Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

261results about How to "Consistent depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

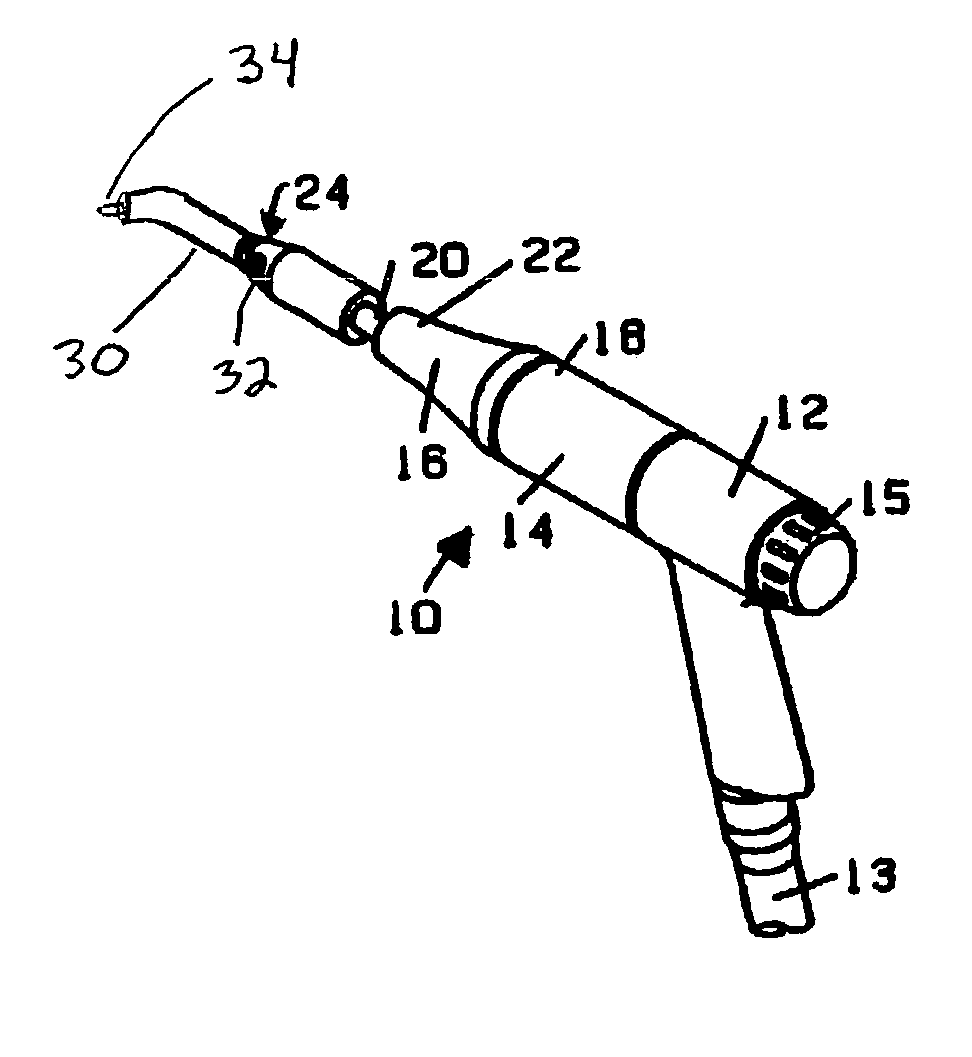

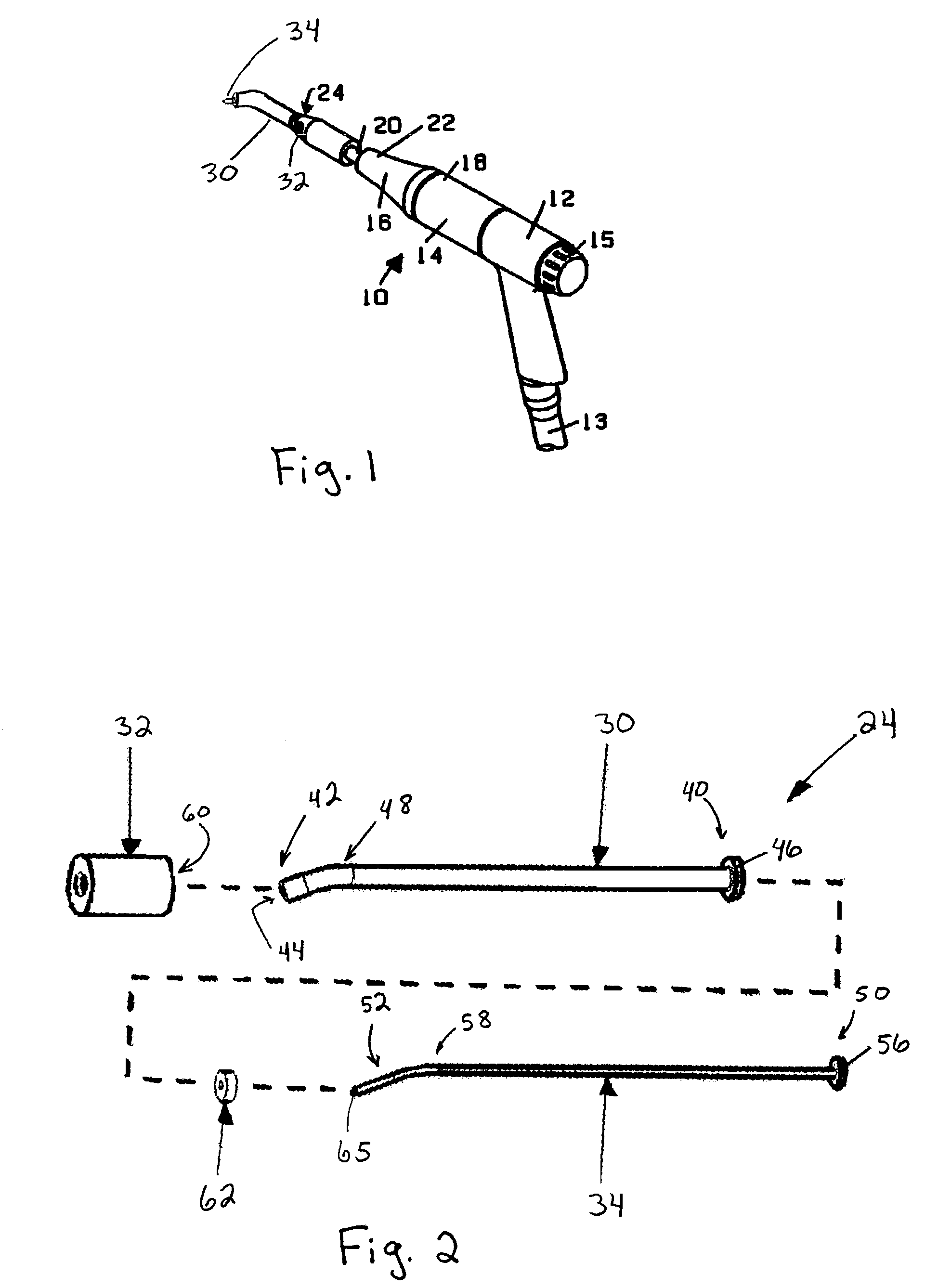

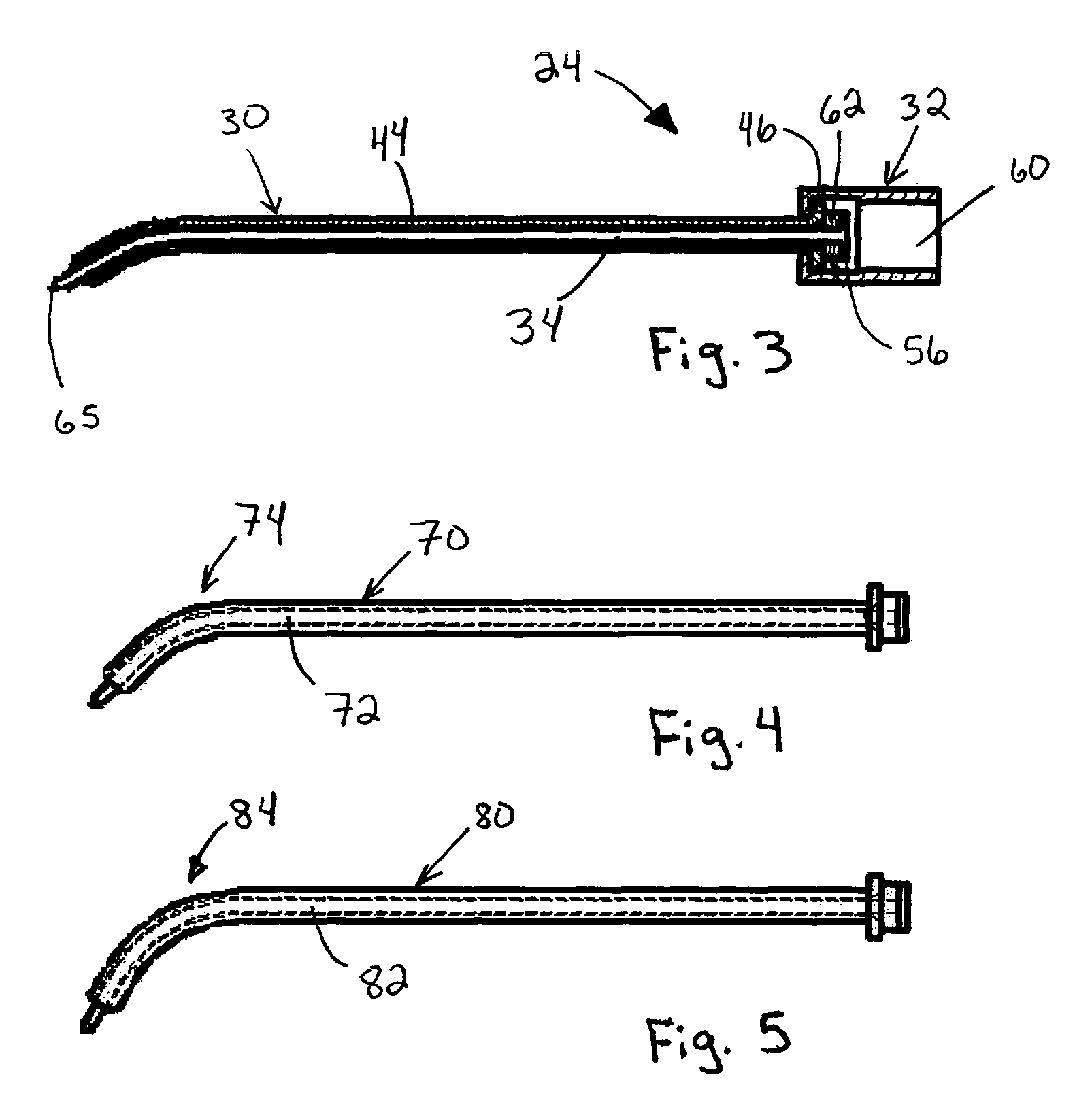

Method for performing automated microfracture

The present invention is directed to a method for repairing defects in articular cartilage and, more particularly, to a new method for performing automated microfracture on subchondral bone to repair articular cartilage. The microfractured holes on the surface of the subchondral bone plate are formed with an automated process using a pneumatically driven orthopedic microfracture instrument. The instrument moves a fracture pin through the end of a guide tube until a sharp end of the fracture pin punctures or penetrates the subchondral bone plate and creates a microfracture or hole in the bone.

Owner:ZIMMER INC

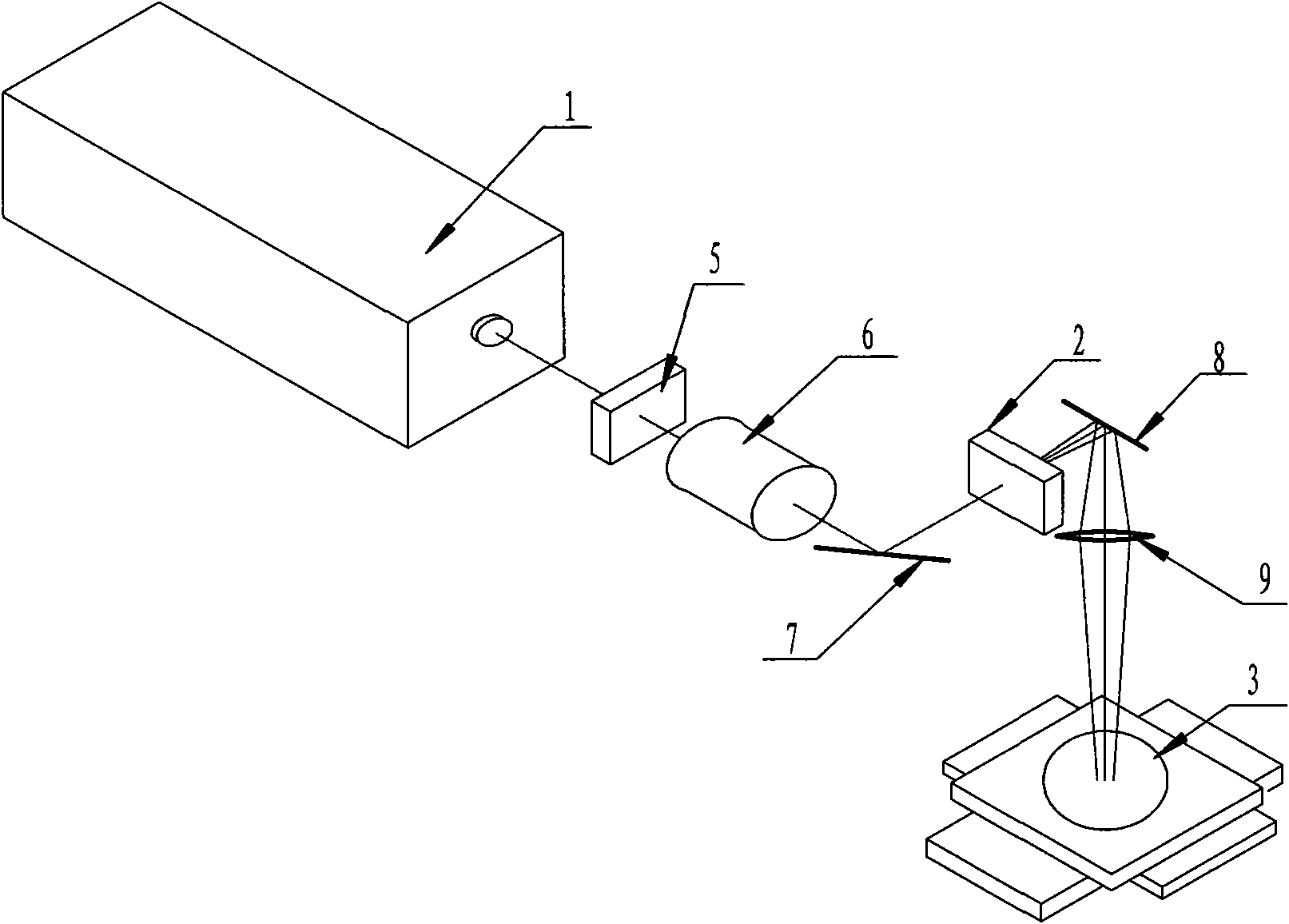

Designing method for LED wafer tri-laser-beam scribing equipment

InactiveCN101670492AConvenient and flexible spot energy distributionControl spot energy distributionLaser beam welding apparatusBeam expanderComing out

The invention relates to a designing method for LED wafer tri-laser-beam scribing equipment, in which the output end of a laser is provided with a light gate, the output end of the light gate is connected with a beam expander, a first total reflecting mirror is arranged at the output end of the beam expander, the output end of the first total reflecting mirror is linked with a laser beam splittingsystem used for splitting a single-beam laser source into tri-laser-beams, the output end of the laser beam splitting system is provided with a second total reflecting mirror which is linked with a focusing mirror, and the focusing mirror in right face of a processing platform; laser light coming out of the laser is emitted to the beam expander via the light gate, the laser light passing throughthe beam expander is emitted to the first total reflecting mirror, the laser light passing through the first total reflecting mirror is emitted to the laser beam splitting system, the laser beam splitting system outputs triple laser beams with equivalent dimension and energy, the triple laser beams are emitted to the second total reflecting mirror, are emitted to the focusing mirror after the angle is intersected by the second total reflecting mirror, and are parallel focused on the processing platform after permeating through the focusing mirror. The equipment realizes parallel scribing on the LED wafer tri-laser-beam and can be widely used for cutting LED wafers.

Owner:SUZHOU DELPHI LASER

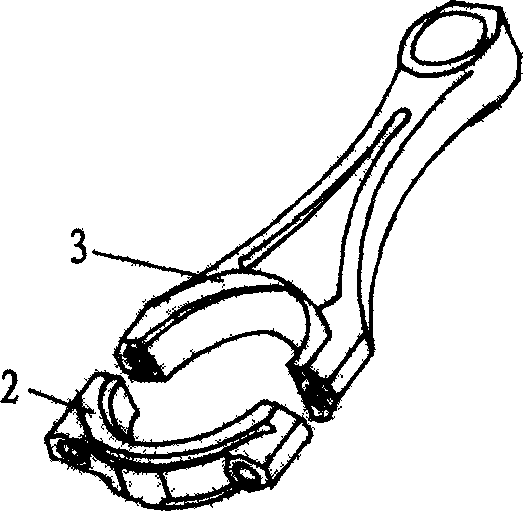

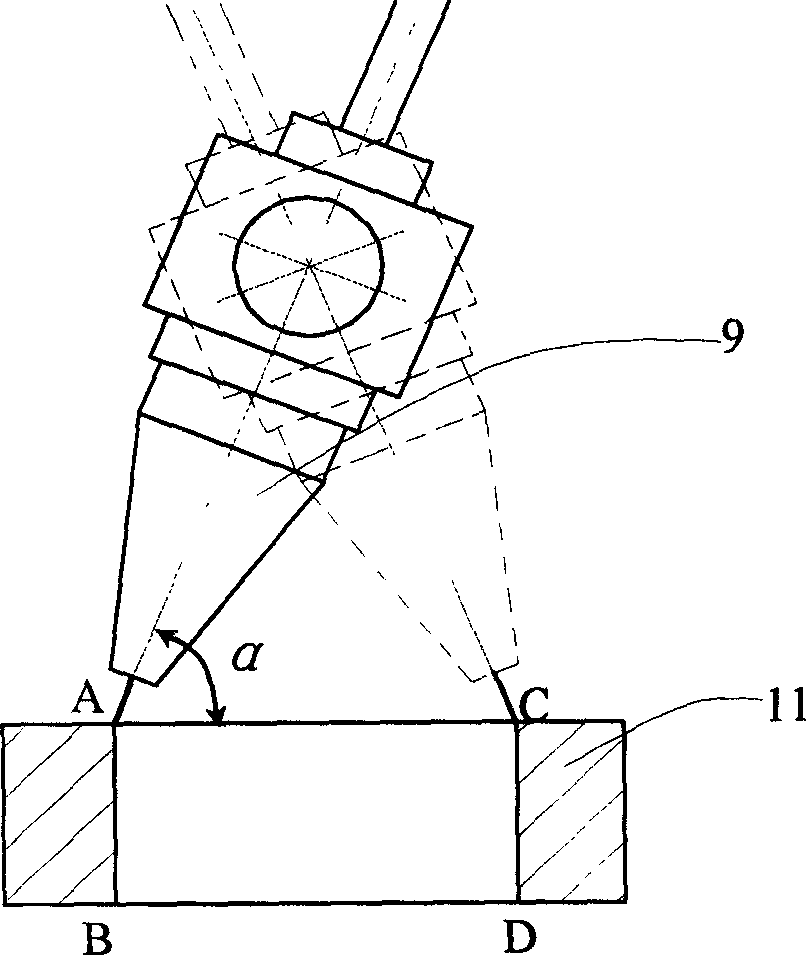

Laser processing method for connecting rod splitting groove and its equipment

InactiveCN1559744ANarrow kerfControllable depthConnecting rod bearingsShearing machinesLaser processingLaser cutting

A method for using laser to premachine the cracking slots before dividing connecting rods from each other includes such steps as fixing the laser cutting head above the position to be machined, which is near the hole on big end of connecting rod, regulating the incident angle of laser beam to 0-70 deg.C, turning on laser device, vertically moving the laser cutting head to machine the cracking slot to predefined depth, and repeating said steps to machine another cracking slot at another end of aconnecting rod.

Owner:JILIN UNIV

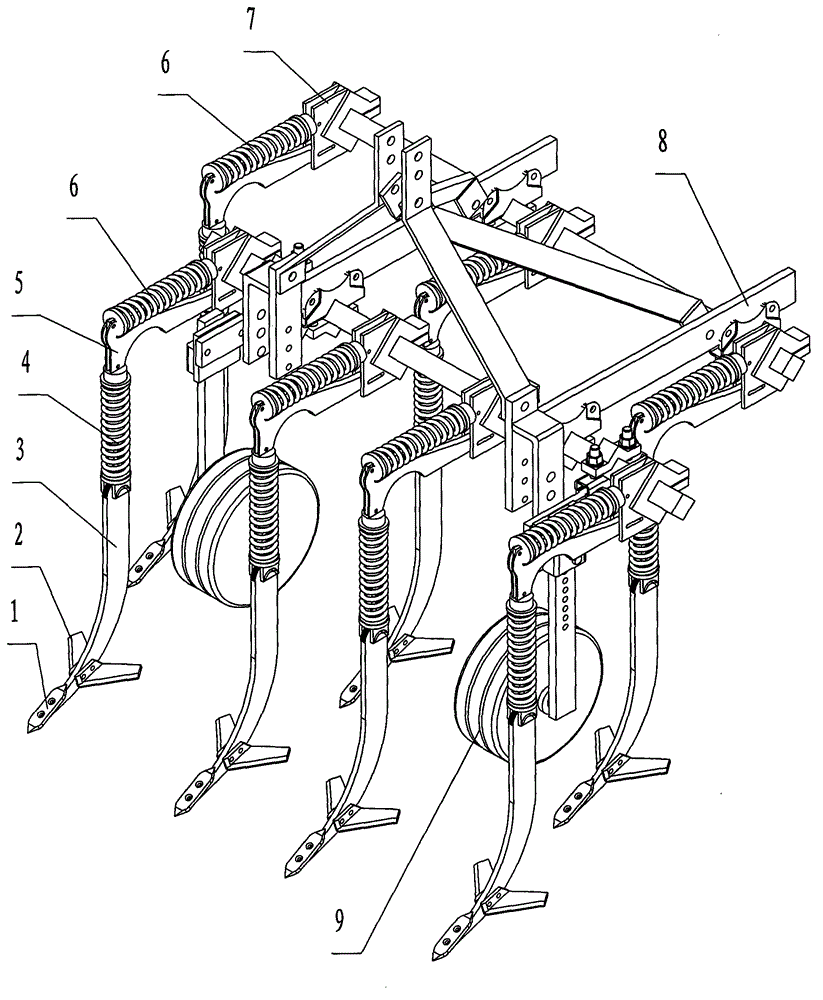

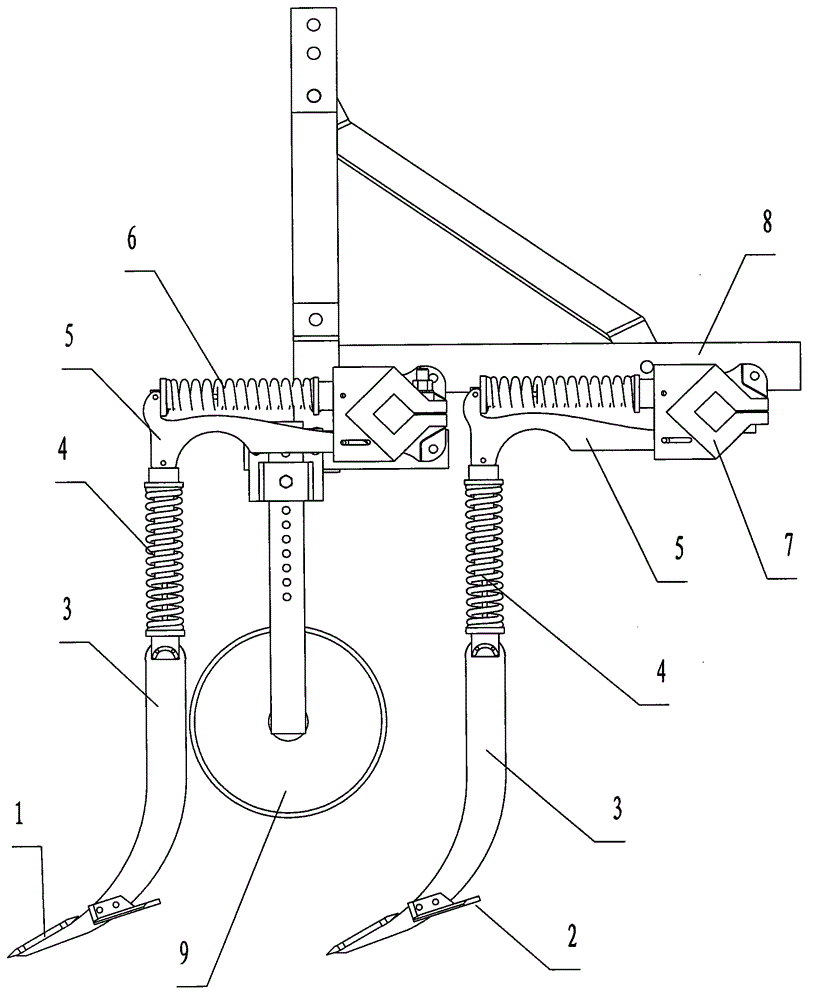

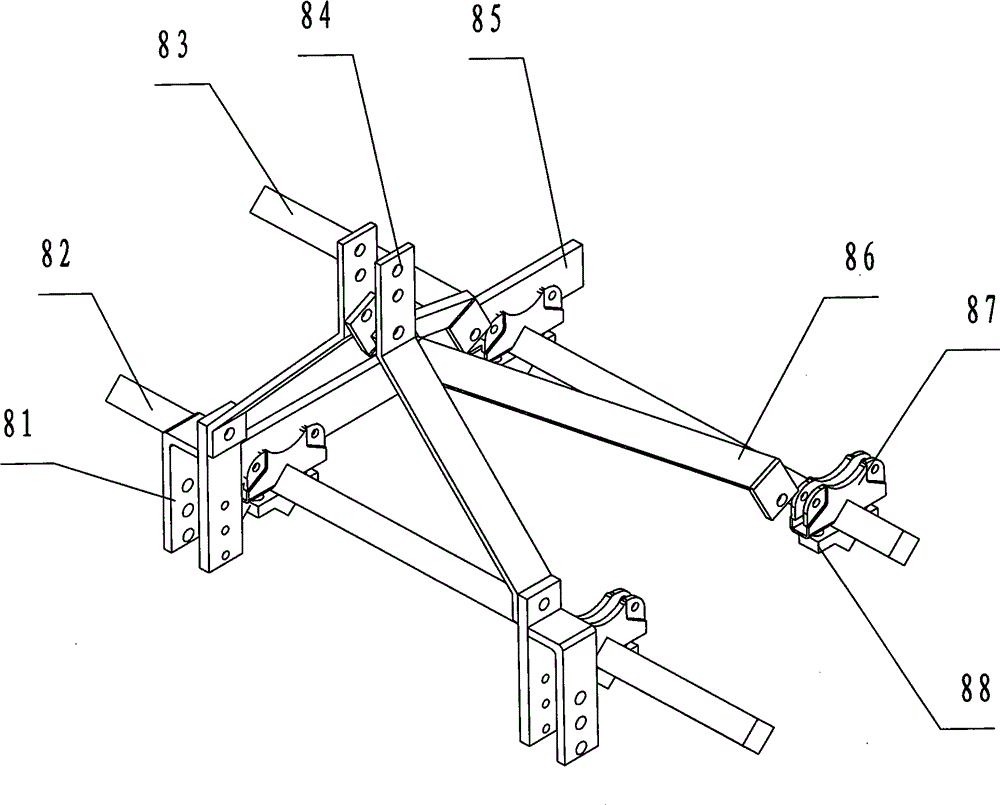

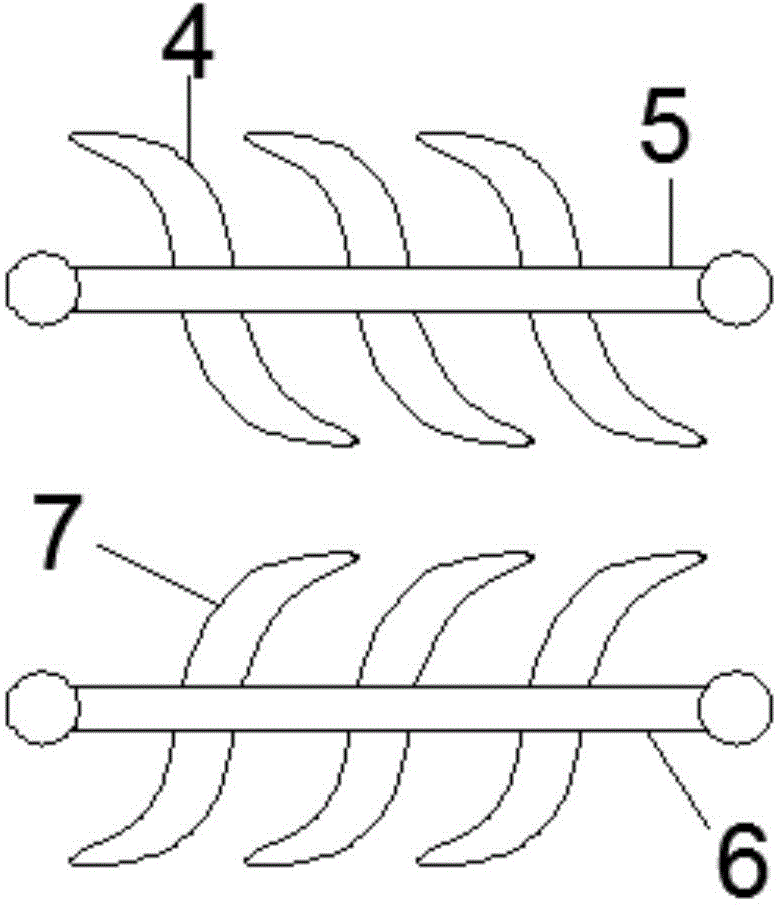

Hydraulic self-induced vibration subsoiler

InactiveCN104604365AAdjust the entry depthReduce physical discomfort and other problemsPloughsAgricultural engineeringTractor

The invention relates to a hydraulic self-induced vibration subsoiler. The hydraulic self-induced vibration subsoiler is characterized by comprising a machine frame and a subsoiling device, wherein the subsoiling device is arranged at the bottom of the machine frame, the machine frame is composed of suspension pair plates, a front beam, a rear beam, an inclined traction rod, a cross beam, a cross traction rod, U-shaped groove fixing pieces and V-shaped locking pieces, and the subsoiling device is composed of shovel points, shovel wings and shovel handles. According to the hydraulic self-induced vibration subsoiler, the stretch and retraction amount of vibration springs is controlled and adjusted through hydraulic oil, the embedded depths of all subsoiling shovels are effectively adjusted, in this way, the tilling depth consistency is guaranteed during subsoiling, and the overall vibration which causes discomfort of a driver of a tractor and the like and is generated due to inconsistency of shake of mechanisms of the subsoiler is reduced; compared with a non-vibration subsoiler and a one-way vibration subsoiler under the same condition, during work, the traction resistance is remarkably reduced; to sum up, the hydraulic self-induced vibration subsoiler can reduce resistance and save energy and is good in operation effect and high in adaptability.

