Automatic suspender

A spreader and automatic technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of threatening the life safety of hoisting workers, high labor intensity, and injury to workers, so as to increase the application range, overcome low efficiency, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in detail below in conjunction with accompanying drawing:

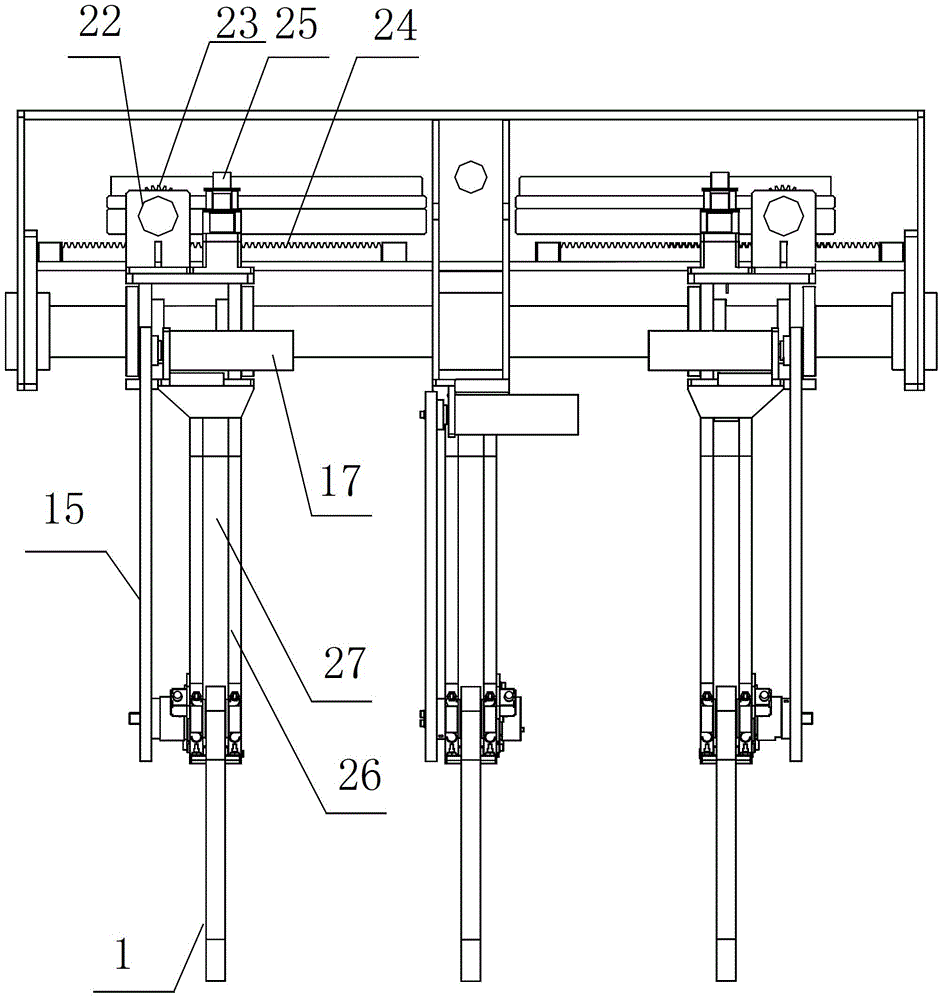

[0031] like Figure 1 to Figure 4 As shown, it is an automatic spreader, including hook 1 and boom 3. Three suspension hooks 1 are installed on the boom 3 . The hook 1 is movably arranged on the boom 3 .

[0032] The boom 3 includes a horizontal beam 31 , a bracket 32 , a sleeve 33 and a transmission support 26 . The horizontal beam 31 is disposed on the support 32 . The upper end of the transmission support 26 is connected with the sleeve 33 . The sleeve 33 is fitted on the horizontal beam 31 so that it can move horizontally along the horizontal beam 26 . The suspension hook 1 is rotatably installed at the lower end of the transmission base 26 . The rack 24 is mounted on the bracket 32 . A rotatable gear 23 is installed on the upper end of the transmission support 26 . The gear 23 meshes with the rack 24 . The gear 23 moves horizontally along the rack 24 when it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com