Rolling mill for rolling tooth marks on surface of metal belt

A technology of metal strips and tooth marks, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve problems such as failure to meet design requirements, poor stability, poor consistency of tooth marks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

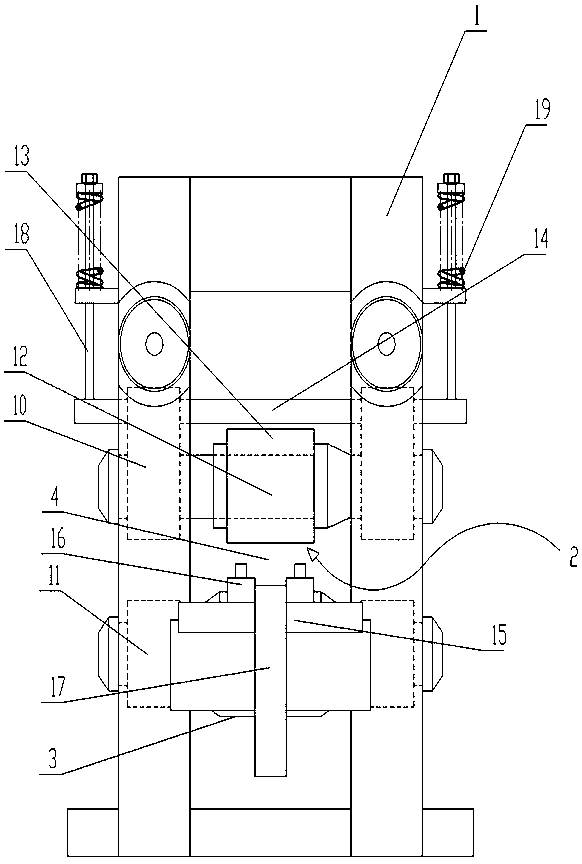

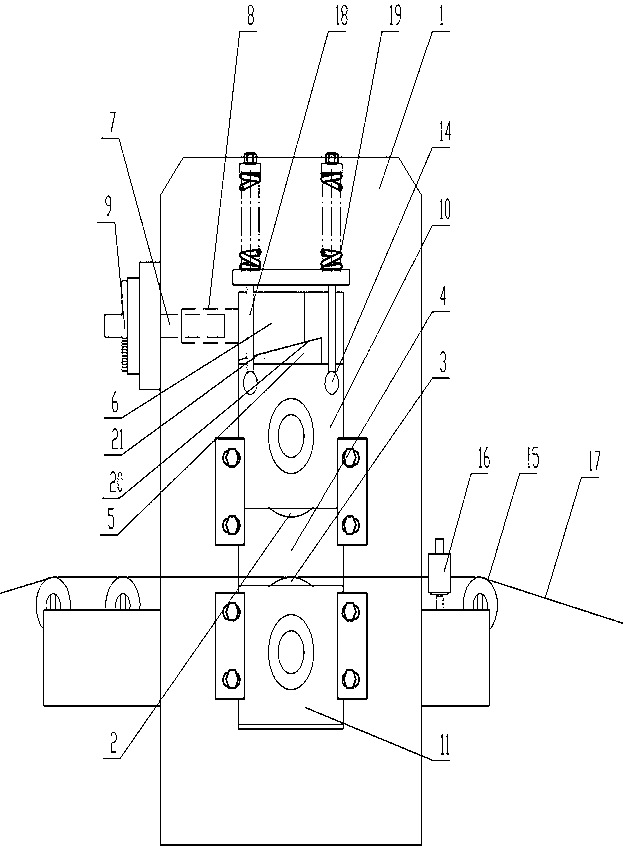

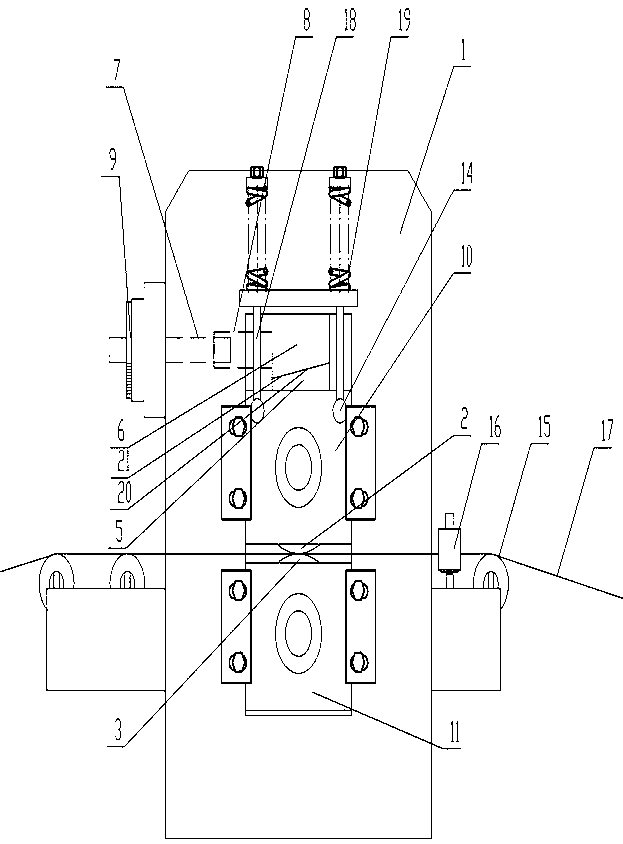

[0028] The technical scheme of the present invention will be further elaborated below in conjunction with accompanying drawing:

[0029] Such as Figure 1-2 As shown, the rolling mill for rolling tooth marks on the surface of metal strips of the present invention includes: machine body 1; mold roll 2; second roll 3; first inclined block 5; second inclined block 6; rotating part 7; fixed part 8 Dial 9; First bearing seat 10; Second bearing seat 11; Shaft core 12; Die 13; Balance shaft 14; First guide roller 15; Second guide roller 16; The first slope 20; the second slope 21.

[0030] Such as Figure 1-2 As shown, the second bearing seat 11 is fixedly arranged on the machine body 1, there are two second bearing seats 11, the second roller 3 is rotatably arranged on the second bearing seat 11, and the two ends of the second roller 3 are supported on Two second bearing seats 11; the first bearing seat 10 is slidably arranged on the body 1, the first bearing seat 10 is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com