Hoisting tool and hoisting method for column component

A component and column technology, which is applied in the field of hoisting equipment and hoisting of large-scale column components, can solve the problems of slow construction speed, unsafe, high safety risk, etc., and achieve the effect of fast construction speed and small safety risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

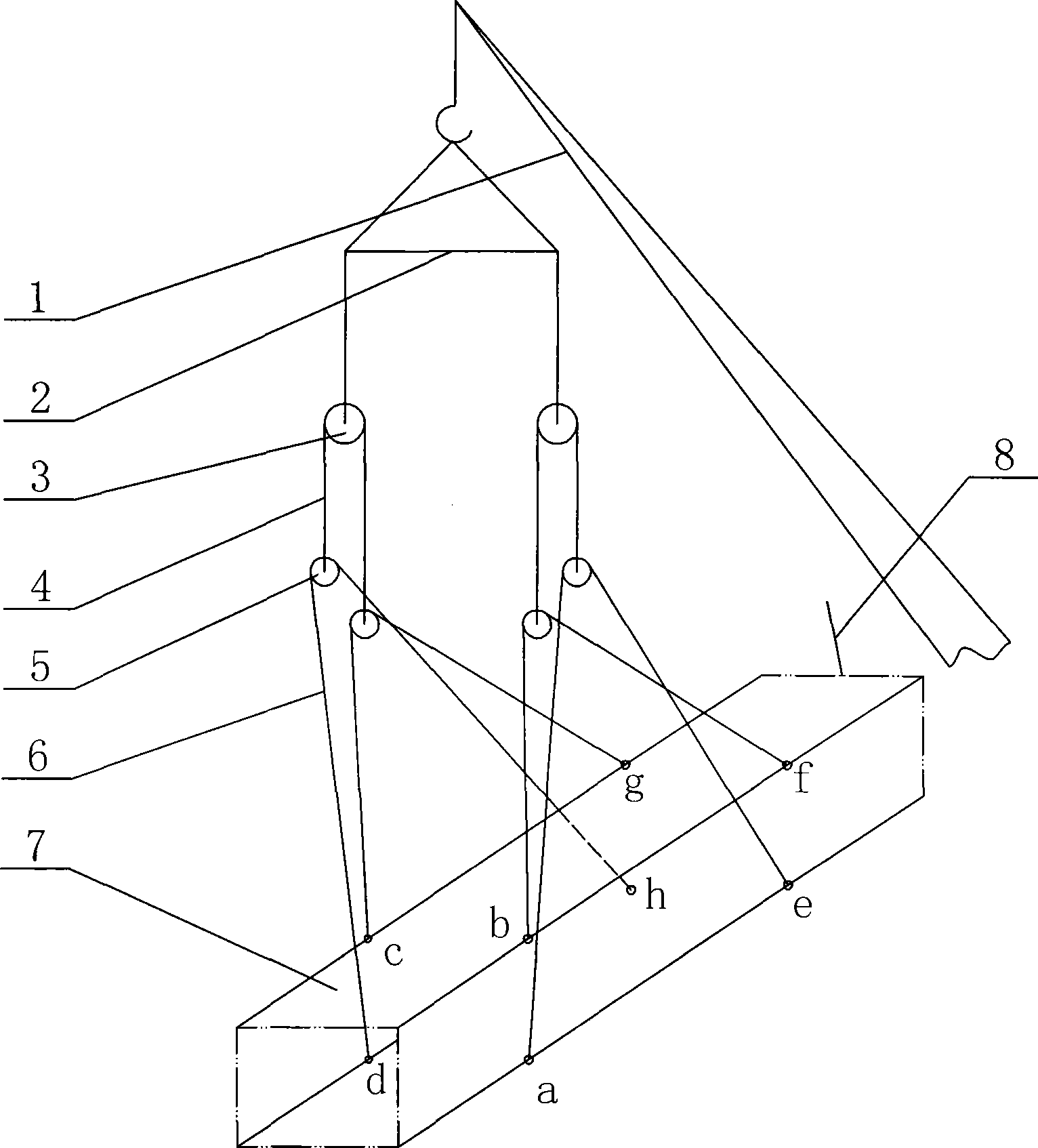

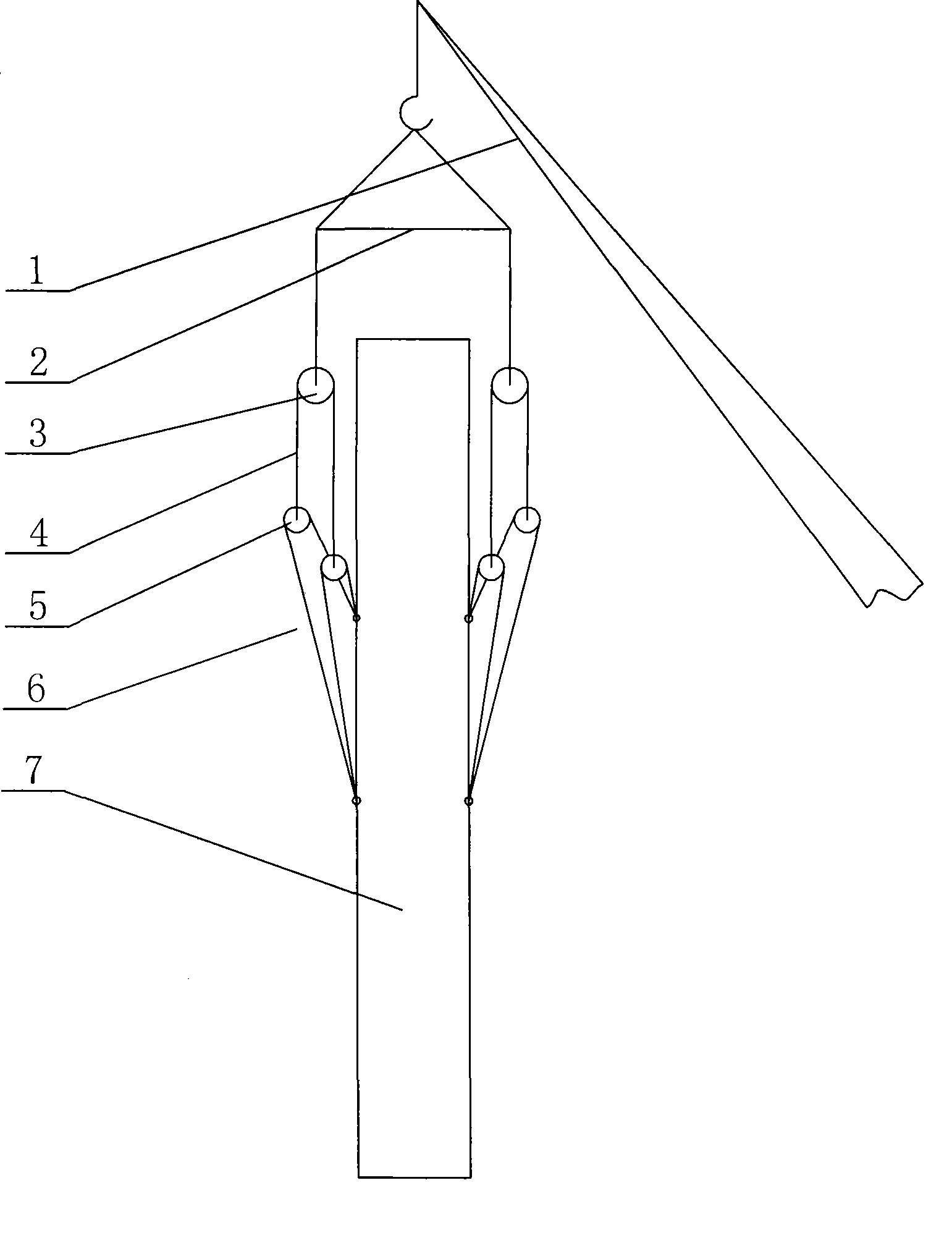

[0015] Such as figure 1 As shown, fixed pulleys 3 are respectively installed at both ends of the hoisting beam 2, two ropes 4 pass around the fixed pulleys respectively, and pulleys 5 are respectively installed at both ends of each rope. In order to ensure that the column member 7 can be turned over smoothly to a position perpendicular to the ground during the hoisting process, the length of the hoisting beam 2 is greater than the width of the column member to be hoisted.

[0016] The main suspension hook of main crane 1 links to each other with the sling for hanging suspension hook fixed on the hoisting beam 2, and the auxiliary suspension rope 8 installed at the bottom of the column member links to each other with the suspension hook of auxiliary crane. After the 4 hoisting ropes 6 go around the 4 pulleys respectively, their 8 rope heads are respectively fixed on the column member 7 and distributed around the center of gravity of the column member, wherein the fixing of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com