Automobile component drilling device

A technology for auto parts and drilling devices, applied in positioning devices, feeding devices, boring/drilling and other directions, can solve the problems of large vibration, low workpiece accuracy and inability to use, inability to master drilling depth, etc., to improve processing The quality and observation drilling depth are improved, and the shock absorption effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

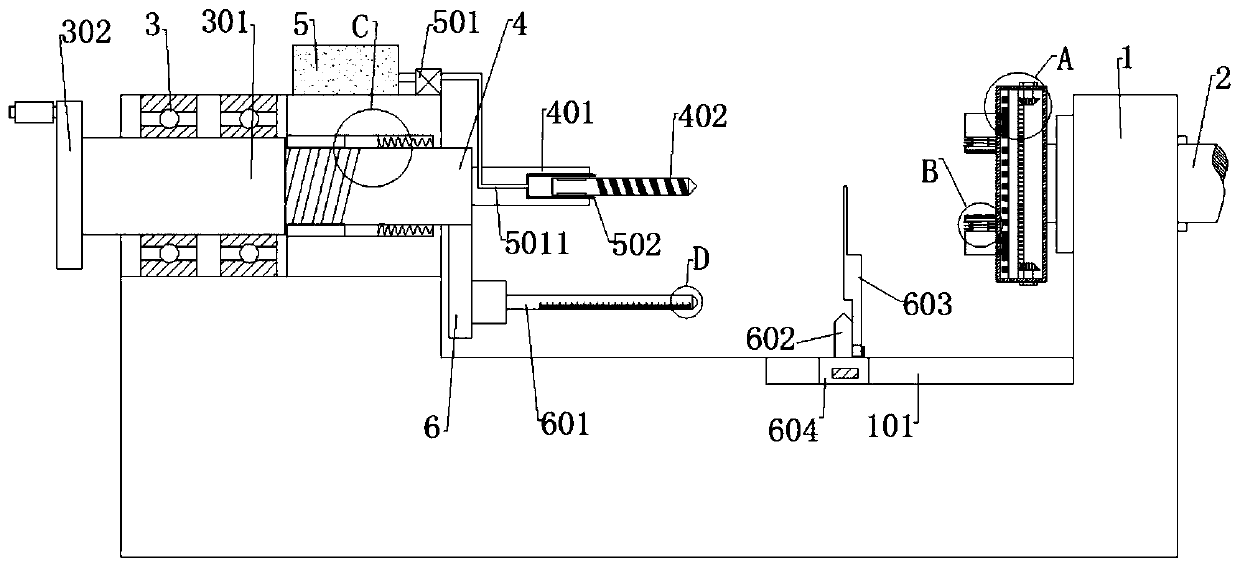

[0038] refer to figure 1, a drilling device for auto parts, comprising a main box body 1, a transmission shaft 2 is rotatably connected in the main box body 1, a clamping mechanism is fixedly connected on the transmission shaft 2, and a bearing 3 is rotatably connected in the main box body 1 Threaded sleeve 301, threaded sleeve 301 internal thread is connected with screw rod 4, on the screw rod 4 slides and is connected with the inner wall of main box body 1 by first slider 403, and the end of screw rod 4 far away from threaded sleeve 301 is connected with drill bit 402 through fixed block 401, and screw rod 4 The bottom is fixedly connected with a measuring mechanism, the top of the main box 1 is connected with a water tank 5, the water tank 5 is connected with a water pump 501 through a pipeline 5011, and the output end of the water pump 501 is connected with a nozzle 502 through a pipeline 5011. Fix by the clamping mechanism, then connect the transmission device through the...

