Forming test mold and method for chopped fiber-cement-based material test piece

A technology of cement-based materials and chopped fibers, which is applied in the field of road materials, can solve the problems of not being able to truly reflect the state of the interface and destroying the integrity of the test piece, and achieve the effect of simple structure, overcoming the influence of human factors, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the solutions of the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments are only It is an embodiment of a part of the present invention, but not all embodiments.

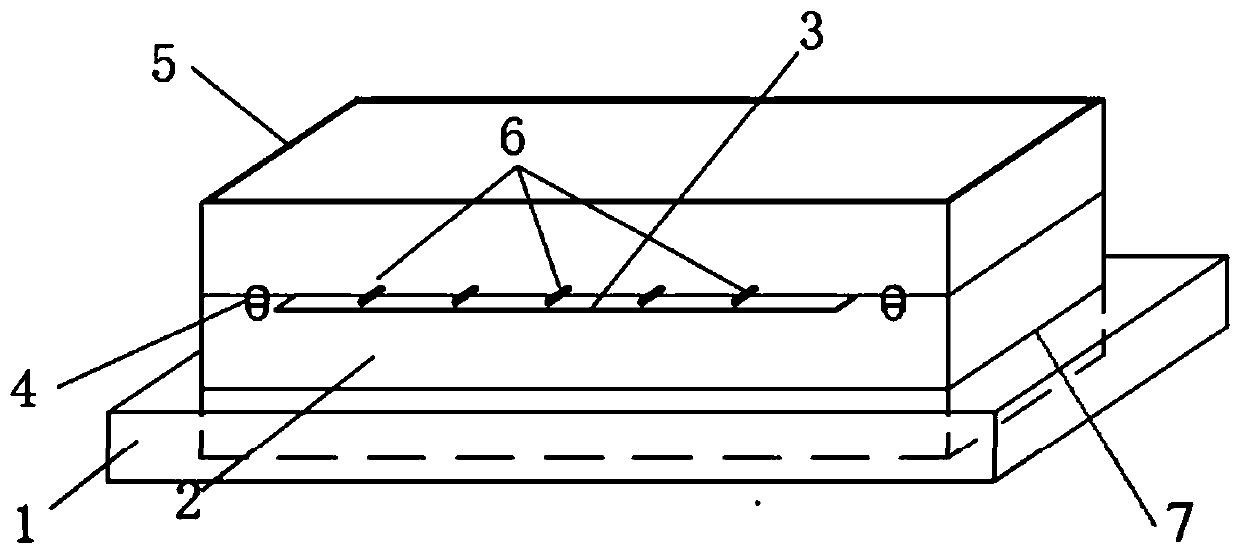

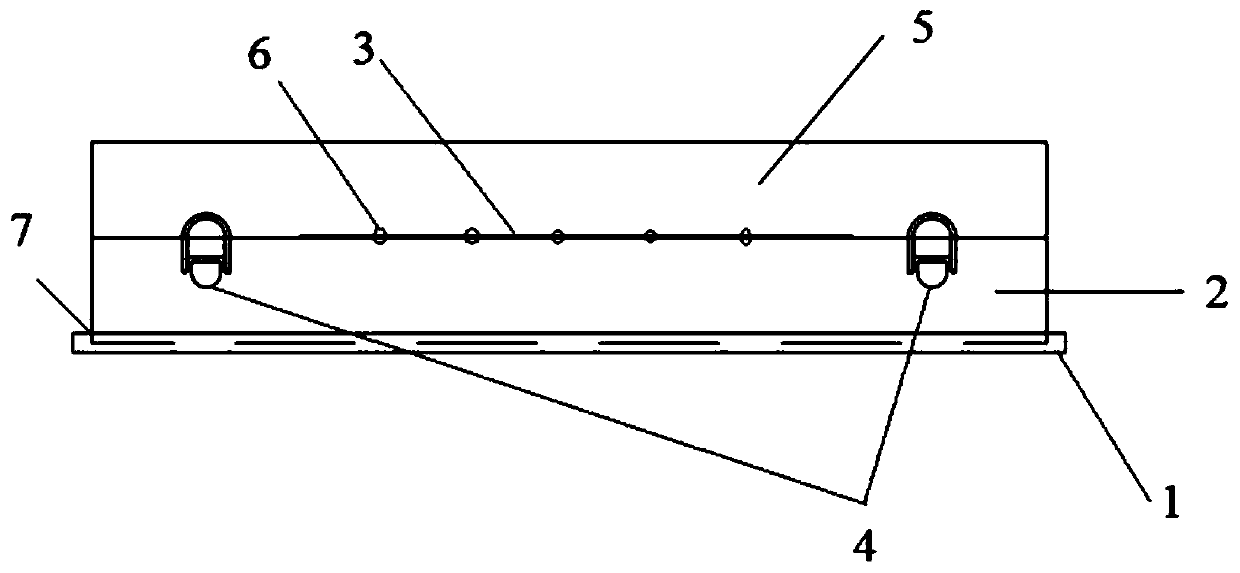

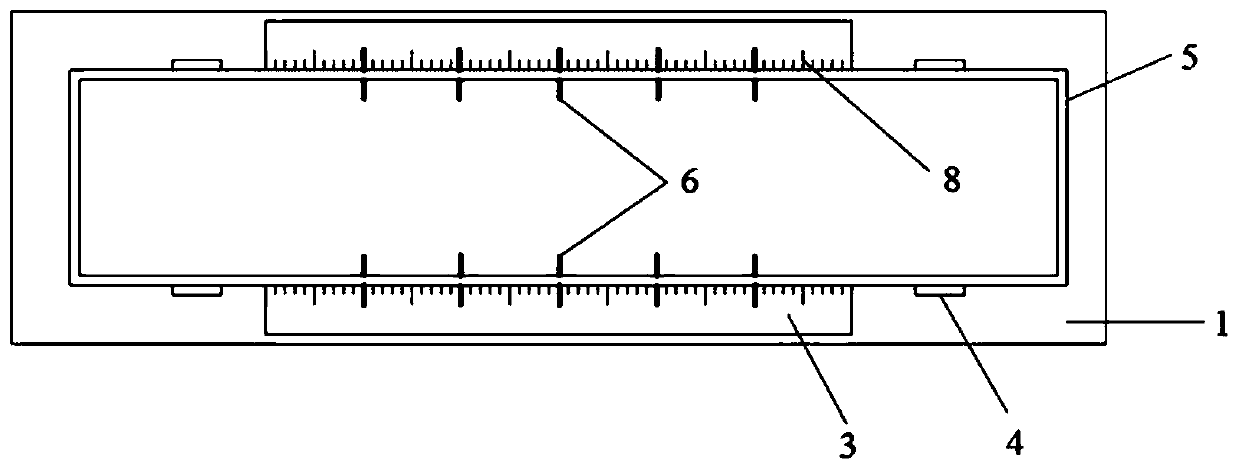

[0035] like figure 1 , figure 2 and image 3 Shown, a kind of molding trial mold of chopped fiber-cement base material specimen of the present invention comprises base 1, lower trial mold 2 and upper trial mold 5;

[0036] The lower trial mold 2 and the upper trial mold 5 all include four straight sides, the four straight sides of the lower trial mold 2 and the upper trial mold 5 form a rectangular frame, and the lower trial mold 2 and the upper trial mold 5 form a frame cross section. The shape of the space is the same; the lower trial mold 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com