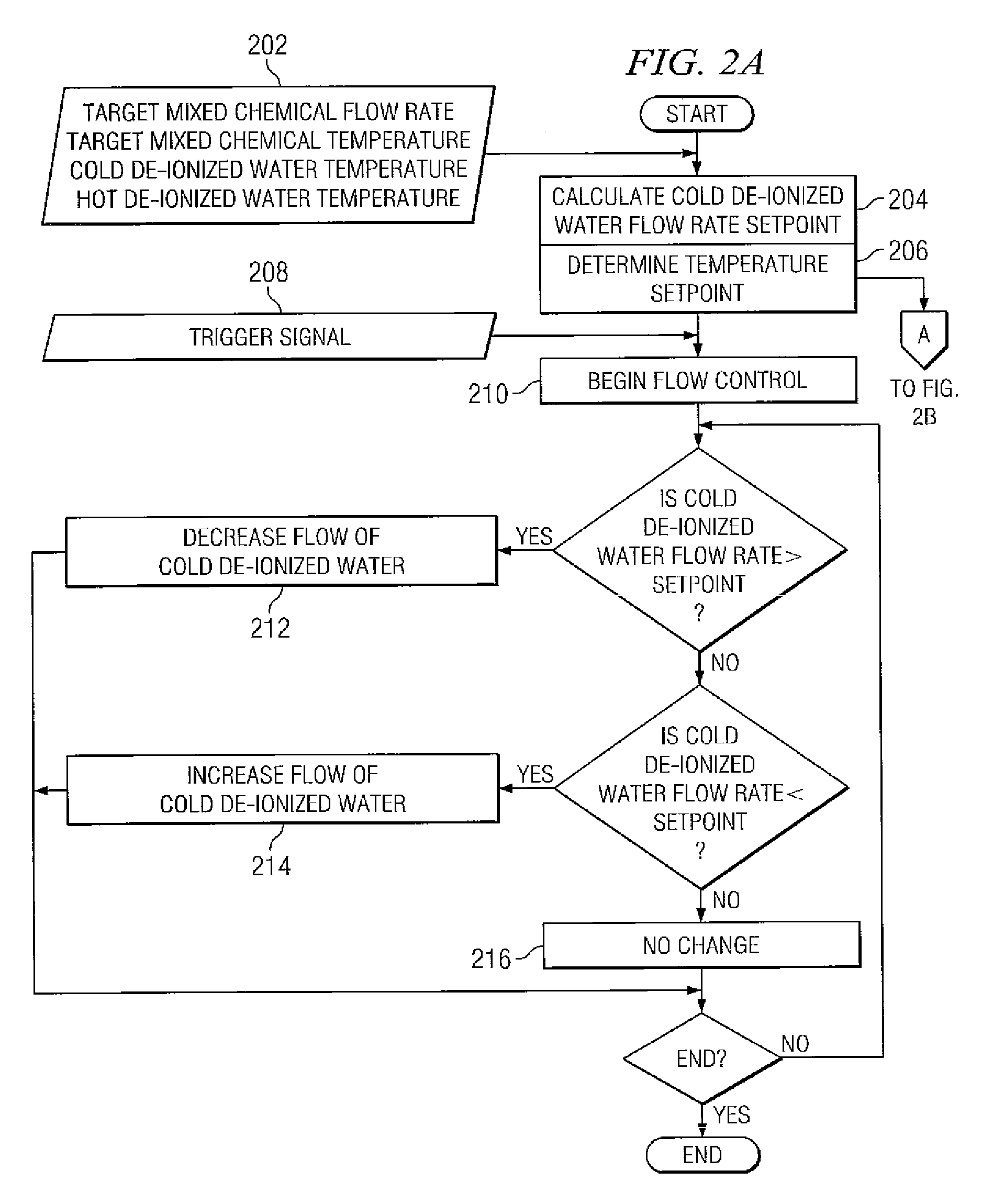

System and method for controlled mixing of fluids via temperature

InactiveUS7494265B2Easy to adjustSimple processControlling ratio of multiple fluid flowsTemperatue controlTemperature controlWater flow

Embodiments of the present invention provide a system and method for continuous flow production of mixed fluids. The mixed fluids can comprise a mixture of different fluids or a mixture of the same fluid having different input properties such as temperature. In general, two streams of fluid of varying temperature are supplied to a mixer. The flow rate of each of the input fluids can be regulated to produce a mixed fluid at a desired flow rate and temperature. As an example, mass flow controllers can regulate the flow rates of a hot and cold stream of de-ionized water to produce a stream of de-ionized water at a desired flow rate and temperature.

Owner:ENTEGRIS INC

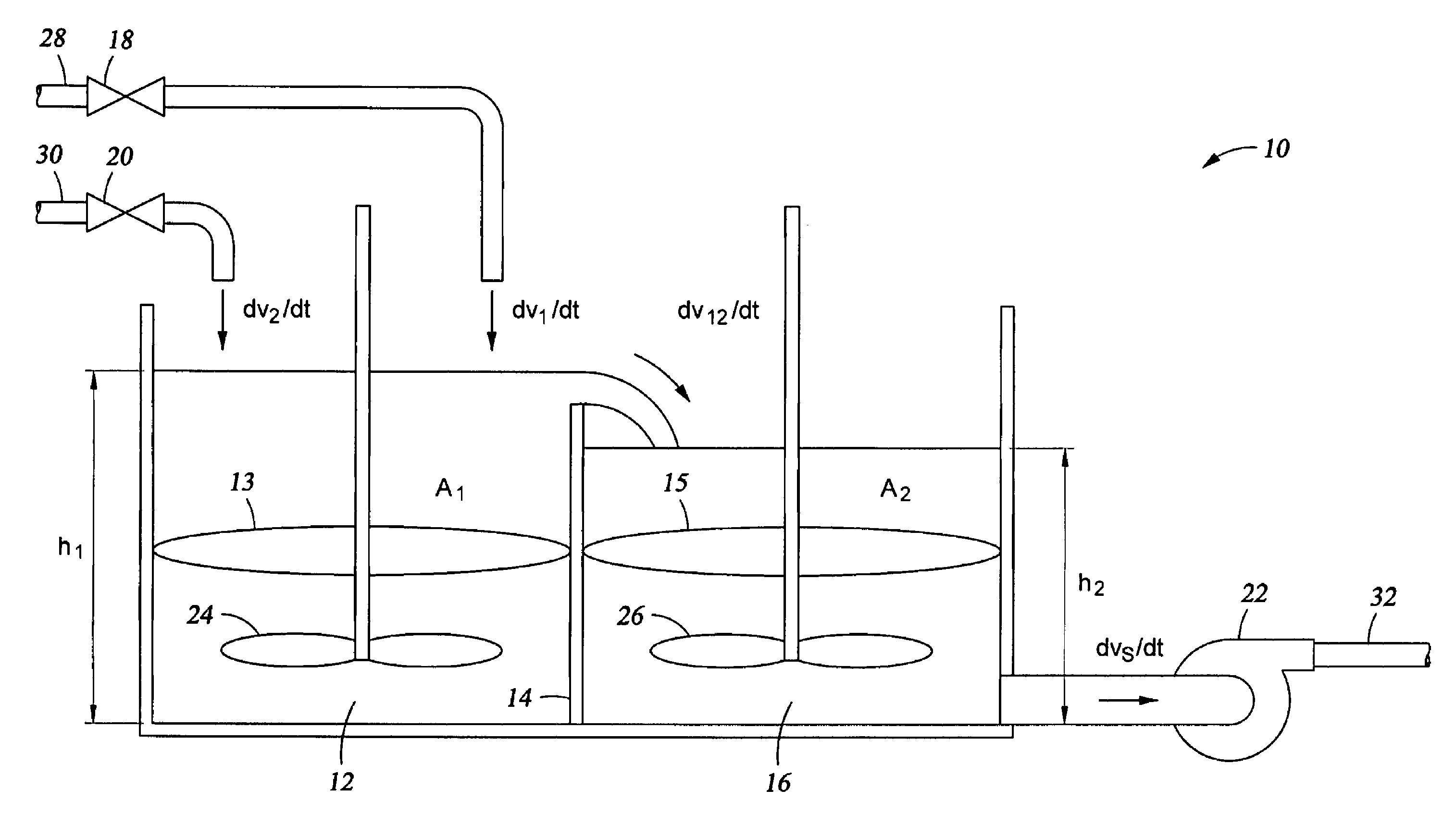

Control system design for a mixing system with multiple inputs

ActiveUS20060233039A1Controlling ratio of multiple fluid flowsMixing operation control apparatusHybrid systemControl system design

A control system for mixing at least two materials in a physical system having two or more tanks comprises at least two actuators, each actuator being operable to introduce a material into a first tank to form a first mixture, the first mixture flowing into a second tank to form a second mixture and a controller operable, based on a commanded input, to control the at least two actuators to obtain a density of either the first mixture or the second mixture and a volume flow rate of the second mixture out of the second tank, wherein the density is controlled independently from the volume flow rate.

