Enzyme modified paper pulp fiber, wood-plastic composite material and preparation method thereof

A wood-plastic composite material and pulp fiber technology, which is applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems of weak interaction, poor dispersion, and poor mechanical properties of wood-plastic composite materials, so as to increase the content, Effect of improving mechanical strength and increasing environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In embodiment 1, the method for enzyme modification pulp fiber, comprises the following steps: after pulp fiber is immersed in water (the mass ratio of pulp fiber and water is 1:15) after 0.5 hour, mix with compound enzyme, use pH value 4.6 citric acid-sodium citrate buffer solution to adjust the pH value of the reaction solution to 4.6, a small amount of 2mol / L disodium EDTA solution was added dropwise to prevent the formation of metal-enzyme complexes, and the reactant solution was reacted at 50°C for 4 After the reaction, the reaction solution is heated to boiling (100° C.) to inactivate the enzyme, then centrifuged and washed until the pH of the clear liquid is 7, and the solid product is dried at 70° C. to a water content≤2%. Obtain enzyme modified pulp fiber. Wherein, the compound enzyme is a mixture of hemicellulase, xylanase and pectinase, the weight ratio thereof is 2:2:1, and the mass of the compound enzyme is 20% of the pulp fiber mass.

[0054] Example 1

...

Embodiment 2

[0068] In embodiment 2, the method for enzyme modification pulp fiber, comprises the following steps: after pulp fiber is immersed in water (the mass ratio of pulp fiber and water is 1:15) after 0.5 hour, mix with compound enzyme, use pH value 4.6 citric acid-sodium citrate buffer solution to adjust the pH value of the reaction solution to 4.6, a small amount of 2mol / L disodium EDTA solution was added dropwise to prevent the formation of metal-enzyme complexes, and the reactant solution was reacted at 50°C for 3 After the reaction, the reaction solution is heated to boiling (100° C.) to inactivate the enzyme, then centrifuged and washed until the pH of the clear liquid is 7, and the solid product is dried at 70° C. to a water content≤2%. Obtain enzyme modified pulp fiber. Wherein, the compound enzyme is a mixture of hemicellulase, xylanase and pectinase, the weight ratio thereof is 2:2:1, and the mass of the compound enzyme is 10% of the pulp fiber mass.

[0069] Example 2

...

Embodiment 3

[0081] In embodiment 3, the method for enzyme modification pulp fiber, comprises the following steps: after pulp fiber is immersed in water (the mass ratio of pulp fiber and water is 1:15) after 0.5 hour, mix with compound enzyme, use pH value 4.6 citric acid-sodium citrate buffer solution to adjust the pH value of the reaction solution to 4.6, a small amount of 2mol / L disodium EDTA solution was added dropwise to prevent the formation of metal-enzyme complexes, and the reactant solution was reacted at 50°C for 3 After the reaction, the reaction solution is heated to boiling (100° C.) to inactivate the enzyme, then centrifuged and washed until the pH of the clear liquid is 7, and the solid product is dried at 70° C. to a water content≤2%. Obtain enzyme modified pulp fiber. Wherein, the composite enzyme is a mixture of hemicellulase and xylanase, the weight ratio thereof is 2:1, and the composite enzyme mass is 30% of the pulp fiber mass.

[0082] Example 3

[0083] (1) Pulver...

PUM

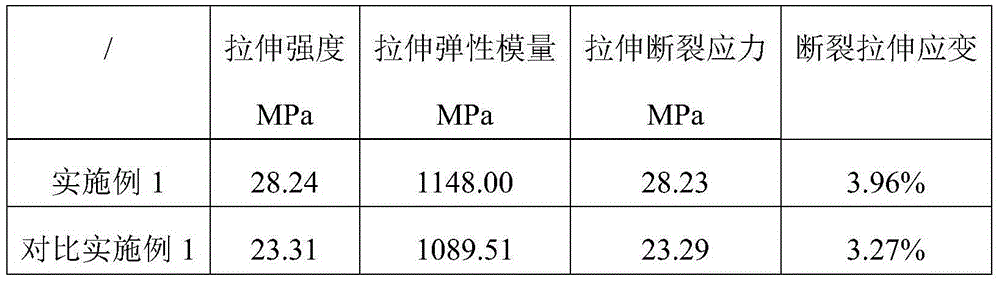

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus of elasticity | aaaaa | aaaaa |

| Tensile fracture stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com