Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Accurate spacing control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

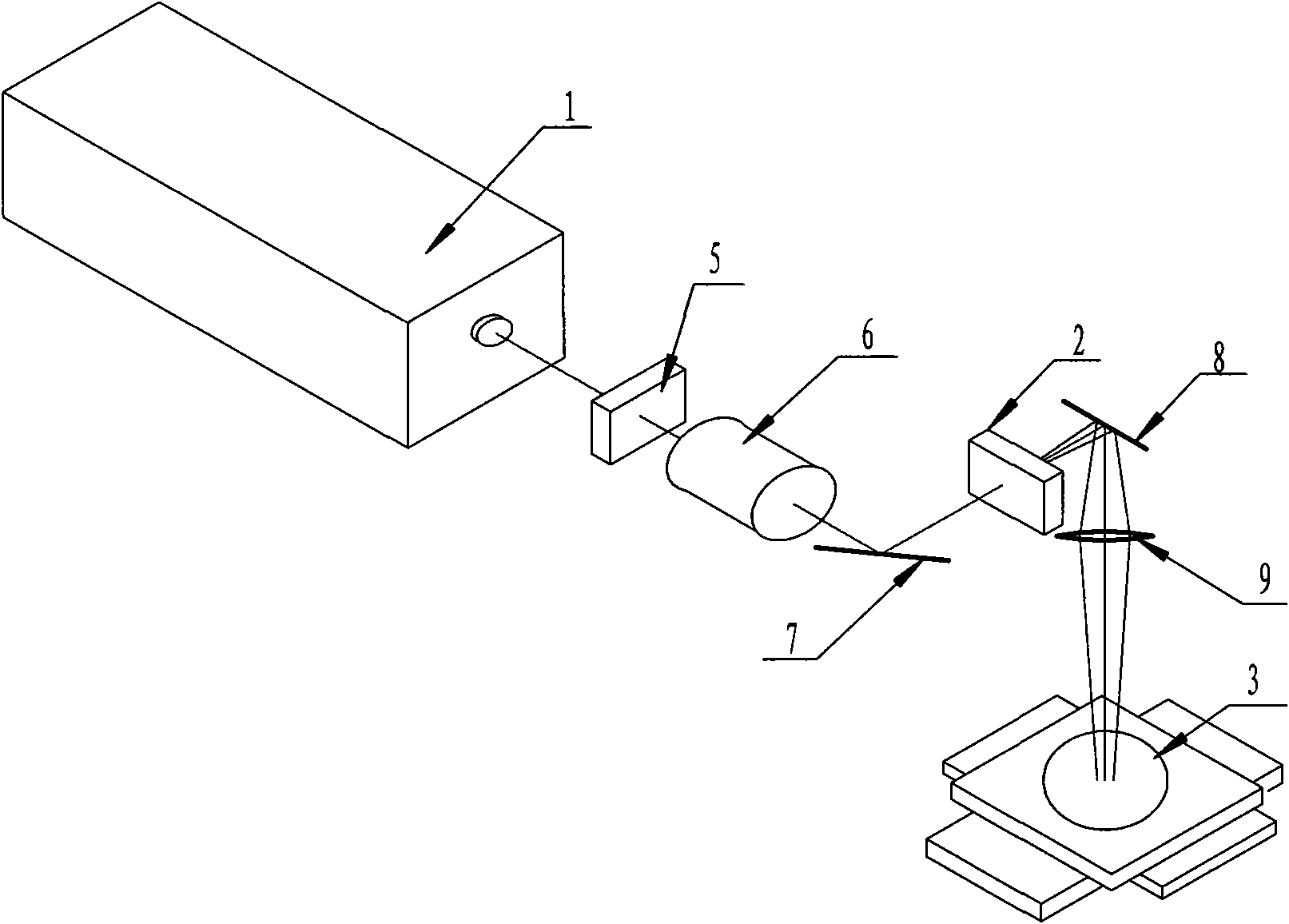

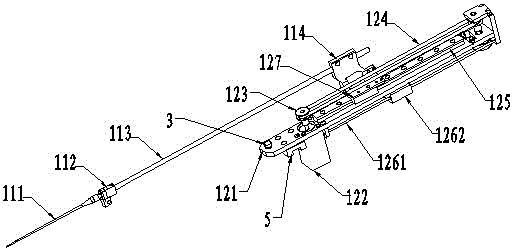

Designing method for LED wafer tri-laser-beam scribing equipment

InactiveCN101670492AConvenient and flexible spot energy distributionControl spot energy distributionLaser beam welding apparatusBeam expanderComing out

The invention relates to a designing method for LED wafer tri-laser-beam scribing equipment, in which the output end of a laser is provided with a light gate, the output end of the light gate is connected with a beam expander, a first total reflecting mirror is arranged at the output end of the beam expander, the output end of the first total reflecting mirror is linked with a laser beam splittingsystem used for splitting a single-beam laser source into tri-laser-beams, the output end of the laser beam splitting system is provided with a second total reflecting mirror which is linked with a focusing mirror, and the focusing mirror in right face of a processing platform; laser light coming out of the laser is emitted to the beam expander via the light gate, the laser light passing throughthe beam expander is emitted to the first total reflecting mirror, the laser light passing through the first total reflecting mirror is emitted to the laser beam splitting system, the laser beam splitting system outputs triple laser beams with equivalent dimension and energy, the triple laser beams are emitted to the second total reflecting mirror, are emitted to the focusing mirror after the angle is intersected by the second total reflecting mirror, and are parallel focused on the processing platform after permeating through the focusing mirror. The equipment realizes parallel scribing on the LED wafer tri-laser-beam and can be widely used for cutting LED wafers.

Owner:SUZHOU DELPHI LASER

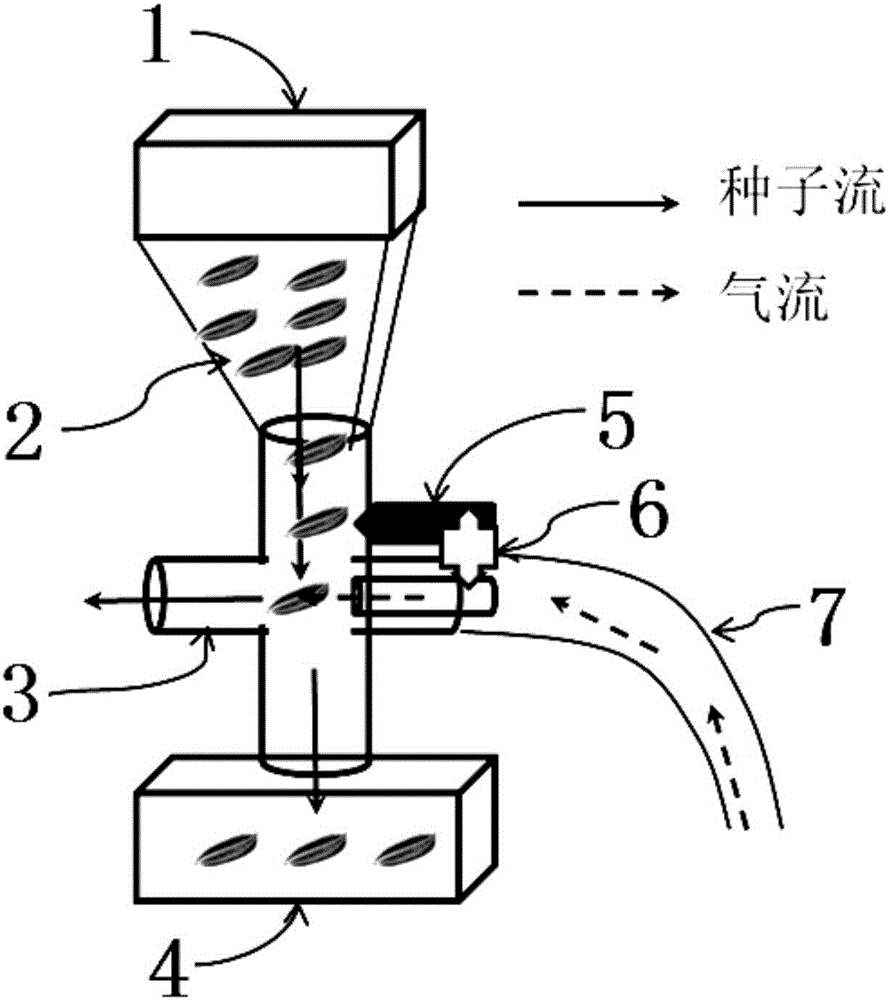

Seed spray device and sowing method

InactiveCN106576528AAchieve precision seedingPrecise control of particle numberSeed depositing seeder partsRegular seed deposition machinesEngineeringSowing

The invention discloses a seed spray device and a sowing method. The seed spray device comprises a seed box, a seed groove, an spray pipe and a blowing device, wherein the seed box is located above the seed groove; the seed groove is communicated with the spray pipe through a seed guidance pipe; the blowing device is communicated with the spray pipe through a pipeline to blow seeds falling down from the seed groove into the spray pipe. The blowing device of the seed spray device blows the seeds falling down from the seed groove into the spray pipe through the pipeline, and then the seeds fall into a field to achieve precise sowing, thus achieving the effects of saving the seeds, improving the efficiency and increasing the yield.

Owner:HUNAN AGRICULTURAL UNIV

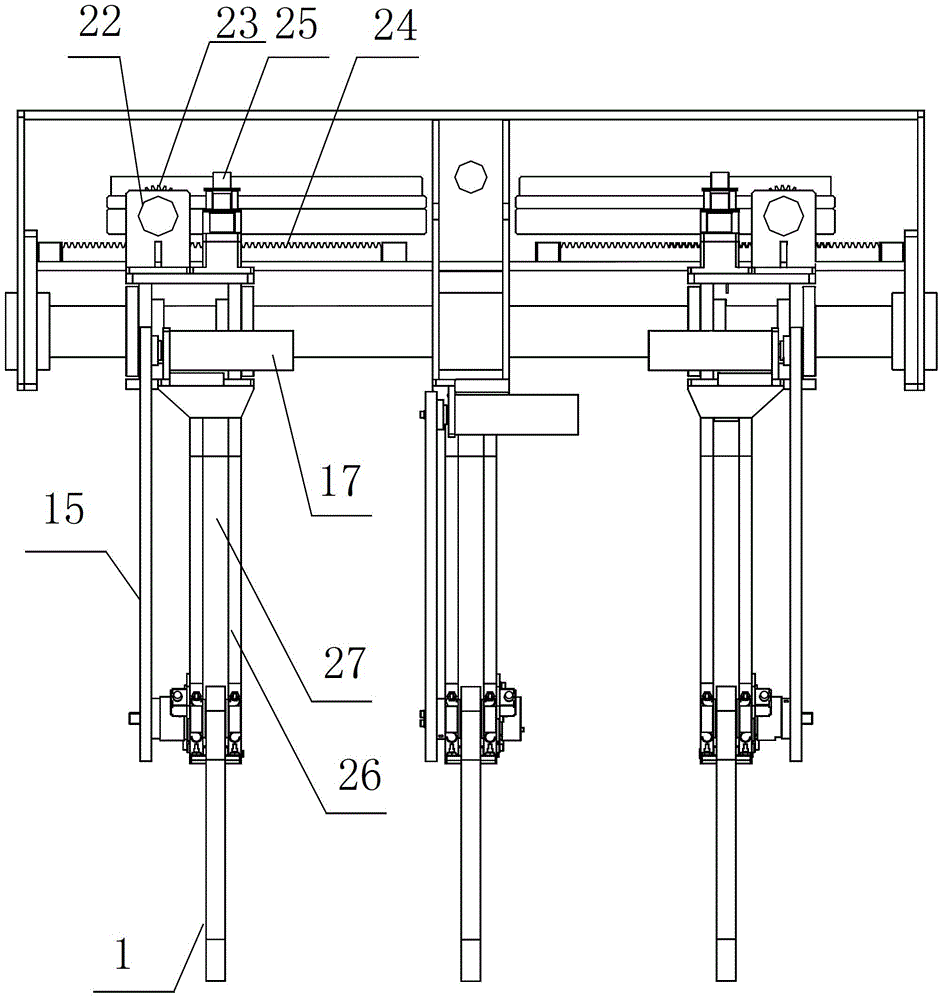

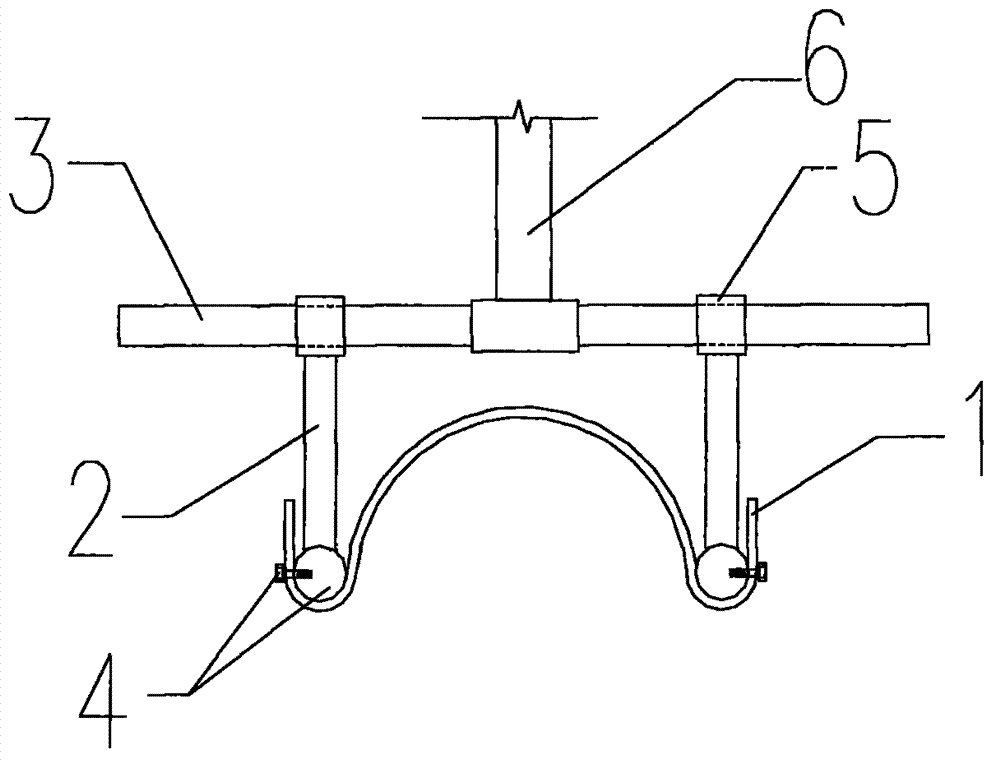

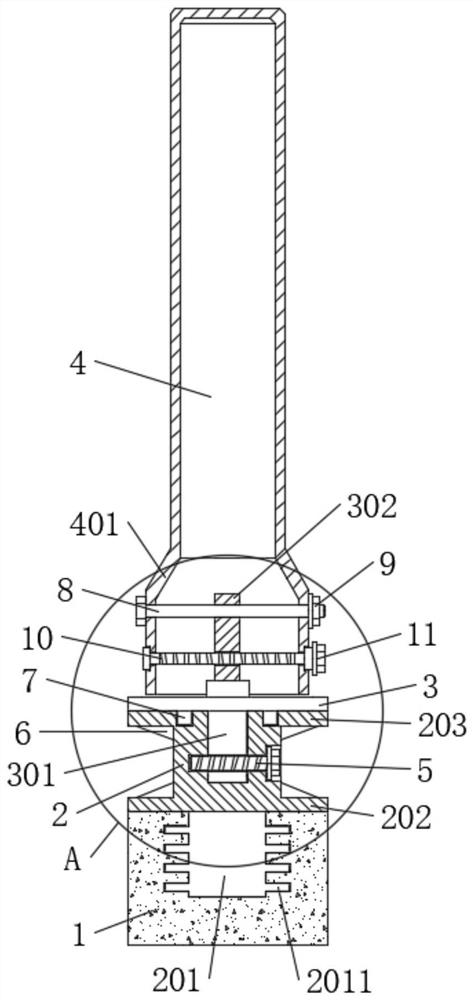

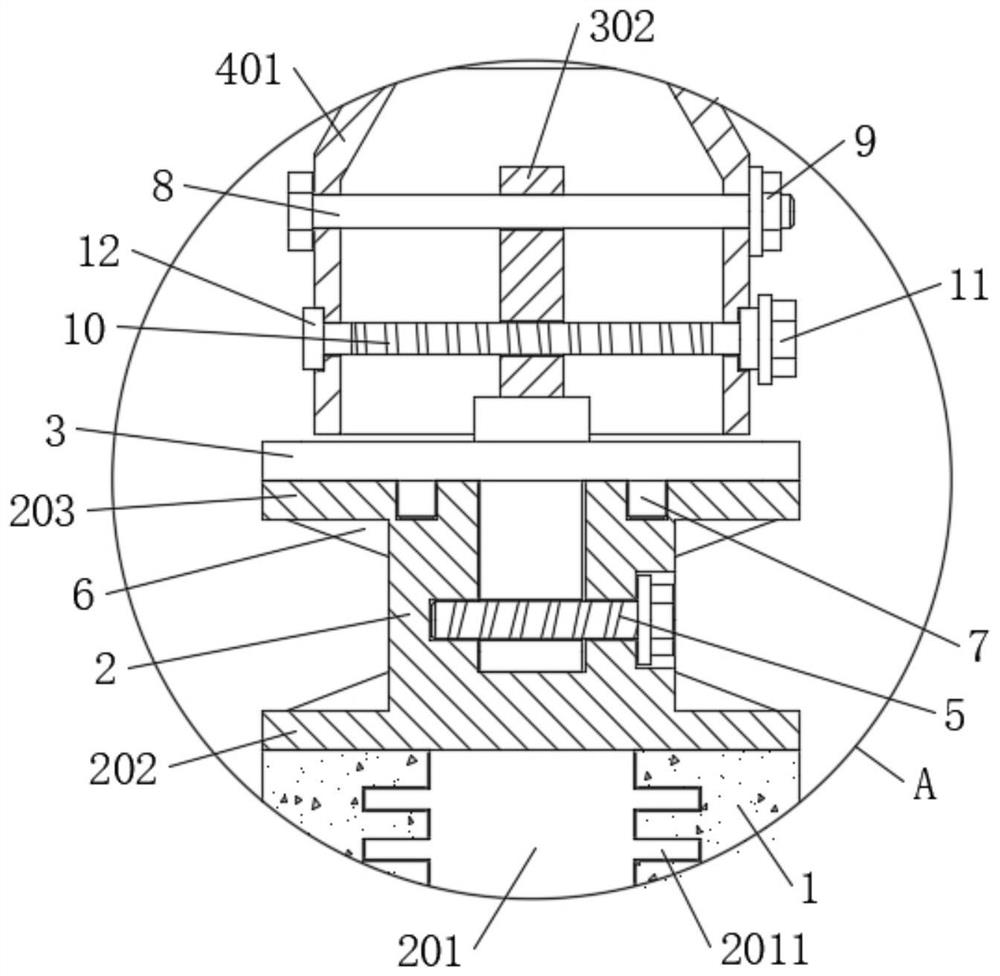

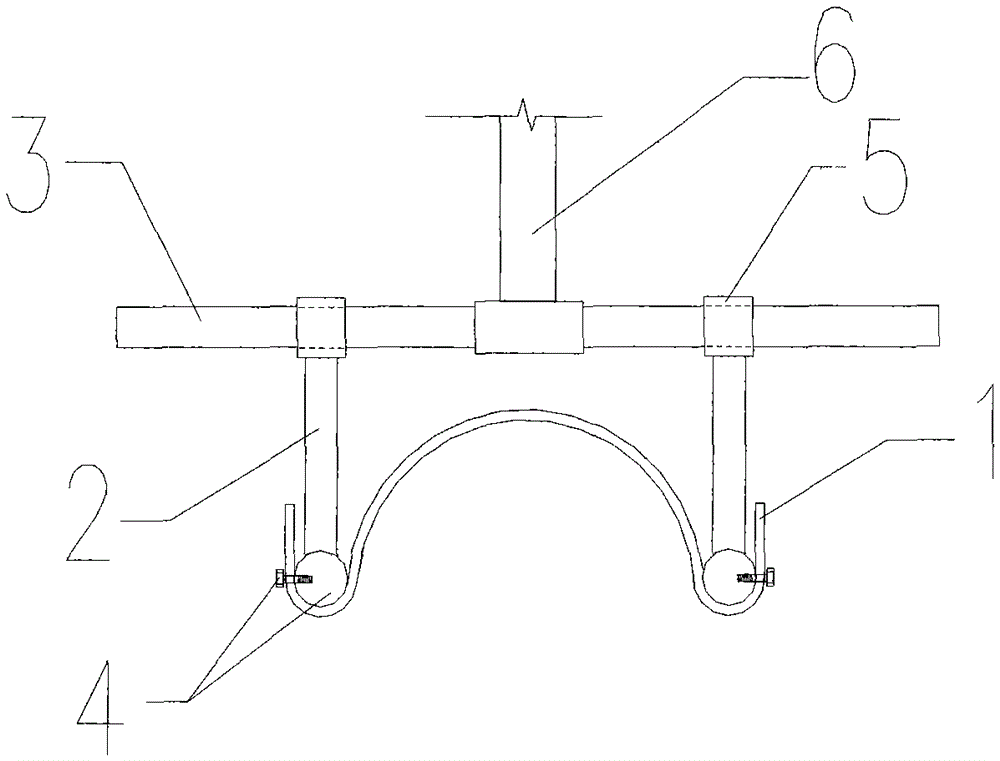

Automatic suspender

ActiveCN103332588AOvercoming inefficienciesImprove work efficiencyLoad-engaging elementsAutomotive engineeringWorkload

The invention discloses an automatic suspender. The suspender comprises a suspension arm and at least a suspension hook. The suspender is characterized in that at least one suspension hook is movably arranged on the suspension arm. The invention provides an automatic suspender. The suspender realizes automatic article lifting, overcomes the shortages of low efficiency, high production cost, large workload, high work strength, and high danger for a person in a handling zone, which are caused by human operation of a conventional suspender, improves work efficiency, and reduces production cost and work strength of workers.

