Interference-free tool path generation method in machining of transitional surfaces by flat-end milling cutter

A flat end mill and transition surface technology, applied in the field of curved surface processing, can solve the problems of reduced processing efficiency, poor surface smoothness, low processing efficiency of ball-end cutters, etc., and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. The description herein is only used to explain the present invention when referring to specific examples, and does not limit the present invention.

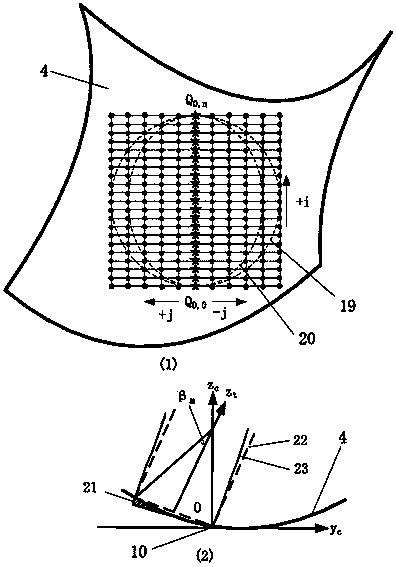

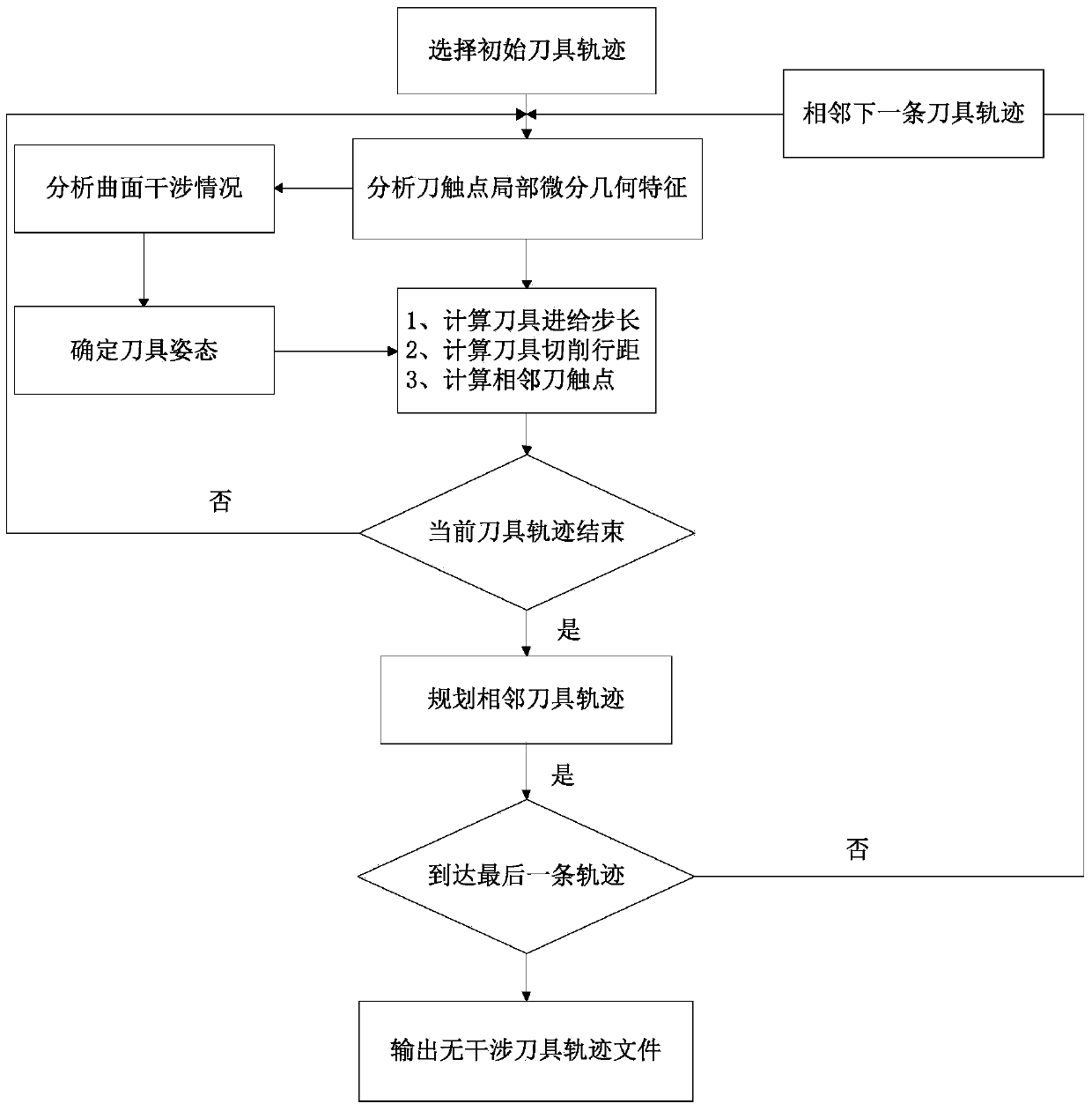

[0048] The flow chart of a method for generating a non-interference tool trajectory for machining a transition surface with a flat end mill in an embodiment of the present invention is as follows figure 1 shown.

[0049] First, an initial machining tool trajectory is selected on the transition surface, and the tool is processed along the ridge line of the transition surface, and the current tool contact is calculated on this path, and the local differential geometric characteristics of the tool contact are analyzed based on the differential geometry theory, mainly including the transition The local relevant data of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com