Owner:HALLIBURTON ENERGY SERVICES INC

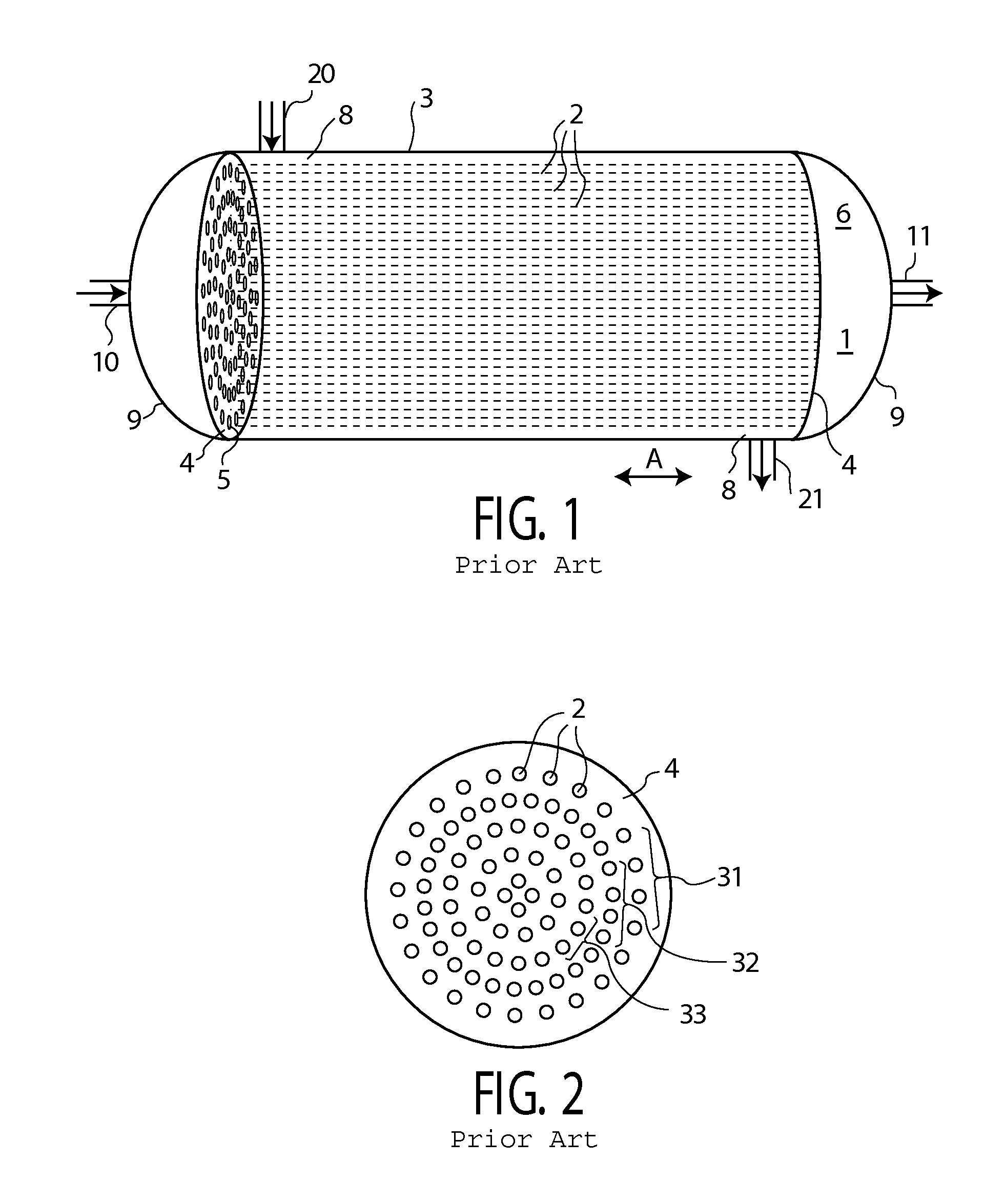

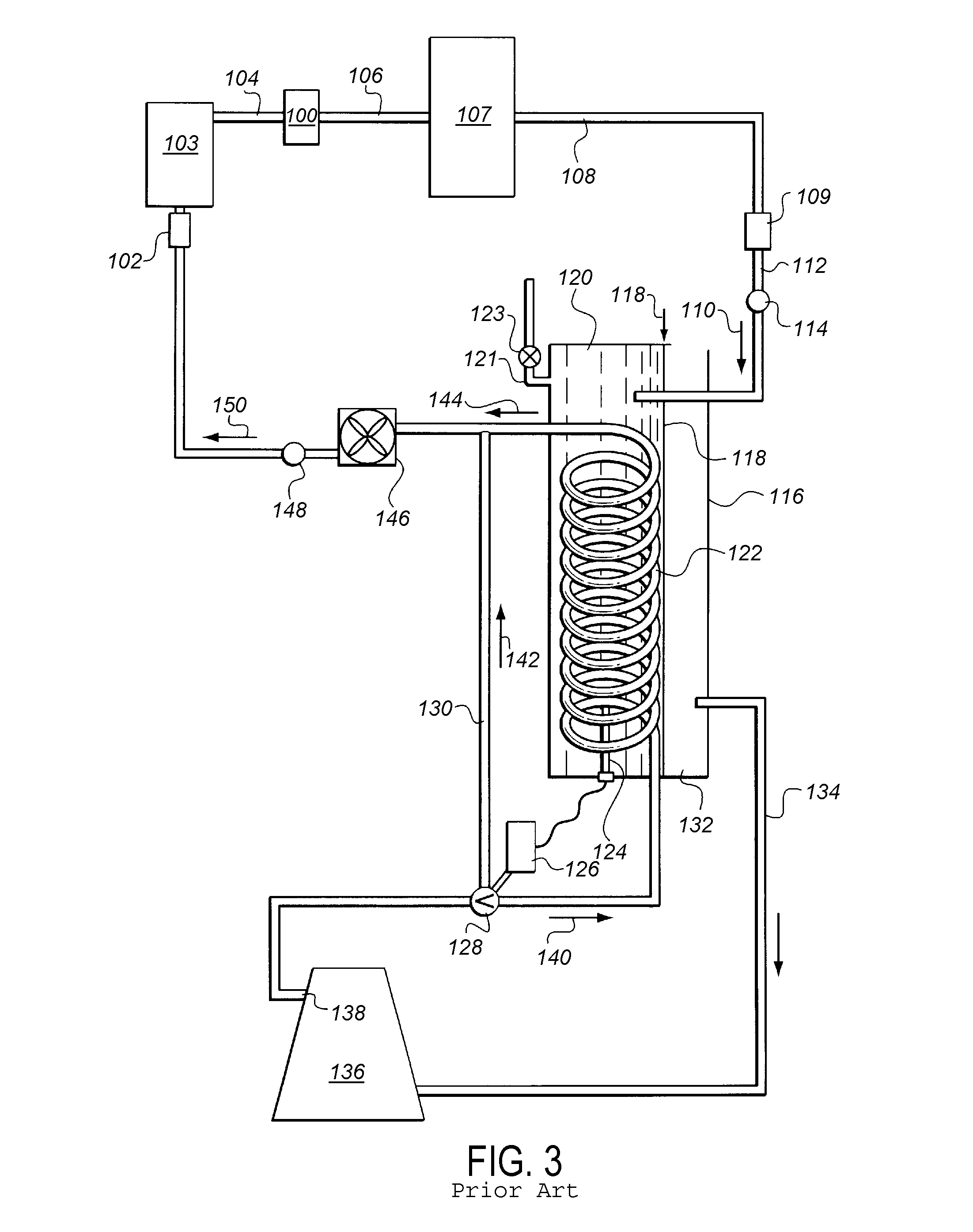

System and method for controlled mixing of fluids

InactiveUS20070206436A1Increased processing flexibilityImprove throughputControlling ratio of multiple fluid flowsTemperatue controlWater flowEngineering

Embodiments of the present invention provide a system and method for continuous flow production of mixed fluids. The mixed fluids can comprise a mixture of different fluids or a mixture of the same fluid having different input properties such as temperature. In general, two streams of fluid of varying temperature are supplied to a mixer. The flow rate of each of the input fluids can be regulated to produce a mixed fluid at a desired flow rate and temperature. As an example, mass flow controllers can regulate the flow rates of a hot and cold stream of de-ionized water to produce a stream of de-ionized water at a desired flow rate and temperature.

Owner:ENTEGRIS INC

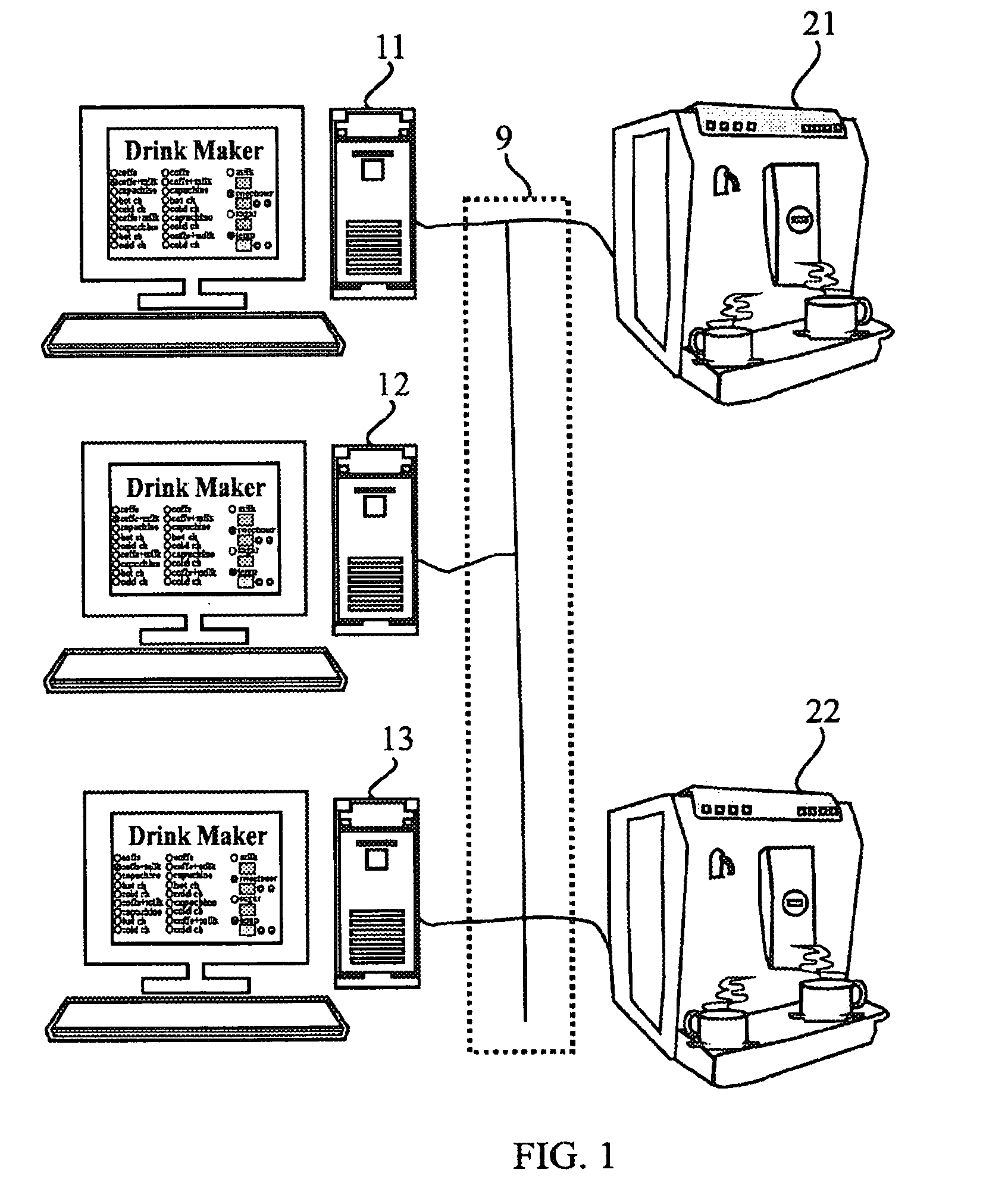

Drinks machine with network drink ordering

InactiveUS20100198643A1Easy to useReduce waste and waste of timeSampled-variable control systemsControlling ratio of multiple fluid flowsOperating system

One or more drinks machines are used for preparing or providing drinks using a computers' network, and an adapter connected in between. The users can order drinks through a graphic interface and monitor the status of the drinks and of the machines. The orders can be managed using a queue and each user can be notified through the computer when the drink is ready or can he prepared. The adapter can he connected to an existing machine or provided with one. Another possibility is that the adapter would include wireless communication support. It may he possible that the adapter would also monitor the drink machine as well as sending commands for preparing ordered drinks.

Owner:FRIEDMAN RAM +3

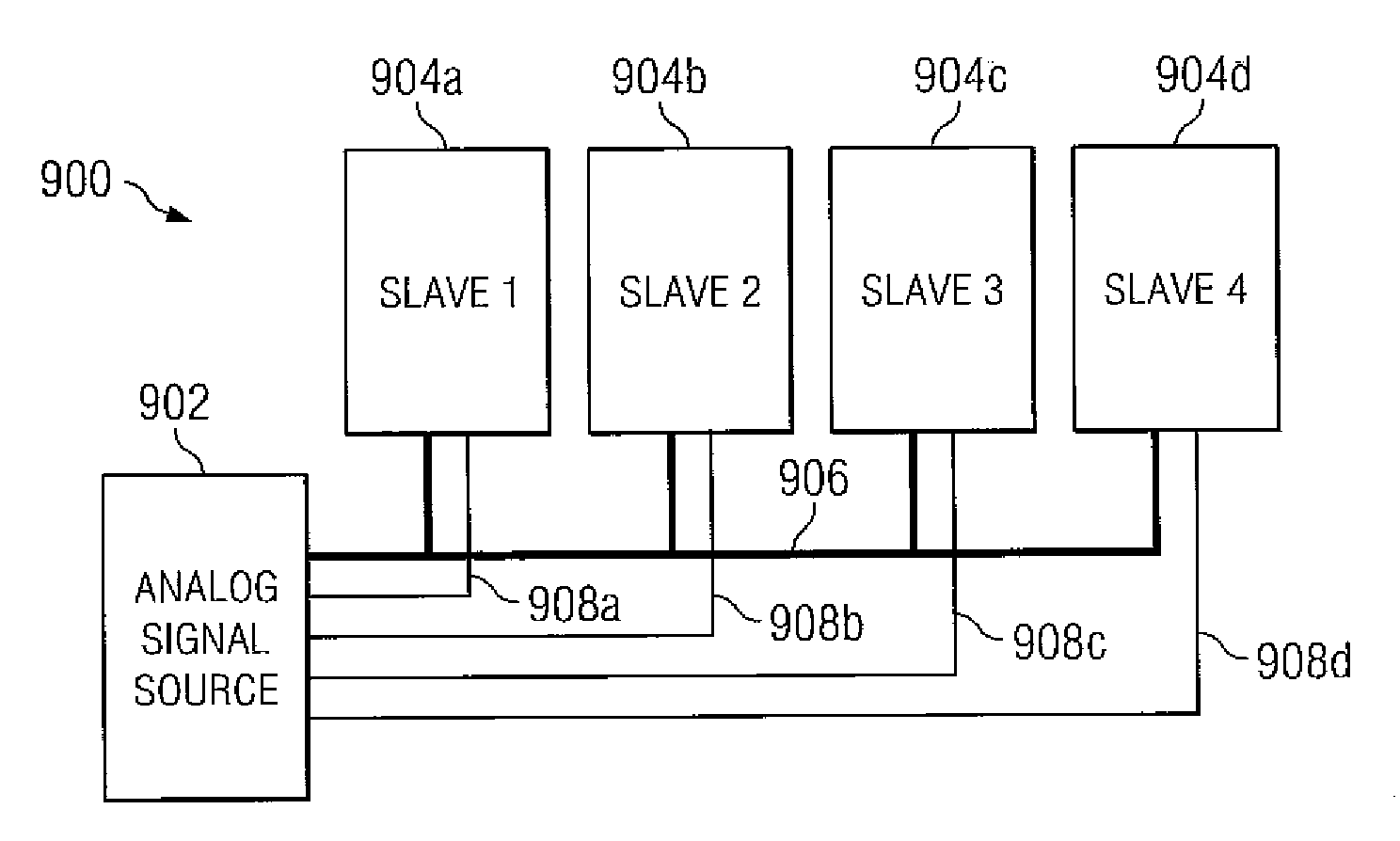

System and method for multiplexing setpoints

InactiveUS7684446B2Reduce the amount requiredError preventionFrequency-division multiplex detailsMultiplexingEngineering

Embodiments of the present invention provide a system and method of providing analog setpoints that eliminate, or at least substantially reduces, the shortcomings of prior art analog setpoint systems and methods. One embodiment of the present invention includes a method of multiplexing analog setpoints comprising transmitting the analog signal to a plurality of target devices, wherein the analog signal represents multiple setpoints, transmitting a first setpoint indicator separate from the analog signal to indicate to a first target device that a first setpoint for the first target device is being represented by the analog signal, saving a first setpoint value asserted by the analog signal at the first target device in response to the first setpoint indicator.