Owner:上海朗卫自动化科技有限公司

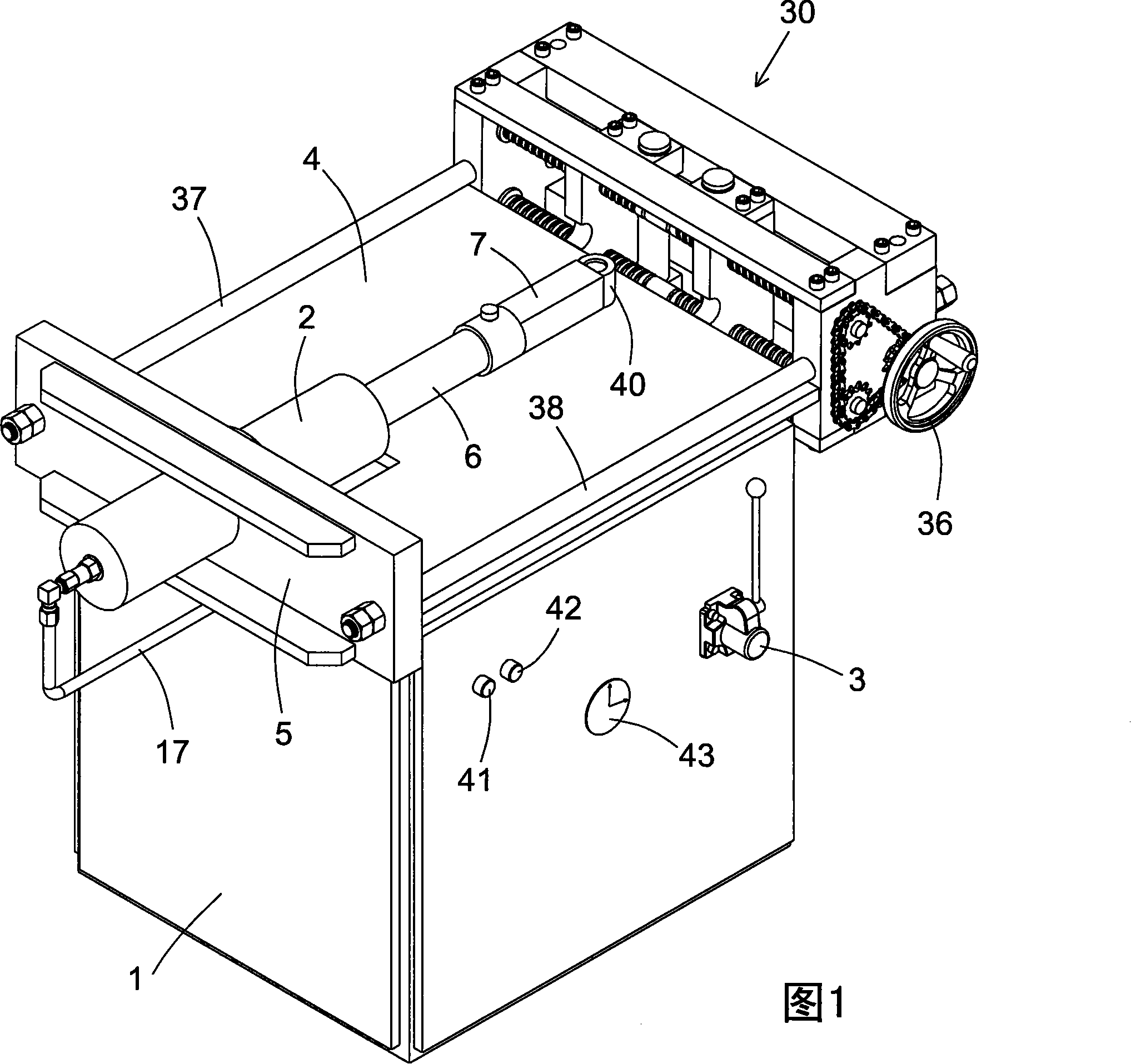

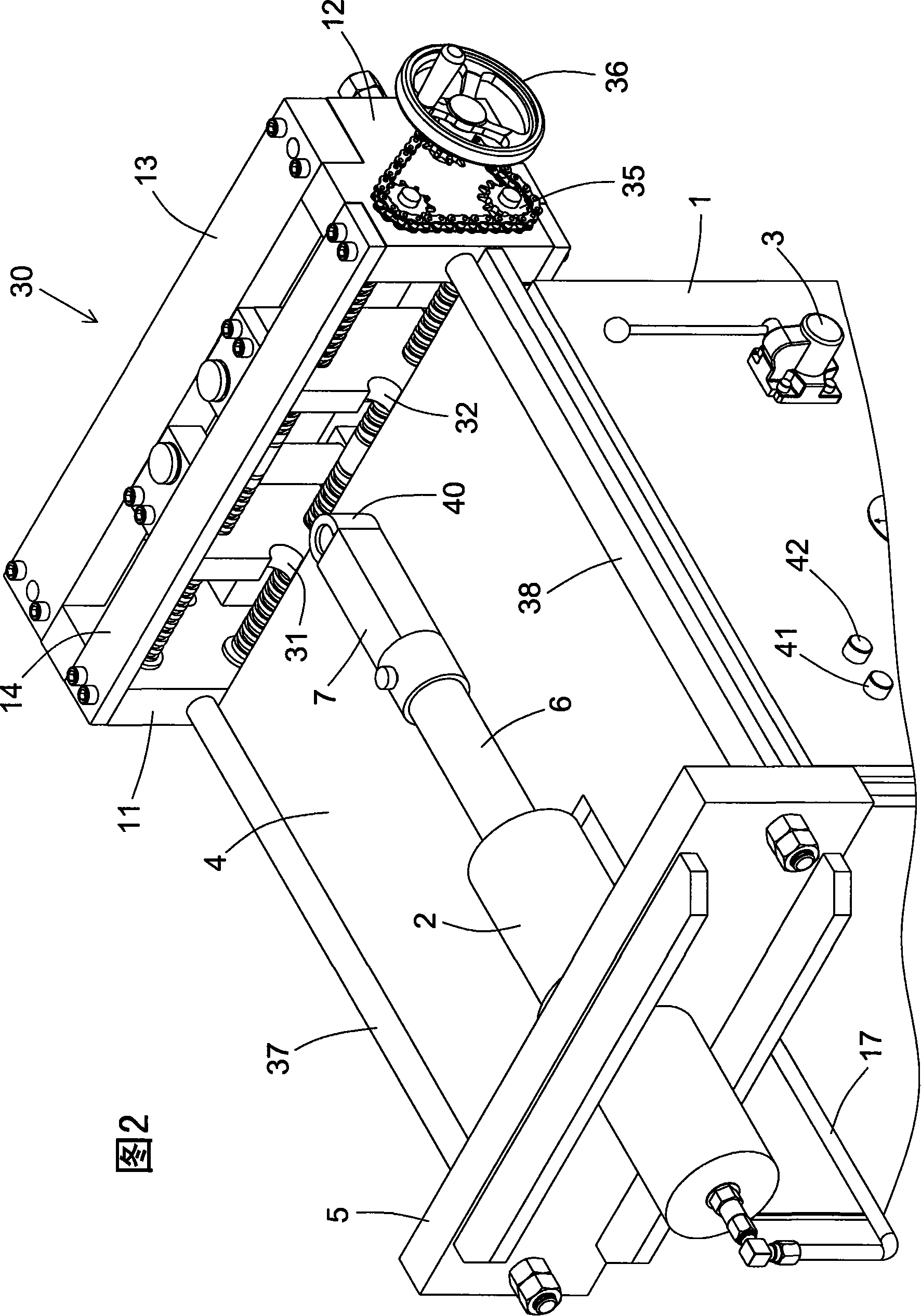

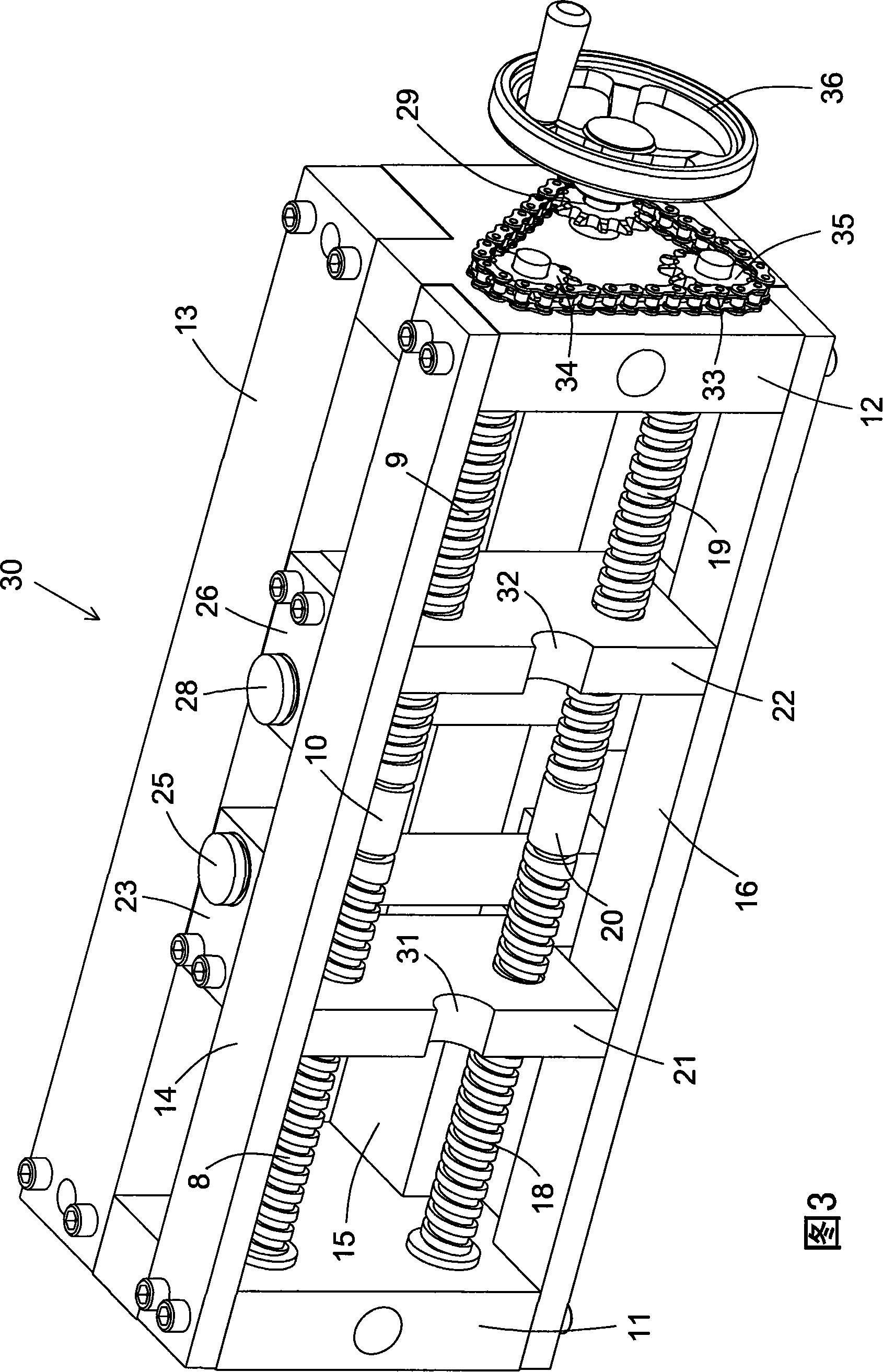

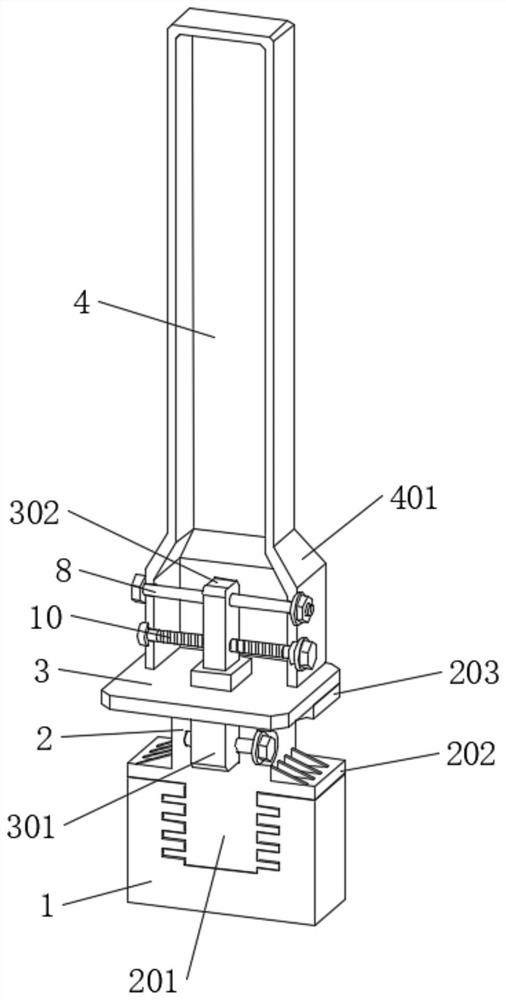

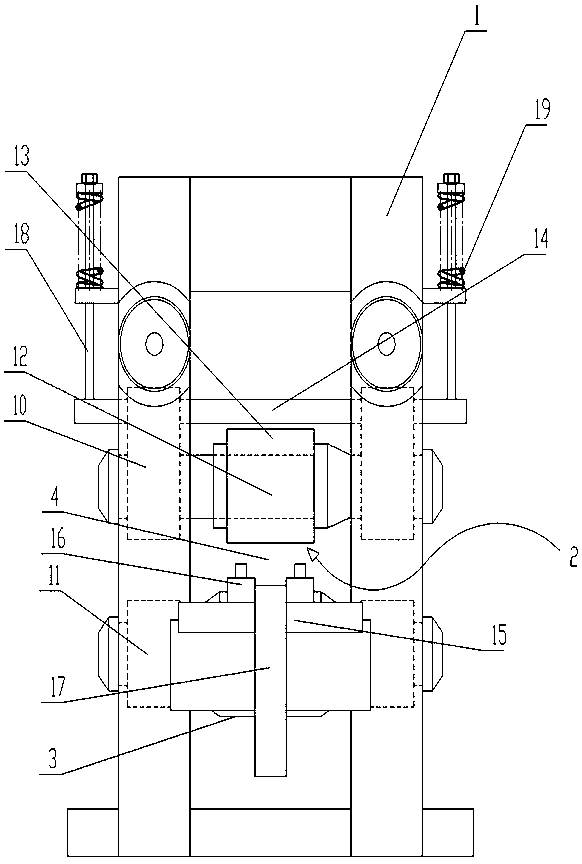

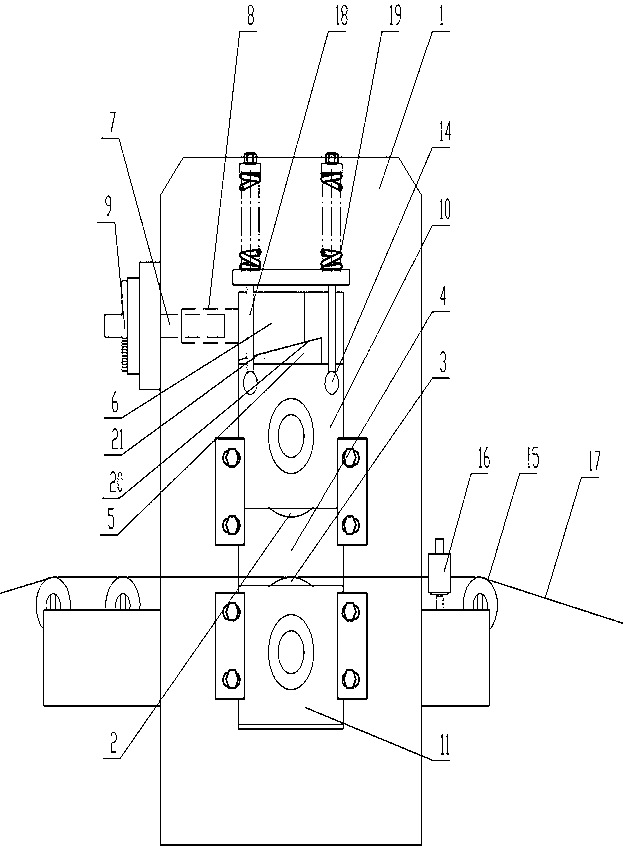

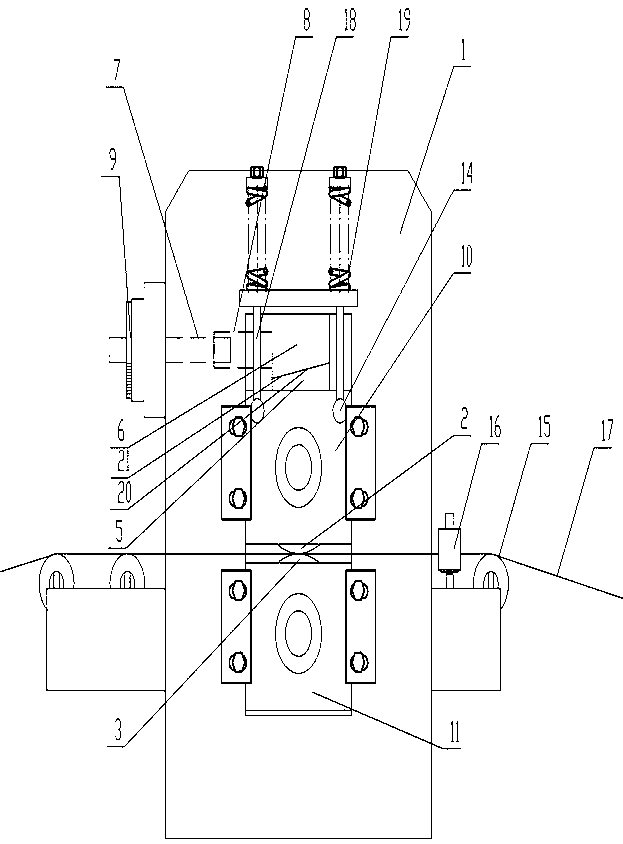

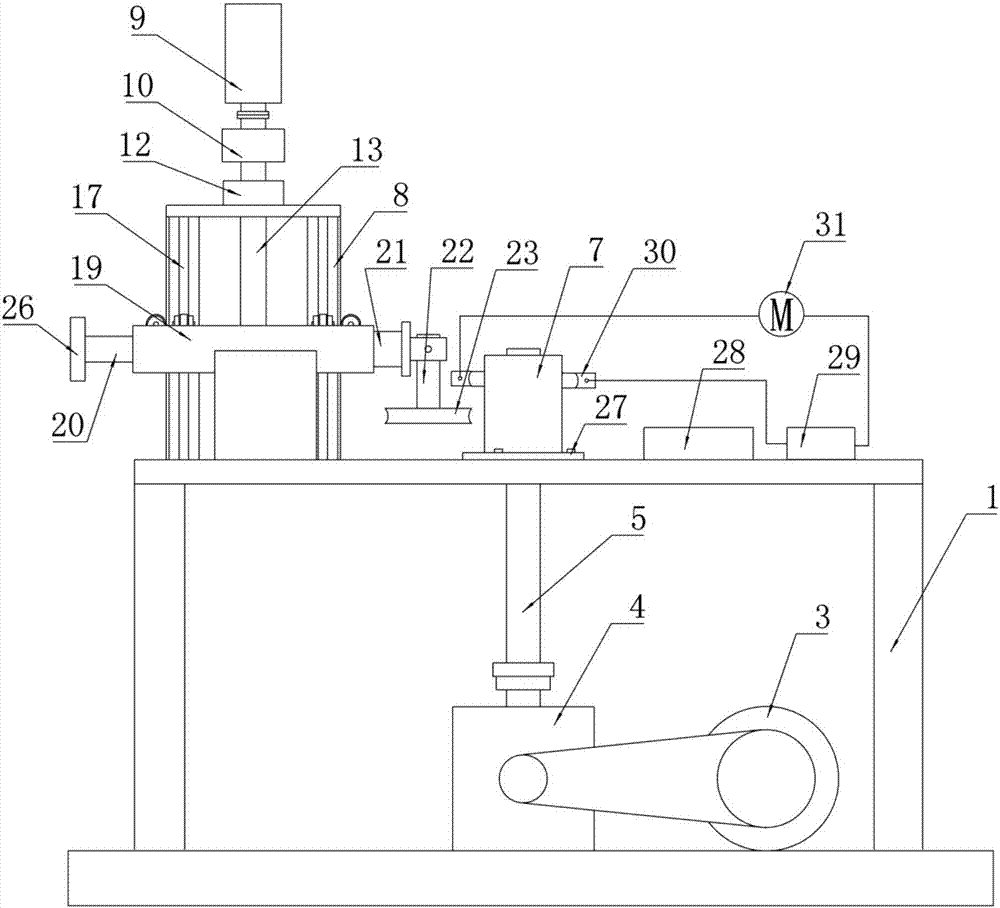

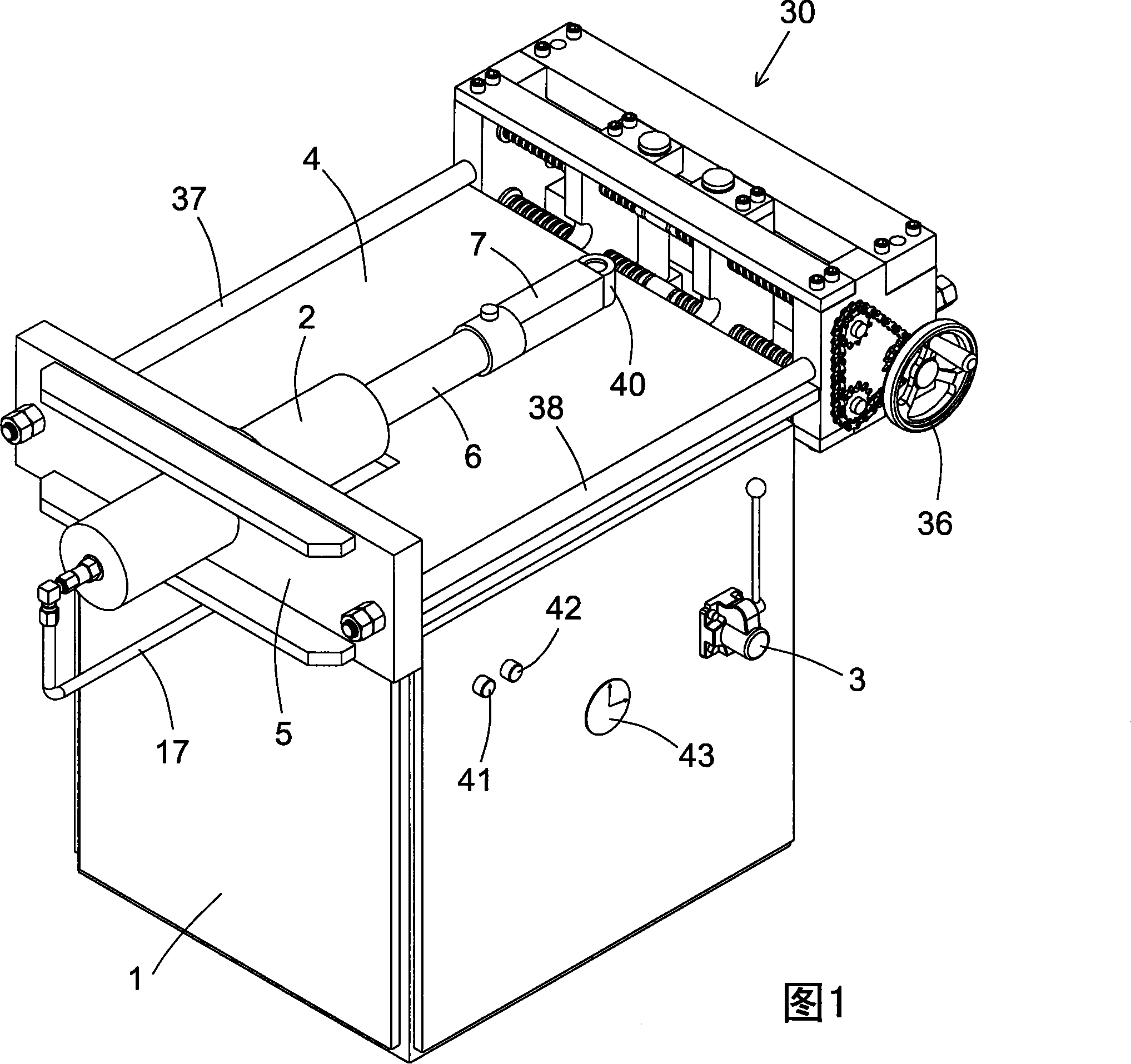

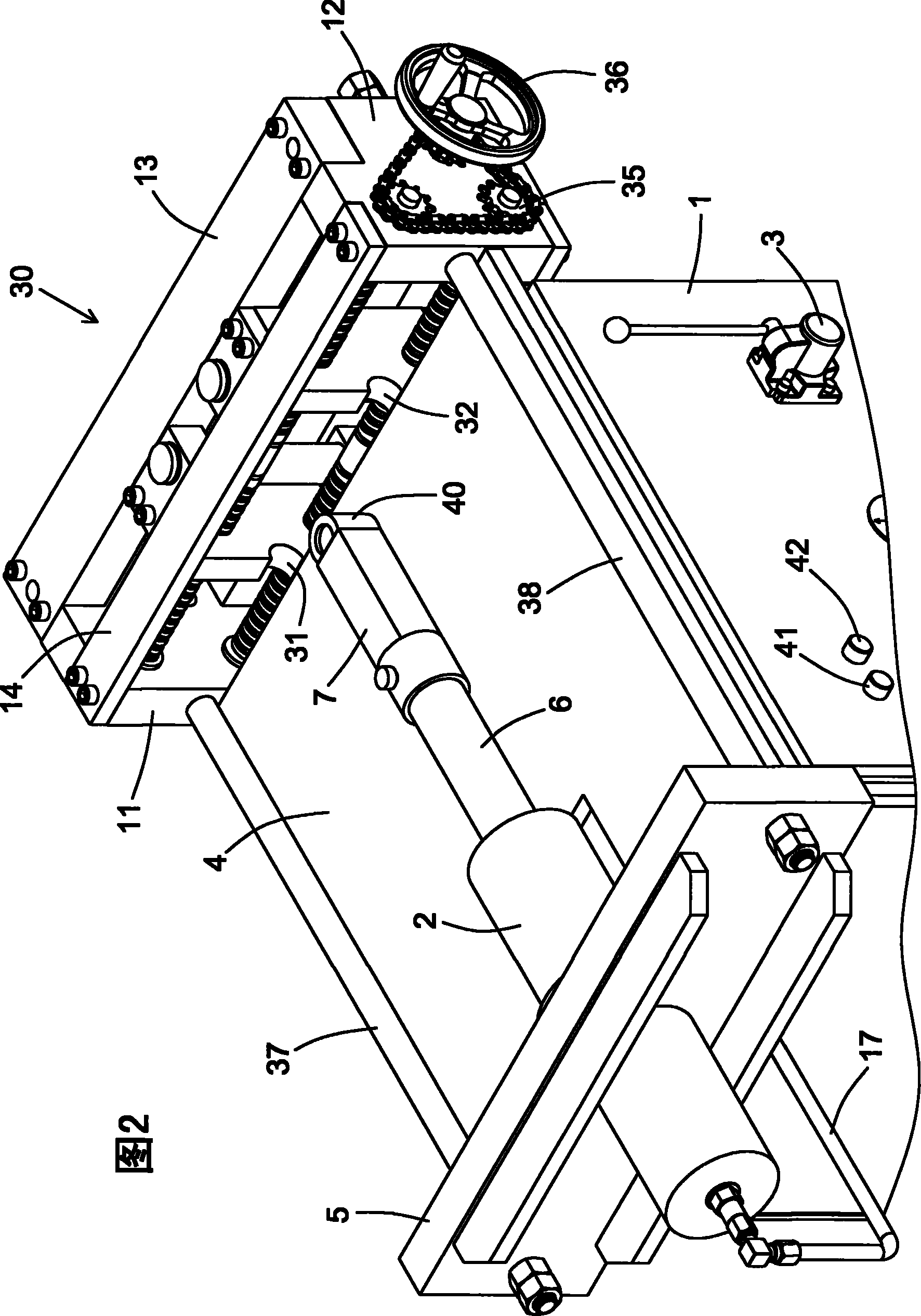

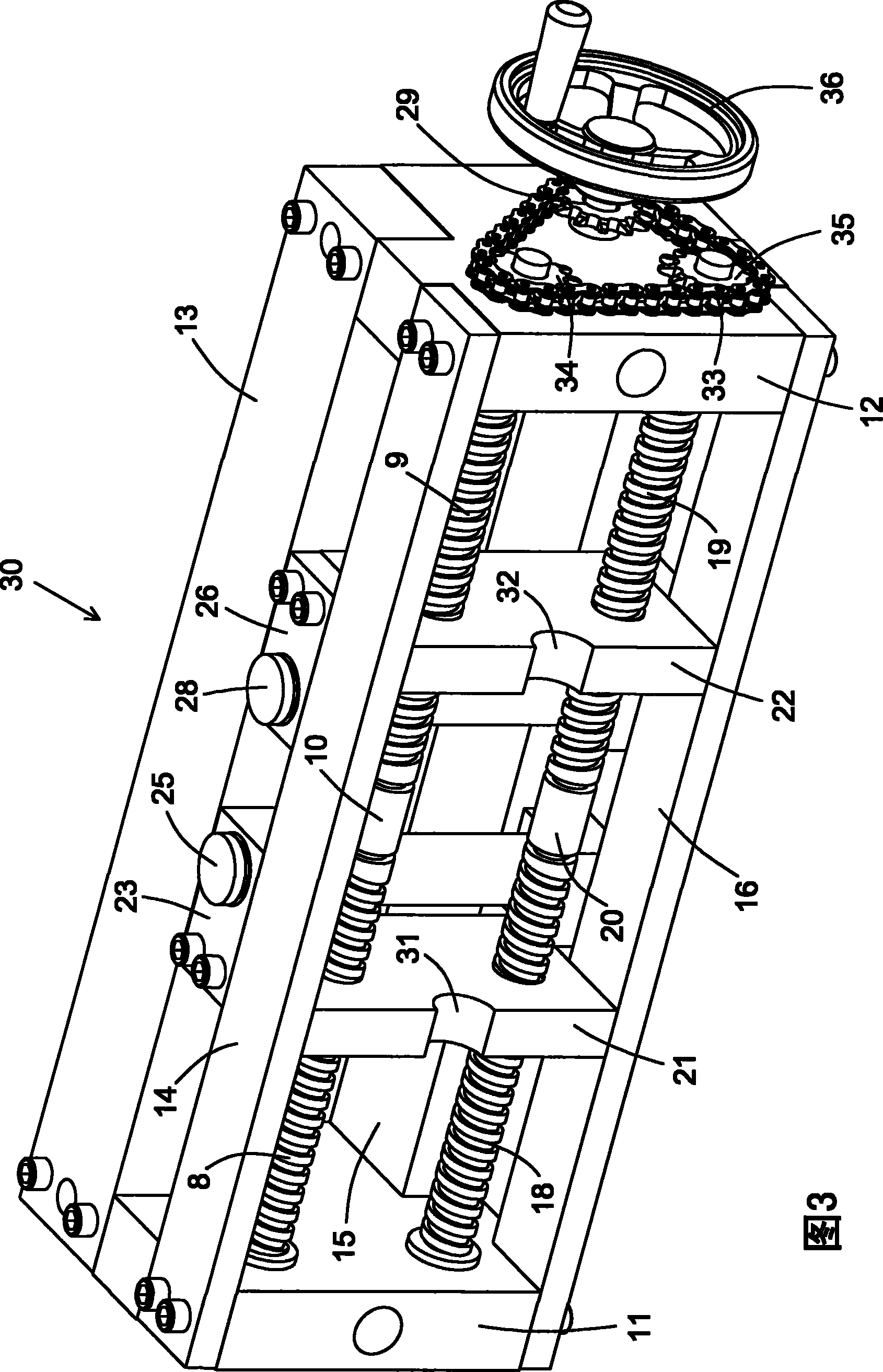

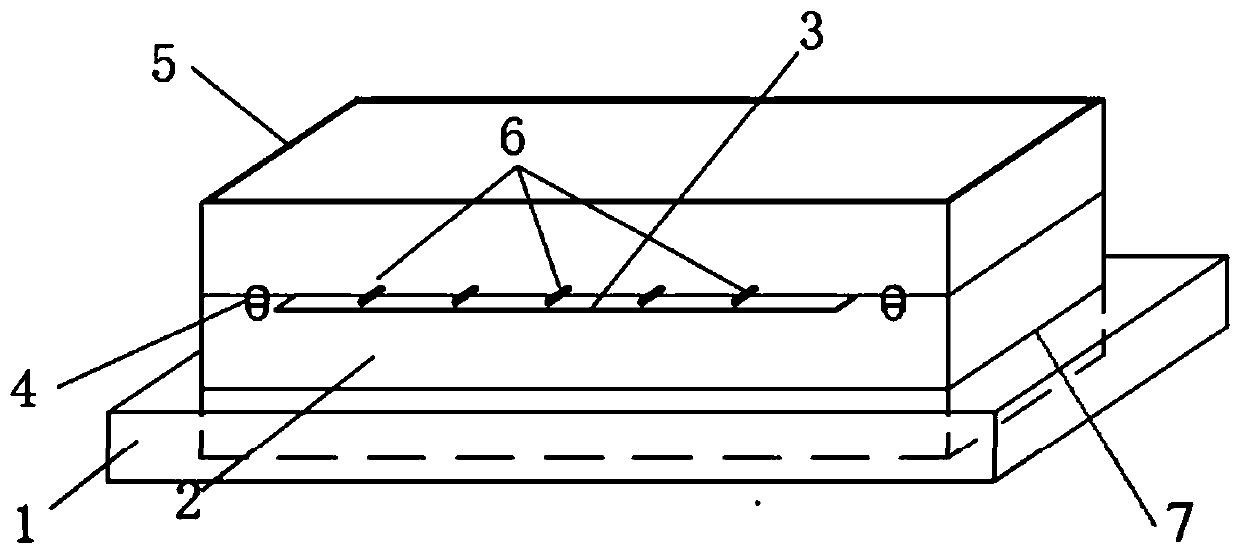

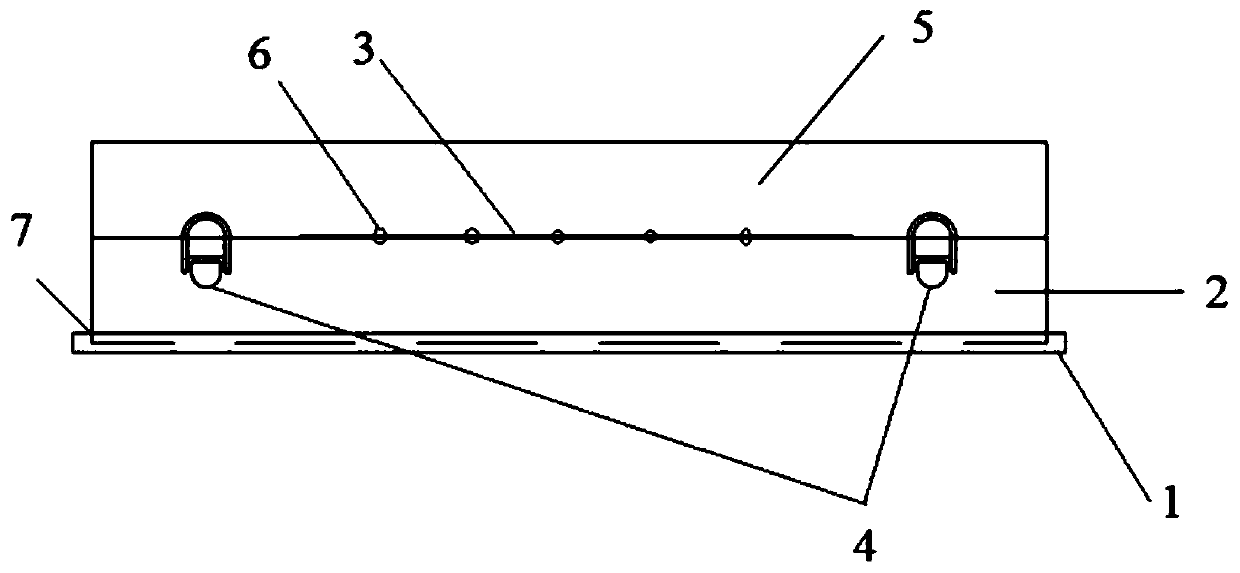

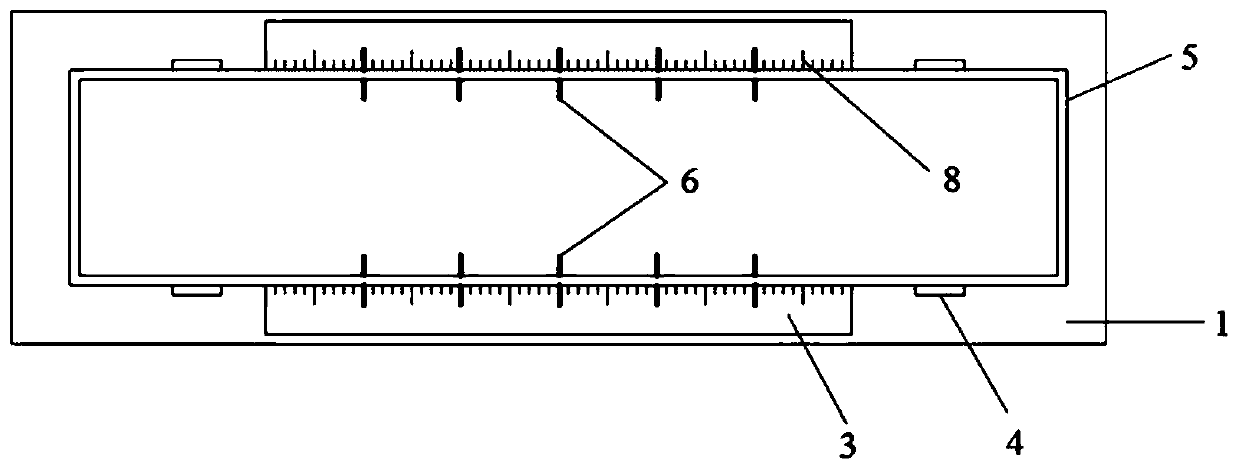

Steel cold bending test machine

ActiveCN101241059AAccurate spacing controlPrecise control of bending angleMaterial strength using steady bending forcesHydraulic cylinderRear quarter

A rolled steel cool-deforming test machine, comprising a case, a hydraulic pressure system which is composed of a hydraulic pressure cylinder, an oil pump, an oil tank, a handle reversing valve. A work table is set at top of the case. A supporting plate is set on rear end of the work table. A regulating bracket is set on front end. The hydraulic pressure cylinder is embedded in middle of the supporting plate. A mandril is connected to a piston rod of the hydraulic pressure cylinder. A punch is connected to front end of the mandril. The regulating bracket is composed of a left plate, a right plate, a front plate, a rear plate, a front bottom plate and a rear bottom plate. A right sliding block and a left sliding block are set between the left and right plates. The left and right sliding blocks are spiro-connected to an upper right chain wheel and a lower right chain wheel via a screw. A right vertical column is connected to front end of the left sliding block; a right vertical column is connected to front end of the right sliding block; ends of the upper and lower screw rods extend from the right plate, connected to the upper right chain wheel and lower right chain wheel. A handle wheel is set outside of the right plate, connected to the driving chain wheel which is connected to the upper right and lower right chain wheels via chains. The product is convenient to operate, save and reliable with high test precision, which is applied to bending test detection of various rolled steels.