Owner:SHIHEZI UNIVERSITY

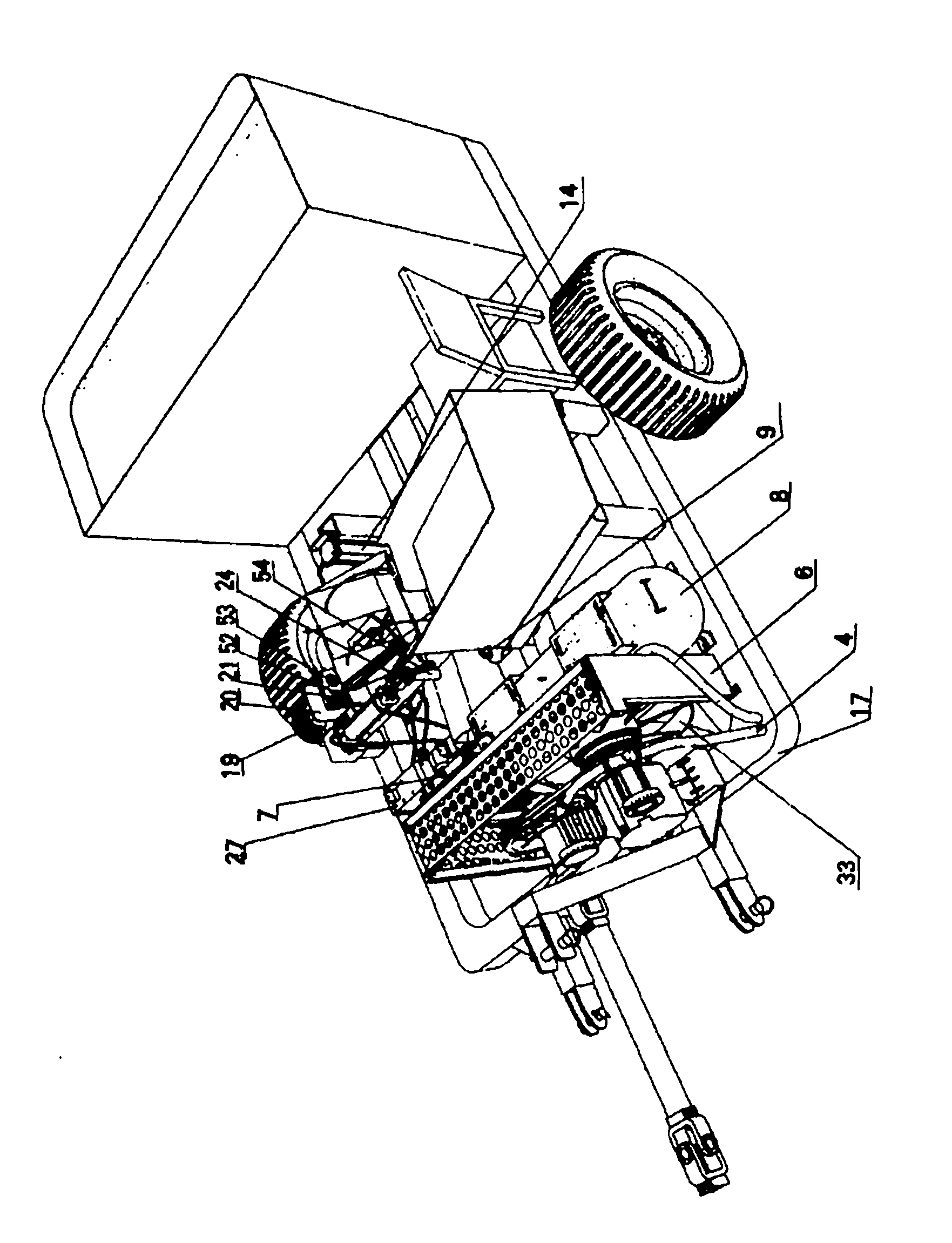

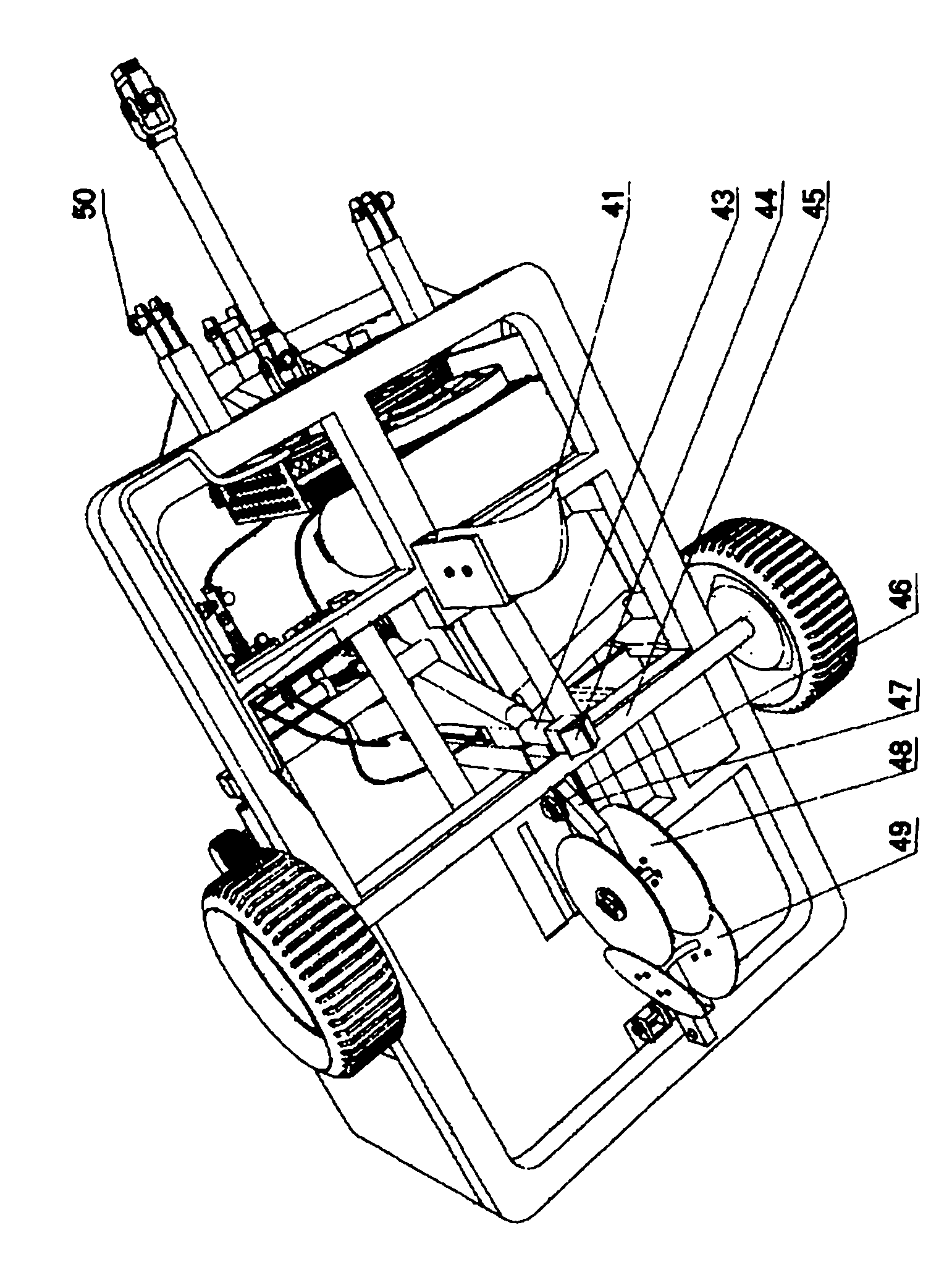

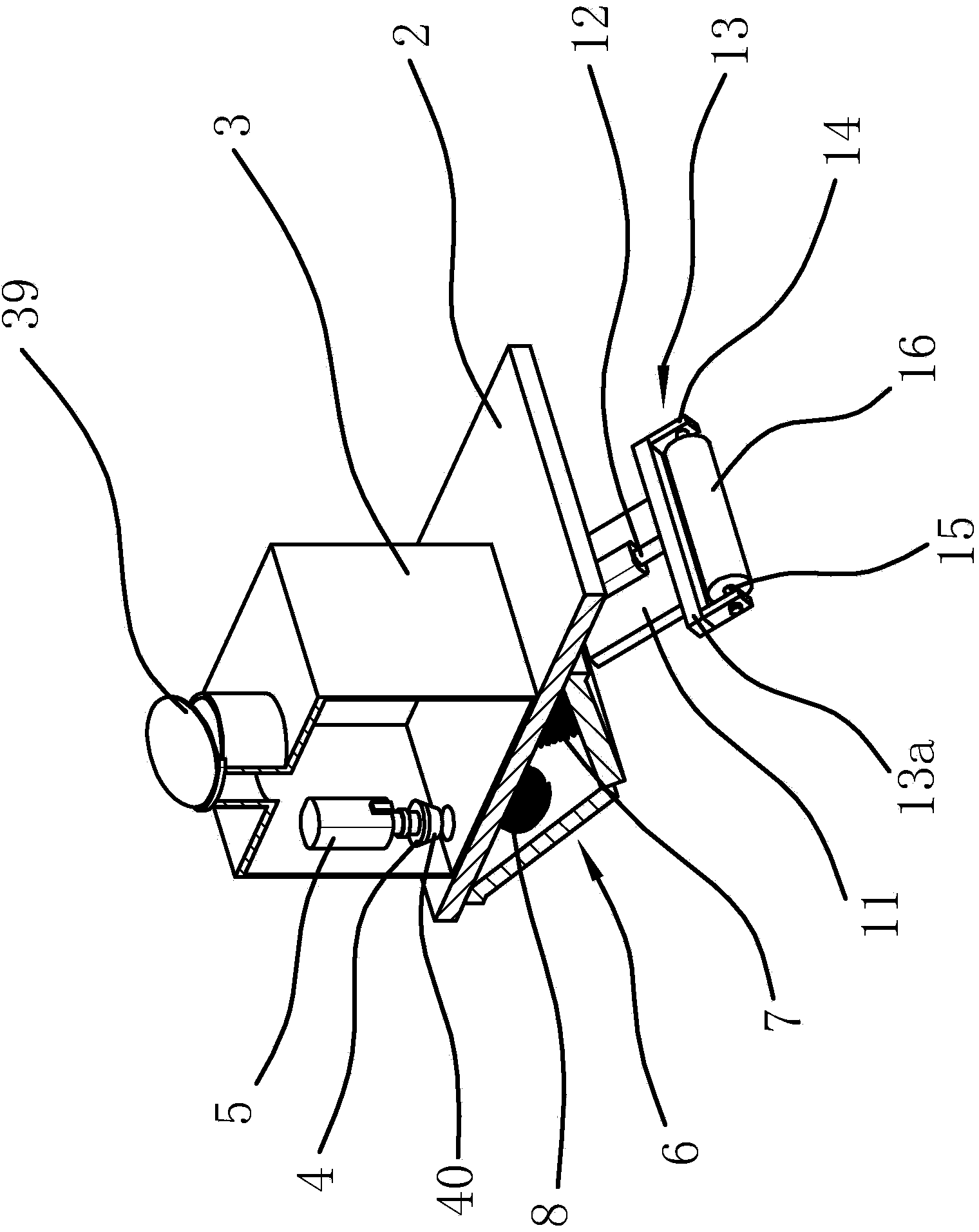

Automatic sand willow planting machine

InactiveCN102318537ACover levelComply with planting process requirementsForestryVegetationDrive wheel

The invention relates to a machine for planting sand willows in farming and stockbreeding areas and desert areas, which comprises a rectangular rack, a three-point suspension traction frame, an air compressor, a wicker inserting cylinder, a wicker gripping cylinder, a continuously variable transmission, a first electromagnetic valve, a second electromagnetic valve, a radiating fan and a walking wheel assembly. The machine is characterized in that the air compressor is driven to work through a universal power input shaft, a walking wheel drives a driven wheel to move to enable the continuouslyvariable transmission to control a multi-tooth cam to work, and the wicker gripping cylinder and the wicker inserting cylinder are driven to work alternately through a bidirectional switch to complete a series of working processes such as wicker gripping and inserting, soil compaction and soil covering. The invention aims at providing an automatic sand willow planting machine which has the advantages that the working efficiency is high, the labor intensity is reduced, the operation quality is ensured and the damage to the original soil vegetation is very small.