Owner:ENTEGRIS INC

Methods for determining a volumetric ratio of a material to the total materials in a mixing vessel

ActiveUS20070153623A1Good estimateStrict controlSampled-variable control systemsControlling ratio of multiple fluid flowsEngineeringMechanical engineering

Owner:HALLIBURTON ENERGY SERVICES INC

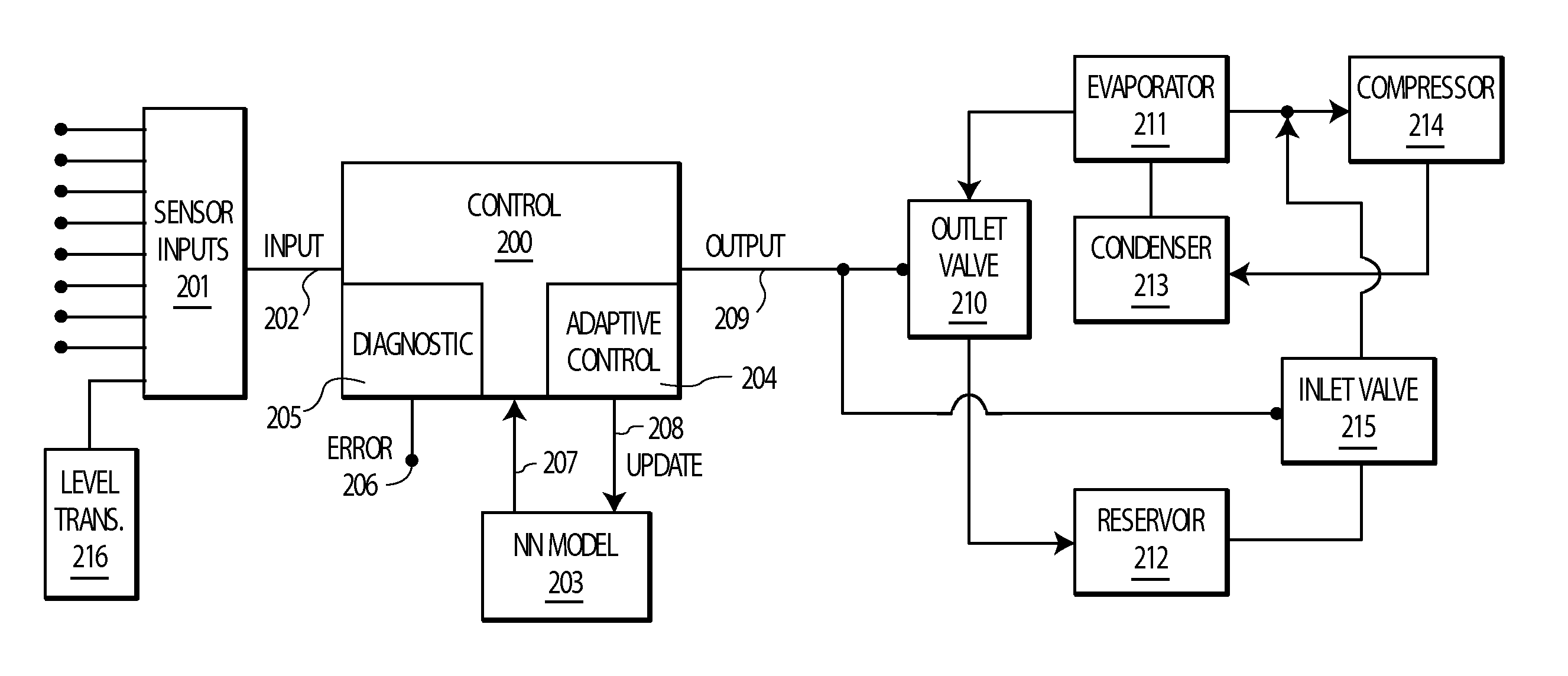

Method and apparatus for optimizing refrigeration systems

InactiveUS20120041608A1Controlling ratio of multiple fluid flowsMaterial thermal conductivityOperating pointControl system

A control system for controlling a refrigeration system having an operating point, comprising: a memory configured to store a relationship of at least an evaporator efficiency, an evaporator heat load, a refrigerant amount in the evaporator, and a variable dependent on a non-volatile liquid mixed with refrigerant in the evaporator an input port configured to receive a signal corresponding to at least a measured evaporator heat load during operation; an output port configured to present an output to selectively alter an operating point of the evaporator, by altering the refrigerant amount in the evaporator and thereby changing the variable; and a processor, configured to receive the signal, access the memory; and generate the output to selectively move toward an optimum operating point. A corresponding method and refrigeration system are provided.

