Gum dipping method for gloves and gum dipping device implementing method

A dipping device and dipping technology, which is applied to household components, household appliances, and other household appliances, can solve problems such as inconsistent initial angles of hand mold frames, inconsistent dipping angles of hand molds, and unfavorable health of workers, and achieve accurate tilting The effect of angle, high dipping quality and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

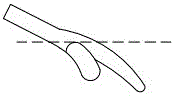

[0030] like figure 1 as shown, figure 1 The horizontal dotted line in the figure is the upper surface of the glue layer. During the dipping process of the glove, it is required that the inside of the palm of the glove is completely immersed in the glue layer, and the thumb and forefinger are both immersed in the glue. The back of the palm does not need to be dipped, so the best The dipping method is, such as figure 1 The hand mold shown in is in a state where the finger ends are inclined downward. After the hand mold enters the glue for a certain period of time, the gloves on the hand mold realize the dipping process.

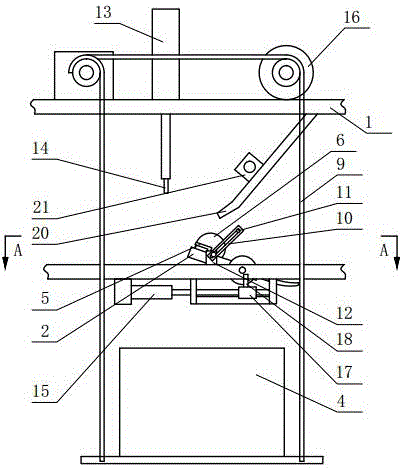

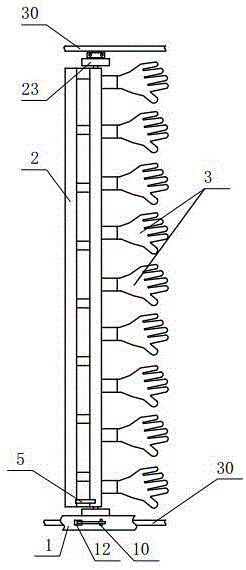

[0031] like figure 2 , image 3 , Figure 4As shown, the present invention provides a glove dipping device, which includes a frame 1, and the frame 1 is connected with a conveyor chain 30 driven by a power device and arranged longitudinally. The power device is not shown in the figure, which includes a power The servo motor and the driving wheel driven by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com