Continuous combustion constant power engine

An engine, constant power technology, applied in the field of vehicles, can solve the problems of incomplete combustion, knocking, low thermal efficiency, etc., and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

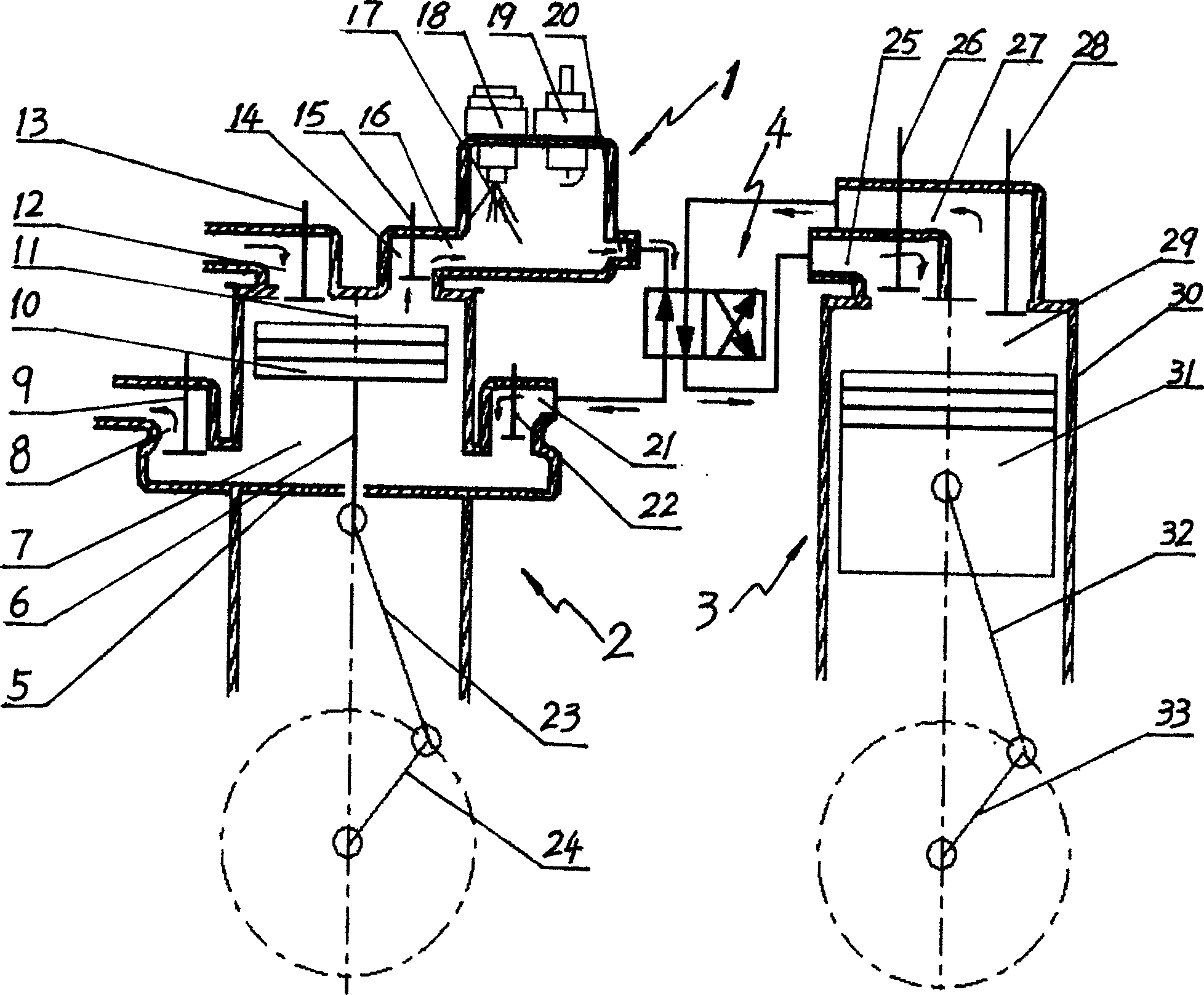

[0010] figure 1 The illustrated embodiment is a unit combination of the present invention, and a practical engine can be designed by combining a plurality of units.

[0011] Depend on figure 1 See, the combined engine embodiment of this unit includes a continuous burner 1 , a compressor 2 , an expansion device 3 and a two-position four-way ventilation valve 4 . A fuel nozzle 18 and a spark plug 19 are arranged on the top surface of the combustion chamber 17 of the continuous burner 1, and a fresh air inlet 16 and a high-pressure high-temperature mixed gas outlet 20 are arranged at the bottom. The cylinder body 5 of the air compressor 2 is provided with a double-acting piston 10 and a guide rod 6, the guide rod 6 is connected with the crankshaft connecting rods 24, 23, the double-acting piston 10 divides the cylinder body 5 into upper and lower parts, and the upper part is the compressor. chamber 11, the lower part is the secondary expansion chamber 7, and the top surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com