Owner:HUDSON TECHNOLOGIES

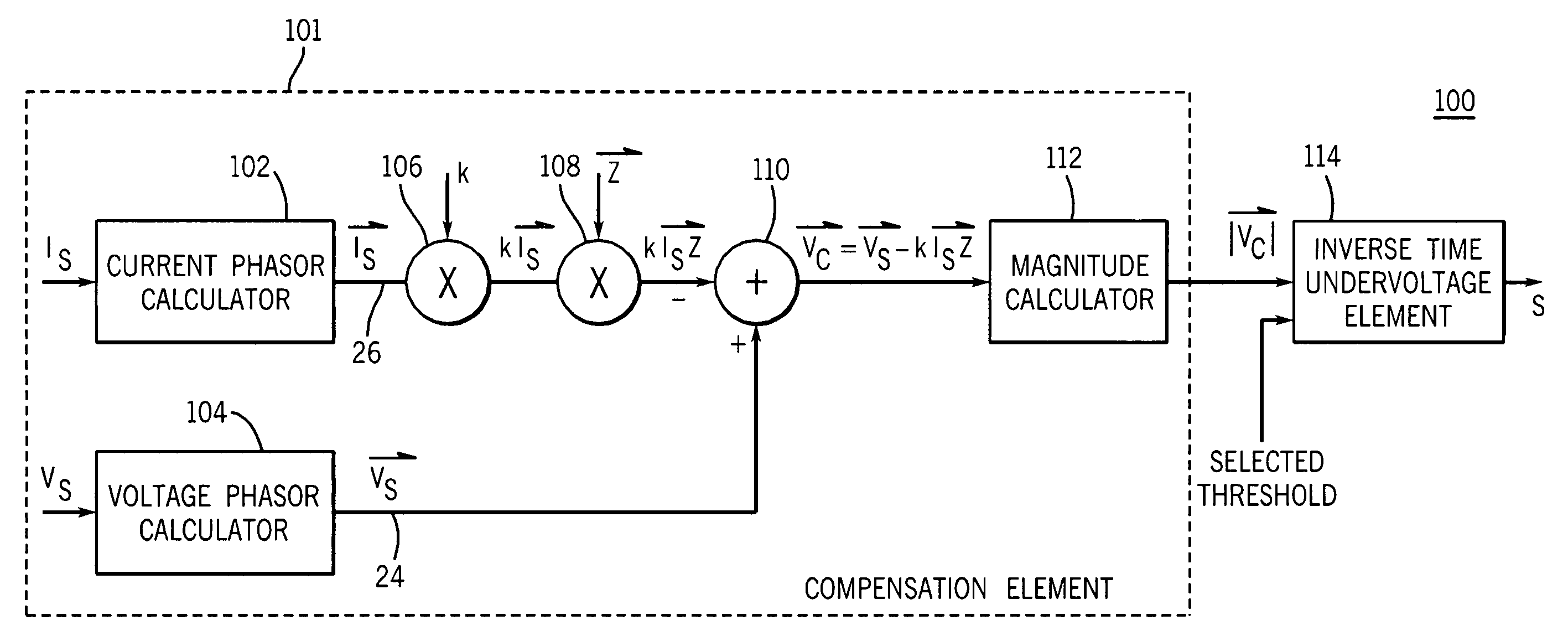

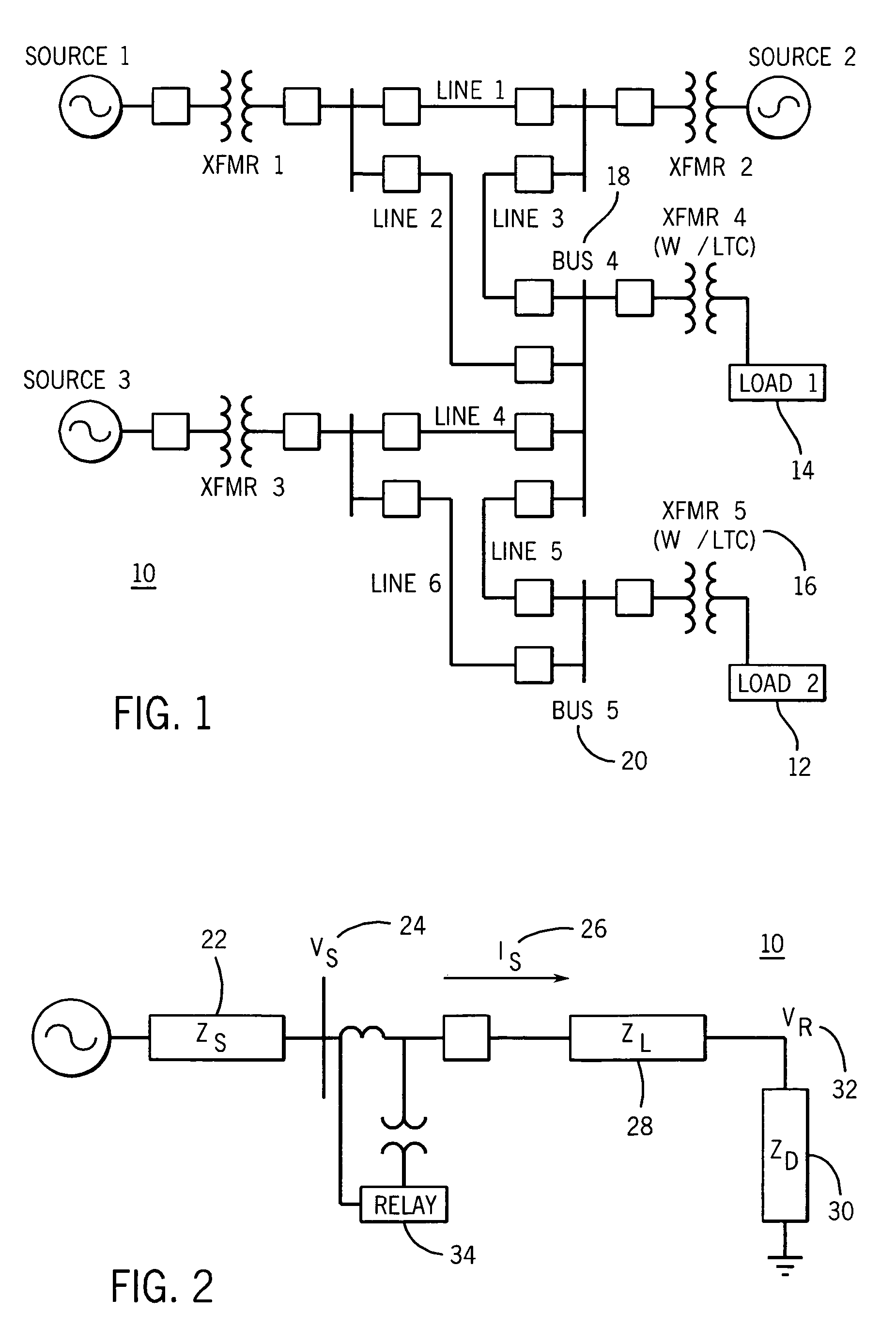

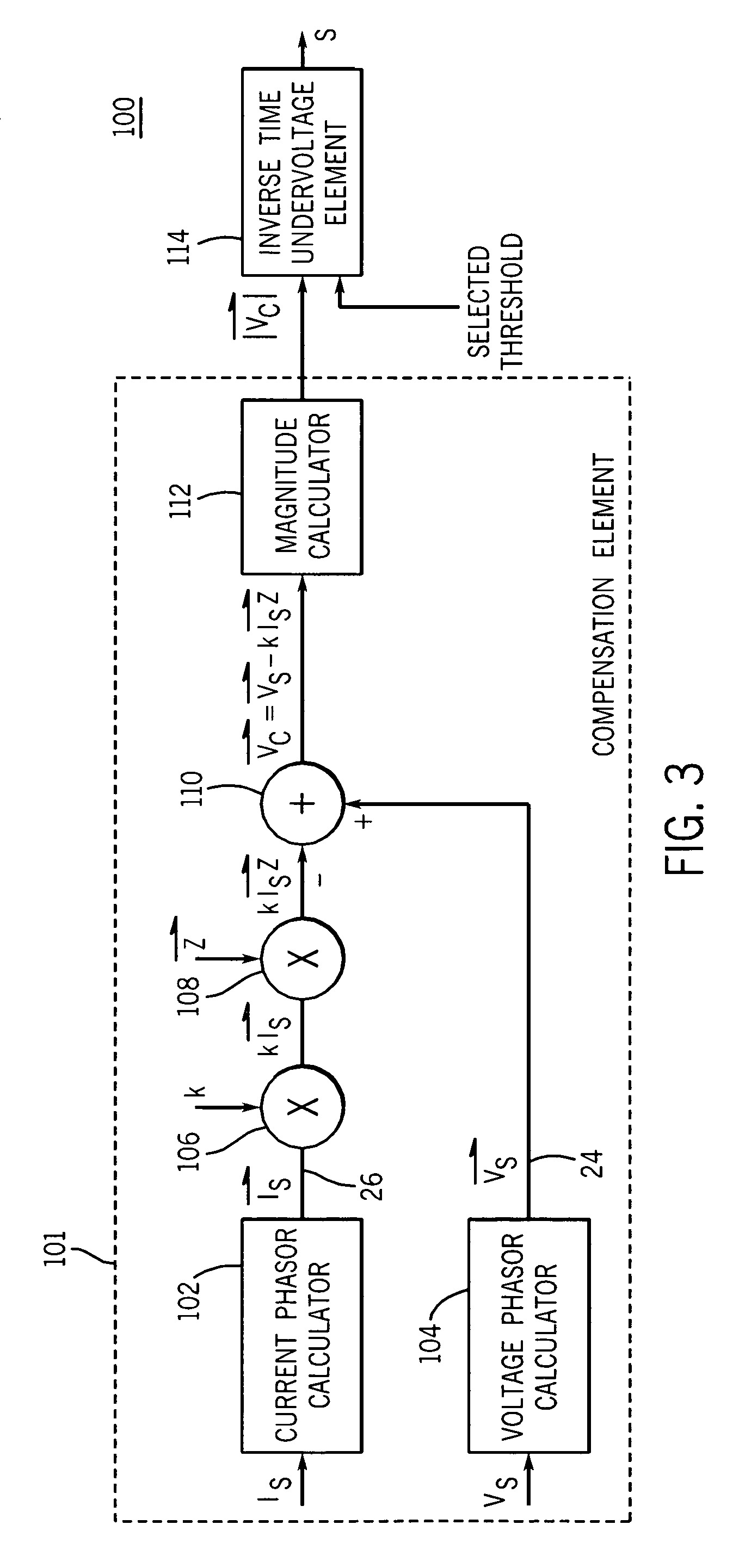

Compensated inverse-time undervoltage load shedding systems

ActiveUS7582986B2Mechanical power/torque controlDc network circuit arrangementsLoad SheddingTime delays

Provided is a compensated inverse-time undervoltage load shedding system and method for use in an electrical power system. The compensated inverse-time undervoltage load shedding system includes a compensation element for determining a compensated value and an inverse-time undervoltage element operatively coupled to the compensation element and enabled based on the compensated value. When enabled, the inverse-time undervoltage element calculates a load shedding time delay value based on the compensated value, and determines a load shedding signal based on the load shedding time delay value. An associated load of the electrical power system is shed based on the load shedding signal. The compensation element may determine the compensated value using a voltage magnitude, a rate-of-change of power system voltage over time, a weighted rate-of-change of power system voltage over time, a current magnitude, a weighted current magnitude, and an impedance phasor value, to name a few.

Owner:SCHWEITZER ENGINEERING LABORATORIES

Methods for volumetrically controlling a mixing apparatus

ActiveUS20070153622A1Good estimateStrict controlSampled-variable control systemsControlling ratio of multiple fluid flowsControl theoryStreamflow

Methods of controlling a volumetric ratio of a material to total materials in a mixing vessel are provided. In various embodiments, the methods may comprise: estimating the volumetric ratio of the material to the total materials in the mixing vessel and an output flowrate of the material from the mixing vessel using a volumetric ratio observer; dynamically recomputing the commanded input flowrate of the material based on outputs of the volumetric ratio observer using a flow regulator; and adjusting an input valve of the material based on the commanded input flowrate of the material using a flow modulator. The mixing vessel may include a first mixing vessel partially separated from a second mixing vessel. In this case, a height of the total materials in the second mixing vessel may be estimated using a height observer.

