Seed spray device and sowing method

A technology of spraying device and seeds, which is applied to the parts of planters, machinery for interval-type quantitative sowing, etc., can solve the problem of inability to achieve precise sowing, and achieve the effects of precise seeding and precise spacing control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

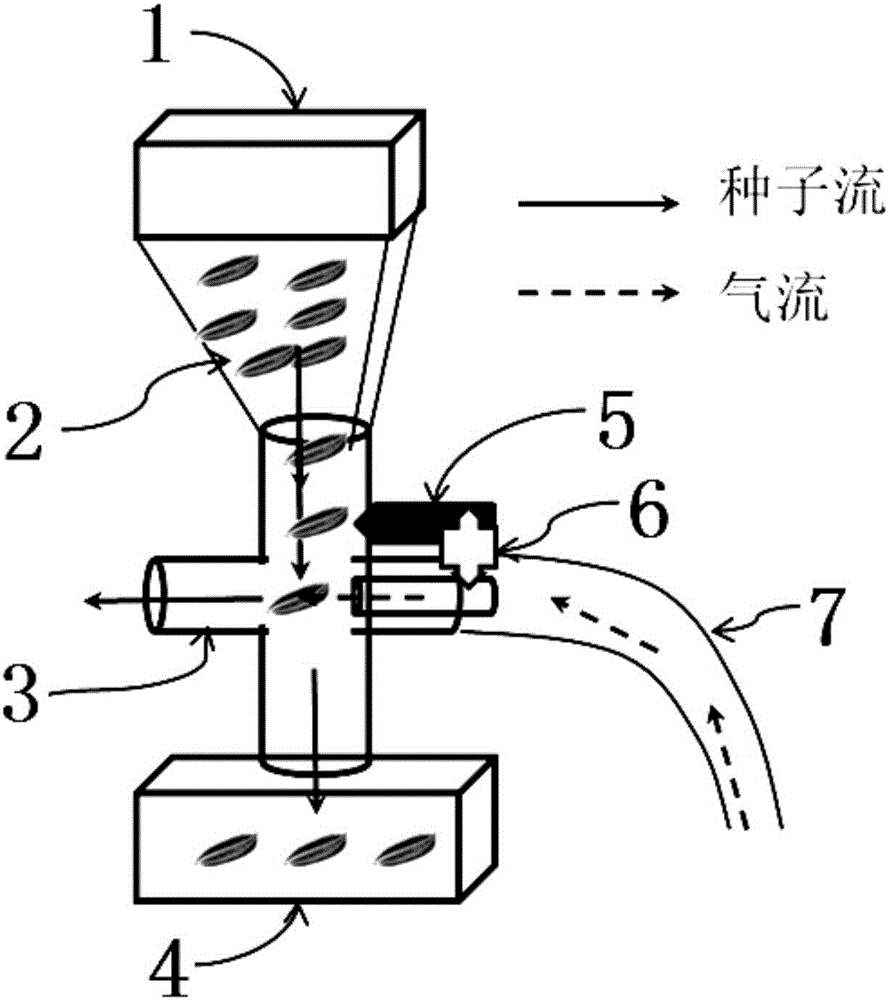

[0029] A seed spraying device, comprising a seed box 1, a seed tank 2, a spray pipe 3 and an air blowing device 7; the seed box 1 is located above the seed tank 2, and the seed tank 2 communicates with the spray tube 3 through a seed guide tube 8, The air blowing device 7 communicates with the injection pipe 3 through a pipe to blow the seeds falling from the seed tank 2 into the injection pipe 3 . The bottom end of the seed introduction tube 8 is provided with a collection box 4 . Described seed guide pipe 8 is provided with the photoelectric sensor 5 that is used to detect seed passing situation and the synchronizer 6 that the electric signal of photoelectric sensor 5 is synchronized with the switch signal of blowing device 7 at the communication place of described seed introduction pipe 8 and injection pipe 3; The outlet of the spray pipe 3 is inclined downward.

[0030] The photoelectric sensor 5 is a reflector type photoelectric switch or a diffuse reflection type photoe...

Embodiment 2

[0034] A kind of rice seed sowing method, comprises the following steps:

[0035] 1) Seed selection and coating; the seed selection utilizes conventional seed selection methods to make the seeds clean to 100%, and the conventional seed selection methods include wind selection, water selection, salt selection and color selection. The coating agent for the seed coating is a chemical agent with a warning color, and the coating method can be manual coating or mechanical coating. The chemical agent can be selected from Dr. Miao and Hanyu Nanny.

[0036] 2) Manufacture of seed spraying device;

[0037] 3) Jet seeding.

[0038] The jet sowing is that when the seeds pass through the jetting device, the photoelectric sensor automatically detects the passing of the seeds, and sends an electrical signal to the synchronizer, and the synchronizer sends a switch signal to the air blowing device after receiving it, and completes a spot jet sowing.

[0039] For sowing on the seedling tray, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com