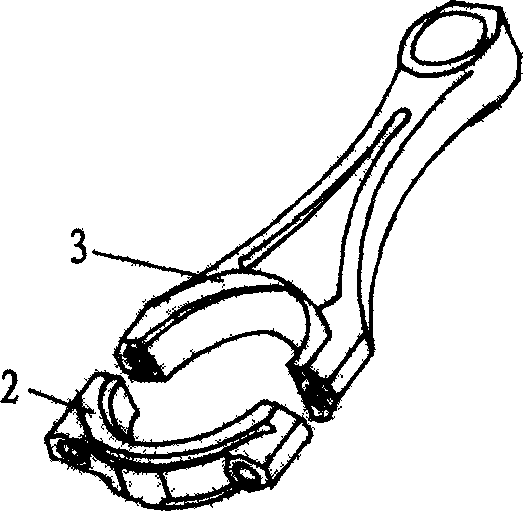

Laser processing method for connecting rod splitting groove and its equipment

A laser processing method and laser processing technology, used in laser welding equipment, metal processing equipment, connecting rod bearings, etc., can solve the problem of affecting the machining accuracy of the big head hole. The assembly quality of the connecting rod body and the connecting rod cover, the poor meshing of the fracture surface, and the fracture It can improve the fracture effect, good dimensional accuracy, and avoid the slag drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The method and equipment of the present invention will be further described in detail in the following embodiments given in conjunction with the accompanying drawings.

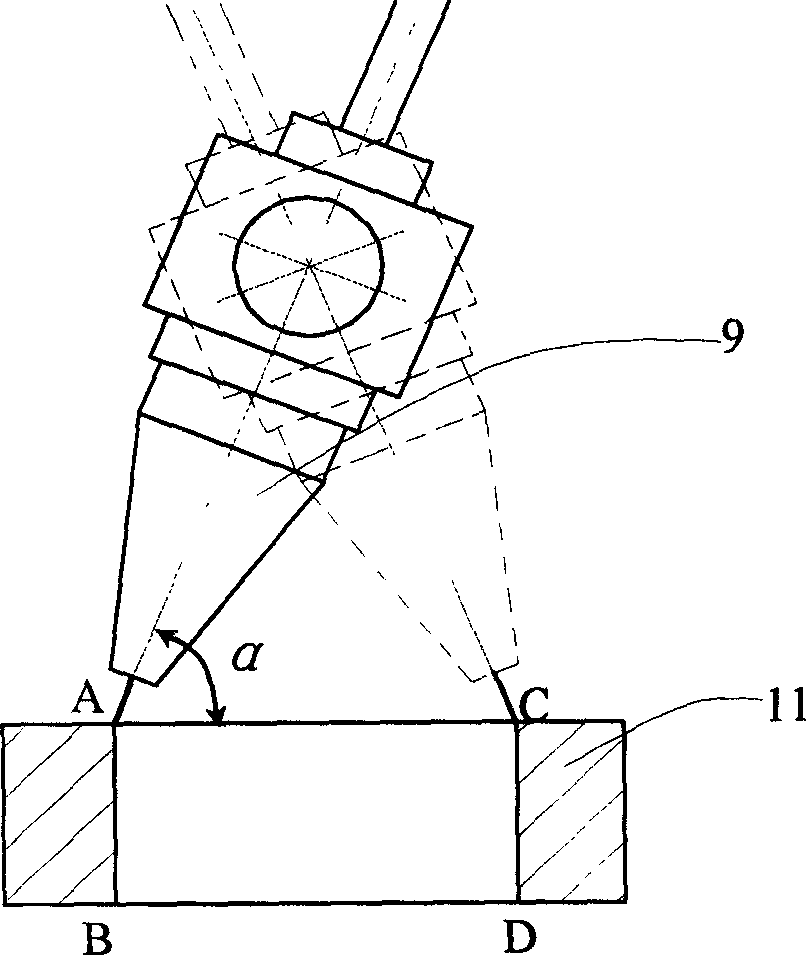

[0038] refer to image 3 , the laser processing method of the prefabricated cracking groove before the splitting of the connecting rod fracture of the present invention is characterized in that it is carried out according to the following steps:

[0039] a. The laser cutting head 9 of the laser processing equipment corresponds to point A of the upper end of the cutting part on the side of the big head hole of the connecting rod 11 fixed on the workbench;

[0040] b. Adjust the laser cutting head so that the laser incident angle (that is, the angle between the laser beam and the surface normal of the workpiece to be cut) α is 0°-70°, turn on the laser, and the laser cutting head moves vertically downward to cut between the connecting rod At point B at the lower end of the big head hole, complete the AB cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com