Fungus bag punching machine for agricultural planting

A mushroom bag and agricultural technology, which is applied in the field of mushroom bag punching machine for agricultural planting, can solve the problems of uneven position, inconsistent depth, difficult operation, etc., and achieve the effect of consistent depth, easy pick and place, and uniform position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

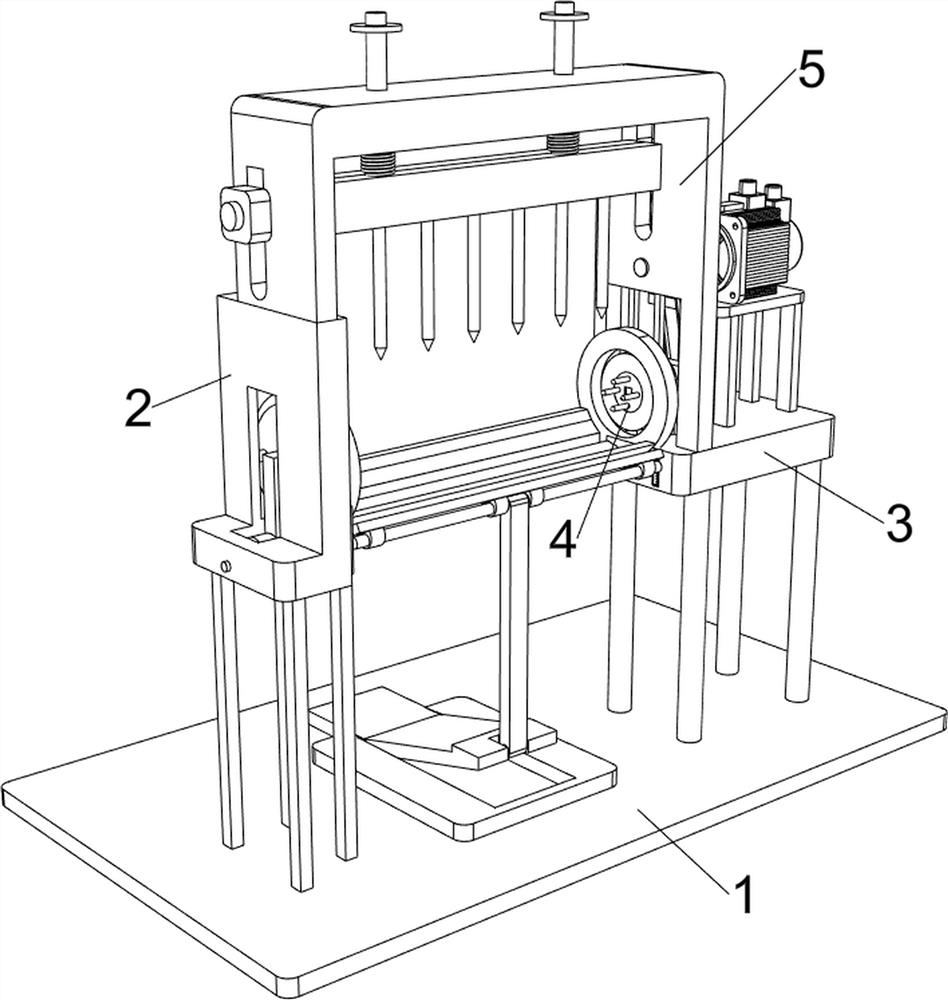

[0025] A fungus bag punching machine for agricultural planting, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, it includes a base plate 1, a frame 2, a support seat 3, a clamping mechanism 4 and a punching mechanism 5. The left side of the top of the base plate 1 is provided with a frame 2, and the right side of the top of the base plate 1 is fixedly connected with a support base 3. A clamping mechanism 4 is provided between the frame 2 and the top of the support base 3 , a punching mechanism 5 is provided between the frame 2 and the support base 3 , and the clamping mechanism 4 is located below the punching mechanism 5 .

[0026] When people need to use this device for work, first people pull the 4 parts of the clamping mechanism outward, then place the bacteria bag on the clamping mechanism 4, and then people loosen the 4 parts of the clamping mechanism to fix the clamping mechanism 4 Live bacteria bag, then people just can start punching mechanism 5, ma...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 5-8 As shown, it also includes a support plate 6, a fourth rotating shaft 7, a belt transmission device 8, a ratchet wheel 9 and a block 11, a support plate 6 is provided on the rear side of the top of the support seat 3, and the support plate 6 is provided with a first rotation in a rotating manner. Four rotating shafts 7, a belt transmission device 8 is connected between the fourth rotating shaft 7 and the square shaft 413, a ratchet 9 is provided on the fourth rotating shaft 7, and a second square groove 10 is provided on the rear side of the second fixed block 59 on the right side. The second square groove 10 of the second fixed block 59 is provided with a locking block 11 rotatably, and the locking block 11 cooperates with the ratchet 9 .

[0033] When the second fixed block 59 on the right side moved downward, the second fixed block 59 on the right side drove the block 11 to move downward, and the block 11 could not drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com