Owner:北京城建建设工程有限公司

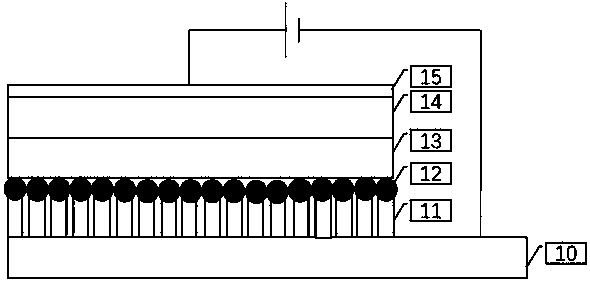

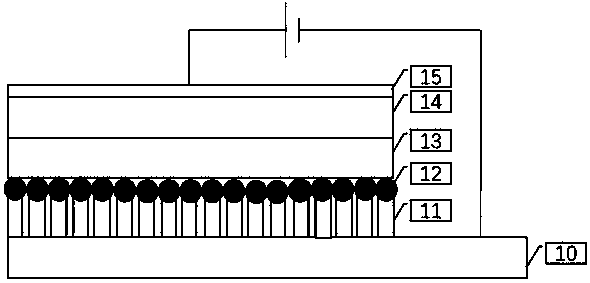

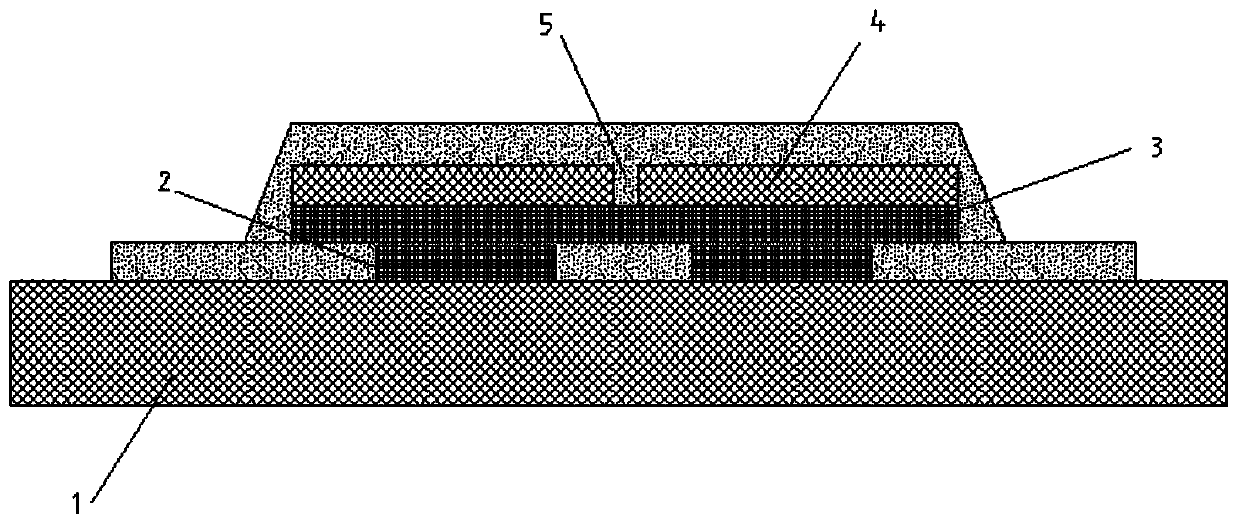

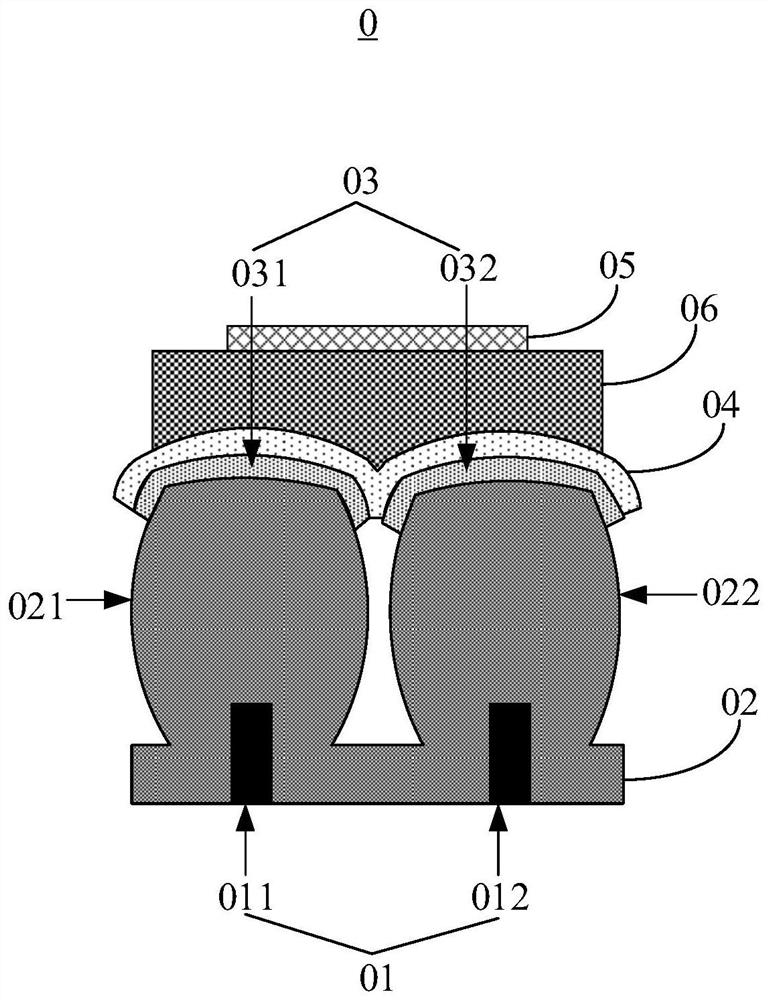

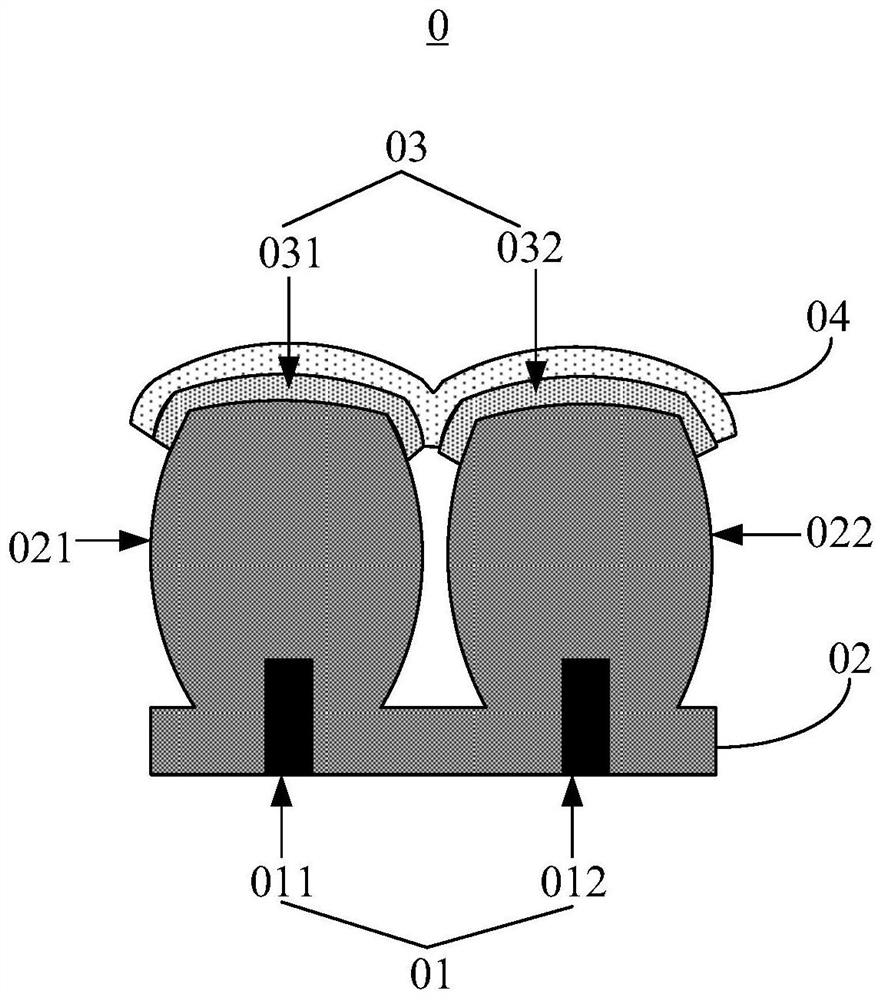

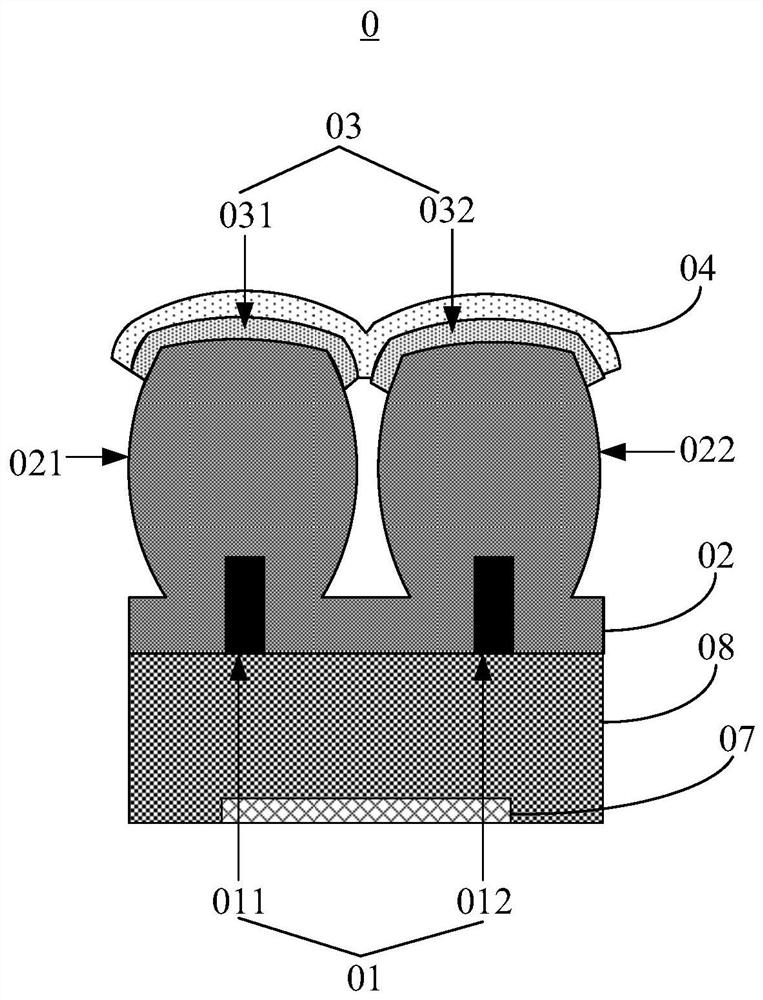

QLED device and preparation method thereof

ActiveCN109980052AImprove performanceAccurate spacing controlSemiconductor devicesQuantum dotSemiconductor

The invention discloses a QLED device and a preparation method thereof, and the QLED device comprises a cathode, an anode, and an electron transmission layer and a quantum dot light-emitting layer which are both arranged between the cathode and the anode. The electron transmission layer is a II-IV group semiconductor nanorod array which is vertically arranged relative to the surface of the cathode. The material of the quantum dot light-emitting layer is quantum dots, and the quantum dots grow at the tops of the II-IV group semiconductor nanorods. Light generated by the quantum dot light-emitting layer can pass in the axial direction of the II-IV group semiconductor nanorods in a more concentrated and lower-loss manner, and light is emitted from the cathode of the device, so that the luminous efficiency and the brightness of the device are greatly improved. According to the invention, the distances between the quantum dots with different particle sizes can be indirectly and accurately controlled through the control of the diameter of the II-IV group semiconductor nanorods and the distance between the adjacent nanorods in the array, thereby achieving the performance optimization of the QLED device.

Owner:TCL CORPORATION

Flexible packing former for concrete face rockfill dam face

The invention provides a flexible packing former for a concrete face rockfill dam face. The flexible packing former is characterized by comprising a machine body, wherein the machine body comprises forming belts for clamping and pressing flexible packing, fixing parts for fixing the two ends of each forming belt and connecting parts for connecting the fixing parts; slot surfaces for clamping and pressing the flexible packing are formed in the forming belts; the slot surfaces are matched with the outer profile of the cross section of the flexible packing to be embedded and filled or matched with the decomposed cross section of the flexible packing to be embedded and filled in shape; the number of the forming belts is no less than 2; the forming belts are made from materials which are easy to deform and good in tensile strength; such materials which are easy to deform and good in tensile strength are nonmetal materials, such as rubber, leather, plastic and the like, or metal materials, such as copper, aluminum, iron and the like; the connecting parts can be used for adjusting the spacing among the fixing parts; and the fixing parts are provided with fixtures capable of clamping the forming belts. According to the flexible packing former, the problems of low efficiency and low quality in embedding and filling joint materials in jointing and caulking construction of the concrete face rockfill dam face can be effectively solved.

Owner:朱博程 +1

Liquid distribution mechanism

Owner:SUZHOU JIEMEI ELECTRONICS

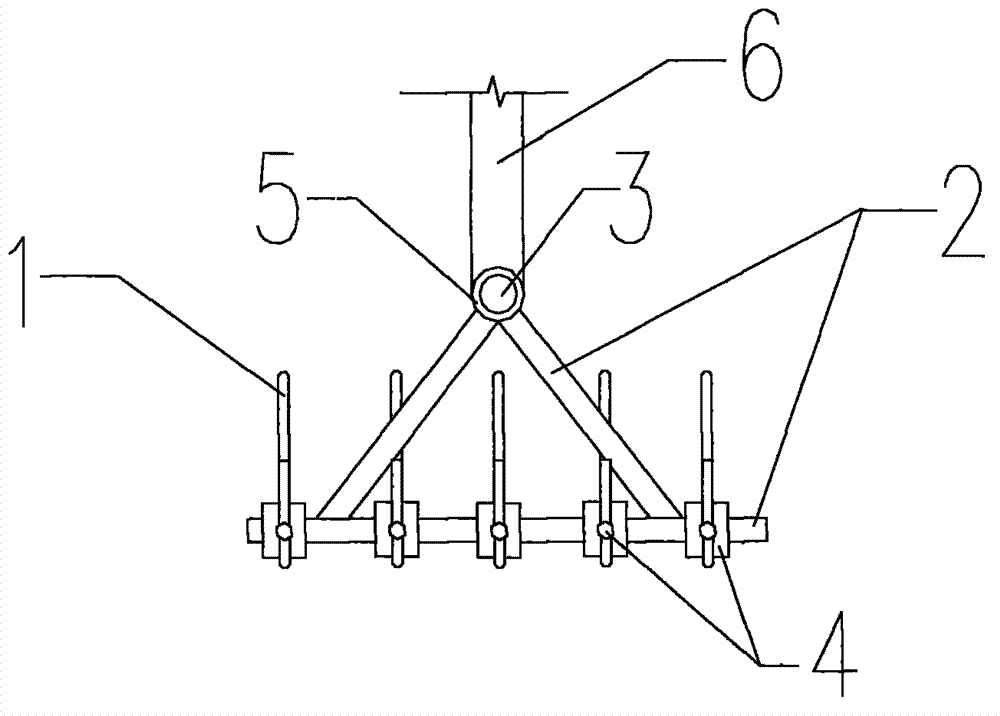

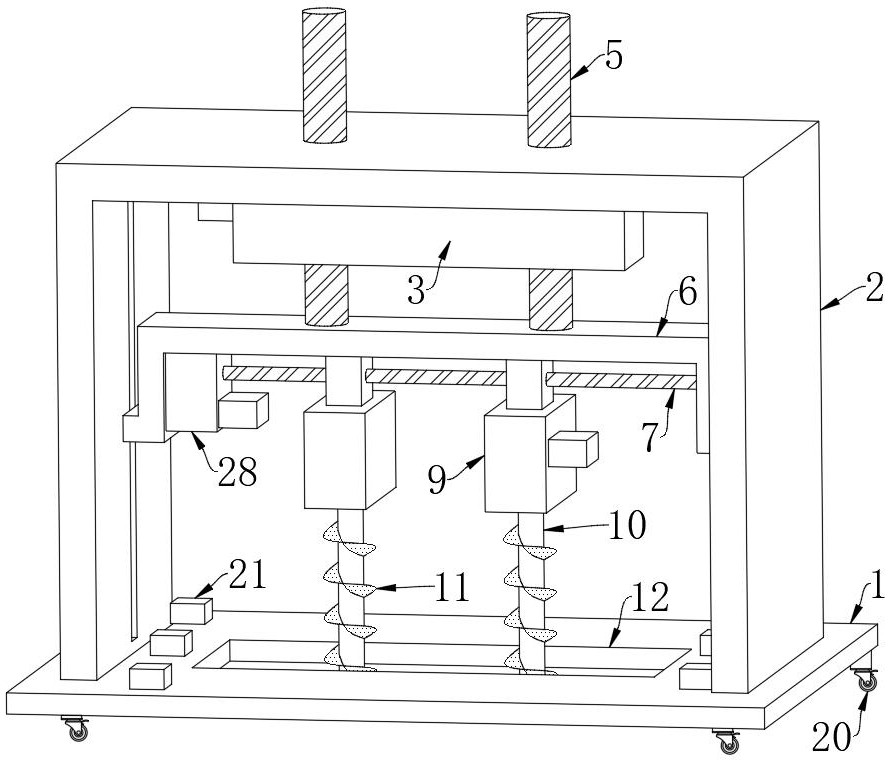

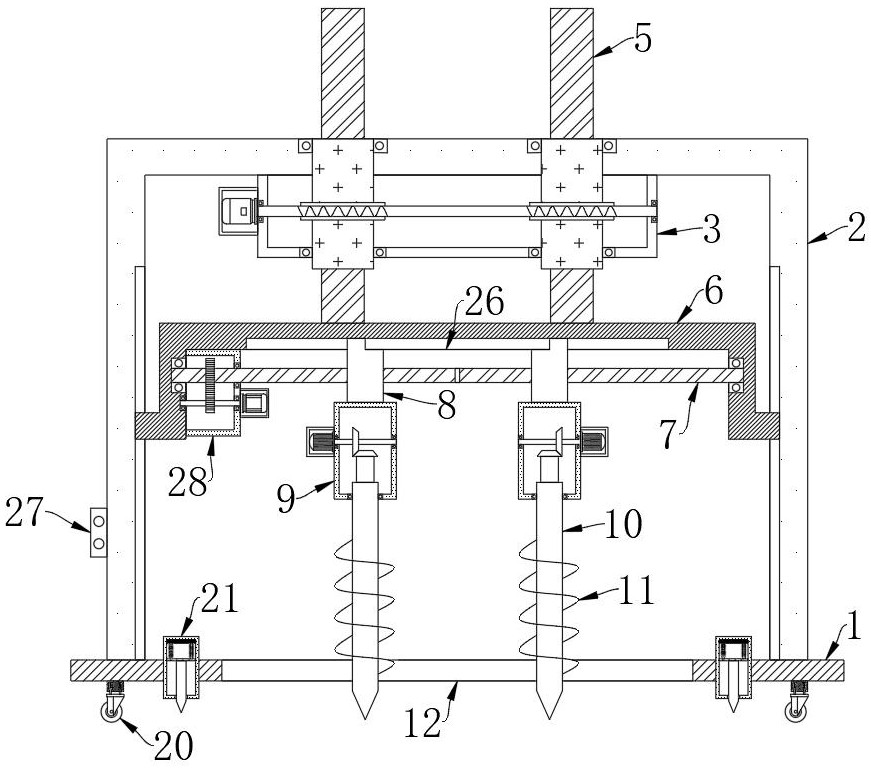

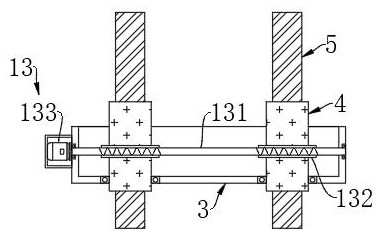

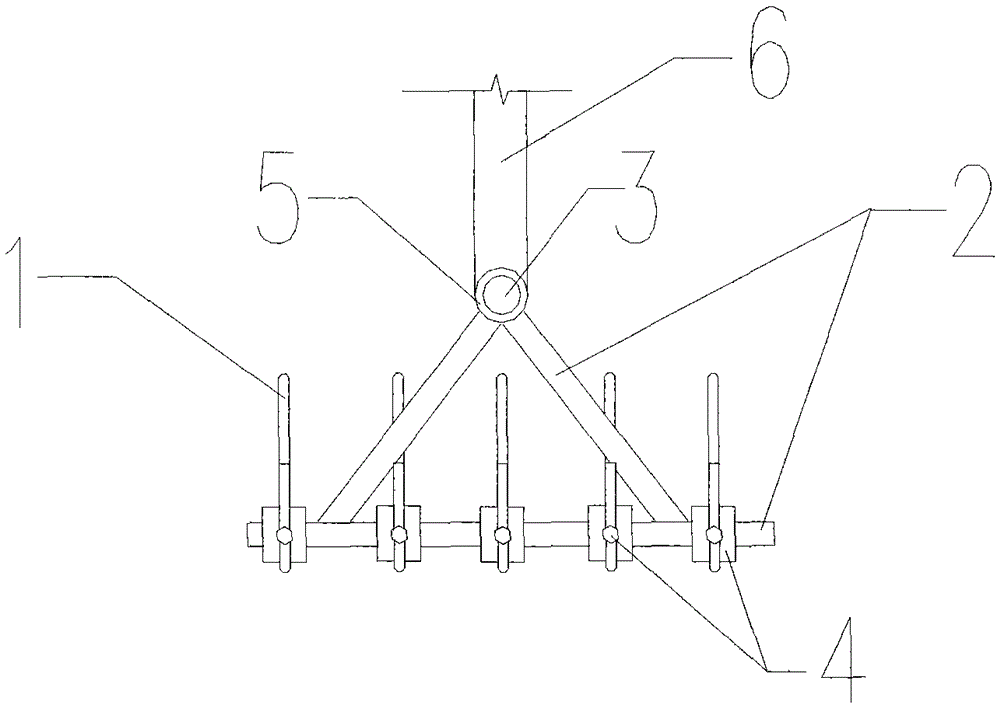

Adjustable pit digging device for agricultural planting

InactiveCN113424680ASave human effortIncrease rotation speedPlantingFurrow making/coveringAgricultural engineeringAgricultural science

The invention belongs to the field of agricultural planting, and particularly relates to an adjustable pit digging device for agricultural planting, which comprises a base, a support frame is fixedly connected to the base, a control box is fixedly connected to the support frame, two threaded sleeves are rotatably connected between the control box and the support frame, screws are in threaded connection in the threaded sleeves, the lower ends of the two screws are jointly and fixedly connected with a frame, the frame is in sliding connection with the supporting frame, the frame is rotationally connected with a two-way lead screw, and the two-way lead screw is in threaded connection with two threaded blocks. Through an arranged control mechanism, the digging depth of drill rods matched with spiral blades can be accurately regulated and controlled, through an arranged speed increasing mechanism, the rotating speed of the spiral blades can be increased, then the digging efficiency is improved, the labor loss of manual digging is avoided, through an arranged driving mechanism, the distance between the two drill rods can be regulated and controlled, and the distance between every two pits can be accurately regulated and controlled.

