Method and device for degrading pollutants through ultraviolet catalytic wet oxidation

A technology for catalyzing wet oxidation and pollutants. It is used in oxidized water/sewage treatment, light water/sewage treatment, etc. It can solve problems such as harsh degradation conditions, and achieve the effects of complete degradation, saving investment and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

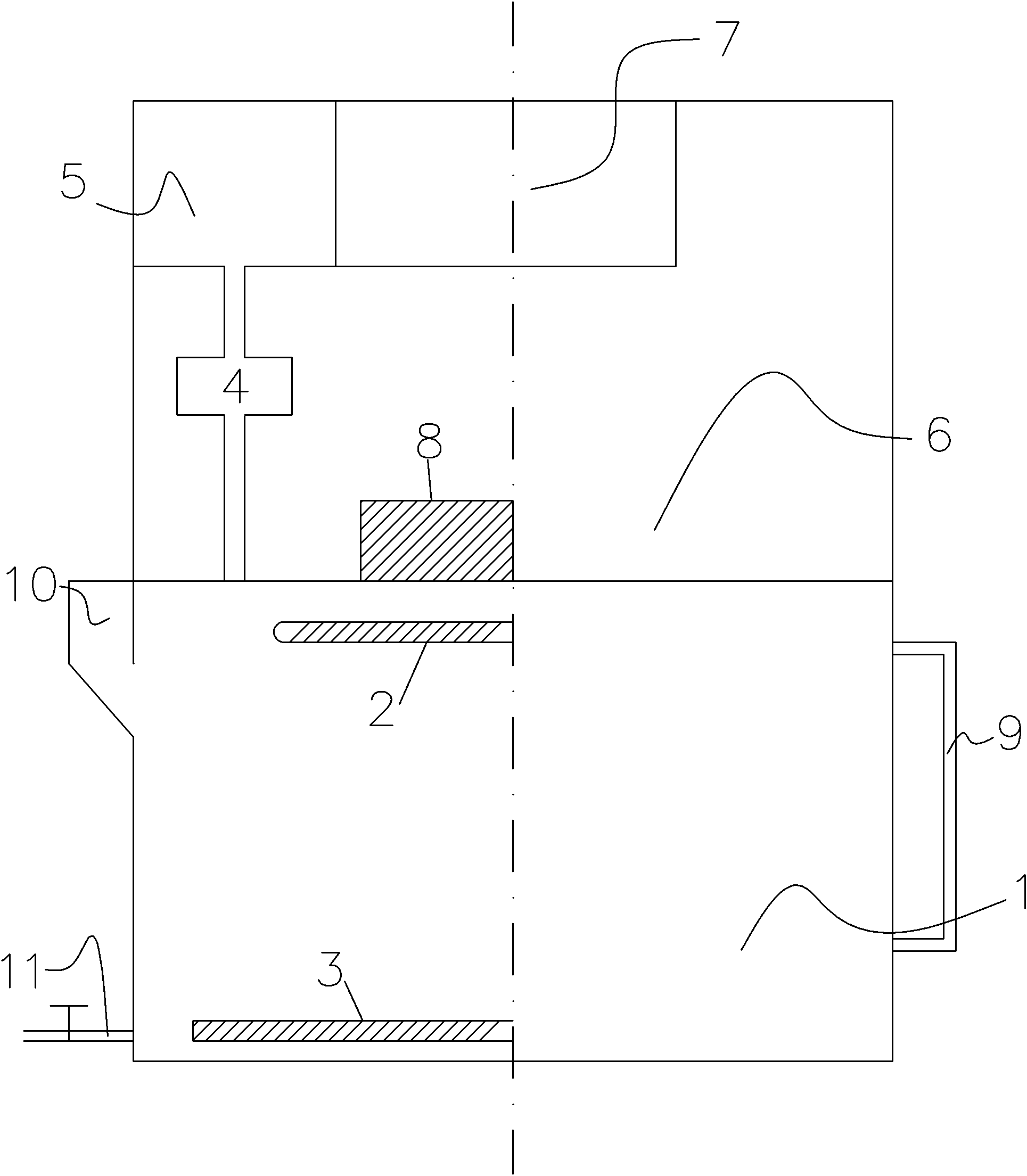

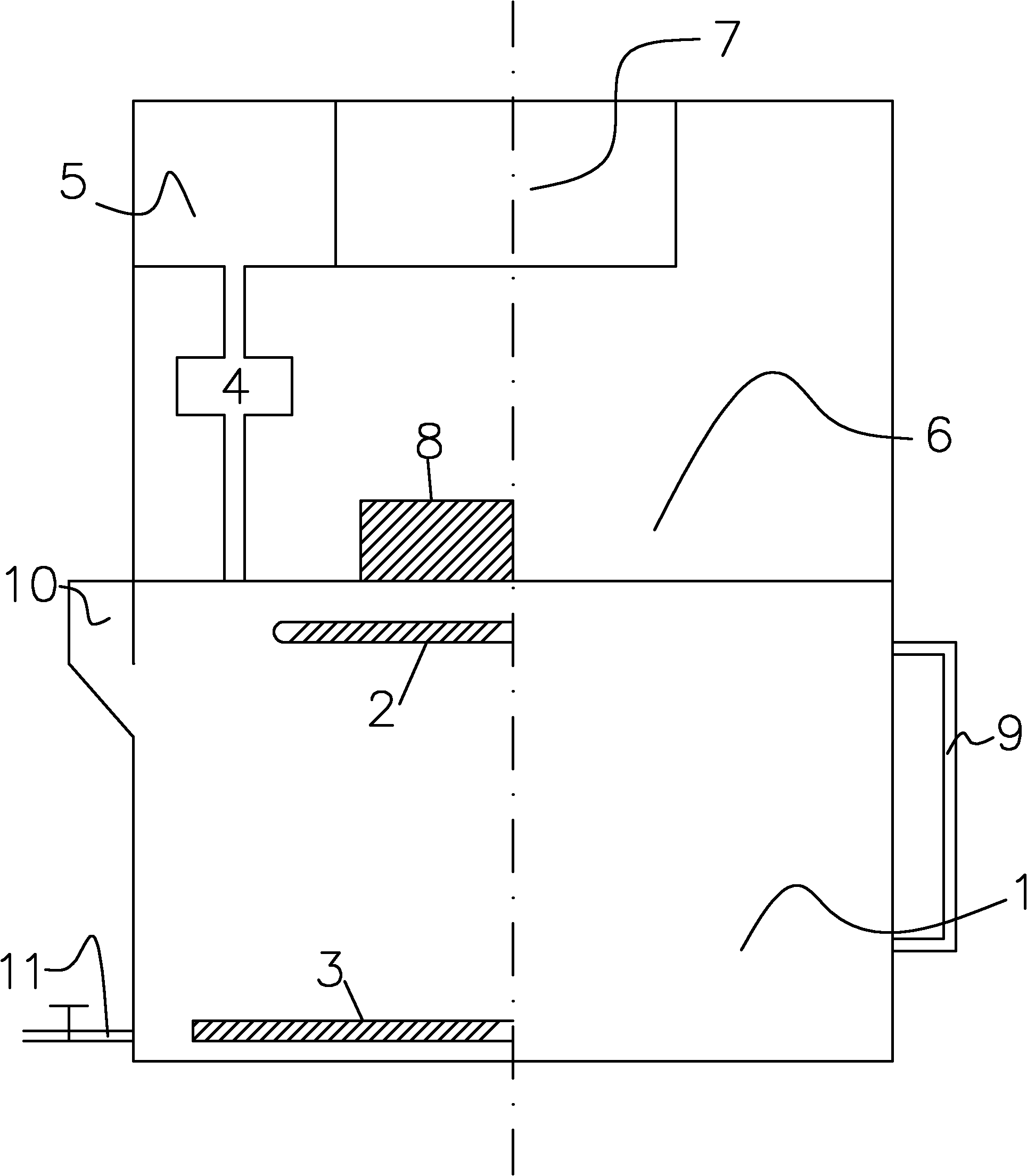

Image

Examples

example 1

[0047] Example one: adopt the present invention to degrade copper nitrate electroplating waste bath liquid:

[0048] Get 4 liters of actual copper nitrate electroplating wastewater from an electroplating factory (after measuring its COD Cr Concentration is 10032mg / L) is put into reaction tank 1, adjusts pH value to 7, and adding concentration is 30% hydrogen peroxide (making H 2 o 2 Concentration is 10g / L) and self-made Cu series nano-catalyst (making the concentration 5g / L), adopt mechanical stirring mode to stir, turn on 80W ultraviolet lamp to start reaction, carry out oxidative degradation. COD at different degradation times Cr The measurement results showed that the CODCr degradation rates of the samples with reaction time of 30min, 90min, and 150min were 18.2%, 49.1%, and 99.1%, respectively, and the final effluent COD Cr It is 90.3mg / L.

[0049] If other conditions are the same, but turn off the UV lamp, COD of samples at 30min, 60min, and 150min Cr The degradation...

example 2

[0050] Example two: adopt the present invention to degrade ink waste water:

[0051] Take a certain amount of actual ink wastewater from an electroplating factory (its COD Cr Concentration is 26192mg / L), adjust the pH value to 3.5 to carry out acid precipitation coagulation precipitation pretreatment, then take 4L supernatant (its COD Cr Concentration is 10372mg / L) is put into reactor, and adds 30% hydrogen peroxide (makes H 2 o 2 Concentration is 10g / L) and self-made Fe, Cu series ion catalyst (making Fe, Cu content to be 1g / L and 0.5g / L respectively), adopt 50L / min air aeration, turn on 80W ultraviolet lamp to start reaction, carry out oxidation degradation. COD at different degradation times Cr The measurement results show that the COD of the samples with a reaction time of 30min, 90min, and 120min Cr The degradation rates are 30.6%, 85.0%, and 99.6% respectively, and the final effluent COD Cr It is 41.5mg / L. In addition, after 90 minutes of treatment, BOD 5 / CODcr ...

example 3

[0052] Example three: adopt the present invention to degrade surfactant wastewater:

[0053] Get 4 liters of certain electroplating factory surfactant wastewater (its COD Cr Concentration is 12032mg / L) puts into reactor, adjusts pH value to 6.5, and adds peroxyacetic acid (making concentration be 11g / L), self-made Fe, P series granular nano-catalyst (making concentration be 2.5g / L), Adopt 50L / min air aeration, turn on 80W ultraviolet lamp to start the reaction, and carry out oxidation degradation. The CODCr measurement results of different degradation times show that the COD of samples with a reaction time of 30min, 90min, and 150min Cr The degradation rates were 18.2%, 49.1%, and 99.8%, respectively, and the final effluent COD Cr It was 24.1mg / L; after 90 minutes of treatment, the BOD was measured by sampling 5 / CODcr increased from 0.12 in raw water to 0.35, and the biodegradability was obviously improved.

[0054] If other conditions are the same, but turn off the UV la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com