Grabbing mechanism distance adjusting device and logistics conveying line

A technology of grasping mechanism and adjusting device, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of precise adjustment, uneven movement in the process of changing distance, insufficient rigidity, etc., and achieve the effect of reliable clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

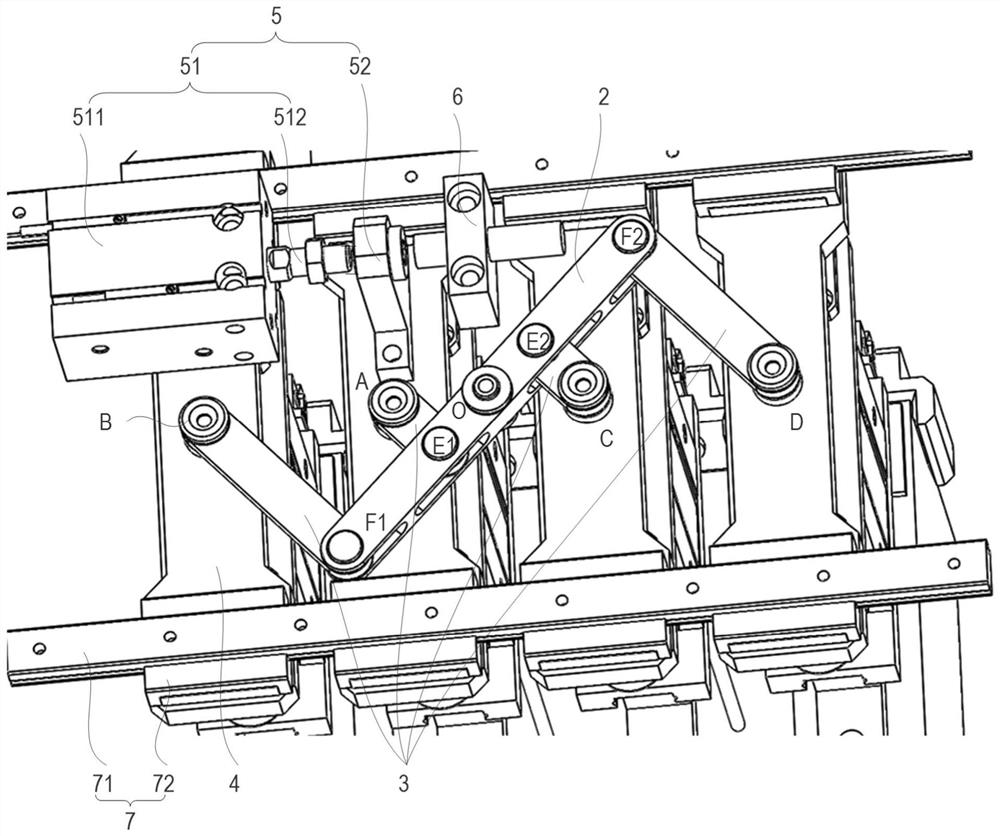

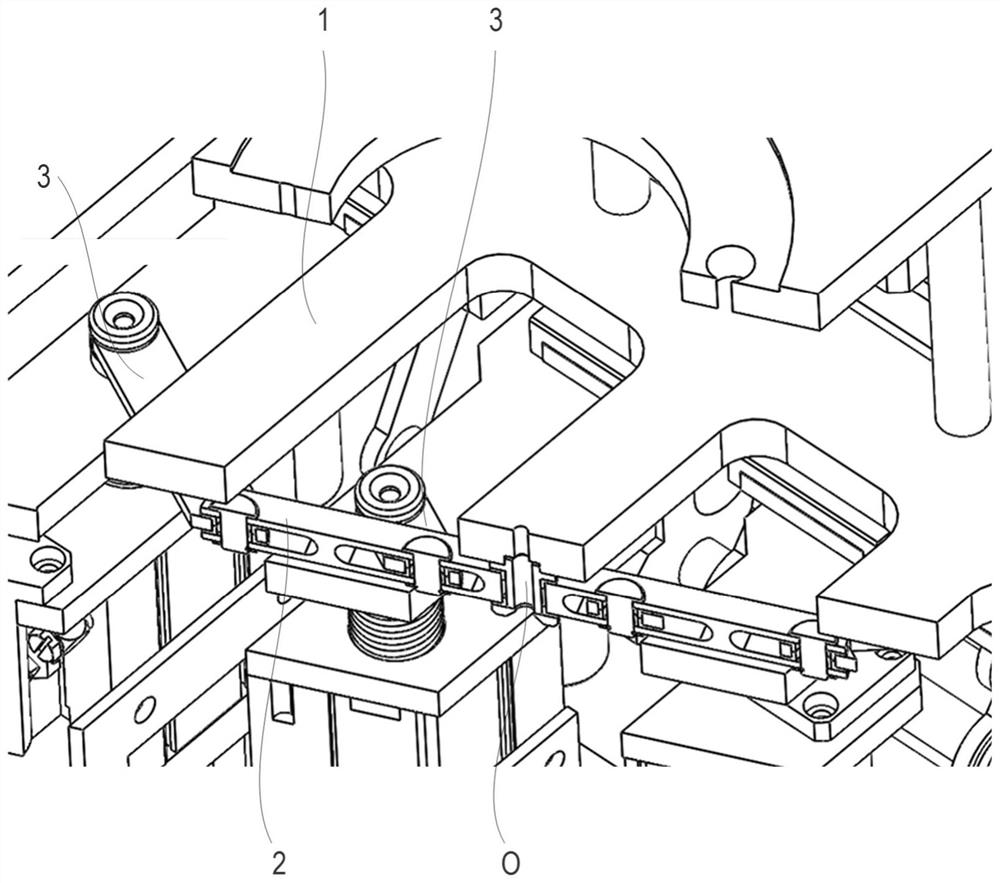

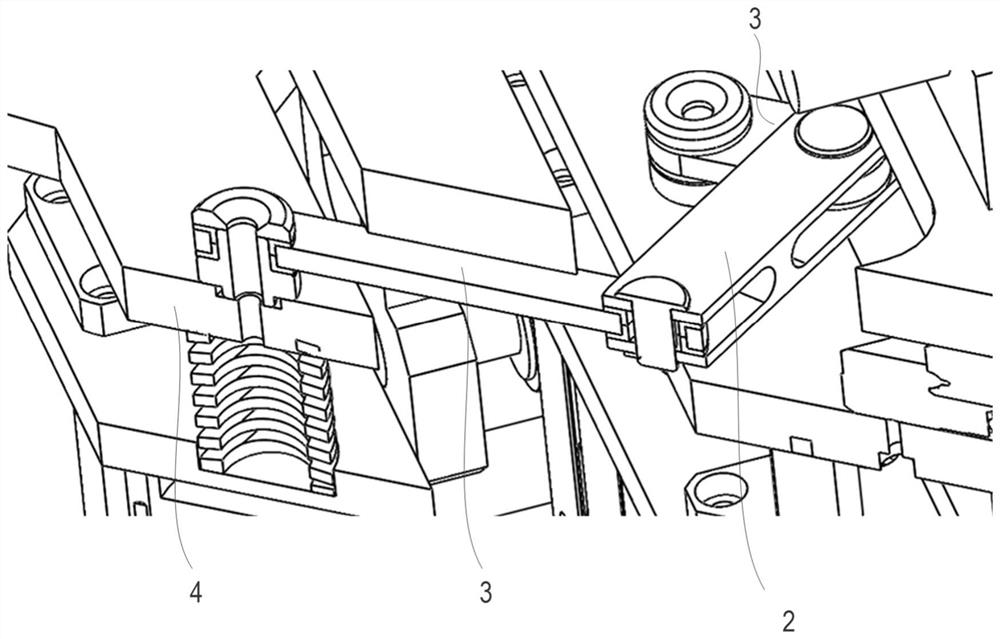

[0044] Combine below Figure 1 ~ Figure 4 The technical solution provided by the present invention is described in more detail.

[0045] In the production process of new energy batteries, the cell production line is one of the most important production lines. There are many processes involved in the production of battery cells. The semi-finished products and finished products of the battery cells need to shuttle in an orderly manner among multiple processes to complete various steps such as liquid injection and packaging. The electric core includes a casing and an electrode assembly housed in the casing. According to the structure of the pole piece of the electrode assembly, the electrode assembly is divided into two types: laminated electrode assembly and wound electrode assembly. The structure of the laminated electrode assembly itself is a cuboid. Correspondingly, a rectangular parallelepiped casing is used to contain the laminated electrode assembly, and finally a rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com