Owner:孙景通

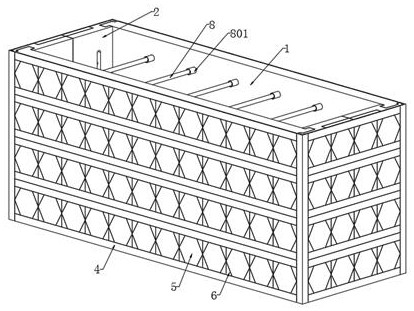

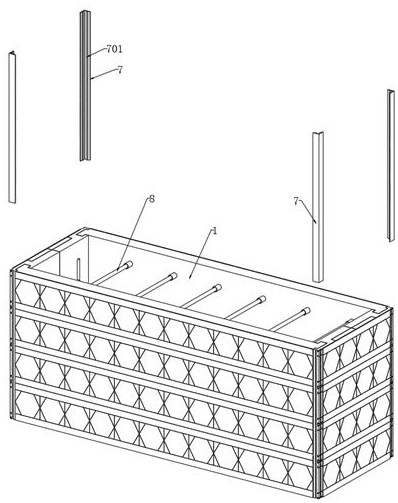

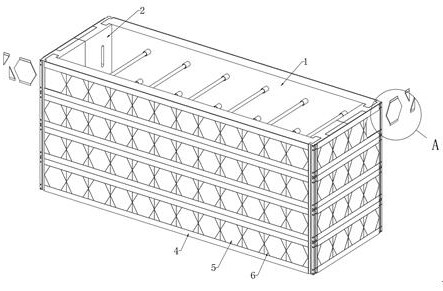

Fabricated building wall structure

ActiveCN113585555AAccurate spacing controlHigh strengthCovering/liningsWallsArchitectural engineeringRebar

The invention provides a fabricated building wall structure, and relates to the field of building walls. The problems that adjustment is inaccurate, and whether internal reinforcing steel bars for improving strength are qualified or not cannot be rapidly detected are solved. The fabricated building wall structure comprises four side clamping plates, one ends of the side clamping plates are provided with vertical clamping grooves, the side clamping plates are in clamping fit with clamping edges of foundation wallboards through the vertical clamping grooves, four adjusting plates are also arranged, and two adjusting plates are integrated and embedded in grooves in the outer ends of two side clamping plates. The distance between two foundation wallboards can be accurately controlled by adjusting the overall width of the side clamping plates, L-shaped vertical insertion plates are inserted into the outer ends of the side clamping plates for blocking, installation strips and decoration plates are prevented from being easily disassembled, whether the thickness of reinforcing ribs is qualified or not can be rapidly detected through the diameters of semicircular cylinders, and meanwhile, the upper and lower semicircular cylinders are not on the same vertical line, so that the reinforcing ribs can be conveniently placed in the semicircular cylinders on the upper sides of the foundation wallboards.

Owner:南通思普信息科技有限公司

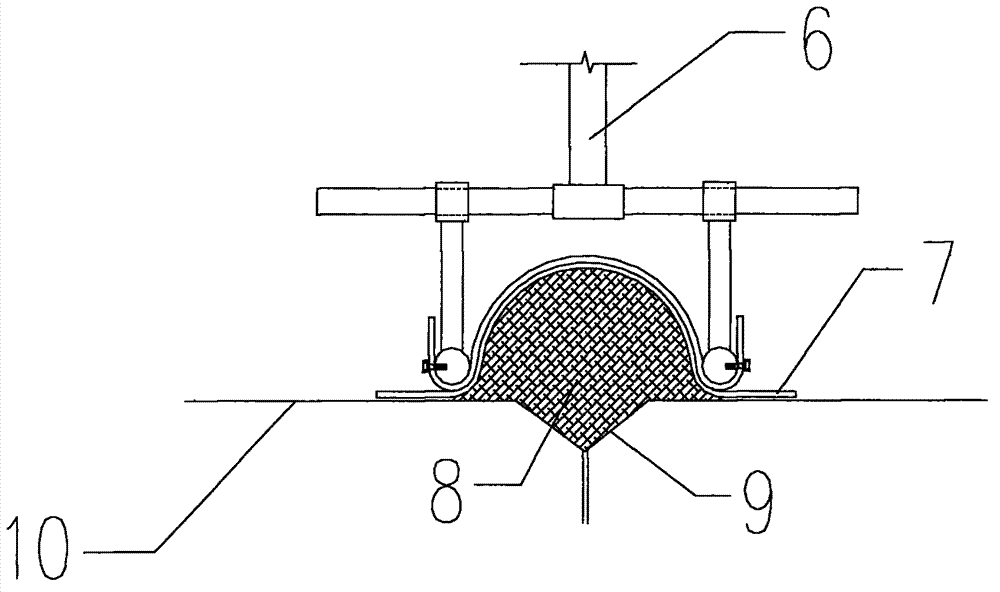

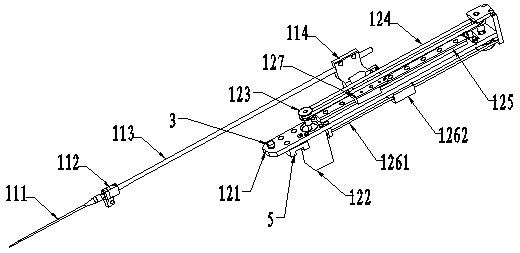

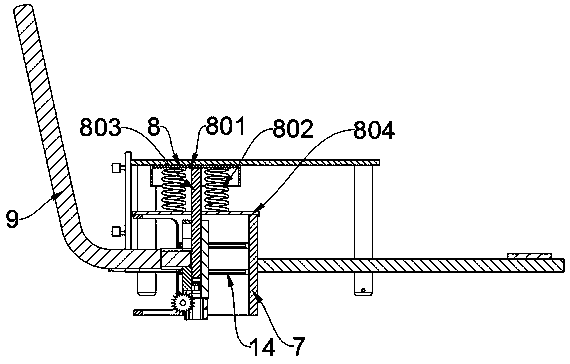

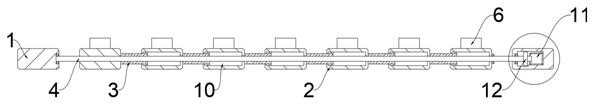

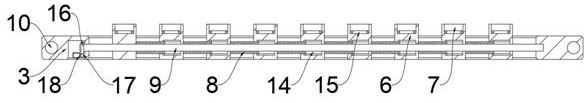

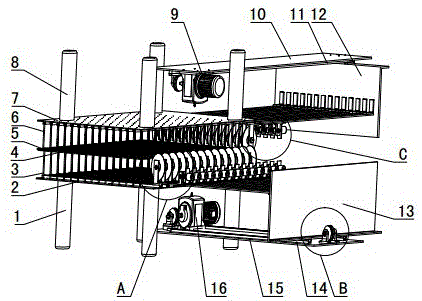

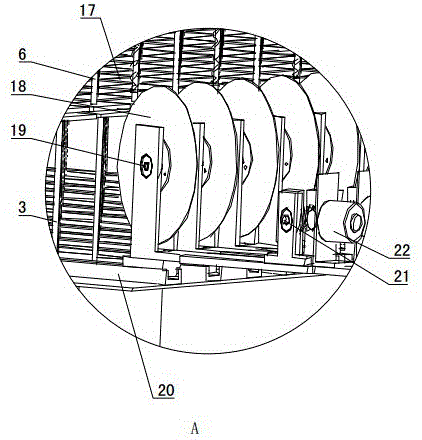

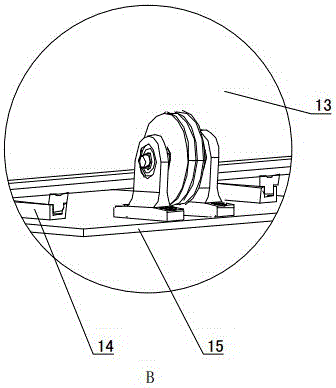

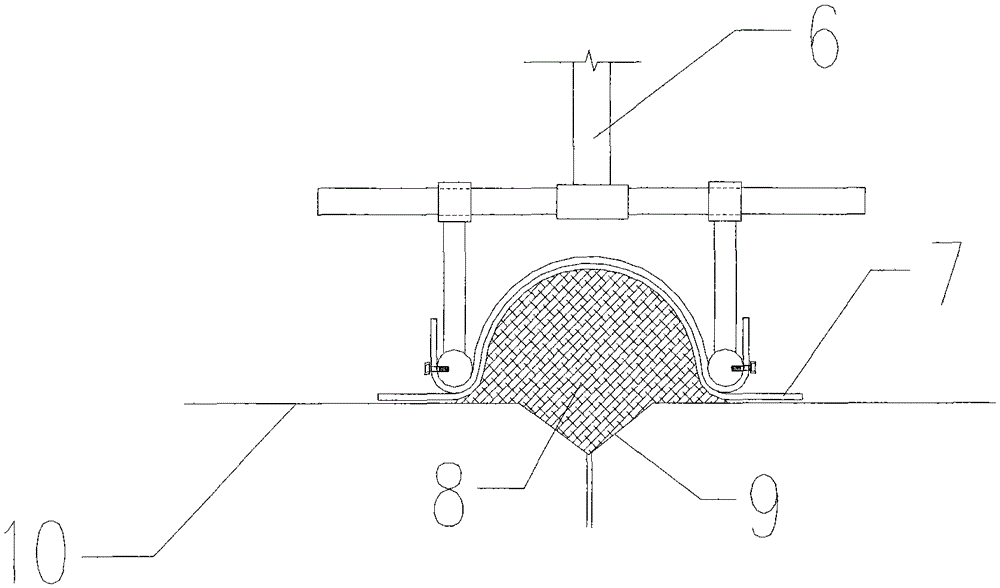

Clamping nail mounting device for underfloor heating laying

ActiveCN110421516AReduce laborReduce the burden onLighting and heating apparatusMetal-working hand toolsUnderfloor heatingEngineering

The invention discloses a clamping nail mounting device for underfloor heating laying and relates to the technical field of underfloor heating decoration. The problems that an existing clamping nail cannot meet the fixation requirements of underfloor heating pipes with different diameters, manual and mechanical mounting brings burden to the arms and the fixed distance between the clamping nails isnot accurate are solved. The clamping nail mounting device for underfloor heating laying comprises two universal wheels; a walking wheel is arranged on one side of each universal wheel; a supportingplatform is arranged on the upper end faces of the universal wheels; a handheld moving mechanism is arranged on the upper end face of the supporting platform; a distance positioning mechanism is arranged at one end of the supporting platform; and the distance positioning mechanism comprises a rotary sleeve, a first telescopic rod, an end part connecting rod, a clamping nail positioning plate, a supporting strip, a rotary lifting rod, a gas bag mounting plate, a buffering gas bag and a mounting positioning plate. The clamping nail mounting device for underfloor heating laying reduces the burdenof the arms through pedaling type mounting, is suitable for mounting of the clamping nails with different diameters and can control the distance between the clamping nails conveniently.

Owner:马鞍山市黄池峰味园食品有限公司

Convenient-to-position metal stamping part for bridge and positioning and mounting method

InactiveCN112112054AEasy to disassemble and replaceEasy maintenanceBridge structural detailsBridge erection/assemblyWrench

The invention discloses a convenient-to-position metal stamping part for a bridge and a positioning and mounting method. The convenient-to-position metal stamping part comprises a bridge concrete base, a fixed base, a connecting seat and supporting columns, the bridge concrete base is connected with the fixed base, the fixed base is connected with the connecting seat, and the connecting seat is connected with adjusting box seats at the bottoms of the supporting columns; a screw rod is rotatably connected between the two side walls of each adjusting box seat, adapter clamping rings are arrangedat the two ends of each screw rod and clamped on the outer wall of the corresponding adjusting box seat, the screw rods are in threaded connection with the middle of the connecting seat, a hexagonalwrench head is arranged at one end of each screw rod, and a guardrail is arranged between every two adjacent supporting columns; and a first magnetic sensor and a second magnetic sensor which are usedfor positioning the distance between every two adjacent adjusting box seats are correspondingly attracted to the hexagonal wrench heads of the two adjacent adjusting box seats in a magnetic manner. When a cross beam protective guard is installed, the distance between the two supporting columns can be finely adjusted, and mounting and positioning of the cross beam protective guard are facilitated.

Owner:陈烁

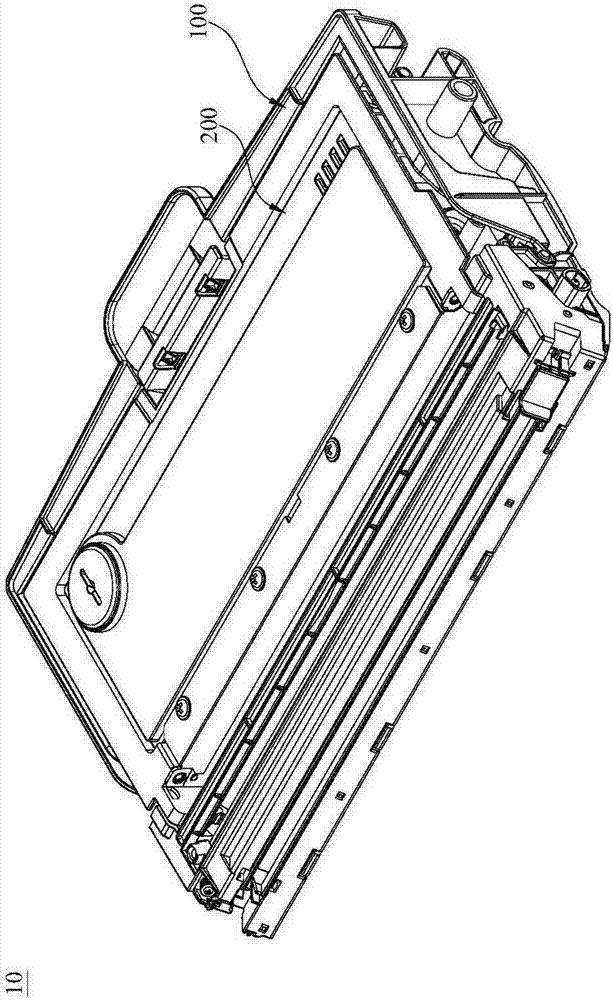

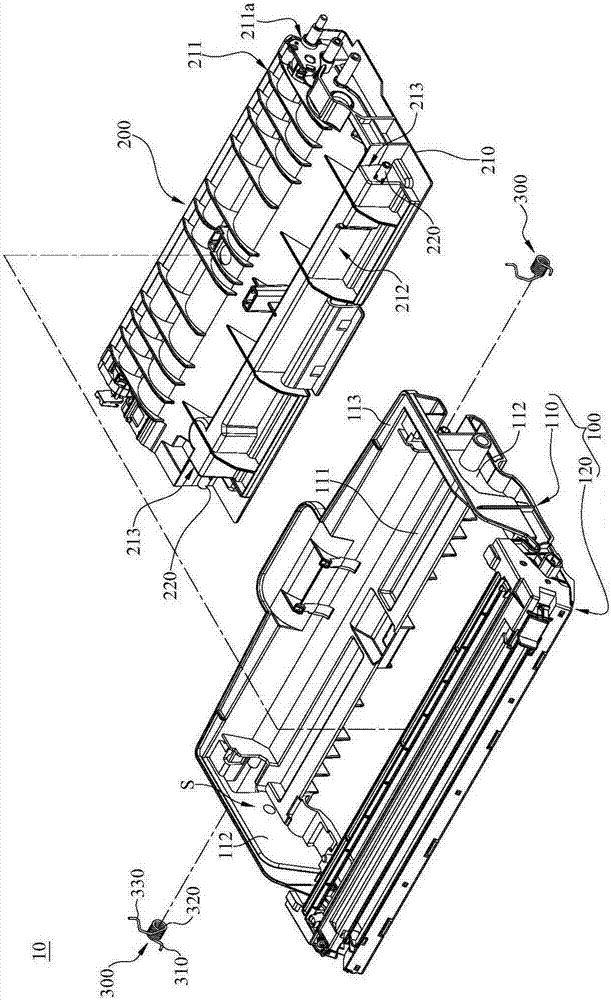

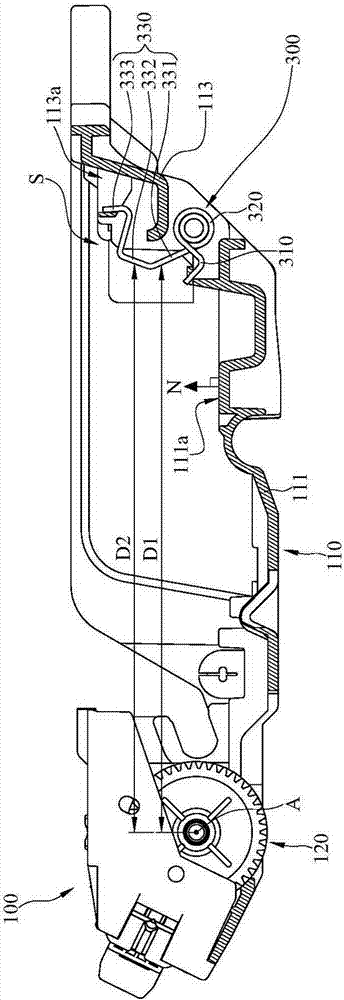

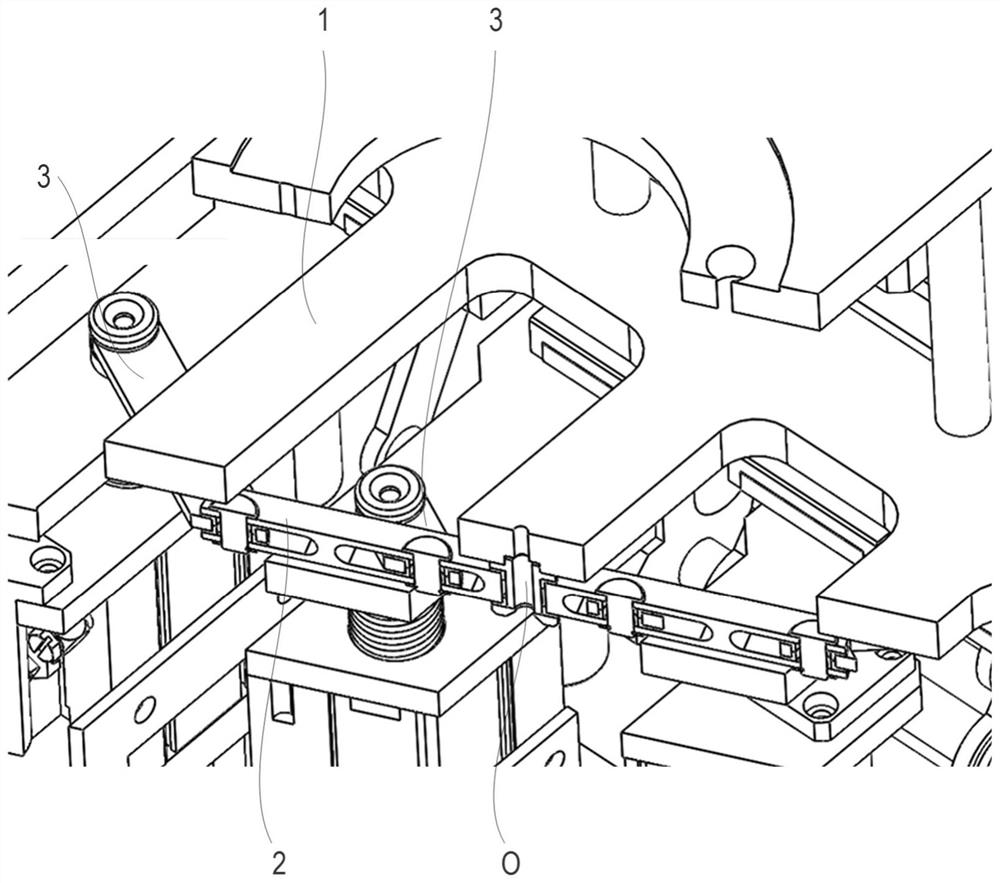

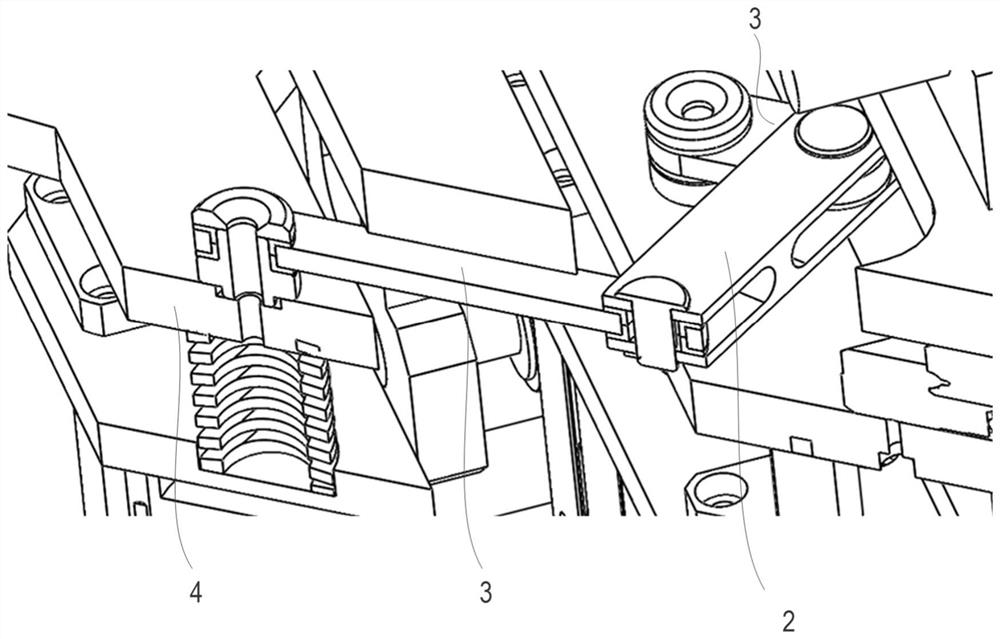

Separated type imaging device

ActiveCN107229210AMeet the needs of environmental protectionImprove image qualityElectrographic process apparatusEngineeringTorsion spring

The invention relates to a separated type imaging device that comprises a sensitive group, a toner cartridge and at least one torsion spring, wherein the sensitive group comprises a housing and a photosensitive drum; the housing comprises a storage groove; the photosensitive drum is arranged on the housing at one side of the storing groove; the toner cartridge is arranged in the storing groove in a detaching way; the torsion spring is arranged in the storing groove; one segment of the torsion spring is arranged in the housing and the opposite segment of the torsion spring is against the side of the toner cartridge back to the photosensitive drum, so that the toner cartridge can move toward the photosensitive drum.