Embodiment 2

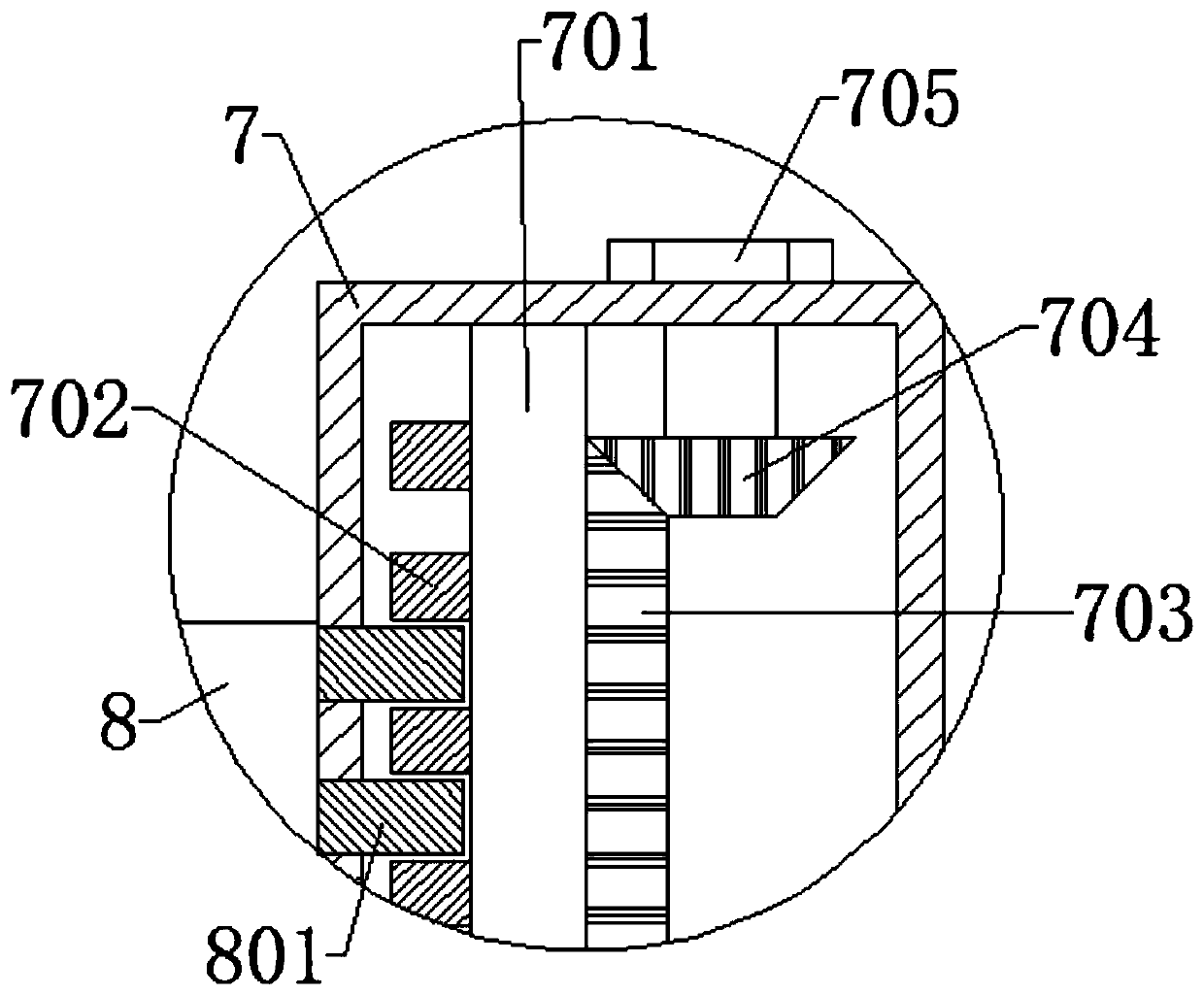

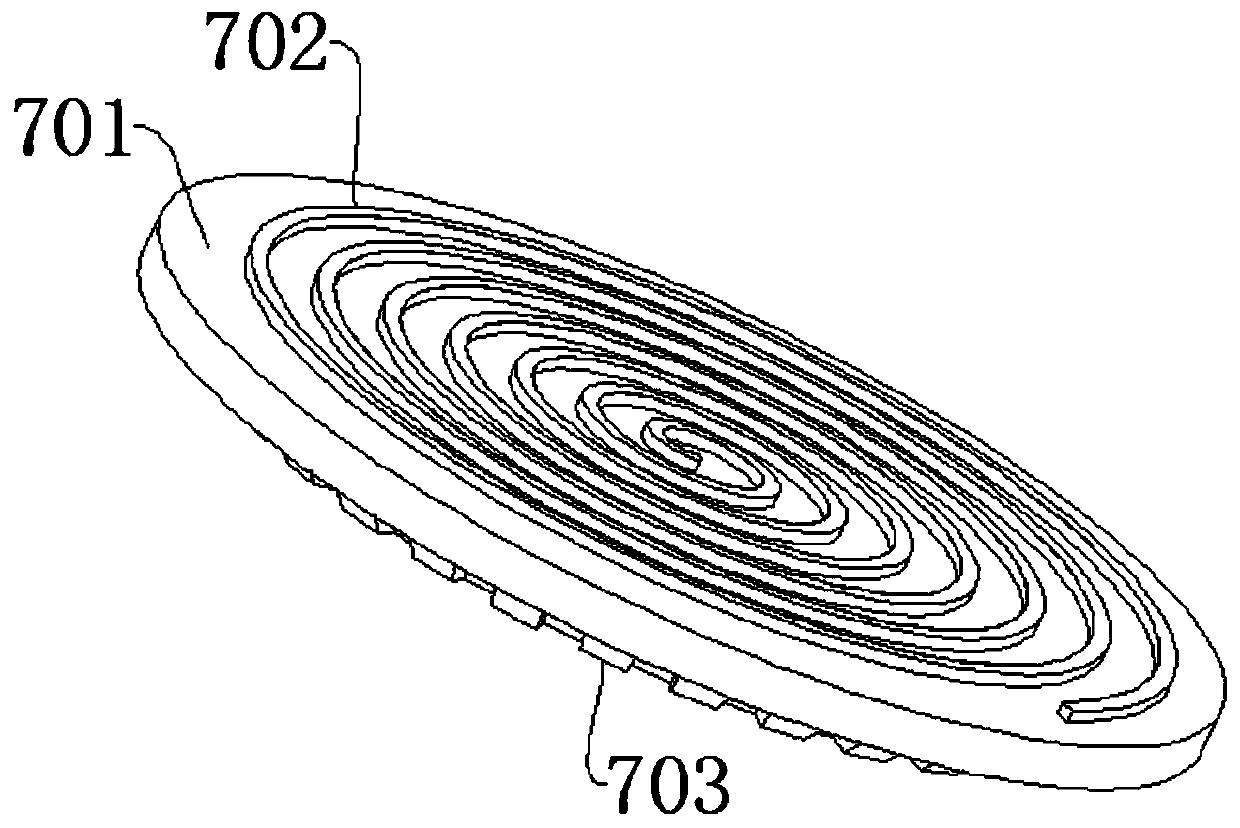

[0040] refer to Figure 1-4 , a drilling device for auto parts, comprising a main box body 1, a transmission shaft 2 is rotatably connected in the main box body 1, a clamping mechanism is fixedly connected on the transmission shaft 2, and a bearing 3 is rotatably connected in the main box body 1 Threaded sleeve 301, threaded sleeve 301 internal thread is connected with screw rod 4, on the screw rod 4 slides and is connected with main box body 1 inner wall by first slide block 403, and the end of screw rod 4 away from threaded sleeve 301 is connected with drill bit 402 through fixed block 401, and screw rod 4 The bottom is fixedly connected with the measuring mechanism, the top of the main box 1 is connected with the water tank 5, the water tank 5 is connected with the water pump 501 through the pipeline 5011, and the output end of the water pump 501 is connected with the nozzle 502 through the pipeline 5011. Fix by the clamping mechanism, then connect the transmission device t...

Embodiment 3

[0043] refer to Figure 1-4 , a drilling device for auto parts, which is basically the same as that of Embodiment 2, furthermore, the chuck 8 is connected with a pressing plate 804 through a telescopic rod 802, and the telescopic rod 802 is sleeved with a first spring 803, and the first spring 803 The two ends are against the chuck 8 and the pressing plate 804 respectively, and the telescopic rod 802 and the first spring 803 play a shock-absorbing effect on the workpiece.

[0044] A rubber pad 8041 is connected to the pressing plate 804, and the rubber pad 8041 plays an anti-slip effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com