Preparation method of RF-MEMS switch composite sacrificial layer

A technology of RF-MEMS and composite sacrificial layer, which is applied in the direction of coating, manufacturing microstructure devices, metal material coating technology, etc. It is difficult to solve the problem of equality, achieve the effect of excellent flatness, avoid mechanochemical polishing process, and have little dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

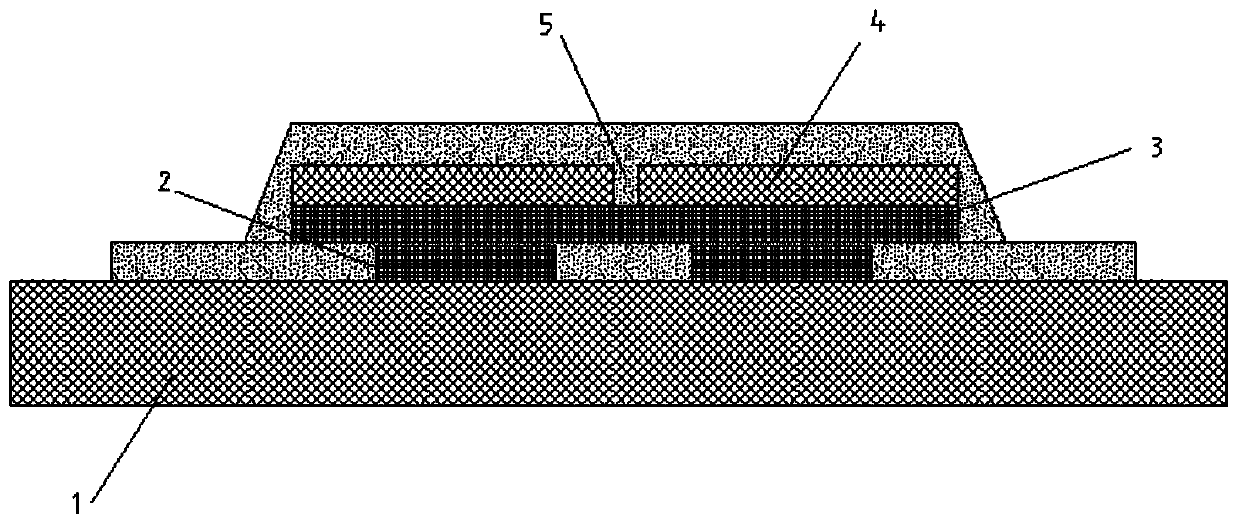

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] A method for preparing a RF-MEMS switch composite sacrificial layer, comprising the following steps:

[0024] (1) Sputter a metal layer on the surface of the MEMS substrate that needs to be a sacrificial layer, and pattern the metal layer, so as to realize the planar filling of the MEMS substrate;

[0025] (2) Deposit a metal layer by sputtering again on the MEMS substrate after step (1) flattening and filling, so as to prepare the first sacrificial layer, and the height of the first sacrificial layer is used to define the gap distance of the switch beam contacts;

[0026] (3) Take out the MEMS substrate sputtered in step (2), perform photolithography and etch to remove the glue, and remove the metal layer in the anchor area of the metal beam;

[0027] (4) Thin-resist lithography is performed on the MEMS substrate etched and removed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com