Owner:AVISION

Preparation method of RF-MEMS switch composite sacrificial layer

PendingCN110329988AAvoid mechanochemical polishing processReduce dependencyDecorative surface effectsChemical vapor deposition coatingManufacturing technologyEtching

The invention discloses a preparation method of an RF-MEMS switch composite sacrificial layer, and belongs to the RF-MEMS device manufacturing technology field. The method comprises the steps of planarization filling, sputtering etching of a metal sacrificial layer, preparation of a photoresist sacrificial layer and the like. By adopting the method disclosed by the invention, the flatness of the MEMS switch beam can be improved, and the preparation of the switch beam with the low contact distance of 10-500nm is realized, so that the reliability of the MEMS switch is improved, and the driving voltage of the MEMS switch is reduced.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Size-adjustable universal printing machine die

The invention discloses a size-adjustable universal printing machine die which comprises two fixed supports. Longitudinal screw rods are installed between the two ends of the two fixed supports, and longitudinal screw rod gears are fixedly installed on the outer sides of one ends of the longitudinal screw rods. A longitudinal adjusting motor gear is installed on one side of each longitudinal screwgear, a longitudinal adjusting motor is fixedly installed at one end of each longitudinal adjusting motor gear, multiple longitudinal threaded sleeves are evenly and movably installed on the outer side of each longitudinal screw rod, and a longitudinal moving sliding block is fixedly installed at one end of each longitudinal threaded sleeve. According to the size-adjustable universal printing machine die. Due to installing of the longitudinal moving sliding blocks, the longitudinal threaded sleeves, the longitudinal screw rods, transverse moving sliding blocks, transverse threaded sleeves andtransverse screw rods, the distance between printing machine dies can be adjusted according to the printing requirement of products, product printing is better facilitated, the structure is simple, and operation is convenient.

Owner:临海市元珊印刷包装有限公司

Transverse-longitudinal multi-layer cattle hide cutting machine

InactiveCN106801112APrevent movementDimensionally stableFur cuttingEngineeringMechanical engineering

The invention discloses a transverse-longitudinal multi-layer cattle hide cutting machine, and belongs to the technical field of cattle hide cutting equipment. The transverse-longitudinal multi-layer cattle hide cutting machine is characterized by comprising a cutting platform (4), a transverse cutting mechanism and a longitudinal cutting mechanism, wherein a pressing mechanism is arranged above the cutting platform (4); the pressing mechanism is matched with the cutting platform (4) to tightly press cattle hide to be cut; the transverse cutting mechanism and the longitudinal cutting mechanism are used for cutting the cattle hide respectively, so that the cattle hide can be cut into pieces. Due to the cooperation of the pressing mechanism and the cutting platform of the transverse-longitudinal multi-layer cattle hide cutting machine, a plurality pieces of cattle hide can be clamped simultaneously, the cattle hide is cut into pieces from two directions by the transverse cutting mechanism and the longitudinal cutting mechanism respectively, and the cattle hide is prevented from being moved when being cut, so that the cutting precision of the transverse cutting mechanism and the longitudinal cutting mechanism can be greatly improved, the size stability of the cut cattle hide can be ensured, later processing processes are simplified, and the product quality can be improved.

Owner:SHANDONG UNIV OF TECH

Rolling mill for rolling tooth marks on surface of metal belt

PendingCN109909300AAccurate spacing controlImprove consistencyMetal rolling arrangementsAcute angleEngineering

A rolling mill for rolling tooth marks on the surface of a metal belt comprises a machine body, a second roller rotationally arranged on the machine body, a first bearing block arranged on the machinebody in a sliding manner and a die roller rotationally arranged on the first bearing block and used for installing a die. The axis line of the die roller is parallel to the axis line of the second roller. The sliding direction of the first bearing block is the direction where the axis line of the die roller is close to the axis line of the second roller. A first inclined block is fixedly arrangedon the first bearing block, the machine body is provided with a second inclined block in a sliding manner, the sliding direction of the second inclined block is perpendicular to the sliding directionof the first bearing block, and the contact face of the first inclined block and the second inclined block is an inclined face parallel to the axis line of the die roller. The extension direction ofthe inclined face and the sliding direction of the first bearing block are in intersection and form an acute angle. The inclined face serves as the displacement conduction face, and the roller gap between the die roller and the second roller is accurately controlled.