Owner:HALLIBURTON ENERGY SERVICES INC

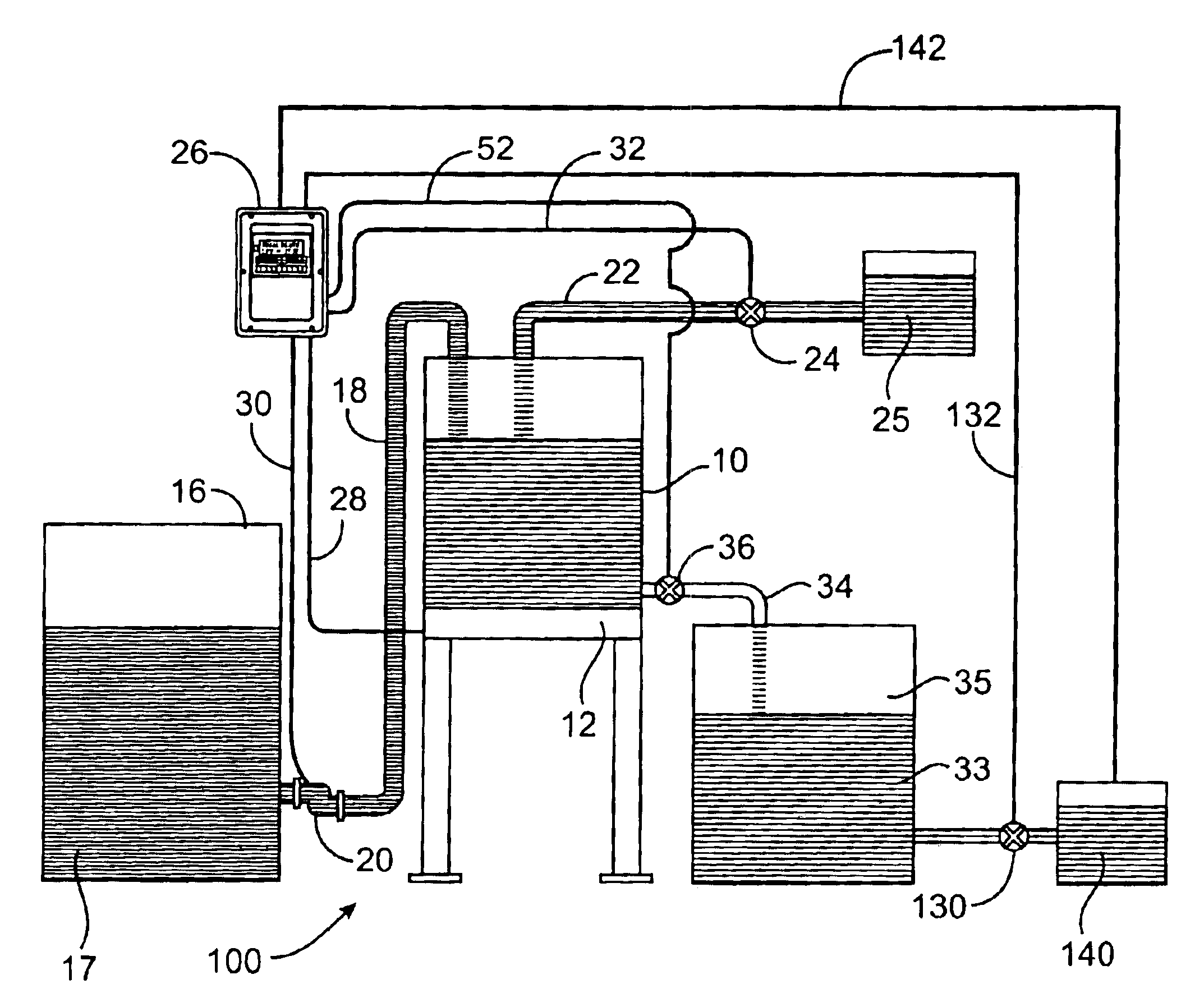

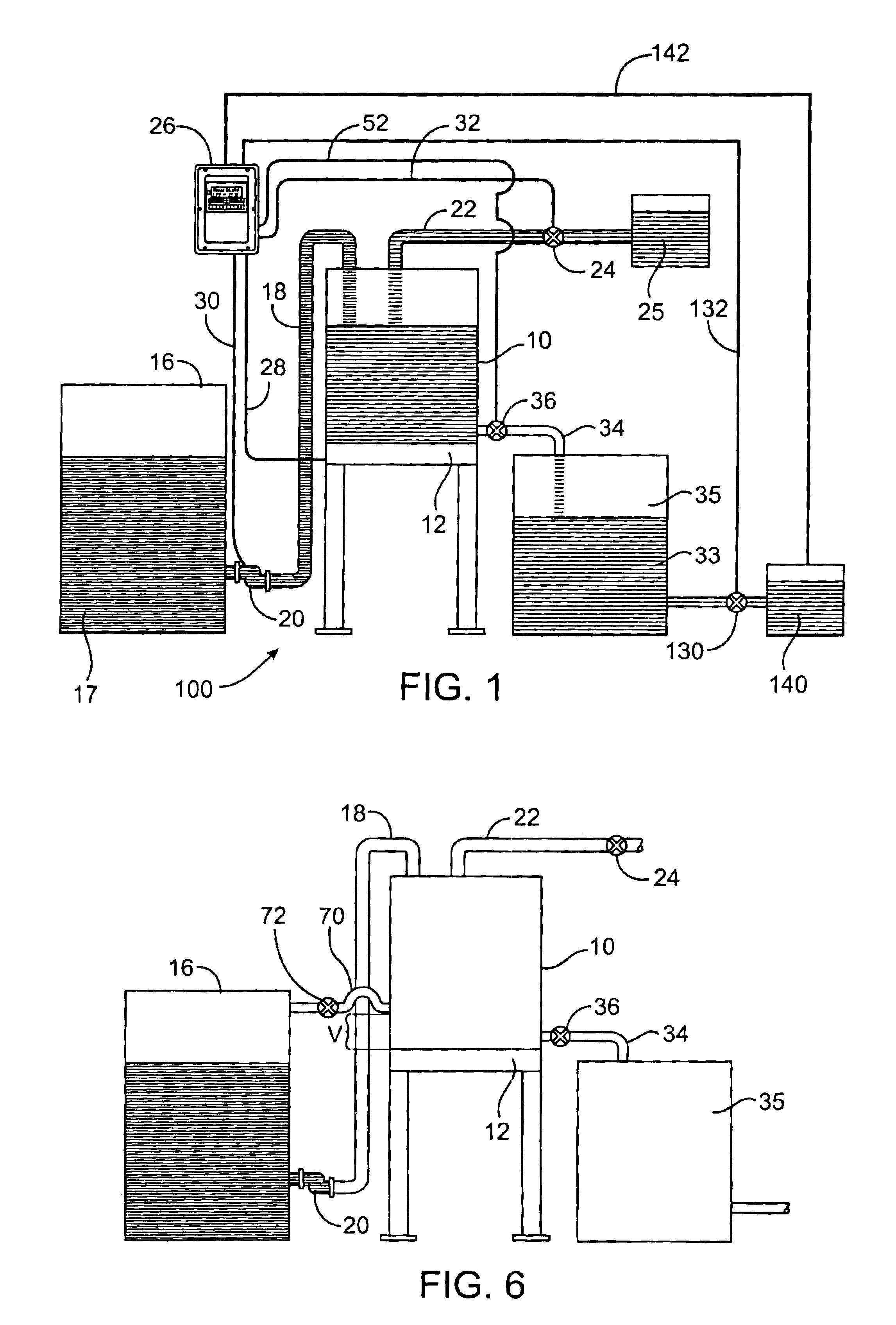

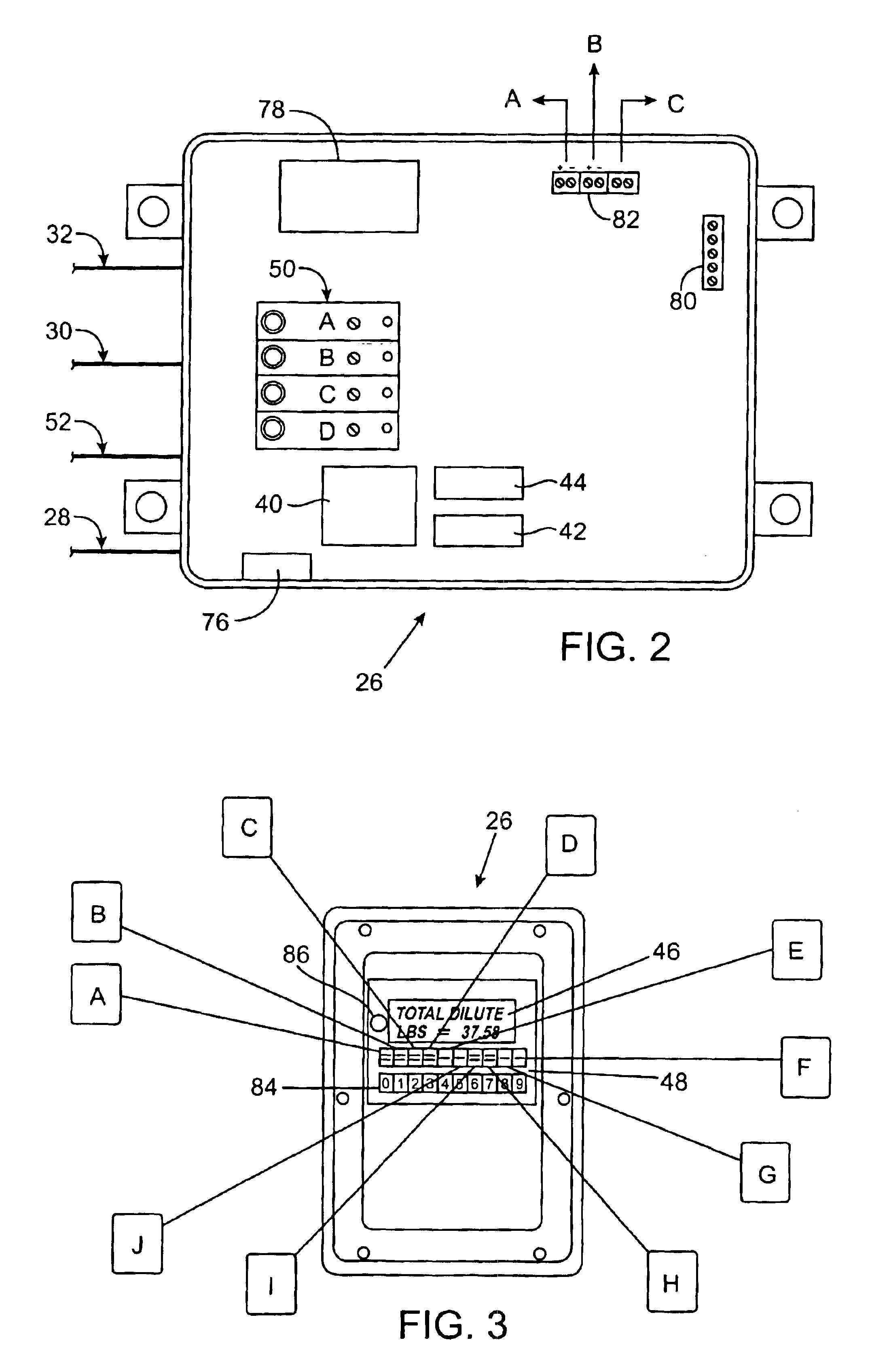

Diluting system and method

InactiveUS6845298B2High degree of automationEasy to correctSampled-variable control systemsControlling ratio of multiple fluid flowsChemical solutionDiluent

A system and a method for automatically, accurately diluting chemical solutions on an industrial scale based upon real time weight measurements of chemical and diluent weight is disclosed.

