Method and device for treating high-salt refractory organic wastewater

A technology of organic wastewater and treatment methods, applied in water/sewage treatment, multi-stage water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of long process flow, high operating costs, high equipment investment, etc., and achieve high The effect of catalytic degradation efficiency, efficiency improvement and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

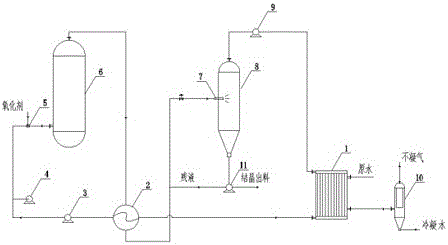

[0034] A certain saccharin sodium production waste water——Adopt the method of the present invention and the corresponding pilot plant to pretreat the iron replacement liquid that replaces the cupric acid water.

[0035] The replacement cupric acid water is first replaced by iron to recover the copper element, adjust the pH to 8.5~9, and precipitate. The COD of the supernatant is 14200~15680 mg / L, COD 2690~3120 mg / L, NaCl~8%, NaCl 2 SO 4 ~3%.

[0036] Subsequent processing of the supernatant includes the following steps:

[0037] (1) Cupric acid hydroferric replacement liquid, the precipitated supernatant liquid is preheated by the gas-liquid heat exchanger 1 and the liquid-liquid heat exchanger 2, pressurized by the booster pump 3 and the compressor fan 4, and then oxidized in WAO Catalytic oxidation reaction occurs in reactor 6, the pressure of WAO oxidation reactor is 3.2~4.1 MPa, and the temperature is 181.2~186.3°C;

[0038] (2) After the mixed liquid after the oxidatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com