Owner:巴图 +2

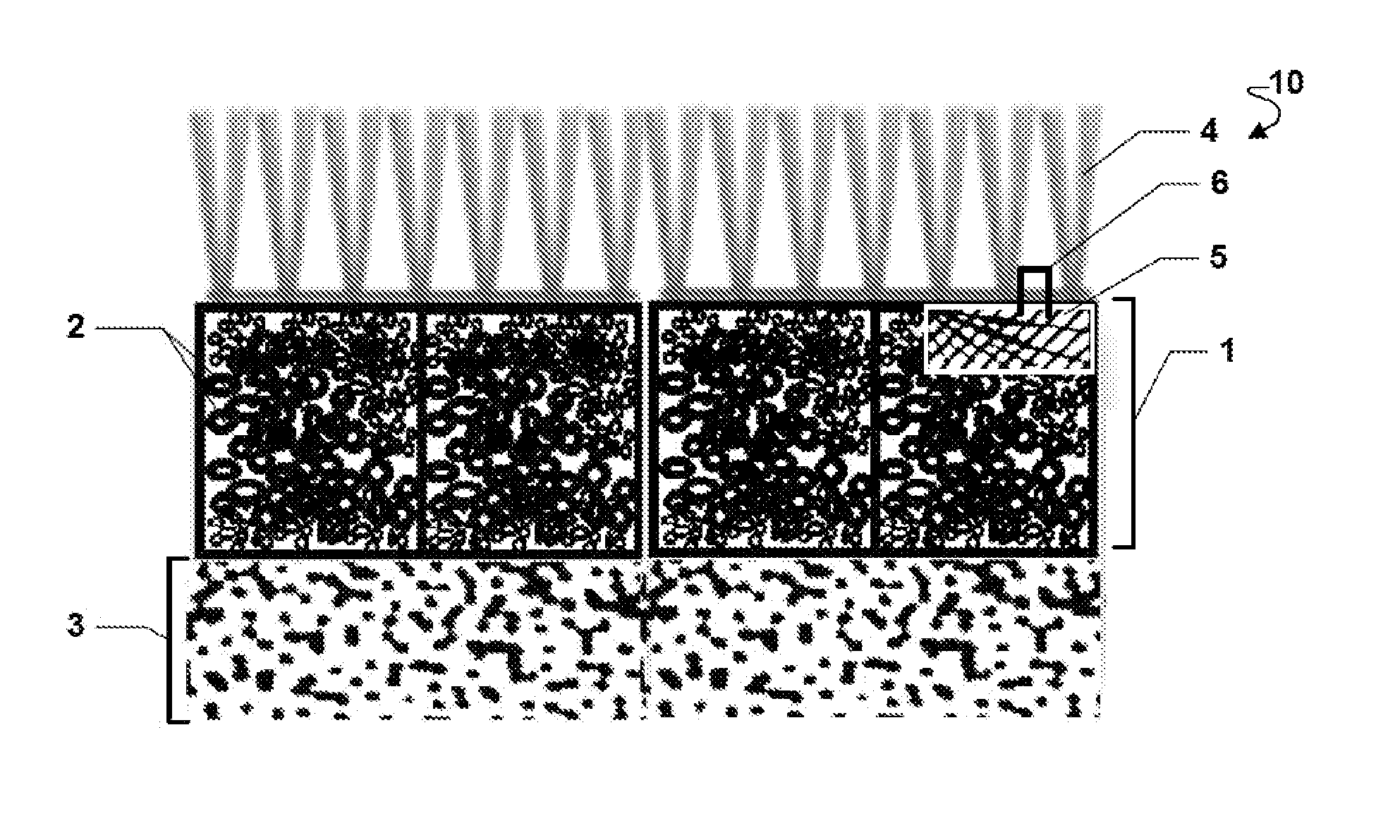

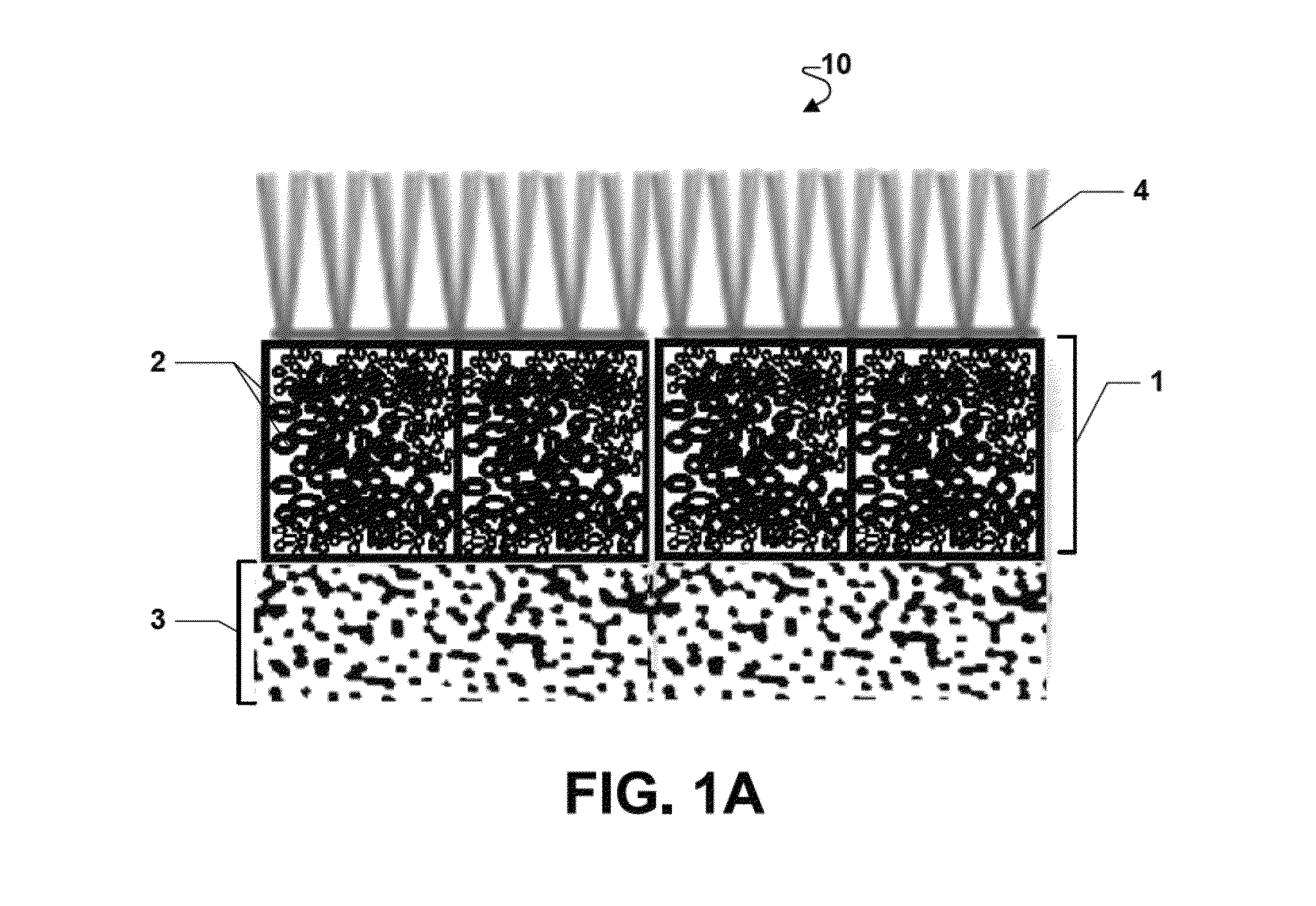

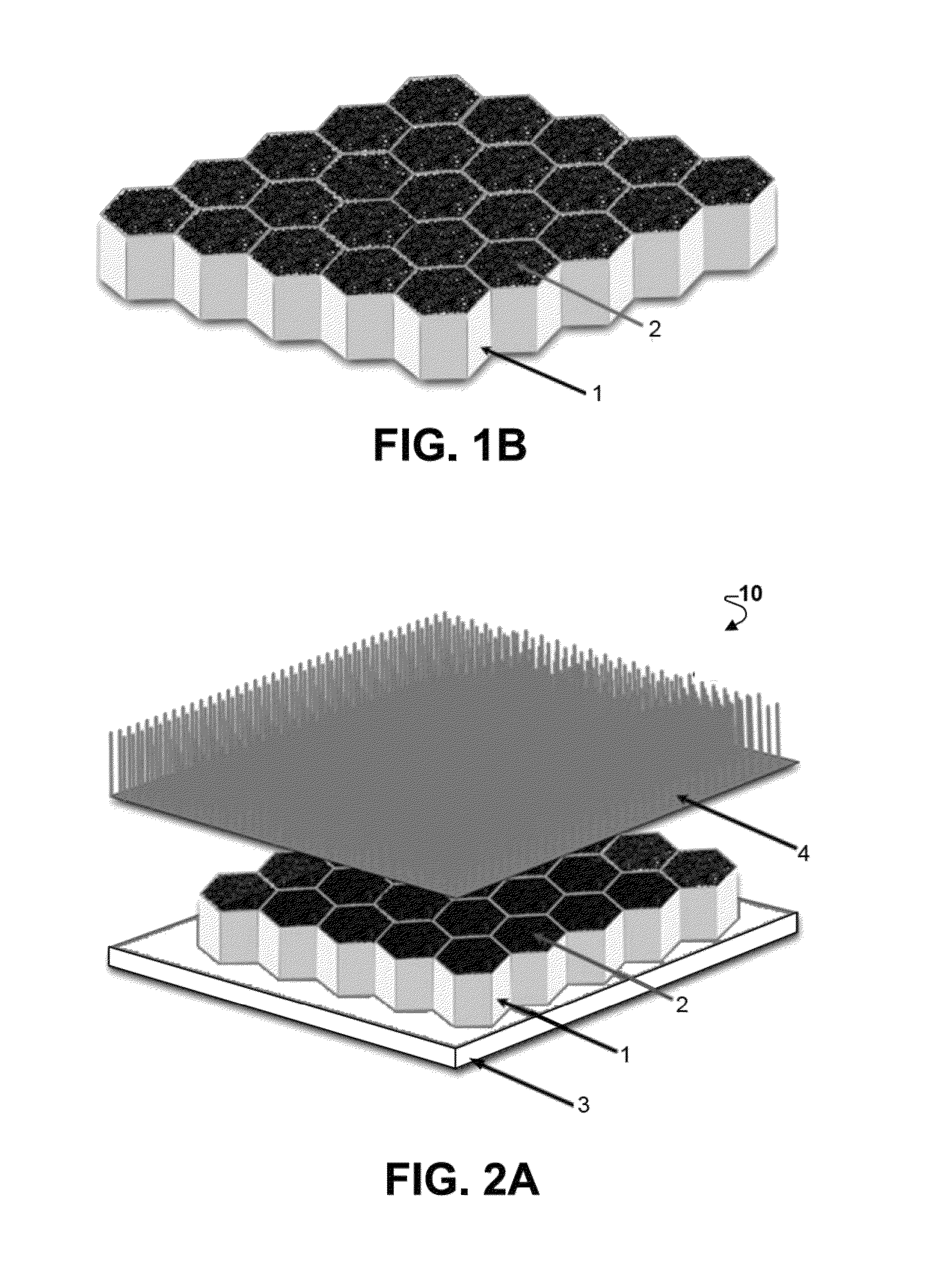

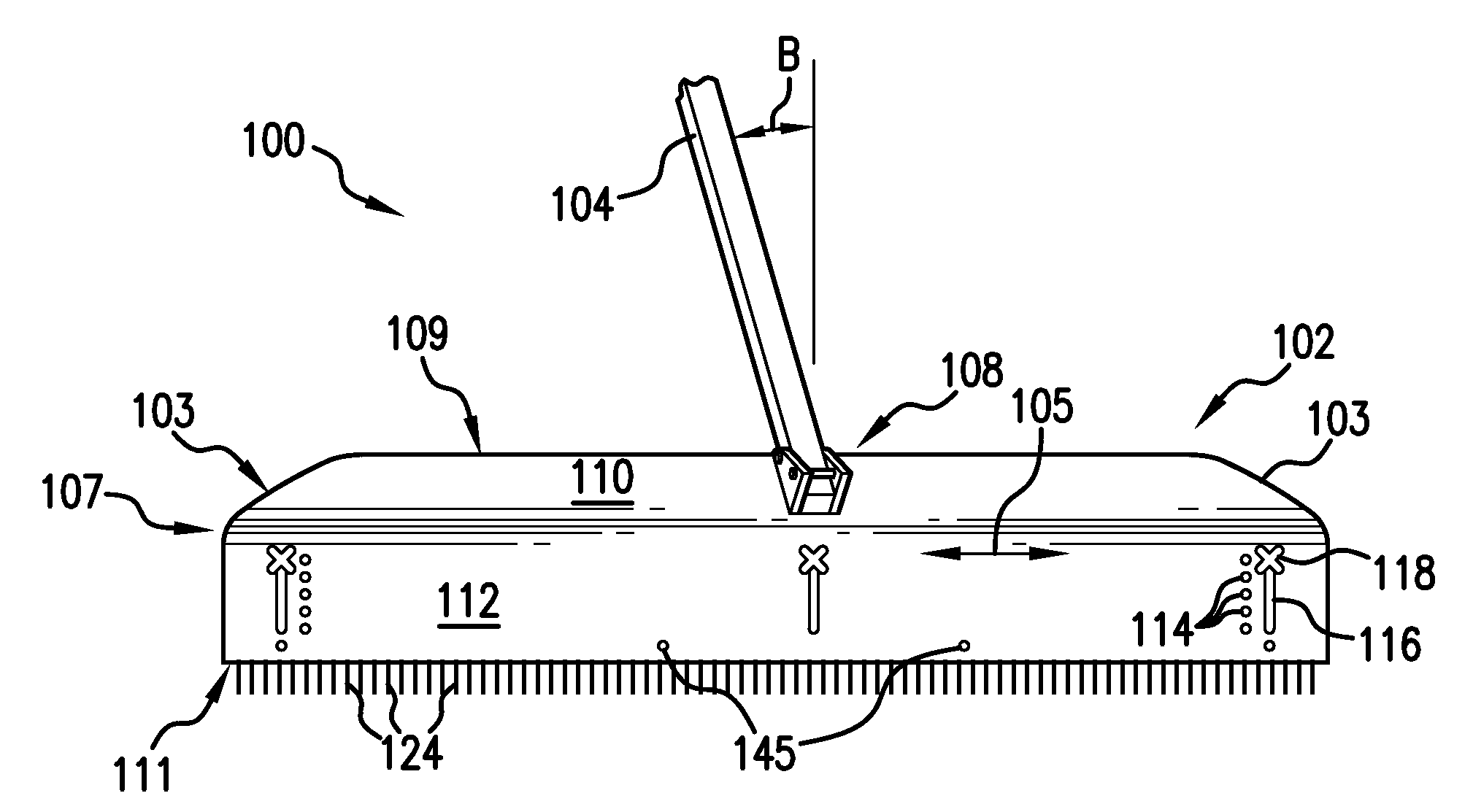

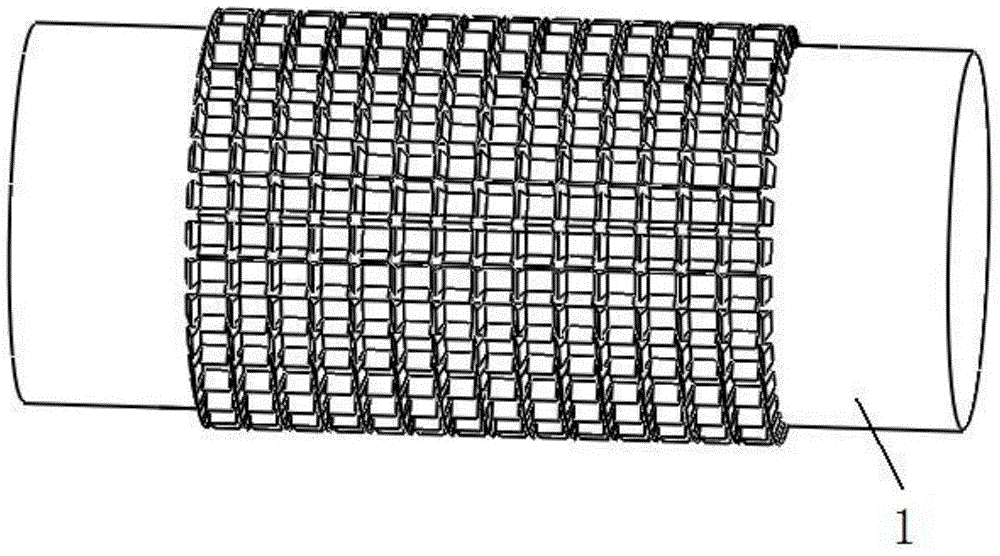

System and method for absorbing shocks impacts while providing water drainage

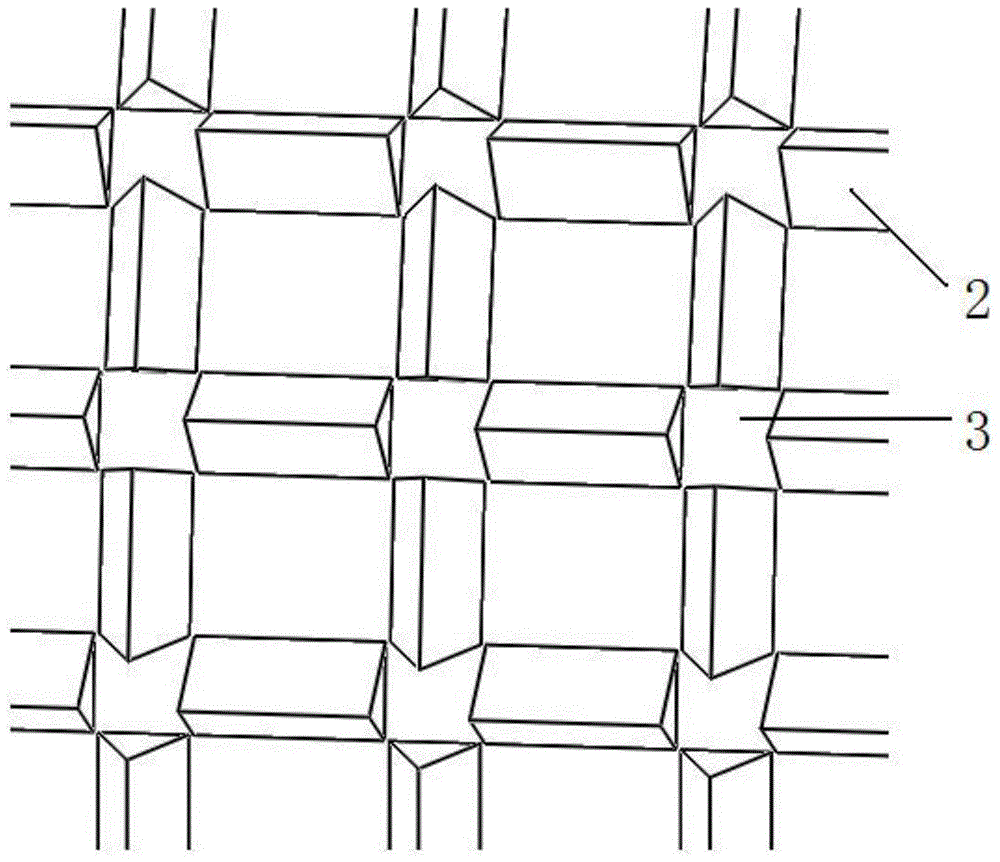

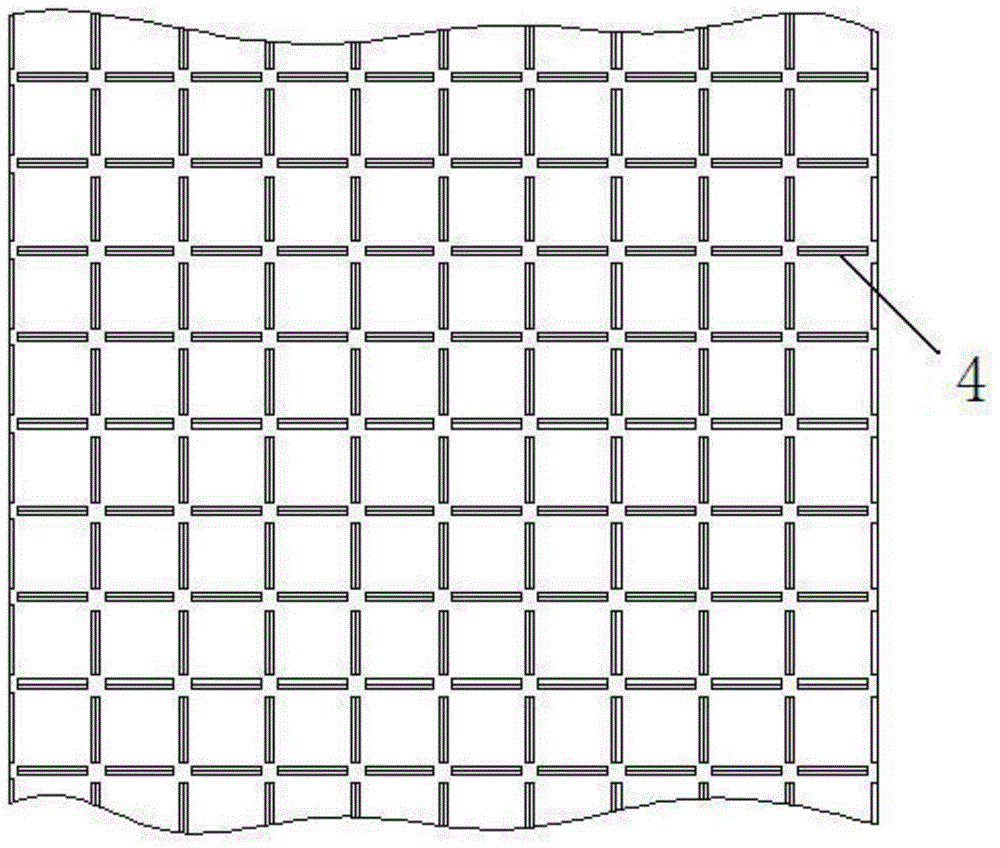

ActiveUS9194086B1Inhibit migrationConsistent depthSynthetic resin layered productsGround pavingsParticulatesEngineering

A vertically draining, particulate confinement structure may prevent side to side migration of particulate materials and may provide a way to ensure a consistent fill depth of the particulate materials. The particulate materials may include rubber granules. The vertical draining feature of the system may prevent water from accumulating on the turf surface by providing adequate vertical drainage. The vertical draining feature may be attributed to the combination of the turf surface with a confinement structure and the particulate materials that support this turf surface. The confinement structure and particulate materials also inhibit underlayment migration of the turf surface.

Owner:KARMIE DALE +3

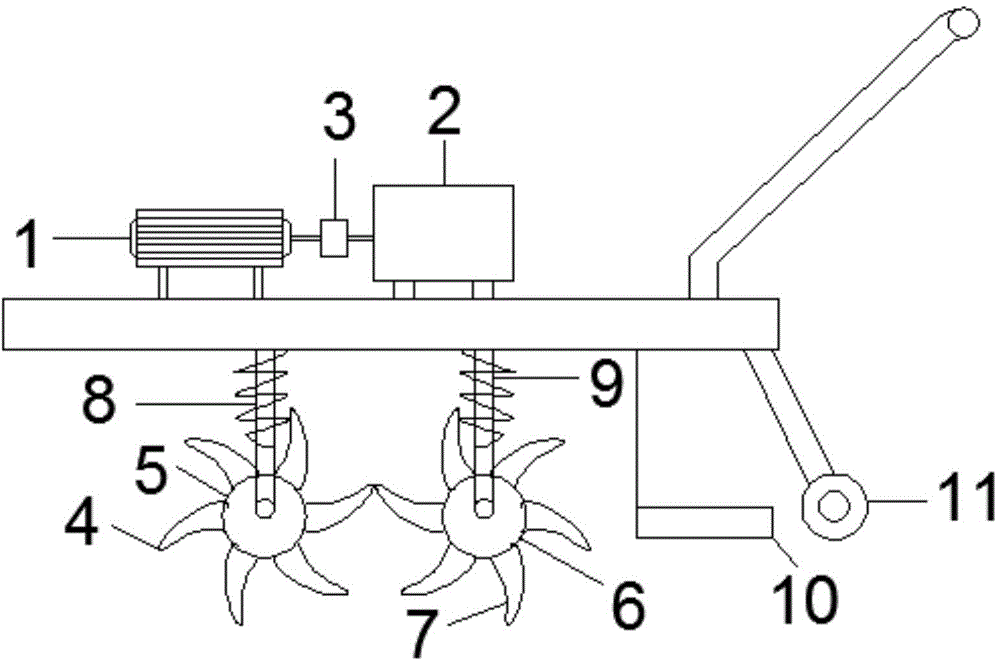

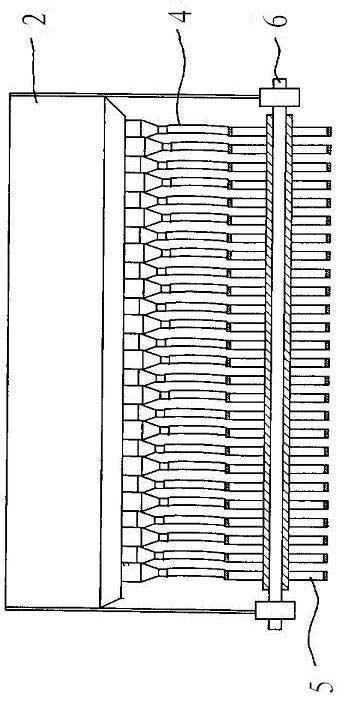

Deep ploughing scarifier

InactiveCN104094686ASimple structureEasy to operateTilling equipmentsGatherer machinesAgricultural engineeringKnife blades

The invention relates to the field of agricultural scarifiers, in particular to a deep ploughing scarifier comprising a frame, a speed reducer and a motor. A roller is mounted on the bottom right of the rack, a first rolling shaft and a second rolling shaft are mounted below the frame, the first rolling shaft is connected with the frame through a first connecting shaft, the second rolling shaft is connected with the frame through a second connecting shaft, a plurality of first blades and a plurality of second blades are mounted on the first rolling shaft and the second rolling shaft respectively, and the first blades and the second blades are arranged alternately. The deep ploughing scarifier has the advantages that the deep ploughing scarifier is simple in structure and convenient to operate, basic consistency in depth of soil scarifying can be ensured, full soil grinding can also be ensured, and subsequent crop planting is facilitated; a stone removing device is mounted on the deep ploughing scarifier, so that smooth removal of stones in soil can be ensured, additional labor is reduced, and normal thriving growth of planted crops is ensured.

Owner:DANYANG SHENGLIYUAN AGRI DEV

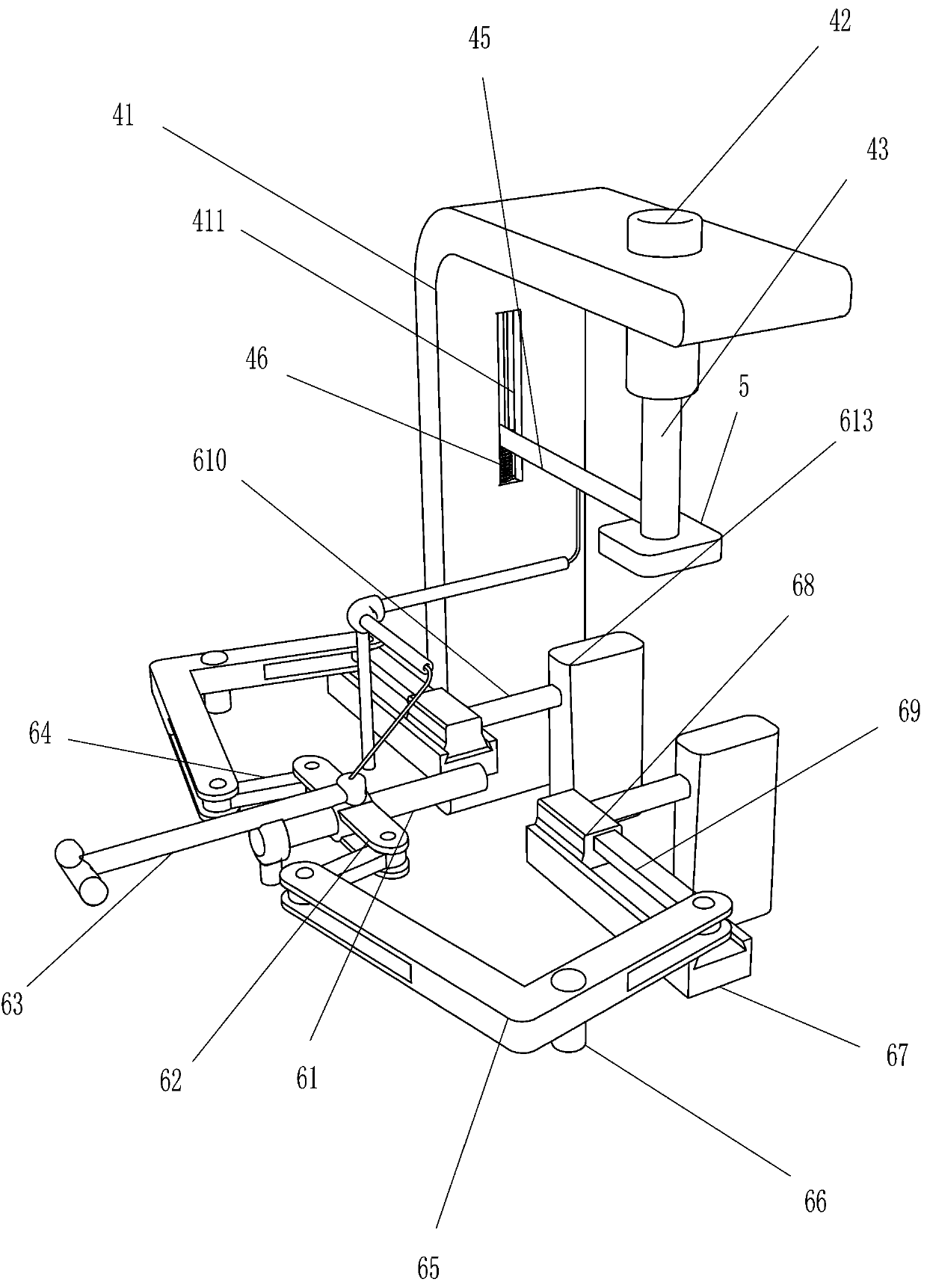

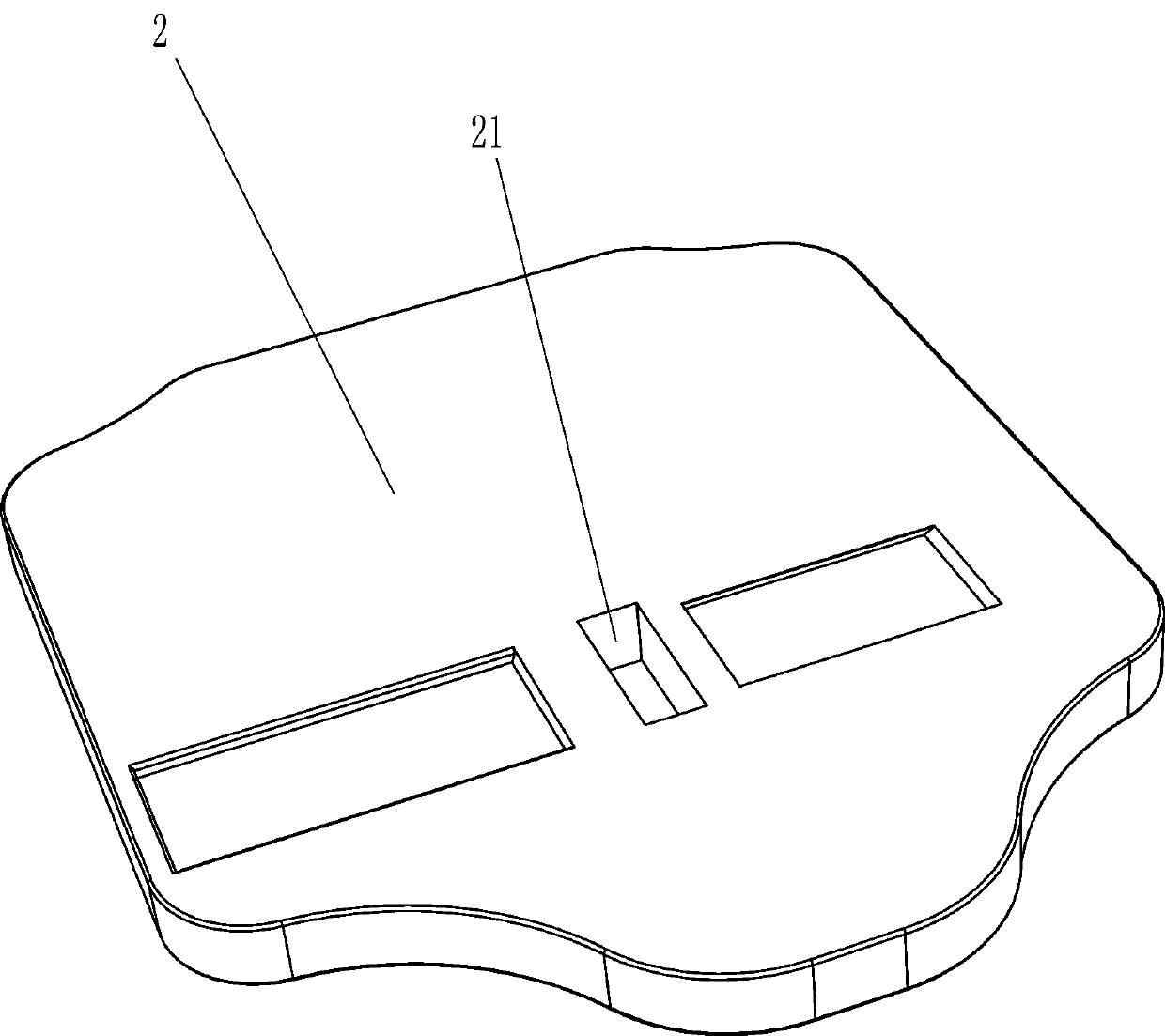

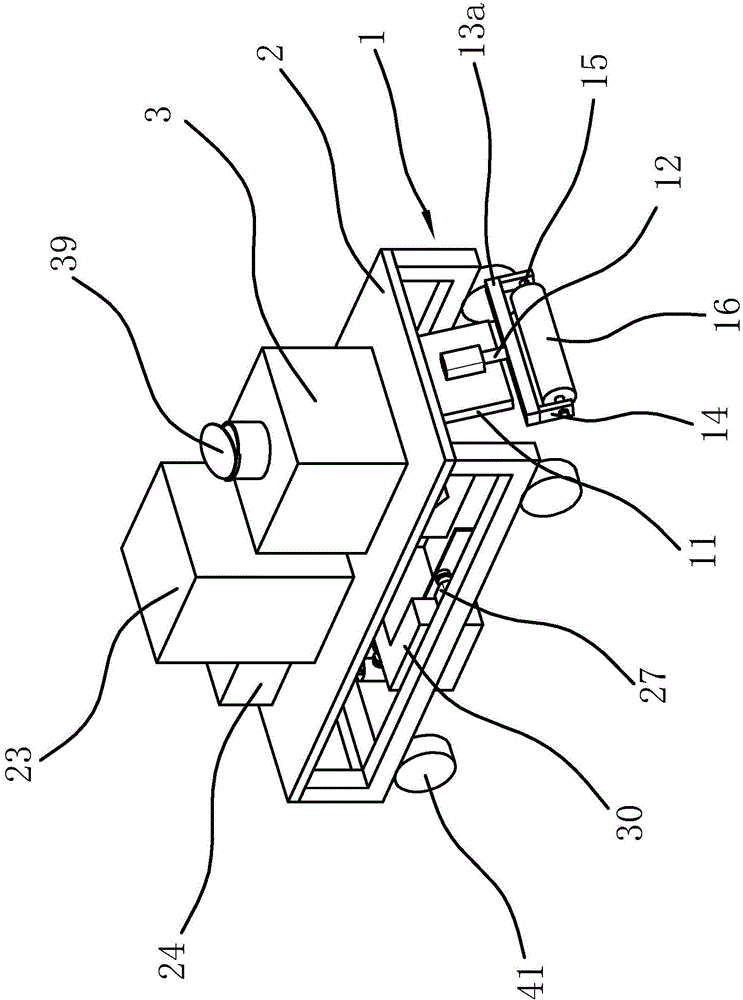

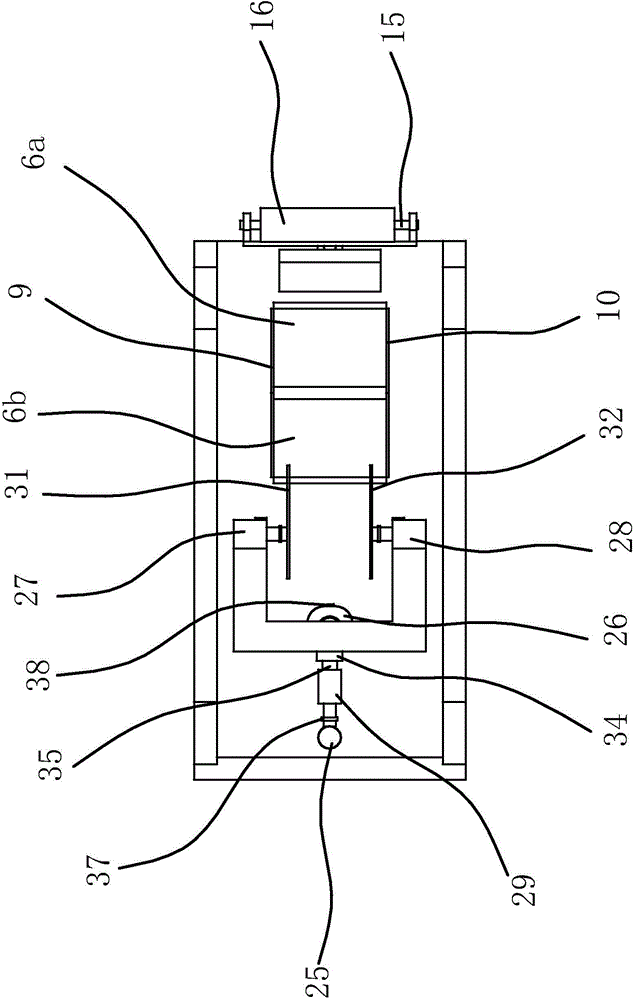

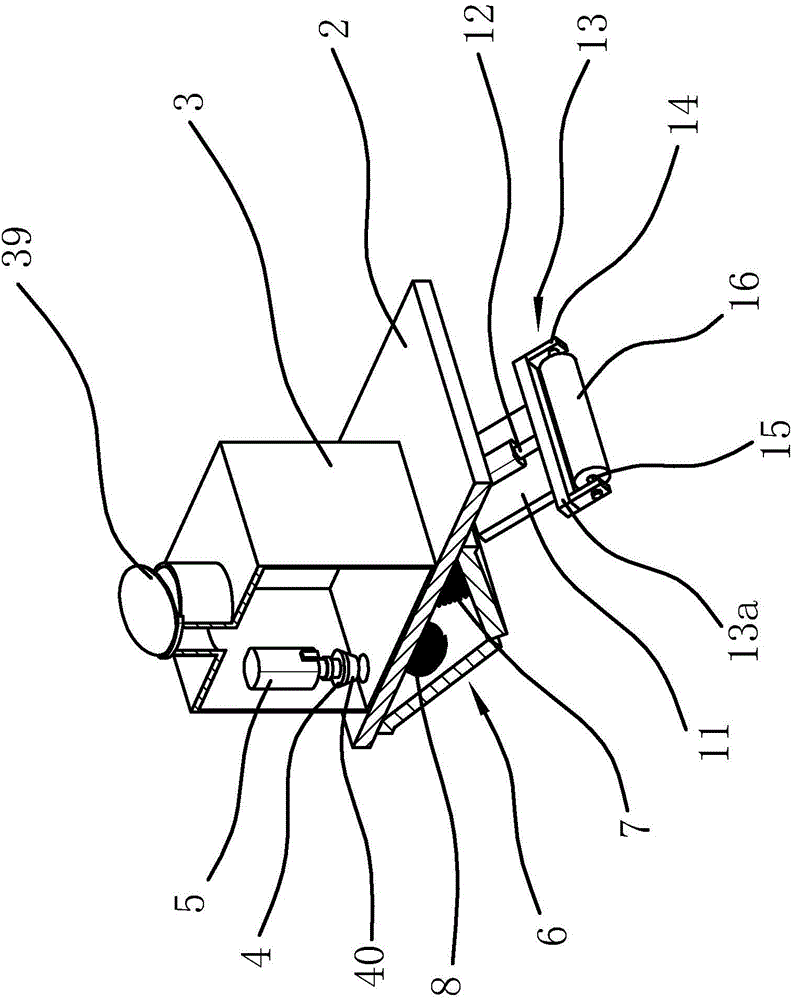

Chopping board side wall grooving equipment

ActiveCN111590143AConsistent depthRealize automatic clampingMetal working apparatusMaintainance and safety accessoriesStructural engineeringWorkbench

The invention relates to grooving equipment, in particular to chopping board grooving equipment. According to the technical scheme, the chopping board side wall grooving equipment which can groove theside wall of a chopping board, improve the grooving efficiency and guarantee that the depths of grooves formed by a cutting machine are consistent is provided. According to the technical scheme, thechopping board grooving equipment comprises a base, a groove and a lifting mechanism, wherein the top of the base is provided with a workbench, the groove is formed in the middle of the side portion of the workbench, a cylindrical containing box is arranged at the position, over the groove, of the side portion of the workbench, round holes are formed in the two sides of the cylindrical containingbox, and the lifting mechanism is arranged on the side part, close to one side of the cylindrical placement box, of the workbench. According to the chopping board side wall grooving equipment, throughthe lifting mechanism, the cutting machine can automatically move up and down and is tightly attached to the side wall of the chopping board, it is guaranteed that the cutting machine makes tight contact with the side wall of the chopping board all the time before grooving work is completed, and it is guaranteed that the depths of the formed grooves are consistent; and through a clamping and rotating mechanism, the chopping board can be automatically clamped and driven to rotate.