Owner:FORCE FLOW

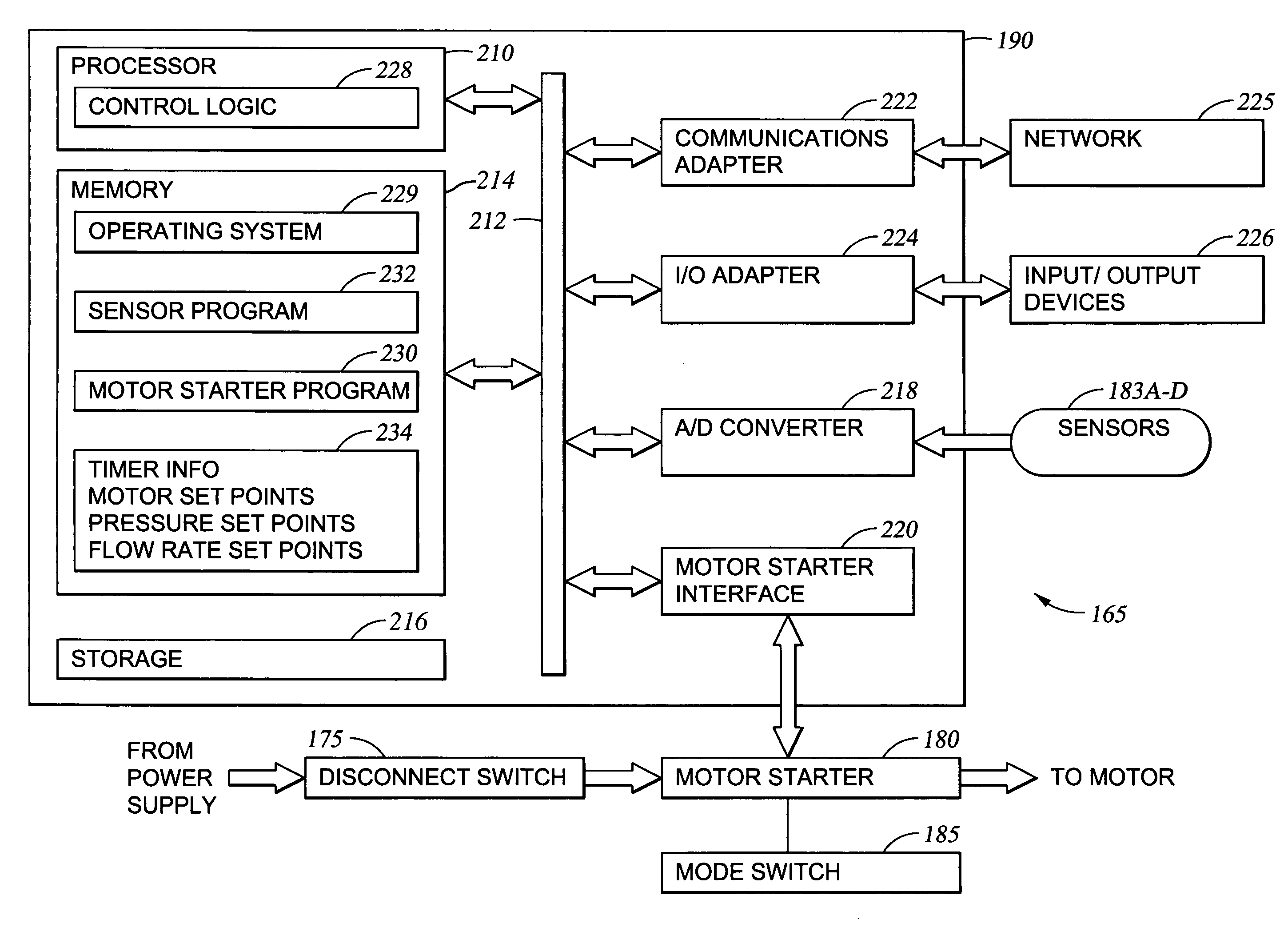

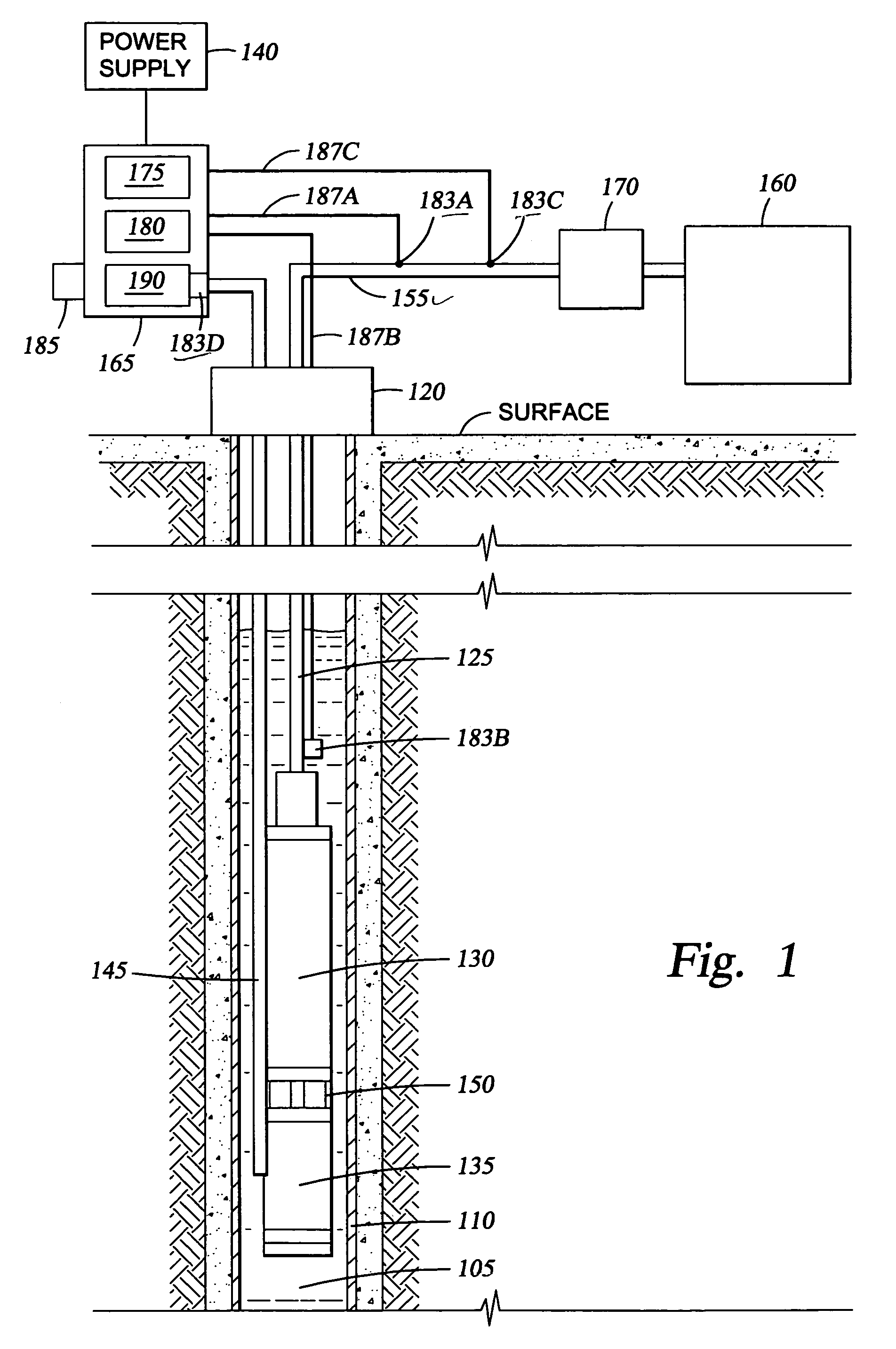

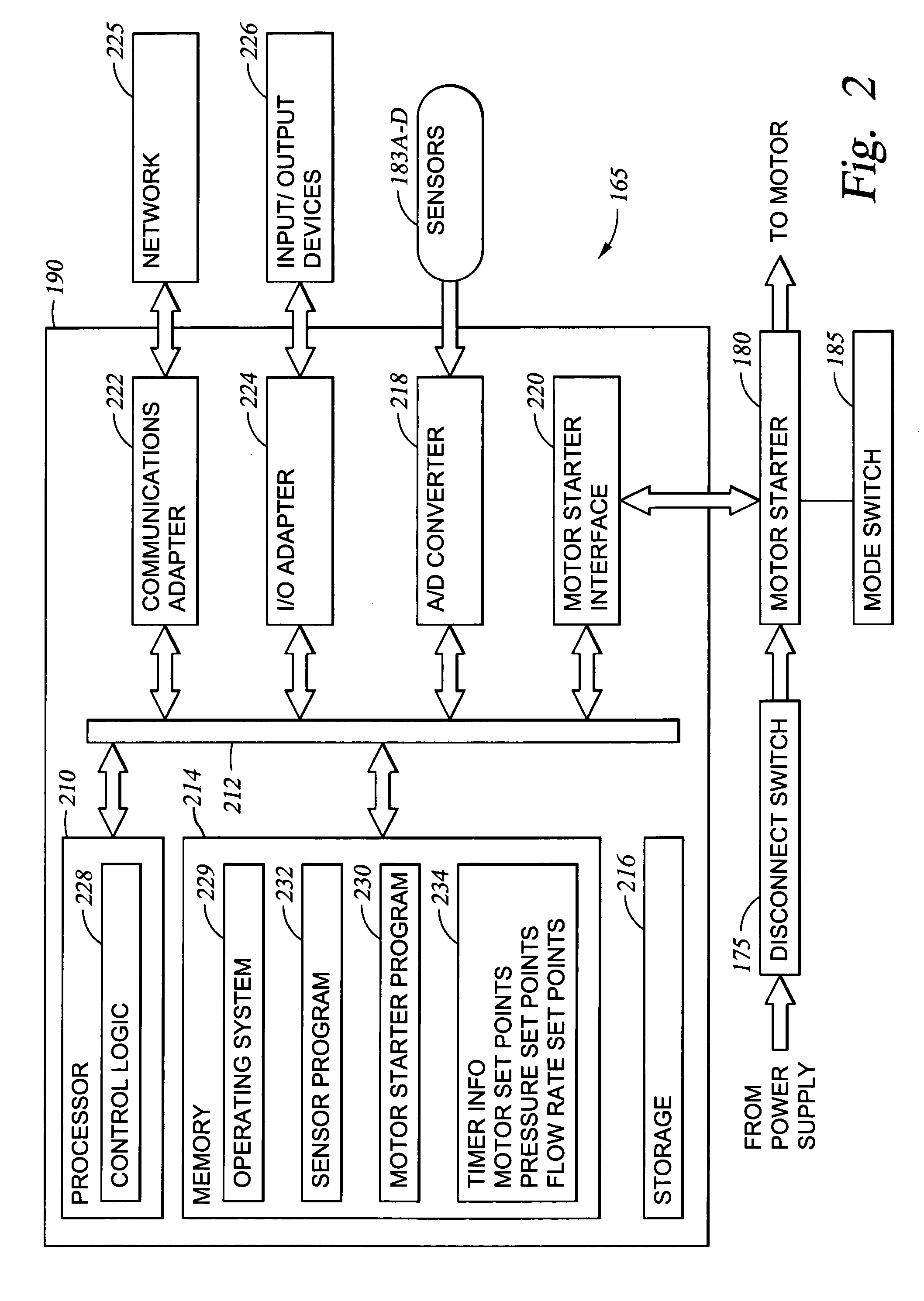

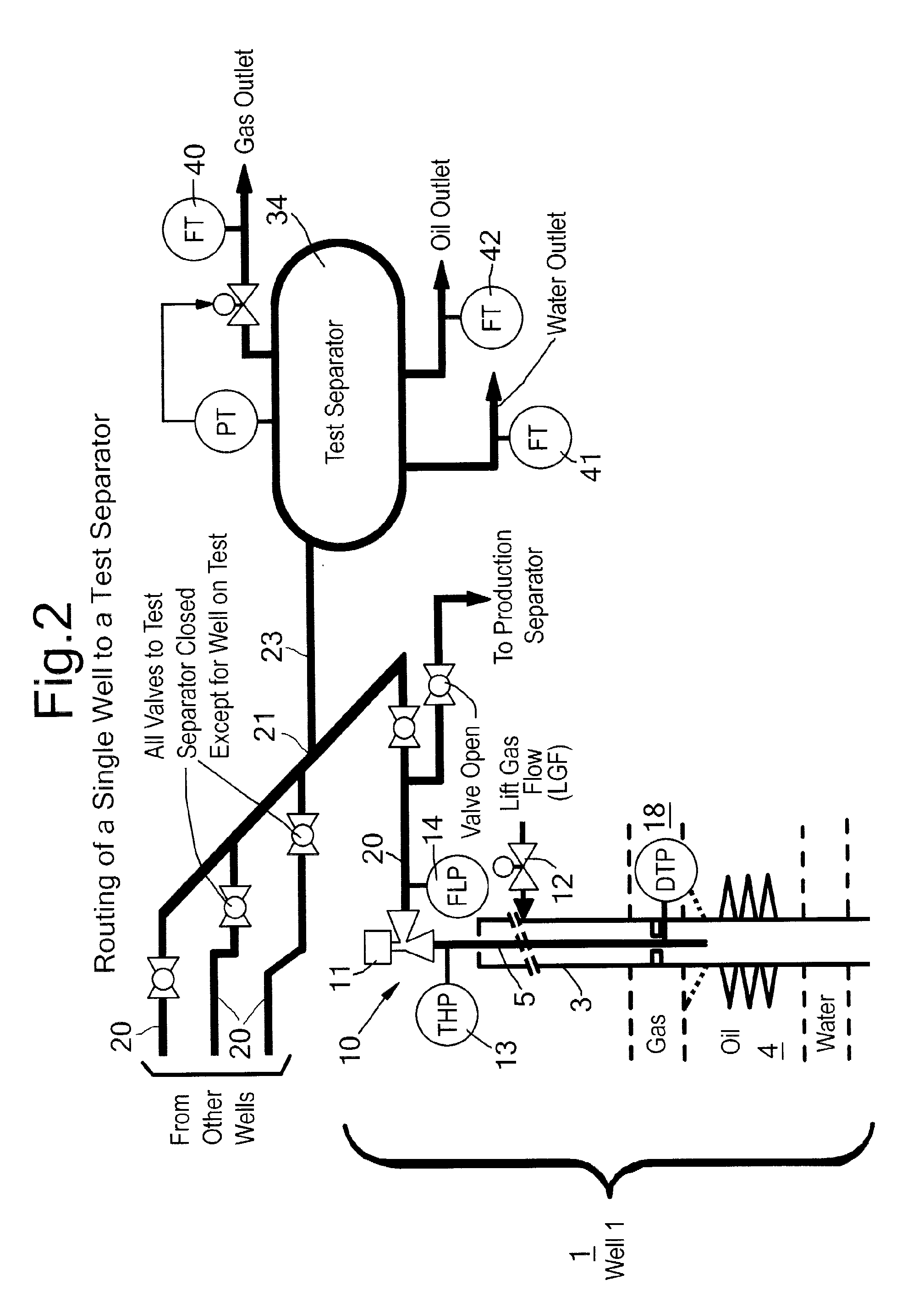

Controller system for downhole applications

The present invention generally provides a closed feedback system for operating peripheral devices in response to environmental conditions. Illustrative environmental conditions include well bore pressure, line pressure, fluid levels, flow rates and the like. In one embodiment, a flow controller disposed in a fluid line is operated in response to operating variable readings (e.g., pressure and / or flow rate) taken in the flow line and / or a well bore. The variable measurements are then compared to target values. If necessary, the flow controller is closed or opened to control the rate of fluid flow through the flow line and thereby achieve the desired target values. In another embodiment, the operation of a pump motor is monitored. Operating variables, such as voltage, current and load, are measured and compared to target values. In the event of a difference between the actual values of the variables and the target values, the flow controller is adjusted to affect the head pressure on a pump being driven by the motor. In some cases, the motor operation may be halted or otherwise adjusted.

