Technique and equipment for preparing sulfuric acid by using sulfur and waste liquid generated from coal gas wet type oxidation sweetening technique

A wet oxidative desulfurization and process technology, which is applied in inorganic chemistry, sulfur compounds, chemical instruments and methods, etc., can solve the problems of no treatment process for waste liquid, low sulfur purity, and difficulty in sales, so as to protect the environment and achieve resource recycling. , Low operating cost, good environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

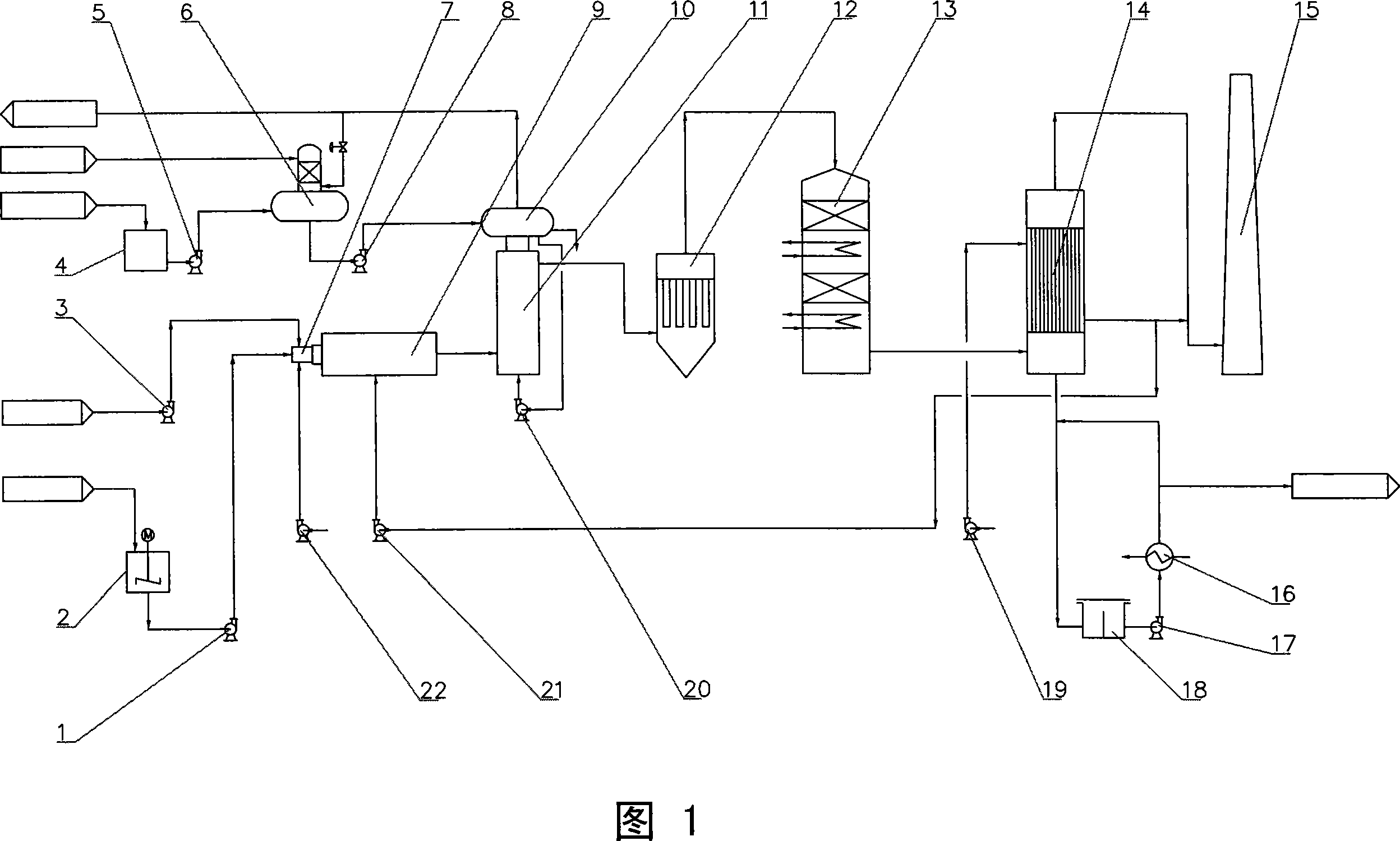

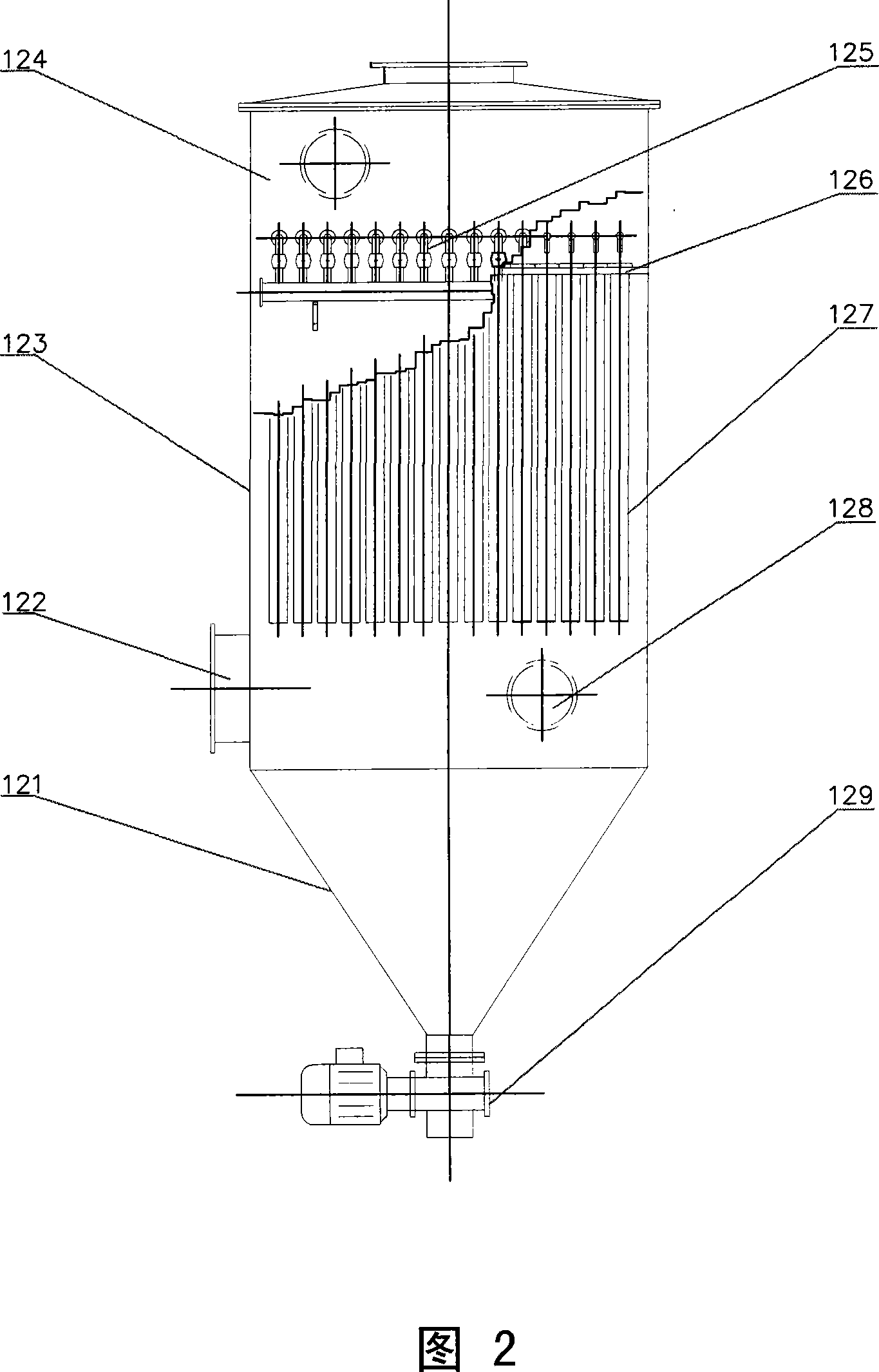

[0056] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

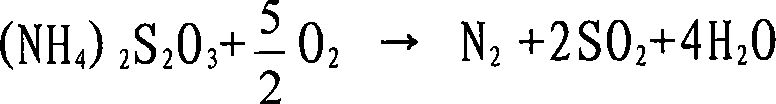

[0057] As shown in Fig. 1, according to a kind of process of the present invention using the sulfur and waste liquid that the coal gas wet oxidative desulfurization process produces sulfuric acid, comprise waste liquid incineration, waste heat recovery, dry type purification, contact conversion, acid gas condensation, its It is characterized in that sulfur and waste liquid produced after wet oxidation desulfurization of coal gas are used as raw materials. The main component of waste liquid is a salt solution containing sulfur element. After incineration, waste heat recovery, dry purification, wet contact conversion and acid gas condensation Production process of sulfuric acid:

[0058] 1) Incineration process: the raw material sulfur slurry mixed with sulfur and a salt solution containing sulfur is sent to the combustion furnace 9 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com