Fabricated building wall structure

A building wall and prefabricated technology, applied in the field of building walls, can solve problems such as inability to quickly detect steel bars and inaccurate adjustments, and achieve good anti-theft effects, improve appearance, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

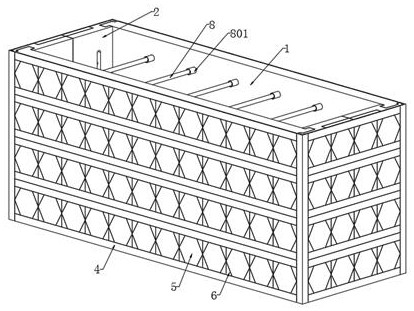

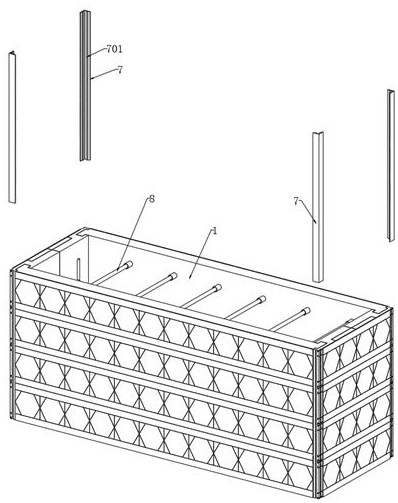

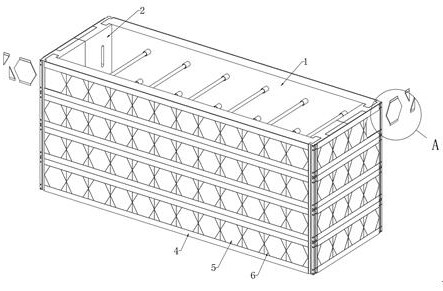

[0048] as attached figure 1 to attach Figure 12 Shown:

[0049] The present invention provides a prefabricated building wall structure, including a basic wall panel 1;

[0050] The basic wall panel 1 is provided with two groups, the two ends of which are respectively provided with L-shaped card edges 101, and the outer end faces are respectively provided with horizontal card slots A103;

[0051] There are four sets of side clamping plates 2, one end of which is provided with a vertical clamping groove 201, and is engaged with the clamping edge 101 of the foundation wall panel 1 through the vertical clamping groove 201, and two groups of side clamping plates 2 form a The whole is clamped on one end of two groups of basic wallboards 1, and the outer end surfaces of the side clamping plates 2 are respectively provided with horizontal clamping grooves B202; there are four sets of adjusting plates 3, and the two sets of adjusting plates 3 are A whole, and embedded in the grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com