Owner:OILFIELD EQUIP DEVMENT CENT

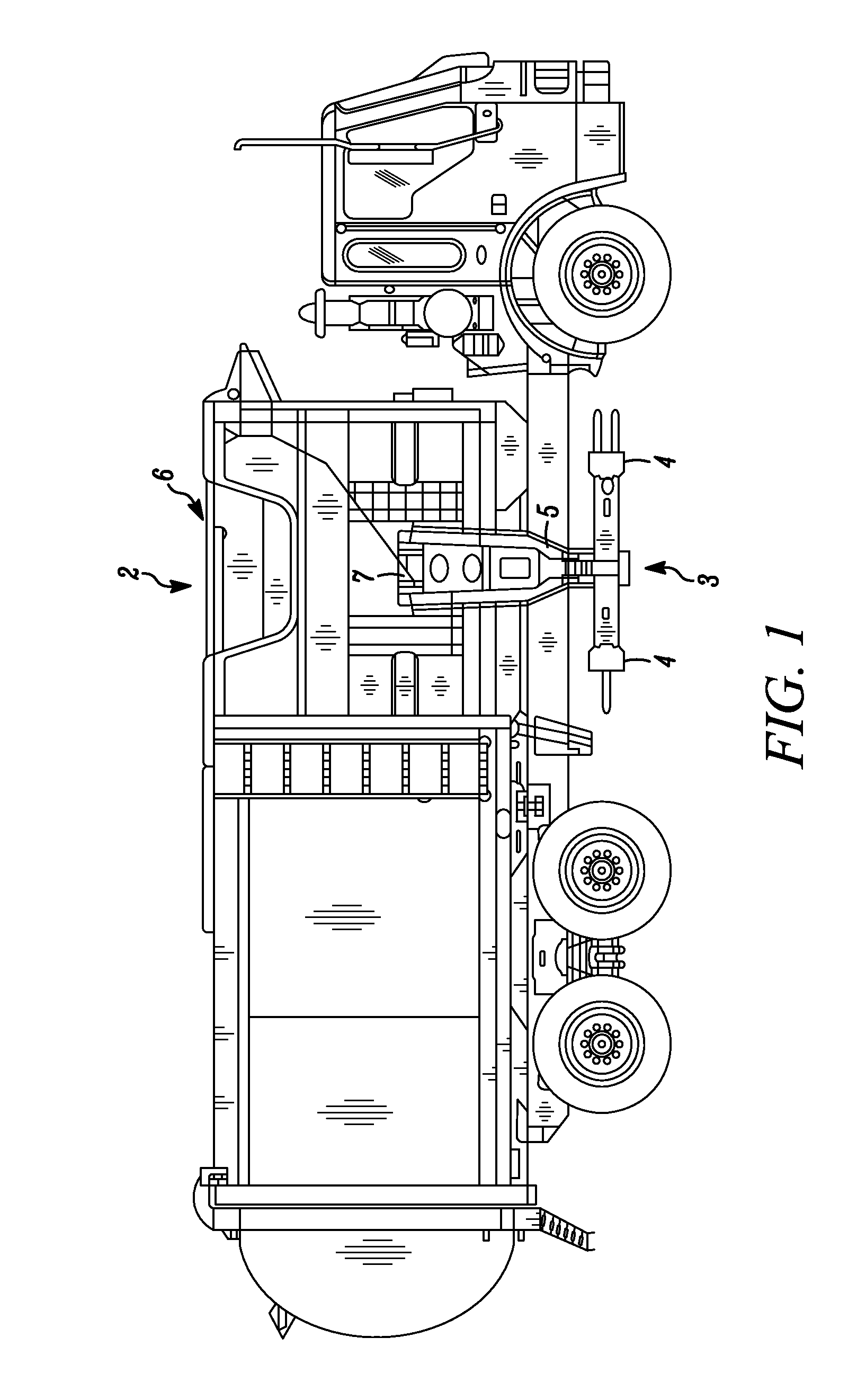

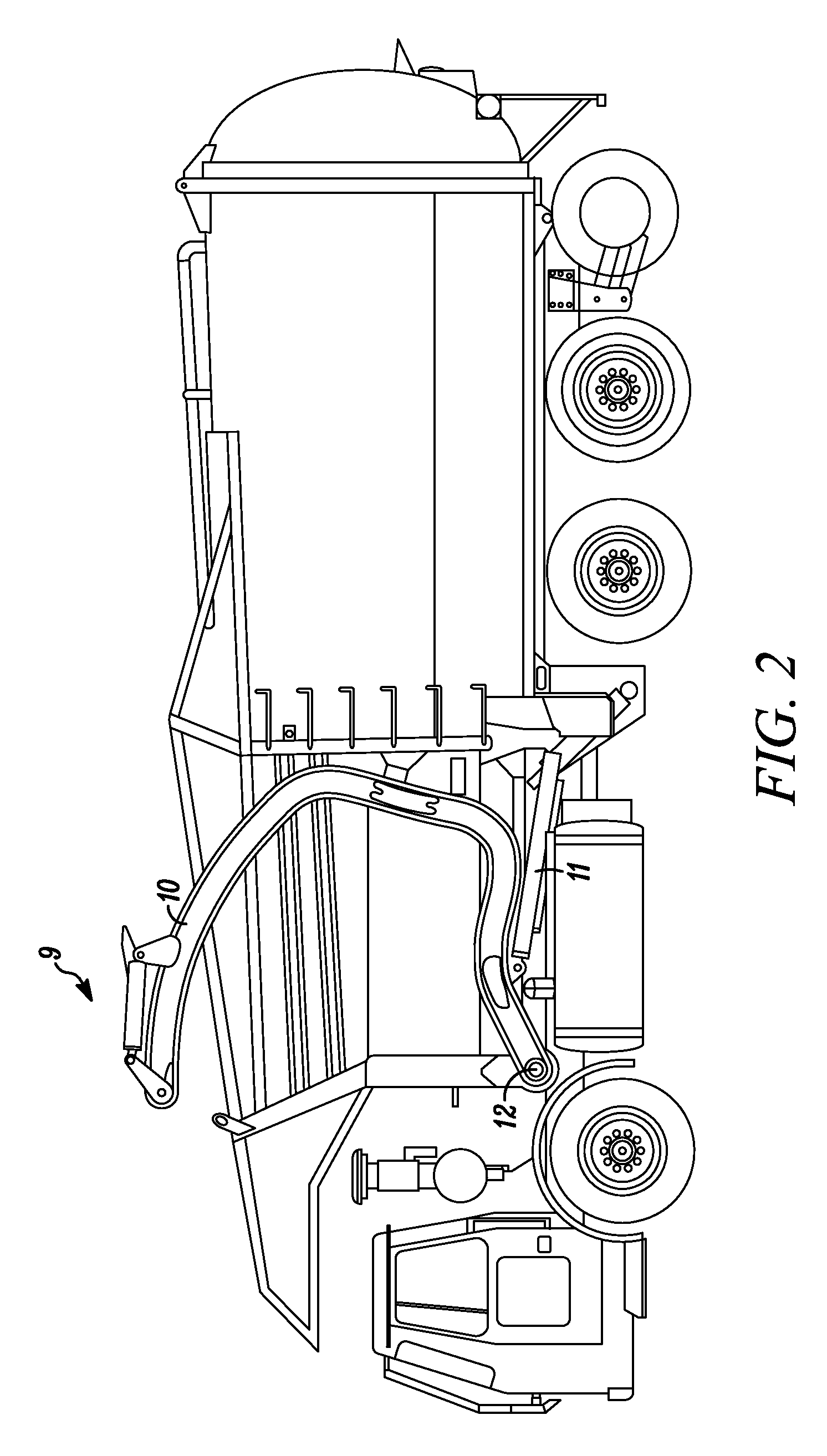

Hydraulic actuator control system

InactiveUS7831352B2Slow motionAnalogue computers for trafficArticle unpackingElectronic controllerRange of motion

A system for controlling motion of a hydraulic actuator during a portion of its range of motion is described, including a sensor on the hydraulic actuator for providing a signal indicating that the actuator is near a portion of its range of motion, and a pneumatic control valve that is configured to selectively modify a pressurized air control signal to in turn restrict flow of pressurized hydraulic fluid to the hydraulic actuator. The hydraulic actuator control system further includes an electronic controller for controlling the pneumatic control valve in response to a signal from the sensor. The hydraulic actuator control system thereby slows the motion of the hydraulic actuator near the portion of its range of motion.