Owner:吴燕灵

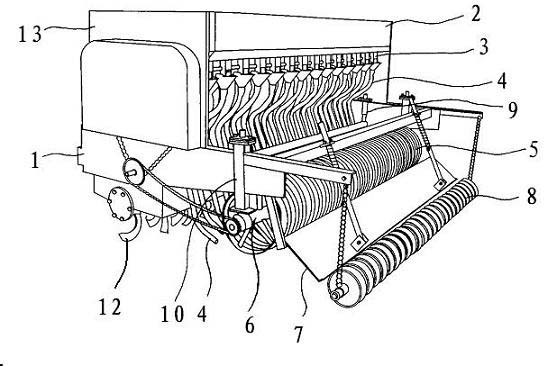

Uniform wheat rolling sowing method and special rolling sowing machine

InactiveCN102550171APlant evenlyIncrease productionSpadesPloughsAgricultural scienceSoil moisture content

The invention belongs to the technical fields of wheat sowing methods and special sowing machines, and in particular discloses a uniform wheat rolling sowing method and a special rolling sowing machine. According to the technical scheme, the method comprises the following steps of: spreading wheat seeds on the surface of a cultivated land in a strip mode, pressing the wheat seeds into the soil by adopting a rolling sowing wheel, covering the seeds with soil, and compacting the soil through a press roller. Therefore, the uniformity of the seeds is improved, and the depth of the seeds is consistent; the depth of the seeds is regulated according to the soil moisture content of the cultivated land, so that the seeds are prevented from being buried deeply and exposed, and the seeds are saved; and the seeds are tightly combined together with the soil in the pressing process, so that imbibition and germination of the seeds are facilitated.

Owner:郝德有 +1

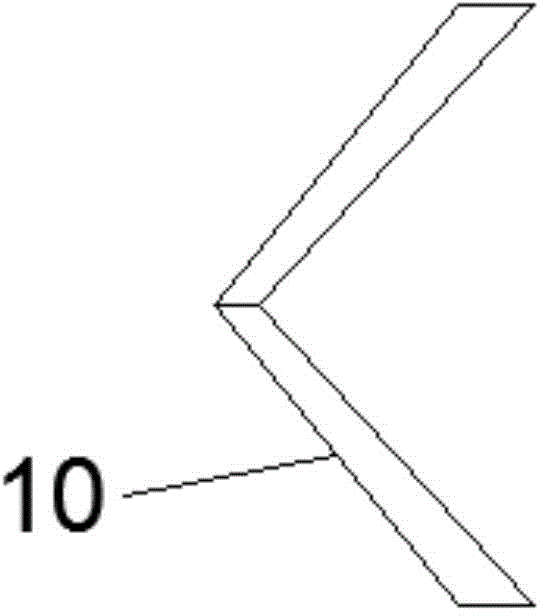

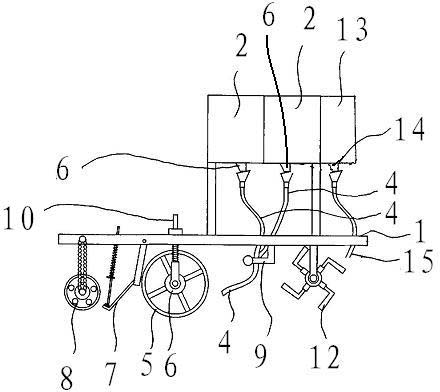

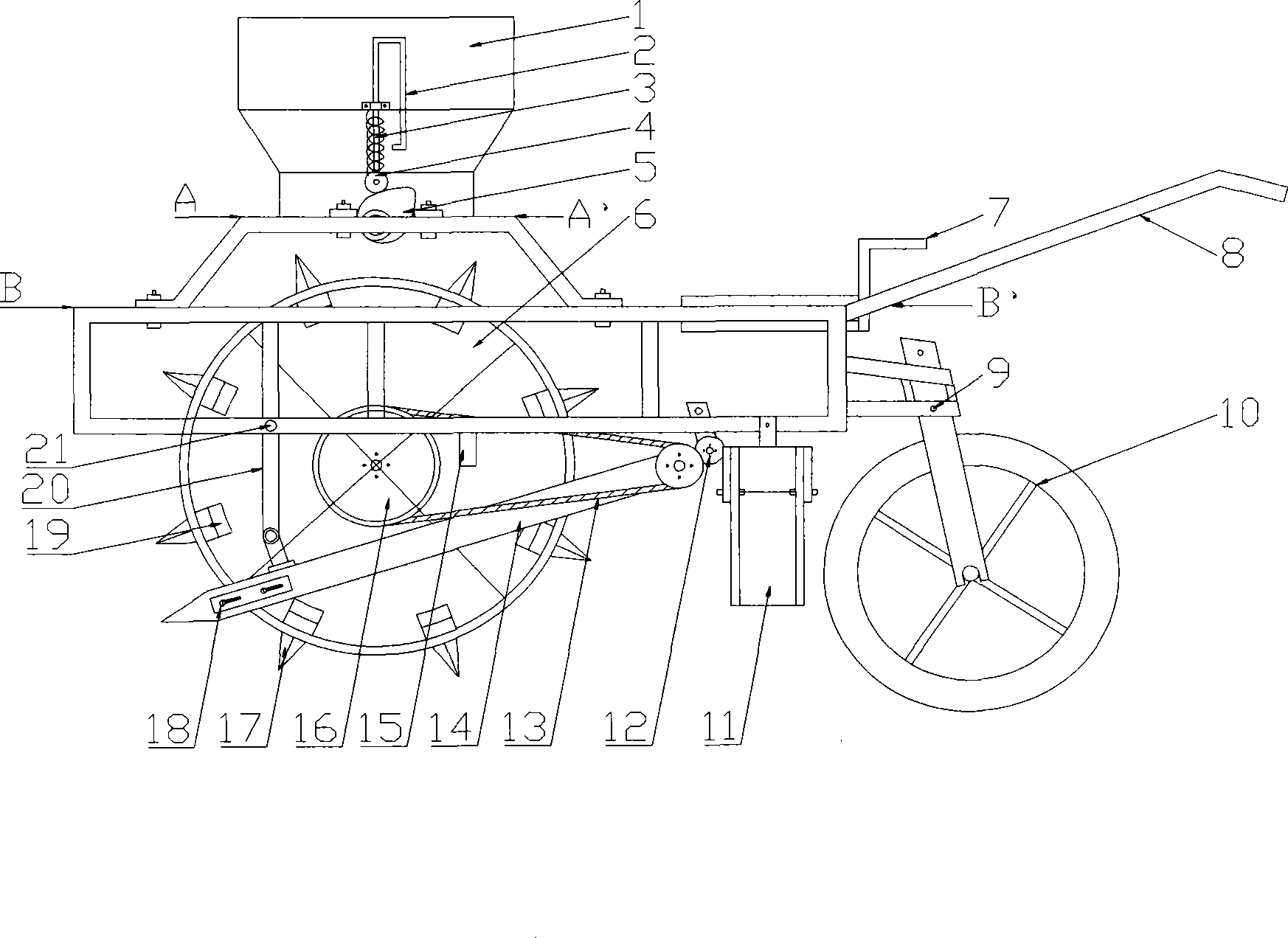

Mountain mulching film peanut seeder

InactiveCN101485248AImprove work efficiencyConsistent depthPlantingSeed depositing seeder partsSeederGear wheel

The invention discloses a mountain land mulching film peanut seeder capable of completing seeding and hilling simultaneously. According to the seeder, a seed box is arranged on the upper part of a machine frame; a sowing wheel on the lower part controls the sowing; a seeding wheel is arranged on the lower part of the machine frame; and a seeding nozzle of the seeding wheel, a seeding nozzle opening and closing draw plate, a seeding nozzle opening and closing pulley and an opening and closing draw plate return spring form an opening and closing structure capable of realizing automatic soil inserting and seeding. A soil distributor lowering chute is arranged on the middle lower part of the machine frame; a seeder sprocket arranged on the left side of the machine frame drives a back sprocket through a chain; and the back sprocket is engaged with a back end gear and drives a scraping conveyer belt through a coaxial transfer gear. The scraping conveyer belt is arranged on the back part of an earth blade tip which can move up and down for scraping earth under the control of an elevating tie bar. A balance wheel 10 is arranged on the back part of the machine frame. The mountain land mulching film peanut seeder has the advantages that the seeder is driven by human efforts or a micromechanism to carry out film rupturing, insertion seeding and hilling simultaneously, thereby greatly improving the working efficiency and having an obvious soil moisture preservation effect; the seeder has low operating strength; and the seeder is suitable for the operations in slopes, and miniature and complex land blocks.

Owner:郭文洋

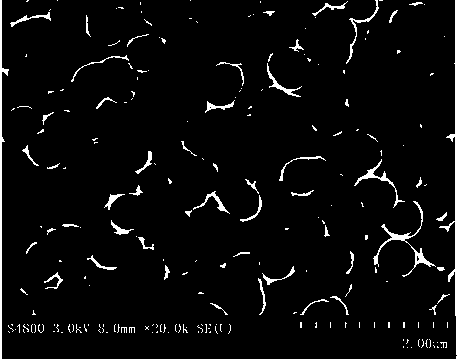

Polycrystal black silicon texturing process

ActiveCN108193281AGood lookingBlurred appearancePolycrystalline material growthAfter-treatment detailsMicro nanoSilver particles

The invention discloses a polycrystal black silicon texturing process. The polycrystal black silicon texturing process includes the following steps that 1), a polycrystalline silicon wafer is polishedthrough polishing liquid; 2), the polished silicone wafer is hole-dug through hole-digging treating liquid, and nano-holes are prepared in the surface of the silicone wafer; 3), the hole-dug siliconewafer is de-silverized, and silver particles on the silicone wafer are removed; 4), the de-silverized silicone wafer is chambered through chambering treating liquid, and micro-nano holes are preparedin the surface of the silicone wafer. According to the polycrystal black silicon texturing process, by means of control over the three key steps of polishing, hole-digging and chambering, the whole black silicone texturing process is controllable, polycrystal black silicon with the good appearance and high efficiency can be prepared, and the prepared polycrystal black silicon is fuzzy in appearance and is provided with uniform holes.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

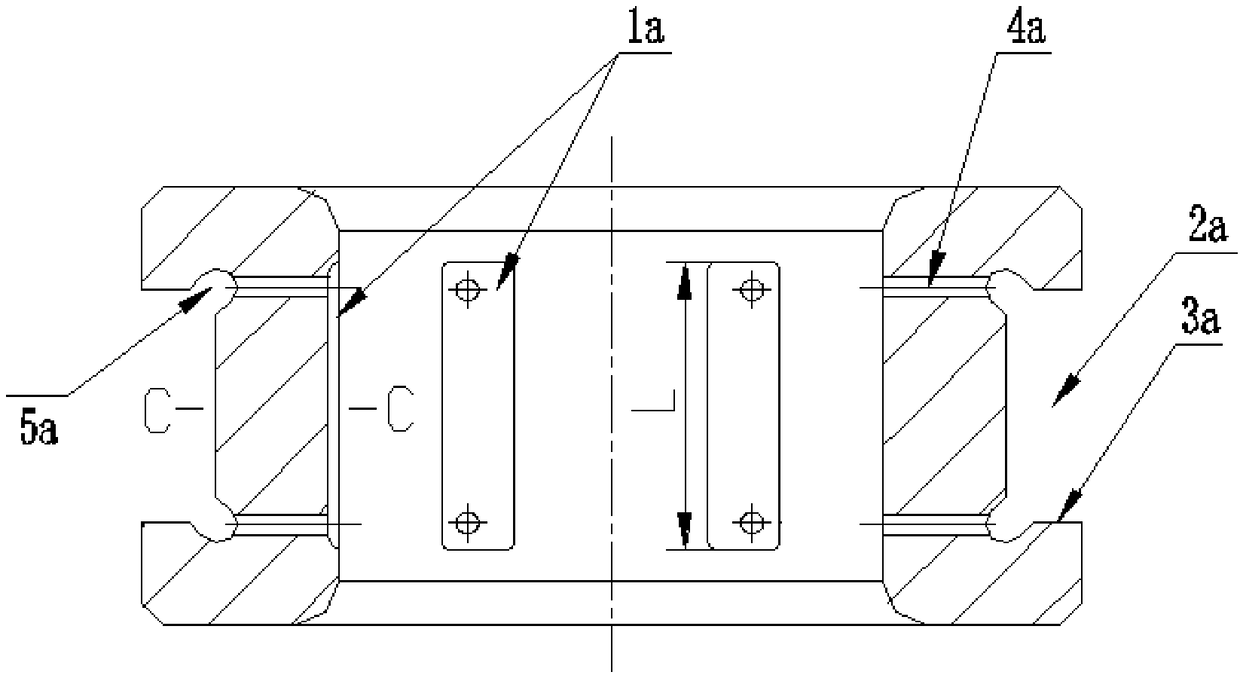

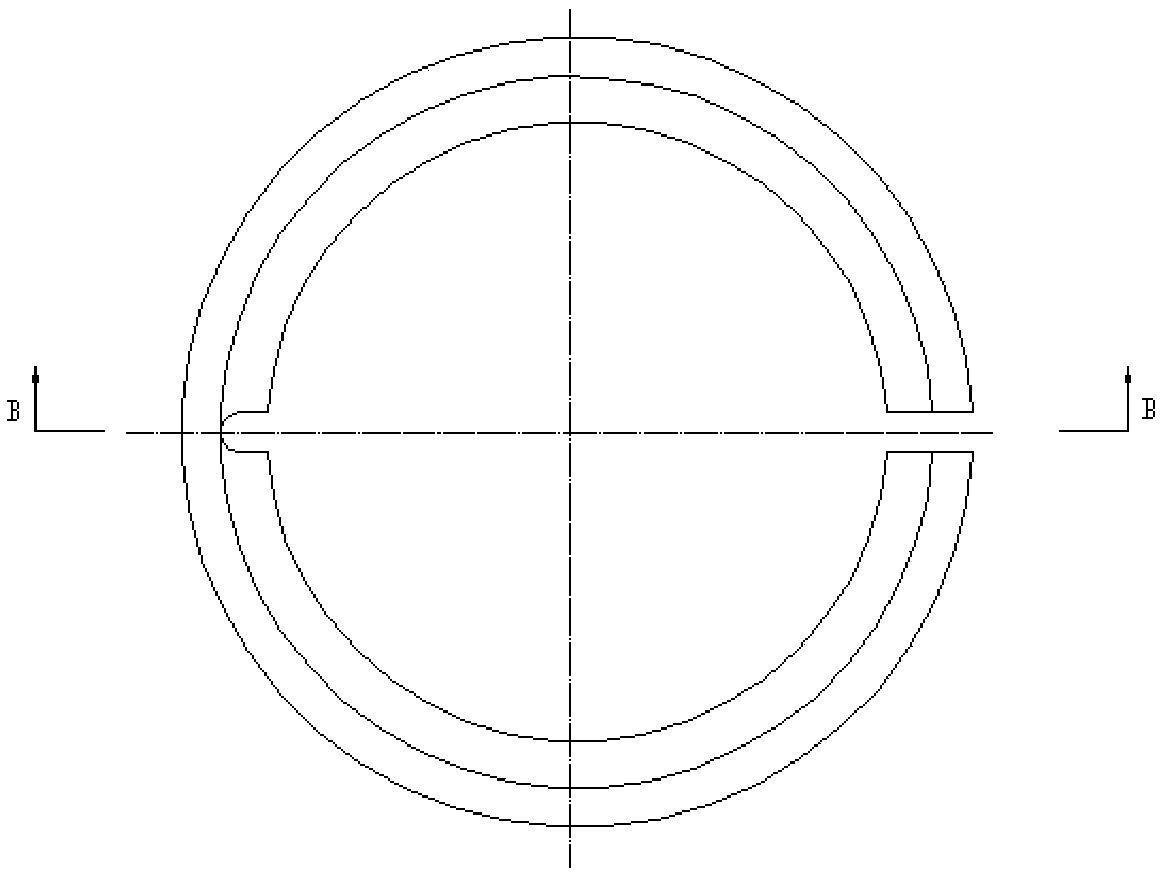

Mould for machining engine main shaft bearing inner ring with inner diameter oil groove and machining method

ActiveCN109483262ATight depth toleranceGuaranteed machining accuracyWork clamping meansPositioning apparatusEngineeringMachining

The invention relates to a mould for machining an engine main shaft bearing inner ring with an inner diameter oil groove and a machining method, and relates to a mould for machining a bearing inner ring and a machining method. The problem of poor machining accuracy of the inner diameter of a bearing inner ring and the size of an inner diameter oil groove is solved. The mould is composed of a mouldbase, a pressing plate and a connecting bolt; and a ring-shaped flange is arranged on a bearing plane. The machining method comprises the steps that an outer circumferential surface is milled softlybefore an inner circumferential surface is turned finally, the outer circumferential surface of an inner ring and one end face of the bearing inner ring are used as a positioning datum to machine theinner circumferential surface of the inner ring; milling of the inner diameter oil groove is performed after the finally turning of the inner circumferential surface of the inner ring; the bearing support flat face of the mould is used for positioning one end face of the bearing inner ring; and the outer circumferential surface positioned by the inner surface of the ring-shaped flange of the baseis used for machining the inner diameter oil groove. According to the mould for machining the engine main shaft bearing inner ring with the inner diameter oil groove, deformation caused by tightly clamping can be avoided, the machining method ensures the machining accuracy of the inner diameter oil groove, and the method is suitable for machining the engine main shaft bearing inner ring with the inner diameter oil groove.

Owner:AVIC HARBIN BEARING

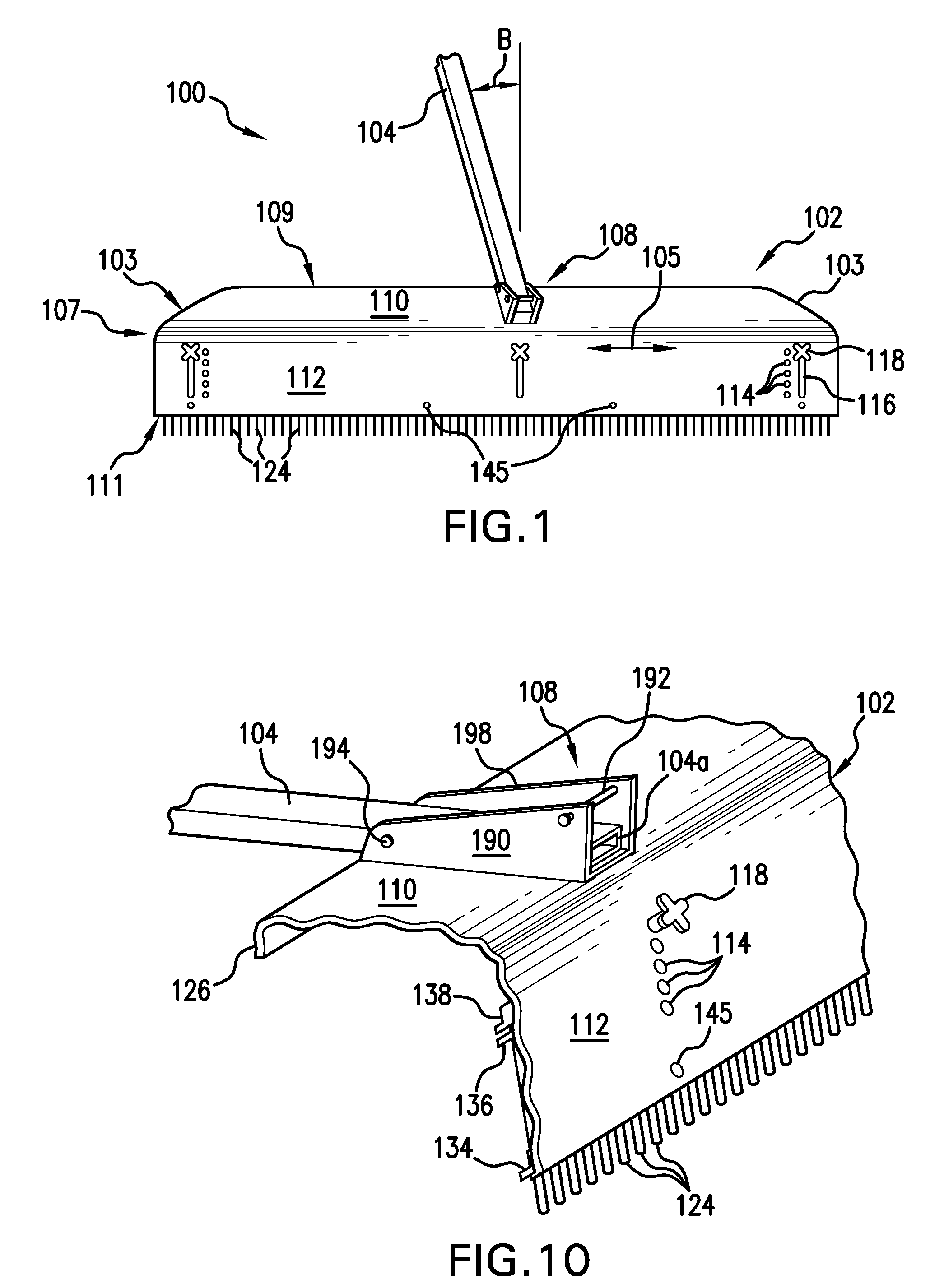

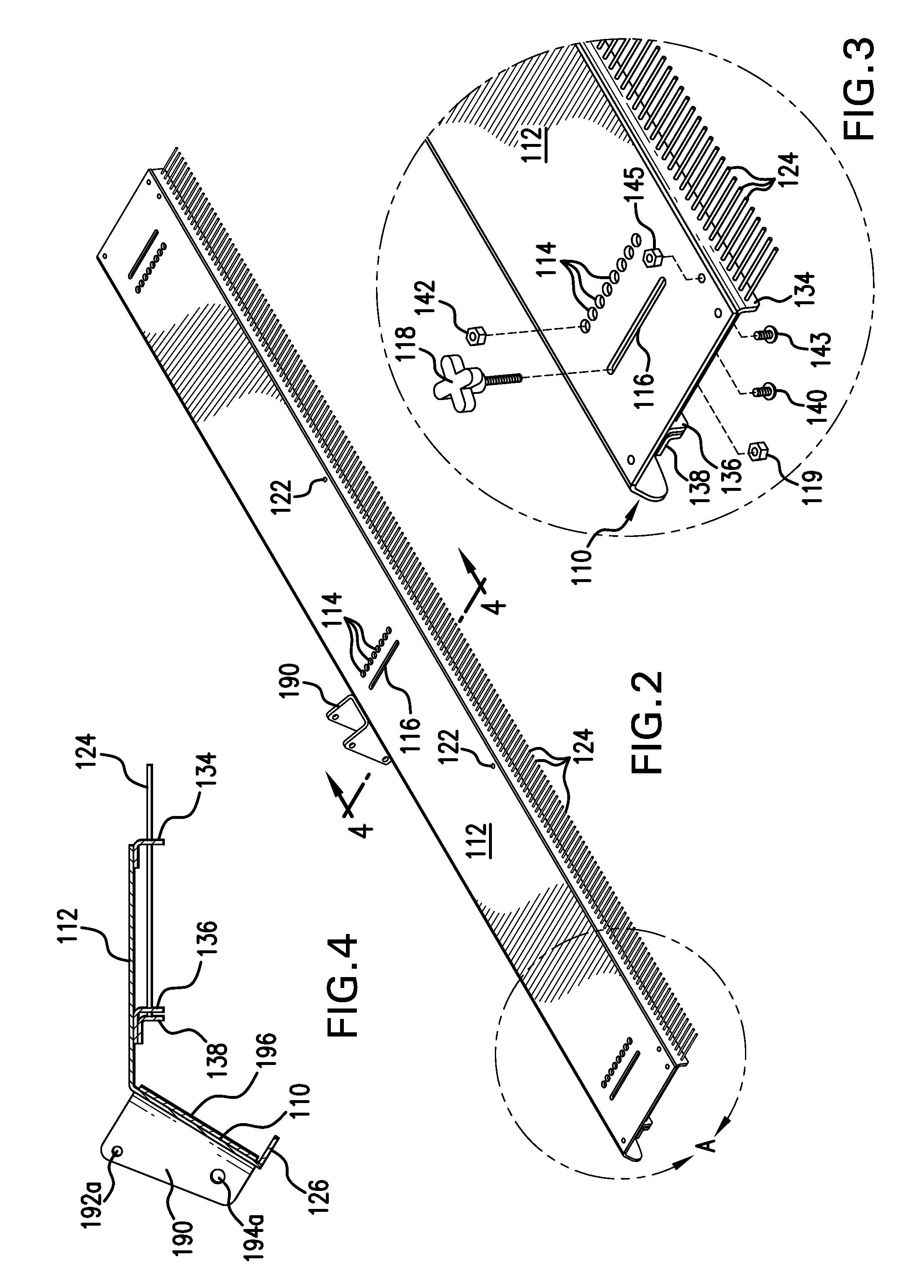

Rake for grooming surfaces

InactiveUS20110067375A1Easily and readily adjustableEasily and readily removeRakesBiomedical engineering

A rake comprising a rake body and a tine assembly that is removably mounted to the rake body. The tine assembly is modular in design so that it can readily be interchanged with other tine assemblies and / or replacement tine assemblies. Additionally, the rake is constructed so that the tines may be advanced by simple manual effort without tools in order to replenish tine length lost to wear during use.