Owner:贺云坤

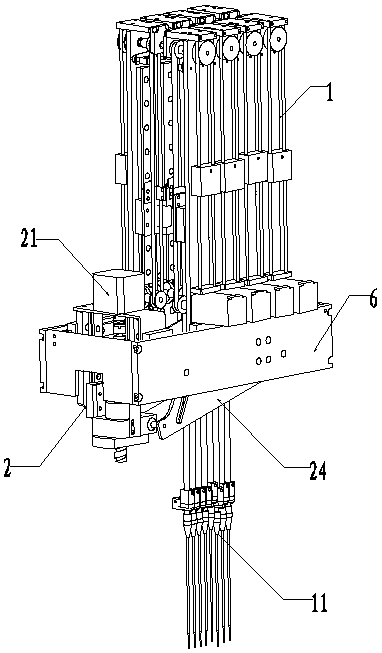

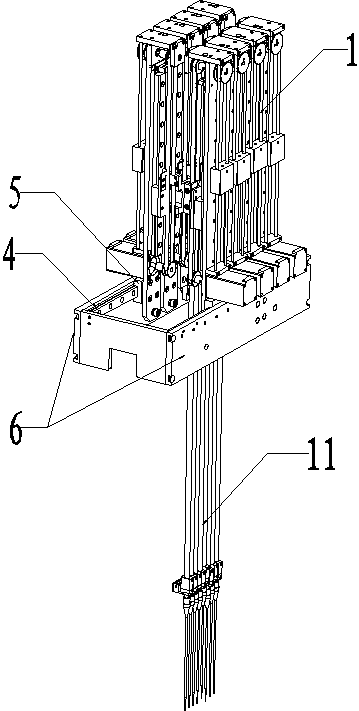

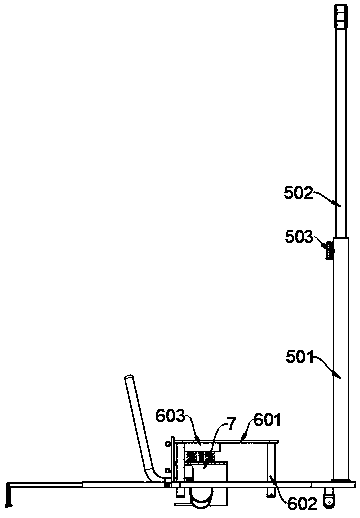

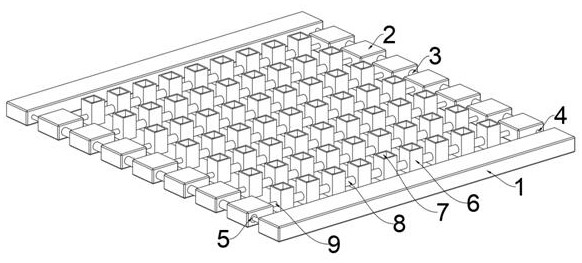

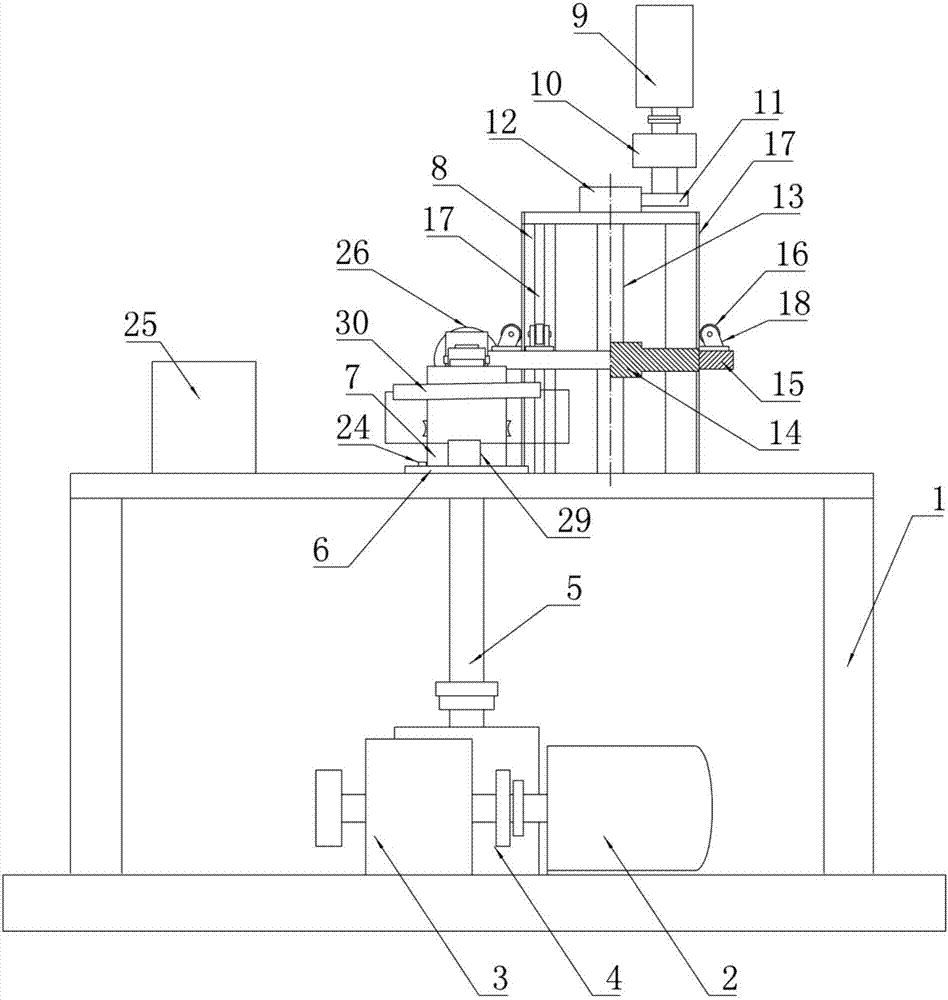

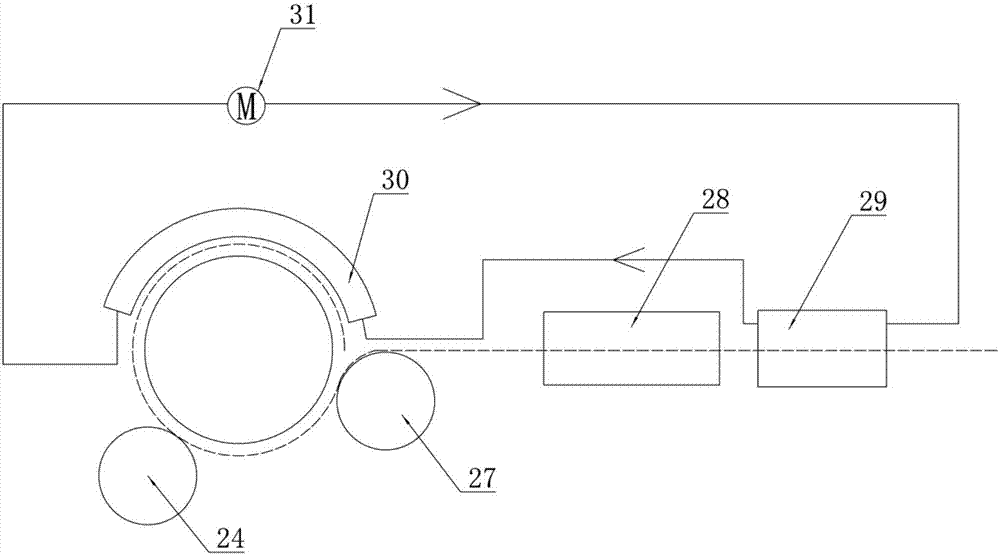

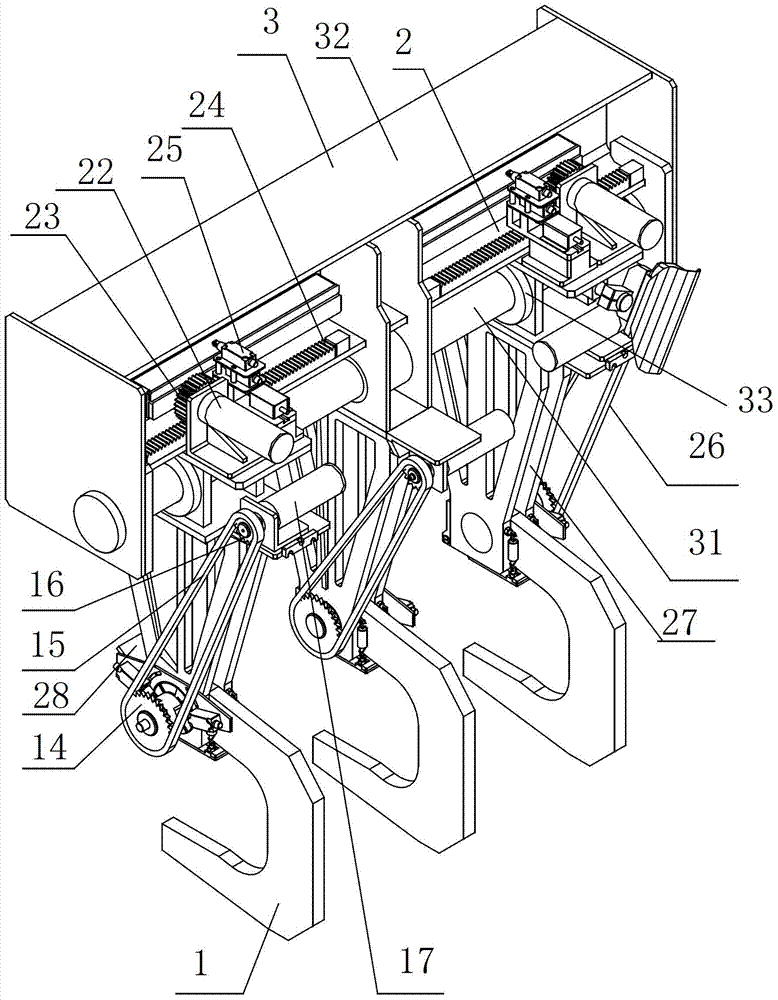

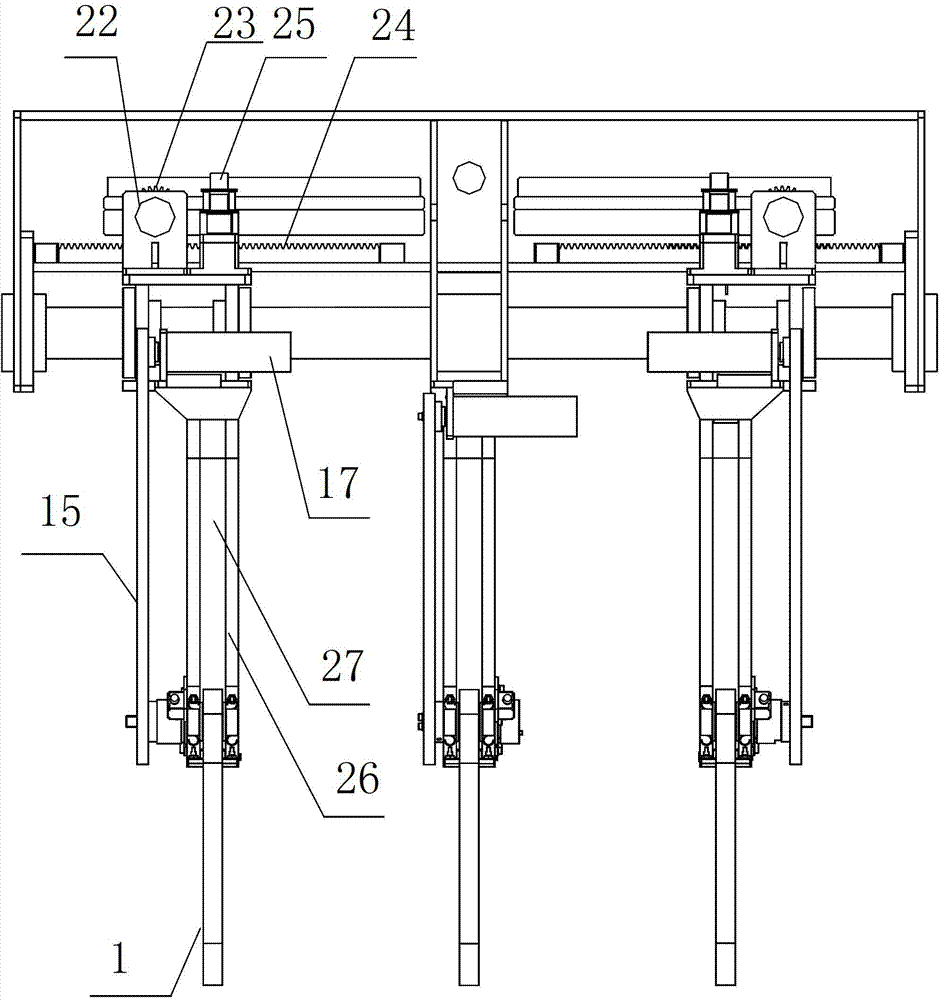

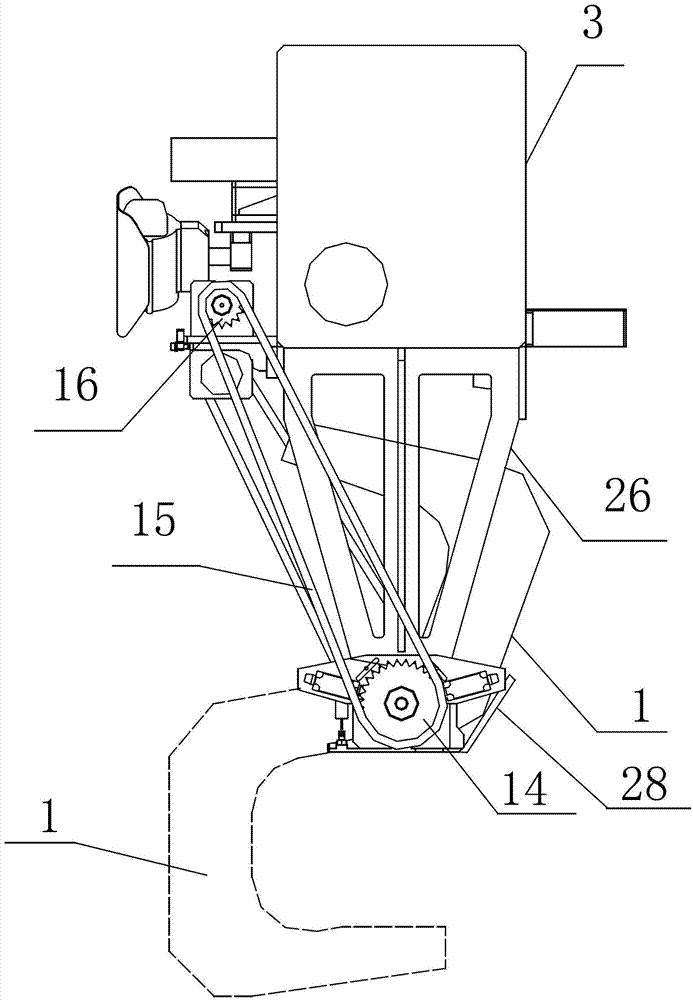

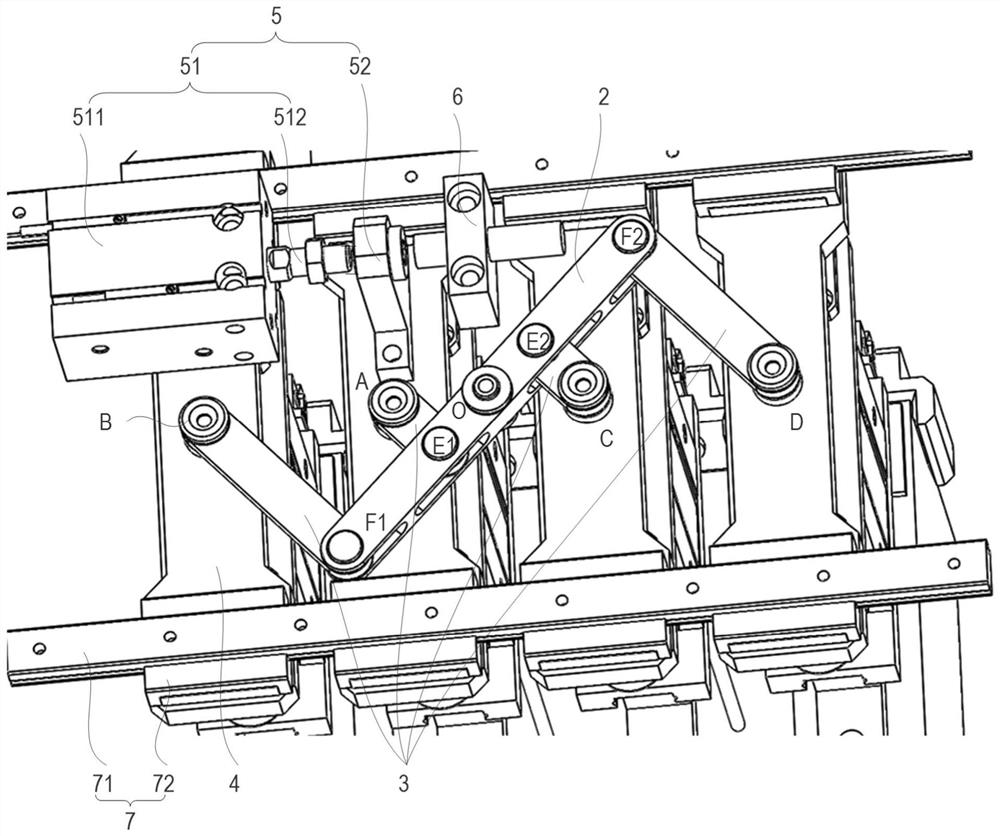

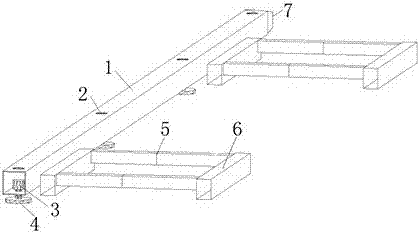

A spiral coil machine

ActiveCN105665496BReduce the coefficient of reboundAccurate spacing controlShaping toolsGear wheelElectric machinery

A spiral coil machine comprises a rack, a main power system, a coil distance adjustment system and a coil auxiliary positioning system. The main power system comprises a motor which is connected with a vertical main axle by two-level speed reduction, the coil positioner is coaxially connected with the upper end of the main axle and extends outside the upper surface of the rack; the coil distance adjustment system comprises a bracket fixed on the rack, a driving gear which is connected with a speed regulation motor is arranged above the bracket and engaged with and drives a driven gear, the driven gear is coaxially connected with a first vertical screw, the first screw is connected with a frame by an axle sleeve, the frame is arranged on the outer side of the bracket and provided with pulleys. The coil auxiliary positioning system comprises a support frame which is fixed on one side of the frame corresponding with the coil positioner, a second horizontal screw is mounted on the support frame and cooperatively provided with a slider, and a top wheel is mounted on one end of the slider corresponding with the coil positioner by a vertical axle. During the pipeline heating process, the automatic degree is high, the size is accurate, one person can produce the coil at high efficiency, and labor and power are saved.

Owner:HEBEI INSTALLATION ENG

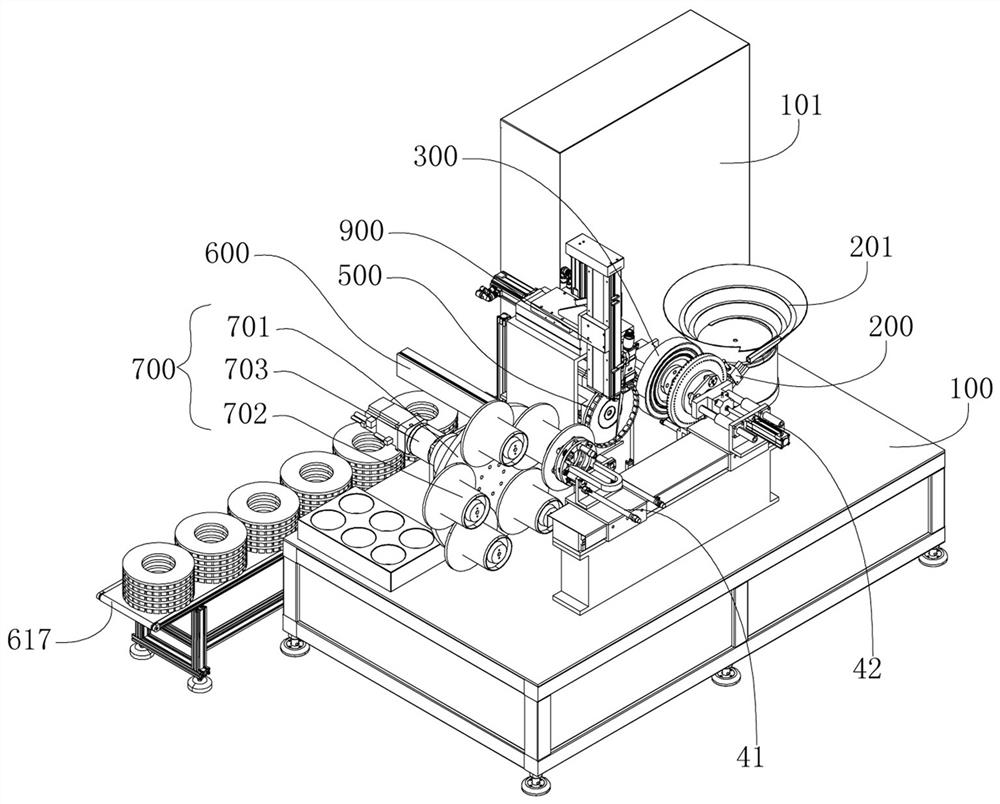

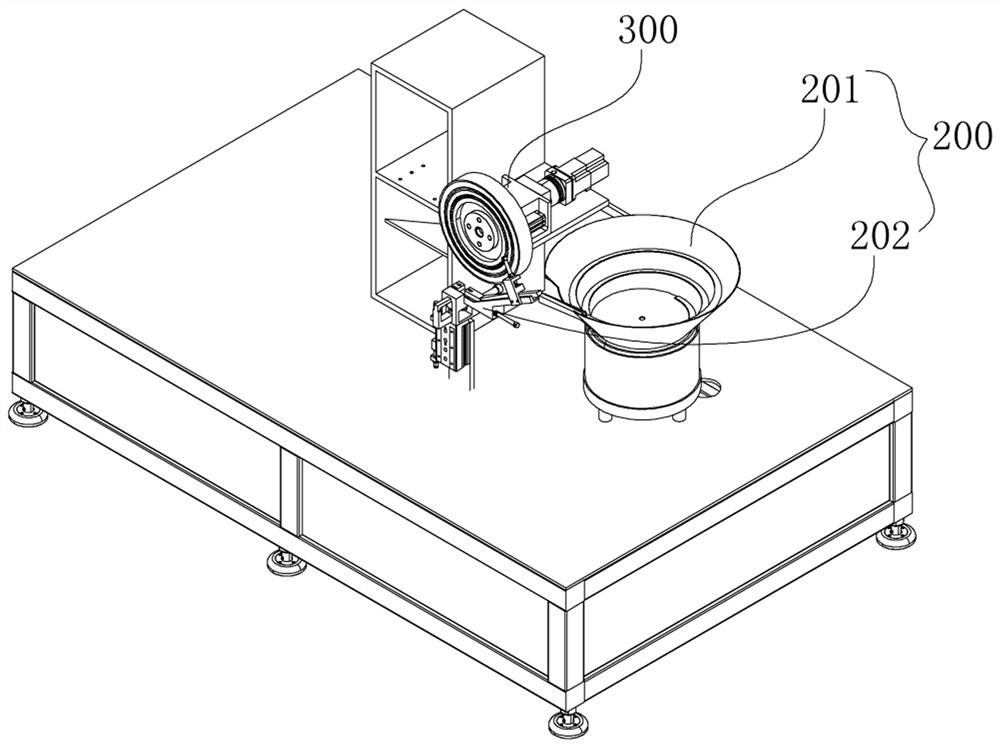

Automatic laser welding machine for edge grinding wheel

PendingCN114346426AEfficient arrangementRealize butt weldingLaser beam welding apparatusTool bitEngineering

The invention belongs to the technical field of edge grinding wheel production. An edge grinding wheel automatic laser welding machine comprises a machine frame, a base body storage frame, a vibration disc, a tool bit arranging and clamping device, an edge grinding wheel welding rotating device, a base body taking and placing device, a tool bit taking and placing device, a laser welding device and an edge grinding wheel discharging and conveying device, and the base body storage frame is used for storing a base body; a tool bit feeding device is arranged at an outlet of the vibration disc; the tool bit arranging and clamping device is used for clamping the tool bits pushed out by the tool bit feeding device and arranging the tool bits annularly at intervals. The edge grinding wheel welding rotating device is used for clamping the base body and driving the base body to rotate. The base body taking and placing device grabs a base body and feeds the base body to the edge grinding wheel welding rotating device. The tool bit taking and placing device is used for grabbing a whole tool bit and aligning the base body. The laser welding device is used for welding the tool bit and the base body. The base body can be automatically grabbed and fed, and tool bits can be effectively arranged and integrally clamped and transferred, so that the tool bits and the base body are integrally aligned and welded.

Owner:郑州金海威科技实业有限公司

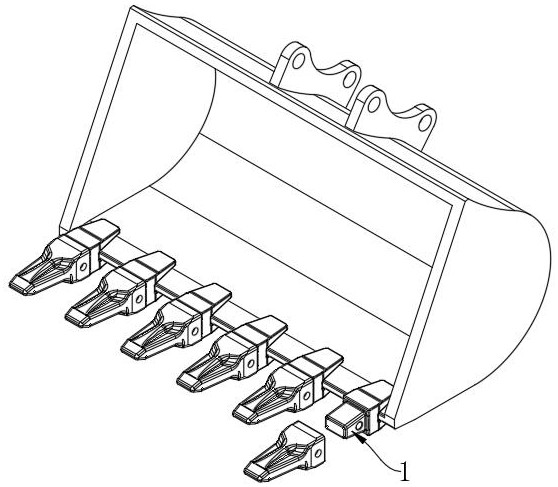

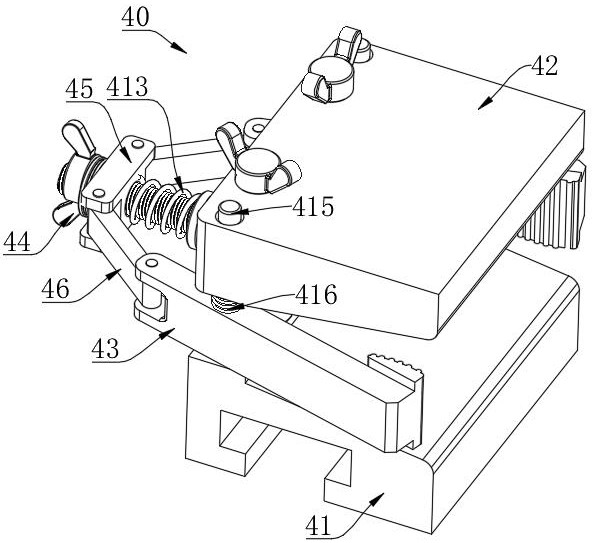

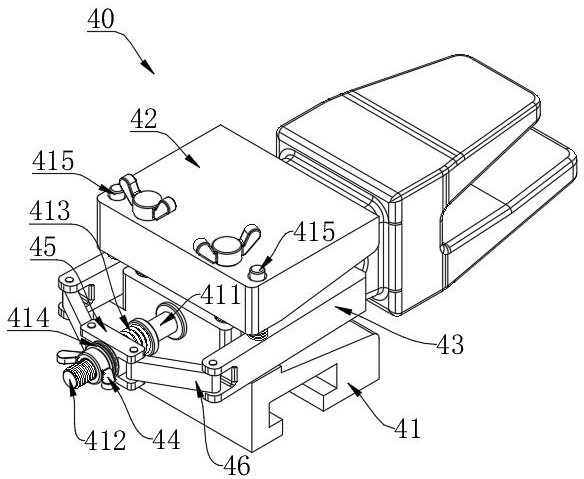

A bucket tooth connecting seat welding device

ActiveCN114310126BAccurate spacing controlEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWorkbench

The present application provides a bucket tooth connection seat welding device, including: a workbench and a fixture assembly. There is a lifting plate on the top of the workbench. The fixture assembly includes an adjustment mechanism and a clamping component. The adjustment mechanism includes a support rod and an adjustment rod. The adjustment rod is moved in a direction perpendicular to the top surface of the support rod. There are multiple sets of connecting rod assemblies below the adjustment rod. Each set of connecting rod assemblies includes two connecting plates. The upper end of the rotating shaft is connected to the same rotating shaft, and the rotating shaft is moved along the length direction of the adjusting rod. There are multiple groups of clamping components along the length direction of the support bar. The clamping component includes a bottom plate, which slides on the support bar along the length direction of the support bar. A pressure plate is arranged above the bottom plate for pressing the connecting seat. The wall is provided with hinged rods, which are parallel to the rotating shaft, and the connecting plates of the connecting rod assembly are respectively connected in rotation with the hinged rods of the clamping components on the adjacent two sides through the lower ends. The welding process of the bucket tooth connecting seat can be simplified and the welding efficiency can be improved.