Owner:HARTFIEL AUTOMATION

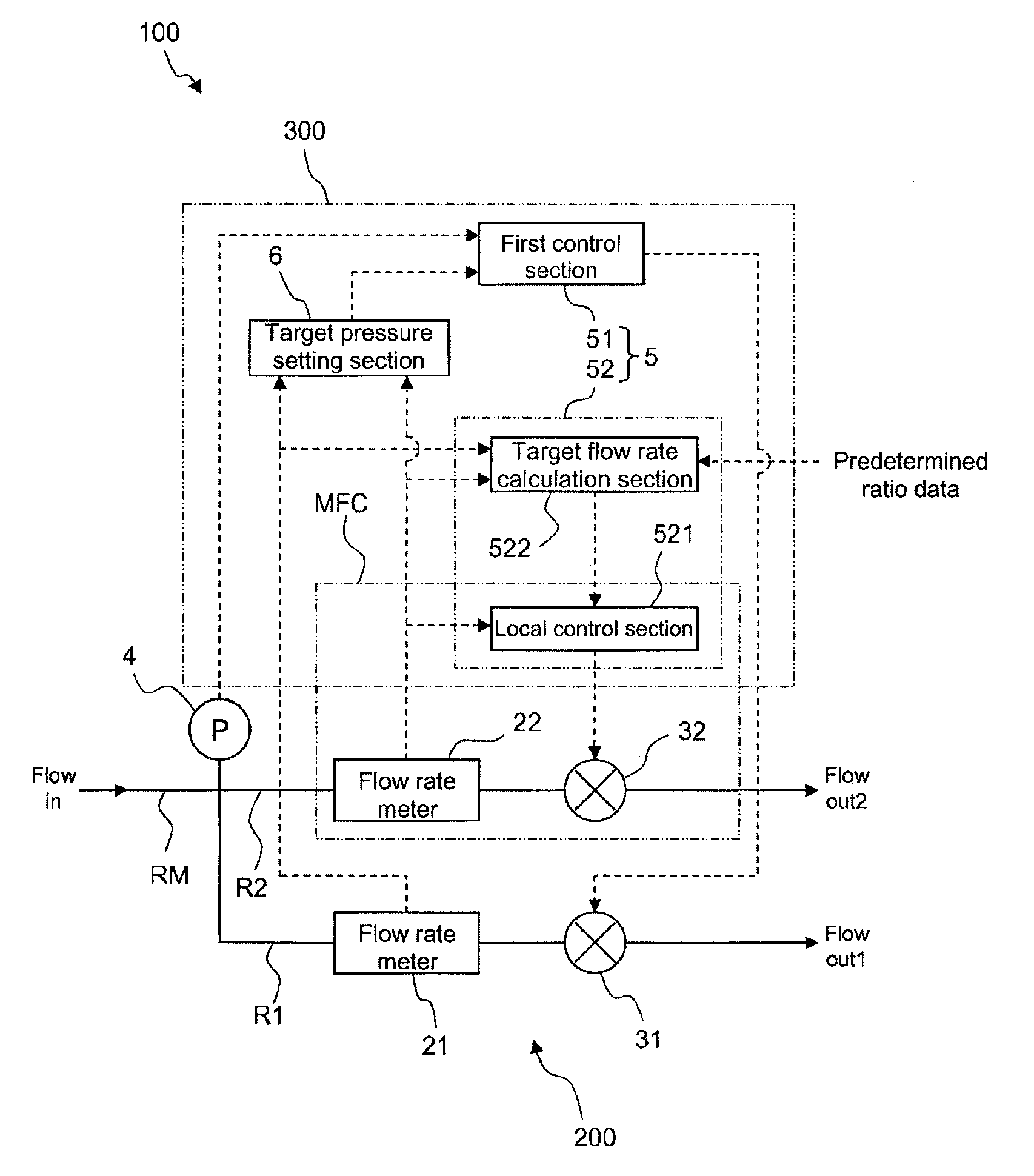

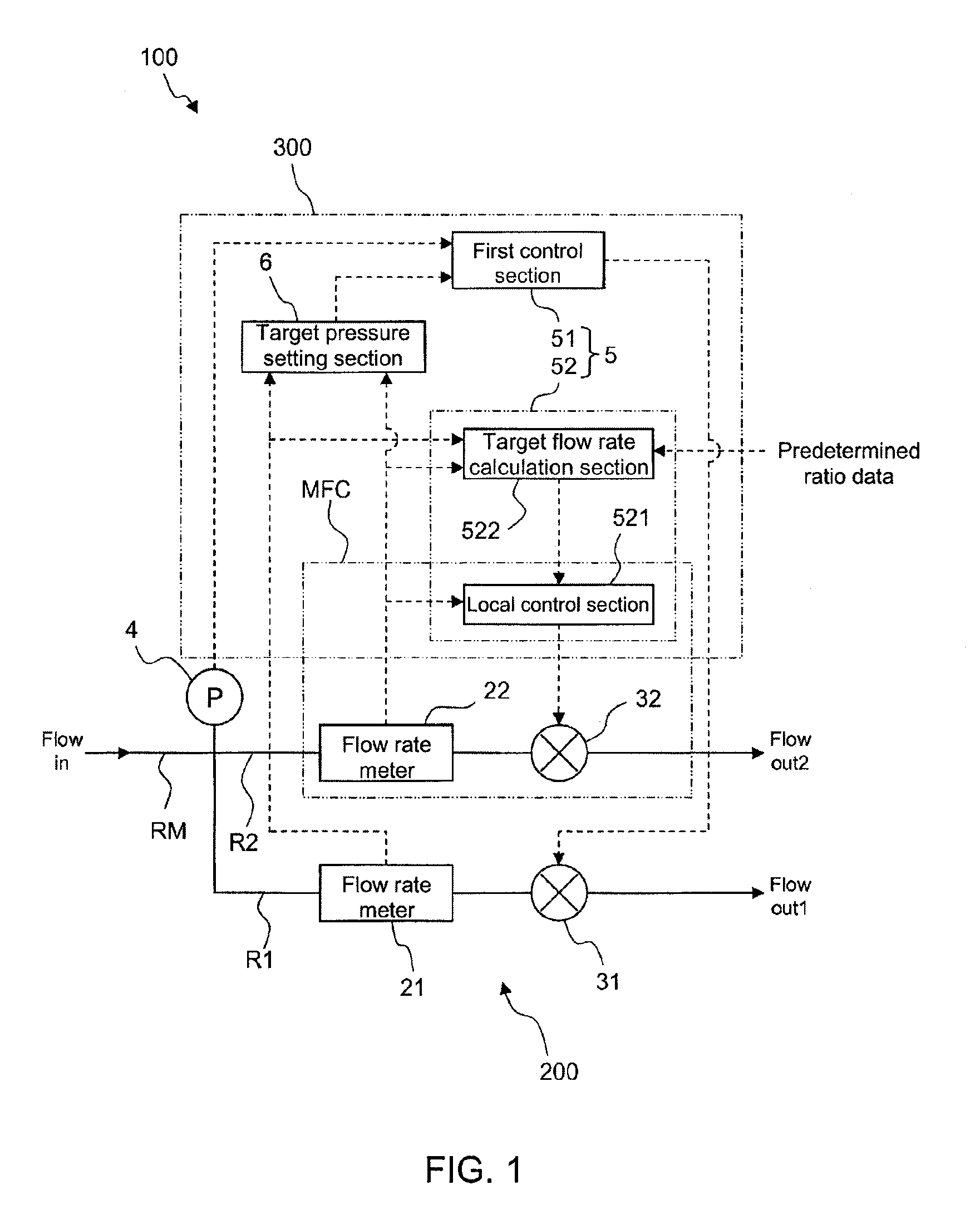

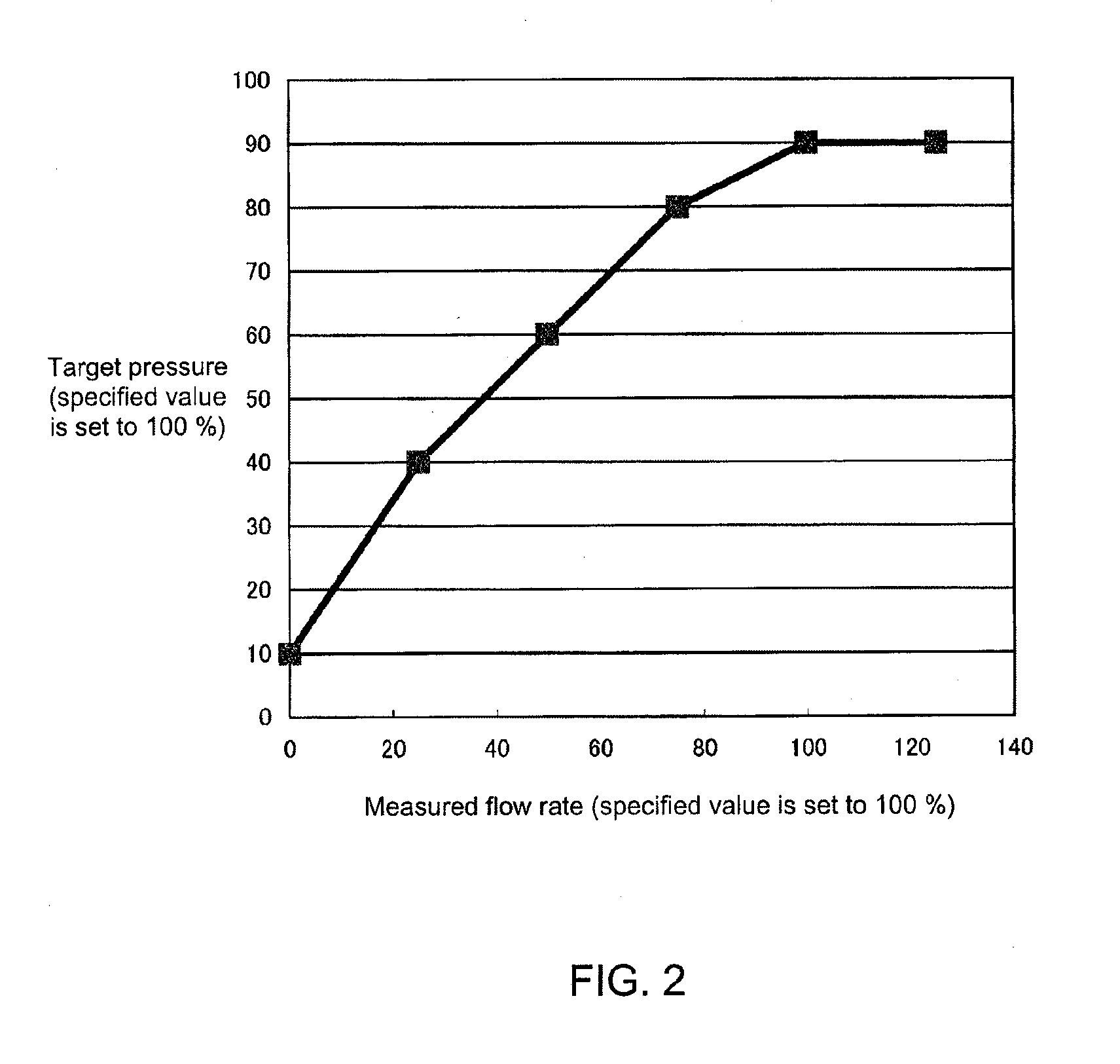

Flow rate ratio control device

ActiveUS20100030390A1Improve control responseLimiting transient performanceOperating means/releasing devices for valvesControlling ratio of multiple fluid flowsMain channelControl valves

A flow rate ratio control device having: a main channel (RM); branch channels (R1, R2) branching from the end of the main channel (RM); control valves (31, 32) respectively provided in the branch channels (R1, R2); flow rate measurement means for measuring the flow rate of the main channel (RM) and the flow rate of each of the branch channels (R1, R2); a valve control section (5) for controlling the a control valve (31) provided in one branch channel (R2) so that the pressure on the upstream side of the control valve (31) is a given target pressure and, only when the upstream-side pressure is near or not less than the target pressure, starting control of the other control valve (32) so that the flow rate ratios of the branch channels (R1, R2) are predetermined ratios; and a target pressure setting section (6) for setting the target pressure such that the smaller the flow volume is in the main channel (RM), the lower is the target pressure.

Owner:HORIBA STEC CO LTD

Methods for self-balancing control of mixing and pumping

ActiveUS7660648B2Reduce needImprove consistencySampled-variable control systemsControlling ratio of multiple fluid flowsThermodynamicsControl signal

Methods for controlling the in-feed and discharge rates of materials flowing into and out of a mixing process where one priority is to achieve a target mixture flow rate from the mixing process and another priority can be to achieve a target value for a mixture property. Actuators can be operated to control material in-feed rates, the mixture composition, and discharge rate, and can maintain a hold-up of the mixture in the mixing process. A total flow rate controller provides a control signal to a controller acting on the discharge rate and a controller acting on the in-feed rates. The mixture discharge flow rate can be automatically reduced from its desired target when the commanded rate of at least one of the materials exceeds its available supply rate as inferred from an inability to maintain the targeted value for the mixture property.

Owner:HALLIBURTON ENERGY SERVICES INC

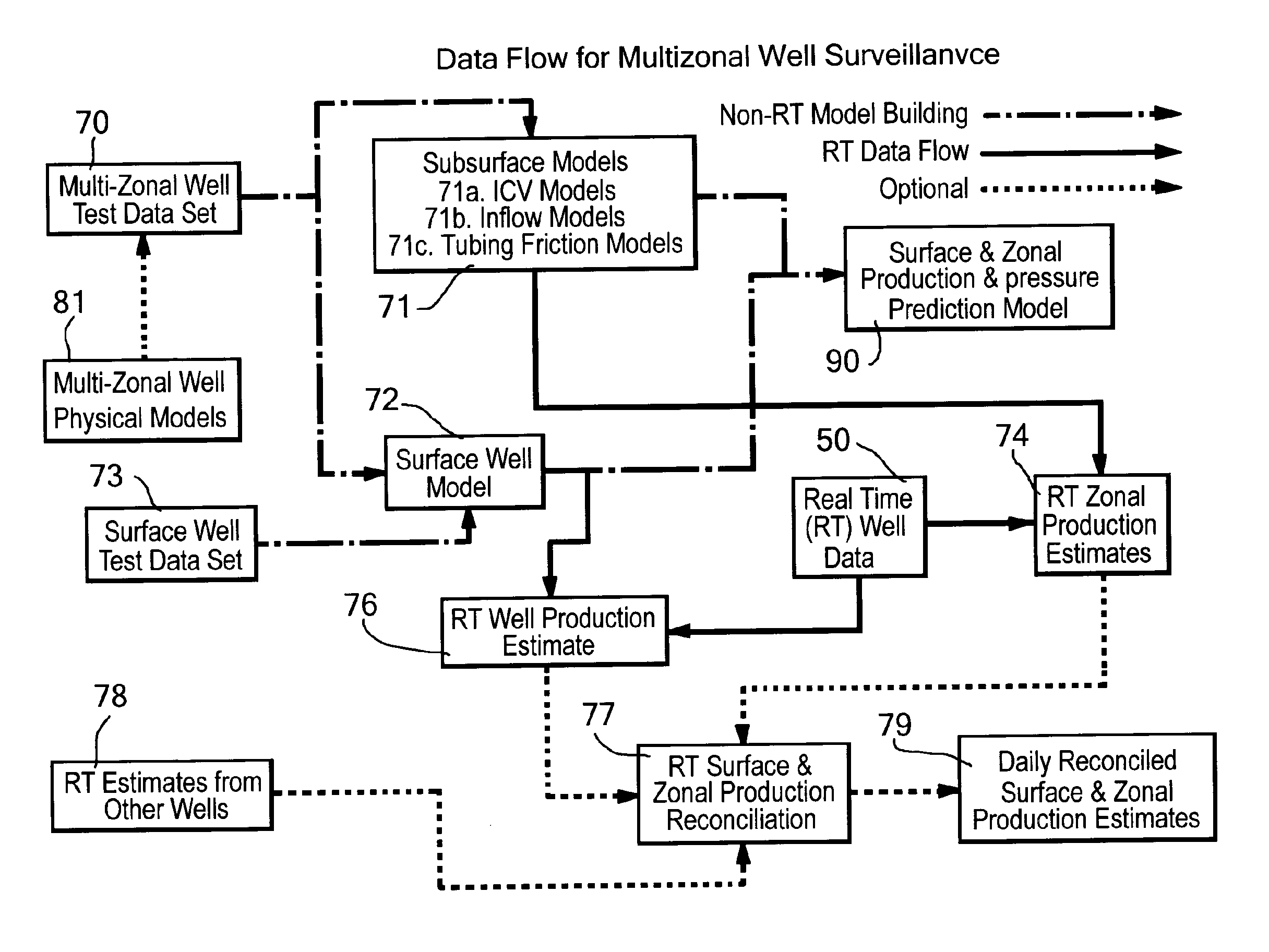

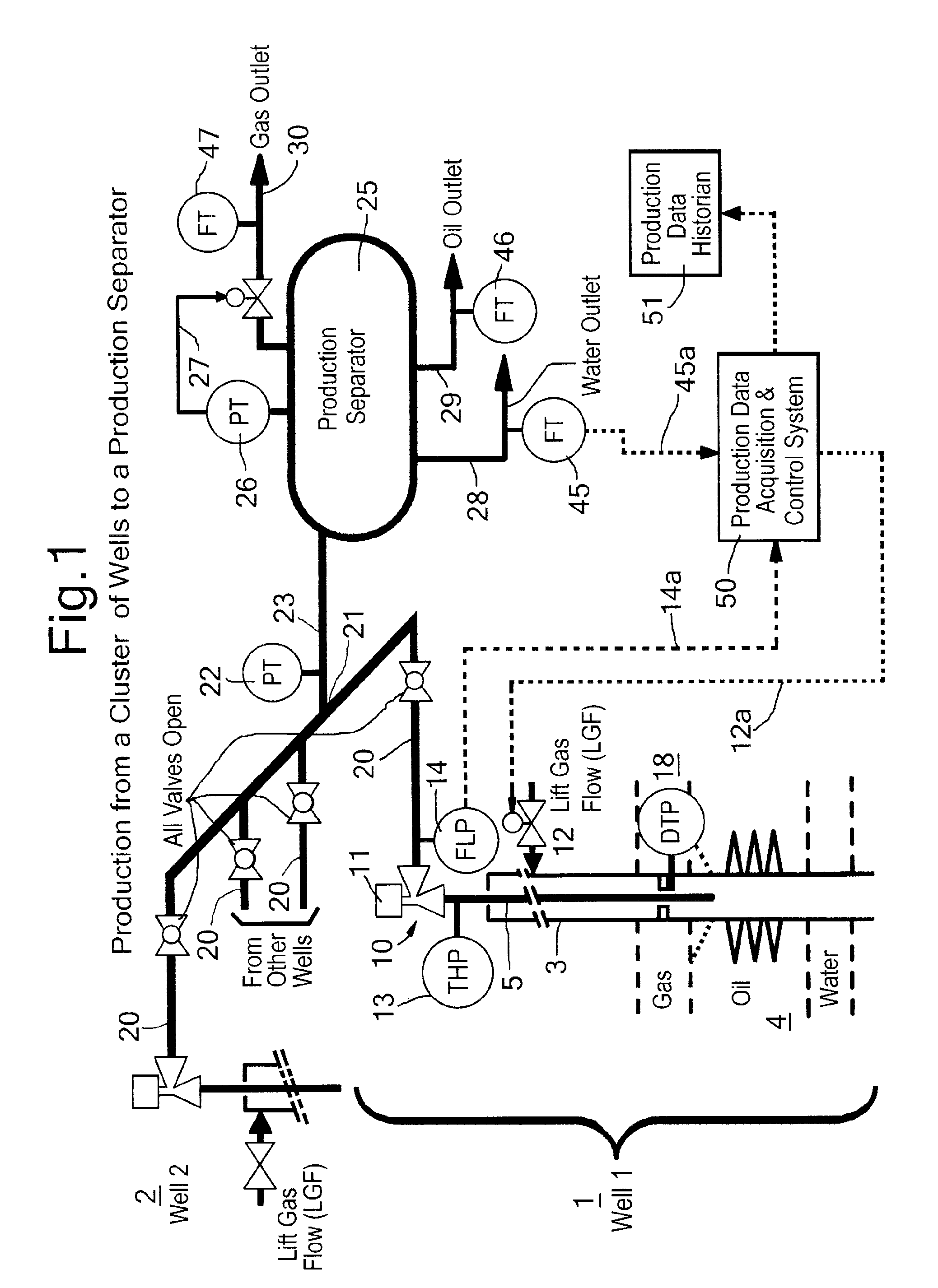

Method for controlling production and downhole pressures of a well with multiple subsurface zones and/or branches

A method for controlling the influx of fluids into a multizone well in which each inflow zone is provided with an inflow control device, comprises: assessing the flux of oil, gas, water and other effluents from the well; monitoring production variables, including ICD position and / or fluid pressure in each inflow zone upstream of each ICD and / or downstream of each ICD; sequentially adjusting the position of each of the ICDs and assessing the flux of crude oil, natural gas and / or other well effluents; monitoring production variables; deriving a zonal production estimation model for each inflow zone of the well; and adjusting each ICD to control the influx of crude oil, natural gas and / or other effluents into each inflow zone on the basis of data derived from the zonal production estimation model for each inflow zone of the well.

Owner:SHELL USA INC

Method and apparatus for plating solution analysis and control

ActiveUS20090157229A1Simultaneous measurementCellsSampled-variable control systemsSolution analysisElectroplating

A plating system comprises a plating solution and an apparatus for control of the plating solution, the apparatus including a Raman spectrometer for measurement of organic components, a visible light spectrometer for measurement of metallic components, and a pH probe. The plating solution can be sampled continuously or at intervals. Dosing of the plating solution adjusts for components consumed or lost in the plating process. The method of dosing is based on maintaining a desired composition of the plating solution.

Owner:LAM RES CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com