Steel cold bending test machine

A technology of cold bending test and steel, which is applied in the direction of applying stable bending force to test the strength of materials, etc. It can solve the problems of complicated installation process, difficulty in placing steel, threat to personal safety of test operators, etc., and achieve high test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

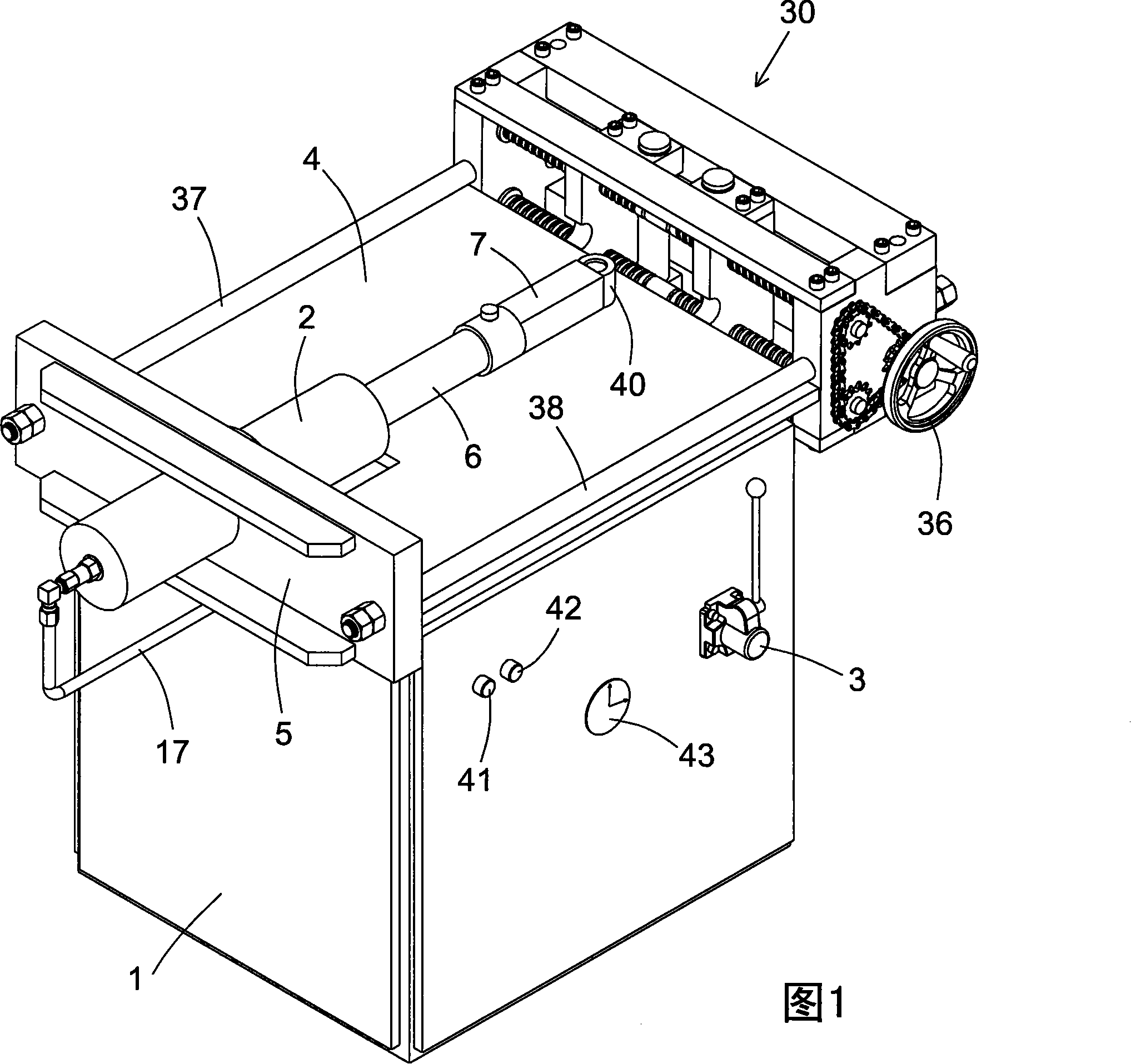

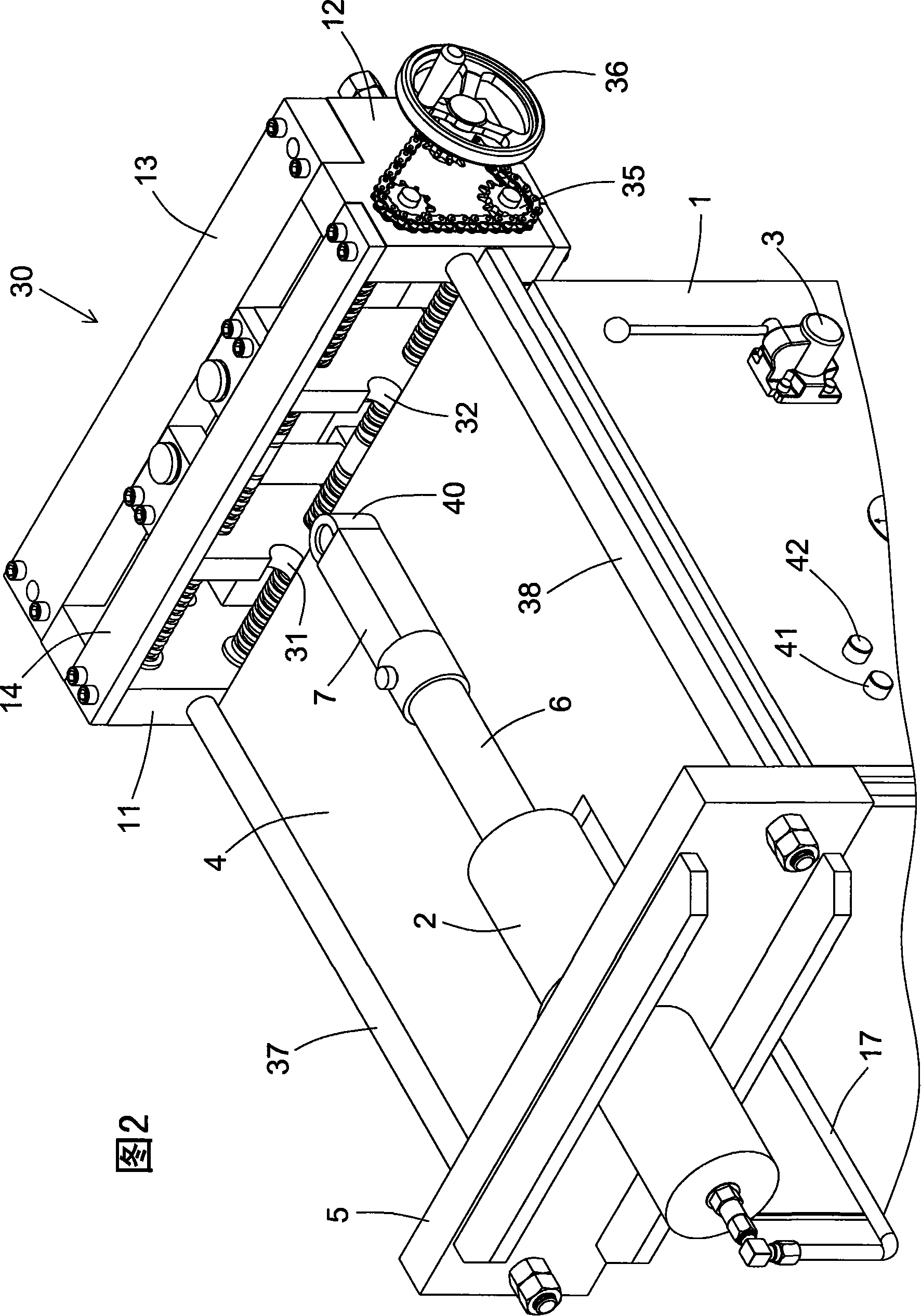

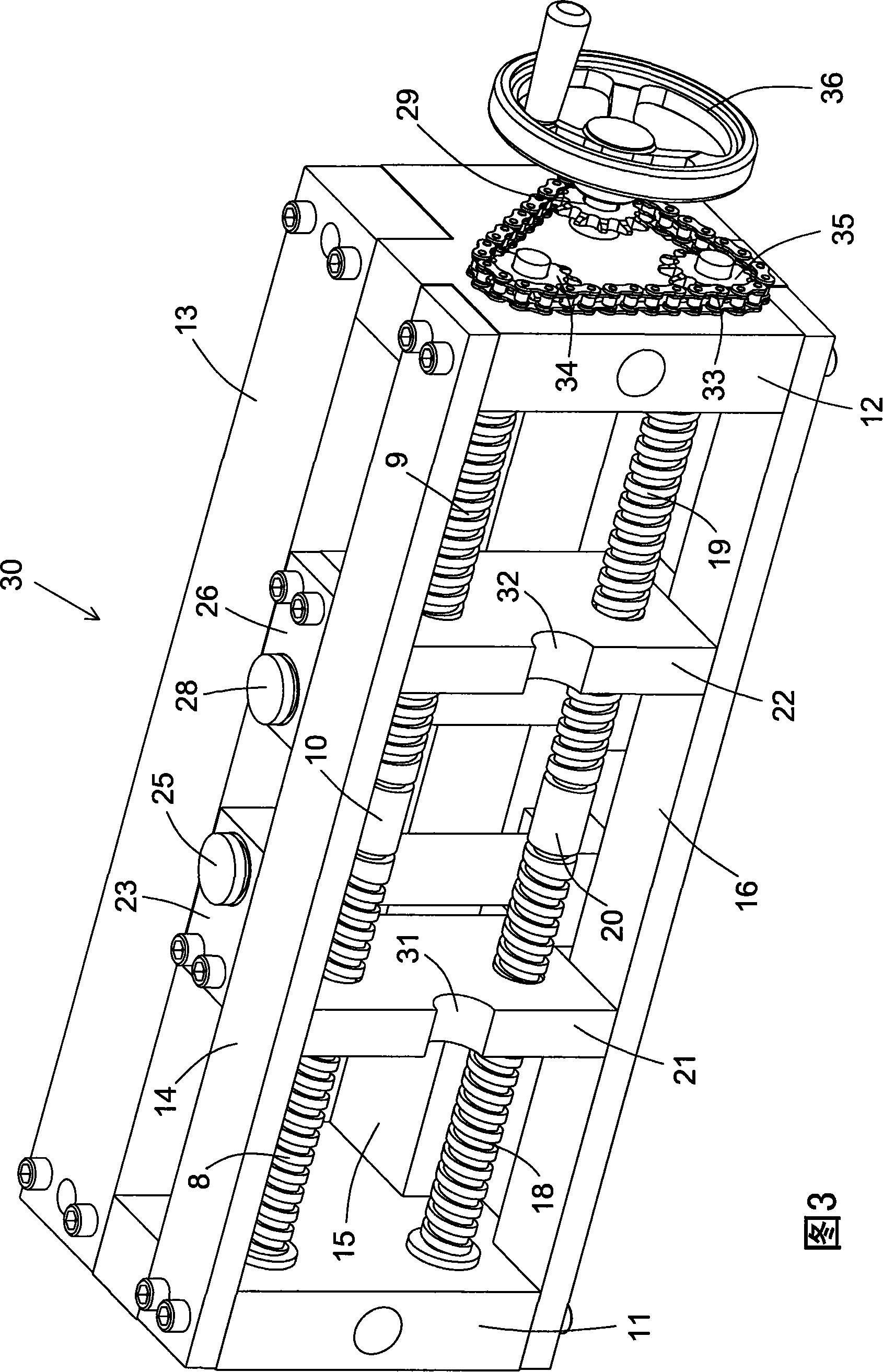

[0019] Label in the figure

[0020] 1 Chassis 2 Hydraulic Cylinder 3 Manual Reversing Valve 4 Workbench

[0021] 5 support plate 6 piston rod 7 ejector rod 8 upper left screw

[0022] 9 Upper right screw 10 Upper lead screw 11 Left side plate 12 Right side plate

[0023] 13 Front cover 14 Rear cover 15 Front base 16 Rear base

[0024] 17 Oil pipe 18 Bottom left screw 19 Bottom right screw 20 Bottom lead screw

[0025] 21 left slider 22 right slider 23 left pressure plate 24 left supporting plate

[0026] 25 left column 26 right platen 27 right supporting plate 28 right column

[0027] 29 drive sprocket 30 adjustment bracket 31 groove 32 groove

[0028] 33 chain 34 upper right sprocket 35 lower right sprocket 36 handwheel

[0029] 37 left pull rod 38 right pull rod 39 steel 40 punch

[0030] 41 Push button switch 42 Push button switch 43 Pressure gauge

[0031] Please refer to Fig. 1, Fig. 2, Fig. 3, Fig. 4, the present invention is a kind of steel cold bending testing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com