Owner:成都中挖金属制品有限公司

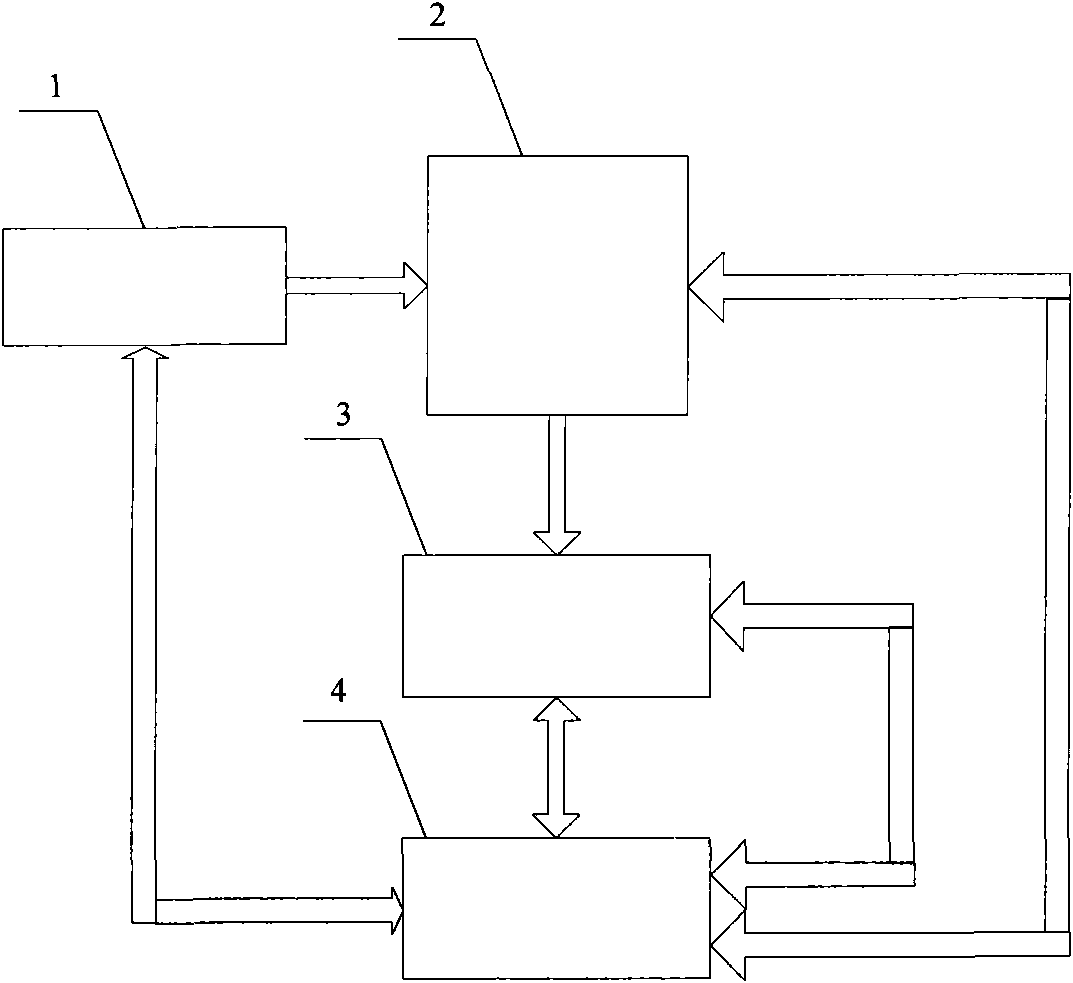

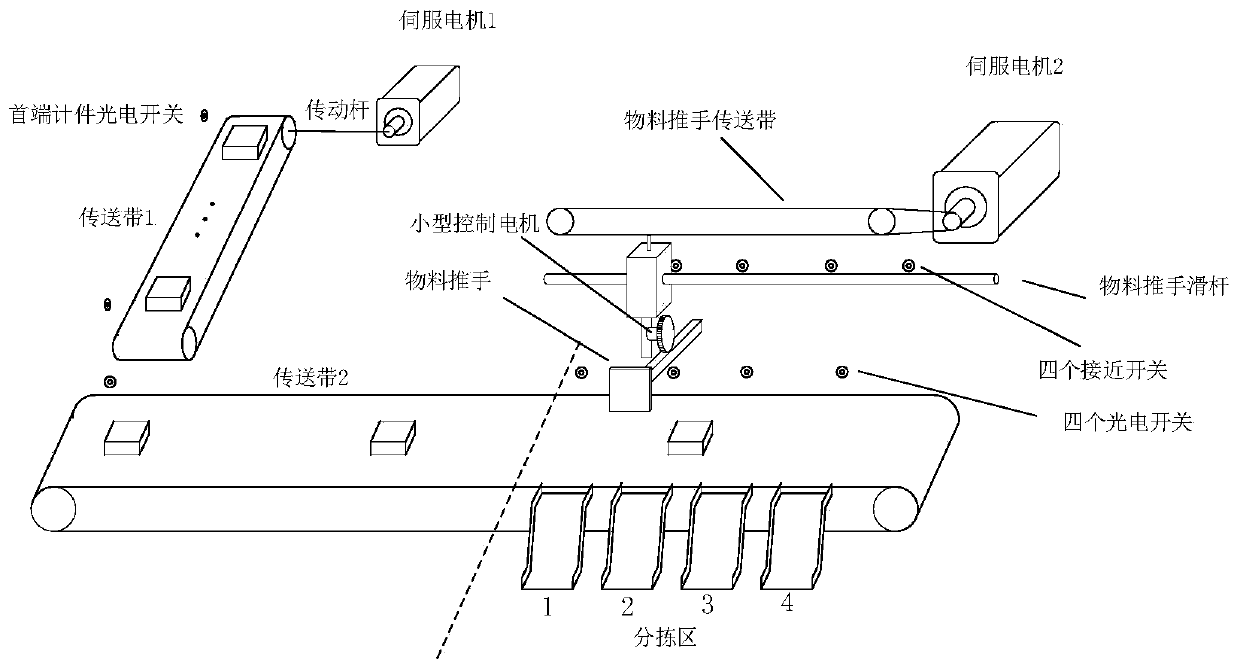

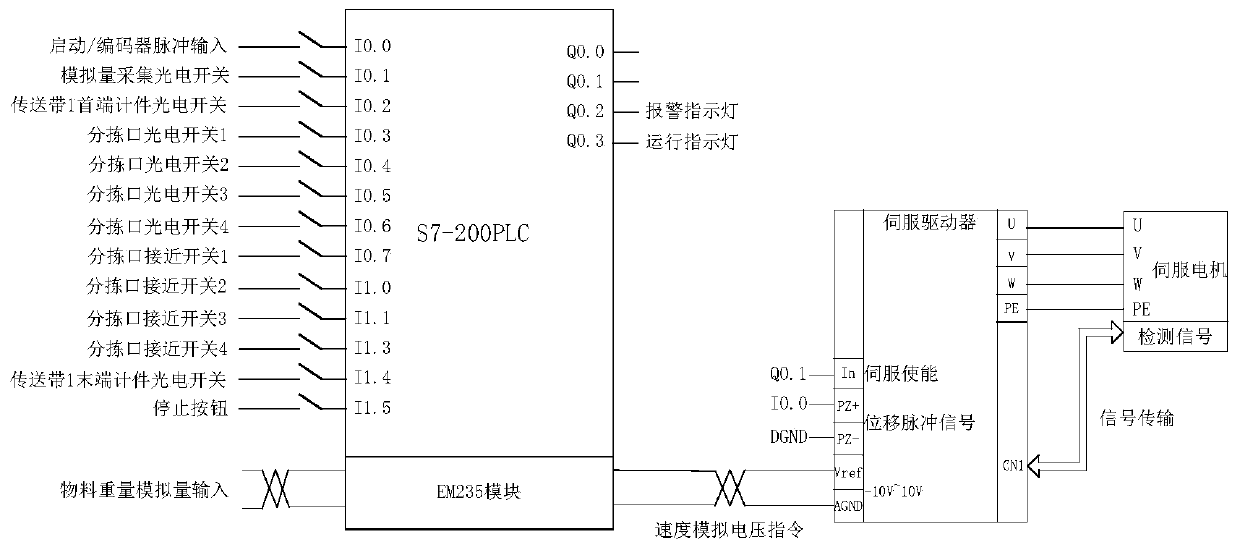

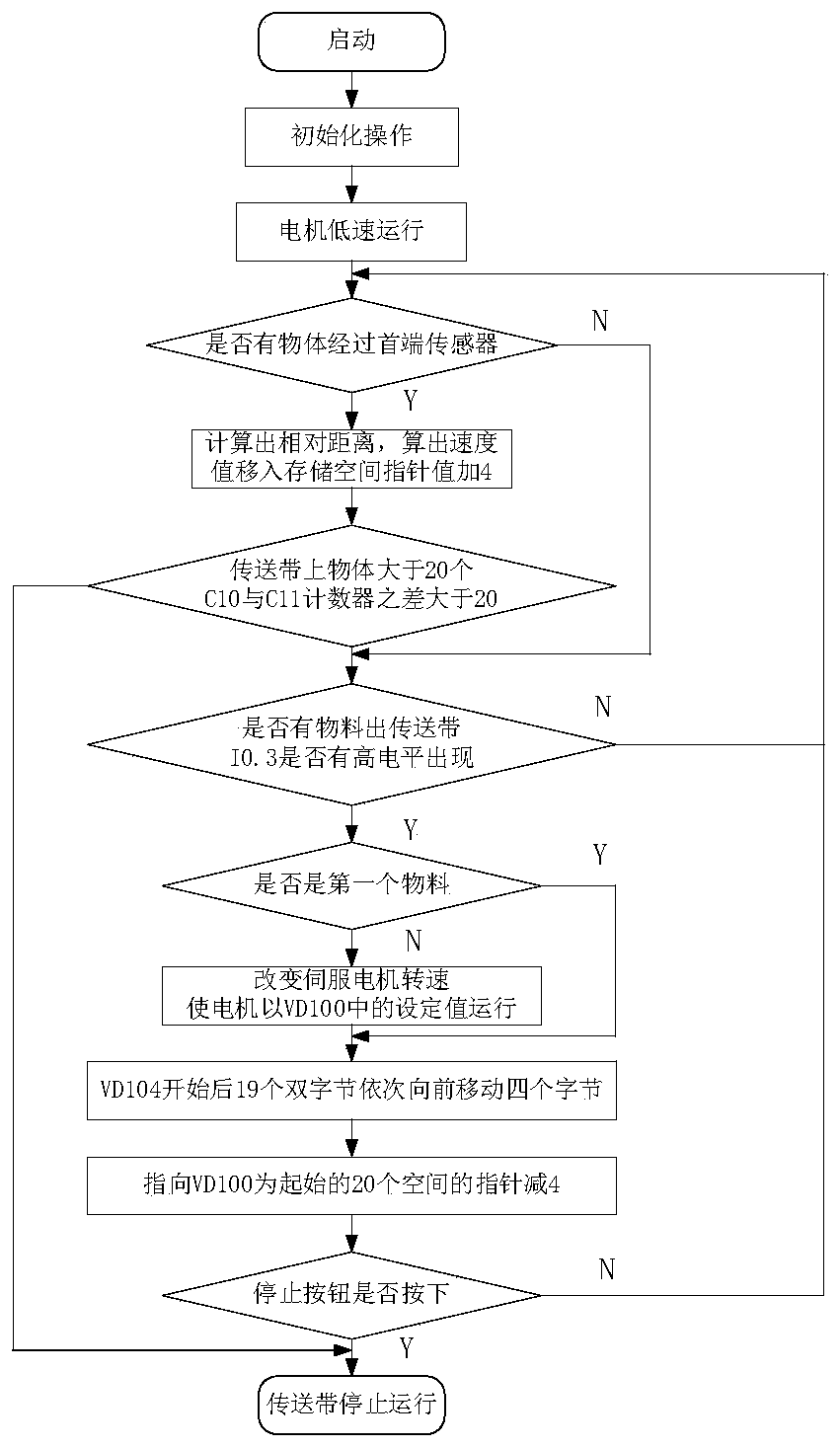

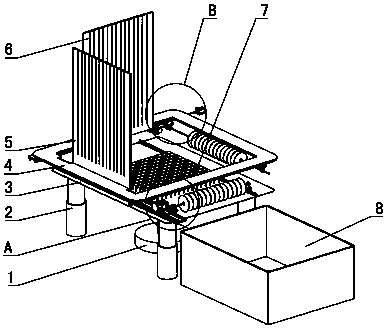

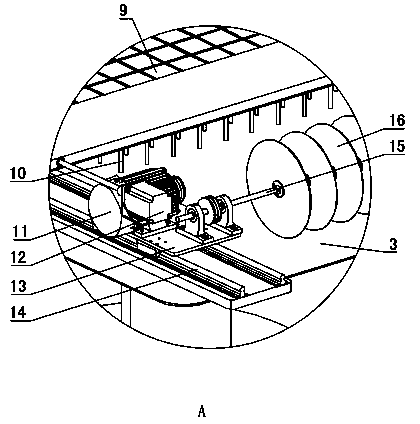

Novel material sorting control system

InactiveCN111570308AControl Synchronization CoordinationControls are simple and preciseSortingProgramme control in sequence/logic controllersControl systemTransmission belt

The invention discloses a novel material sorting control system. The novel material sorting control system mainly comprises a power module, a PLC module, a servo motor control system operating independently, a weight detection module, a servo motor module, a servo driver module, a transmission device, a conveying belt 1, a conveying belt 2, a material pushing hand, a material pushing hand conveying belt, a sorting mouth slide, a material pushing hand sliding rod, a small control module, a proximity switch and a photoelectric induction switch. Two servo drives and servo motors respectively drive the conveying belt 1 and the material pushing hand to move horizontally, and the materials can enter a sorting region equidistantly to sort through mutual cooperation between the conveying belts 1 and 2. The complete control system provided by the invention can control a material sorting line, thereby sorting the materials automatically and accurately.

Owner:ANHUI UNIV OF SCI & TECH

A vertical platen cowhide cutting machine

InactiveCN106881737BPrevent movementDimensionally stableFur cuttingMetal working apparatusEngineeringMechanical engineering

The utility model relates to a vertical platen type cowhide cutting machine, which belongs to the technical field of cowhide cutting equipment. It is characterized in that: it includes a cutting platform (7), a transverse cutting mechanism and a longitudinal cutting mechanism, a longitudinal pressing mechanism and a transverse pressing mechanism are arranged above the cutting platform (7), and the transverse pressing mechanism and the longitudinal pressing mechanism alternate with the cutting The platform (7) cooperates to compress the cowhide to be cut, the horizontal pressing mechanism cooperates with the horizontal cutting mechanism to cut the cowhide, and the longitudinal pressing mechanism cooperates with the longitudinal cutting mechanism to cut the cowhide, thereby cutting the cowhide into blocks. The longitudinal pressing mechanism and the horizontal pressing mechanism of the vertical platen cowhide cutting machine can respectively cooperate with the cutting platform to press the cowhide tightly, avoiding the movement of the cowhide during cutting, so that the cutting accuracy of the longitudinal cutting mechanism and the horizontal cutting mechanism is greatly improved. , to ensure the dimensional stability of the cut cowhide, thereby simplifying the subsequent processing technology and improving the quality of the product.

Owner:SHANDONG UNIV OF TECH

Automatic suspender

InactiveCN103332588BIncrease flexibilityAccurate spacing controlLoad-engaging elementsWork productivityEconomic shortage

The invention discloses an automatic suspender. The suspender comprises a suspension arm and at least a suspension hook. The suspender is characterized in that at least one suspension hook is movably arranged on the suspension arm. The invention provides an automatic suspender. The suspender realizes automatic article lifting, overcomes the shortages of low efficiency, high production cost, large workload, high work strength, and high danger for a person in a handling zone, which are caused by human operation of a conventional suspender, improves work efficiency, and reduces production cost and work strength of workers.

Owner:上海敏坚实业有限公司

Concrete face rockfill dam face flexible packing former

The invention provides a flexible packing former for a concrete face rockfill dam face. The flexible packing former is characterized by comprising a machine body, wherein the machine body comprises forming belts for clamping and pressing flexible packing, fixing parts for fixing the two ends of each forming belt and connecting parts for connecting the fixing parts; slot surfaces for clamping and pressing the flexible packing are formed in the forming belts; the slot surfaces are matched with the outer profile of the cross section of the flexible packing to be embedded and filled or matched with the decomposed cross section of the flexible packing to be embedded and filled in shape; the number of the forming belts is no less than 2; the forming belts are made from materials which are easy to deform and good in tensile strength; such materials which are easy to deform and good in tensile strength are nonmetal materials, such as rubber, leather, plastic and the like, or metal materials, such as copper, aluminum, iron and the like; the connecting parts can be used for adjusting the spacing among the fixing parts; and the fixing parts are provided with fixtures capable of clamping the forming belts. According to the flexible packing former, the problems of low efficiency and low quality in embedding and filling joint materials in jointing and caulking construction of the concrete face rockfill dam face can be effectively solved.

Owner:朱博程 +1

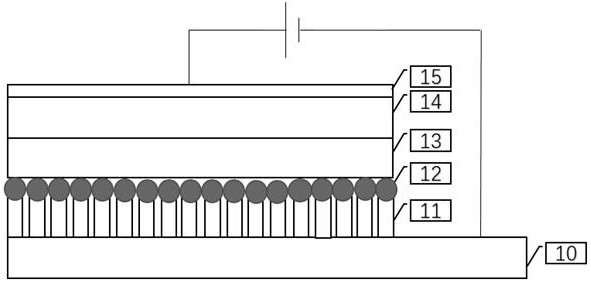

Thin film transistor and its manufacturing method, device, chip and display device

ActiveCN109742155BSmall sizeControl spacingTransistorSemiconductor/solid-state device manufacturingDisplay deviceThin membrane

Owner:BOE TECH GRP CO LTD

A kind of qled device and preparation method thereof

ActiveCN109980052BImprove performanceAccurate spacing controlSemiconductor devicesQuantum dotElectron transporting layer

The invention discloses a QLED device and a preparation method thereof, and the QLED device comprises a cathode, an anode, and an electron transmission layer and a quantum dot light-emitting layer which are both arranged between the cathode and the anode. The electron transmission layer is a II-IV group semiconductor nanorod array which is vertically arranged relative to the surface of the cathode. The material of the quantum dot light-emitting layer is quantum dots, and the quantum dots grow at the tops of the II-IV group semiconductor nanorods. Light generated by the quantum dot light-emitting layer can pass in the axial direction of the II-IV group semiconductor nanorods in a more concentrated and lower-loss manner, and light is emitted from the cathode of the device, so that the luminous efficiency and the brightness of the device are greatly improved. According to the invention, the distances between the quantum dots with different particle sizes can be indirectly and accurately controlled through the control of the diameter of the II-IV group semiconductor nanorods and the distance between the adjacent nanorods in the array, thereby achieving the performance optimization of the QLED device.

Owner:TCL CORPORATION

Grabbing mechanism distance adjusting device and logistics conveying line

ActiveCN114506671AStable clampingReliable clampingConveyor partsLogistics managementStructural engineering

The invention discloses a grabbing mechanism distance adjusting device and a logistics conveying line, relates to the field of material conveying, and aims to accurately adjust the distance between grabbing mechanisms. The grabbing mechanism distance adjusting device comprises a supporting base, a driving piece, at least two distance changing transmission parts and at least two connecting pieces. The supporting seat is configured to provide support; the driving piece is rotatably mounted on the supporting seat; and one end of each variable-pitch transmission part is rotationally connected with the driving part. Each connecting piece can be mounted on the supporting seat in a linear moving manner; the connecting pieces are in one-to-one correspondence with the variable-pitch transmission parts, and the connecting pieces are rotatably connected to the other ends of the variable-pitch transmission parts. According to the technical scheme, precise control over the distance between the connecting pieces is achieved; the connecting pieces are used for installing the grabbing mechanisms, and therefore the distance between the grabbing mechanisms can be adjusted.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

Steel cold bending test machine

ActiveCN101241059BAccurate spacing controlPrecise control of bending angleMaterial strength using steady bending forcesHydraulic cylinderRear quarter

A rolled steel cool-deforming test machine, comprising a case, a hydraulic pressure system which is composed of a hydraulic pressure cylinder, an oil pump, an oil tank, a handle reversing valve. A work table is set at top of the case. A supporting plate is set on rear end of the work table. A regulating bracket is set on front end. The hydraulic pressure cylinder is embedded in middle of the supporting plate. A mandril is connected to a piston rod of the hydraulic pressure cylinder. A punch is connected to front end of the mandril. The regulating bracket is composed of a left plate, a right plate, a front plate, a rear plate, a front bottom plate and a rear bottom plate. A right sliding block and a left sliding block are set between the left and right plates. The left and right sliding blocks are spiro-connected to an upper right chain wheel and a lower right chain wheel via a screw. A right vertical column is connected to front end of the left sliding block; a right vertical column is connected to front end of the right sliding block; ends of the upper and lower screw rods extend from the right plate, connected to the upper right chain wheel and lower right chain wheel. A handle wheel is set outside of the right plate, connected to the driving chain wheel which is connected to the upper right and lower right chain wheels via chains. The product is convenient to operate, save and reliable with high test precision, which is applied to bending test detection of various rolled steels.

Owner:北京城建建设工程有限公司

A liquid dispensing mechanism

ActiveCN104117298BImprove operational efficiencyQuick responseFlow mixersMixing methodsBiomedical engineering

Owner:SUZHOU JIEMEI ELECTRONICS

Forming test mold and method for chopped fiber-cement-based material test piece

PendingCN111175114ASimple structureEasy to pourPreparing sample for investigationUsing mechanical meansMechanical engineeringCement Material

the invention relates to a forming test mold and method for the chopped fiber-cement-based material test piece. The test mold is characterized in that four straight edges of a lower test mold and fourstraight edges of an upper test mold in the test mold form a rectangular frame body, and cross sections of the lower test mold and the upper test mold are the same; the lower test mold is fixed on anupper surface of the base; the upper test mold is arranged on the lower test mold, the upper test mold is fixedly connected with the lower test mold, and the center of the upper test mold frame bodyis located over the center of the lower test mold frame body; the method comprises steps of step 1, coating release agent on the lower test mold and a base, pouring a cement-based material into an upper end of the lower test mold, leveling and flattening; 2, extending the chopped fibers into an upper surface of the cement-based material, then fixing the upper test mold coated with the release agent to an upper surface of the lower test mold, and pouring the cement-based material into an upper end of the upper test mold to be flush with an upper end of the upper test mold and then flattening; 3, after molding for 20-24 h, detaching the upper test mold, and taking out the molded chopped fiber-cement-based material test piece. The method is advantaged in that a real interface state can be better reflected, the structure is simple, manufacturing is convenient, and practicability is stronger.

Owner:CHANGAN UNIV

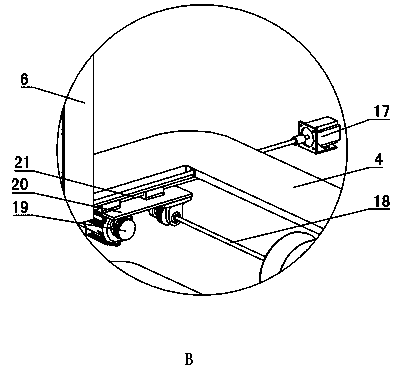

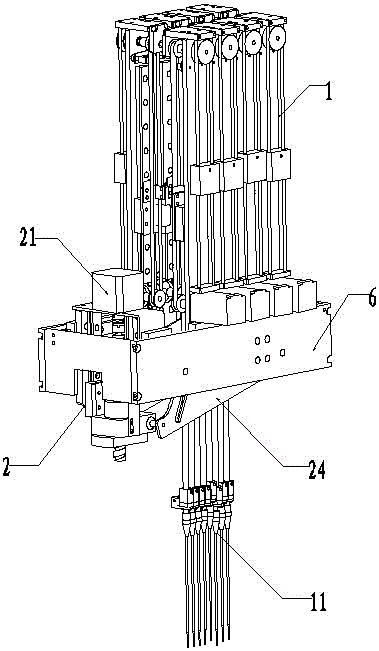

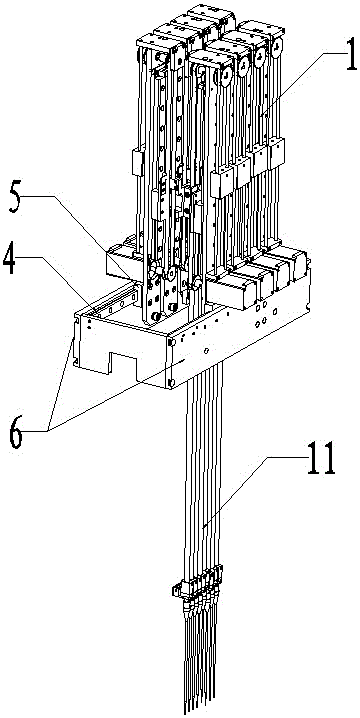

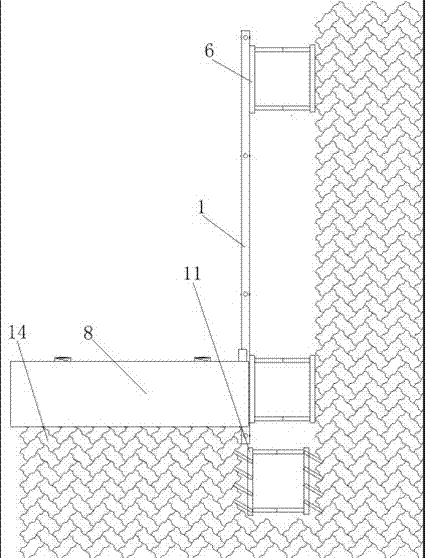

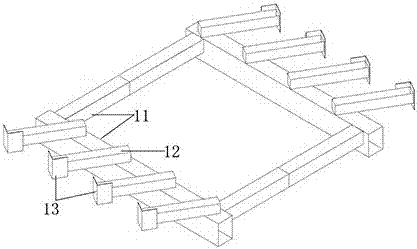

Auxiliary system for interlocking segment large-area paving and achieving method of auxiliary system

ActiveCN107881890AAccurate spacing controlGuaranteed positioning accuracyClimate change adaptationRoads maintainenceIndustrial engineeringBrick

The invention discloses an auxiliary system for interlocking segment large-area paving, and relates to the technical field of road and yard construction machinery, in particular to an auxiliary systemand an achieving method of the auxiliary system which are suitable for areas such as ports, wharfs and yards needing interlocking segment large-area paving. The auxiliary system is characterized in that the auxiliary system includes a brick-laying machine, an adjacent row spacing control device and a brick-laying machine auxiliary guiding and positioning device, wherein the adjacent row spacing control device and the brick-laying machine auxiliary guiding and positioning device are arranged on the positions, corresponding to one sides of adjacent laid interlocking segment ground bricks, of the brick-laying machine; the adjacent row spacing control device comprises a supporting frame body, and the supporting frame body is of a square structure; and the brick-laying machine auxiliary guiding and positioning device comprises a positioning guiding rail and a square limiting frame body, and the positioning guiding rail is provided with a height adjusting mechanism. By means of the auxiliary system, spacing is controlled accurately in the interlocking segment paving process, the applicability is high, the reliability is high, and the positive effects of improving the construction efficiency and the operation precision are achieved.

Owner:SHANDONG HARBOR ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com