Owner:MADAFFER ANTONIO

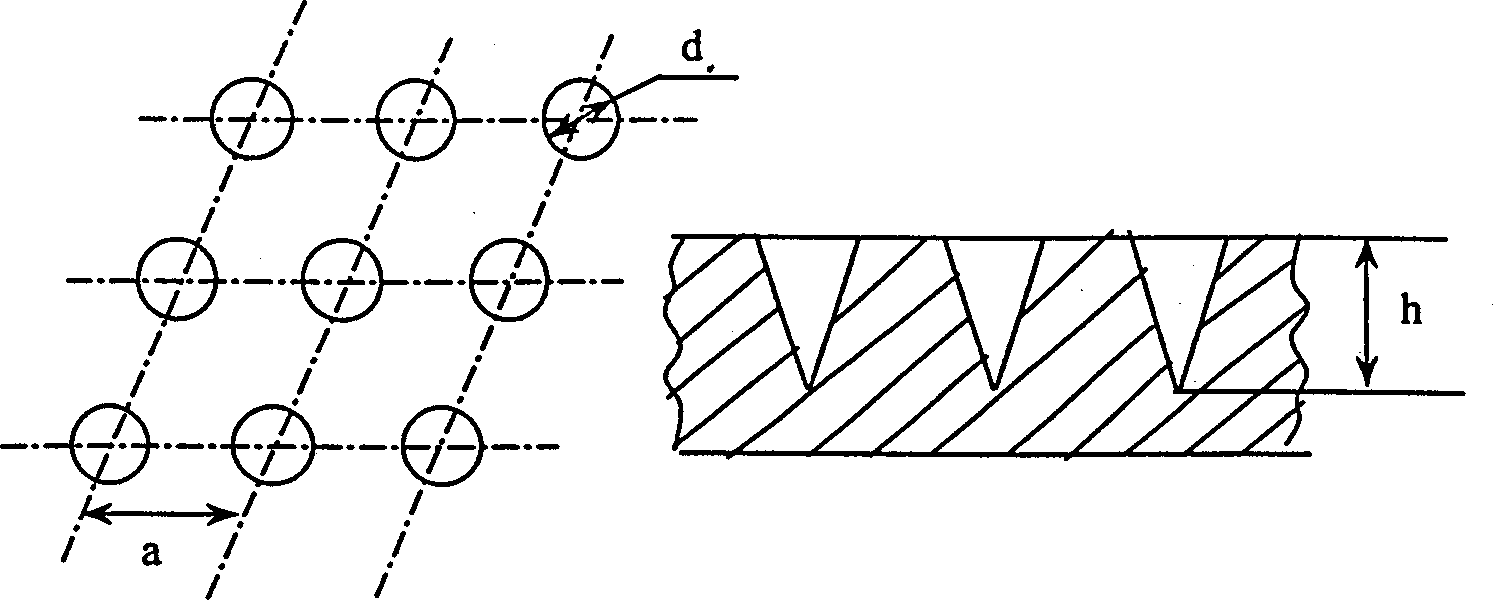

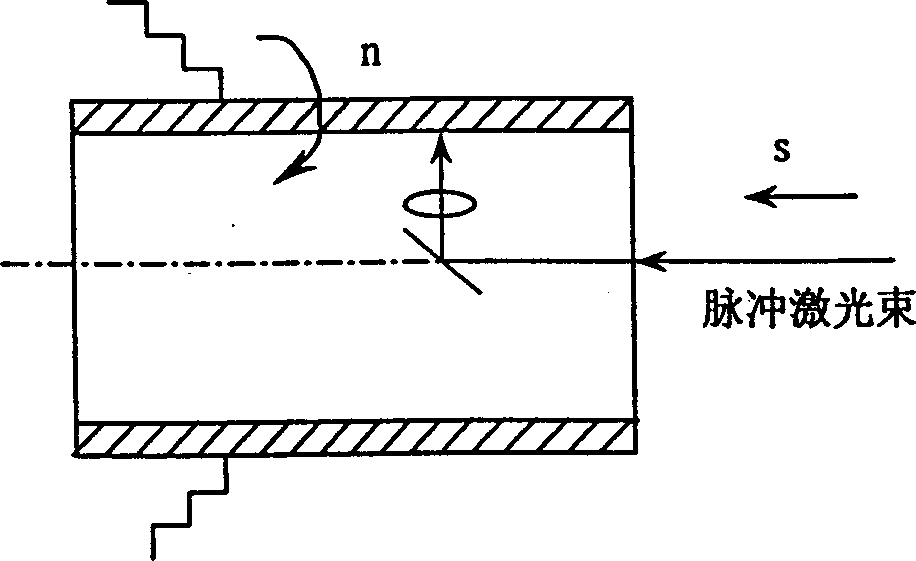

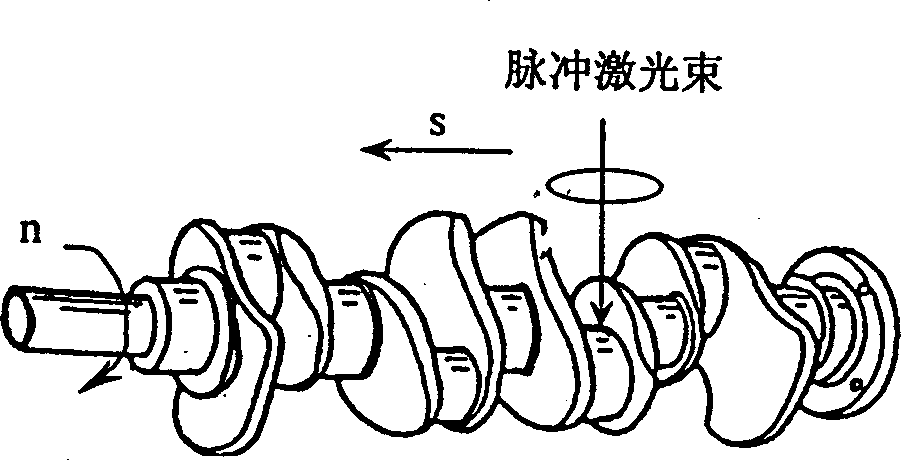

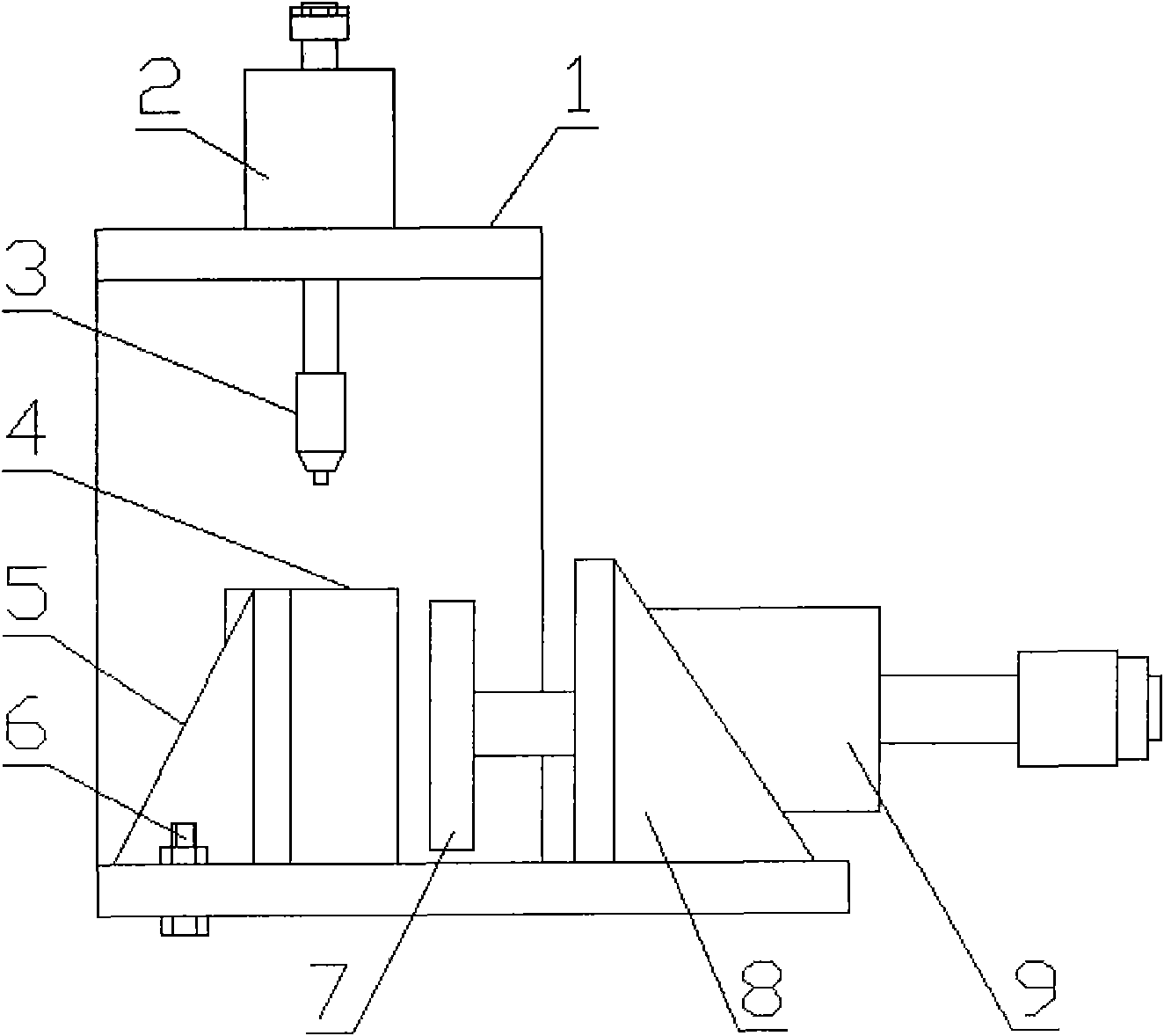

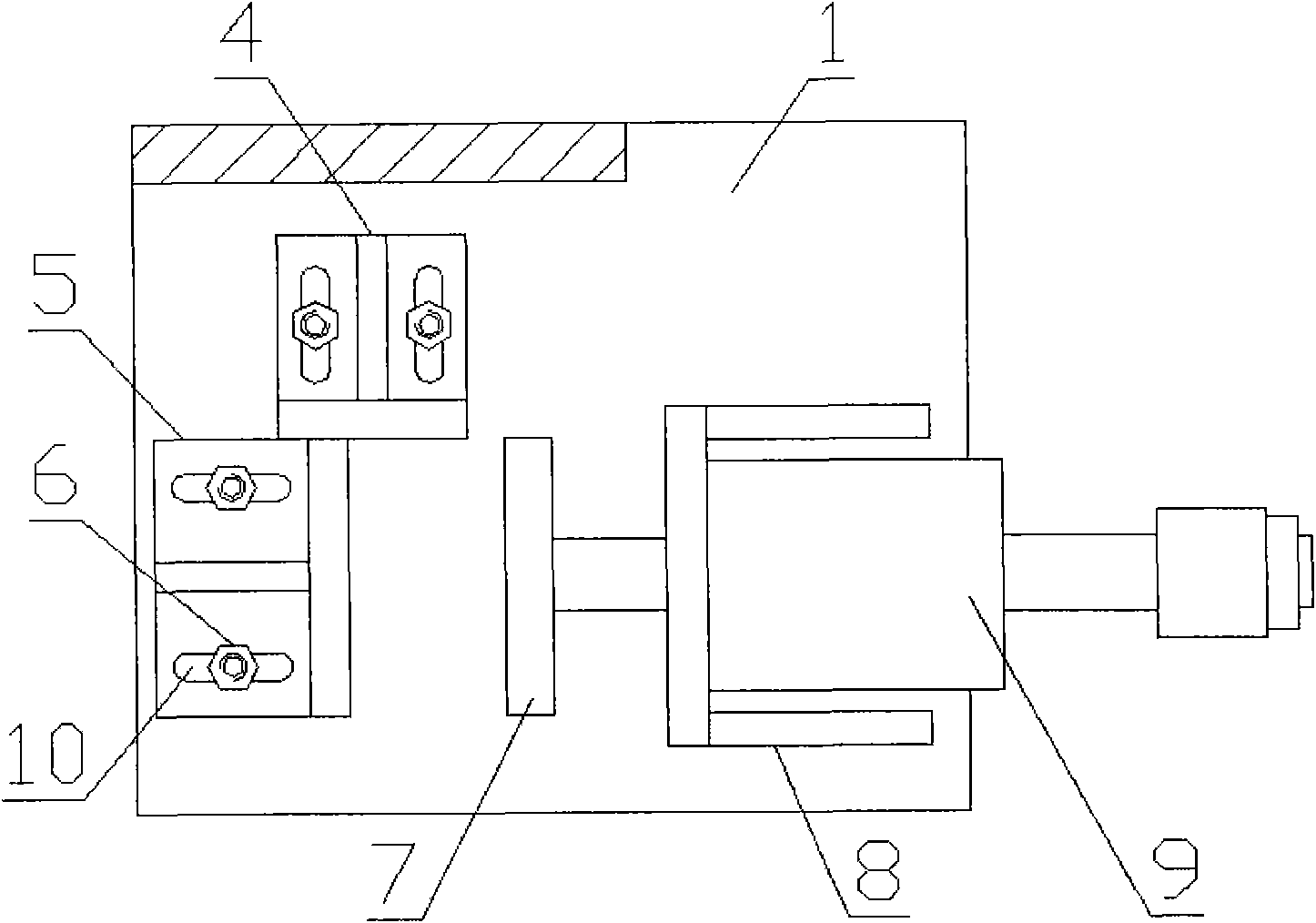

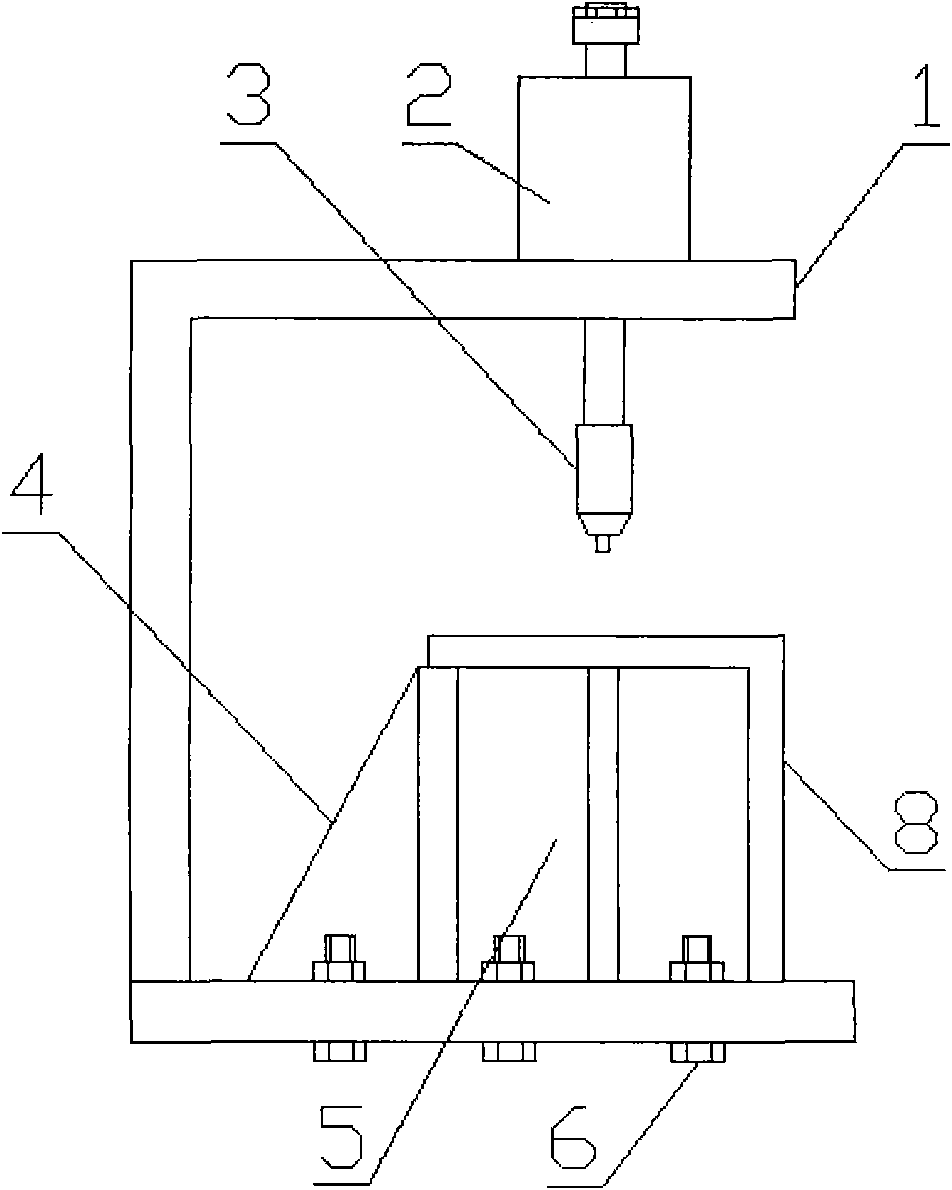

Microconcave digital controlled laser formation method and device on working surface of friction pair

InactiveCN1385277AConsistent depthAdjustable speedLaser beam welding apparatusNumerical controlEngineering

The present invention discloses a micropit numerical control laser forming method on the working surface of friction pair, and is characterized by that the components of the friction pair are rotated, the pulse laser bean can be used and relatively moved along the rotated components of the friction pair, then the focused pulse laser-bean can be used for making micropits on the working surface of friction pair components. Said invention possesses the following advantages: 1. can form micropits with thousands which are mutually independent and identical in depth on the working surface of frictino pair; 2. contactless processing, energy of laser beam and its movement can be regulated, and the rotating speed of components of friction pair also can be regulated; 3. it does not result in deformation of workpiece.

Owner:杭州电子工业学院

Device for sealing steel balls in battery shells

InactiveCN102064288AStrictly control the amount of deformationConsistent stamping pressureFinal product manufactureSecondary cells manufactureEngineeringSteel ball

The invention discloses a device for sealing steel balls in battery shells, which comprises a device body, wherein the device body is provided with a battery shell positioning mechanism; a steel ball stamping mechanism is arranged above the battery shell positioning mechanism; the battery shell positioning mechanism comprises an X-axis positioning seat and a Y-axis positioning seat which are vertical to each other; a shaping movable plate is arranged opposite to the X-axis positioning seat or a Y-axis positioning seat; and the rear end of the shaping movable plate is provided with a shaping cylinder. The device has the advantages that: the positions of the battery shells are limited or fixed through the battery shell positioning mechanism, the steel balls are arranged at steel ball holes and are stamped by the steel ball stamping mechanism so as to seal the steel balls in the shells, the steel ball stamping force and depth are consistent, and the labor intensity is reduced; meanwhile, a shaping mechanism consisting of the shaping cylinder and the shaping movable plate is arranged, surplus gas in the shells is eliminated before the steel balls are sealed, and the deformation of the shells is strictly controlled.

Owner:CHERY AUTOMOBILE CO LTD

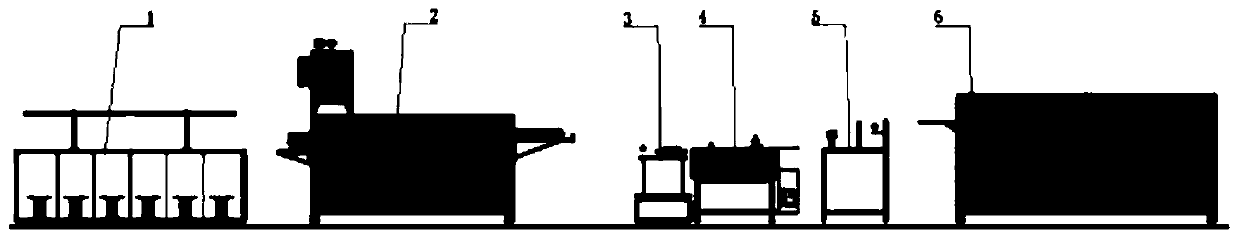

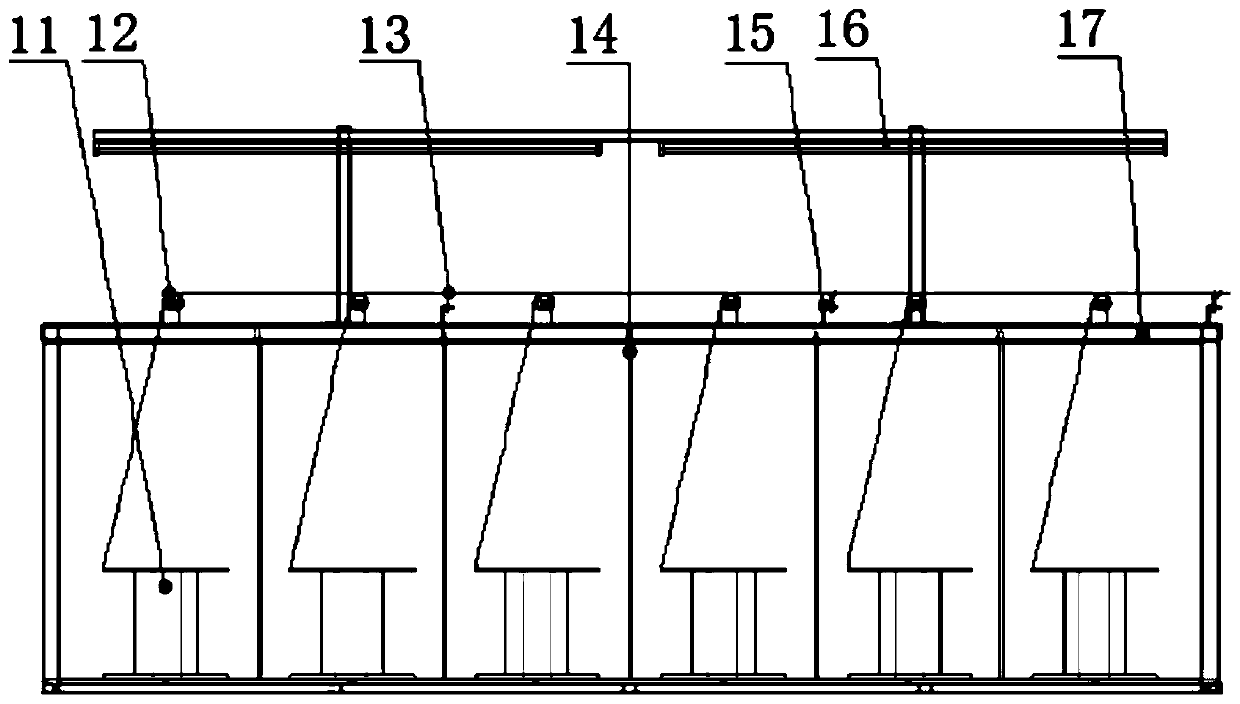

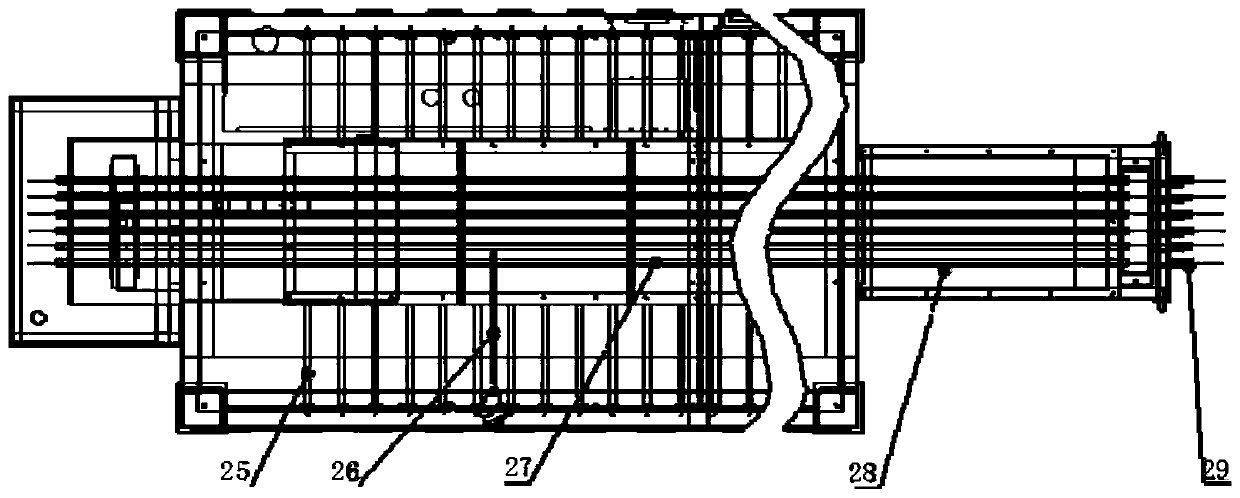

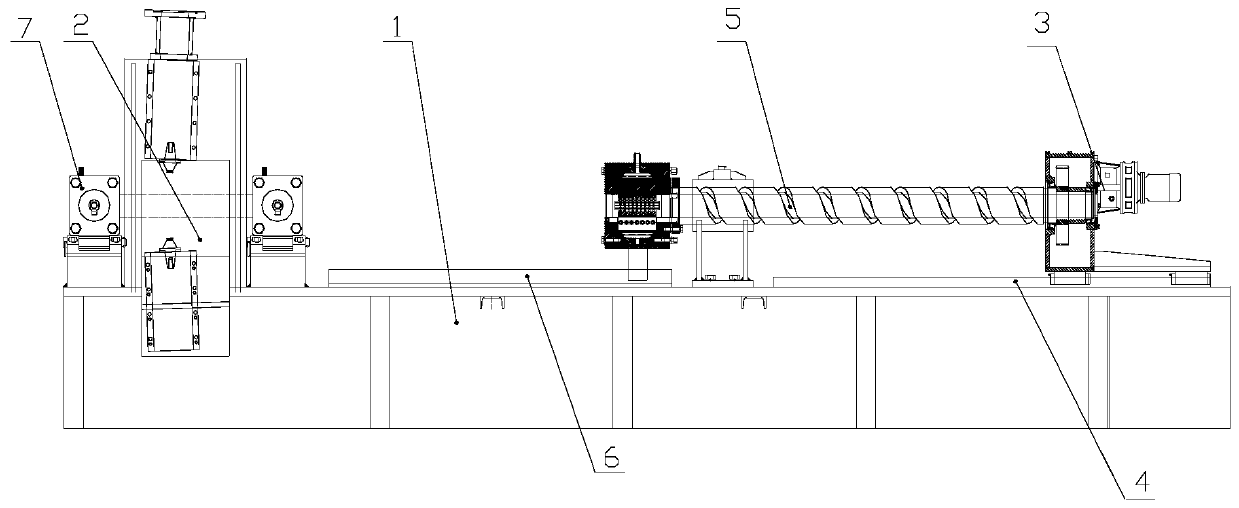

Micro-wire annealing tin plating machine production line

PendingCN109929971AProduction standardizationHigh speed productionHot-dipping/immersion processesFurnace typesFine lineProduction line

The invention discloses a micro-wire annealing tin plating machine production line and belongs to the field of cable machining. The micro-wire annealing tin plating machine production line comprises apay-off frame. A base is arranged at the lower end of the pay-off frame. An annealing furnace, a pickling bath, a tin furnace, a wire passing guide wheel set and a take-up machine. The pay-off frameis provided with a wire shaft. A first wire passing guide wheel is arranged on the surface of the pay-off frame. According to the production line, the special pay-off frame, the annealing furnace, thepickling bath, the tin furnace and the wire passing guide wheel set are arranged to be combined with the take-up machine, thus production of microwires is not troublesome any more, a user only needsto thread wires into the whole production line one by one like that of a traditional machine mode, the equipment can carry out the annealing technology and the tin plated technology automatically, allthe machined wires can be rolled and wound attractively with the standard and at a high speed, the defect that in the current wire industry, the microwires cannot be manufactured in batches is overcome, and the microwires can be produced with the standard and at a high speed.

Owner:鹰潭毅鹏智能科技有限公司

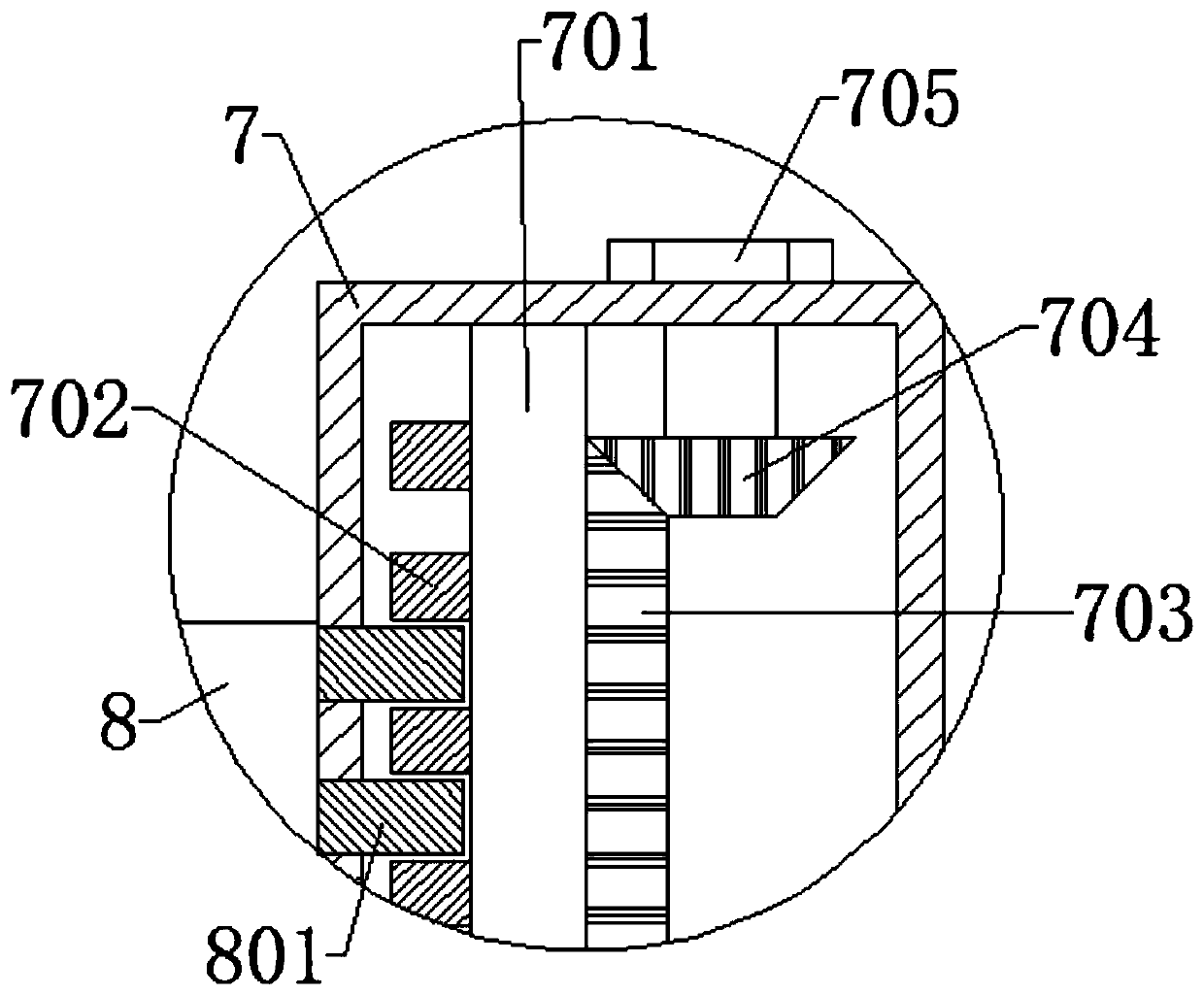

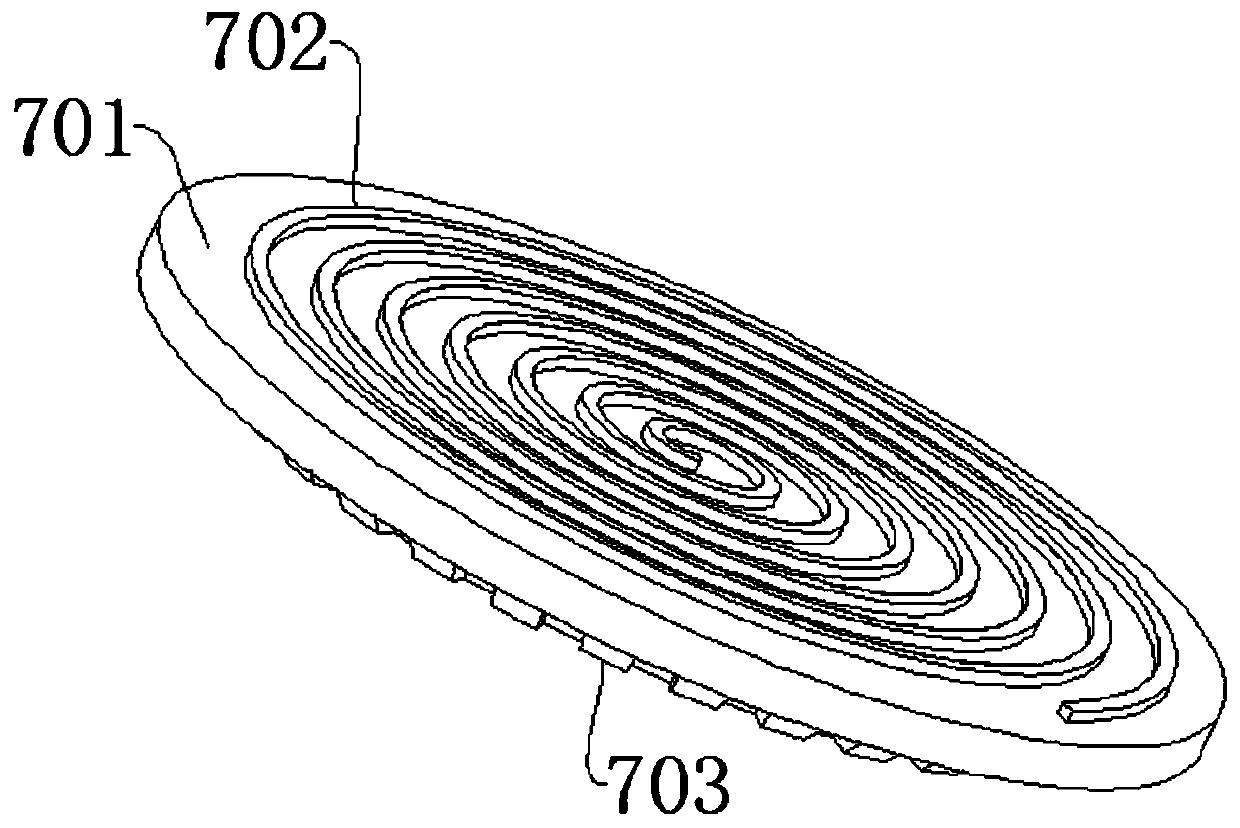

Magnetic-isolating material and flexible treatment method thereof

ActiveCN104647819AConsistent depthGuaranteed flexibilitySynthetic resin layered productsTectorial membraneUltimate tensile strength

