Designing method for LED wafer tri-laser-beam scribing equipment

A technology of laser scribing and design method, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of small space for improving dicing efficiency, and achieve the effect of improving dicing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

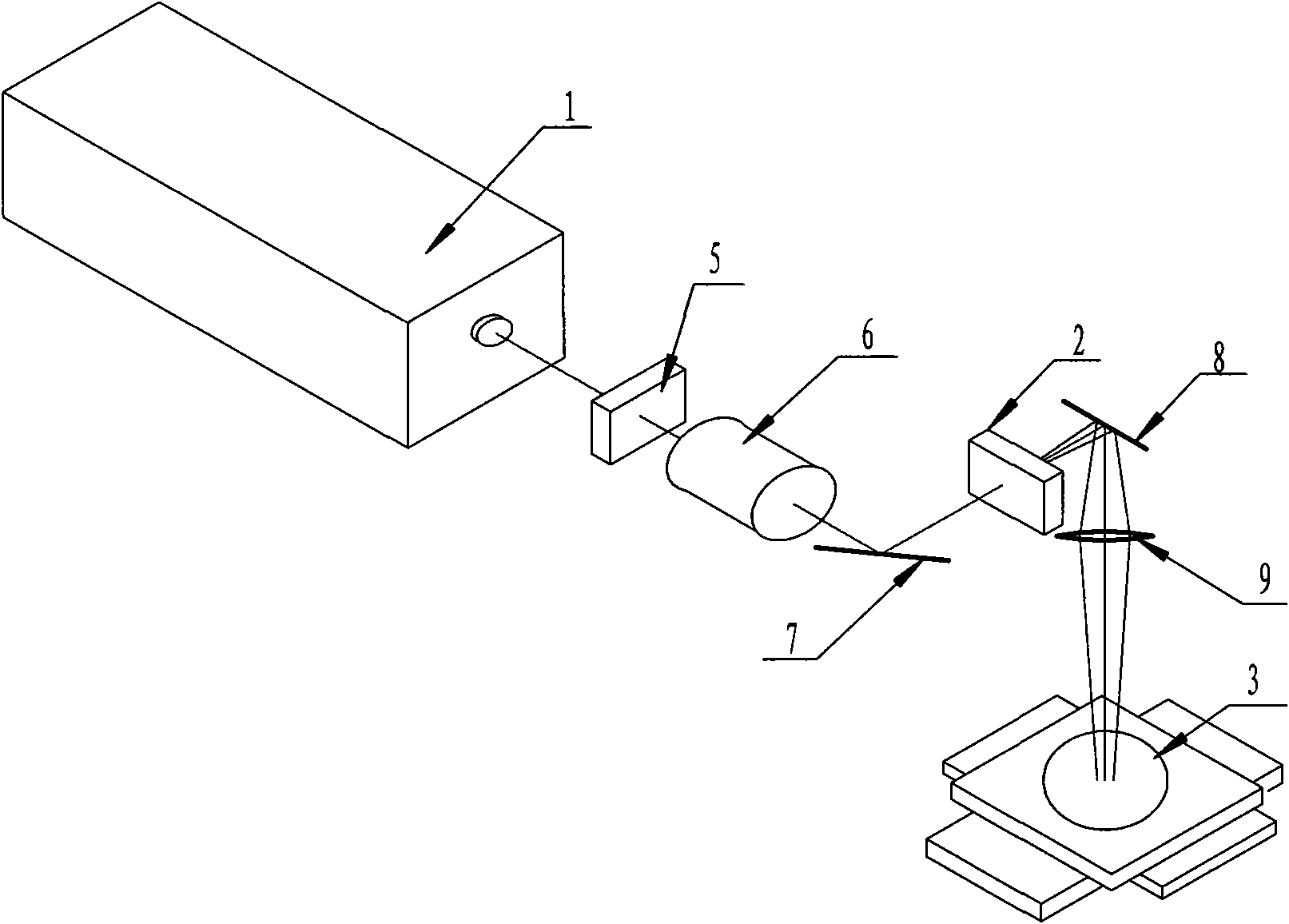

[0024] Design a three-beam laser scribing equipment for LED wafers. It adopts a simple and functional optical path design, which can conveniently and flexibly control the spot energy of the laser on the processing plane, and stabilize the scribing in the entire processing area under the premise of ensuring cutting efficiency. Depth and line width: A unique laser beam splitting system is used to divide the single-beam laser source into three laser beams with equal size and energy and focus on the processing platform in parallel. The angle of the beam-splitting plane is controlled by a precision rotating motor, and then the three beams are controlled to focus on the processing platform. The distance between the X and Y axes.

