High-density precise dibbler

A hole seeder, high-density technology, applied in the direction of seeder parts, etc., can solve the problems of difficult realization, narrowing distance, difficulty, etc., and achieve the effect of low manufacturing cost, convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

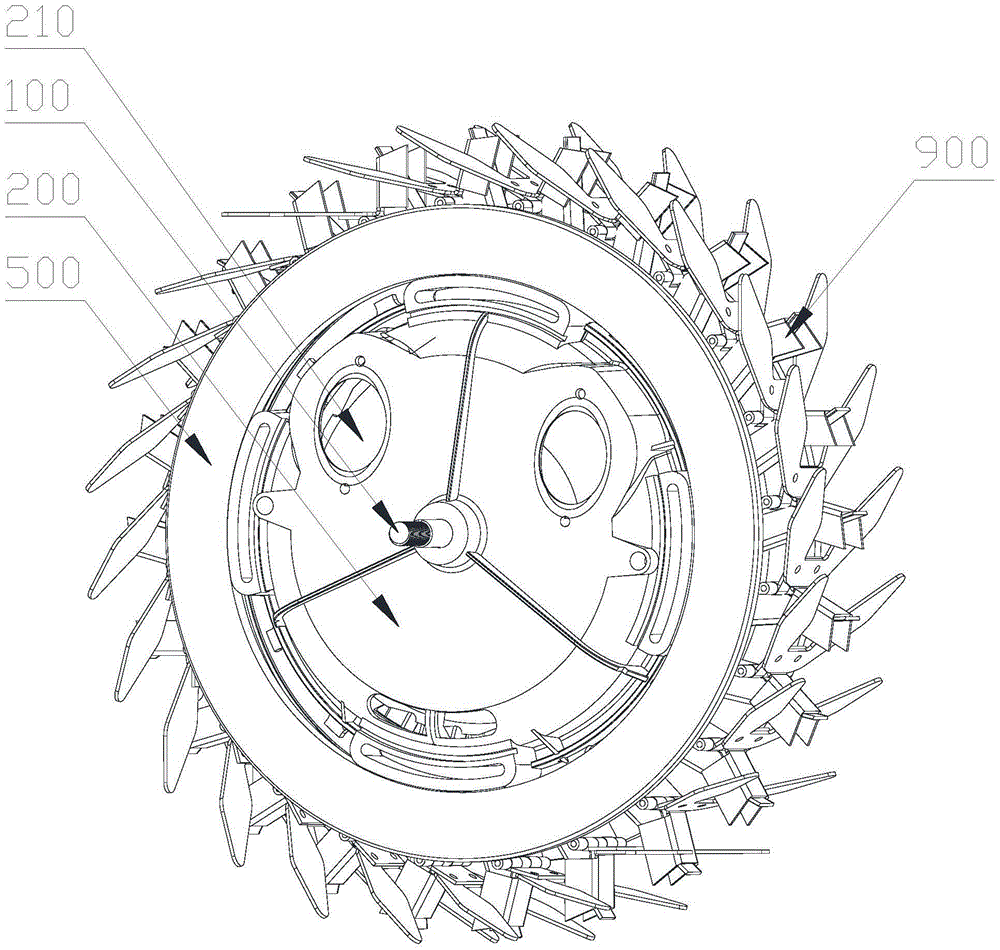

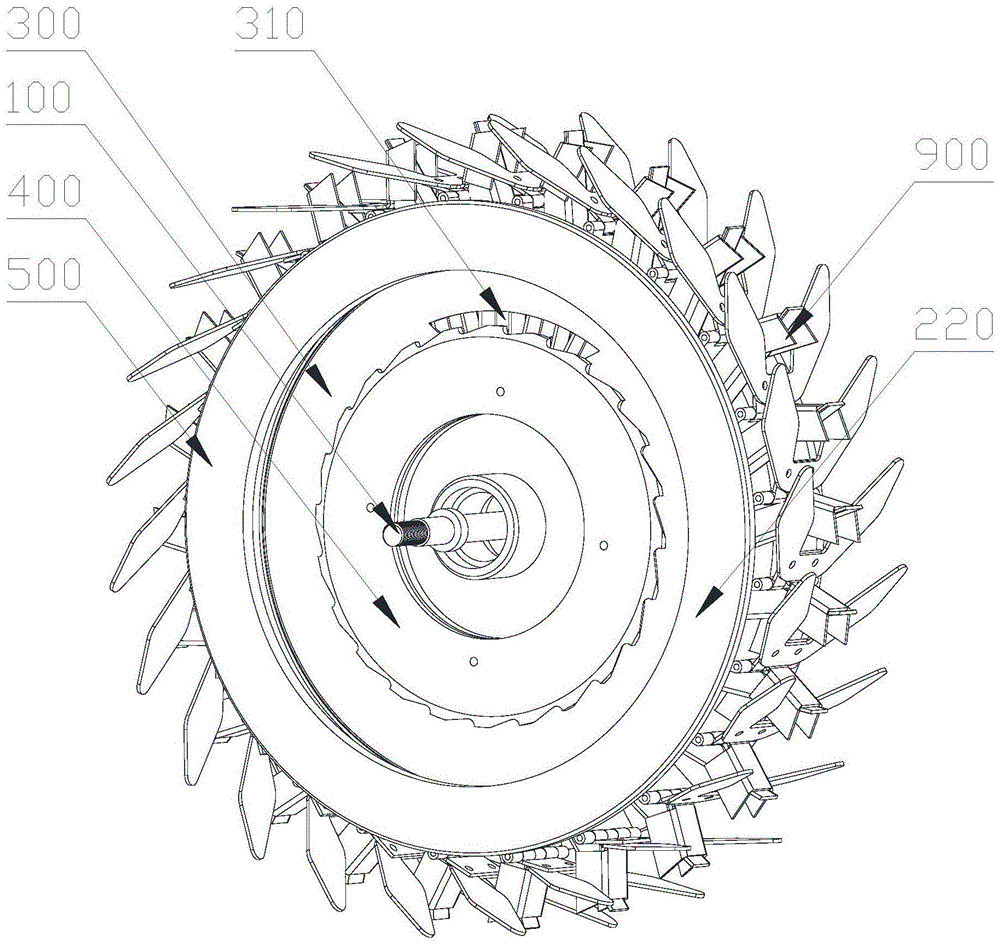

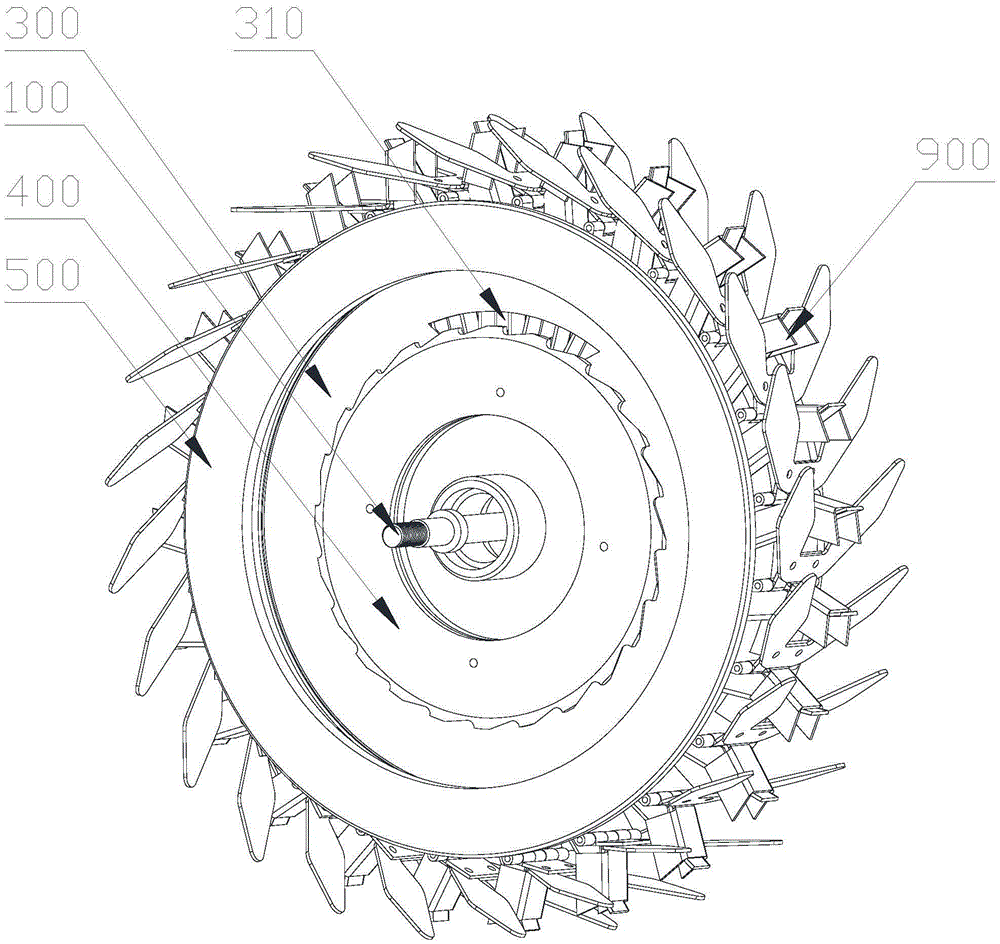

[0049] Such as Figure 1-Figure 7 As shown, a high-density precision hole seeder includes a fixed shaft 100;

[0050] The fixed shaft 100 is sequentially fixedly connected with the seed chamber shell 200, and rotatably connected with the stop plate 600;

[0051] A floating spacer 300 is arranged between the seed chamber shell 200 and the baffle plate 600, and the edge of the floating spacer 300 is fastened with the edge of the seed chamber shell 200 to form a seed chamber 220 for containing seeds. The seed chamber casing 200 is provided with an upwardly facing seed pouring port 210;

[0052] Between the floating spacer 300 and the retaining plate 600 are fixed a plurality of seed guide grooves 700 uniformly distributed along the axis of the fixed shaft 100 , and the length direction of the seed guide grooves 700 is the same as that of the floating spacer 300 . The radial direction is the same;

[0053] The high-density precision hole seeder also includes a seed-taking mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com