The invention discloses a magnetic-isolating material and a flexible treatment method thereof. The magnetic-isolating material comprises a ferrite sintered sheet and protective films on two side surfaces of the ferrite sintered sheet, wherein the protective films are adhered to the ferrite sintered sheet; the ferrite sintered sheet is sintered by ferrite raw sheets; different flexible treatment methods are selected according to the ferrite raw sheets with different thicknesses; when the ferrite raw sheets are 0.14-1.2mm thick, treatment is carried out by virtue of a round roller knife mold; grooves are efficiently formed in the surfaces of the ferrite raw sheets; and when the ferrite raw sheets are 0.04-0.14mm, flexible treatment of the magnetic-isolating material is sequentially reached by adopting a direct sintering method. The flexible treatment method has the beneficial effects that when the ferrite raw sheets are treated by virtue of the round roller knife mold, the grooves in the surfaces of the ferrite raw sheets are consistent in depth; and the method has the characteristic of high efficiency; the work efficiency can be effectively improved by adopting the direct sintering method when the flexibility of the magnetic-isolating material is ensured; the labor intensity is alleviated; and the final magnetic-isolating material can have a good bending effect by different methods.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Garden fertilization device

InactiveCN104380894AGuaranteed depthGuaranteed to be consistentPlantingWatering devicesLand levelingFertilizer

The invention provides a garden fertilization device and belongs to the technical field of machinery. The problem in the prior art that garden vegetation can not be fertilized at high efficiency and high utilization rate is solved. The garden fertilization device comprises a rack and a bottom plate, wherein a fertilization mechanism is fixed on the bottom plate and comprises a chemical fertilizer box; the lower end of the bottom plate is hinged to a sealed door; a ditching structure is further fixed on the bottom plate; a land leveling and irrigation mechanism is fixed on the bottom plate and comprises a water tank, a water pump and a nozzle; the land leveling and irrigation mechanism further comprises a vertical air cylinder, a longitudinal air cylinder I, a longitudinal air cylinder II, a transverse air cylinder and a mounting plate; a pushing plate I is fixed at the end part of a piston rod of the longitudinal air cylinder I; a pushing plate II is fixed at the end part of a piston rod of the longitudinal air cylinder II; and the transverse air cylinder is arranged at the other side of the mounting plate in a sliding manner. The garden fertilization device has the advantages that ditching and fertilization can be carried out automatically and fertilized ditches are filled up and irrigated so that the working efficiency and the utilization rate of chemical fertilizers are improved.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

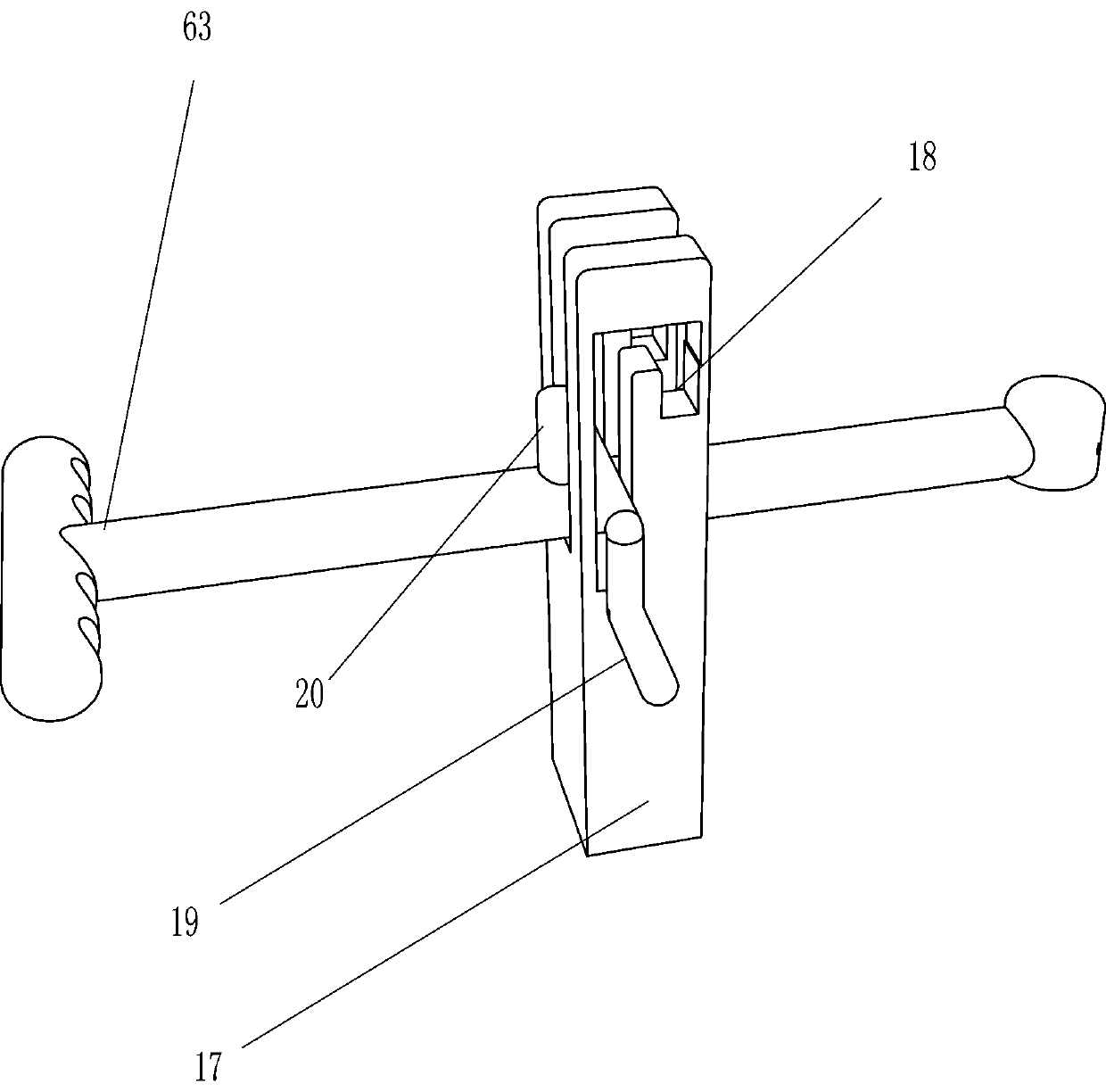

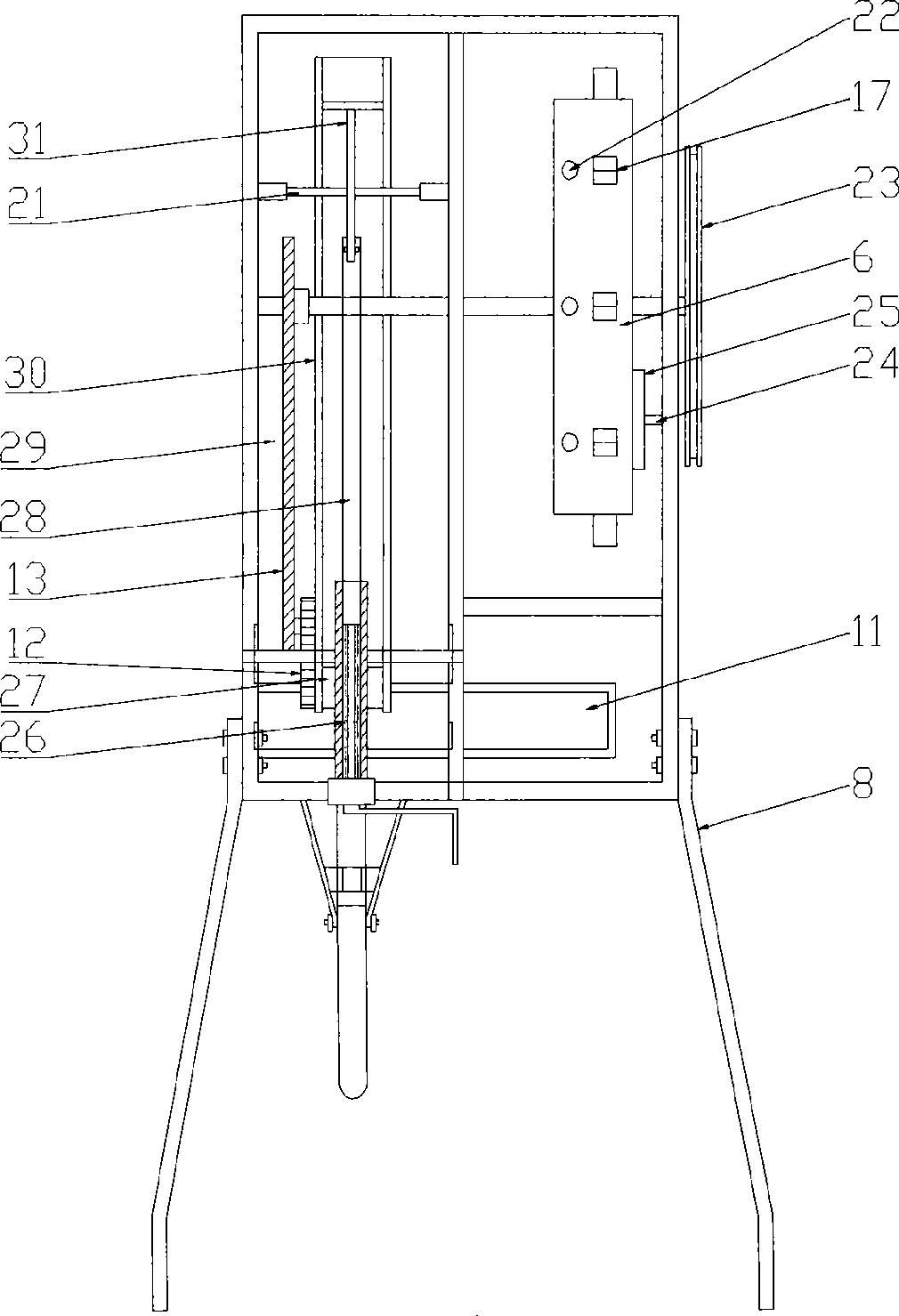

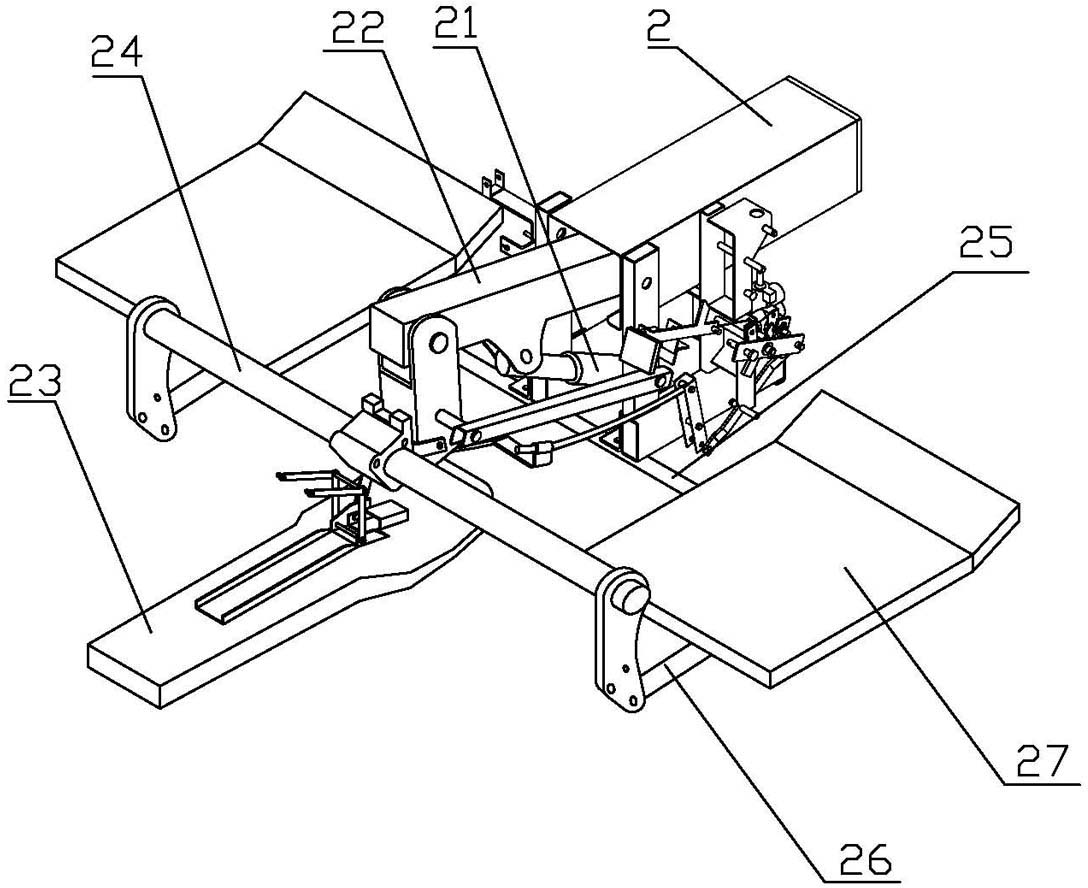

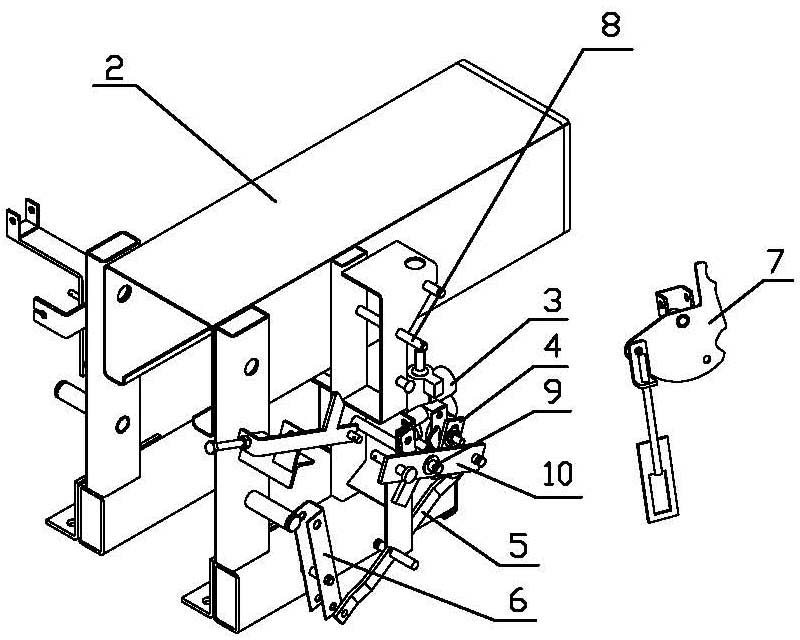

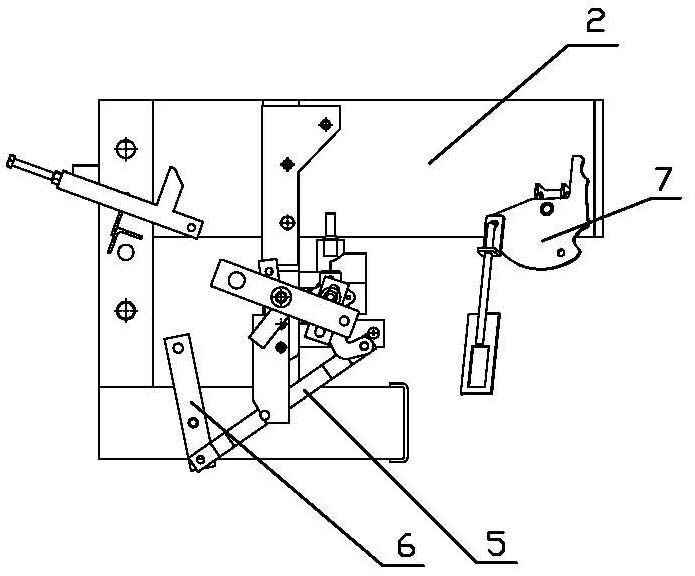

Automatic seedling transplanting depth control device

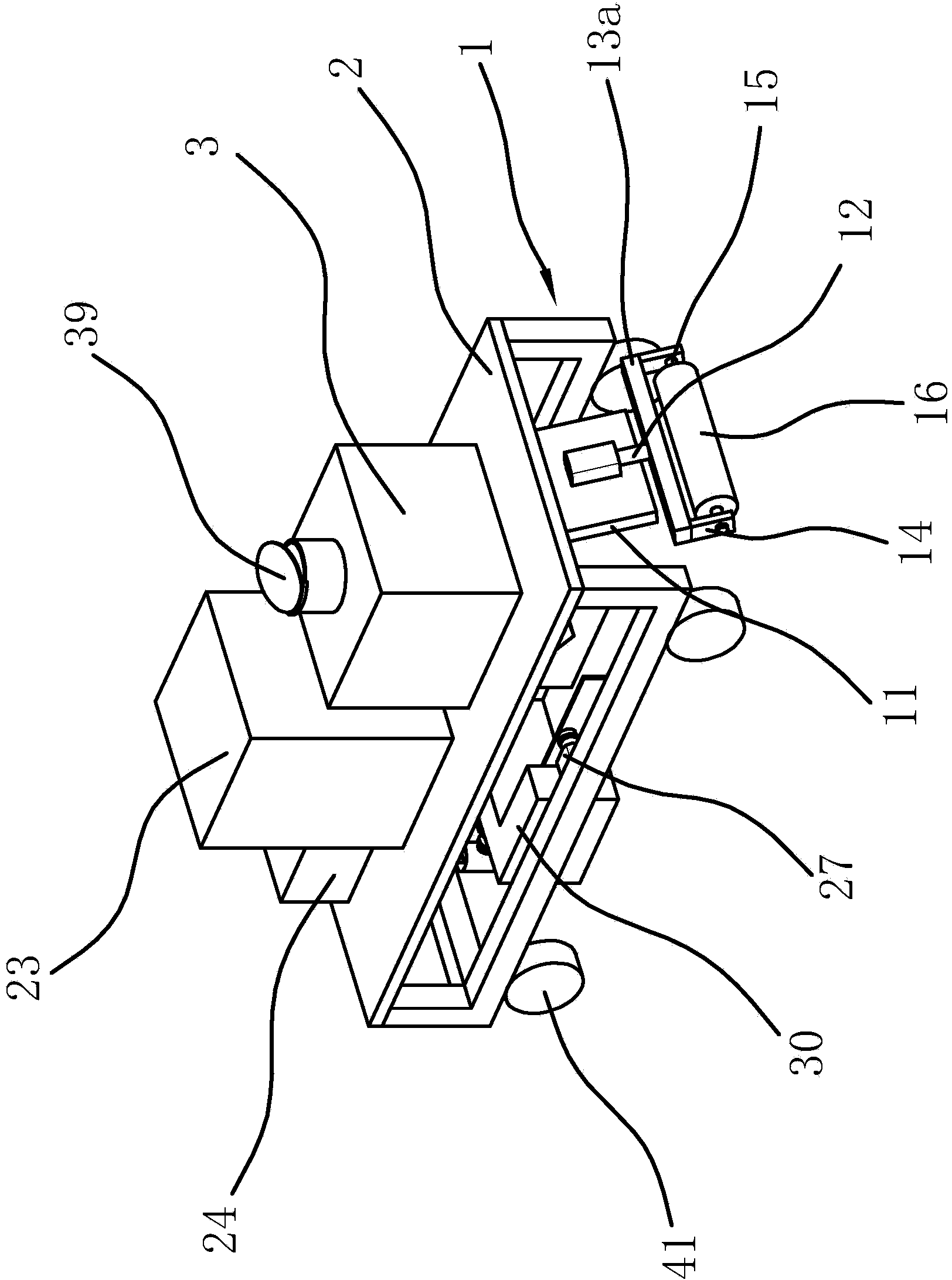

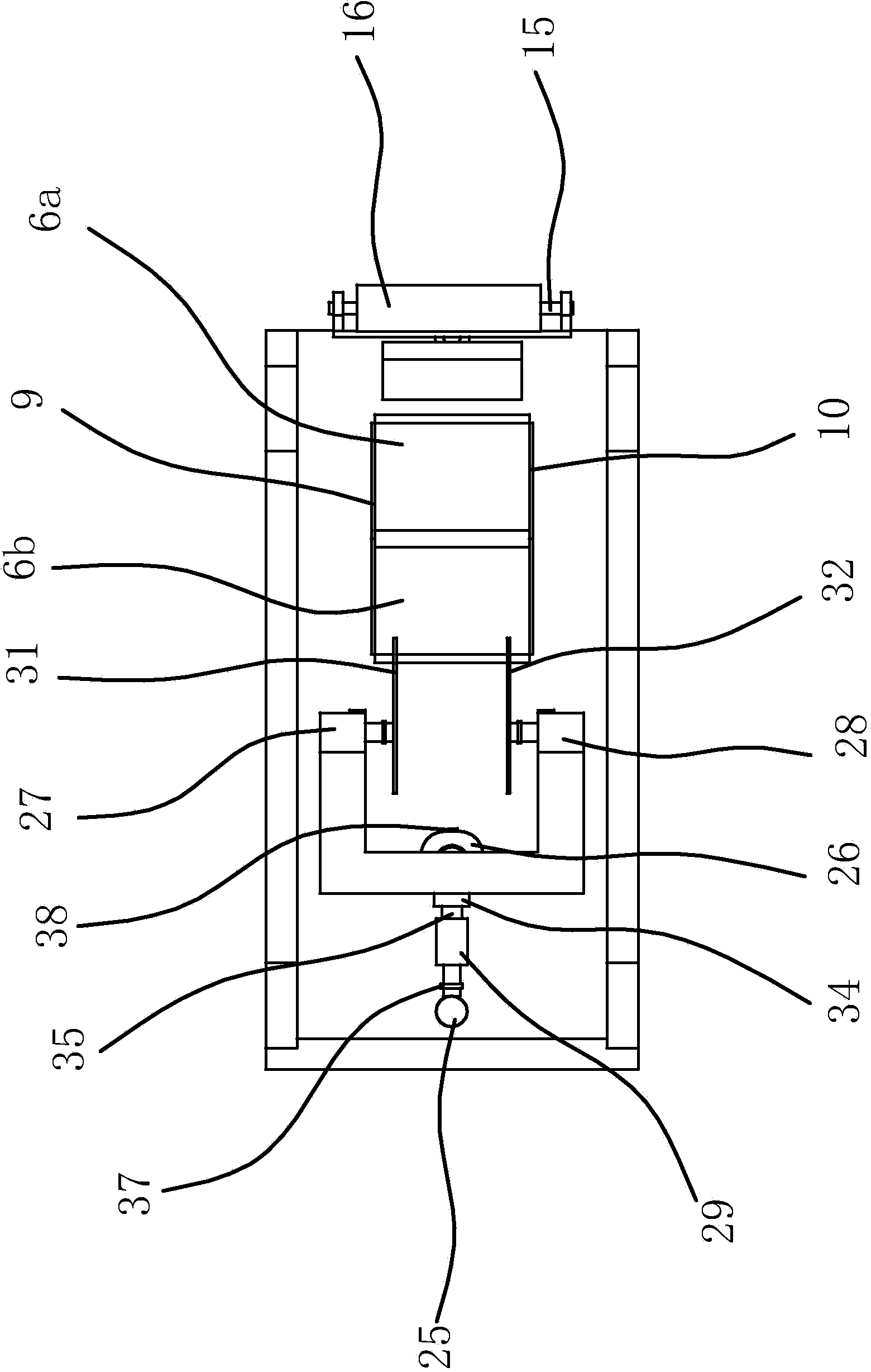

The invention relates to an automatic seedling transplanting depth control device for a transplanter. The automatic seedling transplanting depth control device comprises a transplanter traction frame, a hydraulic control device fixedly connected to the side face of the transplanter traction frame, and a hydraulic oil cylinder arranged on the transplanter traction frame. The hydraulic control device comprises a hydraulic valve and a valve shaft connecting plate; the hydraulic valve is connected to the hydraulic oil cylinder through an oil pipe; an ejection bar of the hydraulic oil cylinder is hinged to a transplanter suspension frame; the valve shaft connecting plate is fixedly connected to a valve shaft of the hydraulic valve; one end of the valve shaft connecting plate is hinged with one end of a pulling plate; the other end of the pulling plate is hinged with one end of an oscillating bar; the other end of the oscillating bar is connected to a transplanter floating plate through a crank arm mechanism; and the middle section of the oscillating bar is provided with a rotating shaft and hinged to the side face of the transplanter traction frame through the rotating shaft. The device can detect the height variation of the ground by the transplanter floating plate and performs corresponding regulation on the height of the transplanter traction frame by pushing the hydraulic valve to work through the crank arm mechanism and the oscillating bar and controlling the lifting of the hydraulic oil cylinder through the action of the hydraulic valve, so the seedling transplanting depths are always kept consistent.

