A spiral coil machine

A coiler and spiral technology, applied in the field of mechanical devices, can solve problems such as unsuitable for hot simmering process, difficult to meet process requirements, small ring diameter, etc., achieve high degree of automation, reasonable structure, and reduce the effect of rebound coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

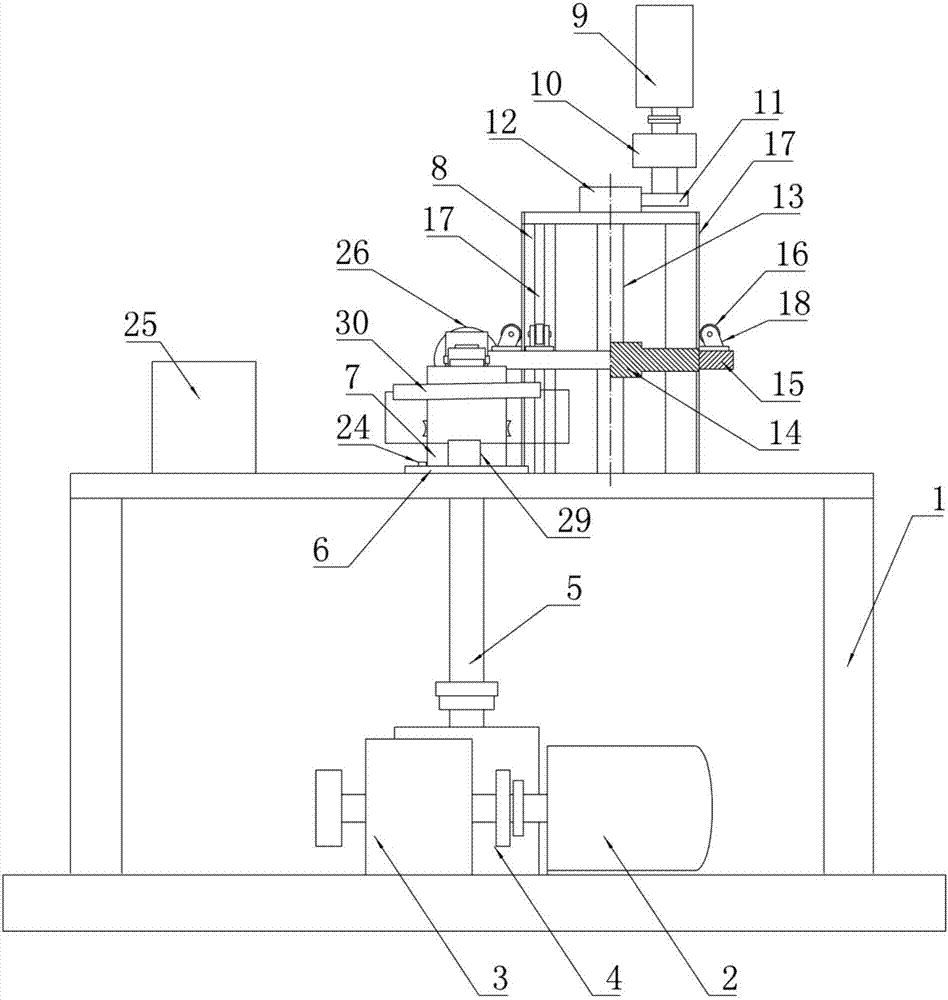

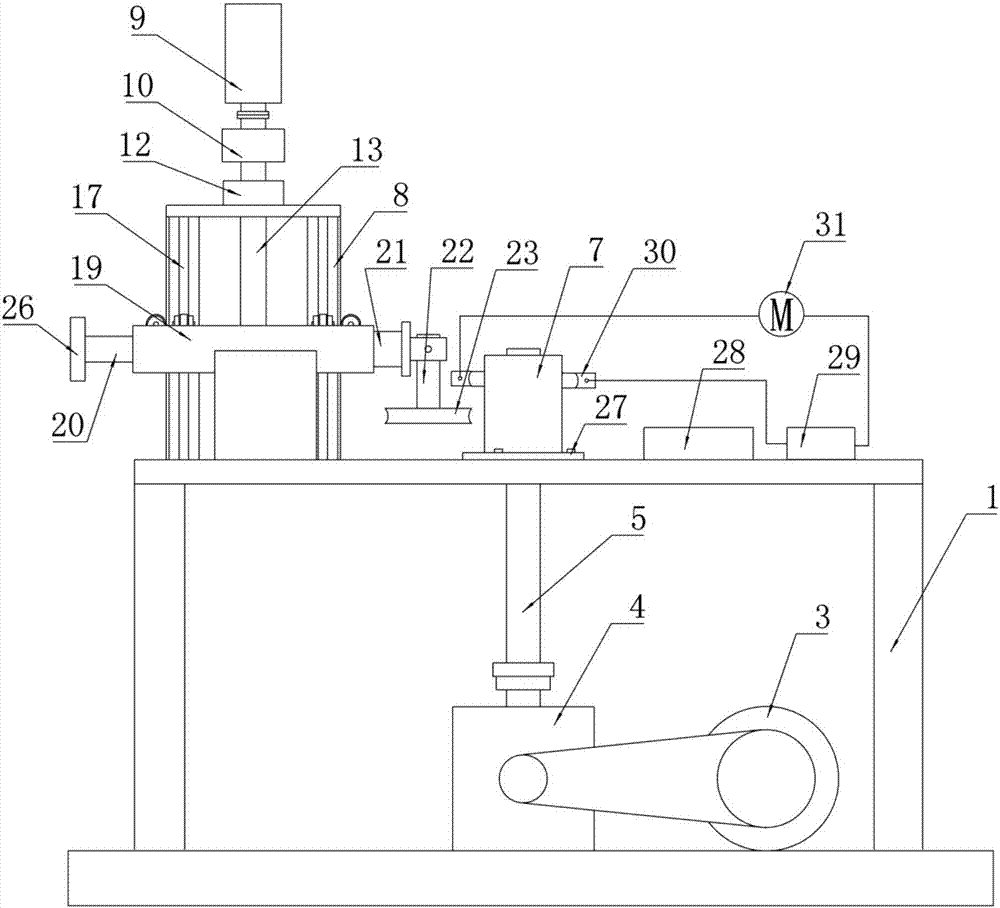

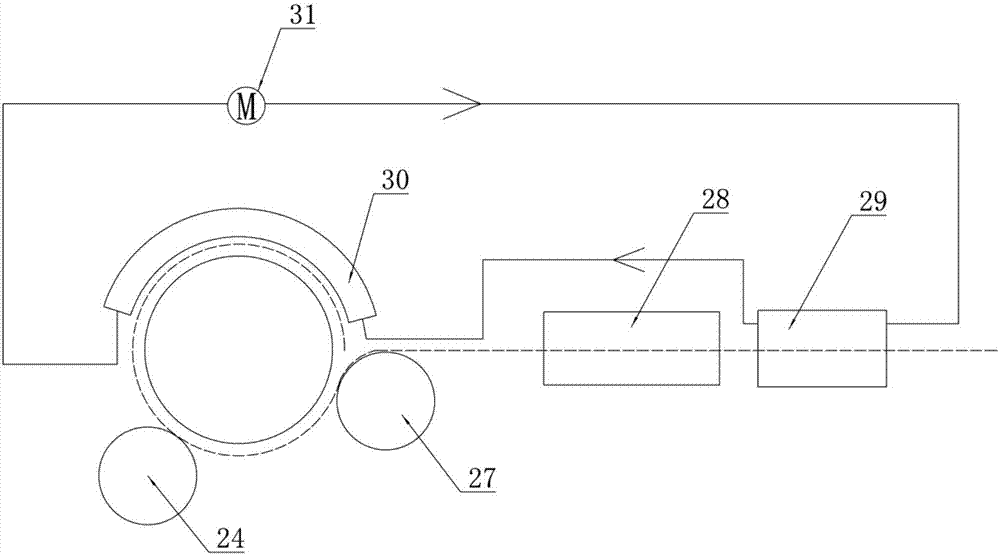

[0026] A spiral coil machine, such as Figure 1 ~ Figure 3 As shown, it includes a frame 1 , a main power system, a coil spacing adjustment system, a coil auxiliary positioning system, an auxiliary anti-rebound system, and an electrical control box 25 installed on the frame 1 .

[0027] The main power system includes a motor 2, a first reducer 3, a second reducer 4, a main shaft 5 and a coil mold. Wherein the motor 2 , the first reducer 3 , the second reducer 4 and the main shaft 5 are located below the frame 1 , and the coil mold is located above the frame 1 . The output shaft of the motor 2 is connected to the first reducer 3 , the output end of the first reducer 3 is connected to the second reducer 4 , and the output end of the second reducer 4 is connected to the vertically arranged main shaft 5 . The output speed of the motor 2 is 1400r / min~1500r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com