Carbonization and gasification of biomass and power generation system

a technology of carbonization and gasification of biomass, applied in the direction of fuel gas production, combustible gas catalytic treatment, combustible gas production, etc., can solve the problem of tar formation risk, achieve high heating value, low water content, and high quality of carbonized fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

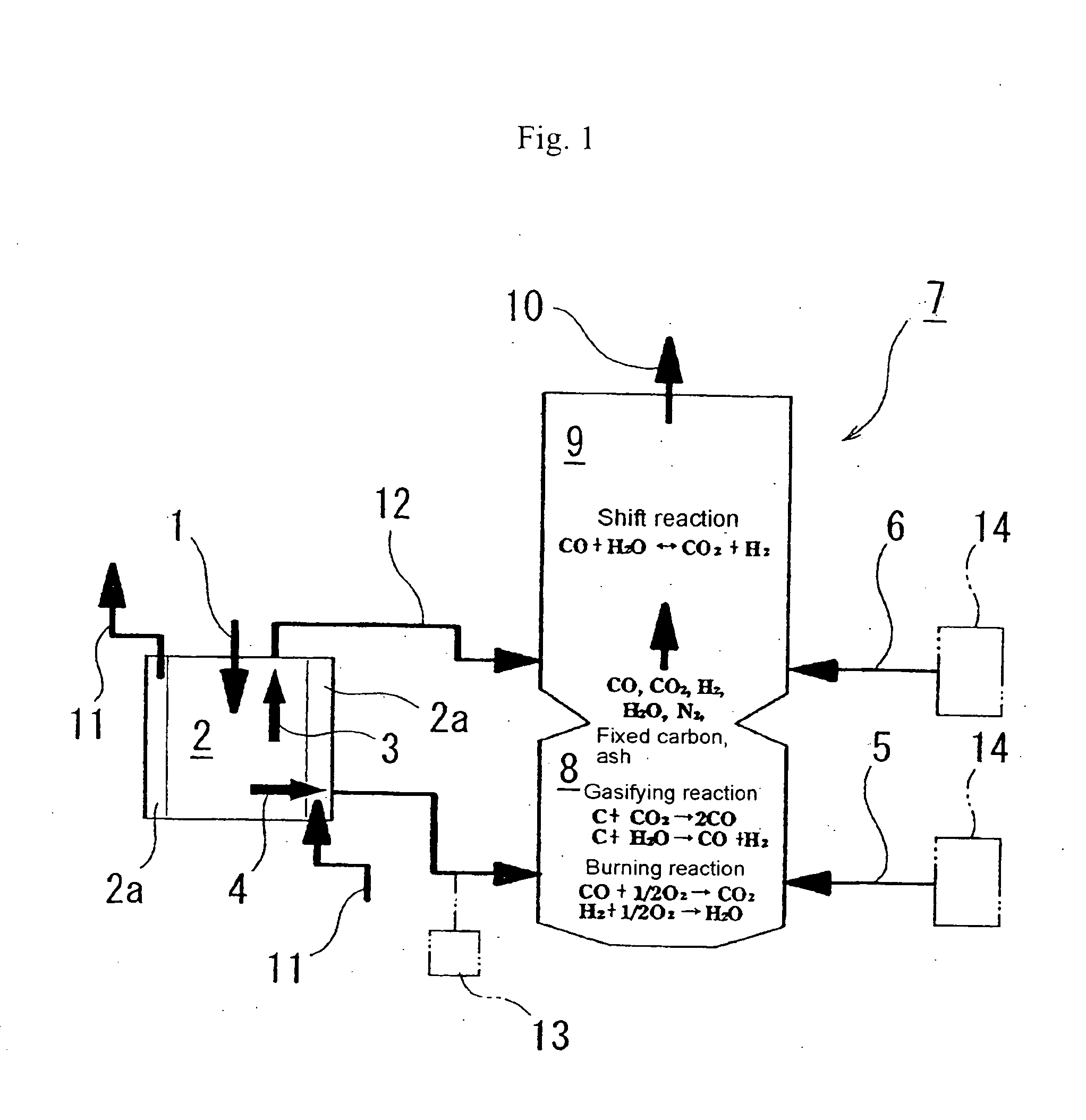

[0055] The embodiment of the invention shown in FIG. 1 is a biomass carbonizing-gasifying system for pyrolytically decomposing a biomass fuel 1, such as wood-based biomass, waste-based biomass including municipal solid waste, and mixtures of such biomasses. The biomass carbonizing-gasifying system comprises a carbonization chamber 2 for receiving and heating biomass fuel 1 to produce a carbonized material 4, a two-stage gasifier 7 composed of a high-temperature gasification part 8 for gasifying the carbonized material 4, and a gas reformer 9 for reforming combustible pyrolysis gas 3, a carbonized material feeder 13 for feeding the carbonized material 4 to the high-temperature gasification part 8 of the gasifier 7, a pyrolysis gas flow path 12 for sending the combustible pyrolysis gas 3 into the gas reformer 9 of the gasifier 7, and gasifying agent feed means 14 for feeding a gasifying agent 5 to the high-temperature gasification part 8 of the gasifier, and feeding a gasifying agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com