Owner:WEIFANG TONGFANG MACHINERY

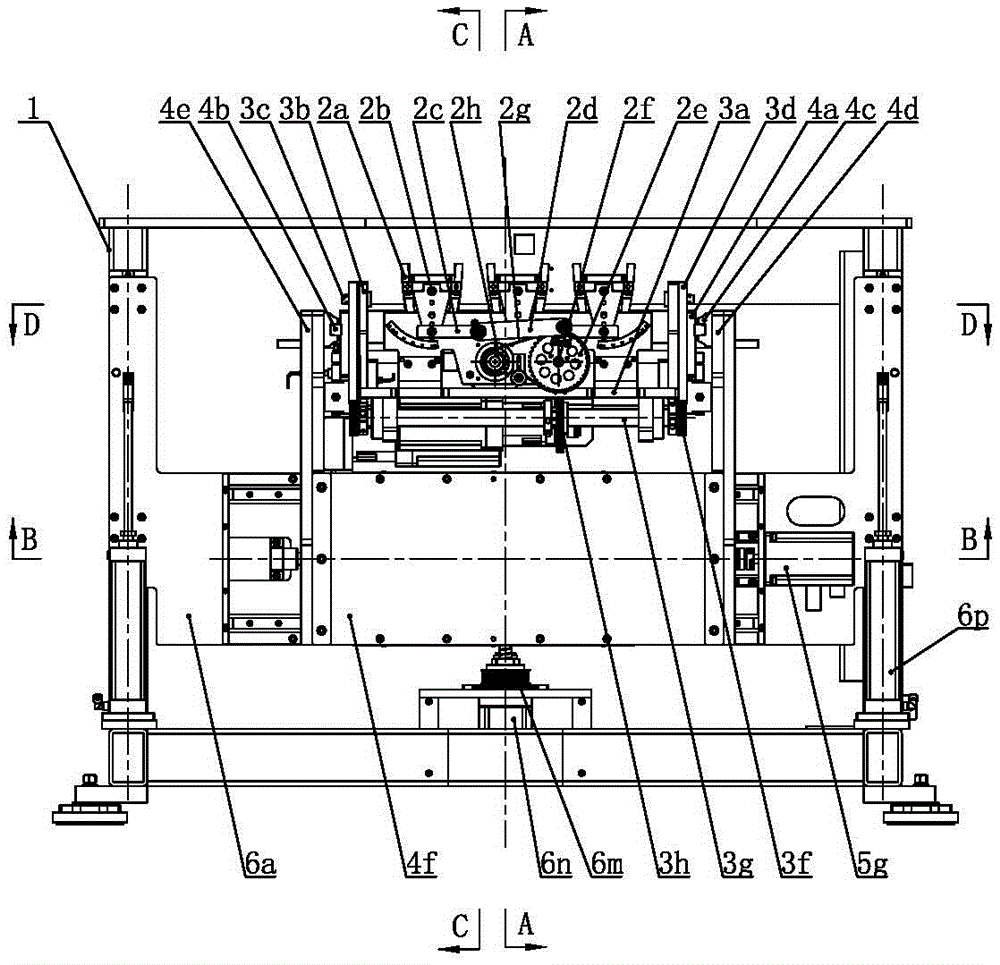

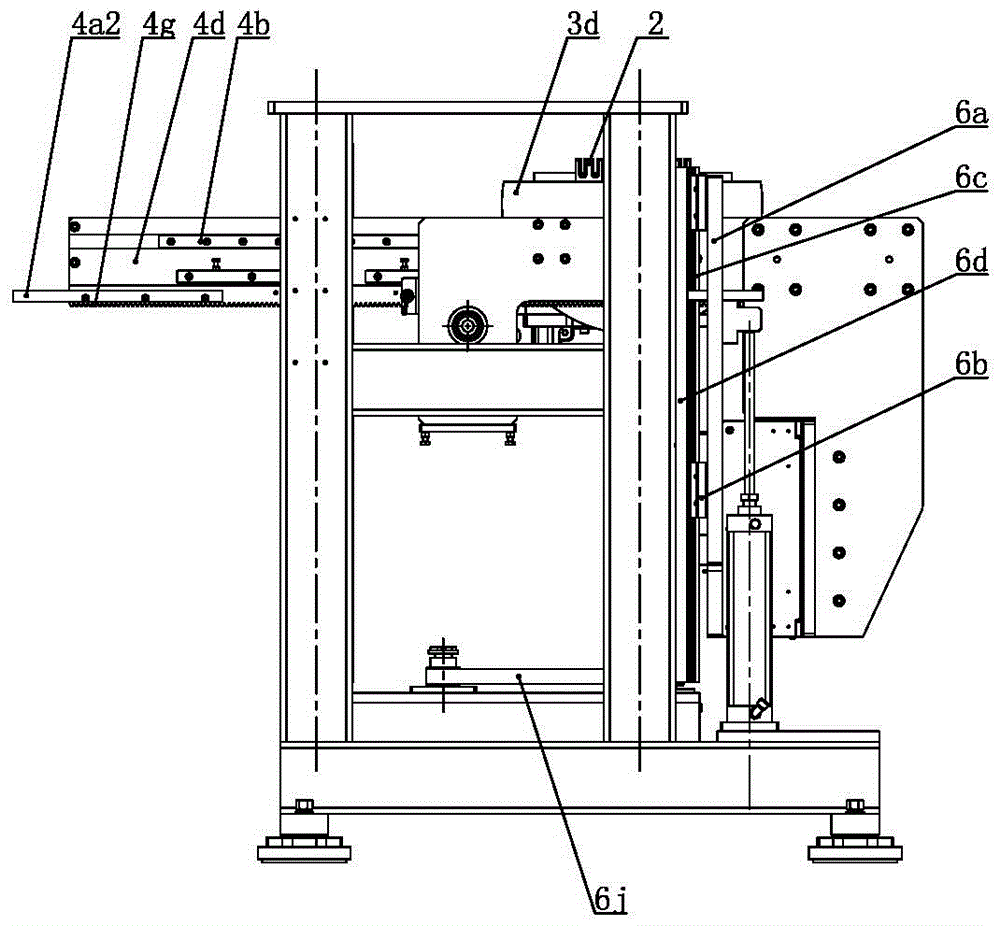

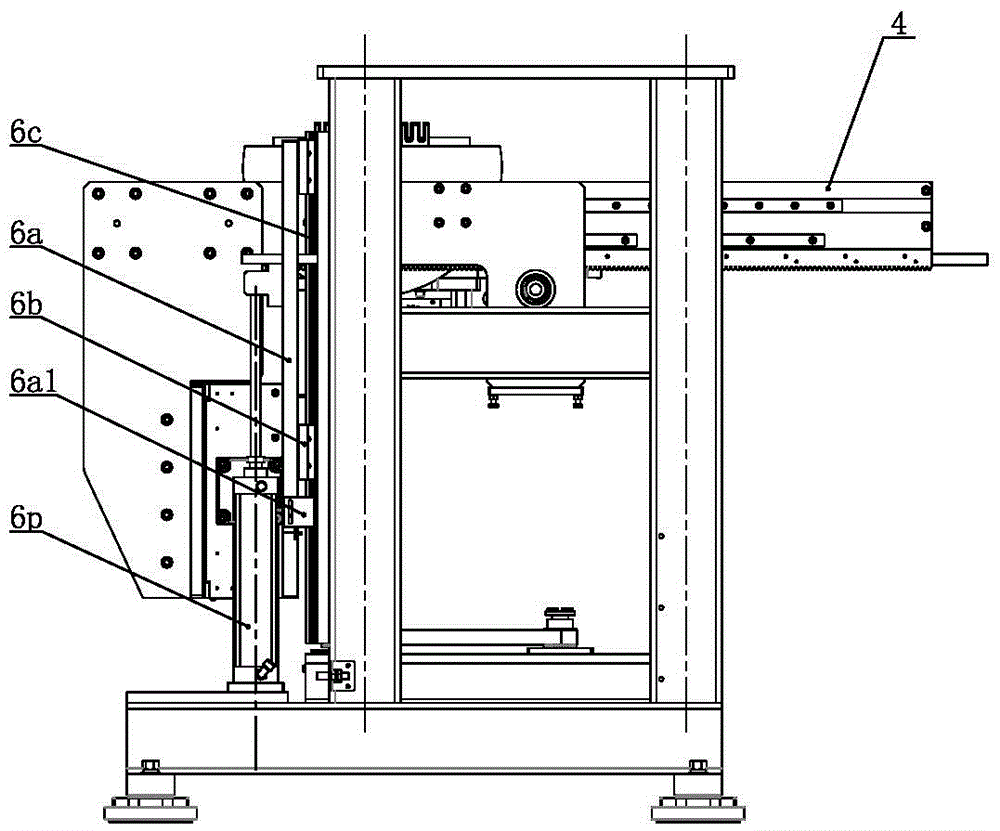

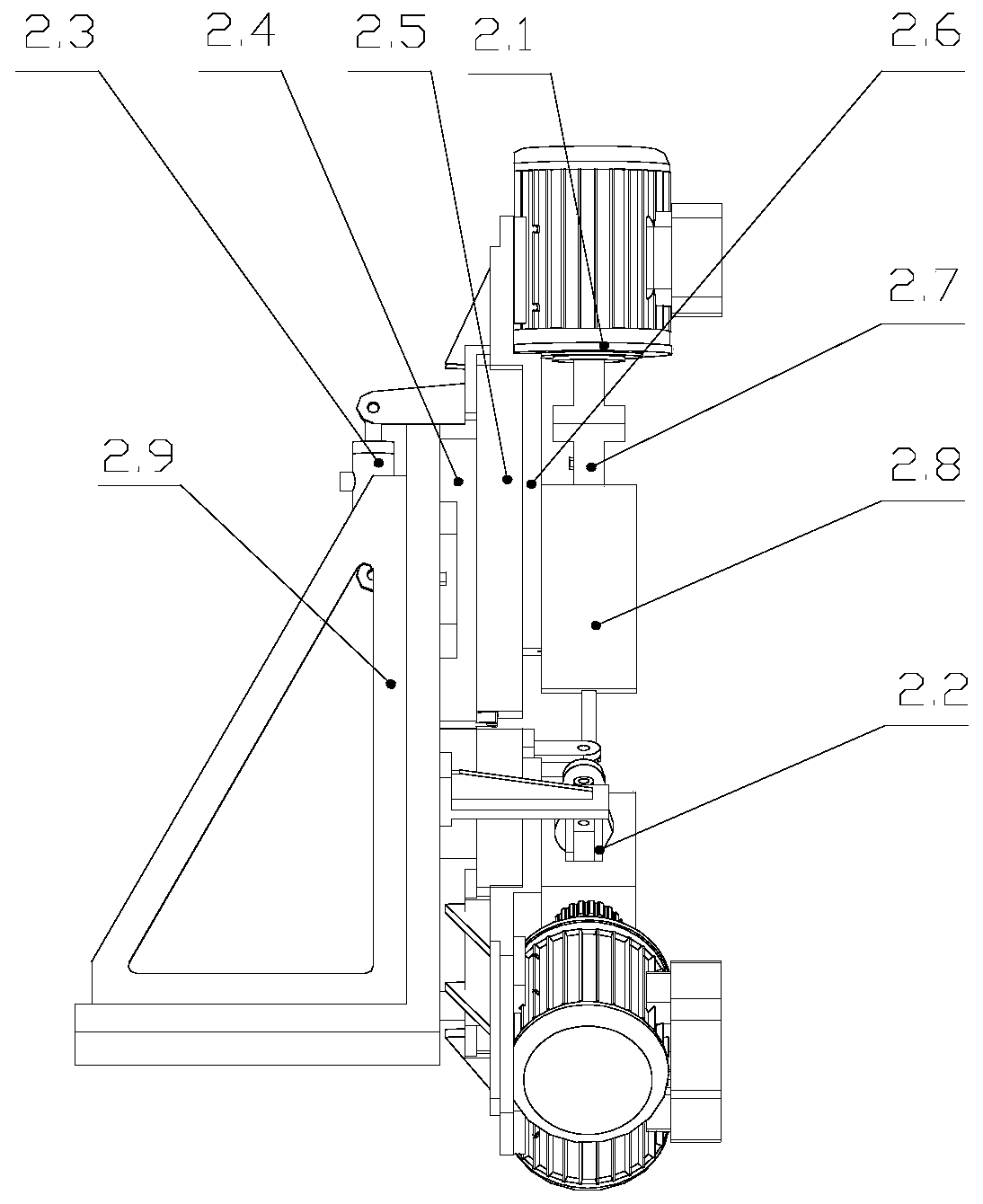

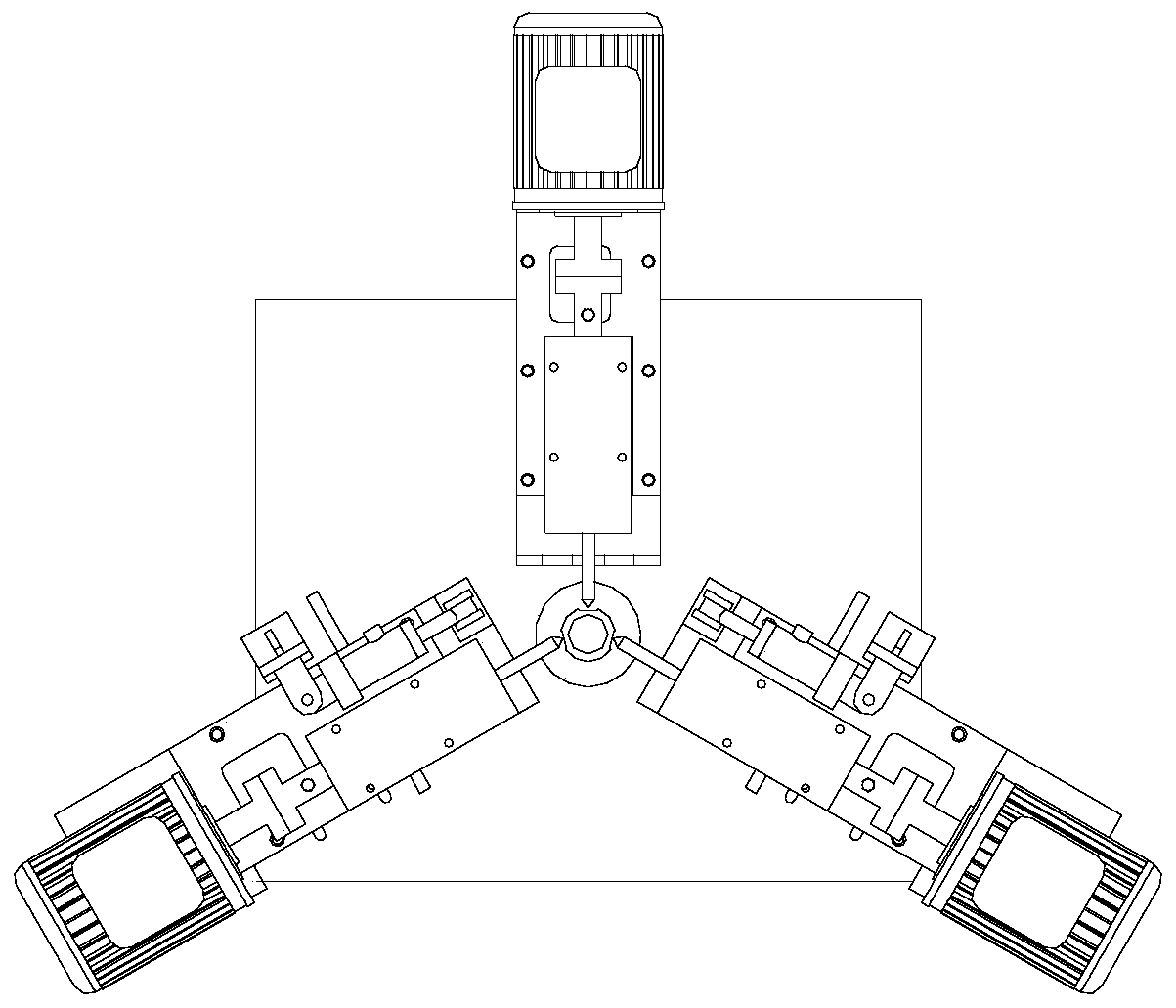

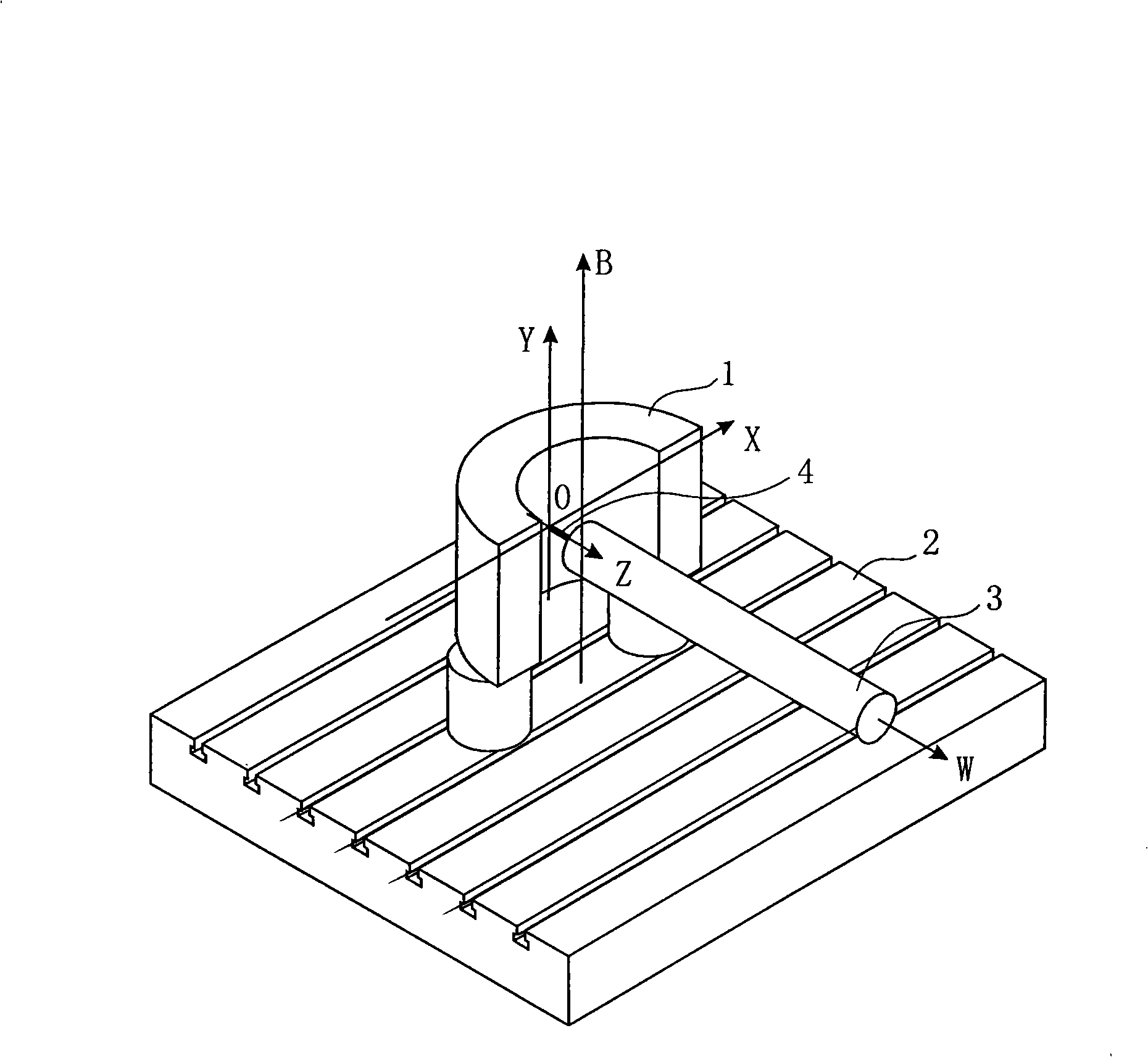

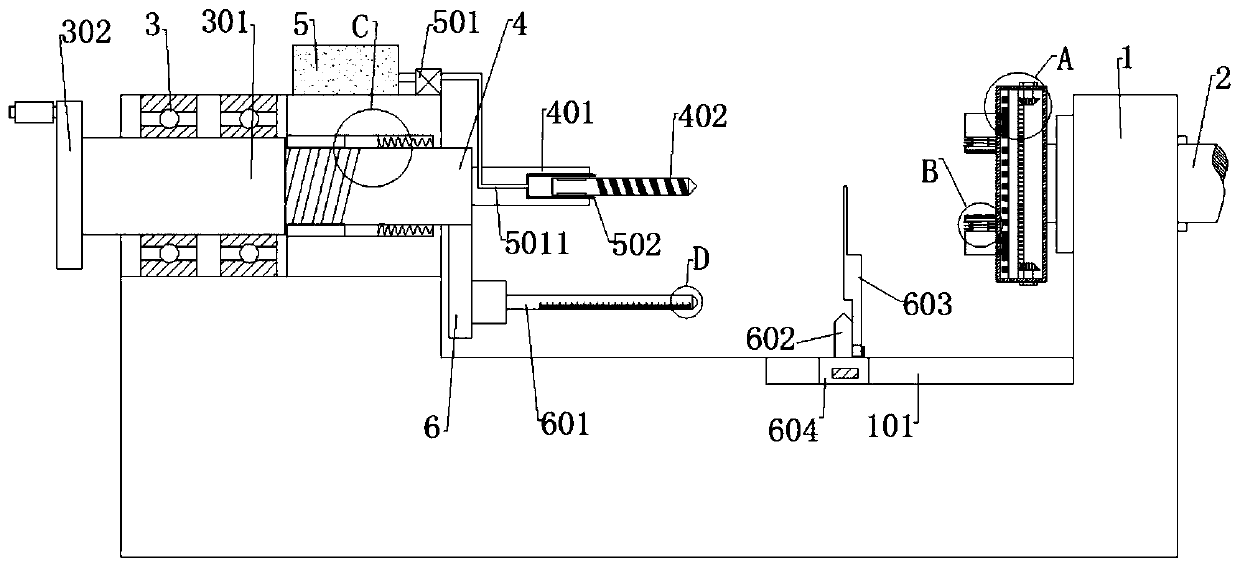

Workbench of five-axis drilling and planting integrated machine

The invention discloses a workbench of a five-axis drilling and planting integrated machine. The workbench comprises a machine frame and a brush body clamp assembly. The brush body clamp assembly comprises an axis-B swinging mechanism and a plurality of brush body clamps capable of clamping brush bodies. Each brush body clamp can be driven by the axis-B swinging mechanism to swing around the axis B. The brush body clamp assembly is fixedly installed on an axis-A swinging mechanism. The axis-A swinging mechanism is installed on an axis-Y translation mechanism capable of moving forwards and backwards. The axis-Y translation mechanism is installed on an axis-X translation mechanism capable of moving left and right. The axis-X translation mechanism is installed on an axis-Z lifting mechanism capable of moving up and down. The rotating axis A of the axis-A swinging mechanism is parallel to the axis X, and the rotating axis B of the axis-B swinging mechanism is parallel to the axis Y. The workbench of the five-axis drilling and planting integrated machine is simple and portable in structure, small in consumed material, low in weight, and capable of promoting modular sub-unit manufacturing.

Owner:YANGZHOU HAIXING CNC BRUSH MACHINERY

Multi-milling cutter processing device of multi-groove carving drilling rod

PendingCN110238435AIncrease productivityConsistent speedFeeding apparatusMilling equipment detailsMilling cutterEngineering

The invention relates to a multi-milling cutter processing device of a multi-groove carving drilling rod. The multi-milling cutter processing device is characterized by comprising a rack, a driving mechanism and a milling mechanism, the driving mechanism and the milling mechanism are installed at the positions of a feeding port and a discharging port of the rack, the driving mechanism has a bidirectional driving function, the output end of the driving mechanism is provided with a screw guiding assembly for conveying and controlling surface milling grooves of the drilling rod, and the driving mechanism and the screw guiding assembly are matched with the rack through a first linear guide rail and a second linear guide rail; the position of the milling mechanism is provided with a gripper for clamping the drilling rod to prevent the drilling rod from retreating, the milling mechanism is provided with a plurality of milling cutter assemblies which can work selectively, and the milling cutter assemblies conduct groove milling operation according to the advancement rotational speed of the screw guiding assembly. According to the multi-milling cutter processing device, the milling mechanism of the multi-head milling cutter is adopted, meanwhile, groove milling operation is carried out on the drilling rod, the previous manner of one-by-one milling is avoided, and the production efficiency is greatly improved; and the quality and the service life of groove carving of the drilling rod are ensured.

Owner:JIANGSU ZHONGMEI MINING EQUIP

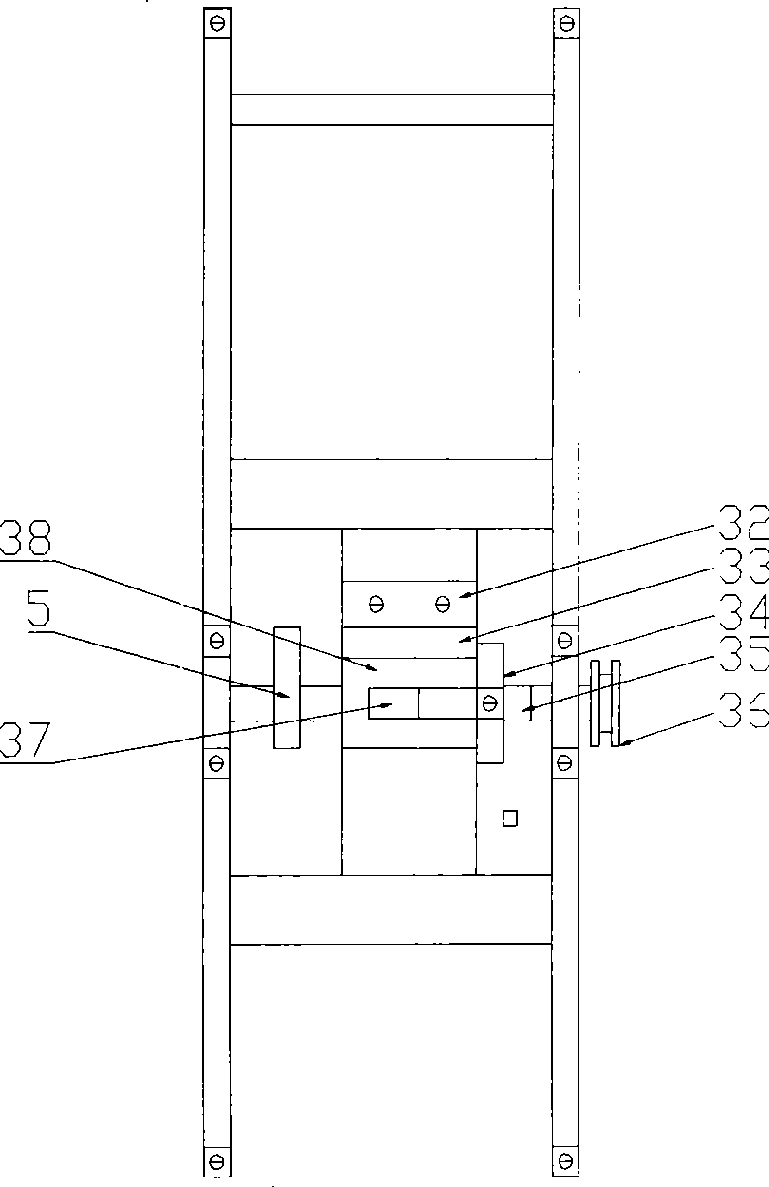

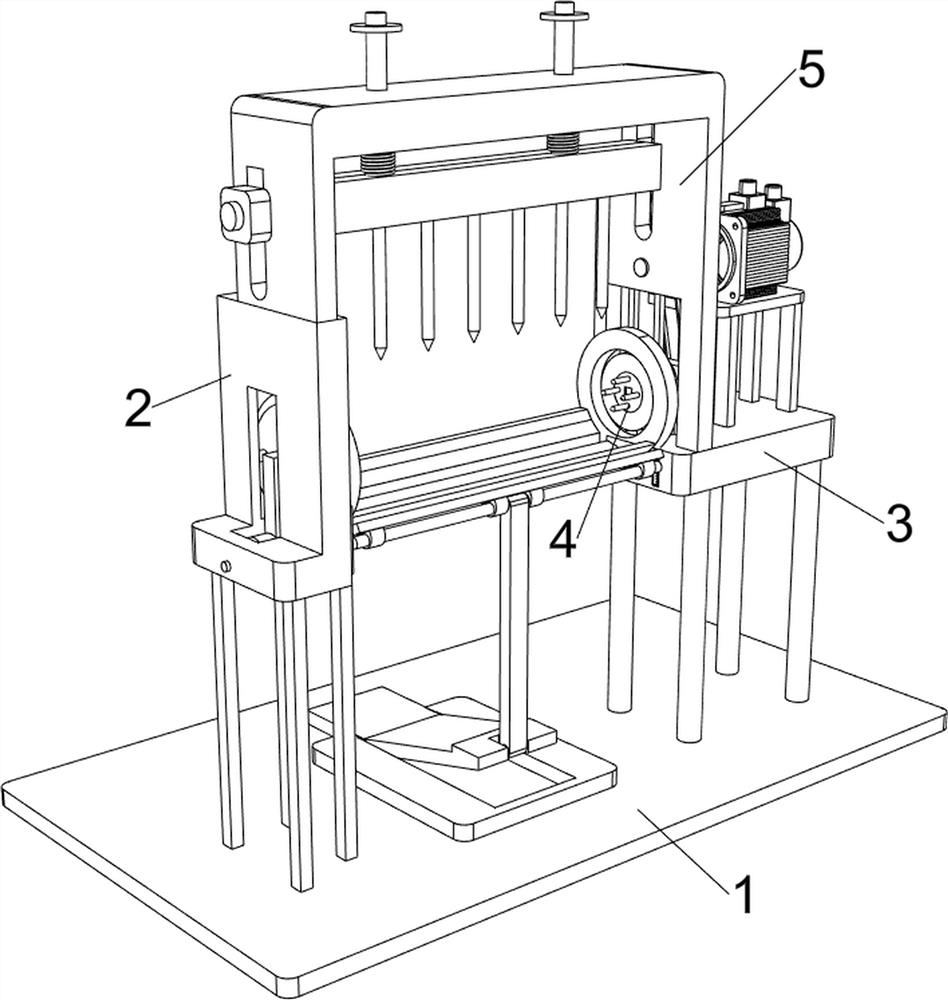

Fungus bag punching machine for agricultural planting

The invention relates to a punching machine, in particular to a fungus bag punching machine for agricultural planting. The invention provides a fungus bag punching machine for agricultural planting, which is simple in operation and convenient to pick and place, and can automatically carry out punching. The fungus bag punching machine for agricultural planting comprises a bottom plate, a support seat, a clamping mechanism and a punching mechanism, wherein a rack is arranged at one side of the bottom plate; the support seat is arranged at the other side of the bottom plate; the clamping mechanism is arranged between the rack and the support seat; the punching mechanism is arranged between the rack and the support seat; and the clamping mechanism is located below the punching mechanism. The fungus bag punching machine clamps a fungus bag through the clamping mechanism and can quickly punch the fungus bag in the cooperation of the punching mechanism at the same time, and the punched holesare consistent in depths and uniform in positions; up-and-down movement of second inserting rods is achieved through the cooperation of shifting blocks and second fixing blocks, so that turnover of the fungus bag is facilitated; automatic turnover of the fungus bag when a second sliding block moves upwards is achieved through the cooperation of a clamping block and a ratchet wheel, so that manualturnover by people is not needed.