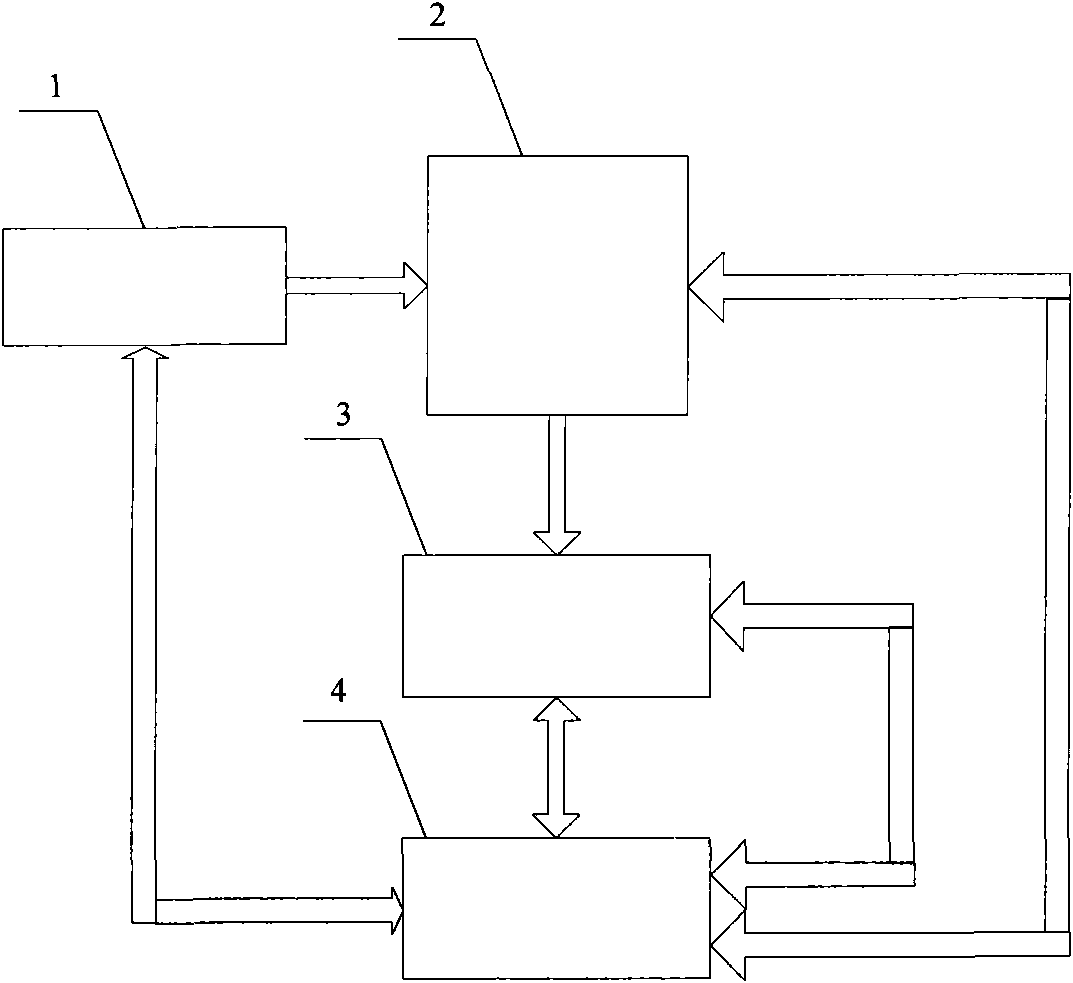

[0025] equipment system such as figure 1 As shown, it mainly includes laser 1, laser beam splitting system 2, processing platform 3 and control system 4. The laser emitted from laser 1 is incident into laser beam splitting system 2, and the energy of a sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com