Seed-pushing and air-blowing combined high-speed precise seed-metering device

A kind of seeding device and high-speed technology, which is applied in the direction of agricultural gas emission reduction, interval quantitative sowing machinery, seeder parts, etc., can solve the problems of complex structure and slow seeding speed of air-blown precision seed metering device, and achieve Achieve precision seeding and high-speed seeding operations, increase the speed of seeding, and improve the effect of operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

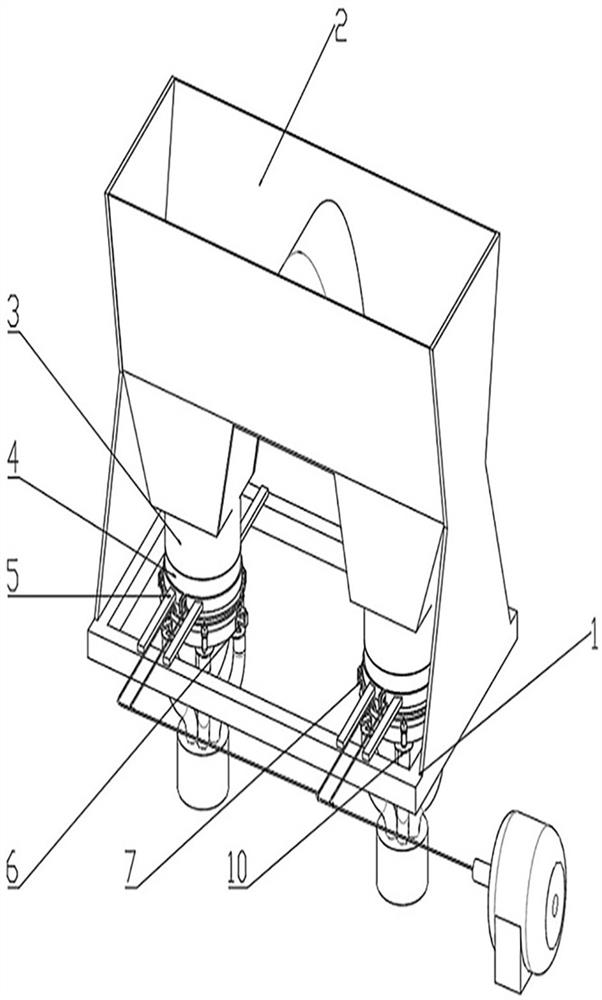

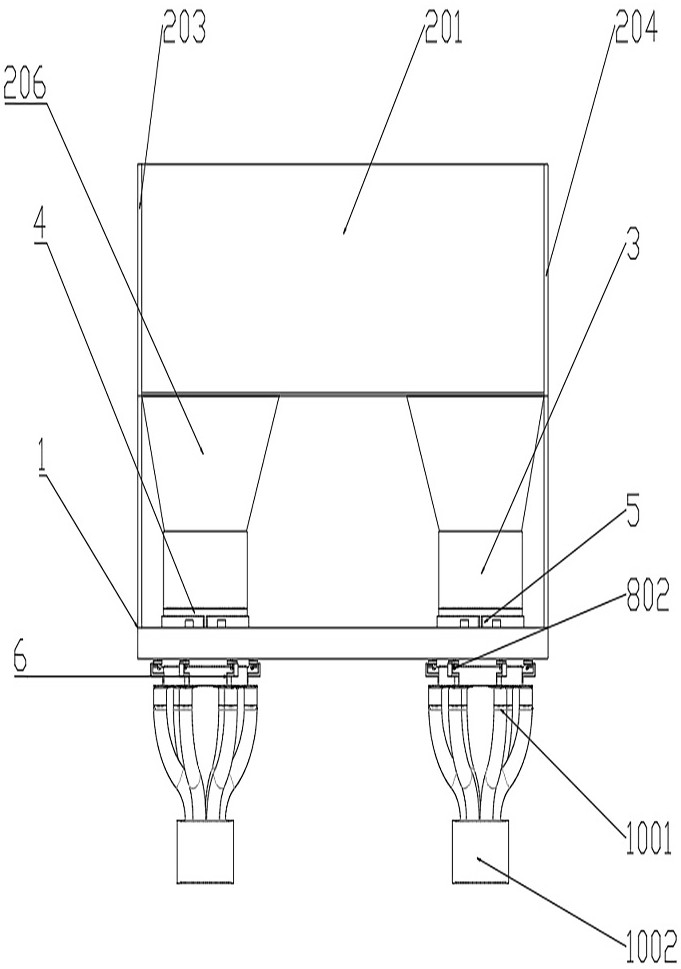

[0037] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. Such as Figure 1A It is a schematic diagram of the overall assembly of a high-speed precision seed metering device combined with seed pushing and air blowing, Figure 1B It is the front view of the high-speed precision seed metering device combined with seed pushing and air blowing. The high-speed precision seed metering device combined with seed pushing and air blowing is mainly composed of Figure 2A The seed-discharging monomer, the frame 1 and the seed box 2 are composed.

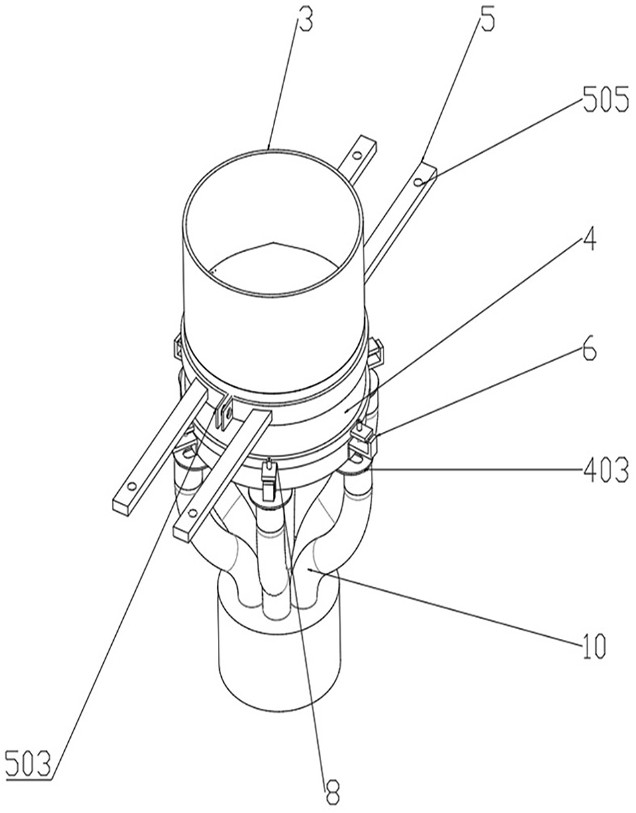

[0038] Such as Figure 2A , Figure 2B Shown are the overall assembly schematic diagram and the internal structure diagram of the seed metering unit respectively. The seed metering unit consists of a seed plate 3, an outer plate 4, an outer plate fixing frame 5, a seed pushing device 6, a spring mounting frame 7, an outer ring air injection device 8, The motor dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com