Owner:刘小红

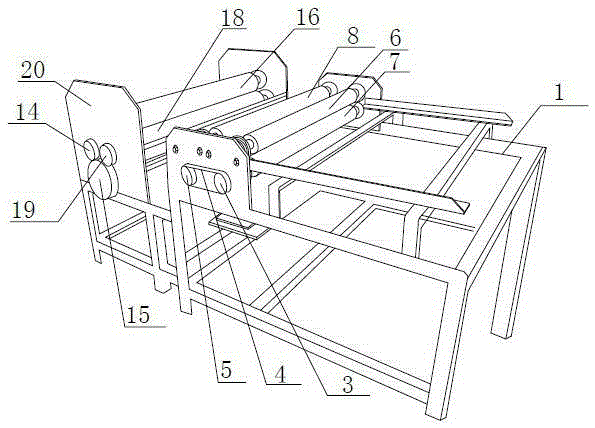

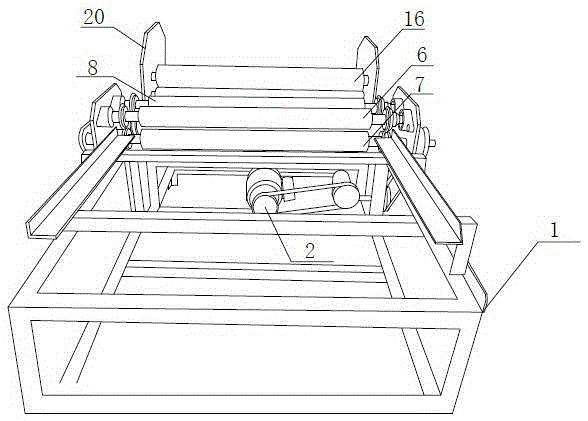

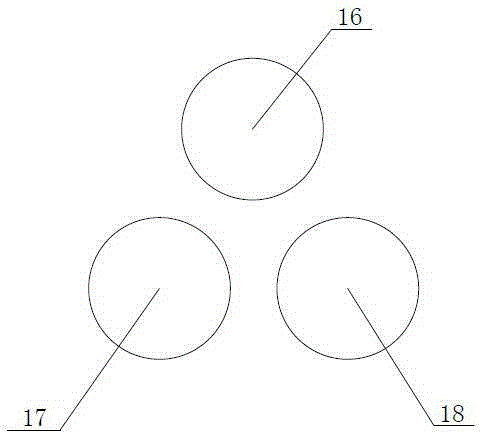

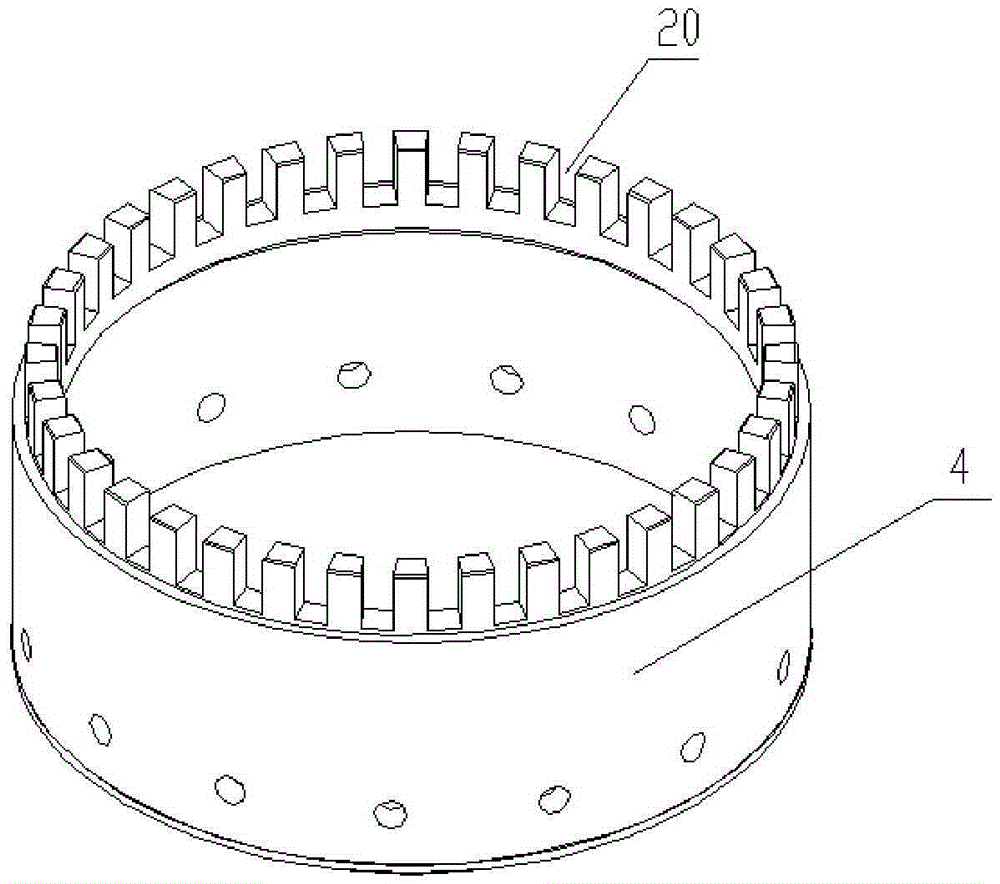

Iron sheet rolling groove winding drum machine

The invention discloses an iron sheet rolling groove winding drum machine and belongs to the technical field of pipeline processing equipment. The iron sheet rolling groove winding drum machine comprises a machine frame, a plate feeding mechanism, a rolling groove mechanism, a winding drum mechanism and a mechanical driving mechanism. The plate feeding mechanism comprises a driving plate feeding compression roller and a driven plate feeding compression roller. The rolling groove mechanism comprises an upper rolling groove compression roller and a lower rolling groove compression roller. The both sides of the upper rolling groove compression roller are each provided with an upper rolling groove pressing wheel. The both sides of the lower rolling groove compression roller are each provided with a lower rolling groove pressing wheel. The upper rolling groove pressing wheels are terrace die type wheels. The lower rolling groove compression rollers are annular groove wheels. The terrace die type wheels are matched with the annular groove wheels. The winding drum mechanism comprises an upper winding drum compression roller, a winding drum lower left compression roller and a winding drum lower right compression roller. An iron sheet is conveyed through the plate feeding mechanism at first and then is subjected to groove rolling through the rolling groove mechanism, and finally the iron sheet is subjected to winding drum forming through the winding drum mechanism. The iron sheet rolling groove winding drum machine is convenient to operate and capable of saving time, completing operations of transmission, groove rolling and drum winding at a time and saving the manual labor; the installation is convenient, and the production efficiency is improved.

Owner:JIHUA 3534 CLOTHING

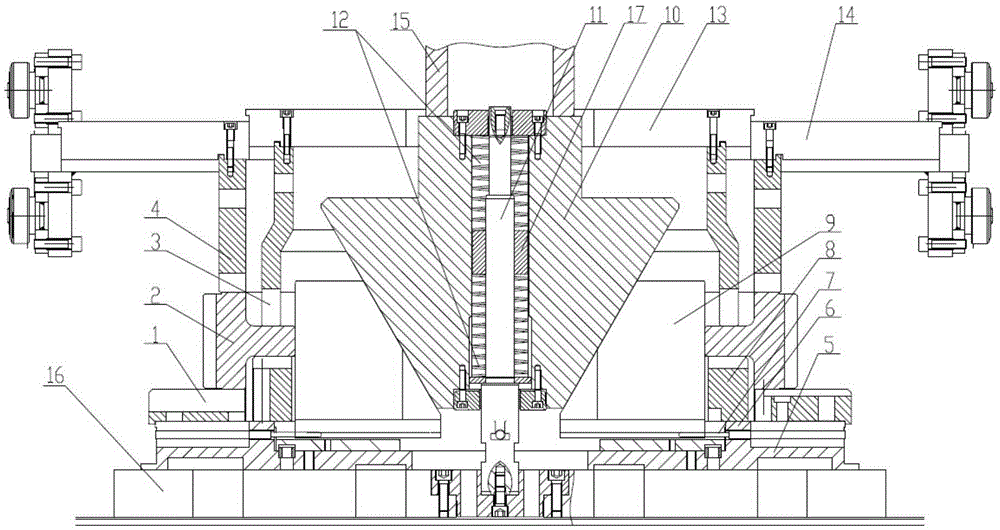

Press quenching mold for locomotive traction gear ring

ActiveCN105420464AUniform stress distributionReduce jumpingFurnace typesHeat treatment furnacesCircular coneHardness

The invention relates to the technical field of thermal treatment molds, in particular to a press quenching mold for a locomotive traction gear ring. The press quenching mold comprises an upper mold body and a lower mold body. The upper mold body comprises a web pressing mold body and an end face pressing mold body. The lower mold body comprises an expanding core, a web supporting table and an end face supporting table. The web supporting table and the web pressing mold body are used for clamping a web of the locomotive traction gear ring; the end face supporting table and the end face pressing mold body are used for clamping the end face of the locomotive traction gear ring; the expanding core comprises a stand column, a circular cone stand, an expander and an expander supporting table; the stand column and the expander supporting table are fixed to a machine tool working table; the circular cone stand is arranged on the stand column in a sleeved mode and can move up and down along the stand column; the expander is arranged around the periphery of the circular cone stand, the bottom of the expander makes contact with the expander supporting table and can perform radial movement on the expander supporting table; the inner inclined surface of the expander is attached to the outer conical surface of the circular cone stand. The press quenching mold for the locomotive traction gear ring is compact in structure and ingenious in design; during carburizing and quenching, the requirement of products for the hardness can be met and deformation of the gear ring due to carburizing and quenching can be effectively controlled; therefore, the qualified rate of the products is increased.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Foundation pit enclosure structure capable of realizing supporting while excavating and foundation pit excavating method

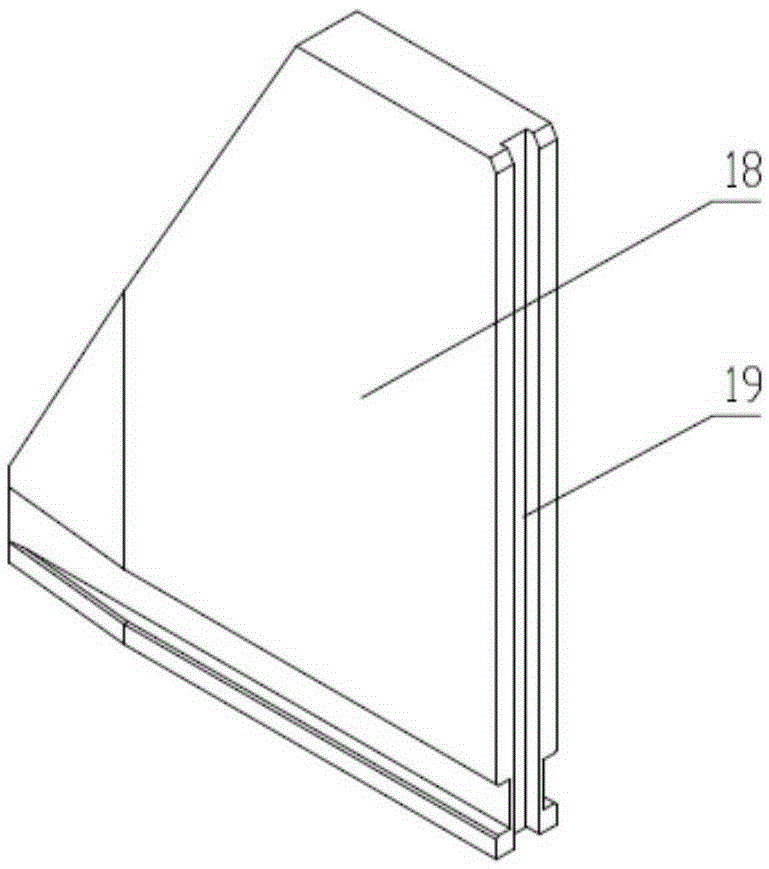

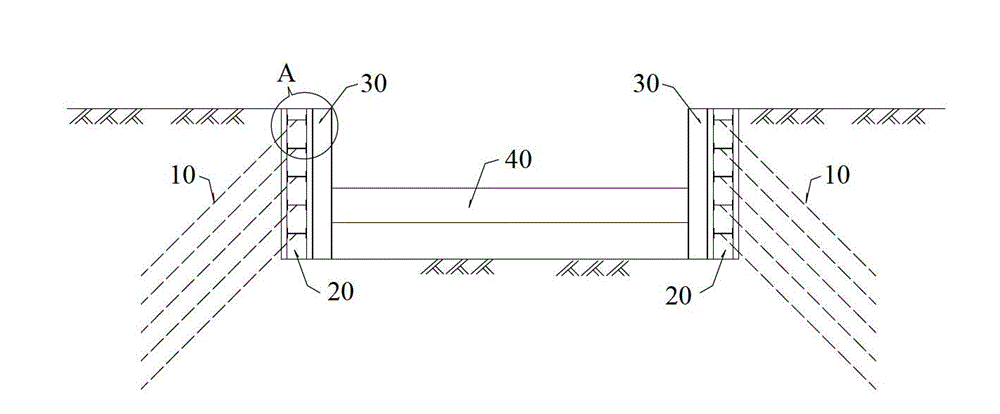

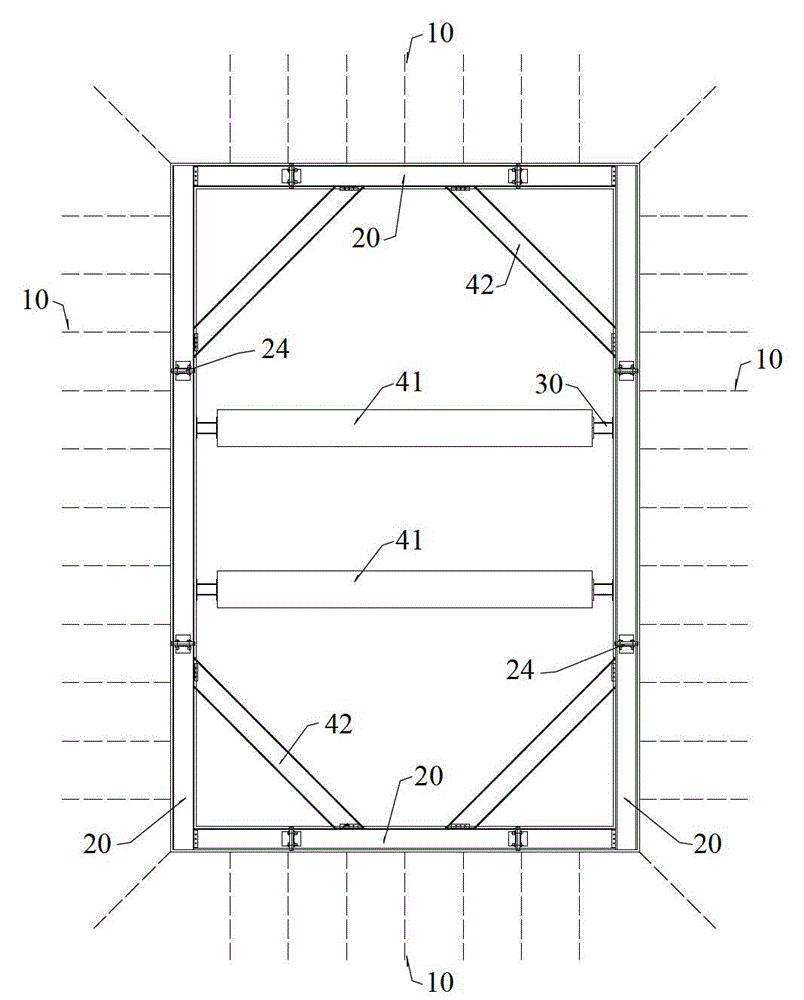

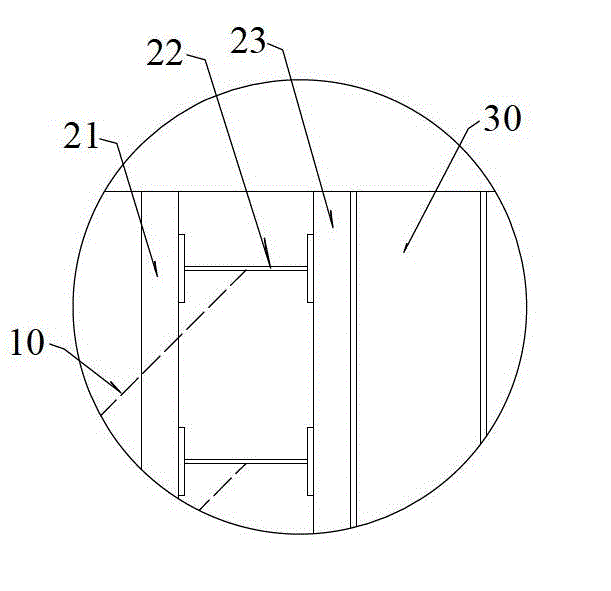

The invention relates to a foundation pit enclosure structure capable of realizing supporting while excavating and a foundation pit excavating method. The geological condition is shown in a targeted way according to the excavation, corresponding supporting parameters are adopted, the supporting reliability is improved, the measures of the enclosure structure are more reasonable, and the construction cost is effectively reduced. The foundation pit enclosure structure comprises an advance support (10), a primary support (20) and a supporting system, wherein the advance support (10) is exerted on a pre-reinforcement rock soil body formed in the rock soil at the outer side of a foundation pit excavation line, the primary support (20) is fully and annularly exerted on the vertical excavation surface of a foundation pit, a sealed rock surface body is formed, the supporting system comprises vertical steel enclosing purlins (30), steel transverse supporters (41) and steel inclined supporters (42), the vertical steel enclosing purlins (30) are arranged at intervals on the outer wall of the relatively sealed rock surface body, the steel transverse supporters (41) are fixedly arranged among the corresponding vertical steel enclosing purlins (30), and the steel inclined supporters (42) are fixedly arranged on two adjacent outer walls of the sealed rock surface body.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

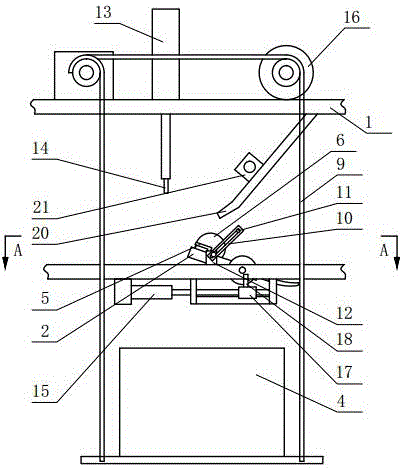

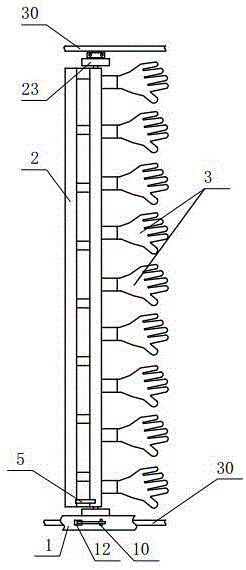

Gum dipping method for gloves and gum dipping device implementing method

ActiveCN106584733AGuaranteed precise tilt angleAvoid anglesDomestic articlesCoatingsEngineeringRejection rate

The invention discloses a gum dipping method for gloves. The gum dipping method comprises the following steps that 1), conveying chains drive a hand mold frame to the designated gum dipping position in a transmission manner; 2), the end of the hand mold frame is rotationally pressed; 3) the rotary shaft position of the hand mold frame is detected through a longitudinal detection switch; 4), the hand mold frame is driven to rotate; 5), the hand mold frame is driven to rotate at the set angle; 6), a gum dipping box moves upwards till hand molds are immersed into gum in the gum dipping box, and the gum dipping box falls off after gum dipping; and 7), the hand mold frame is driven to vibrate, and gum dipping of the hand molds is achieved. The invention further discloses a gum dipping device implementing the method. The gum dipping device comprises a rack. The conveying chains are connected to the rack. The hand mold frame is mounted on the conveying chain. The hand molds are mounted on the hand mold frame. The liftable gum dipping box is arranged below the rack. A rotary drive device is connected to the side of the rack. A positioning rod is mounted on the hand mold frame. A positioning rod detection device and a longitudinal detection device are mounted on the rack. By the adoption of the gum dipping method and the gum dipping device, the inclination angle of the hand molds is precise, and the gum dipping method and the gum dipping device have the beneficial effects that the gum dipping quality is high, and the rejection rate is low.

Owner:SHANDONG DENGSHENG SAFETY PROD

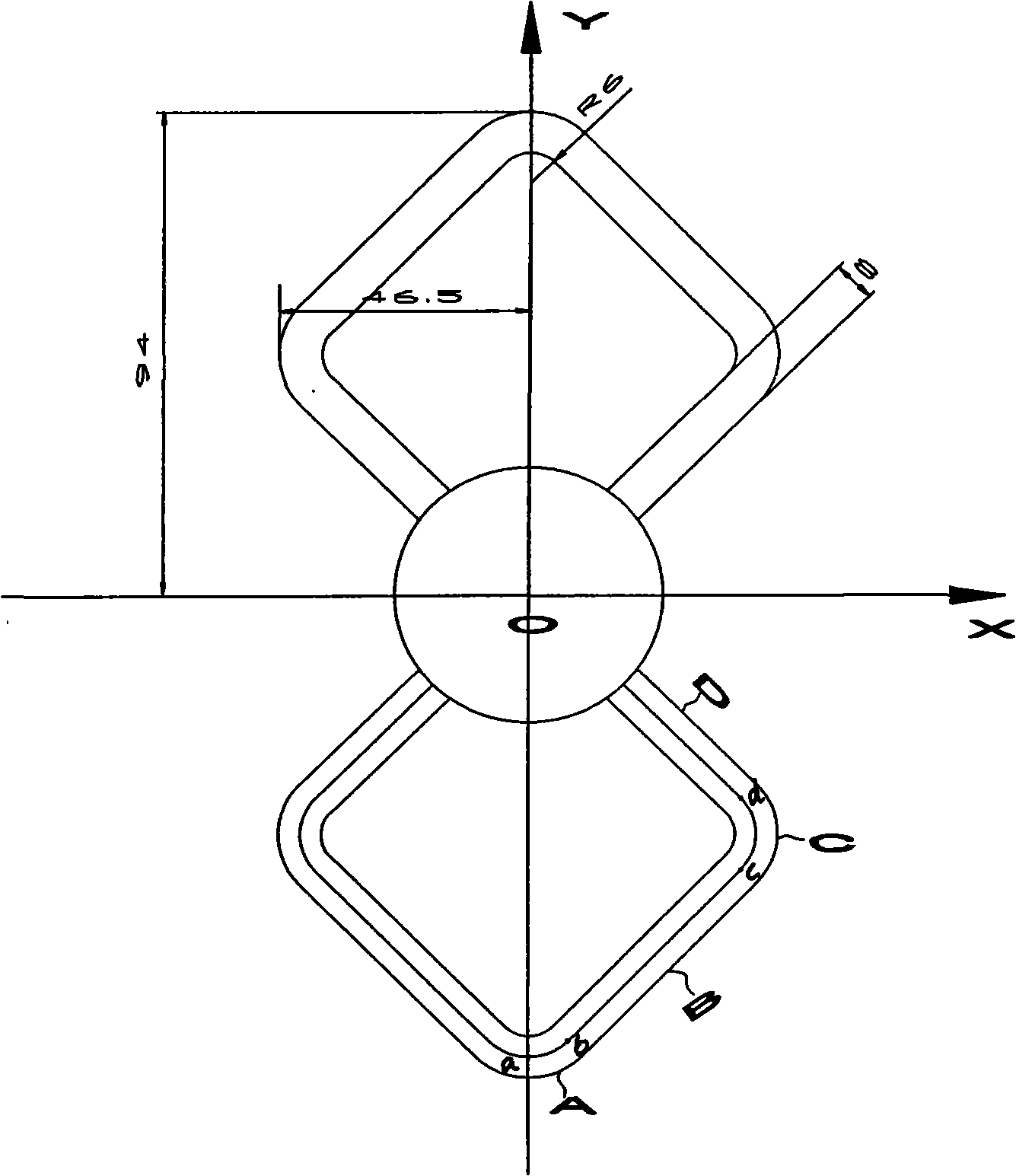

Method for processing 8 shaped oil groove with numerical control boring mill

ActiveCN101314186AApparent quality changeAccurate shapeMilling equipment detailsBoring/drilling machinesNumerical controlMilling cutter

The invention belongs to the numerical control machining technical field and relates to a method for machining a 8-shaped oil sink by a numerical control machine. The method comprises the following steps: the 8-shaped oil sink is divided into four symmetrical sections by a coordinate system XOY with a centre O of the 8-shaped oil sink as a punch mark and the four symmetrical sections are respectively machined by a numerical control boring machine, each symmetrical sections is machined into a one eighth circular arc A, a tangential path B, and a one fourth circular arc C and a tangential path D in turn from a vertex to the centre O of the 8-shaped oil sink by a milling cutter of the numerical control boring machine. The 8-shaped oil sink machined and obtained by the method for machining the 8-shaped oil sink by the numerical control machine has attractive appearance and quality, flat underside, consistent depth and smooth transition of the circular arc, greatly improves machining efficiency, ensures machining quality and is not easy to cause accidental situations of damaging a lead layer in the machining process.

Owner:上海电气集团上海电机厂有限公司

Automobile component drilling device

InactiveCN110496986AImprove processing qualityObservation is intuitiveAutomatic control devicesMeasurement/indication equipmentsDrive shaftEngineering

The invention discloses an automobile component drilling device, and belongs to the field of automobile component processing. The automobile component drilling device includes a main box body, a transmission shaft is rotatably connected into the main box body, a clamping mechanism is fixedly connected to the transmission shaft, a thread bushing is rotatably connected into the main box body througha bearing, a screw is in internal threaded connection with threads in the thread bushing, the screw is slidably connected to the inner wall of the main box body through a first slider, the end, far away from the thread bushing, of the screw is connected with a drill bit through a fixed block, a measuring mechanism is fixedly connected to the bottom of the screw, a water tank is connected to the top of the main box body, a water pump is connected to the water tank through a pipeline, and a nozzle is connected to the output end of the water pump through a pipeline. The drilling depth is measured by the measuring mechanism, so that a worker is capable of observing the drilling depth more intuitively, and the machining quality is improved. When hole drilling is carried out, the good shock absorption effect is achieved, and intuitive observation of the drilling depth is achieved, and the machining quality of a workpiece is improved.

Owner:安徽中运智能科技有限公司

Continuous pad dyeing and shortened wet steaming processing technology for towel and sheet fabric vat dye

ActiveCN103031750AGuaranteed stabilityQuick exchangeSucessive textile treatmentsDyeing processEngineeringUltimate tensile strength

The invention discloses a continuous pad dyeing and shortened wet steaming processing technology for a towel and sheet fabric vat dye. The processing technology comprises the following sequential steps that (1), a small-capacity groove with a capacity of 75-80L and an evenness calender with compression roller oil pressure of 0.440-2.220bar are adopted, towel and sheet fabric is subjected to pad dyeing with the vat dye, and a pick-up ratio is kept as 90-95%; (2), an assistant is supplied by a high liquid supply device, a stain ratio of the assistant on the towel and sheet fabric is kept as 90-100%, and the assistant comprises 100-160ml / L of 42wt% caustic soda solution and 50-80g / L of sodium hydrosulfite; (3), rapid steaming is conducted; (4) high-efficiency water washing is conducted; and (5) oxidation is conducted with hydrogen peroxide oxidation liquid, and the towel and sheet fabric dyed by the vat dye is obtained. According to the processing technology, the dyeing quality of the vat dye is improved greatly, the dip dyeing defect of the vat dye is overcome, the production efficiency is high, the energy consumption is low, the labor intensity is low, and the environmental pollution is little.

Owner:SUNVIM GROUP

Fertilization mechanism in garden fertilization device

InactiveCN104429256AGuaranteed Ditch DepthGuaranteed to be consistentPlantingWatering devicesFertilizerAgricultural engineering

The invention provides a fertilization mechanism in a garden fertilization device, belonging to the technical field of machinery and aiming at solving the problems that ditches can not be automatically dug in soil, and fertilization can not be carried out in the prior art. According to the fertilization mechanism in the garden fertilization device, the garden fertilization device comprises a rack and a bottom plate; the fertilization mechanism comprises a chemical fertilizer box fixed on the bottom plate; a discharging opening is formed in the bottom of the chemical fertilizer box and a piston plate is arranged in the discharging opening; a telescopic air cylinder I is fixed on the inner wall of the chemical fertilizer box; the end part of a piston rod of the telescopic air cylinder I is fixed on the piston plate; a through hole is formed in the bottom plate and the lower end of the bottom plate is hinged to a closed door; and a ditching structure is further fixed on the bottom plate. The fertilization mechanism in the garden fertilization device has the advantages that the ditches with the consistent depth can be automatically dug and the uniform fertilization is carried out.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com